Abstract

Oleaginous microorganisms accumulating more than 20% of their dry weight biomass as lipids are used for the production of microbial lipid, also called as single cell oil (SCO). SCO from oleaginous yeasts with a fatty acid profile comparable to that of vegetable oil can be a potential feedstock for biodiesel production. Biodiesel is a renewable biofuel, alternative to petroleum fuels. Due to increasing energy demand and depletion of existing fossil fuel reserves, intensive research has been focused on sustainable biodiesel production. Oleaginous yeasts are more advantageous compared to other oleaginous microorganisms because of their fast duplication rate, shorter life cycle, easier to scale up, and amenability to genetic modifications. Production of microbial lipid with oleaginous yeasts from nonedible and abundant lignocellulosic biomass has been viewed as a novel potential technology to fulfill the increasing energy demand. But lignocellulosic biomass being recalcitrant requires pretreatment step and hydrolysis for the conversion of complex polymers into their respective monomers like glucose that can be assimilated into lipids by oleaginous yeasts. These pretreatment methods also generate various degradation products that inhibit enzyme hydrolysis and subsequent fermentation. Understanding the mechanism of lipid accumulation, improvement of strains for high lipid yield from lignocellulosic hydrolysate is necessary for sustainable biodiesel production. In this chapter, we discuss the importance of lignocellulosic biomass as a raw material for sustainable single cell oil production from oleaginous yeasts.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

13.1 Introduction

The growing energy demand accompanied with limited reserves of fossil fuels and global environmental degradation associated with the use of fossil fuels propelled the worldwide attention in alternative clean and renewable energy sources. In this respect, biofuels produced from renewable resources are of utmost importance as these are produced directly or indirectly from organic material including plant and animal wastes. Thus, biofuels can serve as a feasible alternate to fossil fuels for easing the world energy crisis and also for mitigating the greenhouse gases emission. The two most common types of biofuels are biodiesel and bioethanol. Biodiesel is a type of biofuel made from methyl esters of fatty acids that are derived from renewable resources. Burning of biodiesel results in lesser emission of carbon monoxide, hydrocarbons, sulfate oxides, and further toxic compounds than that after burning fossil fuels (Lotero et al. 2006).

Vegetable oils like soybean oil, palm oil, and rapeseed oil are used mainly as the triglycerides feedstocks for biodiesel production. Such biodiesel made from vegetable oils as prominent feedstock is termed as first-generation biodiesel. However, due to competition in the food chain leading to the “food vs fuel” controversy, there is a necessity to look for other non-edible eco-friendly renewable oil sources. This has given rise to second-generation biodiesel that is derived from non-edible oil resources like jatropha, jojoba, animal fats, and grease as well as waste oils from cooking. But these non-edible oils are not available in abundance to meet the global needs for biofuel generation. Further, biodiesel from animal fats do not perform well in cold weather. Moreover, using vegetable oils and animal fats as substrate covers 70–85% of the total cost of production and thus unsuitable to substitute the fossil fuels. Microbial sources can be used for biolipid production throughout the year, unlike plants. The above-mentioned limitations in first- and second-generation biodiesel has led to the growth of third-generation biodiesel from microbial resources (oleaginous microbes); the so-called single cell oil (SCO) seems to be an attractive substitute for the plant, animal, and crude oil feedstock for biodiesel. The term single cell oil is used analogously to single cell protein to represent oils of microbial origin. The composition of microbial oil closely resembles that of vegetable oils (Li et al. 2008) and thus makes it appropriate as biodiesel feedstock (Karatay and Dönmez 2010). Oleaginous microorganisms are those species that accumulate more than 20% of their biomass as lipids. These classes of microorganisms include bacteria, algae, fungi, and yeasts that utilize an organic carbon source to synthesize lipids in their intracellular compartment. Oleaginous microorganisms have better productivity than oil-producing crops, with higher lipid yield, lack of any seasonal and climatic changes, less labor intensive, easier to scale up, and amenable to genetic modification.

