Abstract

Due to benefits in terms of cost, complexity, and reliability, sensorless control of BLDC motors has attracted a lot of interest. In order to obtain effective and precise control of a sensorless BLDC motor, a control strategy that combines the skills of an artificial neural network (ANN) and a proportional integral (PI) controller is needed. Traditional BLDC motor control techniques call for sensors to measure things like rotor position or speed. Sensor use, however, raises system complexity and expense. As opposed to this, sensorless control systems estimate the rotor position and speed using the motor’s back-EMF voltage or current. This eliminates the requirement for additional sensors. In this paper, the rotor location and speed of the BLDC motor are estimated using an ANN. An electrical motor signal dataset and a dataset of known rotor locations are used to train the artificial neural network (ANN). The ANN may learn the correlation between the electrical data and the rotor position during the training procedure. Without the use of physical sensors, the ANN can estimate the rotor location and speed in real time once it has been trained. A PI controller is coupled with the ANN-based estimator to improve control performance. The PI controller generates control signals to modify the phase currents in the motor by comparing the estimated rotor position and speed to the intended values. With minimum inaccuracy, the motor can track the intended speed or position, thanks to excellent motor control. On a prototype BLDC motor, the suggested control strategy is put into practice and tested. The results of the experiments show how successful the sensorless control approach is based on an ANN with PI controller.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

A BLDC electric motor, sometimes referred to as an electronically commutated motor (ECM or EC motor), or a BLDC motor, is defined as a “synchronous” sort because the magnetic field generated by the stator and the rotor revolve at the same frequency. The benefit of this construction is that it eliminates the “slip” that induction motors are notorious for. BLDC motors are currently a crucial component of contemporary drive technology. A larger range of industries, including consumer electronics, the automobile industry, industrial automation, chemical and medical, as well as aerospace and instrumentation are employing them as a result of their rapid rise in popularity. The sub-kilowatt range, which has been dominated by brushed DC motors, has always been ambiguous despite the fact that they have long been used for drives and power generation. The development of power electronics and microprocessors has allowed small brushless DC motors to flourish in terms of cost and performance, nevertheless. The biggest benefit of brushless DC motors is that they don’t need any maintenance. Also, this BLDC can be used in EV [1].

1.1 Design and Operational Tenets

This motor’s design is very similar to both traditional DC motors and three-phase induction motors. Like all other motors, this one has a stator and a rotor. BLDC motors can be built in a variety of physical arrangements. These can be set up as single-phase, two- phase, or three-phase motors depending on the stator windings. The most often used motors, though, are three-phase BLDC motors with permanent magnet rotors. The constructional features of BLDC motors are shown in Figs. 1 and 2a, b.

The stator of a BLDC motor has layers of steel lamination that carry the windings. These windings are located in axially recessed locations along the inner circumference of the stator. These windings can be arranged in star or delta shape. However, most BLDC motors use a star-connected three-phase stator. Each winding consists of several coils interconnected with one or more coils placed in each. Each winding is broken around the stator to provide an even frame. Permanent magnets are placed in the rotor of the BLDC motor. Depending on the needs of the application, the number of poles of the rotor can vary from 2 to 8 pole pairs with alternating north and south poles. In order for the motor to produce high torque, the flux density of the material must be high. To create a suitable magnetic field, the rotor must be made of suitable magnetic material.

Ferrite magnets are inexpensive, but they have a low flux density for a given volume. Magnets made from rare Earth metals are often used in new designs. Samarium cobalt (SmCo), neodymium (Nd), and ferrite and boron (NdFeB) are some of these metals.

Basically, there are two ways to build a BLDC motor: one is to place the rotor outside the base and the windings inside, and the other is to place the windings outside the base. In the first configuration, the rotor magnets act as insulators, dissipating heat by slowing the speed of the motor, and the motor runs at low current.

It is mostly used for fans. The motor produces less electricity in the second configuration, which increases its torque. It is an essential part of the hard disk.

Hall sensors for position in a BLDC motor, rotation is electrically controlled as there are no brushes. To turn the motor, the stator windings must be turned on sequentially, and the position of the rotor’s north and south poles must be known to open the correct stator winding set. The position of the rotor is usually sensed using a sensor, usually a Hall sensor (which works on the concept of the Hall Effect and is converted into an electrical signal).

Operating Theory

A BLDC motor works similar to a DC motor, a BLDC motor operates on the principle that a current-carrying conductor encounters a force each time it is placed in a magnetic field. Due to the reaction force, the magnet will be stable. In a BLDC motor, the magnets are in constant motion, while the current-carrying wires remain stationary.

