Abstract

The composition of the cutting fluid wastewater is complex, the chromaticity is high, the liquid is grayish white, and the visibility is poor. In this research work, it used a multiphase Fenton system composed of catalysts CuO/CeO2 and H2O2 to treat the organic wastewater chromaticity, and various influencing factors were studied. The optimal conditions of the experiment would be: The dosage of the catalyst was 1.6 g/L, the dosage of H2O2 was 0.5 mol/L, the reaction time was 180 min, the initial pH was 8, and the reaction temperature was 25 °C. At this time, the removal efficiency of chromaticity could reach 70%.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

With the vigorous development of the mechanical processing industry, cutting fluids with cooling, cleaning, lubricating and anti-rust properties are more and more widely used in the field of metal processing [1, 2]. The replacement of old cutting fluid and its subsequent cleaning process will produce a certain amount of cutting fluid wastewater. It mainly contains base oil, synthetic lubricant, antioxidant, defoamer and other substances. It is generally in a highly emulsified state, with complex ingredients, and is a highly concentrated organic wastewater that is difficult to degrade [3].

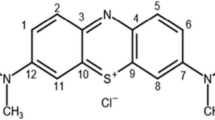

The multiphase Fenton method is a popular advanced oxidation method studied in recent years. The principle of this system is that organic pollutants react with hydroxyl radicals (·OH) and are oxidized into CO2, H2O and other inorganic salts [4]. The generation of hydroxyl radicals (·OH) comes from the catalyst in the reaction system. The catalysts of the heterogeneous Fenton reaction system are divided into solid-phase oxides or supported catalysts [5]. In the system, H2O2 is catalyzed on the surface of the catalyst to produce ·OH, which uses the extremely high oxidizing property of hydroxyl radicals to degrade organic pollutants in water [6]. The following is a schematic diagram of the Fenton reaction (Fig. 1).

The study found that the multiphase Fenton technology has the effect of removing the chromaticity of organic wastewater. Wang et al. [7] found that Fenton oxidation method can treat flax wastewater with a COD concentration of 1747 mg/L and a chromaticity of 200 times. The experimental results show that the COD removal efficiency is 57%, and the chromaticity removal efficiency reaches more than 90% after the reaction time is 1 h. Zhang et al. [8] synthesized the Cu/Al-silica black heterogeneous Fenton catalyst using silica as a carrier and constructed a heterogeneous Fenton catalytic oxidation system for laboratory high concentration organic wastewater treatment experiments. The results showed that when the reaction temperature was 25 °C, the pH of the reaction system was 5, the catalyst dosage was 6 g/L, and the hydrogen peroxide dosage was 55 mmol/L. After 120 min of reaction, the chromaticity removal efficiency was 80%. After five repetitions, the catalytic system still maintained an ideal treatment effect.

2 Methods

The steps of this experiment would be: first take 200 ml of experimental water into the beaker, add the catalyst, turn on the peristaltic pump and add H2O2 into the beaker at a uniform rate. After a period of time, use a pipette to suck the supernatant and measure and record the color value of the solution.

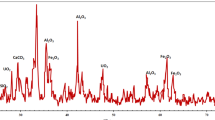

The catalyst used in the research work is a supported catalyst, and the catalyst CuO/CeO2 supported by CeO2 is prepared by the deposition precipitation method.

In this research work, the ET720 microcomputer platinum-cobalt chromaticity tester produced by Lovibond was used to determine the chromaticity of the water sample. By comparing with the blank water sample, the absorbance of the sample at a specific wavelength is converted into the concentration value of the parameter to be measured, and the value can be directly read on the liquid crystal display to obtain the water sample chromaticity. The inoLab pH 730 desktop precision pH meter produced by WTW in Germany was used to determine the pH value of the water sample. The instrument needs to be calibrated before use.

3 Results and Discussion

3.1 Effect of Reaction Time on Removal Efficiency of Chromaticity by Multiphase Fenton System

In this experiment, it studied the effects at six different reaction time instants of 60 min, 120 min, 180 min, 240 min, 300 min and 360 min on the chromaticity removal efficiency.

From Fig. 2, as the reaction time increases, the removal efficiency of chromaticity gradually increases first and then tends to be gentle. When the reaction time reached 180 min, the chromaticity removal efficiency reached 70%. This is because the catalyst CuO/CeO2 catalyzes the ·OH produced by H2O2 to rapidly oxidize and degrade organic pollutants. With the increase of time, more and more ·OH will be produced, resulting in an increase in the removal efficiency. However, the total amount of organic pollutants is limited. After 180 min, even if there is still ·OH, the chromaticity removal does not change and remains stable. So, 180 min would be the best reaction time.

