Abstract

Xylose and XOS become products of interest and have good markets. Xylose and XOS are derived from xylans, which are parts of hemicellulose fraction of lignocellulosic biomass. The demand tends to increase due to depletion of fossil resources and a new paradigm shift in consumer preferences for healthier and natural products. There are different extraction methods or fractionation processes to extract xylose and XOS from lignocellulosic biomass feedstocks, including autohydrolysis and hydrolysis using acid, alkaline, solvent, and inorganic salts. The hydrolysis usually involves high temperature and pressure. It is important to find the most suitable, effective, and affordable method to first fractionate biomass major chemical components and achieve the practical applications of the method. There are some unwanted substances and oligosaccharides of various degree of polymerization (DP) produced during the manufacture of XOS and xylose. These substances should be removed to obtain xylose and XOS with high purity. Some purification methods such as solvent extraction, adsorption separation, chromatographic separation, and membrane filtration, or combinations of those methods could be applied. Xylose can be utilized for a variety of purposes, either directly as xylose or as a feedstock for the subsequent production of a variety of products, including furfural, furfuryl alcohol, xylitol, levulinic acid, ethanol, butanol, and hydrogen through chemical or biological conversion. XOS can be used as antioxidant, prebiotic, gelling agent, cosmetics, plant growth regulator, treatment of diabetes, arteriosclerosis, and colon cancer, and are commercially interesting to be used as animal feed, food, beverage, and pharmaceutical ingredients. The production of xylose and XOS from lignocellulosic biomass still has some challenges regarding the technology to produce the products that are feasible commercially, but it has good prospects in the future as the increasing awareness to use renewable resources to produce healthier and environmentally friendlier products.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The depletion of fossil resources has triggered research on the use of renewable resources for producing fuels and other compounds that are now obtained from fossils. Lignocellulosic biomass is among potential feedstocks for the production of fuels and chemicals, since it is abundantly available as by-products of agriculture and forestry industries. Lignocellulosic biomass can be used for the production of cellulosic ethanol, which can substitute the use of gasoline. Unfortunately, the commercialization of cellulosic ethanol or the second generation of bioethanol is still hampered by the high production cost, which makes the price of cellulosic ethanol high and hard to compete with gasoline. Efforts to produce economical cellulosic ethanol have been conducted through the improvement of technology, starting from pretreatment up to fermentation. Another effort that could be done is by applying biorefinery concept. In biorefinery, the transformation of lignocellulosic into energy, especially cellulosic ethanol, and other chemicals or bioproducts is carried out as an integrated technology, so that each component of lignocellulosic biomass could be converted and utilized efficiently. By doing this, the whole process would be economically more feasible.

Lignocellulosic biomass is made up of three major components: cellulose, hemicellulose, and lignin. In the production of cellulosic ethanol, the focus is to obtain cellulose that will be converted to glucose, which will further fermented to ethanol. Lignin is a challenge and becomes a recalcitrance in the production of cellulosic ethanol, but it is beneficial for producing different kinds of aromatic compounds or monomers that could substitute fossil-derived monomers in polymer industries. Hemicellulose is easily hydrolyzed to its oligomers or monomers, for example through water, acid, alkali, or enzymatic hydrolysis, and then separated from lignin and cellulose. Unlike cellulose, which has orderly packed structure, hemicellulose has amorphous characteristics with different kinds of branches. After being recovered and purified from lignocellulosic biomass, hemicellulose monomers can undergo a variety of transformations that result in compounds with added value, hence increasing the profit margin for the relevant businesses. Before completely hydrolyzed to its monomers, the hemicellulose could also be hydrolyzed to oligosaccharides. As an integrated process, it is important to take advantage of every step in the lignocellulosic biomass conversion to ethanol, for example optimizing the pretreatment process to produce both cellulosic ethanol and sugar monomers or oligosaccharides. Schematic diagram of lignocellulosic biomass fractionation is shown in Fig. 1.

Xylose and XOS become products of interest and have good markets. According to Data Bridge Market Research, during the projection period of 2022–2029, the global xylose market is projected to increase at a CAGR of 5.4% from its value of USD 1,797.80 million in 2021 to USD 2,738.21 million by 2029. The price of XOS is dependent on its purity (70–95%), ranging from USD 25 to 50/kg, and the global market is anticipated to reach USD 130 million by 2025 (Santibáñez et al. 2021; Singh et al. 2018; Brenelli et al. 2022). The global XOS market was worth USD 88.09 million in 2016 and is anticipated to reach USD 119.62 million by the end of 2022, expanding at a compound yearly growth rate (CAGR) of 5.23% from 2016 to 2022 (Ahmad 2019).

There are still some challenges in the recovery of xylose or XOS from lignocellulosic biomass, either in the extraction, isolation, or purification step for producing good quality of xylose and XOS which is economically feasible. However, a new paradigm shift in consumer preferences for heather and natural products as well as consumer health consciousness have significantly increased the sales and attraction for xylose and XOS, especially in the thriving food and beverage industry. In this chapter highlights will be on the xylan sources, structure, and its derivatives; extraction and isolation of xylose and XOS, purification of xylose and XOS, and potential applications of xylose and XOS in food, energy, and pharmaceutical industries.

2 Sources and Structure of Xylans, XOS, and Xylose

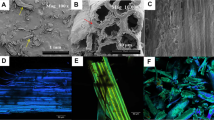

Hemicellulose is the base feedstock for xylose and other xylan-based sugars, particularly xylooligosaccharides (XOS), which are supposed to be utilized in the packaging, food, pharmaceutical, biomedical, cosmetic, textile, and papermaking industries (Yohana et al. 2022; Lu et al. 2021; Zhang et al. 2017a). Hemicellulose is a complex heteropolysaccharide that consists of D-xylose, L-arabinose, D-glucose, L-galactose, D-mannose, D-glucuronic acid, and D-galacturonic acid. Common composition of these sugars in hemicellulose is shown in Fig. 2. Hemicelluloses are found in several polymeric configurations, including xylan, arabinoxylan, xyloglucan, and glucuronoxylan, and develop in 26% of the dry weight of hardwoods, 22% of softwoods, and approximately 25% of agricultural waste (Zhao et al. 2020; Narisetty et al. 2022).

General composition of lignocellulosic biomass (a), and neutral and acid sugars in hemicellulose (b) (Narisetty et al. 2022)

A dominant component in hemicellulose of lignocellulosic biomass is usually xylan. Xylan is also the second major component in lignocellulosic biomass after glucan. The content of glucan and xylan in several lignocellulosic biomass is presented in Table 1. Terrestrial plants xylans are heteropolymers having a β-(1 → 4)-d-xylopyranose backbone and branches formed of short carbohydrate chains, such as D-glucuronic acid or its 4-O-methyl ether, L-arabinose and/or different oligosaccharides, made up of D-xylose, L-arabinose, D- or L-galactose and D-glucose (Ebringerová et al. 2005; Scheller and Ulvskov 2010). Based on its primary structure in plant tissue, xylan is generally divided into homoxylans and heteroxylans, including glucuronoxylan (GX), arabinoglucuronoxylan (AGX), glucurono-arabinoxylan (GAX), arabinoxylan (AX), and complex heteroxylan (CHX) (Ebringerová et al. 2005), with structures shown in Fig. 3a–d. When hydrolyzed, the xylans are converted to XOS and xylose, depending on the severity of the process. Production of xylose and xylooligosaccharides (XOS) from hemicellulose fraction of lignocellulosic biomass would be beneficial to support the commercialization of cellulosic ethanol.

Acid hydrolysis of xylan to xylose (Lu et al. 2021)

XOS (C5nH8n + 2O4n+1) are mixture of oligosaccharides composed of xylose molecules linked through β-1, 4-xylosidic bonds with a number of xylose residues vary between 2 and 10 (Aachary and Prapulla 2008), some have branching structures due to the presence of many side groups (Chen et al. 2021; Yan et al. 2022). As we know besides xylose, xylan usually contains α-D-glucopyranosyl uronic acid or its 4-O-methyl derivative, acetyl groups, or arabinofuranosyl residues. These structures result in some branched XOS containing these side groups which have various biological properties (Aachary and Prapulla 2011). Figure 3e shows the chemical structure of XOS. The structural properties of XOS are affected not only by the origin of the xylan-rich hemicelluloses but also by the manufacturing process (Akpinar et al. 2010; Bian et al. 2013). These variables influence the degree of polymerization (DP), monomeric units, and linkage types (Aachary and Prapulla 2011).

Xylose or D-xylopyranose (D-Xylp) is an aldopentose sugar, having chemical formula C5H10O5 and molecular weight of 150.13, with a relative density of 1.525 and melting point 145–150 °C. soluble in water, hot ethanol, and pyridine, but not soluble in ether. It appears as colorless or white crystal or powder, and it has a sweet taste. Xylose has an aldehyde functional group so that it is classified as reducing sugar. The chemical structure of xylose can be seen in Fig. 3f.

