Abstract

The scale formed on the internal walls of the agricultural equipment that transport water causes huge technical, economic, and energetic problems. The aim of this study was to evaluate the effectiveness of phosphate fertilizer NPK 13:40:13 on inhibiting the precipitation of CaCO3. This study was carried out on synthetic water, which is similar to natural water used for irrigation in the Tata region, (29° 45′ 48.9" N7° 59′ 31.5" W), through the conductivity test and the “Laboratory of environmental chemistry and engineering” technique (LCGE) at a temperature of 25 °C. The obtained results reveal a total inhibition of the precipitation of calcium carbonate after the addition of 1.2 mg/L of inhibitor to the calco-carbonic solution of hardness TH = 40 °F (French degree) at 25 °C. The comparison of the anti-scaling performances of the NPK inhibitor with other inhibitors already tested under the same working conditions has clearly demonstrated the effectiveness of the NPK inhibitor. Consequently, we recommend the use of NPK 13:40:13 fertilizer as an excellent new scaling inhibitor for irrigation installations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In Morocco, agriculture is a strategic sector for the socio-economic development, and it is one of the main catalysts of national economic growth [1]. According to the last general population and housing census, agriculture represents 14% of the Gross domestic product (GDP) and employs more than 40% of the population. Recently, the High Commissioner for Planning has conducted a study on the intersectoral modeling of water consumption in the Moroccan economy [2]. This study revealed that agriculture is the main user of water resources in Morocco with an annual water consumption of 9 billion m3. This represents 87.8% of total water consumption. Consequently, this overexploitation of water has led to an alert situation of water resources.

In the order to find a solution to this water shortage, the Ministry of Agriculture, in the context of the Green Morocco Plan, has invested in the implementation of a new strategy that aims to the development of a modern and high-performance agriculture, in addition to the sustainable and careful use of water resources, by adapting new irrigation systems called Localized Irrigation or Micro-irrigation.

These innovative irrigation technologies irrigate the roots of crops in a precise manner reducing the risk of disease (the foliage is not wet). They also limit evapotranspiration (release of vapor by plants) and increase agricultural productivity. However, this type of micro-irrigation system still suffers from the problem of chemical clogging [3].

The chemical clogging is induced by the precipitation of calcium carbonate [4,5,6]. This precipitation is the result of external modifications of certain parameters [7,8,9], which can cause a disturbance of the calco-carbonic balance. The scale deposits formed lead to pipes obstruction and a significant decrease in water flow [10]. Moreover, they cause inadequate distribution of irrigation water and malfunction of the systems that carry the water. This leads to significant energy and economic losses [11, 12].

In order to prevent this phenomenon of scaling, several physical and chemical processes have been developed. Physical processes [13,14,15] are often inefficient and their practical application is very limited [16]. However, chemical processes include decarbonization, acid vaccination, softening, and the use of chemical inhibitors. The last chemical process is considered to be the most practical and economical way to prevent the precipitation of scale by acting on the growth of crystals [17]. In this regard, phosphorus-containing inhibitors are widely used and their anti-tartar efficacy has been well demonstrated [8, 18].

As part of the contribution to solving the problem of scaling of pipes and irrigation equipment and to avoid the impact of chemicals on the environment, this work aims to evaluate the effectiveness of a phosphate-based fertilizer on the inhibition of scaling. This study was carried out on synthetic water, which is similar to natural water used for irrigation in the Tata region, (29° 45′ 48.9" N7° 59′ 31.5" W), by the conductivity test and LCGE technique.

Materials and methods

Reactants

The chemicals used in this study are illustrated in Table 1, all these chemical reactants were analytical grade without further purification, the solvent used for preparing the solutions was bidistilled water.

Fertilizer NPK 13:40:13

The fertilizer of NPK 13:40:13, which is commercially called SOLAR Starter, is a product available in the local market and currently used by farmers. It is a water-soluble compound which contains 40% of orthophosphates (PO43−), 13% of potassium oxide K2O, 8.5% nitric nitrogen (NO3−) and 4.5% ammonium nitrogen (NH4NO3). It is recommended for all types of crops. This product stimulates the development of the root system and increases the rate of absorption of nutrients.

