Abstract

This study aims to present a multidisciplinary design optimisation (MDO) algorithm for the automatic sizing and design of an unmanned lighter-than-air (LTA) platform, given its mission requirements. The mission in question consists of territorial mapping, made possible through the implementation of several remote sensing on-board systems. Once assigned the parameters of the mission as inputs, the algorithm, through a process of iterations, returns the optimal sizing of the airship, shows the distribution of all the systems’ masses, and chooses the preferable energy system between the two considered (fuel cells or batteries). Moreover, a sensitivity analysis on the main variables allows to examine how the variation of each of the parameters of the mission affects the distribution of the masses in the airship, and therefore, how the optimal design and sizing change. Finally, further studies on the energy systems are presented, to verify the convenience of one option above the other one as a function of the distance from the mission location and the survey area.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Multidisciplinary design optimization

- Lighter-than-air platforms

- Unmanned aerial vehicles

- Remotely piloted aerial systems

- Remote sensing

- Earth observation

- Land use land cover

1 Introduction

This study presents a multidisciplinary design optimisation (MDO) algorithm, conceptualised and developed for the automatic design and sizing of an unmanned lighter-than-air platform (LTA).

The MDO method was chosen to solve the design of the airship since the nature of the problem is based on the integration of several systems and the need to think of an optimisation for the sizing of the entire airship, considering each of the systems and their relations.

This unmanned aerial system (UAS), presented in [1] and further detailed in [2] and [3], is intended for remote sensing at relatively low altitudes, aiming at detailed land use and land cover (LULC) mapping at urban or rural level (i.e. for areas between 105 and 107 m2). The proposed MDO approach is intended to automatically return the best design and sizing according to the intended mission requirements, simplifying the design process. Overall, the proposed algorithm shows the capability to automatically size the structure for the conditions of interest, as well as to return the preferable energy system, choosing between two options (fuel cells or batteries).

Further studies are developed as a sensitivity analysis, to test the possibility to use the algorithm for new missions, with new parameters; to do so, the analysis is focused on the response of each subsystem of the platform (in terms of weight) to the variation of a certain parameter.

1.1 Problem Definition and Formulation

LTA platforms can serve a well-defined niche for earth observation and remote sensing. Specifically, they can be deployed at a lower cost than other heavier-than-air fixed- or rotating-wing alternatives to cover small to large areas (Figs. 1 and 2). More specifically, an unmanned remotely piloted LTA can satisfy different applications for LULC mapping and environmental surveillance. The specific unconventional LTA discussed here (Fig. 3) further integrates all these advantages with an innovative propulsion and control system, without aerodynamic control surfaces, a thrust vectoring technology [4, 5] with a dedicated control law [6], and an axi-symmetric, ellipsoidal envelope. These advantages are graphically summarised in Fig. 4.

Source Retrieved from [1]

Comparison of remote sensing platforms.

Source Retrieved from [1]

Qualitative estimates of costs per surveyed square kilometre.

Source Retrieved from [1]

3D rendering of the LTA platform intended for this study, with an illustration of the propulsion system.

Source Retrieved from [1]

Advantages and limitations of comparable land survey strategies.

This specific design derives from previous studies, performed throughout the last twenty years [7,8,9,10] and that led to the proposal described in [1]. From a structural perspective, it is a single-rib design, with the six propellers and the payload gondola directly attached to this sole load-carrying element.

Thus, this proposed LTA platform is intended to carry a relatively large array of sensors as its payload. This is reported in detail in Table 1.

However, even having the payload and the control and propulsion system defined, both the project and the sizing of the remaining components are not trivial. For instance, there is no a priori optimal choice for the power system; both fuel cells or batteries could be potentially preferable, depending on the mission requirements (in particular, the survey area and the distance from the mission location). In turn, the selection of one specific option affects the total mass of the system, hence the final size (length and diameter) of the airship.

All these parameters depend on the mission requirements, as the LTA platform is supposed to:

-

Depart from a suitable take-off location;

-

Fly to the target survey area at a given cruise speed and altitude;

-

Perform the survey (with a survey speed and altitude defined by the sensing devices’ limitations);

-

Fly back to the starting location.

One can see that the problem can only be solved iteratively, incorporating different assumptions and finding the optimal trade-off among different sizes and different power supply strategies.

For this reason, an optimisation code was specifically realised in MATLAB to automatise the design process. This follows the main principles of multidisciplinary design optimisation [11].

2 Methodology

In general, MDO is a method to solve design problems that include different disciplines, by optimising simultaneously the entire system, not every discipline separately; it is therefore essential to analyse and use the relations and interactions between the subsystems in order to get an overall understanding of the problem.

