Abstract

The precipitation of an insulating layer of scaling on the walls of the water distribution pipes has serious technical and economic consequences. Various methods were used to prevent the scale formation in water such as the chemical methods in which the germination of the CaCO3 crystals is blocked using the inhibitor. In recent years, a few studies have been focused on the aspects of the surface scaling so that the different mechanisms were proposed to explain the differences between the scaling precipitation in bulk solution and scale deposition at the surface. The water distribution of some Algerian town resulting from the drilling water is supersaturated with respect to calcium carbonate. This causes reducing heat transfer in heat exchanger systems, limiting the efficiency of these devices (valves and taps) by decreasing the flow rate in the pipes; this phenomenon is more prevalent at high heating temperature. In this book chapter, we aim to give an overview of the different antiscaling properties in hard water. We also provide the inhibitors used and the researches done on Algerian water.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Water plays a central and general role in human activities, development of social economy, and the ecological environment balance. Water contains mineral salts and dissolved or suspended substances. Indeed, during an increase in temperature, removal of dissolved CO2, an increase in the concentration of certain dissolved salts, or, more generally, a change in chemical equilibrium, dissolved solids can crystallize. A compact and insulating adhesive layer is then formed on the surface of the water pipe. This deposit causes the decrease of heat exchange, the reduction of the partial or total diameter of water pipes, the dysfunction of domestic and industrial installations and equipment, and the inhibition of detergency and ultimately significant financial losses. The primary agents responsible for crystallization fouling are the carbonates and sulfates of calcium or magnesium, barium salts, silicate, and phosphate.

Scaling is essentially linked to the formation of calcium carbonate (CaCO3). Scaling may contain other residues such as algae, calcium sulfate, clays, and the brucite Mg (OH)2. But it is always calcium carbonate that precipitates first, usually in the colloidal form, because its solubility is lower than that of others.

The formation of scale is a very complex phenomenon which can be subdivided into two phases: a crystal of calcium carbonate is formed, and the precipitate is formed around the initiator crystal and then its growth; it is the stack of adsorbed germs that forms CaCO3 growth sites (Fig. 1).

Scaling in natural hard water is a major concern in different facets of industrial processes and domestic installations (Fig. 2). Undesirable scale deposits often cause numerous technical and economic problems such as total or partial obstruction of pipes leading to a decrease in flow rate; reduced heat transfer as scale precipitate is 15 to 30 times less conductive than steel; seizure of valves and clogging of filters; etc. Therefore, it is essential to establish appropriate methods to study this phenomenon and find effective ways to combat it. Among the methods used to inhibit this phenomenon, the use of products to block the formation of tartar by preventing crystal growth (called tartrifuges products): organic molecules such as tannins, humic acids, citric acid, or glutamic acid, there is also chemicals: polyphosphates, phosphonates [1].

Pipeline obstructed by scale of Ouargla city [2]

The ideal inhibitor would be a compound in a solid form whose solubility would be very low but largely sufficient to ensure a total scaling inhibition. It could thus be brought into direct contact with the water to be treated without having to worry about its concentration, which would be automatically regulated by its solubility. Environmental requirements impose many challenges in the field of water treatment. Thus, the concept of “green chemistry” has been proposed, and the use of “green” chemicals has become a necessity. It is, therefore, of paramount importance to develop “green” scaling inhibitors in order to combat scaling phenomena that have disastrous or even catastrophic consequences [3].

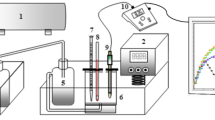

For decades, various attempts have been made to estimate the scaling power of natural waters and characterize the scaling formation mechanisms. These methods can be roughly divided into two categories: electrochemical methods and chemical methods. For the first one, we can use the chronoamperometry, chronoelectrogravimetry, and electrochemical impedance technique. All these techniques are based on the reduction of the oxygen dissolved in the water. Among the chemical methods, we can enumerate the critical pH method an evaporation method, the LCGE method, the rapid controlled precipitation method, a polymer scaling test, and a continuous test on tubes and others.

2 Scale

In this section, we introduce the definition of scale, the different type of scale, and the influence on industrial processes.

2.1 Definition

Water contains a number of dissolved species that can react under specific conditions to form a precipitate. Some of the precipitated salts have a very low solubility which is called poorly soluble salts. The precipitation reaction can be triggered by changes in conditions such as supersaturation, temperature, pH, or pressure. Precipitation results in deposition and scale formation on all surface materials, including pipe walls, heat transfer surfaces, pumps, etc. This process is also called fouling by crystallization (Fig. 3)

Schematic illustration of scale formation schemes [6]

.

Calcium and magnesium carbonates and sulfates are the main agents responsible for the fouling of crystallization, although barium salts, silicates, and phosphate deposition play an important role in some industries. Deposits formed by water, usually observed, include calcium carbonate, calcium and barium sulfate, silica deposits, iron deposits, magnesium, and calcium phosphates. If we extend our area of interest to wastewater, struvite is the main cause of the mineral scale [4]. Scaling is a phenomenon that occurs when a surface is in contact with incrusting water, likely to cause the formation of a product of very low solubility in the form of an adherent deposit. In the case of natural waters, the compound likely to precipitate first is calcium carbonate [5].

2.2 Different Type of Scale

2.2.1 Calcium Carbonate CaCO3

Calcium carbonate (CaCO3) is the most common compound (in terms of geographical distribution and abundance) in mineral precipitates of biological origin (marine and geological organisms) [7]. It is an essential element of sedimentary rocks [8] and a major constituent of scale that is found in drinking water pipes and in various structures in contact with natural or distribution water. It may be accompanied by various poorly soluble salts according to:

-

The origin of the water

-

The treatment he has suffered

-

Temperature

-

The nature and the state of corrosion of the pipes

It is mainly CaSO4, Mg (OH)2, Fe (OH)3, and salts of various metals [9]. But it is always the calcium carbonate that precipitates first, usually in the colloidal form, because its solubility is lower than that of the others [10].

There are three crystallographic varieties of calcium carbonate:

The Calcite

Thermodynamically, calcite (Fig. 4a, b) is the most stable polymorph of calcium carbonate, and it comes in many forms in nature. According to the data of the literature, calcite can present 700 different crystal forms always in the same system and also a certain number of twins (intimate association of two or more crystals according to precise plans).

The SEM images of CaCO3 forms: (a) amorphous calcite, (b) layered and rhombohedral calcite, (c) spherical vaterite, and (d) needle aragonite [12]

The Vaterite

Unlike calcite and aragonite, there is a very little occurrence of vaterite in natural minerals [11]. In fact, exposed to water, vaterite is very unstable and generally recrystallizes in the form of calcite. The most common facies is in lens (Fig. 4c); but we also encounter facies in the form of “roses of the sands.”

The Aragonite

Aragonite is orthorhombic pseudohexagonal and is usually in the form of a needle (Fig. 4d). It is metastable at ordinary temperature and transforms into calcite at high temperature.

Calcite is the most stable crystalline form at 25°C. Calcite is the least soluble (pK = 8.35). Aragonite is more soluble than calcite (pK = 8.22); it precipitates hot (T > 60°C). The vaterite form is the most unstable of the three crystallographic forms of CaCO3 and makes its identification difficult. The solubility of calcium carbonate increases with temperature (Table 1).