3 Extraction and Isolation of Xylose and Xylooligosaccharides

There are different extraction methods or fractionation processes used to extract xylose and XOS syrup from an abundance of lignocellulosic biomass feedstocks. In order to produce xylose and XOS efficiently, finding the most suitable, effective, and affordable method to first fractionate biomass’ major chemical components and achieve the practical applications of biomass is critical. According to Fernandez (2019), many existing methods for isolating xylose start with biomass hydrolyzates or sugar in solution derived from a renewable resource and involve energy-intensive processes such as evaporation and phase transitions. This is distinct from typical sugar production, which may be quickly harvested from sugar cane or sugar beets.

3.1 Acid Hydrolysis Method

A popular method for hydrolyzing hemicellulose with a significant conversion efficiency is using diluted acid hydrolysis. Hemicellulose breakdown in the solid phase can be catalyzed by dilute acid and heat to dissolve various oligosaccharides ranging from xylose to xylotriose and above in the liquid phase. Inorganic acids, including sulfuric, hydrochloric, and nitric acids, as well as organic acids, such as oxalic, phosphoric, acetic, maleic, succinic, and citric acids can be used in the conventional diluted acid hydrolysis. Thus, by introducing acids from outside, the hemicellulose depolymerization process can be accelerated (Huang et al. 2021; Krishania et al. 2018; Paiva et al. 2009; Rahman et al. 2007; Rocha et al. 2014). In addition, Chen et al. (2020) described that the activation energy of organic acid degradation is usually higher than that of inorganic acids, but the degree of glucose and xylose dissolved in the hydrolysate with organic acids is less than that of inorganic acids, such as sulfuric acid.

The primary limitation of the acid hydrolysis approach is the production of unfavorable reactions at the same time. The acid hydrolysates usually contain three groups of undesired chemical components: (a) compounds derived from the hemicellulose structure (organic acids); (b) sugar breakdown derivatives (furfural and hydroxymethylfurfural (HMF)); and (c) excessive lignin derivatives (aromatic and polyaromatic compounds). To increase the xylose yield and decrease the creation of undesired compounds, the precise processing parameters, such as solid-to-liquid ratio, acid concentration, temperature, and duration of heating, must be followed (Delgado Arcaño et al. 2020; Harahap 2020; Shahbazi and Zhang 2010).

The two forms of acid employed in the acid-based process are concentrated acid and diluted acid. Concentrated acids not only dissolve cellulose crystals but also break down cellulose and hemicellulose into sugars and stimulate the cleavage of glycosidic bonds. In the United States, sulfuric acid converts hemicellulose and cellulose into sugars at a rate of 80–90%. However, there are risks related to the use of concentrated acids, as well as difficulties in acid recovery, which limit the acceptance of the technology. Concentrated acid can be produced efficiently at moderate temperatures, requiring less heating energy. Shahbazi and Zhang (2010) described that hemicellulose can be efficiently extracted and recovered as dissolved sugars at medium temperatures (140–190 °C), and the extraction process can be made more effective by adding an acid solution. On the contrary, dilute acid hydrolysis often requires greater temperatures with less chemicals. As a result, organic acid hydrolysis has steadily gained prominence and the issue caused by equipment corrosion can be prevented (Harahap 2020; Cheng et al. 2018; Inamuddin 2021). At temperatures below 160 °C, acid hydrolysis caused the hemicellulose to become nonhomogeneous and dissolve into soluble oligomers, such as XOS and sugar monomers, such as xylose. Furthermore, the oligomers formed during the hydrolysis of hemicellulose by a random acid attack have different degrees of polymerization (Lee et al. 1999). According to studies on the effects of conventional heating with organic and inorganic acids on the sugar monomers produced in the hydrolysate and from the saccharification and fermentation of the solid corncob residues, organic acids such as maleic acid and oxalic acid could produce more monomer sugars in the hydrolysates and more ethanol from the solid residuals (Lee and Jeffries 2011).

Some benefits of utilizing dilute acid include a faster reaction rate, lower acid consumption, lower cost than alkaline pretreatment, and no need for recycling. It is interesting to note that under particular process circumstances, diluted acid hydrolysis preferentially extracted the hemicellulose component (Harahap 2020; Cheng et al. 2018; Inamuddin 2021). The acid hydrolysis approach is a conventional method for dissolving hemicellulose to xylose or XOS. Unfortunately, numerous factors, such as chemical stability, side reactions, toxic pollution, and proton selectivity, must be addressed in the near future (Yan et al. 2022; Huang et al. 2021). The summary of some research regarding the xylose yield after acid hydrolysis method in various biomass is shown in Table 2.

According to earlier research by Zhang et al. (2017b), concentrated acetic acid was discovered to perform better than inorganic acid for hydrolysis. Hydronium ions disrupt the connections in the interiors and/or exteriors of hemicelluloses during acetic acid hydrolysis, which causes XOS to become soluble. The solid phase of XOS has more exposed cellulose that is ready for cellulolytic hydrolysis due to its solubility. The majority of the severe inorganic acids have the ability to catalyze and dissolve the glycosidic linkages that connect xylose units in the skeleton of the xylan polymer, but their action is random. Consequently, much xylose rather than XOS is generated (Zhang et al. 2017b). Meanwhile, Yohana et al. (2022) discovered that the maximum XOS content from sugarcane trash and corncob was 4.74 g/L after hydrolysis with 2% oxalic acid for 45 min and 1.31 g/L after hydrolysis with 2% acetic acid for 60 min. Furthermore, according to Zhang et al. (2017a), acetic acid in corncob hydrolysate generated XOS yields of roughly 45.91%. The XOS yields from hydrochloric acid and sulfuric acid are 22.54% and 9.38%, respectively. It is also worth noting that the XOS derived from acetic acid prehydrolyzate was mostly made up of xylobiose, xylotriose, and xylotetrose, with substantially less xylopentaose and xylohexaose. This was attributed to the fact that acetic acid pretreatment resulted in a reduced degree of polymerization (DP) enrichment. Han et al. (2020) discovered that gluconic acid treated in corncob was effective to produce XOS with a yield 56.2%. Gluconic acid is a mono-carboxylic acid that could release H+ to depolymerize hemicelluloses. It is adopted as a green and environmentally friendly solvent for the extraction of sugars.

3.2 Alkaline Hydrolysis Method

In complement to acid hydrolysis method, the alkaline method is frequently used to isolate hemicellulose from lignocellulosic biomass by causing cellulose to swell, rupturing the links between hemicellulose and lignin, and diluting the hemicellulose. It has been discovered that the yield of hemicellulose is affected by the type and concentration of alkali, extraction time, and temperature (Huang et al. 2021). Figure 5 illustrates the general mechanism for alkaline hydrolysis, in which the ester link between lignin’s ferulic acid and the sugar residue of hemicellulose is cleaved (Lu et al. 2021).

Alkaline hydrolysis of xylan (Lu et al. 2021)

The alkaline hydrolysis was the subject of groundbreaking work by Adams and Castagne (1951) as stated by Huang et al. (2021). The research was regarding the various hemicellulose fractions obtained from the holocellulose of wheat straw. The process also produced the D-xylose and monomethoxyl galacturonic acid complex, which was resistant to acid. Inorganic alkali solutions are extensively utilized in alkaline hydrolysis, and sodium hydroxide is one of the most prevalent. In addition, hydrogen peroxide extraction is a frequent alkaline procedure for isolating hemicellulose from biomass. High extraction rates, purity, and DP are features of hemicelluloses extracted through alkaline hydrolysis. As a result, alkaline-extracted hemicellulose is predicted to be used in a variety of industries. The standard alkaline procedure, on the other hand, involves significant pollution and costs (Lu et al. 2021).

Samanta et al. (2012) reported that sodium hydroxide was superior to potassium hydroxide in terms of xylan recovery from corncobs. Furthermore, the study discovered that increased alkali concentrations led to higher hemicellulose degradation. Besides that, a study by Jiang et al. (2019) using sorghum steam discovered that alkaline hydrolysis using 1.4% NaOH at 37.5 °C and 9.9 h resulted in a maximum xylose yield (57.7%). The study also stated that increasing alkali loading, reaction time, and temperature enhanced xylose yield. By using only alkali extraction, the yield of xylan is relatively low. Combination with other procedures, such as steam and ultrasound, might be rising the xylan yield. For instance, ultrasound-assisted alkali extraction could significantly increase XOS yield in corncobs, with a release level of 174.81 mg/g matrix (Yan et al. 2022; Kawee-ai et al. 2016).

3.3 Autohydrolysis Method

The autohydrolysis process requires specialized equipment at specific temperatures and pressures. The principle of autohydrolysis is that the hydronium ions are formed as a result of water autoionization, which results in the catalytic depolymerization of hemicelluloses to XOS and xylose. The addition of the hydronium ion to the mixture, which causes cleavage of acetyl groups in acetic acid, allows for the synthesis of XOS. When the processing severity factor is increased, the DP decreases, and the degradation of XOS into xylose increases. The downside of this procedure is the need for specialized equipment as well as the production of undesirable compounds in the XOS mixture (Samanta et al. 2015; Surek and Buyukkileci 2017).