Chemical inhibition of scaling

The formation of scale deposits in the internal walls of installations conveying water takes a long time. Therefore, the study of the phenomenon of scaling in the laboratory imposes the adoption of techniques that make it possible to study scaling in a relatively short time.

Accelerated methods for the study of scaling marked a decisive turning point in the study of the parameters influencing calcium carbonate incrustation. Precipitation kinetics is essential for the encrusting character of water; that’s why different tests have been developed to quantify the scaling power. To understand the kinetics of calcium carbonate precipitation, we first applied a quick and simple conductivity test to evaluate the preliminary efficacy of the inhibitor. However, this test does not make it possible to study the phenomenon of scaling under these realistic thermodynamic conditions. For this purpose, we used in a second step, the accelerated scaling technique "LCGE"; which was developed by "laboratory of Chemistry and Environmental Engineering" [19, 20].

Conductivity test

To evaluate the inhibitory effectiveness of a chemical compound's scaling, a simple and rapid test has been developed [21]. The experimental setup consists of a thermostat cell with a conductivity electrode and a magnetic stirrer. This assembly also contains a conductivity meter connected to a computer and a thermostat. Before starting the test, it is strongly recommended to rinse all material thoroughly with H2SO4 (1 M) sulfuric acid and then with deionized water to remove any deposits that may cause a measurement error.

The test was carried out at 25 °C and consisted of introducing 4 mL of the CaCl2 (0.1 M) solution with increasing concentrations of the inhibitor to be tested into a thermostat cell. Then, it is completed with distilled water to a volume of 80 mL. The solution of Na2CO3 0.1 M was added in 0.2 mL portions. The conductivity values were recorded after one minute of stabilization. This allows to trace the representative curve of the evolution of the conductivity as a function of the volume of the Na2CO3 solution added.

LCGE method

Principle

The LCGE technique provides the ability to follow the kinetics precipitation of calcium carbonate under realistic conditions. It consists in provoking the precipitation of calcium carbonate by controlled degassing (displacement of the calco-carbonic equilibrium in the sense of calcium carbonate formation) according to the following reaction:

The evolution of pH, calcium titer TCa, complete alkalinity titer TAC, partial pressure of carbon dioxide PCO2, and the degree of supersaturation βCal over time of a pure synthetic calco-carbonic water, with a hardness of 40 °F at a temperature of 25 °C, allows us to describe the kinetics of calcium carbonate precipitation (Fig. 1).

Description of the experimental setup

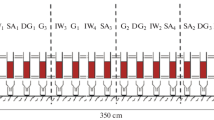

The gas is dispersed through a diffuser. It is a plate with 50 mm in diameter with 16 holes on its perimeter of 0.7 mm diameter. This plate is placed at the bottom of the cell. This cell is a PVC cylinder with a height of 145 mm, a diameter of 100 mm, and a capacity of 500 cm3. Then, the gas is admitted through a threaded hole with a diameter of 13 mm to which a Serto coupling is screwed to ensure a perfect seal (Fig. 2).

Before the gas enters the cell, it passes into a copper coil. Then, it passes through a humidifier and then through two humidity traps so that only a gas saturated with water vapor is admitted into the cell at the working temperature. The copper coil and the humidifier are immersed in a bath at a temperature of 40 °C. Humidity traps and the cell are immersed in a second bath at 30 °C. This is done to avoid any variation in temperature and concentration in the liquid phase. This can be done through evaporation or dilution by vesicles entrained in the humidifier. The cover contains four holes to support the pH meter electrode, the plot holder and to allow sampling of the solution for TH and TAC dosing.

Preparation of the calco-carbonic solution

A pure calco-carbonic solution is a solution that contains Ca2+ ions and HCO3− ions. It is prepared by dissolving calcium carbonate in deionized water with bubbling carbon dioxide, according to the reaction:

The total dissolution of calcium carbonate is obtained after 30 min (Fig. 3). This solution contains only Ca2+ cations and HCO3− anions except carbonate anions which may be formed by slight dismutation of hydrogen carbonate anions according to the reaction:

Results and discussion

Conductivity test

The first step was to test the effectiveness of NPK fertilizer in inhibiting the formation of CaCO3 precipitates. Derla et al. in 1998 have developed a simple and fast chemical test based on conductivity measurements [21].

