Abstract

Kinetic evaluation of an acidogenic completely stirred tank reactor (CSTR) treating a chemical synthesis-based pharmaceutical wastewater was investigated. For kinetic modeling of the acidogenic reactor (Monod, Contois, Grau, et al.), first-order kinetic models were used. These models have high correlation coefficients in this study. Monod models have shown high correlation coefficients (99%) which were used in describing the process kinetics of the anaerobic acidogenic reactor. Kinetic studies showed that sludge yield (Y) and decay rate (K d ) were 0.25 mg VSS/mg COD and 0.79 1/day, respectively.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

Introduction

Pharmaceutical wastewaters are characterized by high dissolved organics and changeable amount of salts [1, 2]. The high organic content of chemical synthesis-based pharmaceutical wastewater makes it especially suitable for processes based on anaerobic biotechnology [3]. Anaerobic digestion performance, both in terms of removal efficiency and energy recovery, a proper model, as well as dependable kinetic and stoichiometric parameters are required. In the literature, there is a general compromise on considering the hydrolysis as it is a kinetically limiting step of the all process [4]. Microbial kinetics plays a considerable role in the setup and operation of anaerobic digesters. Based on the biochemistry and microbiology of the anaerobic process for process analysis, control, and design, literature on kinetics of degradation was unavailable on chemical synthesis-based wastewater using first-order, Monod, Contois, and Grau kinetic models. Some researchers have investigated different wastewater treatment performance and its compounds using these models [5,6,7,8,9]. For biokinetic modeling of the reactor, Monod, Contois, Grau, and first-order kinetic models were used. These models have shown high correlations at studies. Although microbial kinetics of various types of industrial wastewaters has been studied, there is still lack of information in the literature about kinetics of chemical synthesis-based pharmaceutical wastewaters. In this study, these four types of kinetic models for describing the process kinetics of an acidogenic reactor chemical synthesis-based pharmaceutical wastewater were compared.

Materials and Methods

The reactor was made of Plexiglas with an active volume of 5 L. Characteristics of the wastewater are given in Table 1.

Inoculation sludge was obtained from an anaerobic reactor in alcohol industry. Analytical methods were used to determine reactor performance, and routine analyses were carried out in steady-state conditions. During the operation of the reactor, pH, temperature, gas production, and VFA were monitored daily. COD and TS/TVS analyses were carried out once every other day. All the analyses such as COD, solids, pH, etc. were conducted in accordance with the standards methods [10].

Reactor Operation

Acidification degree was interpreted according to different SRTs, HRTs, and OLRs, processing the chemical synthesis-based pharmaceutical wastewater.

Results and Discussion

Performance of Acidogenic Reactor

Optimum operating conditions for acidification of wastewater were found to be an HRT of 12 h, pH range of 5.5 ± 0.1, and OLR of 13 kg COD/m3 day. At this point, maximum acidification of 44% was achieved.

Determination of Microbial Kinetic Constants

For a completely stirred reactor without biomass recycle, the rate of accumulation of microorganisms can be shown as:

where dx/dt is the rate of change of microorganism concentration and is measured in terms of volatile suspended solids (VSS), V r is the reactor volume (liter), X 0 and X are the concentrations of biomass in the influent and the reactor/effluent (mgVSS/L), and μ and K d are the specific growth and decay rates (1/day), respectively.

Monod Model

If assumed that the concentration of microorganisms in the influent can be neglected, then at steady-state, dx/dt = 0. Equation (1) can be written as follows:

The relationship between the specific growth rate and the rate-limiting substrate concentration can be expressed by the Monod equation [11]:

where: S: Effluent concentration (mg COD/L), μ m : The maximum specific growth rate (1/day), K S : Half saturation concentration (Monod constant) (mg COD/L)

The general expression of Monod kinetic model is given below:

Y: Cell yield coefficient (mg VSS/mg COD)

If Eq. (4) is integrated and then reduced, the equation can be written as:

If Eq. (5) is linearized, the equation obtained will be:

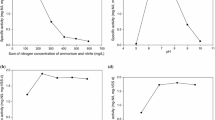

By plotting Eq. (6), the values of μ max and K S can be calculated from the slope and the intercept of the line. Figure 1 was plotted for determining the values of μ max and K S .