3.2 Effect of Catalyst Dosage on Removal Efficiency of Chromaticity by Multiphase Fenton System

The catalyst dosage can affect not only the reactivity of the reactants, but also the mass transfer rate during the oxidative degradation process. Moreover, the catalyst CuO/CeO2 itself has a certain adsorption effect on the reactants and the removal substances [9]. Therefore, this experiment set seven different gradients of 0.4 g/L, 0.8 g/L, 1.2 g/L, 1.6 g/L, 2.0 g/L, 2.4 g/L and 2.8 g/L to investigate the effect of catalyst dosage on the degradation of chromaticity.

From Fig. 3, with the increase of the catalyst dosage, the chromaticity removal efficiency changes little, and the removal rate was the highest when the dosage was 1.6 g/L. However, the minimum and maximum are 68% and 70%, respectively, and the difference is only 2%. This may be because the minimum amount of catalyst added is much higher than the amount of catalyst required to remove chromaticity. Thus, 1.6 g/L was chosen as the best catalyst dosage.

3.3 Effect of H2O2 Dosage on Removal Efficiency of Chromaticity by Multiphase Fenton System

The dosage of H2O2 will directly affect the production rate and production of ·OH, which are the main functional groups of oxidative degradation [10]. In the experiment, it studied seven different H2O2 dosages of 0.1 mol/L, 0.2 mol/L, 0.3 mol/L, 0.4 mol/L, 0.5 mol/L, 0.6 mol/L and 0.7 mol/L on the degradation of chromaticity.

According to Fig. 4, as the dosage of H2O2 increases, the chromaticity removal efficiency increases first and then becomes gentle. The removal efficiency reached the maximum when the dosage of H2O2 was 0.5 mol/L, which could be about 70%. This is because, as the amount of H2O2 added increases, the amount of ·OH generated during the effective time will increase. At the same time, the adsorption of the catalyst CuO/CeO2 and H2O2 itself has strong oxidizing, which will also accelerate the oxidative degradation reaction, increasing in the removal efficiency of chromaticity. However, when the H2O2 dosage is greater than 0.5 mol/L, the ·OH content required to remove chromaticity is relatively small, resulting in the ineffective decomposition of H2O2 [11]. Therefore, the chromaticity removal efficiency does not change much after H2O2 excessive. The optimal H2O2 dosage used in this experiment was 0.5 mol/L.

3.4 Effect of Reaction Temperature on Removal Efficiency of Chromaticity by Multiphase Fenton System

During the chemical reaction, temperature is an important factor that affects the reaction rate [8]. In the experiment, it studied five different reaction temperatures of 25 °C, 35 °C, 45 °C, 55 °C and 65 °C on the degradation of chromaticity.

According to Fig. 5, initially, with the increase in temperature, the removal efficiency of chromaticity did not change much, the temperature increased again, and the removal efficiency decreased. This is because increasing the temperature will promote the reaction and facilitate the progress of the oxidative degradation reaction of ·OH. However, if the temperature is too high, the H2O2 in the solution will become unstable and decompose [12], resulting in a decrease in the ·OH content, so the removal efficiency of chromaticity decreases after the temperature is 35 °C. This experiment does not adjust the reaction temperature, and normal temperature is enough.

3.5 Effect of Initial pH on Removal Efficiency of Chromaticity by Multiphase Fenton System

The pH value of the Fenton reaction system is one of the important influencing factors. The pH value not only affects the existence form of copper ions in the solution but also affects the activity of the reaction catalyst [8]. In this experiment, it studied eight initial pH values and the effect of the initial pH value on the degradation of chromaticity.

From Fig. 6, the removal efficiency of chromaticity is significantly better under alkaline conditions than under acidic conditions. The removal efficiency is maintained at around 70% under alkaline conditions, and around 65% under acidic conditions. This is because the alkaline reaction can effectively avoid the side reaction of CuO under acidic conditions [13]. Even if part of the ·OH is wasted, the removal of chromaticity can also rely on the adsorption of the catalyst CuO/CeO2 to reduce. The effect of reduced ·OH content, which in turn shows a higher chromaticity removal efficiency under alkaline conditions. Since the pH was 7, the removal rate started to change. To ensure accuracy, the optimal pH was 8.

