Abstract

Nowadays, the intermediate of digital fabrication technology is also referred to as 3D printing or assembling production, the continuous addition of all these elements to create physical objects from geometric representations. Fused deposition modeling (FDM) 3D printers work by adding one layer after another through FDM filaments. Some commonly used FDM filaments are polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), polyethylene terephthalate (PET), polyethylene terephthalate glycol (PETG), thermoplastic polyurethane (TPU), polycarbonate (PC), nylon, acrylonitrile styrene acrylate (ASA), and polyetherimide (PEI). Also, FDM filament allows the adjustment of several process parameters which are strength, temperature resistance, visual quality, impact strength, wear and chemical resistance, flexible, etc. Thus, confusion arises for the selection of the best filament to create any desired object. So, to get rid of this confusion need to know some immediate decision-making techniques. Analytical network process (ANP) and multi-objective optimization by ratio analysis (MOORA) are one of the most important immediate decision-making techniques. These two methods provide a basis for decision-making processes, where there are many criteria, along with a number of options. In this study, the selected five criteria are density (g/cm3), printing temperature (0C), tensile strength (MPa), elongation at break (%), and flexural strength (MPa). Also, the selected six alternatives are polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), polyethylene terephthalate glycol (PETG), nylon, acrylonitrile styrene acrylate (ASA), and polycarbonate (PC) for the best filament. Design/Procedure/Method: Multi-objective optimization by ratio analysis (MOORA) and analytical network process (ANP) have been used to fulfill the purpose of this work. In this method, ANP is used because a variety of criteria and alternatives are used to select a good FDM 3D printer filament that follows the MOORA method. Originality/Value: This work is done to select a good FDM 3D printer filament. The systematic way of choosing a good FDM 3D printer filament helps the manufacturer to implement printing quality.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

A three-dimensional (3D) printer is now an advanced technology among several technologies. In the field of production, 3D printing is commonly known as additive manufacturing (AM) which is used to create three-dimensional layers by layers from 3D models to rapid prototyping (RP), and it is a different method to a subtractive manufacturing process that includes cutting of three-dimensional objects layer by layer. Nowadays, the manufacturing industry is growing rapidly, and more varieties of FDM 3D printers and filament are available in the market. For this reason, the manufacturer cannot choose the desired quality filament for the right FDM 3D printer within a short time period. The multi-criteria decision analysis process is the only solution to find the best alternative within different product criteria. MCDA is a benchmark-based decision-making analytical process that is classified as an important research infrastructure.

The rapid prototyping process is a developing region in the manufacturing sector to produce products rapidly, accurately. The demand for customization in the global market has multiplied because nowadays the volume production is less than the quantity expected to provide innovative designs to the industry [1, 2], and engineering has become a powerful tool in the field of 3D printing prototyping. According to a report published by Allied Marketing Research, 3D printing is one of the fastest-growing processes in the world today [3]. According to another report published by Gartner [4], the global rate of 3D printers has increased by 75% by 2014 and will double every year. Hideo Kodama of the Noyoga Municipal Industrial Research Institute is mostly believed to have printed the first solid objects from CAD design [5]. The technology has evolved since 1984 when Charles W. Hull of 3D Systems Corporation first conceived and realized 3D printers, and these processes have become more usable, as they have become less cost-effective and more affordable [6].

In today's competitive industrial situation, it is important to build a consistent and long-term relationship between customers and manufacturers. For this reason, multiple-criteria decision-making (MCDM) supports decision-makers with a wide range of solutions to complex problems with multiple and consistent criteria. MCDM is usually a decision based on the presence of multiple and contradictory criteria. It may have different units of measurement in different scales, quality properties, and relative weight [7]. It is possible that some criteria can be measured numerically and other criteria can only be described thematically. Multi-criterion decision-making (MCDM) or multi-criterion decision analysis (MCDA) is usually a sub-discipline of operational research that evaluates different types of criteria for explicit decision-making. When the stakes are high, it is important to create the problem correctly and clearly evaluate several criteria [8].