2 Artificial Neural Networks (ANNs) Using PI Controller Approach

The input, output, and hidden layers of the artificial neural network (ANN) are simple networks containing a series of nodes. Because ANNs can process more binary data, their use in Electrical and Electronics Engineering consistently yields desired results. Brushless DC motors (BLDC motors) use an electric motor to transfer DC current to the motor windings and create a magnetic field. BLDC motors are versatile due to their high speed, low maintenance costs, and high torque capacities. This motor is preferred over other motors because of its better performance and ease of speed control via the power switch. This article describes a technique for controlling the speed of a BLDC motor by varying the DC input voltage to the bridge converter that drives the motor windings. PI-based speed control is used for control. The motor is modeled in MATLAB/Simulink and a PI controller is used to provide speed control. Simulate EMF signals, rotor speed, electromagnetic torque, Hall Effect signals, PWM, and EMF signals. The obtained data is processed using a binary neural network, so the ANN model can predict adverse effects. Arithmetic-based simulations and data-based predictions perform well [2, 3].

Deep learning is implemented using neural networks, a type of biology-inspired neural network. A neuron is a group of connected points that form an artificial neural network (ANN). Information processing and transmission are similar to the way neurons and synapses in the human brain transmit and process information, respectively. Input processes, output processes, and most importantly many hidden processes make up a large part of ANN models. Input neurons receive inputs (data), weight them, and combine the weights. It is then added and sent to the next neuron using the activation function [4].

This process goes in a circle. Through this iterative process, the model can learn from ideas and complete complex tasks. As mentioned earlier, the process begins by applying weights to the information transmitted between neurons. The weight change determines the main working ability of the neural network.

When training the neural network with training data, the weights are adjusted. Each time the model is trained, weights are adjusted to help the model understand and identify patterns in the input data. Through training, a trained neural network can predict new information fed into it. Refer Fig. 3a–c.

The truth depends on many parameters. It just depends on the size of the neural network, the size of the dataset, the activation function used, and the type of dataset.

The neural network’s propagation is forward propagation, and backward propagation principles. Data is delivered into the forward propagation process. A sample with characteristics is taken. The result is based on these characteristics. The functions of summation and activation are then carried out. In the procedure, the weights are added together. Then it is subjected to an activation function and sent to a subsequent hidden layer. In the equation below, I represents the number of inputs, W represents the given weights, and X represents the feature (data) [5].

The basic goal of backward propagation is to lower the overall error. Backward propagation, as the name implies, starts with error measurement and ends with weight modifications to lower the error Test it by enabling the function and see the full error. Back propagation uses the chain rule, identify and correct the weighting error that is the cause of the problem, as seen below.

Lack of Robustness: ANNs are susceptible to hostile attacks or input data noise. It is possible for outputs to differ greatly or for categorization to be incorrect with even minor input changes. Preserving ANNs’ robustness and dependability in the presence of unexpected or hostile inputs an area of study that is active.

Memory and Scalability Requirements: Large-scale ANNs with millions of parameters may need a lot of memory and processing power to train and deploy. The storage and computational demands of deploying ANNs in resource-constrained environments can pose challenges [6].

It is important to consider these disadvantages alongside the advantages when deciding to use ANNs for a particular task or problem.

ANN benefits include:

-

1.

Adaptive Learning: ANNs are capable of learning from their past performance or training data. They are suitable for activities with changing conditions or changing data because they can automatically modify their internal parameters to improve their performance over time.

-

2.

Nonlinear Modeling: ANNs may capture sophisticated nonlinear dependencies and patterns in the data by capturing complex nonlinear correlations between input and output variables. They can thus be used for a variety of applications involving nonlinear events or intricate data distributions.

-

3.

Parallel Processing: ANNs have the ability to process information in parallel, allowing them to run several computations at once. Because of their ability to handle data in parallel, ANNs are effective for time-sensitive or large-scale applications.

-

4.

Fault Tolerance: ANNs have fault tolerance, which allows them to continue operating and producing outputs that are reasonably accurate even in the presence of noisy or imperfect data or when some of the network’s components fail.

-

5.

Generalization: ANNs can extrapolate from training data to make predictions or categorize previously unknown or novel situations. They can make judgments and infer patterns from data outside of the examples they were trained on, which enable them to handle tasks with ambiguous or variable inputs.

In a variety of disciplines and sectors, artificial neural networks are a powerful and adaptable method for resolving complicated issues, learning from data, and making wise decisions.

ANN drawbacks include:

-

1.

Training Complexity and Computational Requirements: When training large or complicated networks or datasets, ANNs can be computationally time-consuming and labor-intensive. Iterative optimization approaches may be used throughout the training process, which can be time-, money-, and energy-intensive. Training normally calls for a lot of computational resources.

-

2.

The Need for Enough Training Data: For ANNs to learn relevant patterns and correlations, they often need a sizable amount of training data. Poor generalization and unreliable predictions might result from insufficient or unrepresentative training data. Large and diverse datasets can be difficult to acquire and prepare, which could hinder ANN performance.

PI controller:

Proportional plus integral (PI) controller is another name for controller. It is a controller with proportional control action, so it is called PI controller. Proportional integral controller uses both proportional and integral controllers to control motion. When two different controllers are combined, a better controller is created to address the shortcomings of each controller [7, 8].

In this case, the control signal is proportional to the error signal and its value. The numerical representation of the proportional plus integral controller is as follows:

Block Diagram:

Figure 4 represents the block diagram of PI controller.

Advantages of PI Controller:

-

1.