The use of synthetic media makes the microbial oil economically uncompetitive; therefore, the use of low-cost carbon substrates for microbial lipid synthesis will be of great significance. Among the various low-cost substrates, non-edible biomass like lignocellulosic biomass seems to be a suitable option because of its availability and low cost. Lignocellulose is a recalcitrant biopolymer and is composed of several classes of polymers including cellulose, hemicellulose, pectin, and lignin. The recalcitrance of lignocellulosic biomass makes its hydrolysis into desired monomers ineffective. Therefore, pretreatment is needed to degrade the crystalline structure and to separate these polymers, thus making each of the polymers available for enzymatic hydrolysis. Several methods including physical, physicochemical, and biological pretreatments have been developed which are suitable for different types of plant materials (Saritha et al. 2012). However, the pretreatment process leads to the formation of some inhibitors like neutral and acidic phenolics, hydroxymethyl furfural, furfural, and acetic acid necessitating detoxification and also the selection of microbial strains that can tolerate such inhibitors during fermentation (Almeida et al. 2009). The lignocellulosic material will be saccharified after pretreatment using microbial cellulases to release monosaccharides and oligo-saccharides. In nature, hydrolytic enzymes are secreted by microbes such as bacteria and fungi. At the industrial scale, commercially available cellulase cocktails comprising cellulases, hemicellulases, and pectinases are utilized for the deconstruction of lignocellulosic biomass. Following saccharification, a mixture of monosaccharides like glucose and xylose is obtained, out of which glucose is fermented to bioethanol by yeast leaving behind the xylose part. Therefore, oleaginous yeasts that can co-metabolize both glucose and xylose available in saccharification hydrolysates will be better suited for single cell oil production.

13.2 Oleaginous Yeasts

For thousands of years, yeasts have been used commercially for several biotechnological applications including the production of recombinant proteins. Recent years of research in yeasts are dedicated to the sustainable and renewable production of fuels and value-added chemicals. Torula pulcherrima was found with the ability to accumulate intracellular fat by Lindner in 1899 (Woodbine 1959). In 1915, Lindner observed that lipid accumulation in Endomycopsis vernalis (currently, Guehomyces pullulans) occurs in the medium under nitrogen-limited conditions and used the term “Fetthefe” (yeast fat in German) for the lipids accumulated by oleaginous yeasts. Sulfite waste liquor as carbon source was used for industrial fat production by Endomycopsis vernalis (Lundin 1950). Lipids stored in intracellular lipid bodies in oleaginous yeasts are mainly of diacyl and triacylglycerols (TAGs). Fatty acid composition of lipids accumulated (palmitic acid, stearic acid, myristic acid, oleic acid, linolenic acid, and linoleic acid) makes oleaginous yeasts, the most preferred microorganism for the production of triglyceride feedstock (Sagia et al. 2020; Wang et al. 2019; Fakas et al. 2009).

Oleaginous yeasts can accumulate lipids in the range of 40–70% of their dry weight with the capability to grow on a multitude of carbon sources (glucose, xylose, glycerol, arabinose, mannose, etc.). The typical oleaginous yeast genera include Rhodosporidium, Rhodotorula, Candida, Lipomyces, Trichosporon, Yarrowia, and Cryptococcus. Oleaginous yeasts for SCO production possess advantages over other microorganisms like filamentous fungi and microalgae viz. shorter duplication period, higher growth rates, higher lipid content, easier scale-up, no requirement of light, and better control of bacterial contamination due to lower pH requirements. Lipid accumulation in oleaginous yeasts is categorized into two types of mechanism—de-novo and ex-novo lipid accumulation. De-novo lipid accumulation occurs with hydrophilic substrates under nitrogen limited conditions, whereas ex-novo lipid accumulation occurs when hydrophobic resources are used as a substrate.

The composition and proportion of fatty acids in the single cell oil (SCO) vary depending on the type of cultivation process and the substrate (Tanimura et al. 2014). Yeasts can utilize several types of carbon source for biomass and lipid production including glucose, xylose, cellobiose (Yu et al. 2014b), acetate (Gong et al. 2015), molasses (Karatay and Dönmez 2010), glycerol (Polburee et al. 2015), hydrolysate of cassava starch (Wang et al. 2012), industrial and municipal organic wastes (Zhou et al. 2013), and lignocellulose hydrolysates such as rice straw (Huang et al. 2009), corncob (Gao et al. 2014), sugarcane bagasse (Huang et al. 2012), wheat straw (Yu et al. 2011), and fruit pulp (Patel et al. 2015). Accumulation of lipid in oleaginous yeasts occurs under the limitation of nitrogen or other nutrient sources except for carbon (Zhao et al. 2008; Wu et al. 2010), and the lipid accumulation is found to be optimal at molar C:N ratio of 65–100 (Calvey et al. 2016). Hydrolytic properties in addition to lipogenic properties possessed by certain yeasts prove to be advantageous in using low-cost substrates for oil production. Trichosporon asahii was reported with endoglucanase (CMCase) and β-glucosidase activity of about 0.11 IU/mL and 0.55 IU/mL, respectively. Lipase activity of about 50 IU/mL and 64% w/w lipid production with soap stock of pomace olive oil refining was reported in Yarrowia lipolytica (Ayadi et al. 2018).