Natural waters contain in solution many chemical species at very different concentrations according to their origins. We can classify them into two groups according to:

-

The fundamental elements: CO2(free), H2CO3, HCO3−, CO3 2−, H+, OH−, and Ca2+, which participate in the carbonic and calcocarbonic equilibrium.

-

The characteristic elements: Mg2 +, Na +, and K+ for the cations and SO42−, NO3−, and Cl− for the anions. These ions do not intervene in the preceding equilibria except by their action on the ionic strength of the solution.

-

(a)

The carbonic equilibrium

When we dissolve CO2 in water, we have the following equilibrium:

At ordinary temperature, so that there is only 3% of carbon dioxide in the form of H2CO3

The latter has in solution, the behavior of a diacid according to:

If we note: [CO2 (free)] = [H2CO3] + [CO2]

We write the balance:

In addition, we have the autoprotolysis of water:

The previous constants depend on the temperature of the water, the ionic strength of the solution, i.e., the concentration, and the charge of all the ions present (fundamental and characteristic).

-

(b)

The calcocarbonic equilibrium

For water in equilibrium with solid calcium carbonate, the equilibrium:

This equilibrium, called calcocarbonic, is governed by the law of mass action, which establishes between the concentrations of the ions Ca2+ and CO32− the following relation:

Ks depends on the temperature and the ionic strength of the solution. It also depends on the crystallographic variety. Under the usual conditions and at ordinary temperature, the Ks = 10−8.3 is often adopted.

If the product [CO32−][Ca 2+] is lower than Ks, it will not be possible to precipitate.

Conversely, for having precipitation of calcium carbonate, it is necessary to have:

Generally, in a circuit of water, one can write at any point of this circuit:

where δ is the local supersaturation coefficient of water. Indeed, three cases can occur at one point:

δ < 1: the water is locally aggressive.

δ = 1: the water is locally at equilibrium.

δ > 1: the water is thermodynamically capable of locally precipitating CaCO3 according to the increasing germination process mentioned above.

The germs of CaCO3 can have varied evolutions:

-

The germ will grow and regress and then dissolve.

-

The seed will grow and evolve into a crystal. We then go to a phenomenon of sludge generating precipitation.

-

The seed will be produced at the level of a metal wall. We will be in a scaling process if the connection with the wall is strong enough.

-

The germ will remain suspended in the water and be carried away by the flow.

The solubility of CaCO3 depends on the pH. It is shown in Fig. 5. The solubility of CaCO3 can be increased by the addition of carbon dioxide according to the equilibrium:

The distribution of carbonate species as a fraction of total dissolved carbonate in relation to solution pH [12]

2.2.2 Calcium Sulfate

Calcium sulfate is one of the most common scalants in processes involving seawater, such as desalination. It is also often referred to as nonalkaline scale. Pure calcium sulfate is white in color with a similar resemblance to calcium carbonate. It exists as CaSO4⋅nH2O. All these forms are more soluble than calcium carbonate and magnesium hydroxide [13]. The most common is gypsum with a monoclinic prismatic crystal structure, with four or eight molecules in the unit cell. It crystallizes as white crystals according to the following reaction [10]:

Layers of gypsum can settle and form a shell with layers of anhydrite. These relatively thin layers (0.6 mm) of calcium sulfate scale on the tubes of low-pressure boilers can cause a massive temperature drop of 180°C [14]. This had previously been shown by Bansal and Müller-Steinhagen [15] for calcium sulfate fouling on plate heat exchangers.

Crystallization of calcium sulfate is a complex phenomenon influenced by a number of parameters, such as temperature, pressure, electrolytes, and dissolved organic matter, and the presence of other minerals [16]. Research by Bansal and Müller-Steinhagen [15] showed that the measured calcium sulfate resistance of a plate heat exchanger was 50% lower than 85°C compared with 90°C. Temperature also influences the formation of polymorphs. Gypsum is the most formed deposit in all reverse osmosis and cooling systems that use moderate temperatures (up to 50°C), while calcium sulfate hemihydrate and anhydrite are the most formed in applications at high temperature [17, 18]. Calcium sulfate is found in many cooling systems, but since most of these systems operate at pH = 7–9, calcium carbonate is the most predominant scale, and calcium sulfate only precipitates when all carbonate is eliminated [19]. Precipitation of calcium sulfate is insensitive to pH, unlike other calcareous deposits [20]. Calcium sulfate may be in the form of hard rock or soft granules [10].

2.2.3 Magnesium Scales

A number of magnesium scales, such as magnesium hydroxide (Mg(OH)2), magnesium carbonate (MgCO3), and hydromagnesite (Mg5(CO3)4(OH)2⋅4H2O), can be formed in applications using water. Magnesium hydroxide is commonly known as brucite but may also precipitate as amorphous magnesium hydroxide. Magnesium carbonate is known as magnesite (magnesium carbonate anhydrite) [15].

Magnesium hydroxide is the most common of magnesium scales. The magnesium hydroxide is formed in a series of the following reactions [13]:

Other magnesium containing deposit is magnesium silicate (MgSiO3) and its hydrated form known as talc. Possibly less known magnesium containing minerals also include iowaite [Mg6Fe2 (OH)16 Cl2⋅4H2O], new beryite (MgHPO4⋅3H2O), serpentine (3MgO⋅2SiO2⋅2H2O), merille [Ca18Na2Mg2 (PO4)14], and other phosphates [Mg3(PO4)⋅Mg(OH)2, Mg3(PO4)2⋅8H2O, and Mg3(PO4)2⋅22H2O].

The formation of magnesium scales is affected by a number of parameters. The rate of magnesium hydroxide crystallization in seawater depends on temperature, pH, concentration of bicarbonate ions, the development of carbon dioxide, magnesium ion concentration, and total dissolved solids. It has been noted previously that magnesium hydroxide supersaturation is pH dependent and that brucite is formed at a higher pH [21,22,23]. The effect of temperature is important in the case of nesquehonite, which occurs mainly at temperatures below 42°C, and hydromagnesite, which formed at temperatures between 60 and 90°C [23]. Magnesium hydroxide is a salt of inverse solubility, generally formed at temperatures above 95°C, mainly because of the increased formation of hydroxyl ions at such high temperatures [13].

The two alkaline scales (magnesium hydroxide and calcium carbonate) are closely related, and the presence of magnesium affects the formation of calcium carbonate. It has already been reported that the presence of dissolved magnesium favors the formation of aragonite compared to other polymorphs, with magnesium concentrations in seawater explaining the presence of aragonite rather than calcite when seawater is used [23].