The output is inversely proportional to the integral of the input signal, which is one benefit of the PI controller.

-

2.

The type of the system expands as the integrator gets more involved. As a system type grows, accuracy rises as steady-state error decreases.

-

3.

Integral action in Pl controllers eliminates offset, a significant drawback of a P-only controller. Thus, PI controllers are the algorithms that process control applications use the most because they provide a balance between complexity and capacity.

-

4.

As the system’s type is enlarged, there are some detrimental consequences on the stability of the system.

-

5.

PI control is a kind of feedback control. A speedier response time than I-only control is achieved by adding the proportionate action.

Disadvantages of PI Controller:

-

1.

The technique requires only moderate load modifications to eliminate oscillations caused by the integral overshoot, yet this is necessary due to the integration duration.

-

2.

Before settling to the operational point, the integral action during the initiation of a batch process creates a large overshoot of the error and output.

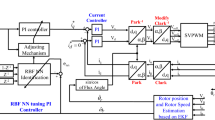

3 Simulation Model

Simulation model for sensorless BLDC motor control by artificial neural nework (ANN) with PI controller method is as shown in Fig. 5.

4 Result

The speed of a sensorless BLDC motor is controlled by combining an ANN with the PI controller approach. Reference speed in a simulation model is set to 1500 rpm. It displays the outcome that machine speed response comes close to 1500 rpm approximately and also provides electromagnetic torque generated during motor operation (Figs. 6 and 7).

5 Conclusion

In conclusion, a promising method with a number of benefits is provided by the coupling of an ANN with a PI controller for sensorless brushless DC (BLDC) motor control. Without the use of extra sensors, an ANN can estimate rotor position and speed, which lowers system costs, complexity, and possible weak points.

The ANN is more resilient and able to handle various operating situations since it can learn from and adapt to changes in motor parameters. By providing feedback control based on the discrepancy between the desired and estimated values, the PI controller supports the ANN. It aids in system stabilization, steady-state error reduction, and general motor control performance improvement. The BLDC motor can be precisely controlled, achieving exact speed and position tracking, thanks to the integration of an ANN and PI controller. The control algorithm is optimized by the ANN to increase efficiency and reactivity by learning from historical data and modifying its parameters accordingly. The sensorless technique also simplifies the design of the motor, lowers maintenance needs, and increases dependability by doing away with the need for mechanical sensors like Hall Effect sensors or encoders.

Overall, the sensor-free BLDC motor control system using an ANN and a PI controller provides a reliable, accurate, and affordable solution for a variety of applications. It achieves high-performance motor control without the use of extra sensors by combining the advantages of cutting-edge machine learning techniques with traditional control algorithms.

References

Thakre MP, Mahadik YV, Yeole DS Potentially affect of a vehicle to grid on the electricity system. IOP Conf Ser: Mater Sci Eng 1084(1):012077. https://doi.org/10.1088/1757-899X/1084/1/012077

Li C, Yu W, Tang W (2010) Study on rotor position of sensorless brushless DC motors through back electromotive force detection. Presented at International conference on E-product E-service and E-entertainment (ICEEE), 7–9 Nov 2010

Xiong H, Xue Y (2010) The design of Brushless DC motor back-EMF control. Presented at International conference on environmental science and information application technology (ESIAT), 17–18 July 2010

Nikhil SS, Sampath K (2019) Neural network based BLDC motor speed control. Int J Electr Electron Data Commun 7(10). ISSN(p): 2320-2084, ISSN(e): 2321-2950. http://iraj.in

Mamadapur A, Mahadev GU Speed control of BLDC motor using neural network controller and PID controller. Electrical Engineering Department Zeal College of Engineering and Research Pune, India

Leena N, Shanmugasundaram R, Member, IEEE (2014) Artificial neural network controller for improved performance of Brushless DC motor. In: International conference on power, signals, controls and computation (EPSCICON), 8–10 Jan 2014

Mirtalaei SMM, Moghani JS, Malekian K, Abdi B (2008) A novel sensorless control strategy for Bldc motor drives using a fuzzy logic based neural network observer. In: Speedam 2008 international symposium on power electronics, electrical drives, automation and motion

Wongkhead S (2021) State space model for speed control Bldc motor tuning by combination of Pi-artificial neural network controller. In: Ecti-Con 2021-smart electrical systems and technology

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Talke, S.A., Tamboli, A.M., Shinde, Y.M., Yeole, D.S. (2024). Sensorless PMBLDC Motor Control Strategies by Artificial Neural Network (ANN) with PI Controller. In: Shaw, R.N., Siano, P., Makhilef, S., Ghosh, A., Shimi, S.L. (eds) Innovations in Electrical and Electronic Engineering. ICEEE 2023. Lecture Notes in Electrical Engineering, vol 1109. Springer, Singapore. https://doi.org/10.1007/978-981-99-8289-9_23

Download citation

DOI: https://doi.org/10.1007/978-981-99-8289-9_23

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-8288-2

Online ISBN: 978-981-99-8289-9

eBook Packages: EnergyEnergy (R0)