4 Conclusion

In this research work, the catalyst CuO/CeO2 and H2O2 constitutes a multiphase Fenton system to study the effect of experiments on the removal of chromaticity of cutting fluid wastewater. In addition, it studied the effects of reaction time, catalyst dosage, H2O2 dosage, reaction temperature and initial pH in the experiment and determined the best experimental conditions for the heterogeneous Fenton system. At that time, the chromaticity removal efficiency could reach 70%. Through research work, it is once again confirmed that the multiphase Fenton system has a certain effect on removing the chromaticity of organic wastewater.

References

Han, L.H., Zhang, X.L., Zhang, X.D.: Treatment of waste emulsified cutting fluid with inorganic and organic composite flocculants. J. Hebei Inst. Technol. (Natural Science Edition). 24(1), 115–119 (2002) (in Chinese)

Zhang, Q., Zhang, Z. W., Wang, X.: Research of application of ceramic membrane in waste metal cutting fluid treatment. Contemp. Chem. Ind. 47(4), 707–710 (2018) (in Chinese)

Zhou, N.L., Wang, Z.Q., Xu, X.D.: Study on treatment of metal working fluids wastewater by Fenton/UV. Environ. Sci. Technol. 22(6), 6–7 (2009) (in Chinese)

Liu, X.C., Zhou, Y.Y., Zhang, J.C.: Insight into electro-Fenton and photo-Fenton for the degradation of antibiotics: mechanism study and research gaps. Chem. Eng. J. 347, 379–397 (2018)

Liu, B.C., Gao, J.B., Cao, B.S.: Ultrasound-assisted Fenton oxidation degradation of oilfield fracturing flowback fluid. Oilfield Chem. 37(2), 358–361 (2020) (in Chinese)

Zhang, X.Y., Ding, Y.B., Tang, H.Q.: Degradation of bisphenol A by hydrogen peroxide activated with CuFeO2 microparticles as a heterogeneous Fenton-like catalyst: efficiency, stability and mechanism. Chem. Eng. J. 236, 251–262 (2014)

Wang, L., Du, M.A., Li, X.: Advanced treatment of wastewater from flax production by Fenton-oxidation process. Ind. Water Wastewater 39(1), 52–54 (2008) (in Chinese)

Zhang, J., Ding, M.H., Pan, K.: Experiment on high concentration organic wastewater in multiphase Fenton catalytic oxidation laboratory. Res. Explor. Lab. 38(12), 57–60 (2019) (in Chinese)

Lin, K., Zhou, M., Zhou, H.J., Zhang, F., Zhong, Z.X., Xing, W.H.: Controlled synthesis of Cu2O microcrystals in membrane dispersion reactor and comparative activity in heterogeneous Fenton application. Powder Technol. 36(2), 847–854 (2019)

Zhang, J., Wang, Z.B., Zhu, Y.P., Ji, Z.M.: Fenton reagent-microelectrolysis pretreatment test of nitrobenzene wastewater. J. Yangzhou Univ. (Natural Science Edition) 9(2), 74–78 (2006) (in Chinese)

Wu, C., Zhu, J.J., Cui, Z.W.: Synergetic degradation of phenol waste water by microwave-assisted Fenton reagent. Chem. World 59(6), 334–340 (2018) (in Chinese)

Zhou, L.Y., Guo, W.: CuO-H2O2 heterogeneous catalytic oxidation of dye wastewater. Ind. Water Treat. 33(06), 61–64 (2013) (in Chinese)

Yang, W.L., Gang, Z.X., Wu, J.: Advanced treatment of secondary biochemical effluent by CuO-Fe2O3/γ-Al2O3/ H2O2/O3. Chem. Ind. Eng. Prog. 37(06), 2399–2405 (2018) (in Chinese)

Acknowledgements

This project was supported by the National Natural Science Foundation of China (51778374). The authors thank the anonymous reviewers for their valuable comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Wu, N. et al. (2021). Study on the Treatment of Cutting Fluid Wastewater Chromaticity by Multiphase Fenton System. In: Li, Y., Zhu, Q., Qiao, F., Fan, Z., Chen, Y. (eds) Advances in Simulation and Process Modelling. ISSPM 2020. Advances in Intelligent Systems and Computing, vol 1305. Springer, Singapore. https://doi.org/10.1007/978-981-33-4575-1_31

Download citation

DOI: https://doi.org/10.1007/978-981-33-4575-1_31

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-4574-4

Online ISBN: 978-981-33-4575-1

eBook Packages: EngineeringEngineering (R0)