2.2.4 Silica Scales

Large amounts of silicon dioxide and many silicate minerals are present in the Earth’s crust, resulting in high concentrations in natural environments. They can be in a soluble form (silicic acid, soluble silicates) or in an amorphous state (colloidal silica) [6]. The solubility of crystalline silica (quartz) is quite low with 5–6 mg L−1 at 25°C and pH < 9 with the solubility of amorphous silica ranging from 120 to 150 mg L−1 at 25°C and pH < 8–8.5. Amorphous silica is usually classified as dissolved (reactive), colloidal (nonreactive), and particulate (suspended) silica [24]. Ning [25] states that natural waters may contain dissolved and suspended silica concentrations that subsequently form on the surface of boilers, RO membranes, and cooling towers in the form of deposits and scales that may include layers of glass, gels, powders, or nanoscopic particles virtually “invisible.” Fouling of silica in water treatment equipment has been dealt with since the earliest developments in industrial water chemistry. As with the previous types of scales, it was reported that a SiO2 scale layer 0.5 mm thick results in a 90% decrease in heat transfer [16]. Colloidal silica that enters equipment with the feed water can then settle on the boiler tubes or turbines in the form of silicates including SiO2, Na2SiO3⋅9H2O, NaFeSiO6, or Mg6[(OH)8Si4O10] that are not soluble in water and extremely difficult to remove and therefore resulting in losses in turbine efficiency and capacity [26].

Ning [25] has described that “reactive” and “non-reactive” silica in water has a broad spectrum of molecular sizes ranging from silicic acid monomer (Si(OH)4) to dissolved oligomeric forms, through the colloidal polymer suspensions and optionally in the form of silica (SiO2)n of silicate particles, n representing very large numbers. If metal hydroxides such as aluminum, iron, magnesium, and calcium are incorporated during dehydration polymerization reactions, metal silicates are formed. It is widely accepted that the polymerization of silica monomers is the formation mechanism of amorphous silica deposits [6, 27].

According to Ning, monomeric silicic acid (the “reactive silica”) is the predominant dissolved silica species found in natural waters with concentrations varying from 1–3 mg L−1 in mountain lakes to 50–300 mg L−1 in well waters in oil production fields. The silicic acid concentration in seawater is reported to range between 1 and 10 mg L−1 and is unregulated in municipal drinking water [25].

2.3 Influence of Scale on Industrial Processes

Scale formation affects most industries, as it can occur in a number of industrial processes, such as heating or cooling, desalination, and oil production. Boilers, cooling towers, pipes, tubes, and other equipment used in water-intensive processes pose serious problems, often hampering the overall process and increasing production costs due to associated maintenance costs [28]. The severity of the problem will vary depending on the composition of the water and the operating conditions. The formation of a deposit or layer can take weeks, even months or shorter, leading to major operational problems. This formation of deposits or scale can lead to reduced flow and heat transfer; this leads to additional maintenance or even equipment failure and increased operating costs, not to mention that the deposits formed on the heat transfer surfaces will significantly degrade the performance of the heat exchangers and can lead to a complete failure of the equipment, the mineral deposits affect the nuclear center; chemical, food and beverage industry; the oil and gas industries.

The major sources of concern are cooling water and associated processes due to widespread use in many industries. During cooling applications, flaking is caused by solids concentration, temperature changes, and pressure drop [10]. The other type of recirculating cooling system is an open recirculating system in which water is continuously reused by cooling probably of the greatest interest here. Such systems are frequently used in large central utility stations; in chemical, petrochemical, and petroleum refining plants; in steel mills and paper mills; and in all types of processing plants [21]. Unfortunately, these systems also have the greatest potential for all types of problems, including fouling due to the excessive amount of mineral ions present in the water flowing through the system at high temperatures and a compliment constant fouling potential when replacing evaporated steam. The main types of scales that form in these types of systems include calcium carbonate, calcium sulfate, calcium phosphate, and magnesium silicate [21]. The formation of scale is a major problem in areas such as energy production, including geothermal energy. This process offers many advantages because it is renewable, clean, safe, and flexible, but to make production competitive with other energy resources such as natural gas, it is necessary to minimize operating costs. In this case, the mineral deposits not only reduce the capacities of the wells but also the heat exchange zones, thus limiting the degree of use of the heat transported by the fluids [29].

In many industries, such as mineral processing, increasing scarcity of freshwater and stricter environmental regulations are leading to a mandatory increase in the use of recycled water, leading to more problems with mineral scale formation [30]

3 Scale Inhibition by Chemical Additives

In the face of scale formation problems, several chemical methods based on the use of scale inhibitors have been largely effective [31,32,33]. Admitting the appearance of crystals as fatal, this treatment directly attacks the time and type of germination. For this purpose, products are used which delay the appearance of the seeds (germination time longer than the residence time of the water in the circuit) and promote the formation of little adherent crystals (homogeneous germination) and/or which decrease the growth rate of crystals [1].

The term “tartrifuges” refers to substances that have one or more of these properties. The tartrifuge effect has been known for a long time. Also, the search for new tartrifuges and their development still remains an approach marked by certain empiricism. For this reason, it is important to specify test conditions in which the effectiveness of a tartrifuge can be appreciated.

3.1 Classification of Different Tartrifuge

The big family of tartrifuges is growing every day, which does not allow us to give an exhaustive list of all the products on offer. However, most of these products can be grouped into families with a common grouping or structure that is the basis of the properties of the tartrifuge. By limiting ourselves to the most classical and the most used, this classification is represented according to Fig. 6.

3.1.1 Condensed Phosphates

These products whose properties are known for a long time and which are widely used in Europe, particularly in the formulation of washing powders, hydrolyze easily above 70°C and give orthophosphate (PO43−), which once released into the natural environment is considered to be the main cause of the eutrophication phenomena in aquatic environments. In the late 1960s, these products were replaced by organophosphonates.

Sodium tripolyphosphate is the most used. Its structural formula is given in Fig. 7.

3.1.2 Organophosphonates

They are characterized by one or more groups associated with an organic radical. The most used are:

-

(a)

Phosphonates: These compounds have an advantage over polyphosphates since the CP bond of 1.87 Å length is more hydrolysis resistant than the PO bond of 1.5 Å in length, and they are easily biodegradable. On the other hand, they have better stability in the presence of chlorine. The best product is 1-Hydroxyethylidene-1,1-diphosphonic acid (HEDP)

-

(b)

Phosphonates with carboxylic function: As the name implies, they are composed of two functional groups: -PO3H2 and -COOH. These acids have remarkable resistance to hot hydrolysis in the presence or absence of bactericides/oxidants [34].

-

(c)

Amino phosphonates: These compounds have both a -PO3H2 group and a nitrogen group [34].

3.1.3 Polyelectrolytes

A number of macromolecules have tartrifuge properties. We can distinguish:

-

(a)

Polycationics: the most used correspond to quaternary ammonium compounds, for example, polyethylenimines. They are relatively little used because their effectiveness is low [35].

-

(b)

Polyanionics are polycarboxylic or sulfonic acids [34, 35]. Let’s mention the polyarilics, the polymetacrylics, the polyvinysulfonic ones, etc. [36,37,38].

-

(c)

Non-ionic: they generally have less efficiency than anionics but much higher than cationic, for example, polyacrylamides [35].

3.2 Additional Work on Scale Inhibitors

Several types of scaling inhibitors, mineral or organic, have proven effective and are already marketed. The inhibiting effect of metal ion scaling (Cu2+, Zn2+) results in the formation of mixed carbonates of calcium and copper CuxCa1−xCO3 and zinc and calcium carbonates ZnxCa1−xCO3. The mechanism of inhibition is based on the dehydration energy of Cu2+ and Zn2+ ions, which is greater than that of Ca2+ ions. This makes it possible to block the growth of the seeds formed [39,40,41]. Metallic iron ions play an important role in inhibiting scaling [42,43,44,45].