Figure 4 shows the evolution of the conductivity of the CaCl2 solution (0.1 M) in the absence and the presence of different concentrations of the NPK compound as a function of the added volume of the Na2CO3 solution (0.1 M).

At the beginning of the experiment, the conductivity increases in a linear way by adding the sodium bicarbonate solution until a maximum value at which the solution becomes supersaturated is reached. Then, a rapid precipitation of CaCO3 begins and is accompanied by a remarkable decrease in conductivity. After precipitation, we notice a second increase in conductivity because of the addition of sodium carbonate which produces an excess of ions in the solution. A similar result is observed by Hajizadeh et al. in studying the effect of the aqueous extract of the roots of Gypsophila aretioides on the inhibition of CaCO3 precipitation [22]. Moreover, it has been observed that the value of the supersaturation point increases proportionally with the amount of inhibitor used which indicates that the NPK product can delay or inhibit the precipitation of CaCO3.

LCGE method

The scale-inhibiting performance of fertilizer NPK has been studied, using the LCGE method, in pure calco-carbonic water with a hardness of TH = 40 °F at a temperature of 25 °C. The temporal evolution of the pH, TCa, TAC, PCO2, and βcal parameters, in the absence and presence of inhibitor, are illustrated in Figs. 5, 6, 7, 8 and 9. This allows us to make a description of the kinetics of calcium carbonate precipitation.

Figure 5 indicates the variation in pH values as a function of time for increasing concentrations of the inhibitor over the course of the experiment. After a few minutes from the beginning of the experience, the pH values increase until a maximum value pHg. This increase was explained by the transfer of CO2 of the liquid phase into the gases phase according to the following reaction.

Then, the pH starts to decrease as the precipitation of calcium carbonate begins. After that, the pH tends to equilibrate.

The experimental results allow us to deduct that the germination time in the case of the calco-carbonic solution at 40 °F without inhibitor is 16 min. It increases with the addition of inhibitor concentrations, which show that the addition of inhibitor delays the homogeneous precipitation of CaCO3. The germination pH rises from 8.62 for 0 mg/L to 8.82 for 1.0 mg/L.

Figures 6 and 7 reveal the evolution of TCa and TAC as a function of time for increasing concentrations of the inhibitor over time. TCa and TAC values begin to decrease at the same time as the pH indicating the start of precipitation according to the following reaction:

Figure 8 shows the variation in CO2 pressure values as a function of time for increasing concentrations of the inhibitor over the course of the experiment. As soon as the precipitation of calcium carbonate begins, the pressure tends towards a maximum value. It then descends again indicating that germination begins before degassing is not complete.

Figure 9 indicates the evolution of the supersaturation coefficient βCal as a function of time for the increasing concentrations of the inhibitor. The test steps can be subdivided into three steps:

In the first step of degassing is characterized by a significant increase of βCal. Despite this evolution, the precipitation is not yet evident. In the second phase, βCal starts to decrease which indicates the beginning of precipitation. In the final phase, the βCal values tend to be constant revealing the end of the precipitation.

The kinetic modeling shown in Table 2 allows us to deduce that the precipitation follows a diffusion model for the test without inhibitor, whereas it follows the Reddy model for all tests with the inhibitor.

After adding 1.2 mg/L of inhibitor NPK to the calco-carbonic solution, the speed of the curve does not decrease any more. As a result, the precipitation of calcium carbonate is totally inhibited under the conditions of the experiment.

The efficacy of phosphate-based compounds, tested as scaling inhibitors, has been successfully demonstrated and their mechanism of action has been advanced by several studies [18, 24, 25]. The mechanism of scaling inhibition using NPK has been attributed to the active functional groups PO43−. It is very probable that the active functional group of PO43− can block normal growth of calcium carbonate crystals by adsorbing on the active growth sites of CaCO3 [26] according to a simple adsorption model of Langmuir [27], as a result of the modifications in the morphology of the crystals formed (Fig. 10). According to Guicai et al. [28], the antiscalant efficacy of an inhibitor is determined by its ability to modify the morphology of the crystals significantly compared to those formed in the absence of an inhibitor. Other studies revealed the ability of PO43− ions to form the soluble complexes with Ca2+ and Mg2+ ions, thus delaying germination by sequestration [26].