Nabarlatz et al. (2007a) have used a variety of biomass, consisting of wheat straw, barley straw, rice husks, corncobs, olive stones, and almond shells, for XOS production using autohydrolysis. This study discovered that the XOS yield varied with xylan content and accessibility and was inversely related to the acetyl concentration in the biomass feedstock. According to Surek and Buyukkileci (2017), autohydrolysis of hazelnut shells produced XOS with the highest percentage of low-DP XOS at higher severity values. To achieve the appropriate DP, temperature and holding time must be precisely regulated. Additionally, the results indicated that the severity factor was effective in determining the patterns of oligomers, monomers, and by-products produced after autohydrolysis.

3.4 Combination Hydrolysis (Physical–Chemical Hydrolysis) Method

Physical hydrolysis includes processes using hydrothermal, steam explosion, ultrasonic, and microwave (Yan et al. 2022). A hydrothermal is an instant conversion of biomass in hot water with controlled high pressure and/or temperature, which involves the self-expansion of a material. In this process, the moisture in the biomass is vaporized under the impact of the rapid pressure transfer to a vacuum, which causes the material to expand and become more texturized. Sometimes the hydrothermal combines with alkaline hydrolysis or acid hydrolysis to separate hemicellulose to improve the yield of xylose or XOS (Lu et al. 2021; Yan et al. 2022). The research conducted by de Sá et al. (2020) found that the hydrothermal-assisted acid hydrolysis in sugarcane bagasse resulted in 80.13 mmol/L xylose. The XOS produced (35 g/L) by hydrothermal pretreatment of sugarcane bagasse with sulfuric acid was totally hydrolyzed by the acid post-hydrolysis, which happened in less than 20 min (Nakasu et al. 2017).

Harahap (2020) and Dulie et al. (2021) stated that the oligomeric form of hemicellulose predominates in the solution as a result of steam explosion circumstances. Hemicellulose oligomers need to be post-treated in order to be broken down. To maximize the performance of the steam explosion, pre-treatment is also required before the operation. The steam explosion pretreatment method has drawbacks, such as the destruction of a portion of the pentosan, despite being a cheap pretreatment method. A xylose yield of 27.58 g/g dry corn cob was obtained by Zhang et al. (2014) from the pilot-scale production of xylose using a screw-steam explosion extruder and prior sulfuric acid impregnation. On the other hand, Duangwang et al. (2016) discovered that a combination between sulfuric acid hydrolysis and superheated steam explosion in a pilot scale gave the highest yield of xylose, up to 87.58 g/kg of dry oil palm empty fruit bunches. The yield of XOS was 37%, obtained from acetic acid hydrolysis of wheat straw with steam explosion (Cao et al. 2021).

In the case of alkaline extraction of hemicellulose, the use of ultrasonic has been shown to be successful. The breaking of the polysaccharide glycoside bond brought on by ultrasonic pretreatment considerably increases the yield of the extracted hemicellulose at low temperature and short time. Additionally, hemicellulose extracted with the use of an ultrasonic method has a higher molecular weight, greater thermal stability, fewer acidic groups, fewer linked lignin molecules, and a lower branching degree (Lu et al. 2021). Sun and Tomkinson (2002) determined that the yield of hemicellulose from ultrasonic method in wheat straw hydrolysate was 1.8% higher than that of conventional alkaline hydrolysis.

Compared to conventional approaches, microwave extraction of hemicellulose has some benefits, such as energy savings and low toxicity. Additionally, the extraction of branched hemicellulose with microwave assistance is more successful, resulting in reduced yield and molecular weight of the hemicellulose recovered through microwave extraction. It has been challenging to implement in large-scale industrialization thus far (Lu et al. 2021). A study conducted by Lin et al. (2017) stated that a practical method for developing XOS production from various hemicellulose was by utilizing organic acids as catalysts and induced with microwave irradiation. Using this process, the XOS yield from beechwood xylan, corncob, and waste liquor pulp is 39.42, 27.46, and 30.89%, respectively. Another research by Hermiati et al. (2020) demonstrated that the use of maleic acid in combination with microwave assistance could result in a 24.3% yield of xylose. Meanwhile, microwave-assisted acid hydrolysis of rice husk could obtain 32.96% of xylose yield (Zhang et al. 2020b).

3.5 Solvent Hydrolysis Method

Organic solvents, such as pure organic solvent and complex organic solvent systems, can be used to separate hemicellulose. Lu et al. (2021) divided the solvent hydrolysis method into organosolv extraction, ionic liquid extraction, deep-eutectic solvent extraction, and high-pressure CO2/H2O technology. Organosolv extraction has the benefit of immediate hemicellulose extraction without delignification. The acetyl functional groups found in lignocellulosic biomass’ cell walls are not transformed to acetic acid and then expelled. Nevertheless, organic solvents are poisonous, combustible, volatile, and difficult to decompose, which causes environmental problems (Lu et al. 2021). Liu et al. (2018) demonstrated that xylose and XOS concentration from ethanol-based auto-catalyzed organosolv method in bamboo can reach up to 15 g/L and 18 g/L, respectively.

The merits of ionic liquid (IL) extraction include excellent high-recovery effectiveness and toxic-free solvent recycling. Even though ILs are not always costly, the preparation process is frequently complex and more expensive than using conventional media. Furthermore, hemicellulose recovered by ILs frequently contains certain contaminants and is only mildly decomposed, which causes some side chains to partially break. As a result, ILs’ continued commercial application is still challenging (Lu et al. 2021; Chen et al. 2014). The extraction of xylose by IL is affected by temperature and time. When temperature raised, the amount of xylan recovered in the solid fraction of corn stover is reduced, meaning that more xylan was dissolved into the hydrolysate (Xu et al. 2012). Xylose yield was also increased decreased when the temperature was increased from 50 to 110 °C, reaching maximum (75.9%) at 110 °C, but then decreased at higher temperature, implying that at higher temperature some of the dissolved xylan was degraded to lower molecular weight compound, such as furfural (Xu et al. 2012). At low temperature (70 °C), the xylose yield is increased when the duration of corn stover extraction using ionic liquid was increased from 3 to 24 h (Xu et al. 2012).

Deep-eutectic solvent (DES) extraction was an alternative solvent with 100% atomic economy compared to the previous common solvent for xylose and XOS extraction. The other advantages of DES are non-toxic, simple preparation, recyclable, low purity, and low extraction selectivity of hemicellulose (Lu et al. 2021). Research by Morais et al. (2018) shows that a yield of 14.81% was obtained when the optimized aqueous DES solutions were used to extract the hemicelluloses from Eucalyptus globulus wood. These results are higher than the yields resulting from water or alkaline hydrolysis.

A growing number of studies have focused on high-pressure fluids as potential solvent substitutes. In light of green chemistry principles, CO2 and H2O are the most promising high-pressure fluids since they are renewable and inflammable and give high xylose yield. As much as 100 mol% of xylose conversion was obtained using high-pressure CO2 in H2O/tetrahydrofuran system (Morais and Bogel-Lukasik 2016). Furthermore, the high-pressure CO2/H2O method does not require an additional catalyst, in contrast to conventional hydrothermal processes. Despite its similarity comparable to the pretreatment catalyzed by a mild acid, the depressurization process for removal of CO2 ensures that the medium acidity does not provide a risk to the environment. Unfortunately, under conditions of high pressure and temperature, a significant number of by-products are often produced (Lu et al. 2021; Morais and Bogel-Lukasik 2016).

3.6 Inorganic Salts Hydrolysis Method

Inorganic salts, such as NaCl, KCl, CaCl2, MgCl2, FeSO4, FeCl3, and other inorganic salts, do not include C–H bonds and contain environmentally favorable substances. The inorganic salt solution is mostly used to dissolve lignocellulosic biomass. The inclusion of salts can help accelerate lignocellulose hydrolysis and remove more hemicellulose. As a result, this can lower the reagent distribution cost. The researcher discovered that the addition of NaCl allowed the reaction to proceed more quickly and produce the highest amount of xylose (90%) with few secondary reaction products (Harahap 2020; Jiang et al. 2018).

3.7 Enzymatic Hydrolysis Method

Recent studies have shown that the potential of enzymatic hydrolysis is greater than that of chemical hydrolysis because of its many benefits. Since managing enzymes is simpler than handling acids, enzymatic hydrolysis is an eco-friendly process. Furthermore, it is not necessary to use expensive corrosive equipment. Enzymes create just one product from substrates because they are highly specific and selective (Inamuddin 2021).