The most effective is 1,1-hydroxyethylenediphosphonic acid (HEDP) and is active at a concentration of 0.62 μmol L−1 (0.2 mg L−1) [46]. A concentration of 9.1 × 10−8 M HEDP is sufficient to completely prevent crystal growth of calcium carbonate for more than 100 h [47].

Rosset and Douville [48] have shown that very low concentrations of organic phosphonate or polycarboxylate inhibitors inhibit the precipitation of calcium carbonate in EL Hamma’s borehole water. Effective concentrations of these inhibitors are in the range of 1.1–1.5 mg L−1.

Reddy and Nancollas [49] noted with the Crystal Growth Criterion that HEDP is the best among a range of phosphonates studied, for pure product concentrations of 0.5 ppm. The same result was obtained by Shiliang and Kan [50] when comparing a range of phosphonates as scale inhibitors.

The addition of 0.5–0.6 ppm amino trimethylene phosphonic acid “ATMP” inhibits calcium carbonate encrustation under chronoamperometric conditions [51].

A certain number of organic substances of natural origin have recognized tartrifuge power: this is the case for the metabolites of planktonic algae [52] and humic substances [53].

Abd-El-Khalek et al. [54] studied the antiscaling properties of sodium hexametaphosphate (SHMP) using electrochemical methods as well as a comparison between SHMP and polyacrylic (PPA). This study showed that SHMP is more effective against scale formation than PPA. They also studied the antiscaling properties of the palm leaf extract by chronoamperometry, impedance meter, and optical microscope. The results showed that this extract could be considered as a precipitation inhibitor of CaCO3 with a concentration of 75 ppm on salt water [55].

Gao et al. [56] synthesized the polyaspartic acid derivative (PASP-SEA-ASP) which showed excellent antiscaling properties in marine waters, with a 100% inhibition rate for the assay of 14 mg L−1. This study demonstrates the potential of PASP-SEA-ASP for scale and corrosion inhibition in domestic and industrial facilities using seawater [56].

Touir et al. [57] based their study on the mechanism of action of sodium gluconate on ordinary steel. They evaluated the effect of temperature on the inhibition rate of sodium gluconate, which becomes more important with increasing temperature, which has been explained by the formation of a stable GS-Ca2+ complex.

Henghui Huang et al. [58] investigated the scale inhibition behavior of PESA with linear and hyper-branched structure against CaCO3 and CaSO4 scales that were evaluated using static scale inhibition method, and their ability to retard deposition of CaCO3 was also examined. The experimental results showed that, for CaCO3 and CaSO4, the PESA with hyper-branched structure provides a scale inhibiting efficiency as high as 95.9% and 94.3%, respectively, at an inhibitor concentration of 15 mg L−1.

4 Natural Inhibitors of Calcium Carbonate Scaling

Nowadays, one of the major axes of research is to find economic and environmentally friendly inhibitors. Research is underway for new environmentally compatible inhibitory formulations called “green inhibitors.” A chemical is defined as “green” based on three criteria: toxicity, bioaccumulation, and biodegradation [35, 59]. The advance on green scale inhibitors is surprising, and numerous researches and discoveries have emerged. These green inhibitors may be petrochemical derivatives, or using “natural” organic molecules or plant extracts, such inhibitors could be used in various fields such as energy, water, and the food industry.

4.1 Petrochemical Derivatives

In this section, we took the initiative to make a selection of interesting green organic molecules from petrochemicals. In a recent article, Hasson et al. [60] reported that the most promising green scale inhibitors relied primarily on polyaspartic acid (PASP).

Polyepoxysuccinic acid (PESA) is a green scale inhibitor developed in the 1990s in the United States. Static experiments performed by Sun et al. at 30°C [61] showed that at a concentration of 10 mg L−1, the scale inhibition ratio of PESA to CaCO3 at three different concentrations of calcium (40, 100 and 200 mg L−1) was greater than 90%. Liu et al. [62] showed that the anticalcination performance of PESA was higher than that of PASP. Therefore, PESA can be considered as an interesting alternative to PASP in water treatment technology. However, the performances of these molecules in field tests are limited [63, 64], and these molecules deserve to be studied further. However, it should be noted that the inhibition performance of PASP was studied in a pilot cooling water plant by Laborelec (Belgium) [64]. The effectiveness of the tested PASP would be similar to that of low molecular weight polyacrylate, a polymer used in some industrial processes. Laborelec has implemented a PASP scale control in a power plant [60]. PASP was developed in the early 1990s and has many applications, such as scale and corrosion inhibition, water softening, and green chemical formulations for detergent formulations [60]. PASP has non-nitrogenous, non-phosphorous, and biodegradable characteristics, which makes it a good green inhibitor. Indeed, the degradation properties of PASP have been examined by Thombre et al. [65] in the laboratory, Gao et al. indicated by the biodegradability of PASP prepared from poly(succinimide) by 70% thermal condensation in 1 month [66] Martinod et al. [67]. This study describes the effect of PASP on the desquamation of breasts reproducing the composition of the North Sea, where the concentration of Ca2+ was 14,225 mg L−1. In addition, PASP significantly reduced the growth rate of CaCO3 crystals by blocking the active sites of growth. Recently, Liu et al. used in diluted mineral water (concentration of Ca2+ 253 mg L−1) at 80°C [62].

Carboxymethyl inulin (MIC) is a biodegradable and nontoxic polysaccharide-based polycarboxylate, obtained from inulin by chemical synthesis. It has significant inhibitory effects on the crystallization of calcium carbonate by the presence of carboxylic acid groups in its structure. Verraest et al. [68] investigated for the first time the effect of small amounts of MIC between 0.1 and 200 mg L−1 on the crystallization of calcium carbonate and concluded that MIC is a good inhibitor of CaCO3 by changing the morphology of the crystals formed. They also showed that the MIC could influence the growth rate of calcium carbonate seed crystals by using constant composition experiments to study the growth kinetics of constant supersaturation seed crystals. The authors suggested that MIC molecules with a high degree of substitution and a high degree of polymerization were the most effective. Figure 8 presents the structures of some green antiscalant from petrochemistry.

4.2 Natural Organic Molecules

Environmental requirements impose many challenges in the field of water treatment. Thus, the concept of “green chemistry” has been proposed. In their study of the inhibition of the growth of calcite crystals by a humic substance [69], Hoch et al. [70] performed constant composition experiments in a sealed reactor. Solutions with equal molar concentrations of calcium and carbonate have been implicated. They quantified the kinetic effects of humic acid and fulvic acid from different sources on the crystalline growth of calcite by adding seed crystals to a supersaturated solution.