Comparison between certain fertilizers used as scaling inhibitors

The optimum concentration values of various phosphate-based fertilizers, tested as scale inhibitors under the same working conditions using the LCGE technique [29], are shown in Table 3. These results show that the NPK 13:40:13 fertilizer can be classified as one of the most effective inhibitors tested to date with an efficacy concentration of 1.2 mg/L.

Conclusion

This work was carried out with the aim of contributing to the resolution of the problem of scaling in pipes and irrigation equipment. We studied the effect of an NPK fertilizer on scale inhibition using a preliminary test based on conductivity measurements and subsequently the LCGE method. This method permits studying the phenomenon under thermodynamic conditions closer to the realistic conditions.

Total inhibition is achieved after the addition of a low concentration of 1.2 mg/L of the inhibitor to the calco-carbonic solution under the conditions of the experiment (TH = 40 °F, T = 25 °C). The inhibitory performance of the fertilizer NPK was more efficient than other phosphate-based fertilizers MAP, DAP, and SSP. This prompted us to recommend the fertilizer NPK 13:40:13 as a new scale inhibitor for irrigation water.

References

El AO, Afilal ME, Laiche H, Elfarh A (2020) Evaluation of physicochemical, microbiological, and energetic characteristics of four agricultural wastes for use in the production of green energy in Moroccan farms. Chem Biol Technol Agric. https://doi.org/10.1186/s40538-020-00187-3

Samih I (2020) Modélisation de la consommation en eau intersectorielle dans l’économie marocaine. Les brefs du Plan 212:14–17. https://www.hcp.ma/file/217869/

Elattir H (2005) La Conduite et le Pilotage de L’Irrigation Goutte à Goutte en. Bull Mens d’information liaison du PNTTA 124:77–80. https://www.agrimaroc.net/bulletins/btta_124.pdf

Belattar M, Hadfi A, Ben-Aazza S et al (2020) Kinetic study of the scaling power of sanitary water in the tourist area of Agadir. Mater Today Proc 22:61–63. https://doi.org/10.1016/j.matpr.2019.08.076

Karmal I, Mohareb S, El Housse M et al (2020) Structural and morphological characterization of scale deposits on the reverse osmosis membranes: case of brackish water demineralization station in Morocco. Groundw Sustain Dev 11:100483. https://doi.org/10.1016/j.gsd.2020.100483

Mohareb S, Karmal I, Hadfi A et al (2020) Investigation of pipes and sprinklers scaling at the golf course turf irrigated by treated wastewater of Mzar plant in Agadir-Morocco. Mediterr J Chem 9:440–446. https://doi.org/10.13171/mjc960200104984ah

Mpelwa M, Tang SF (2019) State of the art of synthetic threshold scale inhibitors for mineral scaling in the petroleum industry: a review. Pet Sci 16:830–849. https://doi.org/10.1007/s12182-019-0299-5

de Morais SC, de Lima DF, Ferreira TM et al (2020) Effect of pH on the efficiency of sodium hexametaphosphate as calcium carbonate scale inhibitor at high temperature and high pressure. Desalination 491:114548. https://doi.org/10.1016/j.desal.2020.114548

Bouargane B, Biyoune MG, Mabrouk A et al (2020) Experimental investigation of the effects of synthesis parameters on the precipitation of calcium carbonate and portlandite from moroccan phosphogypsum and pure gypsum using carbonation route. Waste Biomass Valoriz. https://doi.org/10.1007/s12649-019-00923-3

Cheap-Charpentier H, Gelus D, Pécoul N et al (2016) Antiscalant properties of Spergularia rubra and Parietaria officinalis aqueous solutions. J Cryst Growth 443:43–49. https://doi.org/10.1016/j.jcrysgro.2016.03.020

Saleah AO, Basta AH (2008) Evaluation of some organic-based biopolymers as green inhibitors for calcium sulfate scales. Environmentalist 28:421–428. https://doi.org/10.1007/s10669-008-9163-7