In order to reduce xylose formation in the hydrolyzates when using enzymatic hydrolysis for XOS production, it is notable that the enzyme preparations should have decreased exoxylanase activity. The essential enzyme for generating XOS product from xylan are β-xylosidase, glycosynthases and endo- xylanases. In addition, the most popular technique for extracting XOS using xylanase is enzymatic hydrolysis because of the favorable circumstances and superior results. The extraction of XOS from xylan varies depending on the xylan source, the activity of the enzyme, and the incubation conditions. The compact lignin-hemicellulose structure may have a significant impact on its extraction from lignocellulose materials. In order to reveal more hemicelluloses and demonstrate the extraction yield, it is crucial to disrupt the compact structure. Hence, simultaneous enzymatic hydrolysis in the hemicellulose could be only used on non-recalcitrant biomass (Chen et al. 2021; Yan et al. 2022; Samanta et al. 2015).

Currently, Aspergillus xylanases are the most common ones utilized in XOS manufacturing. Immobilizing xylanase can increase its efficiency and reduce its cost, making it a viable option for subsequent production. Because of its beneficial impact, selectivity, and specificity, adjustable degree of hydrolysis, high yield and purity of XOS, and fewer by-products, enzymatic hydrolysis currently becomes the preferred method for producing XOS in industrial applications (Yan et al. 2022).

4 Purification of Xylose and Xylooligosaccharides

4.1 Purification of Xylooligosaccharides

Unwanted substances and oligosaccharides from a variety of DP are produced after the manufacture of XOS (Gullon et al. 2008). This unwanted substances like glucose and xylose raise the caloric value and alter the sweetening capacity of XOS and also impurities, such as furfural and HMF, have very little toxicity or adverse effects on human health in XOS with DP ranges up to 12 (Vazquez et al. 2000). Downstream processing is necessary to eliminate undesirable components and achieve the desired product (XOS of DP between 2 and 6) (Aachary and Prapulla 2011). Therefore, the next primary step in the creation of food-grade XOS is to purify the principal product by isolating the advantageous high-molecular-weight oligosaccharides from the unfavorable low-molecular-weight sugars and unwanted compounds. The crude liquors have been refined using a variety of methods to get rid of unwanted compounds and concentrate XOS with a yield from 75 to 95% as much as possible to achieve the required DP (Aachary and Prapulla 2011; Vazquez et al. 2000; Moure et al. 2006). The purification procedures used and the number of necessary stages have a direct impact on production costs and, thus, on the Minimum Product Selling Price (MPSP). For instance, purifying galacto-oligosaccharide (GOS) using activated carbon and celite for protein and color removal, ion exchange, and simulated moving bed (SMB) chromatography, known as AO-CH process, increases the MPSP linearly from 2 to 9 USD/kg as the final purity increases from 40% (unpurified) to up to 90% (Illanes et al. 2016). Understanding the above, numerous purification approaches, such as solvent extraction, adsorption using surface-active compounds, as well as chromatographic and membrane separation, have been investigated in recent decades.

4.1.1 Solvent Extraction Method in XOS Purification

Solvent extraction is often used to extract hemicellulose-based compounds from pretreatment and treatment steps in the production of XOS (Qing et al. 2013). In the first stage, vacuum evaporation is used to eliminate volatile components, concentrate XOS solutions, and removal of possible explosives (Vazquez et al. 2000; Qing et al. 2013). The solvent extraction method is useful for removing non-saccharide parts, resulting in a particularly purified liquid phase and also a solvent component containing phenolics as well as extractive-derived residues (Moure et al. 2006). The yield and degree of purification, however, are dependent on the solvent used for extraction and the kind of lignocellulosic biomass used. Organic solvent precipitation, on the other hand, allows for the extraction of XOS and/or xylose by eliminating phenolics and extractive-derived chemicals. The most often used solvents for this process are acetone, ethanol, and 2-propanol (Qing et al. 2013). Other procedures of varying nature have frequently been used, such as the work of Vegas et al. (2006) can reach 90.7% XOS purity, by applying a combination of nanofiltration, solvent extraction, and double ion-exchange chromatography.

4.1.2 Adsorption Separation Method in XOS Purification

Adsorption is a technique that has been used to separate XOS or to eliminate undesirable chemicals. The most often utilized adsorbents, such as diatomaceous earth, acid clay, titanium, bentonite, activated charcoal, aluminum oxide, silica, and other synthetic materials, are commonly used in combination with other refining procedures (Vazquez et al. 2000; Xu et al. 2019). Activated charcoal was found to be the most widely used adsorbent and also has been demonstrated to be a feasible solution for the elimination of substances derived from extractives, lignin, and carbohydrate-degradation present in XOS mixtures (Nabarlatz et al. 2007b). The XOS were initially held by activated charcoal in the study by Pellerin et al. (1991), and then were eluted with various concentrations of ethanol. A similar technique was used by Reddy and Krishnan (2014) to extract XOS generated by B. subtilis utilizing activated charcoal. Activated charcoal (10% w/w) was added to the culture extract, and it was retained by vacuum filtering. After being adsorbed onto charcoal, XOS was subsequently eluted with serial percentage of ethanol, resulting in XOS separation depending on molecular weight. Ion-exchange resins are used in conjunction with other purification methods to eliminate heavy metal ions, salts, negatively or positively charged organic molecules, and pigments from XOS solutions (Vazquez et al. 2000; Chen et al. 2016). Chen et al. (2016) successfully produce high XOS recovery (91.3%) and also show that the oligomer composition is not altered by the ion-exchange resin treatment.

4.1.3 Chromatographic Separation

This method utilizes high-performance liquid chromatography (HPLC), ion-exchange, affinity, and size-exclusion chromatographic separation techniques to obtain highly purified XOS at the analytical level (Geetha and Gunasekaran 2017). In the purification of XOS, chromatographic approaches such as adsorption in activated charcoal column chromatography and gel filtration chromatography (GFC) have been studied (Ho et al. 2014). Ho et al. (2014) have purified XOS that produced by agro-residue autohydrolysis using GFC, which was demonstrated to be effective in the elimination of oligosaccharides with high DP as well as undesirable small compounds, such as monosaccharides, acetic acid, and degradation chemicals (furfural, HMF and phenolics). This method also indicates a competitive advantage over membrane purification (Moniz et al. 2014). Despite the fact that the reported final XOS purities were greater than 70%, the product exhibited a wide DP range (5–40 and 3–23, respectively). As a result, if XOS having DP 2–6 is considered as the desired product, the purity was greatly overestimated. Chapla et al. (2012), on the other hand, had employed activated charcoal column chromatography for the purification of XOS generated from enzymatic saccharification of pre-extracted corncob xylan. The refined XOS preparation consists mostly of xylobiose and xylotriose, and the purity level was not specified. Study by Yang et al. (2007) had successfully isolated XOS from xylan enzymatic hydrolysis using a packed charcoal column followed by ethanol elution. The authors used this process to produce XOS mixture of 71.4% purity, mostly constituted of xylobiose, xylotriose, and xylotetrose, with a 95% XOS recovery.

SMB is a method of chromatographic separation that improves productivity of the separation and purity of products. Furthermore, this approach lowered solvent consumption, provided simple operational controls, and increased the performance of the separation in systems with limited selectivity and resolution (Li et al. 2020). In a continuous-separation mode, Choi et al. (2016) was able to recover 92.3% xylobiose from XOS with a purity of 99.5%, which will be beneficial in allowing large-scale, cost-effective manufacture of high-purity xylobiose.

4.1.4 Purification Through Membrane Filtration

Prebiotic purification to remove proteins and polysaccharides followed by ion exchange chromatography was employed in the work by Broekaert et al. (2011), but this process is not economical for industrial application. Membrane technology is currently regarded as the best downstream approach for industrially producing high-purity XOS. Membrane technology is a viable technique for concentrating and refining XOS since it has a high recovery rate, uses little energy, and is a straightforward process that does not need other compounds as a solvent.

Membrane technology techniques, such as ultrafiltration (UF) and nanofiltration (NF) seem to be the favored technologies for refining XOS due to their excellent recovery rate with no solvent (Nabarlatz et al. 2007b). The XOS generated by autohydrolysis of almond shells was successfully purified by employing commercial thin-film polymeric membranes (Nabarlatz et al. 2007b). The findings show that lignin-related low molar mass compounds are not rejected by low MWCO (1 kDa) polymeric membranes, enabling continuous diafiltration to remove impurities and recognize as an appropriate technique to purify XOS solutions produced by the autohydrolysis of lignocellulosic biomass. However, in the case of XOS, UF appears to be a pre-treatment alternative rather than a method for creating a highly pure product containing short-chain oligosaccharides (Cordova et al. 2019).

A combination of UF and NF was employed to purify XOS produced from the sequential autohydrolysis and enzymatic saccharification of almond shells to increase the elimination of tiny pollutants (Singh et al. 2019a, 2021). In the NF step, the XOS mixture was concentrated and monosaccharides and acetic acids were removed, while in the UF step components having high molecular weight, such as enzymes, were removed, with results similar to those obtained by Akpinar et al. (2007) and Kumar and Satyanarayana (2015).