In this research work, we are choosing analytical network process and multi-objective optimization by ratio analysis procedures for selecting FDM 3D printer filament in the market. A large number of scholars have chosen the ANP–MOORA method for solving simple or complex problems in different areas and have generally used the ANP–MOORA method for solving a variety of problems [9, 10].

2 Methodology

2.1 Overview of MCDA/MCDM

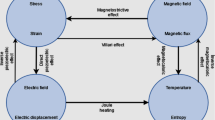

Multi-criterion decision-making (MCDM) or multi-criterion decision analysis (MCDA) is usually a sub-discipline of operational research that evaluates different types of criteria for explicit decision-making in both everyday use and business settings, such as medicine and car. MCDM uses a variety of methods in the literature, such as analytic hierarchy process, analytic network process, inner product of vectors, best worst method, choosing by advantages, evaluation based on distance from average solution, dominance-based rough set approach, evidential reasoning approach, goal programming, gray relational analysis, simple multi-attribute rating technique, multi-attribute global inference of quality, multi-objective optimization by ratio analysis, non-structural fuzzy decision support system, stochastic multi-criteria acceptability analysis, and technique for the order of prioritization by similarity to ideal solution. Although the literature mentions a variety of MCDM strategies that can be used to help decision-makers make better judgments, in all of these methods, the ranking of options is determined by the weight of the criteria. However, some of these methods are very complex to understand and apply because they require a great deal of mathematical knowledge. All the steps of the ANP–MOORA method are given below. Figure 1 provides an overview of the MCDA workflow.

2.2 Overview of ANP Method

Many decision-making problems cannot be solved immediately because they involve the dependence of the higher-level elements of a sequence on the lower-level elements. In this case, the ANP allows for a complex interrelationship between the decision and the features. The ANP system consists of four basic steps. Figure 2 exhibits the stepwise procedure for performing the ANP method.

2.3 Overview of MOORA Method

Multi-objective optimization or programming, also known as multi-criteria or multi-attribute optimization, is the process of optimizing two or more conflicting objectives simultaneously, subject to certain limiting features. The MOORA method was first introduced in 2009 by Brauers and Zavadskas as a multi-purpose optimization strategy to solve a variety of complex problems in the production environment. The MOORA method begins with a decision matrix that succeeds in showing different types of performance depending on different characteristics:

Step 1: The first step in the MOORA approach is to create a problem-solving matrix. The criteria and alternatives are listed in columns and rows of the decision matrix, respectively. The decision matrix shows the work of different alternatives subject to different criteria.

Here, xij is the performance value of ith number of alternatives on jth number of criteria, and m and n are the numbers of alternatives and criteria, correspondingly.

Step 2: The performance of an alternative to a standard is calculated against the performance of other alternatives to that standard:

where \(x_{ij}^{*}\) is a dimensionless number between [0, 1] and the normalized performance of ith number of alternatives on jth number of criteria.

Step 3: For multi-objective optimization, these normalized performances are added in the case of beneficial attributes and subtracted in the case of non-beneficial attributes. Then, the optimization problem is

Step 4: The Yi value can be positive or negative dependent on the totals of its beneficial attributes and non-beneficial attributes in the decision matrix. A general ranking of Yi shows the final choice. Thus, the best option has the highest Yi value, while the worst option has the lowest Yi value. Figure 3 shows that the block diagram of the MOORA method.

3 Result and Discussion

Figure 4 shows the first level of the hierarchy for the choice of a good FDM 3D printer filament. The second level of the hierarchy is formed by the criteria used for the purchase. In this research work, the selecting five criteria are density (g/cm3), printing temperature (0C), elongation at break (%), tensile strength (MPa), and flexural strength (MPa) for choosing a good FDM 3D printer filament. The third level is made up of the necessary options among the various filaments available in the market. In this research work, selecting six alternatives are shown in Table 1.

Criteria required for the process of multi-objective optimization based on the ratio analysis that influences their calculation options. Selective different types of alternatives and their various criteria can be seen in Table 2 and Fig. 5 shows that selected different alternatives and their various criteria data chart in this research work.

3.1 Calculation of ANP Method

The first step in AHP analysis is to create a hierarchy for decision-making. It is also called decision modeling and is used only to create a hierarchy to analyze the choice.