Vasyliev G, Vorobyova V, Zhuk T (2020) Raphanus sativus L. extract as a scale and corrosion inhibitor for mild steel in tap water. J Chem. https://doi.org/10.1155/2020/5089758

Donaldson J, Grimes S (1988) Lifting the scales from our pipes. New Sci 117:43–46

Gabriel JM, Girou A (1984) Le traitement électrique anti-tartre. Perspectives d’application. Informations Chim 201–202

Rosset R (1992) Les procédés physiques antitartre: mythe ou réalité. L’actualité Chim 1–2

Tlili MM, El Fil H, Ben Amor M (2001) L’inhibition chimique de l’entartrage: détermination de la concentration efficace d’inhibiteurs par les techniques LCGE et CEG. Cah l’Association Sci Eur pour l’Eau la Santé 6:29–39. https://doi.org/10.1051/asees/20010601029

Dedieu L, Hort C, Martin-Dominguez A et al (1994) Contribution à l’étude des phénomènes d’entartrage. I: Généralités et méthodes d’étude LCGE. La Trib l’eau 47:3–19

Hadfi A, Aazza SB, Belattar M et al (2018) Evaluation of the irrigation water quality in Biougra circle along with highlighting the effectiveness of a scaling inhibitor. Mediterr J Chem 7:272–285. https://doi.org/10.13171/mjc74181121-hadfi

Hort C, Martin-Dominguez A, Rabut C, Roques H (1995) D La Trib l’eau 48:31–46

Roques H (1964) Contribution à l’étude statique et cinétique du système H2O–CO2–CaCO3

Drela I, Falewicz P, Kuczkowska S (1998) New rapid test for evaluation of scale inhibitors. Water Res 32:3188–3191. https://doi.org/10.1016/S0043-1354(98)00066-9

Hajizadeh A, Lotfabad TB, Bahmaei M (2019) Assessment of aqueous extract of Gypsophila aretioides for inhibitory effects on calcium carbonate formation. Green Process Synth 8:464–473. https://doi.org/10.1515/gps-2019-0014

Hadfi A, Aazza SB, Mohareb S, Driouiche A (2018) Study of the physico-chemical quality of the water of irrigation in Biougra circle along with highlighting the effectiveness of an inhibitor of calcium carbonate precipitation. Mediterr J Chem 7:272–285. https://doi.org/10.13171/mjc74181121-hadfi

Ben-Aazza S, Hadfi A, Belattar M et al (2017) Characterization of scaling power of Tiznit region waters. J Water Resour Prot 9:339. https://doi.org/10.4236/jwarp.2017.94022

Rosset R, Douville S, Ben Amor M, Walha K (1999) L’inhibition de l’entartrage par les eaux géothermales du sud tunisien. Étude sur site. Rev des Sci l’eau/Journal Water Sci 12:753–764. https://doi.org/10.7202/705376ar

Martinod A, Neville A, Euvrad M, Sorbie K (2009) Electrodeposition of a calcareous layer: effects of green inhibitors. Chem Eng Sci 64:2413–2421. https://doi.org/10.1016/j.ces.2009.01.024

Lin Y-P, Singer PC (2005) Inhibition of calcite crystal growth by polyphosphates. Water Res 39:4835–4843. https://doi.org/10.1016/j.watres.2005.10.003

Guicai Z, Jijiang GE, Mingqin S, et al (2007) Investigation of scale inhibition mechanisms based on the effect of scale inhibitor on calcium carbonate crystal forms, 50. https://doi.org/10.1007/s11426-007-0010-3

Hadfi A, Ben-aazza S, Belaatar M, et al (2015) Study of the inhibitor scaling effect of the agricultural water by a phosphate fertilizer, 1234–1241. https://doi.org/10.4236/jwarp.2015.715100

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

El housse, M., Hadfi, A., Karmal, I. et al. Study of the effect of inorganic inhibitor on the calcium carbonate precipitation in the localized irrigation systems. Nanotechnol. Environ. Eng. 6, 13 (2021). https://doi.org/10.1007/s41204-021-00107-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41204-021-00107-2