Membrane that separates higher-molecular-weight molecules from oligosaccharides requires less energy and is simple to operate and scale-up (Czermak et al. 2004). However, membrane technology alone cannot perform the best technique to purify XOS, because membrane has also a drawback due to its poor performance when small molecules such as monosaccharides should be separated. The hydrolysis of previously extracted hemicellulose and autohydrolysis from lignocellulosic biomass produce XOS, which is then purified using UF membrane.

Monosaccharides have the most major impurities that have less difference in molecular weight (MW) such as glucose (MW = 180 g/mol), which difficult to separate between xylose (MW = 150 g/mol) and xylobiose (MW = 282 g/mol) (Mah et al. 2019). The membrane technology mostly does not have a very small cut-off molecular weight difference. For that reason, the study by Wijaya et al. (Wijaya et al. 2020), has performed a strategy of elimination glucose by the enzymatic reaction that does not convert cellulose to glucose before the process enters membrane separation unit. This process is a combination of alkali pretreatment and enzymatic reaction by xylanase free from cellulase (Wijaya et al. 2020). However, the research for a suitable way to purify XOS from hemicellulosic hydrolysate has not yet been resolved. Table 3 presents different techniques for recovering XOS using recent purification methods that have been published.

4.2 Purification of Xylose

The procedures used to convert lignocellulose resources into ethanol include polysaccharide hydrolysis to xylose and glucose, fermentation, and ethanol purification. Among these steps, acid hydrolysis is the most important in generating inhibitors, such as acetic acid, which restrict the fermentation processes in ethanol production (Mussatto and Roberto 2004). More particular, the existence of acetate can inhibit yeast fermentation development and metabolism by lowering intracellular pH (Lohmeier-vogel et al. 1998). There are several ways for removing acetic acid from hydrolysate. The detoxification procedures have been thoroughly evaluated in some studies (Mussatto and Roberto 2004; Parajo et al. 1998; Huang et al. 2008). Some of the treatments investigated for removing acetic acid include extraction, neutralization, over-liming, vacuum evaporation, steam stripping, charcoal adsorption, and ion exchange resins adsorption. There have been many membrane processes developed recently, including adsorptive membrane and membrane extraction (Han et al. 2006; Grzenia et al. 2008).

The next step, which is the separation of xylose from glucose, can be challenging. Desal-5 DK NF membrane with molecular weight cut-off 150–300 Da was used to remove acetic acid from xylose (Weng et al. 2009). Separation between xylose and glucose by tailored thin-film composite (TFC) nanofiltration membrane has been studied as well (Mah et al. 2019). Other strategy involves an enzymatic reaction as studied by Morthensen et al. (2015). They had done an enzymatic method for converting glucose to gluconic acid, followed by nanofiltration to separate xylose from gluconic acid. The method for separation of xylose from glucose using concentrated monosaccharide solutions also needs consideration (Sjoman et al. 2007).

Older methods, such as liquid chromatography (LC) by ionic liquid-modified silica can also be considered (Bi et al. 2010). The chromatographic separation method can use a cation exchange resin (Chen et al. 2018). In the future, the purification of xylose can use a combined strategy to achieve a product either ethanol or xylose as purified sugar.

5 Potential Applications of Xylose and Xylooligosaccharides

5.1 Potential Applications of Xylose

Xylose can be used in a variety of applications, either as is or as a feedstock for further chemical or biological conversion to a variety of products such as xylitol, furfural, furfuryl alcohol, levulinic acid, levulinic ester, ethanol, butanol, and hydrogen. Table 4 shows value-added products that could be created from xylose through chemical and biological catalytic processes and various applications of the products generated in food, healthcare, feed, personal care, cosmetics, pharmaceuticals, medical, materials, etc. Some important products will be discussed in more detail in the following paragraphs. The conversion of xylose through chemical process produces lower yields, and the employment of acidic catalysts and reaction operation at higher temperatures and pressures renders the process ecologically unfriendly (Narisetty et al. 2022). Due to the high cost of manufacturing and environmental incompatibility, the long-term viability of many commercial chemical processes, including xylitol production, is questionable (Narisetty et al. 2022).

5.1.1 Food and Healthcare

Xylose is usually used as a sweetener that has a high market value (Fernandez 2019). The relative sweetness of xylose is about 70% of sucrose sweetness. This natural sweetener has a low calorie, is easily absorbed into small intestine, and is not metabolized by the liver (Fernandez 2019). Therefore, it is beneficial for people with obesity, diabetes or other illnesses that should limit sugar consumption. Other health benefits of xylose are its ability to activate and promote the growth of beneficial bacteria in the human gut, such as Bifidobacterium and Lactobacillus, to prevent dental caries, to serve as dietary fiber that decreases blood fat, lowers cholesterol, and prevent colon cancer, and to be compatible with food (Hongzhang et al. 2012).

Xylose is chemically relatively inert and stable, which contributes to the strong demand for food items, particularly confectionaries, as it is easy to combine into other food products without altering the recipe. Xylose is a good flavor enhancer by inducing Maillard reaction compounds, such as amino acids and peptides in meats, fish, seafood, milk, beans, or peas. The Maillard reaction is a significant nonenzymatic process that occurs when amino compounds, such as amino acids or peptides, combine with carbonyl molecules, typically a reducing sugar like xylose or glucose (Newton et al. 2012; Sun et al. 2019; Martins et al. 2001). Maillard reaction products (MRPs) containing a variety of volatile compounds have a significant impact on food flavor and quality. D-xylose is better than glucose or sucrose in remedying the color, flavor, and fragrant of the food. The addition of 0.05–2% of D-xylose is enough to enhance the flavor of the food. The usage of xylose provides advantages to the flavor industry that uses the Maillard reaction for the creation of thermally produced flavorings (Gaspar et al. 2012).

5.1.2 Pharmaceutical and Medical

Xylose has been used in an absorption test to evaluate small intestinal absorption since 1937 because the method is simple and reproducible. The method involves an oral dosage of xylose and its serum and urine determination after 5 h collection period. Upon ingestion of xylose, the body is expected to use 75% of its content, and the 25% remaining is excreted through the urine within 5 h (Gaspar et al. 2012). Due to the fact that xylose is absorbed unmodified by the duodenum and jejunum, its inadequate absorption makes it suitable for use as a malabsorption test (Craig and Atkinson 1988). The study confirms that the intake of 25 g D-xylose followed by a 5 h urine collection and a 1 h serum analysis is a very sensitive and specific diagnostic for malabsorption.

Earlier study by Cook (1975) shows that in healthy Africans, gamma-globulin serum levels were significantly inversely linked to D-xylose urine excretion. This indicates that when the D-xylose content in the bloodstream increases or less D-xylose is excreted in the urine, the concentration of gamma-globulin serum increases dramatically, hence enhancing the immunological response. Besides that, many other studies also show that xylose has anti-inflammatory, antiviral, antiglycemic, and anticancer properties for lung cancer (Cheudjeu 2020). These induce the idea of using xylose as an alternative therapeutic regimen for a severe case of Covid-19 (Cheudjeu 2020). Nevertheless, this hypothesis should be proved by pre-clinical and clinical trials. Xylose has a unique and useful texture-enhancing properties, which are needed in some products, such as cosmetics and personal care products.

5.1.3 Feedstock for Production of Fuels and Chemicals

The major purpose of xylose as an industrial raw material is for producing xylitol. Xylitol is a platform chemical, having five-carbon sugar alcohol that are widely used in food, confectionary, personal care, and pharmaceutical industry. The sweetness of xylitol is the same as that of sucrose, but it has lower calorific value and glycemic index (2.4 cal/g; 7%) than sucrose (4 cal/g; 60–70%). The metabolism of xylitol is insulin-independent. Xylitol has a high endothermic heat, thus as it dissolves in the mouth, a pleasant feeling of cooling and freshness is immediately noticed. These characteristics mask the unpleasant flavor of numerous pharmacological active components and excipients. Asia–Pacific, Europe, and the United States account for the majority of xylitol production. The process of producing xylitol is expensive, which prevents its production from expanding to other continents.

Currently, the method of producing xylitol from pure D-xylose on an industrial scale is a chemical process at high temperature and pressure (180 °C, 50 atm) using aluminum or nickel catalyst for hydrogenation of the xylose (Rafiqul and Sakinah 2013; Carneiro et al. 2019). This process consumes high energy and generates catalyst residues which causes environmental problem. The amount of xylitol recovered is around 50–60% of the xylan or 8–15% of the initial feedstock. The following procedures to obtain pure xylitol involve extensive separation and purification processes which are also time-consuming, energy-intensive, and costly, causing high price of the product (Saha 2003). Alternative process using bioprocess has been studied and reported. The bioprocess which usually involves xylose-fermenting yeasts to convert xylose into xylitol has gained attention, because it is low cost, operates at moderate reaction conditions, is more sustainable, and environmentally friendlier (Oktaviani et al. 2021). The yeast could be directly added to the hemicellulose hydrolysate that contains xylose, followed by the separation of xylitol from the fermentation broth using different methods, and purification of the xylitol that has been separated.