Step 1: Model construction and problem constructing: This is called intensity judgment or simply judgment in each of the comparative pairs to reflect the relative preference. It is considered that C1 is more strongly important than C2; C1-C2 comparison cell (i.e., the intersection of row ‘C2’ and column ‘C1’). Mathematically, this means that the ratio of the importance of C1 to the importance of C2 is two.

For this reason, inverse comparisons, the importance of C1 with the importance of C1, the comparison of Table 3, as shown in cell C1-C2 in the matrix, gives the result of the relative value of 1/2 of this value. The approximation method requires normalization of the comparison matrix; that is, values must be added to each column shown in Table 4.

Step 2: Pairwise comparisons and priority vectors: But, keep in mind that this method offers a valid estimate of the overall weight only when very few variations in the comparison matrix are observed. Then divide each cell by the total of the columns shown in Table 5. From this normal matrix, only the average value of each row has to be calculated as shown in Table 6.

Step 3: Supermatrix creation: The concept of the supermatrix is similar to the Markov chain process. To get a global priority in a system with interdependent effects, the priority vectors are inserted into the appropriate column of a matrix shown in Table 7. The result is a supermatrix commonly known as a split matrix, where each matrix segment represents the relationship of two clusters in a system. The supermatrix is a fragment-based on factors and sub-factors. The corresponding results are shown in Table 8. Weighted supermatrix drives a supermatrix multiplied by the collection weight.

3.2 Result and Discussion of ANP Method

In this research work, ANP method is used to get the average value of supermatrix and put this value for plotting graph between supermatrix and criteria as publicized in Fig. 6. The bar graph illustrations that C4 is preferable then C1, C2, C3, and C5, so C5 is the most important criteria in this research work.

From the Fig. 7, it is clearly shown that the final result. From the result, A2 is ranked as best and appropriate alternative which has extremely good % of elongation at break (C4) then A1, A3, A4, A5, and A6.

3.3 Calculation of MOORA Method

Multi-objective optimization through ratio analysis is the most imperative selection technique strategy for this problem. In this research work, MOORA method is used to compare the ANP method and verify the result of the ANP method. Table 9 shows that selected different alternatives and their various criteria in this research work.

Step 1: The strategy of the decision matrix: The first and foremost step in the TOPSIS algorithm is to create a decision matrix that determines the weight of a criterion. In this case, relative weights are determined quantitatively and qualitatively not only on the basis of each criterion but also on their importance. Since defining the weight of a criterion is a main step in the decision-making process, in this case, a high degree of accuracy is important for defining the weight for each criterion and value.

Step 2: Normalized decision matrix: The normalized value is determined by the normalized decision matrix, which represents the relative performance of the alternatives created. Typically, MCDM problems have both a benefit attribute and a cost feature. From equation-1, calculating the value Xij is shown in Tables 10 and 11 shows the construct normalized decision matrix in this research work.

Step 3: All selection criteria may or may not be of equal importance, and so the introduction of weights from the MOORA strategy has been suggested to measure the relative importance of different selection criteria. The weight determination decision matrix is made by multiplying the table of each element in each column of the generalized decision matrix by the random weights shown in Tables 12, and 13 shows the weighted normal decision matrix of this research work (Table 14).

Step 4: Estimation of assessment values (Yi): The Yi value can be positive or negative depending on the sum of its beneficial properties and non-beneficial properties in the decision matrix.

A general ranking of Yi is shown in the final. Thus, the highest Yi value of the best option is determined, while the lowest Yi value is shown in Table 11.

3.4 Result and Discussion of MOORA Method

In this research work, MOORA method is used to get the relative closeness value and put this value is plotting between % of elongation at break versus alternatives shown in Fig. 8. From the Fig. 8, it is shown that % of elongation at break is the major and best criteria and plotting the graph between % of elongation at break versus criteria. From this graph, it is shown that the result that A2 is ranked as best and appropriate alternative which has extremely good % of elongation at break than A1, A3, A4, A5, and A6.