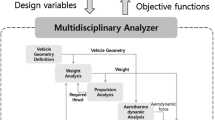

The main steps to develop a MDO algorithm are: (1) the selection of the design variables and their constraints (in this case, some mission parameters and the respective ranges of interest), (2) the selection of the objective to minimise or maximise (in the design of an airship, this is represented by the weight or volume which should be minimised), and (3) a model to link these objects.

Several MDO strategies are already available from the published scientific literature (see e.g. [16]). However, almost all of these algorithms and concepts are intended for heavier-than-air platforms, which have different needs and limitations than the ones of interest here.

Thus, a novel strategy, not based on any existing alternatives, is developed. The code consists of an iterative procedure varying four main parameters:

-

1.

The total length of the LTA platform L;

-

2.

The cruise speed (from the take-off point to the target survey area) v;

-

3.

The cruise altitude (from the take-off point to the target survey area) z;

-

4.

The slenderness ratio of the envelope d/L.

These are varied in pre-set intervals of interest. For each iteration, a logical process is followed that leads to the selection of only those solutions that meet the mission requirements and sustenance of the airship; finally, among these, the combination of parameters that guarantees the lowest weight is saved and stored.

The script, therefore, allows obtaining the size and weight of the airship as an output, especially considering how the masses are distributed (in percentage) among the several components (payload, load-bearing structure, power system, etc.).

The code is intended to adapt for the specific mission requirements, as described before, receiving the following inputs:

-

1.

Survey speed, in m/s;

-

2.

Survey altitude, in m;

-

3.

Payload, in kg (considering the one reported in Table 1, a subset of it, or another selection of remote sensing devices);

-

4.

Survey area, in m2.

The strategy followed is one of concurrent subspace optimisations [17]. That is to say, three subsystems—the power system, the propulsion system, and the load-bearing structure— are concurrently optimised. This is necessary since these subsystems are coupled with one another.

All the components of the energy and propulsive systems are computed for both the cruise and the survey phases, in terms of mass and associated power. Eventually, the higher weight solution is saved; this step is summarised in Fig. 5 under the label ‘on-board system’, and displayed at the side of the complete diagram.

Each solution, if feasible, is saved. At the end of the process (i.e. after all the four main parameters have been tested on their respective ranges, considering all the potential combinations), the feasible solutions are searched for the optimal trade-off. The complete algorithm is graphically depicted in Fig. 5.

3 Results

3.1 Variation of Payload and Associated Power

Several combinations of sensors have been evaluated, with and without the laser scanning and/or the hyperspectral camera. The removal of these sensors, which contribute the most to the estimation of the payload and the related power, has a direct influence on the total mass of the airship, affecting also the energy system; however, it does not involve relevant changes in the optimal configuration of the platform, and it still ensures the advantage of the fuel cells system above the use of batteries.

3.2 Energy Systems

A comparison between the two proposed energy systems has been developed, to establish which solution is more convenient, in terms of weight, as a function of the distance from the mission location; this analysis has been repeated for different values of the survey area (105–106–107 m2).

The outcomes of this specific study show that in case of low autonomies (i.e. for a survey area of 105 m2), the battery configuration proves to be more convenient below a certain distance from the mission location. The results are displayed in Figs. 6 and 7 as graphs that illustrate the relationship between the distance and the respective weight of the two energy systems.

Furthermore, a methodic sensitivity analysis is performed accordingly to the mission requirements—considering a cruise altitude varying between 500 and 1000 m, a cruise speed between 10 and 30 m/s, a survey area between 105 m2 and 107 m2, and a length of the airship fixed between 30 and 50 m.

Out of all the feasible solutions, the fuel cell solution prevailed over the battery option for all the possible mission requirements except that for very small areas and very short cruise distances (i.e. when the required autonomy was minimal), showing a result that proves to be consistent with the outcomes of the original algorithm for the design of the airship. It was found that the cruise altitude affects the overall mass especially due to the weight increase of the ballonets. The cruise speed has an impact on flight time and the power needed when cruising: higher speeds require more energy, thus heavier solutions, which must provide more power to overcome the increased drag. Nevertheless, at least one feasible solution was found for any specific set of mission requirements. Indeed, under all conditions, the automatic MDO algorithm returned designs that were deemed acceptable from an expert user.

4 Discussion and Conclusions

The topic of multidisciplinary design optimisation is of great interest in the field of aerospace design, yet not much addressed for the specific case of LTA platforms, let alone for RPAS medium- to large-size airships. The proposed algorithm allows sizing and designing an unmanned, remotely piloted, low-altitude LTA in a parallel and automated fashion, accordingly to the mission requirements. This automation can return the optimal LTA parameters almost immediately. This is a noteworthy improvement with respect to the long time required by human-made, sequential, trial-and-error-based traditional design procedures. For this specific aim, the goal (at both system and subsystem level) was to find the feasible design which satisfies all the constraints for the minimum total mass and given survey conditions. These constraints were mainly weight and power balance, that is to say, to guarantee buoyancy and self-propelling capabilities at any time throughout the whole duration of the mission. However, this can be further modified if needed, making the algorithm even more versatile and applicable for similar tasks, not limited to LULC survey.