A pilot-scale study was undertaken for biodiesel production with single cell oil from Rhodosporidium toruloides with sugarcane juice as the carbon source (Soccol et al. 2017). Lipid productivity of about 0.44 g/L/h was obtained in the study. Diesel engine test with the obtained lipids showed 220% reduction in CO2 emission, seven-fold reduction in CO emission, and 50% reduction in NOx emission when compared with first-generation biodiesel from soybean oil. Although the main storage form of yeast lipids is triacylglycerol (TAG), they also contain a relative amount of C16 and C18 fatty acids. Apart from being a potential feedstock for biodiesel, lipids from yeasts can also be used as cocoa butter substitute (CBS). Cocoa butter is chiefly composed of three types of triacylglycerols—1,3-dipalmitil-2-oleoil glycerol (POP) (C16:0–C18:1–C16:0), 1(3)-palmitil-3(1)-estearil-2- glycerol (POS) (C16:0–C18:1–C18:0), and 1,3-diestearil-2-oleoil glycerol (SOS) (C18:0–C18:1–C18:0) (Tanimura et al. 2014). Trichosporon oleaginosus was reported to produce 28% POP and POS with a total TAG of about 0.3 g/g dry cell weight (Dionisi et al. 2004; Wei et al. 2017).

13.3 Biochemistry of Lipid Accumulation in Oleaginous Yeasts

De-novo accumulation of lipid in oleaginous yeasts occurs through quasi-inverted β-oxidation process with acetyl Co-A from intermediate cellular metabolism as the basic unit. The fatty acids being formed will be esterified with glycerol forming structural and storage lipids (TAG-triacylglycerol). Glucose and xylose are the abundant simple sugar compounds found in the lignocellulosic biomass. Glucose metabolism and xylose metabolism yield about 1.1 and 1.2 moles of acetyl Co-A per 100 g of glucose (~0.56 moles) and 100 g of xylose (0.66 moles), respectively. If all acetyl Co-A produced from glucose and xylose metabolism is channelized to lipid biosynthesis, theoretical lipid yield will be 0.32 g g−1 and 0.34 g g−1 for glucose and xylose, respectively (Ratledge 1988).

Pyruvic acid, the net product of glycolysis, will be decarboxylated by pyruvate dehydrogenase to acetyl Co-A. This acetyl Co-A either enters the Krebs cycle or into the pathway for lipid biosynthesis. However, in oleaginous microorganisms, acetyl Co-A for lipid accumulation comes from the TCA cycle intermediate, citric acid. Under the limitations of nitrogen in the culture media, AMP deaminase (adenosine monophosphate deaminase) of oleaginous yeasts converts AMP into IMP (Inosine monophosphate) and NH4+. This NH4+ serves as an intracellular nitrogen source for cell material synthesis under nitrogen exhaustion conditions. The events result in a decrease in the concentration of intracellular AMP which in turn alters the TCA cycle. Isocitrate dehydrogenase (responsible for isocitrate to α-ketoglutarate transformation) which is allosterically activated by AMP loses its activity. Loss in the activity of isocitrate dehydrogenase leads to the accumulation of isocitric acid inside the mitochondria (at concentration equilibrium with citric acid). Citric acid enters the cytoplasm in exchange with malic acid when the citric acid concentration inside the mitochondria reaches the critical value. Citric acid will be broken down into oxaloacetate and acetyl Co-A by ATP-citrate lyase (ATP-CL), a key enzyme of lipid bio-synthesis in oleaginous microorganisms. This acetyl Co-A will be used for fatty acids synthesis by the quasi-inverted β-oxidation pathway. ATP-citrate lyase (ATP-CL) is found to be absent in non-oleaginous yeasts. In non-oleaginous yeasts, the citric acid accumulated as a result of nitrogen exhausted is secreted into the extracellular environment or accumulated as intracellular polysaccharides on inhibiting 6-phosphofructokinase (Boulton and Ratledge 1980; Boulton and Ratledge 1981; Wynn et al. 2001).