Kumar et al. [71] test the performance of pteroyl-L-glutamic acid (PGLU) scale inhibition by conducting static and dynamic experiments, a specific form of commercially available vitamin M. PGLU is found in almost all leafy vegetables and is essential for many bodily functions, including nucleotide synthesis. Scale inhibition at 100% [72, 73] was obtained by pot experiments at 70°C with 120 mg L−1 PGLU. The synthetic waters tested were representative of those found in an oil field at sea. The waters contain high amounts of calcium and bicarbonate. At 90 and 110°C, higher concentrations of PGLU, between 160 and 200 mg L−1, were required to inhibit the formation of the latter result which was confirmed by dynamic tube blocking tests performed at 110°C, where the minimum concentration of PGLU for scale inhibition was 160 mg L–1. The authors suggested using FTIR, XRD, and SEM that scale inhibition occurred by formation of a soluble complex with calcium ions and deformation of CaCO3 crystalline morphology. They concluded that PGLU could be an excellent green chemical for scale inhibition in oil wells.

The authors have shown that certain hydrophobic aquatic organic acids derived from higher plants in the Florida Everglades were able to reduce the rate of calcite growth from a concentration of 0.2 mg L−1. The growth of calcite was almost completely inhibited with a concentration of 5 mg L−1 in dissolved organic matter. An SEM study suggested that crystal growth sites were blocked by adsorbent ligands. In a recent work, Gauthier et al. [74] investigated the calcium carbonate scale ability of humic acid in synthetic water (100 mg L−1) at 35°C, purchased as sodium salt. Humic acid also had a significant effect on scaling at a concentration as low as 0.2 mg L−1. The associated efficiency was 78%, as determined by the resistivity response of the FCP. This work may explain the ability of raw rivers to scale, depending on water quality and season, flow [74]. These results could have an impact on many industrial facilities supplied with raw river water, knowing that humic substances are not used as inhibitors in technical applications.

Reddy et al. [75] used the constant composition technique to determine the growth rate of calcite in the presence of citric acid at 25°C and pH 8.55. A solution with constant calcite supersaturation was seeded with calcite crystals synthetically prepared in the presence of citric acid. Then they made a titration of Ca2+ ions remaining in solution order to follow the crystallization of calcium carbonate. The authors showed that citric acid exhibited only a moderate reduction in the growth rate of calcite crystals at concentrations as high as 10 mg L−1 and did not lead to a reduction in growth rate in the range of 0.01–0.1 mg L−1 (total calcium concentration 76 mg L−1). This could be explained by the fact that citric acid is a linear polycarboxylic acid. The authors suggested that cyclic and rigid polycarboxylic acids, such as tetrahydrofuran-2-carboxylic acid or cyclopentane-tetracarboxylic acid, were much more effective in descaling [75].

The structures of some green antiscalant from petrochemistry are presented in Fig. 9.

4.3 Plant Extracts as Scale Inhibitors

The most promising alternatives to “natural” organic molecules are the use of plant extracts as scale inhibitors. Recently, the scale inhibition properties of plant extracts have been investigated.

Certain authors suggested that fig leaf extract may complex the cations present in the brine solution or disperse the suspended solids through adsorption. They carried out the same study concerning the olive leaf extract [76]. Indeed, olive leaves contain many phenolic molecules including oleuropein, the most abundant biophenols in olive leaves [77] and caffeic acid [78, 79] The concentration of the inhibitor was 10 mg L−1. The authors assumed that these extracts were more effective than polyaspartic acid in preventing calcium carbonate formation. Indeed, the percentage of inhibition was 16.7% for both soy-based polymer and polysaccharides from sea weeds, whereas it was only 6.6% for polyaspartic acid.

A second strategy was to consider plants containing well-known compounds that can complex calcium cations. In this respect, polyphenols or polysaccharides, which have hydroxyl and/or carboxyl functional groups that interact with divalent ions such as Ca2+ or Mg2+, are very good candidates. Abdel-Gaber et al. [80] studied the antiscaling properties of Punica granatum hull and leaf extract in alkaline brine at 25°C using conductivity measurements, electrochemical impedance spectroscopy, and chronoamperometry in conjunction with SEM, EDX, and optical microscopic examinations. According to chronoamperometry measurements, the current density increased from 87% when the concentration of the Punica granatum extracted from hull increased from 10 to 100 mg L−1. This indicated that the extract is an efficient antiscalant. It must be noticed that the aqueous extract at 50 mg L−1 concentration was still effective as a scaling inhibitor after 28 days of storage at 5°C.

Castillo et al. reported inhibition results of calcium carbonate scale performed with aloe vera in Venezuelan oilfields [81, 82]. The scale inhibitor was obtained by dissolving aloe vera gel in the water at a concentration in the range 5–50% wt/wt. This solution contains polysaccharides [83] that can complex with Ca2+ ions. Some field tests were carried out on Venezuelan oil wells with water containing high bicarbonate ions (total calcium concentration of 535.4 mg L−1). Information on the inhibitory performance of aloe vera is unfortunately limited. Weekly inspections of coupons performed during field tests with inhibitors (20 or 30 days of duration) led the authors to define the recommended concentration for the inhibitor. The aloe vera solution was reported to provide very effective scale inhibition with a concentration of 15.2 mg L−1. Pressure and temperature were also recorded through the entire field test and remained almost constant during the tests. This indicated the absence of precipitated solids in the system in the presence of aloe vera.

5 Research on Scale Inhibitors in Algeria

Unfortunately, the work done so far on the scale and scale inhibitors in Algeria are not many, but we cannot fail to mention some researchers who worked on ambitious projects. Figure 10 shows the location of hard waters already studied in Algeria (Bordj Bou Arreridj, Setif, Constantine, Tebbessa, Aïn M’lila, and Ouargla).

Ghizellaoui et al. [84] studied the effect the temperature and the concentration of NaOH and K3PO4 inhibitors on hard water in Constantine (Hamma), as well as the effect of CaOH, Na2CO3, and KH2PO4 concentration as inhibitors on Fourchi drilling water [85].

A new green inhibitor, based on the aqueous extract of Paronychia argentea (PA), for the reduction of CaCO3 formation on metal surfaces, have developed by Belarbi et al. [86]. They tested the PA extract at different temperatures and with the addition of several biocides. The results concluded that 70 ppm is necessary to completely inhibit scale at 20 and 45°C. However, its efficiency decreases at 60°C [86]. Another green inhibitor has been tested by Kahoul et al. [87] scaling power of Hammam drinking water. The addition of olive leaf extract to the Hammam water even at low concentration (20 ppm) prevents scale coverage of the surface, indicating that the extract can be used as a good antiscalant.

Karar et al. [88] have published an interesting paper; this paper focuses on the study of the glutamic acid (GA) for reducing CaCO3 scale formation on metallic surfaces in the water of Bir Aissa region. This study showed that at 30 and 40°C, a complete scaling inhibition was obtained at a GA concentration of 18 mg L−1 with 90.2% efficiency rate. However, the efficiency of GA decreased at 50 and 60°C. This team also investigated the inhibitive effect of citric acid (CA), sodium citrate (SC), and their mixture (CA–SC) on the CaCO3 scale. The electrochemical study showed that CA provides a slight inhibition of CaCO3 deposit at a concentration of 70 ppm on stainless steel surface. The use of SC alone inhibits very little formation of scale. The use of the mixture (50% of CA and 50% of SC) with small concentration led to a significant inhibition of the CaCO3 formation [89, 90]. The works done so far on scale inhibitors in Algeria are given in Fig. 11.