If the rate of change in the substrate concentration in the acidogenic reactor is expressed mathematically, this becomes:

Then, the above equation can be arranged according to Monod equations (4) and (7) and defined as follows:

Equation (8) can be linearized, and then the equation obtained will be:

where, by plotting, the values of Y and K d obtained in Eq. (9) can be calculated from the slope and the intercept of the line. The values of Y and K d were determined from Fig. 2.

Contois Model

By applying Contois model to the experimental data, the kinetic constants were calculated, and these obtained values of kinetic constants of the model were found to be same as the calculated values of the Monod model. The relationship between μ m and the rate of limiting S concentration can be expressed by the Contois equation [12] as follows:

where B is the kinetic parameter mg COD/mg VSS, BX = K S according to the Contois kinetics

The general expression of the Monod kinetic model is given below:

By applying the Contois model given above to Eq. (5), a kinetic evaluation can be done. Substituting the Contois expression, Eq. (10), in Eq. (5) gives:

If Eq. (12) is linearized, the equation obtained will be:

Similarly, the values obtained in Eq. (13) can be used for plotting values of μ max and B. The value of μ max can be calculated from the intercept of the straight line, while B can be obtained from the slope line. Figure 3 was plotted to determine the kinetic values (μ max and B) according to the Contois model .

Grau Model

Grau model in Eq. (14) that was established by Grau et al. [13] is that the predicted effluent substrate concentration is function of the influent substrate concentration.

Acidogenic reactor is a complete stirred reactor and behaves as a chemostat reactor; therefore, θ c and θ have the same values. According to the Grau model, for determining kinetic constants, Eq. (14) is reduced and linearized, and then the obtained equation is shown below:

The values obtained in Eq. (15) can be used for plotting values of μ max and K d . Similarly, the value of K d can be calculated from the intercept of the straight line, and μ max can be obtained from the slope line of Fig. 4.

First-Order Kinetic Model

Finally, using the first-order model , kinetic constants were determined. Effluent substrate concentration (S) is calculated by the first-order model. According to θ c and maximum substrate utilization rate k (mg COD/mg VSS day), the first-order kinetic model [14] expressions are as follows:

If Eq. (17) is integrated and rearranged for estimating effluent S concentration, it can be written as:

the effluent biomass concentration under steady-state condition and Eq. (16) is used to plot 1/E values versus μ values. The values of k and K d are obtained in Fig. 5.

Overall Evaluation of Applied Kinetic Models

By the application of the Monod kinetic model to the experimental data, μ max and K S were found to be 0.845 1/day and 55 mg COD/L, respectively, at high correlation (R 2 = 0.96). Y and K d were found to be 0.25 mg VSS/mg COD and 0.79 1/day, respectively, at the highest correlation (R 2 = 0.99) in this study. Substrate utilization rate was calculated as 3.37 mg COD/mg VSS day. In the application of the Contois model, the Contois kinetic constant (B) was found to be 5.72 mg COD/mg VSS for each hydraulic retention time. In the application of the Grau model, K d and μ max were determined as 0.60 1/day and 0.096 1/day, respectively, at low correlation (R 2 = 0.87). Lastly, according the first-order kinetic model, k and K d were found to be 6.05 mg COD/mg VSS day and 6.37 1/day, respectively. All the kinetic constants in this study found in accordance to the four different biokinetic models for best describing the acidogenic reactor are given in Table 2 as compression in the literature studies. The Monod model was found to be more assembled than the other kinetic models according to (Y) 0.25 mg VSS/mg COD and (K d) 0.79 1/day, respectively. On account of the wastewater structure, these values were higher than the given literature values. A big part of the wastewater includes dissolved organics (approximately 70%) and is reduced to VFAs. Chemical synthesis-based pharmaceutical wastewater also contains large amounts of simple form alcohol, such as isopropyl alcohol, ethanol, etc. Since the hydrolyze phase of this wastewater takes a very short time, Y coefficient is slightly higher than the literature values [15,16,17,18,19,20,21]. On the other hand, (μ max) 0.43 1/day was calculated by the Contois model and this value to more appropriate than the Monod model. The reason was using the equation proposed by the Contois , the specific growth rate is considered as a function of the growth-limiting nutrient in both input and effluent S concentration by using an empirical constant, which was related to the microbial population [11]. The Monod and the Contois models are more aptly than the other kinetic models, especially when it comes to treating chemical synthesis-based pharmaceutical wastewater.