In ex-novo lipid accumulation, free fatty acids which are produced by the hydrolysis of the hydrophobic substrates with extracellular lipase are first incorporated inside the microbial cells. These fatty acids may either be dissimilated for cellular growth or subjected to bio-transformations, wherein lipid profile with new fatty acid profile indifferent to the initial hydrophobic substrate will be synthesized. Ex-novo lipid accumulation is a growth-coupled process, i.e., lipid accumulation takes place concurrently with cell growth and is independent of nitrogen limitation in the culture media (Papanikolaou et al. 2001; Papanikolaou et al. 2002) (Fig. 13.1).

13.4 Low-Cost Substrates for SCO Production

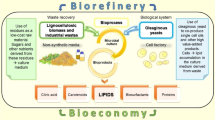

Being a developing technology, the cost of microbial oil production is higher than that of plant oils due to the high cost of culture media. Therefore, exploration and use of low-cost substrates together with efficient oleaginous yeasts to utilize low-cost renewable substrates are essential. The substrates used for lipid accumulation can be categorized into two major groups—hydrophilic and hydrophobic substrates—based on the type of lipid accumulation (de-novo and ex-novo). Various hydrophilic substrates like cane and beet molasses, glycerol, acetate, wastewater, lignocellulosic hydrolysate, cellobiose, brine, starch hydrolysate, propionic acid, and butyric acid have been used for de novo lipid production. Hydrophobic materials like fatty esters, vegetable oils, soap stocks, pure free fatty acids, and fish oils are used for ex-novo lipid production (Qin et al. 2017) (Fig. 13.2). The fatty acid profile varies with the yeast strain and substrate used (Table 13.1).

13.4.1 Hydrophilic Substrates

13.4.1.1 Molasses

Molasses is a brown viscous liquid byproduct of sugar manufactured from sugarcane or sugar beet. Major sugars present in the molasses include sucrose, fructose, and glucose and therefore are widely used for industrial fermentation of ethanol, levan, biosurfactant, and lactic acid. Even though oleaginous microorganisms grow well in molasses, lipid accumulation is limited due to the low C/N ratio (12.5) of molasses (Jiru et al. 2018).

13.4.1.2 Crude Glycerol

Crude glycerol (80% glycerol) is a major byproduct of biodiesel production. The manufacture of 10 kg biodiesel generates about 1 kg glycerol as a byproduct (Bauer and Hulteberg 2013). This crude glycerol is treated as a waste since its purification is expensive and cumbersome. A wide variety of oleaginous yeasts were reported to convert glycerol into single cell oil. With a greater degree of reduction, low cost, and less competition with food production, crude glycerol can be a potential carbon source for SCO production from oleaginous yeasts. The re-use of crude glycerol from biodiesel production for oil production by oleaginous yeasts not only reduces the cost of production but also serves to recycle the waste glycerol. Moreover, crude glycerol also possesses other macro elements like calcium, potassium, and magnesium which support the growth of yeast. Yeast genera, namely Rhodosporidium, Rhodotorula, Candida, Trichosporonoides, Lipomyces, Yarrowia, Cryptococcus, and Schizosaccharomyces, are reported to utilize crude glycerol for SCO production (Guerfali et al. 2020).

13.4.1.3 Wastewaters

Wastewaters from food processing and agro-industries are difficult and expensive to treat since it has very high concentrations of organic matter. Such wastewaters with abundant organic materials and free sources of nutrients can be used as a carbon source for yeast lipid production. The use of wastewater as a raw material for lipogenesis can also reduce the energy spent on treating wastewaters. Several wastewater sources like industrial wastewaters, olive mill wastewaters, sewage sludge, monosodium glutamate wastewater, butanol wastewaters, and livestock wastewaters have been used for SCO production. Several yeast species have been found capable of producing versatile extracellular enzymes like protease, lipase, and lignin peroxidase for better utilization of nutrients in wastewater (Yang et al. 2013). However, there is a necessity to screen and improve the yeast strains to be capable of lipogenesis in high organic concentrations in wastewater for efficient and cost-effective lipid production. Since oleaginous yeasts can flourish at a low pH, this criterion can be exploited for scaling up of SCO production with unsterilized wastewater as a substrate. Acidic pH can be used to generate a yeast-dominated microflora under non-sterile conditions since it is cumbersome to sterilize large volumes of wastewater.