Lactic acid, also known as 2-hydroxyproponoic acid, is an optically active compound that comes in L and D forms. Lactic acid, as a platform chemical, has numerous industrial applications in food, cosmetics, polymers, and packaging. The most valuable application of lactic acid as a monomer is the production of polylactic acid (PLA), a commercial petrochemical polymer substitute (Narisetty et al. 2022). Lactobacillus pentosus and L. brevis naturally can ferment xylose via the pentose phosphate and phosphoketolase routes, creating lactic acid and a combination of acetic and lactic acids, respectively (Qiu et al. 2018). Other microbes that have been reported could produce lactic acid from xylose are Pediococcus acidilactici (Narisetty et al. 2022; Qiu et al. 2018, 2017), engineered Escherichia coli, Lactobacillus delbrueckii, Lactobacillus lactis, Lactobacillus plantarum, Bacillus sp., Bacillus coagulans, Corynebacteria glutamicum, and Rhizopus oryzae (Abedi et al. 2020).

Succinic acid is an aliphatic dicarboxylic acid with four carbon atoms that is used extensively as a precursor in the pharmaceutical, polymer, and chemical industries. Similar to lactic acid, succinic acid is a platform chemical that, due to the presence of two carboxyl acid groups, can be transformed into a range of compounds including succinic anhydride, succinic esters, 2-pyrrolidine, and polyesters for the synthesis of biodegradable plastics (Dai et al. 2020).

Ethanol/ethyl-alcohol/bioethanol is the most frequently used biofuel in the transportation industry and offers a number of benefits, including higher octane number, greater combustion efficiency, and better heat of vaporization. Bioethanol is less hazardous, rapidly biodegradable, and emits fewer airborne pollutants than petroleum fuel and other viable fuel options. Due to its hygroscopic nature, however, ethanol cannot completely replace gasoline because water vapor might damage the engine (Narisetty et al. 2022). Currently, ethanol is mixed with gasoline at varying percentages (5–20%) over the world. The combined fuels reduce emissions of hydrocarbons and greenhouse gases significantly. The generation of ethanol from xylose follows the production of X5P via the pentose phosphate route and continues via the EMP pathway (Narisetty et al. 2022). The end product of the EMP route, pyruvate, is transformed to ethanol via the intermediate acetaldehyde. Unfortunately, the common ethanol-fermenting yeast, Saccharomyces cerevisiae, cannot assimilate the xylose. There are some other yeasts, such as Pachysolen tannophylus and Pichia stipitis, that can use glucose and xylose to produce ethanol. However, their activities are restricted due to substrate and product-mediated inhibition. Genetic engineering of S. cerevisiae is needed to make the yeast assimilate both glucose and xylose (Kwak and Jin 2017). Even though xylose could be converted to ethanol, it might be more advantageous if it is converted to other chemicals that have better values than ethanol.

n-Butanol is a four-carbon alcohol with a straight chain and is regarded as a superior biofuel to ethanol due to its higher heating value, ignition issues, lower volatility, high octan number, low miscibility with water, and higher viscosity (Vivek et al. 2019). n-Butanol could be produced via chemical or biological route. The chemical process of producing n-butanol is through aldol condensation (oxo process), which consists of hydroformylation and hydrogenation of propylene. The biological process for n-butanol production is a part of acetone–butanol–ethanol (ABE) fermentation using microorganisms, such as Clostridium spp., well-known cell factories with ABE fermentation (Chacon et al. 2020; Gottumukkala et al. 2013). However, the manufacture of bio-butanol is hindered by low concentration and yield as well as product-mediated inhibition. Optimization of solid loading has been performed to increase the ABE fermentation and reveals that the ideal biomass loading of 10% combined with the liquid hot water (LHW) pretreatment resulted in a sustainable route for a successful sugarcane straw ABE fermentation (Pratto et al. 2020). In addition, the integrated process of hydrolysis and fermentation eliminates problems of substrate inhibition. Despite the fact that the yield of n-butanol is 20% lower than that of ethanol, the energy produced by n-butanol is 32% greater than that of ethanol (Baral and Shah 2016). With the current concentration and yield, the cost of producing biobutanol is approximately USD 1.8/L. However, further optimization of the biocatalysts and process conditions could reduce the cost to USD 0.6/L, which is equivalent to that of gasoline and other fossil fuels (Liu et al. 2016).

Hydrogen is often regarded as one of the most potentially useful alternative energies because when combined with oxygen, it produces only water and has a 2.75 times higher energy yield (122 kJ/g) than hydrocarbons (Liang et al. 2012). Fermentation of sugars to produce hydrogen is usually conducted using thermophilic anaerobic bacteria, thus, it is usually called dark fermentation. Hydrogen-producing microbes can utilize both hexoses and pentoses, while some others prefer xylose over glucose or vice versa. Caldicellulosiruptor members have adapted to xylose and disaccharides (cellobiose) as principal substrates rather than glucose, which may provide them a competitive advantage in thermophilic lignocellulosic breakdown (Vongkampang et al. 2021). C. saccharolyticus, C. owensensis, and C. kristjanssonii consume xylose faster than glucose (Zeidan and Niel 2009). In comparison to glucose, C. kronotskyensis prefers xylose and cellobiose the most (Vongkampang et al. 2021). Co-culture of microbes has been shown could improve hydrogen production. The hydrogen yield from the co-culture of C. saccharolyticus and C. kristjanssonii came close to the theoretical maximum stoichiometry and was much higher than that of the monoculture of either organism, suggesting the two bacteria synergistic effects on hydrogen generation (Zeidan and Niel 2009). Genetically engineered microbes could also increase hydrogen production during fermentation. Higher hydrogen yield and productivity were observed in the Thermoanaerobacterium aotearoense SCUT27/nfnAB mutant relative to the original strain (Li et al. 2019a).

Besides microbes, enzyme can also be used in the hydrogen production from xylose. First, the cellulose and hemicellulose of the biomass were converted to glucose and xylose, which serve as substrates for phosphorylation and hydrogen generation using enzyme mixtures. The process is continued with separation and purification of the hydrogen. The enzymatic production of hydrogen from biomass hydrolysate in aqueous solution has some benefits over the production of other biofuels because the process can use lower concentration of sugars and the product separation is not expensive (Lastname et al. 2015). Hydrogen gas could be easily separated from an aqueous sugar solution regardless of its concentration. In the case of ethanol, for energy-efficient distillation of ethanol, its concentration in the fermentation broth should be 4% minimum, which means about 9% sugars in the hydrolysates.

Furfural is an important bio-based platform chemical derived from C5 sugars, including xylose. Currently, it is industrially produced from biomass, such as corn cob or sugarcane bagasse through acid hydrolysis of hemicellulose, especially xylan, in the biomass, and followed with dehydration of the sugar monomers, especially xylose (Zhang et al. 2017a, b). The dehydration of xylose to furfural is usually conducted through chemical processes, without or with different kinds of catalysts, which is explained in quite detail and comprehensively by Delbecq et al. (2018). Furfural could be applied in wide variety of applications, such as mentioned in Table 3. Based on its physical or chemical characteristics, furfural is categorized as a hazardous substance and listed under numerous globally determined classifications of hazardous materials (Delbecq et al. 2018).

Furfuryl alcohol (C4H3OCH2OH, 2-furylmethanol, 2 furancarbinol) is produced through hydrogenation of furfural, which is previously derived from xylose through dehydration. Both steps usually utilize chemical catalysts. Chemical production of furfuryl alcohol can give high yields and good selectivity, however, it consumes high-energy and creates environmental issues that might limit its application. The conversion of furfural to furfuryl alcohol has been conducted through biological methods by using some bacteria, such as Bacillus coagulans, Bacillus cereus, and Escherichia coli that have been genetically engineered. This method has gained attraction due to its energy-saving and environmentally friendly performance (Liang et al. 2022). Perez et al. (2017) introduced a one-step conversion of xylose to furfuryl alcohol via a sulfated zirconia-supported Pt catalyst with balanced acid and metal sites. In a one-step conversion of xylose to furfuryl alcohol, the reaction takes place on vicinal acid-metal pare sites formed on single multifunctional catalysts, whereas in a two-step process furfuryl alcohol is generated through consecutive dehydration hydrogenation reactions on independent acid and metal sites on dual catalytic systems. Furfuryl alcohol is widely used in the production of synthetic fiber, rubber resin, furan resin, vitamin C, lubricant, lysine, and hypergolic rocket fuel (Liang et al. 2022; Millán and Sixta 2020).