References

Gili P, Civera M, Roy R, Surace C (2021) An unmanned lighter-than-air platform for large scale land monitoring. Remote Sens 13:2523

Gili P, Civera M, Roy R, Cibrario Bertolotti S, Cosenza D, Gili A, Surace C (2021) Design of a prototype unmanned lighter-than-air platform for remote sensing: control, alimentation, and propulsion systems. In: Proceedings of the 32nd Congress of the International Council of the Aeronautical Sciences (ICAS 2021), Shanghai

Surace C, Roy R, Civera M, Allaio D, Barbieri R, Grava A, Tufilli R, Gili P (2021) Design of a prototype unmanned lighter-than-air platform for remote sensing: structural design and optimization. In: Proceedings of the 32nd Congress of the International Council of the Aeronautical Sciences (ICAS 2021), Shanghai

Gili P, Lerro A, Vazzola M, Visone M (2011) A new approach for the estimation of the aerodynamic damping characteristics of the ETF demonstrator. SAE Int J Aerosp 4:1115–1124

Battipede M, Lando M, Battipede M, Lando M, Gili PA (2004) Peculiar performance of a new lighter-than-air platform for monitoring

Battipede M, Lando M, Gili P (2006) Mathematical modelling of an innovative unmanned airship for its control law design. In: Proceedings of the IFIP International Federation for Information Processing. Springer, Boston, MA, Vol 202, pp 31–42

Battipede M, Gili P, Maggiore P, Lando M (2006) Risk assessment and failure analysis for an innovative remotely-piloted airship. In: Proceedings of the Collection of Technical Papers - 6th AIAA Aviation Technology, Integration, and Operations Conference, Vol 1, pp 119–129

Cappadona A, Lecca R, Vazzola M, Gili P, Farina P, Surace C (2009) Innovative unmanned airship structural analysis: Dual-hull and exoskeletal configurations. J Phys: Conf Series Institute of Physics Publishing 181:12097

Battipede M, Gili P, Lando M (2005) Ground station and flight simulator for a remotely-piloted non conventional airship. In Proceedings of the Collection of Technical Papers—AIAA Guidance, Navigation, and Control Conference 5:3660–3671

Battipede M, Gili P, Vazzola M (2013) Structural and aerodynamics analysis on different architectures for the elettra twin flyer prototype. J Intell Robot Syst Theory Appl 72:123–144

Sobieszczanski-Sobieski J (1993) Multidisciplinary design optimization: An emerging new engineering discipline

iXM-RS150F technical data sheet. https://downloads.phaseone.com/7e71b0a2-f42d-42c7-896b-2c16968f79c3/English/iXM-RS_Brochure_letter.pdf. Last accessed 8th march 2021

Thermo Tracer TH9260 technical data sheet. https://www.infrared.avio.co.jp/en/products/ir-thermo/lineup/th9260/index.html. Last Accessed 8th March 2021

AISA DUAL hyperspectral sensor technical data sheet. http://www.adept.net.au/cameras/specim/systems/pdf/Aisa_Dual.pdf. Last accessed 8th March 2021

ALTM Galaxy T1000 Airborne Lidar Terrain Mapper technical data sheet. https://geo3d.hr/sites/default/files/2018-06/2017-11-02_Optech_Galaxy-Brochure_HR.pdf. Last accessed 8th March 2021. Available online: www.teledyneoptech.com. Accessed on 8th March 2021

Martins JRRA, Lambe AB (2013) Multidisciplinary design optimization: a survey of architectures 51:2049–2075. https://doi.org/10.2514/1.J051895

Liang H, Zhu M, Guo X, Zheng Z (2012) Conceptual design optimization of high altitude airship in concurrent subspace optimization. 50th AIAA Aerosp Sci Meet Incl New Horizons Forum Aerosp Expo, 1–17

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Gili, P., Castronovo, L., Civera, M., Roy, R., Surace, C. (2023). A Multidisciplinary Design Optimisation (MDO) Algorithm for the Automatic Sizing of an Unmanned Lighter-Than-Air Platform. In: Shukla, D. (eds) Lighter Than Air Systems . Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-6049-9_10

Download citation

DOI: https://doi.org/10.1007/978-981-19-6049-9_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-6048-2

Online ISBN: 978-981-19-6049-9

eBook Packages: EngineeringEngineering (R0)