The effect of mineral inhibitor on the precipitation of CaCO3 in two Algerian groundwaters has been examined by Bendaoud et al. [91]. Chronoamperometry tests show that the antiscale treatment with mineral phosphates (KH2PO4) is more efficient for the Hamma (Constantine) than Negrine water (Tebbessa) with 2 mg/L. Tested inhibitors affect strongly the nucleation growth kinetics in the case of Hamma water and only the scale compactness in Negrine water. This was attributed to the difference in the chemical composition of the studied waters.

Djallal et al. [92] studied the electrochemical behavior of a carbon steel electrode against scale of barium sulfate. Tests conducted on water in the absence of scale inhibitors revealed the formation of a thick layer on the surface composed mainly of barium sulfate BaSO4. Scale of barium sulfate naturally forms and evolves with immersion time. In the presence of inhibitors, the electrochemical impedance spectroscopy spectra show a decrease in the resistances and reveal that this inhibiting effect is a tendency to the formation of small quantities of precipitated barite solid on the surface of the electrode and that their effectiveness of inhibition increases with increasing concentration. This study shows that the inhibitor (phosphonate) is much effective at a low dose and at a high concentration. Its efficiency is limited because of the apparition of the micelles. However, the polyacrylate combined with phosphate ester has a satisfying inhibiting effect which increases with increasing of inhibitor concentration. Figure 10 shows the location of hard waters already studied in Algeria.

6 Conclusion

In recent years, many efforts have been made to generate green inhibitors, either from plant extraction or by using natural organic molecules. Green inhibitors obtained from natural products, especially by exploring the international pharmacopoeia, are clearly a growing field. Such green inhibitors could be advantageously used in situations where the use of organic materials would be limited by environmental regulations and/or application difficulties (i.e., toxicity). The Algerian researchers are not sparing themselves to find new inhibitors of nature and health, knowing that the country is full of inexhaustible resources and new discoveries are in prospect.

7 Recommendations

Scale in hard water is a major concern for industrial processes and domestic installations. Undesirable scale deposits cause many technical problems with serious safety and economic consequences, such as:

-

Total or partial obstruction of pipes leading to a decrease in the flow velocity

-

The reduction of heat transfer due to the precipitate of calcium carbonate whose conductivity is 15–30 times less than steel

-

The clogging of the filters

Energy production in nuclear power plants is often limited by scale in cooling towers. In Great Britain, non-productive expenses related to scaling have been estimated at 600 £ million a year. These same expenses are about 1.5 billion euros per year in France. Therefore, it is important to establish appropriate methods to study this phenomenon and find effective ways to combat it.

This study aims to shed light on the phenomenon of scaling and inhibitors that can fight or reduce the formation of scale on industrial and domestic facilities, among the recommendations necessary to minimize this phenomenon:

-

Make a complete study on the phenomenon of scaling in the entire territory of Algeria, and educate industry and the government on the risk of scaling and the use of harmful scaling inhibitors.

-

Focus research on more economical and environmentally friendly green inhibitors based on toxicity, bioaccumulation, and biodegradation.

-

Improve the approach to the study of scaling in Algeria, look for new hard water sites to test inhibitors, and reduce the risk of scaling.

References

Leroy P (1995) Mechanism of precipitation of calcium carbonate. Tribune de l’eau 573:31–46. (translated from French)

Ketrane R, Leleyter L, Baraud F, Jeannin M, Gil O, Saidani B (2010) Characterization of natural scale deposits formed in southern Algeria groundwater. Effect of its major ions on calcium carbonate precipitation. Desalination 262:21–30

Franck HUI (2011) Research on performance evaluation and anti-scaling mechanism of green scale inhibitors by static and dynamic methods, PhD thesis, Paris University, Paris

Amjad Z, Demadis ND (2015) Mineral scales and deposits (scientific and technological approaches). Elsevier, Amsterdam

Stumm W, Morgan JJ (1996) Aquatic chemistry, chemical equilibria and rates in natural waters. Wiley, New York

Antony A, Low JH, Gray S, Childress AE, Le-Clech P, Leslie G (2011) Scale formation and control in high pressure membrane water treatment systems: a review. J Membr Sci 383:1–16

Günther C, Becker A, Wolf G, Epple M (2005) In-vitro synthesis and structural characterization of amorphous calcium carbonate. Z Anorg Allg Chem 631:2830–2835

Pascal P (1958) New mineral chemistry treaty. Tome IV, Masson, Paris (translated from French)

Zidoune M (1996) Contribution to the knowledge of scaling mechanisms by various electrochemical methods. PhD thesis, Paris VI University, p 160 (translated from French)

Dugniolle E (1994) The general scale problem in pipes. Tribune de l’eau 567:6–8. (translated from French)

Grasby S (2003) naturally precipitating vaterite (μ-CaCO3) spheres: unusual carbonates formed in an extreme environment. Geochim Cosmochim Acta 67:1659–1666

Al Omari MMH, Rashid IS, Qinna NA, Jaber AM, Badwan AA (2016) Calcium carbonate. In: Profiles of drug substances. Excipients and related methodology, vol 41. Elsevier, Amsterdam, pp 31–132

Patel S, Finan MA (1999) New antifoulants for deposit control in MSF and MED plants. Desalination 124:63–74

Smith C, Coetzee PP, Meyer JP (2003) The effectiveness of a magnetic physical water treatment device on scaling in domestic hot-water storage tanks. Water SA 29:231–236

Bansal B, Müller-Steinhagen H (1993) Crystallization fouling in plate heat exchangers. J Heat Transfer 115:584–591

Trivedi TJ, Shukla J, Kumar A (2014) Effect of nitrate salts on solubility behaviour of calcium sulfate dehydrate (gypsum) in the aqueous sodium chloride system and physicochemical solution properties at 308.15 K. J Chem Eng Data 59:832–838

Amjad Z (2013) Gypsum scale formation on heated metal surfaces: the influence of polymer type and polymer stability on gypsum inhibition. Desalin Water Treat 51:4709–4718

Muryanto S, Bayuseno AP, Sedion W, Mangestiyono W (2013) Influence of flow rates and copper (II) ions on the kinetics of gypsum scale formation in pipes. Int J Technol 3:217–223

Strauss SD, Puckorius PR (1984) Cooling-water treatment for control of scaling, fouling, corrosion. Power 128:S1–S24

Shih WY, Rahardianto A, Lee RW, Cohen Y (2005) Morphometric characterization of calcium sulfate dihydrate (gypsum) scale on reverse osmosis membranes. J Membr Sci 252(1–2):253–263

Glade H, Kromer K, Will S, Loisel K, Nied S, Detering J, Kempter A (2013) Scale formation and mitigation of mixed salts in horizontal tube falling film evaporators for seawater desalination. Proceedings of international conference on heat exchanger fouling and cleaning, Budapest, Hungry, June 9–14, 2013

Glade A, Ulrich J (2003) Influence of solution composition on the formation of crystalline scales. Chem Eng Technol 26:277–281

Andrews A, Davé B, López-Serrano P, Tsai SP, Frank R, Wilk M, Koutsakos E (2008) Effective scale control for sea water RO operating with high feed water pH and temperature. Desalination 220:295–304