Levulinic acid, sometimes referred to as 4-oxopentanoic acid or gamma ketovaleric acid, is a C-5 fatty acid with the chemical formula C5H8O3 and one of the key platform chemicals (Morone et al. 2015). Levulinic acid has a ketone carbonyl group (C=O) and an acidic carboxyl group (COOH), which endows it with the capacity to react with various functional groups to generate a vast array of derivatives, making it a good platform chemical (Morone et al. 2015; Bozell et al. 2000). Due to the presence of highly reactive carbonyl and carboxyl groups, levulinic acid can be converted into a variety of high-value-added chemicals and other bioproducts (Elumalai et al. 2016; Galletti et al. 2012; Rackemann et al. 2011). Most studies focus on the generation of levulinic acid from starch or cellulose, or through C6 sugars, and fewer studies are using C5 sugars, such as xylose. Furfural, which was produced from C5 sugars, such as xylose, could be transformed into furfuryl alcohol (FA) through a transfer-hydrogenation (TH), and subsequently, into levulinic acid through a hydrolytic ring opening reaction (Lange et al. 2009; Chamnankid et al. 2014). While levulinic acid has been successfully produced in the lab, its commercialization has been hampered by a number of factors. These include the high cost of raw materials and equipment, the low yield of levulinic acid due to undesirable side reactions, the difficulties in efficient product recovery, the high cost of recovering the catalyst, the inefficiency of the process economy, and the high cost of energy (Morone et al. 2015).

Polyhydroxybutyrate (PHB), is a biodegradable polymer that is made up of 3-hydroxybutyrate and can reach a degree of polymerization of 2000. PHB is a member of the polyhydroxyalkanoate group, that can be used as an alternative to plastics that are made from petrochemicals (Li et al. 2019b; Lee et al. 2021). The physical and mechanical properties of PHB such as optical purity, a high melting point, crystallinity, and desirable water and gas barrier properties, are similar and comparable to those of commercial polymers or plastics derived from fossils (Saratale et al. 2019). Unfortunately, the cost of producing PHB (USD 2.25–2.75/lb) is three to four times that of conventional plastics (USD 0.60–0.87/lb), limiting its use in the industrial and commercial sectors (Saratale et al. 2019; Singh et al. 2019b). The high price of PHB is due to the low productivity, content, and yield as well as the high price of carbon substrate (Singh et al. 2019c). PHB is produced by numerous microbes, including Ralstonia, Halomonas, and Bacillus species, that consume sugar monomers, including glucose, fructose, xylose, arabinose, etc. However, there are only a small number of strains capable of producing PHB from xylose, the second abundant and inexpensive carbon source in lignocellulosic biomass (Lee et al. 2021). R. eutropha, the strain with the highest PHB-producing capacity, cannot readily absorb and metabolize xylose (Lee et al. 2021; Bhatia et al. 2018; Lopes et al. 2009). Some efforts to increase the yield of PHB have been reported, for example by screening for xylose-utilizing microbes, co-culturing of the microbes (Lee et al. 2021), or optimizing sugar compositions during fermentation (Li et al. 2019b). Some other solutions to produce more economical PHB are co-production with other value-added products, design of an appropriate bioreactor system, and production of PHB using synthetic biology (Singh et al. 2019c).

5.2 Potential Applications of XOS

XOS has been reported used as antioxidant, prebiotic, plant growth regulator, cosmetics, gelling agent, and for the treatment of diabetes, arteriosclerosis, and colon cancer (Ahmad 2019). XOS is commercially appealing for use as animal feed, food, beverage, and pharmaceutical ingredients (Pinales-Márquez et al. 2021). Furthermore, XOS is utilized in the manufacture of micro or nanoparticles and hydrogels for medication administration and therapies, particularly for the prevention of gastrointestinal problems (Shimoda et al. 2011; Gupta et al. 2016). The relative sweetness of xylobiose and XOS is 0.34 and 0.26, respectively (Park et al. 2017).

5.2.1 Antioxidant

Antioxidant is a compound that can delay or prevent oxidation of a substrate by scavenging or neutralizing free radicals. The free radical scavenging capability of XOS is a result of the efficient release of total phenolic compounds and the transfer of the hydrogen atom from the phenolic compounds (Huang et al. 2005; Gowdhaman and Ponnusami 2015). The precise mechanism of action of XOS in reducing the negative effects of oxidative stress has yet to be established by scientific evidence (Samanta et al. 2015). The scavenging capacity of an antioxidant is determined using various methods, for example, 2,2-diphenyl-1-picrylhydrazyl (DPPH) assay, beta carotene bleaching assay, 2,2A-azinobis(3-ethylbenzthiazoline)-6-sulfonic acid (ABTS) assay, and ferric reducing antioxidant power (FRAP) assay (Antolovich et al. 2002).

The antioxidant activity of XOS depends on several factors, such as types of feedstocks or sources of XOS, methods of XOS extraction, concentration and degree of polymerization of XOS, and total phenolic contents in XOS (Bian et al. 2013; Samanta et al. 2015; Gowdhaman and Ponnusami 2015). A DPPH assay demonstrates that the antioxidant activity of XOS derived from sugarcane bagasse is dose-dependent (Bian et al. 2013). The antioxidant activity of the XOS-rich fraction recovered from wood using ethyl acetate extraction (EC50 = 0.39 g/l) was equivalent to 61% of that presented by butylated hydroxy anisole (BHA) and 12 times higher than that of butylated hydroxy toluene (BHT), and the fraction contained up to 0.43 g of gallic acid equivalents per 100 g of dry wood (González et al. 2004). The EC50 (0.23 g/l) was similar to that of BHA when the acid hydrolysis was performed under circumstances that led to extracts with maximum antioxidant-specific activity (González et al. 2004). The varied concentrations of XOS from corn cob were shown to have a range of scavenging abilities between 9.7 and 74.2% (Gowdhaman and Ponnusami 2015). The antioxidant activity of XOS was shown to have an IC50 value of 1 mg/ml, which is comparable to earlier results on the antioxidant activity of XOS extracted from maize and sugarcane bagasse (Aachary and Prapulla 2008; Gowdhaman and Ponnusami 2015). Study by Rashad et al. (2016) reveals that the XOS derived from a variety of agricultural wastes demonstrated concentration-dependent antioxidant activity. This finding is consistent with prior findings regarding XOS derived from wheat, millet brans, and sugarcane bagasse (Bian et al. 2013; Veenashri and Muralikrishna 2011; Rivas et al. 2013). The overall antioxidant capacity of XOS mixes is heavily influenced by both the total phenolic acid concentration and the type of those phenolic acids (Veenashri and Muralikrishna 2011). The existence of a higher quantity of total phenolic acid contents in XOS combinations formed from orange peels and mango peels compared to other XOS mixtures may account for their considerably stronger antioxidant activity (Rashad et al. 2016).

5.2.2 Prebiotics

A prebiotic is “a nondigestible food element that promotes the health of the host by selectively encouraging the growth and/or activity of one or a restricted number of bacteria in the colon” (Gibson and Roberfroid 1995). A more precise definition of prebiotic is a fermented element that induces certain changes in the composition and/or activity of the microbiota of the gastrointestinal tract and offers health benefits (Aachary and Prapulla 2011; Gibson et al. 2004). The current daily dose of XOS that is recommended to generate a prebiotic effect is low, which allows them to compete favorably in terms of pricing. In order to achieve an essential regulatory status and boost their commercial value, however, additional in vivo experimental data is required (Amorim et al. 2019).

Several researchers have documented the prebiotic effects of XOS. The XOS streams utilized as carbon sources for the in vitro fermentability evaluation with human fecal inoculum exhibited prebiotic effects by stimulating the formation of lactate, formate, and SCFA (acetate, propionate, and butyrate), as well as alterations in the selected bacterial populations (Bifidobacterium genus, Lactobacillus, Enterococcus group and Bacteroides, Prevotella group) (Buruiana et al. 2017). It appears that XOS promotes gut health by selectively stimulating the growth of bifidobacteria and lactobacilli. Additionally, XOS reduces the number of potentially pathogenic organisms (Chen et al. 2021). In vitro fermentation of the putative probiotic L. brevis strain validated prebiotic property of XOS-mixture derived from wheat (Faryar et al. 2015).

5.2.3 Food Processing

According to Deutschmann and Dekker ( 2012), XOS is resistance to high temperature up to 100 °C and has a good adaptability in large range of pH (2.5–8). XOS has a better resistance to low pH (<4) and high temperature (>90 °C) than other oligosaccharides and inulin, which is beneficial in food processing point of view and makes the XOS can be used in carbonated drinks, low-pH juices, and acidic foods (Aachary and Prapulla 2011). Current study also shows that XOS is stable under high pressure processing (100–600 MPa) combined with heat treatment (100 °C) (Silva et al. 2022). In food industry, XOS can also be used as a low-calorie sweetener or feedstock for producing low-calorie sweeteners, such as xylitol. XOS has been reported as flavor enhancer in formulating a beverage (Gupta et al. 2016). The addition of XOS in a non-alcoholic carbonated drink has a positive impact with other sweeteners, such as mixture of ace sulfame K and aspartame (Gupta et al. 2016). The addition of XOS in beverages significantly enhances full body character of the beverages without any drawback of off-flavor perception or mouth feel (Gupta et al. 2016, 2012).