3.5 Comparison of ANP and MOORA Results

In this research work, applying ANP and MOORA technique for selecting an FDM 3D printer filament with a high % of elongation at break. Table 15 shows the comparison between ANP and MOORA methods. From this table, it is shown that the result that A2 is ranked as best and appropriate alternative which has extremely good % of elongation at break than A1, A3, A4, A5, and A6.

4 Conclusions

This research work provides a multi-criteria decision analysis and solves a selection problem of different models of a car based on the ANP and MOORA methods. As the number of options and their selection criteria increases, so does the complexity of choosing them. To solve this problem, ANP–MOORA methods are chosen to solve supply chain problems so that the best option can be selected from a variety of options. It is therefore believed that the use of the MCDM method is unparalleled in the decision-making of an ANP-based structure and in the development and selection of the best supply chain. The problems and sub-issues mentioned in this study will help decision-makers to analyze them by visualizing the impact on different types of supply chains. There may be some inconsistencies in the ranking of options due to the different opinions of the decision-makers so the weight of the issues may vary depending on the method used and the dependence or interdependence of the issues. The results obtained from this study will help to select an FDM 3D printer filament with high % elongation during the break. The application of the ANP–MOORA approach to an extensive variety of problems in the choice of dissimilar types of supply chains will guide upcoming research work.

From the calculations, it is proved that acrylonitrile butadiene styrene (ABS) is ranked as best and appropriate alternative which has extremely good % of elongation at break than polylactic acid, nylon, polyethylene terephthalate glycol, acrylonitrile styrene acrylate, and polycarbonate. Thus, it is clear that existing research work on multi-criteria decision analysis is the only solution to find the best option within different product criteria. And the ANP and MOORA method are a very much efficient technique for alternative selection under multiple criteria.

References

Wang, X., Jiang, M., Zhou, Z., Gou, J., Hui, D.: 3d printing of polymer matrix composites: a review and prospective. Compos. B Eng. 110, 442–458 (2017)

Zeltmann, S.E., Gupta, N., Tsoutsos, N.G., Maniatakos, M., Rajendran, J., Karri, R.: Manufacturing and security challenges in 3d printing. Jom 68(7), 1872–1881 (2016)

Person, L.: Global 3d printing market (2019). https://www.alliedmarketresearch.com/3d-printing-market. Feb (2019)

Umair, M., Kim, W.S.: An online 3d printing portal for general and medical fields. In: 2015 International conference on computational intelligence and communication networks (CICN). 2015, pp. 278–282. IEEE (2009)

Agarwal, G., Vijayvargy, L.: An application of supplier selection in supply chain for modeling of intangibles: a case study of multinational food coffee industry. Afr. J. Bus. Manage. 5(28), 11505–11520 (2011)

Brauers, W.K.M., Zavadskas, E.K.: Robustness of the multi-objective MOORA method with a test for the facilities sector, technological and economic development of economy. Baltic J. Sustain. 15(2), 352–375 (2009)

Brauers, W.K.M., Zavadskas, E.K., Peldschus, F., Turskis, Z.: Multi‐objective decision‐making for road design. Transport 23(3), 183–193 (2008)

Buyukozkan, G.: An integrated fuzzy multi-criteria group decision-making approach for green supplier evaluation. Int. J. Prod. Res. 50(4), 2892–2909 (2012)

Chung, S., Lee, A.H.I., Pearn, W.L.: Analytic network process (ANP) approach for product mix planning in semiconductor fabricator. Int. J. Prod. Econ. 96(1), 15–36 (2005)

Deng, X.Y., Hu, Y., Deng, Y., Mahadevan, S.: Supplier selection using AHP methodology extended by D numbers. Expert Syst. Appl. 41(1), 156–167 (2014)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Maity, M., Mondal, J.K., Das, S., Das, S. (2023). ANP–MOORA-Based Approach for Selection of FDM 3D Printer Filament. In: Ramesh Babu, N., Kumar, S., Thyla, P.R., Sripriyan, K. (eds) Advances in Additive Manufacturing and Metal Joining. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-7612-4_3

Download citation

DOI: https://doi.org/10.1007/978-981-19-7612-4_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-7611-7

Online ISBN: 978-981-19-7612-4

eBook Packages: EngineeringEngineering (R0)