Hermosilla D, Ordóñez R, Blanco L, De la Fuente E, Blanco A (2012) pH and particle structure effects on silica removal by coagulation. Chem Eng Technol 35:1632–1640

Ning RY (2010) Reactive silica in natural waters e a review. Desalin Water Treat 21:79–86

Vidojkovic S, Onjia A, Matovic B, Grahovac N, Maksimovic V, Nastasovic A (2013) Extensive feedwater quality control and monitoring concept for preventing chemistry-related failures of boiler tubes in a subcritical thermal power plant. Appl Therm Eng 59:683–694

Nishida A, Shimada Y, Saito T, Okaue Y, Yokoyama T (2009) Effect of aluminium on the deposition of silica scales in cooling water systems. J Colloid Interface Sci 335:18–23

Amjad Z, Koutsoukos PG (2014) Evaluation of maleic acid based polymers as scale as scale inhibitors and dispersants for industrial water applications. Desalination 335:55–63

García AV, Thomsen K, Stenby EH (2005) Prediction of mineral scale formation in geothermal and oilfield operations using the extended UNIQUAC model, part I. Sulfate scaling minerals. Geothermics 34:61–97

Dávilla-Pulido GI, Uribe-Salas A (2014) Effect of calcium, sulfate and gypsum on copper activated and non-activated sphalerite surface properties. Miner Eng 55:147–153

Lin W, Colin C, Rosset R (1990) Caractérisation du pouvoir incrustant d’une eau par chronoampérométrie au potentiel optimal d’entartrage. TSM-L’eau 12:613–620

Rosset R, Sok P, Poindessous G, Ben Amor M, Welha K (1998) Characterization of the compactness of calcium carbonate deposits in geothermal waters of southern Tunisia by impedancemetry. C R Acad Sci Paris t.1:751–759. (translated from French)

Tlili MM, Elfil H, Ben Amor M (2001) Chemical inhibition of scaling. Cahiers Eur Sci Assoc Water Health 6:29–39. (translated from French)

Trade Association of Research and Production (1993) Oil and natural gas commits technicians circuits seawater treatment and materials, vol 95. Editions Tech, Paris, pp 99–195. (translated from French)

Roques H (1989) Theoretical foundations of chemical treatment of water, vol 1, Edition lavoisier TEC et DOC 217–508. (translated from French)

Geffroy C, Persello J, Foissy A, Cabane B, Tournilhac F (1997) The frontier between adsorption and precipitation of polyacrylic acid on calcium carbonate. Rev Institut Fr pétrole 52:183–190

Guofeng C, Yao N, Aksay LA, Groves JT (1998) Biomimetic synthesis of macroscopic-scale calcium carbonate thin films, evidence for a multistep assembly process. J Am Chem Soc 120:11977–11985

Boggavarapu S, Chang J, Calvert P (2000) A test for mineralization inhibition for calcium salts using agarose hydrogels. Sci Eng C 11:47–49

Ghizellaoui S, Lédion J, Chibani A (2004) Study of the inhibition of the scaling power of Hamma waters by rapid controlled precipitation and an accelerated scaling test. Desalination 166:315–327. (translated from French)

Lédion J, François B, Vienne J (1998) Characterization of the scaling power of water by fast controlled precipitation. J Eur Hydrol 28:15–35. (translated from French)

Urion E, Lejeune G (1950) The role of zinc in inhibiting scaling. Revue de l’Eau 37(2):23–28. (translated from French)

Peters RW, Stevens JD (1982) Effect of iron as a trace imurity on the water softening process. AICHE Sympos Ser 78:46–67

Katz JL, Parsiegla IK (1995) Calcite growth inhibition by ferrous and ferric ions. In: Amjad Z (ed) Mineral scale formation and inhibition. Plenium Press, New York, pp 11–21

Katz JL, Reick MR, Herzog RE, Parsiegla KI (1993) Calcite growth inhibition by iron. Langmiur 9:1423–1430

Pernot B, Euvard M, Simo P (1998) Effet of iron and manganese on the scaling potentiality of water. J Water SRT-Aqua 47:21–29

Rosset R, Mercier D, Douville S (1997) La mesure du pouvoir entartant des eaux par méthodes électrochimiques et les procédés antitartre. Ann Fasl Exp Chim 90:41–65

Nancollas G, Kzmierczak G, Schuttringer E (1981) A controlled composition study of calcium carbonate crystal growth: the influence of scale inhibitors. Corrosion 37:76–81

Rosset R, Douville S, Ben Amor M, Welha K (1999) Inhibition of scaling by the geothermal waters of southern Tunisia. Rev Sci Eau 12(4):753–764. (translated from French)

Xu G, Yao N, Aksay LA, Groves JT (1998) Biomimetic synthesis of macroscopic-scale calcium carbonate thin films, evidence for a multistep assembly process. J Am Chem Soc 120:11977–11985

Shiliang H, Amy T, Thompson MB (1999) Inhibition of calcium carbonate precipitation in NaCl brines from 25 to 90 °C. Appl Geochem 14:17–25

Zidoune M, Khalil A, Sakaya P, Colin C, Rosset R (1992) Demonstration of the anti-encrusting effect of aminotri-(methylenephosphonic acid) by chronoamperometry and chronoelectrogrovimetry. C R Aca Sci Paris 315:795–799. (translated from French)

Ladel J, Leroy P (1997) Demonstration of the inhibitory effect of planktonic algae metabolites on the precipitation of calcium carbonate in natural waters of superficial origin. J Eur Hydrol 28:69–86. (translated from French)

Bailly JR, Couffin N, Lebugle A, Domingueza M, Revel JC, Roque H (1998) Contribution to the study of phenomena of scaling. Tribune de l’eau 592:3–36. (translated from French)

Abd-El-Khalek DE, Abd-El-Nabey BA (2013) Evaluation of sodium hexametaphosphate as scale and corrosion inhibitor in cooling water using electrochemical techniques. Desalination 311:227–233

Abd-El-Khalek DE, Abd-El-Nabey BA, Mervat A-KMA, Ramadan SR (2016) Investigation of a novel environmentally friendly inhibitor for calcium carbonate scaling in cooling water. Desalin Water Treat 57:2870–2876

Gao Y, Fan L, Ward L, Liu Z (2015) Synthesis of polyaspartic acid derivative and evaluation of its corrosion and scale inhibition performance in seawater utilization. Desalination 365:220–226

Touir R, Dkhireche N, Touhami ME, Bakri ME, Rochdi AH, Belakhmima RA (2014) Study of the mechanism action of sodium gluconate used for the protection of scale and corrosion in cooling water system. J Saudi Chem Soc 18:873–881

Huang H, Yao Q, Jiao Q, Liu B, Chen H (2018) Polyepoxysuccinic acid with hyper-branched Structure as an environmentally friendly scale inhibitor and its scale inhibition mechanism. J Saudi Chem Soc 23:61–74

Lui D (2011) Research on performances evaluation and anti-scaling mechanism of green scale inhibitors by static and dynamic methods. PhD thesis, Ecole nationale supérieur d’Arts et Métiers, Paris, pp 19–20