5.2.4 Other Biological Functions

XOS has a wide range of biological activities, including anti-inflammatory, antioxidant, antitumor, and antimicrobial properties (Chen et al. 2021). Experiments in rats show that XOS reduces concentration of sugars and lipids in blood of diabetic rats, improves calcium absorption in rats, enhances phagocytic activity of neutrophils in mice, and improves gastrointestinal health of rats (Liang et al. 2012). XOS is non-cariogenic, preserve pancreatic insulin production, and promote intestinal mineral absorption (Moure et al. 2006). In human health, XOS has been reported to reduce risk of colon cancer and have a cytotoxic effect on human leukimia cells (Liang et al. 2012).

6 Concluding Remarks

Lignocellulosic biomass is a potential feedstock because it is widely available, and relatively inexpensive. It is very beneficial for producing high-value-added products, including fuels and chemicals, that can be used in various fields and applications. The production of xylose and XOS from lignocellulosic biomass has become interesting as a part of lignocellulosic biorefinery, which could promote economic viability of the biorefinery. Despite significant progress in xylan-based bioproduction over the last few decades, many challenges remain to be overcome before xylan can be used as a feedstock at the industrial level. The first challenge comes from the feedstock itself, which usually varies or not uniform, the scattered existence, and sometimes has problem with continuous supply. In the process and technology sector, it is important to select the appropriate pretreatment or fractionation of biomass which could be applied in a wide variety of biomass, and subsequently facilitate the extraction, isolation, and purification of xylose and XOS from the biomass using different kinds of techniques available. The choice of extraction, isolation, and purification should be feasible technologically and economically. For example, the process should be able to recover more xylose or XOS, minimize the production of undesirable products, and retain more cellulose in solid residue. Xylose and XOS could be used as they are, or to be further transformed to different kinds of chemicals that could be used for fuels and various applications in food, health care, pharmaceutical, cosmetics, and personal care. The challenge in this transformation is to find a robust, practical, inexpensive, efficient, and environmentally friendly process, to generate products of economic value. Standardized methods of process and analysis of the products are also important to obtain consistent quality and standardized bioproducts.

References

Aachary AA, Prapulla SG (2008) Corncob-Induced endo-1, 4-D-Xylanase of Aspergillus oryzae MTCC 5154: production and characterization of Xylobiose from Glucuronoxylan. J Agric Food Chem 56:3981–3988. https://doi.org/10.1021/jf073430i

Aachary AA, Prapulla SG (2011) Xylooligosaccharides (XOS) as an emerging prebiotic: microbial synthesis, utilization, structural characterization, bioactive properties, and applications. Compr Rev Food Sci Food Saf 10:2–16. https://doi.org/10.1111/j.1541-4337.2010.00135.x

Abedi E, Mohammad S, Hashemi B (2020) Heliyon Lactic acid production—Producing microorganisms and substrates sources-state of art. Heliyon 6:e04974. https://doi.org/10.1016/j.heliyon.2020.e04974

Adams G, Castagne A (1951) Hemicelluloses of wheat straw. Can J Chem 29:109–122

Ahmad R (2019) Better health with plant oligosaccharides: trends and future. Second Int Conf Food Agric 601–607

Akpinar O, Ak O, Kavas A et al (2007) Enzymatic production of xylooligosaccharides from cotton stalks. J Agric Food Chem 55:5544–5551. https://doi.org/10.1021/jf063580d

Akpinar O, Gunay K, Yilmaz Y et al (2010) Enzymatic processing and antioxidant activity of agricultural waste autohydrolysis liquors. BioResources 5:699–711

Amorim C, Silvério SC, Gonçalves RFS et al (2019) Downscale fermentation for xylooligosaccharides production by recombinant Bacillus subtilis 3610. Carbohydr Polym 205:176–183. https://doi.org/10.1016/j.carbpol.2018.09.088

Antolovich M, Prenzler PD, Patsalides E et al (2002) Methods for testing antioxidant activity. Analyst 127:183–198. https://doi.org/10.1039/b009171p

Baral NR, Shah A (2016) Techno-economic analysis of cellulosic butanol production from corn stover through acetone-butanol-ethanol (ABE) fermentation techno-economic analysis of cellulosic butanol production from corn stover through. Energy Fuels 30:5779–5790. https://doi.org/10.1021/acs.energyfuels.6b00819

Bhatia SK, Gurav R, Choi T et al (2018) Bioconversion of plant biomass hydrolysate into bioplastic (polyhydroxyalkanoates) using Ralstonia eutropha 5119. Bioresour Technol 271:306–315. https://doi.org/10.1016/j.biortech.2018.09.122

Bi W, Zhou J, Row KH (2010) Analytica chimica acta separation of xylose and glucose on different silica-confined ionic liquid stationary phases. Anal Chim Acta 677:162–168. https://doi.org/10.1016/j.aca.2010.08.004

Bian J, Peng F, Peng XP et al (2013) Structural features and antioxidant activity of xylooligosaccharides enzymatically produced from sugarcane bagasse. Bioresour Technol 127:236–241. https://doi.org/10.1016/j.biortech.2012.09.112

Bozell JJ, Moens L, Elliott DC et al (2000) Production of levulinic acid and use as a platform chemical for derived products. Resour Conserv Recycl 28:227–239

Brenelli LB, Bhatia R, Djajadi DT et al (2022) Xylo-oligosaccharides, fermentable sugars, and bioenergy production from sugarcane straw using steam explosion pretreatment at pilot-scale. Bioresour Technol 357:127093. https://doi.org/10.1016/j.biortech.2022.127093

Broekaert W, Courtin C, Delcour J (2011) (12) Patent Application Publication (10) Pub. No.: US 2011/0020498A1. 1

Buruiana CT, Gómez B, Vizireanu C, Garrote G (2017) Manufacture and evaluation of xylooligosaccharides from corn stover as emerging prebiotic candidates for human health. Lwt 77:449–459. https://doi.org/10.1016/j.lwt.2016.11.083

Cao R, Liu X, Guo J, Xu Y (2021) Comparison of various organic acids for xylo-oligosaccharide productions in terms of pKa values and combined severity. Biotechnol Biofuels 14:1–8. https://doi.org/10.1186/s13068-021-01919-9

Carneiro CVGC, de Silva FCP, Almeida JRM (2019) Xylitol production: identification and comparison of new producing yeasts. Microorganisms 7:1–15. https://doi.org/10.3390/microorganisms7110484

Chacon SJ, Matias G, Ferreira C et al (2020) Enabling butanol production from crude sugarcane bagasse hemicellulose hydrolysate by batch-feeding it into molasses fermentation. Ind Crop Prod 155:112837. https://doi.org/10.1016/j.indcrop.2020.112837

Chamnankid B, Ratanatawanate C, Faungnawakij K (2014) Conversion of xylose to levulinic acid over modified acid functions of alkaline-treated zeolite Y in hot-compressed water. Chem Eng J 258:341–347. https://doi.org/10.1016/j.cej.2014.07.036

Chapla D, Pandit P, Shah A (2012) Bioresource technology production of xylooligosaccharides from corncob xylan by fungal xylanase and their utilization by probiotics. Bioresour Technol 115:215–221. https://doi.org/10.1016/j.biortech.2011.10.083

Chen L, Sharifzadeh M, Mac Dowell N et al (2014) Inexpensive ionic liquids: [HSO4] based solvent production at bulk scale. Green Chem 16:3098–3106. https://doi.org/10.1039/c4gc00016a

Chen MH, Bowman MJ, Cotta MA et al (2016) Miscanthus × giganteus xylooligosaccharides: purification and fermentation. Carbohydr Polym 140:96–103. https://doi.org/10.1016/j.carbpol.2015.12.052

Chen X, Li H, Sun S et al (2018) Co-production of oligosaccharides and fermentable sugar from wheat straw by hydrothermal pretreatment combined with alkaline ethanol extraction. Ind Crops Prod 111:78–85. https://doi.org/10.1016/j.indcrop.2017.10.014

Chen Y, Yan Z, Liang L et al (2020) Comparative evaluation of organic acid pretreatment of eucalyptus for kraft dissolving pulp production. Materials (basel) 13. https://doi.org/10.3390/ma13020361

Chen Y, Xie Y, Ajuwon KM et al (2021) Xylo-Oligosaccharides, preparation and application to human and animal health: a review. Front Nutr 8:1–10. https://doi.org/10.3389/fnut.2021.731930

Cheng B, Zhang X, Lin Q et al (2018) A new approach to recycle oxalic acid during lignocellulose pretreatment for xylose production. Biotechnol Biofuels 11:1–9. https://doi.org/10.1186/s13068-018-1325-3

Cheudjeu A (2020) Since January 2020 Elsevier has created a COVID-19 resource centre with free information in English and Mandarin on the novel coronavirus COVID-19. The COVID-19 resource centre is hosted on Elsevier Connect, the company’s public news and information