References

Benitez J, Rodriguez A, Malauer R (1995) Stabilization and dewatering of wastewater using hollow fiber membranes. Water Res 29:2281–2286

Kilroy AC, Grey NF (1992) The toxic of four organic solvents commonly used in the pharmaceutical industry of activated sludge. Water Res 26:887–892

Oktem YA (2004) Comparison of system performances of single and two phase anaerobic digestion treating a chemical synthesis-based pharmaceutical wastewater. Dissertation, Istanbul Technical University

Tomei MC, Braguglia CM, Mininni G (2008) Anaerobic degradation kinetics of particulate organic matter in untreated and sonicated sewage sludge: role of the inoculum. Bioresour Technol 99:6119–6126

Tiwari MK, Guha S (2013) Kinetics of the biodegradation pathway of endosulfan in the aerobic and anaerobic environments. Chemosphere 93:567–573

Wei Q, Zhang W, Guo J, Wu S, Tan T, Wang F, Dong R (2014) Performance and kinetic evaluation of a semi-continuously fed anaerobic digester treating food waste: effect of trace elements on the digester recovery and stability. Chemosphere 117:477–485

Deng L, Yang H, Liu G, Zheng D, Chen Z, Liu Y, Pu X, Song L, Wang Z, Lei Y (2014) Kinetics of temperature effects and its significance to the heating strategy for anaerobic digestion of swine wastewater. Appl Energy 134:349–355

Wu S, Yassine MH, Suidan MT, Venosa AD (2015) Anaerobic biodegradation of soybean biodiesel and diesel blends under methanogenic conditions. Water Res 87:395–402

Li Y, Jin Y, Li J, Li H, Yu Z, Nie Y (2017) Effects of thermal pretreatment on degradation kinetics of organics during kitchen waste anaerobic digestion. Energy 118:377–386

APHA (1995) Standard methods for the examination of water and wastewater, 19th edn. APHA, Washington

Monod J (1950) La technique de culture continue. Théorie et applications. Ann Inst Pasteur 79:390

Contois DE (1957) Kinetics of microbial growth. Theory and applications. Ph.D. Thesis, University of California, Los Angeles

Grau P, Dohanyas M, Chudoba J (1975) Kinetic of multicomponent substrate by activated sludge. Water Res 9:637–642

Lagergren S (1898) Zur theorie der sogenannten adsorption gelöster stoffe. Kungl Svenska Vetenskapsakademiens Handlingar 24(4):1–39

WC H, Thayanith K, Forster CF (2002) A kinetic study of the anaerobic digestion of ice-cream wastewater. Process Biochem 37:965–971

Massey ML, Pohland FG (1978) Phase separation of anaerobic stabilization biokinetic controls. J Water Pollut Control Fed 50:2204–2222

Ghosh S, Pohland FG (1974) Kinetics of substrate assimilation and product formation in anaerobic digestion. J Water Pollut Control Fed 46:748–758

Mazijat A, Mitsunori Y, Mitsunori W, Michimasa N, Jun’ichiro M (1997) Hydrogen gas production from glucose and its microbial kinetics in anaerobic systems. Water Sci Technol 36:279–286

Pavlostathis SG, Giroldo-Gomez E (1991) Kinetics of anaerobic treatment. Water Sci Technol 24(8):35–59

Fang HPH, Yu HQ (2001) Acidification of lactose in wastewater. J Environ Eng 127:825–831

Dinopoulou G, Sterritt RM, Lester JN (1988) Anaerobic acidogenesis of a complex wastewater: kinetics of growth, inhibition, and product formation. Biotechnol Bioeng 31:969–978

Acknowledgments

The author gratefully acknowledges the support of the Scientific Research Projects of Istanbul Technical University and would like to thank them for the financial support given to the project with grant numbers 1536.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer International Publishing AG, part of Springer Nature

About this chapter

Cite this chapter

Öktem, Y.A. (2019). Microbial Growth Kinetics of an Anaerobic Acidogenic Bioreactor. In: Balkaya, N., Guneysu, S. (eds) Recycling and Reuse Approaches for Better Sustainability. Environmental Science and Engineering(). Springer, Cham. https://doi.org/10.1007/978-3-319-95888-0_19

Download citation

DOI: https://doi.org/10.1007/978-3-319-95888-0_19

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-95887-3

Online ISBN: 978-3-319-95888-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)