Hasson D, Shemer H, Sher A (2011) State of the art of friendly “green” scale control inhib itors: a review article. Ind Eng Chem Res 50:7601–7607

Sun Y, Xiang W, Wang Y (2009) Study on polyepoxysuccinic acid reverse osmosis scale inhibitor. J Environ Sci Suppl 21:S73–S75

Liu D, Dong W, Li F, Hui F, Lédion J (2012) Comparative performance of polyepoxysuccinic acid and polyaspartic acid on scaling inhibition by static and rapid controlled precipitation methods. Desalination 304:1–10

Schweinsberg M, Hater W, Verdes J (2003) New stable biodegradable scale inhibitor formulations for cooling water: development and field tests. 64th International Water Conference, Pittsburgh, PA, Oct 19–23

Girasa W, De Wispelaere M (2004) Polyaspartate, an New Alternative for the Conditioning of Cooling Water. 14th International Conference on the Properties of Water and Steam, Kyoto, Japan, Aug 29–Sep 3

Thombre SM, Sarwade BD (2005) Synthesis and biodegradability of polyaspartic acid: a critical review. J Macromol Sci 42:1299–1315

Gao Y, Liu Z, Zhang L, Wang Y (2010) Synthesis and performance research of biodegradable modified polyaspartic acid. Third international conference on bioinformatics and biomedical engineering, Beijing, China, Jun 11–12

Johannsen FR (2003) Toxicology profile of carboxymethyl inulin. Food Chem Toxicol 14:49–59

Verraest DL, Peters JA, Bekkum H, Rosmalen GM (1996) Carboxymethyl inulin: a new inhibitor for calcium carbonate precipitation. J Am Oil Chem Soc 73:55–62

Stevenson FJ (1994) Humus chemistry: genesis, composition, reactions. Wiley, New York

Hoch AR, Reddy MM, Aiken GR (2000) Calcite crystal growth inhibition by humic substances with emphasis on hydrophobic acids from the Florida Everglades. Geochim Cosmochim Acta 64:61–72

Kumar T, Vishwanatham S, Kundu SS (2010) A laboratory study on pteroyl-L-glutamic acid as a scale prevention inhibitor of calcium carbonate in aqueous solution of synthetic produced water. J Pet Sci Eng 71:1–7

NACE Standard TM 0197-97 (1997) Laboratory Screening Test to Determine the Ability of Scale Inhibitors to prevent the Precipitation of Barium Sulfate and/or Strontium Sulfate from Solution (for Oil and Gas Production Systems), Item No 21228, NACE International

Amjad Z (1995) Mineral scale formation and inhibition. Plenum Press, New York

Gauthier G, Chao Y, Horner O, Alos-Ramos O, Hui F, Lédion J, Perrot H (2012) Application of the fast controlled precipitation method to assess the scale-forming ability of raw river waters. Desalination 299:89–95

Reddy MM, Hoch AR (2001) Calcite crystal growth rate inhibition by polycarboxylic acids. J Colloid Interface Sci 235:365–370

Abdel-Gaber AM, Abd-El-Nabey BA, Khamis E, Abd-El-Khaled DE (2011) A natural extract as scale and corrosion inhibitor for steel surface in brine solution. Desalination 278:337–342

Bonoli M, Bendini A, Cerretani L, Lercker G, Tosci TG (2004) Qualitative and semiquantitative analysis of phenolic compounds in extra virgin olive oils as a function of the ripening degree of olive fruits by different analytical techniques. J Agric Food Chem 52:7026–7032

Maciejewska G, Zierkiewicz W, Adach A, Kopacz M, Zapala I, Bulik I, Cies’lak-Golonka M, Grabowski T, Wietrzyk J (2009) A typical calcium coordination number: physico-chemical study, cytotoxicity, DFT calculations and in silico pharmacokinetic characteristics of calcium caffeates. J Inorg Biochem 103:1189–1195

Lee OH, Lee BY, Lee J, Lee HB, Son JY, Park CS, Shetty K, Kim YC (2009) Assessment of phenolics-enriched extract and fractions of olive leaves and their antioxidant activities. Bioresour Technol 100:6107–6113

Abdel-Gaber AM, Abd-El-Nabey BA, Khamis E, Abd-El-Rhmann H, Aglan H, Ludwick A (2012) Green anti-scalant for cooling water systems. Int J Electrochem Sci 7:11930–11940

Castillo LA, Torin EV, Garcia JA, Carrasquero MA, Navas M, Ailoria A (2009) New product for inhibition of calcium carbonate scale in natural gas and oil facilities based on Aloe Vera: application in Venezuelan oilfields. Latin American and Caribbean Petroleum Engineering Conference, Cartagena de Indias, Colombia, 31 May–3 June

Viloria A, Castillo L, Garcia JA, Carrasquero Ordaz MA,Torin EV (2011) Process using Aloe for inhibiting scale. US Patent US 8039421 B2

Woodward C, Davidson EA (1968) Structure-function relationships of protein polysaccharide complexes: specific ion-binding properties. Proc Natl Acad Sci U S A 60:201–205

Menzri R, Ghizellaoui S (2012) Chronoamperometry study of the Inhibition of groundwater scaling deposits in Fourchi. Energy Procedia 18:1523–1532

Labiod K, Ghizelloui S (2012) Contribution to the inhibitors methods study of the scaling: chemical, electrochemical processes in the presence of Ca(OH)2, Na2CO3 and KH2PO4. Energy Procedia 18:1541–1556

Belarbi Z, Gamby J, Makhloufi L, Sotta B, Tribollet B (2014) Inhibition of calcium carbonate precipitation by aqueous extract of Paronychia Argentea. J Crys Growth 386:208–214

Aidoud R, Kahoul A, Naamoune F (2017) Inhibition of calcium carbonate deposition on stainless steel using olive leaf extract as a green inhibitor. Environ Technol 3:14–22

Karar A, Naamoune F, Kahoul A, Belattar N (2016) Inhibitory effect of glutamic acid on the scale formation process using electrochemical methods. Environ Technol 37:1996–2002

Karar A, Naamoune F, Kahoul A (2016) Chemical and electrochemical study of the inhibition of calcium carbonate precipitation using citric acid and sodium citrate. Desalin Water Treat 57:16300–16309

Karar A, Naamoune F (2018) Inhibition of calcium carbonate precipitation by citric acid. Mater Biomater Sci 1:019–023

Bendaoud YB, Ghizellaoui S, Tlili M (2012) Inhibition of CaCO3 scale formation in ground waters using mineral phosphates. Desalin Water Treat 38:271–277

Labraoui-Djallal K, Bounoughaz M (2016) Evaluation efficiency of barium sulfate scale inhibitors by electrochemical impedance spectroscopy. Int J Electrochem Sci 11:1777–1788

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Karar, A., Henni, A. (2020). Scale Inhibition in Hard Water System. In: Negm, A.M., Bouderbala, A., Chenchouni, H., Barceló, D. (eds) Water Resources in Algeria - Part I. The Handbook of Environmental Chemistry, vol 97. Springer, Cham. https://doi.org/10.1007/698_2020_530

Download citation

DOI: https://doi.org/10.1007/698_2020_530

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-57894-7

Online ISBN: 978-3-030-57895-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)