13.4.1.4 Lignocellulosic Biomass Hydrolysate

Lignocellulosic biomass serves as the most abundant and promising feedstock for future renewable biofuels. Among the various low-cost substrates, non-edible biomass like lignocellulosic biomass seems to be efficient which would be converted into fuel. Almost in most of the developing countries, lignocellulosic biomass is subjected to direct combustion for heat generation, cooking, and waste elimination in agricultural fields. This direct combustion leads to various problems including environmental pollution. Instead, lignocellulosic biomass can be valorized into high-quality products like bioethanol and lipids using microbes (Cherubini and Ulgiati 2010).

13.4.2 Hydrophobic Waste Resources

Hydrophobic wastes like volatile fatty acids, n-alkanes can be used as a feedstock for ex-novo lipid production. This ex-novo lipid accumulation results in the intra-cellular biomodification of lipid substrates by oleaginous yeast leading to the production of new fatty acid profiles. Therefore, waste fat resources can be upgraded to lipid products of higher value like cocoa butter substitutes (Vajpeyi and Chandran 2015). Lipid yield in oleaginous yeast was found to increase with supplementation of volatile fatty acids with an additional simple carbon source. Volatile fatty acids (VFAs) which are derived from wastes also contain organic acids like propionic acid, isobutyric acid, acetic acid, n-butyric acid, and isovaleric acid (Huang et al. 2016). Conversion of these organic acids into SCO by oleaginous yeasts can therefore help in sustainable waste management (Bialy et al. 2011).

13.5 Lignocellulosic Biomass as a Substrate for SCO Production from Oleaginous Yeasts

13.5.1 Structure, Composition, and Recalcitrance of Lignocellulosic Biomass

Lignocellulose is composed of several polymers including cellulose, hemicellulose, lignin, pectin, starch, and ashes in lesser quantities. Cellulose is the most abundant biopolymer and is made of glucopyranose units (500–1400) linked by β 1–4 glycosidic linkage. Cellobiose is the fundamental repeating unit of cellulose (Robak and Balcerek 2018). Cellulose concentration ranges from 34 to 50% in softwood species, 41–50% in hardwood species, and 15–45% in most of the agricultural crop species, and it increases with maturity of the plant (Monlau et al. 2014). The degree of polymerization and crystallinity plays a critical role in the recalcitrance of lignocellulosic biomass. Lignocellulosic biomass with shorter cellulose chains and fewer hydrogen bonds is easier to hydrolyze than long cellulose chains with more hydrogen bonds. Crystalline cellulose fibers are slower to hydrolyze than amorphous cellulose. Hemicelluloses constitute 20–35% of lignocellulosic biomass and may be homoglycans or heteroglycans (Chandel et al. 2018). Hemicellulose is a branched heteropolysaccharide and composed of hexoses like mannose, glucose, and galactose; uronic acids like glucuronic and galacturonic acids; and pentoses like xylose and arabinose. Xylan is the predominant hemicellulose ranging from 12 to 37% of the lignocellulosic biomass in the case of agricultural residues (Monlau et al. 2014). Acetylation of hemicellulose units limits the cellulose accessibility to enzymatic hydrolysis (Pan et al. 2006).

Lignin is a polymer of aromatic nuclei made up of a single repeating unit or several similar components. It is a very complex heteropolymer with phenyl propane (sinapyl, coumaryl, and coniferyl alcohol) as the basic unit of lignin. Lignin constitutes about 15–35% of the lignocellulosic biomass of wood species and 3.5–30% of grass species (Monlau et al. 2014). Cellulose and lignin content is higher in hardwood and softwood plant species than in agricultural crops. Lignin is insoluble in neutral organic solvents and hot water. Cellulose and hemicellulose remain associated with hydrogen bonds, and lignin is linked covalently to hemicellulose thus forming a lignin-carbohydrate complex (LCC). Lignin thus presents a physiochemical barrier to enzymatic degradation of lignocellulosic biomass by forming close inter-linkage with cellulose and hemicelluloses. Hydrophobic structural characteristics of lignin also adsorb hydrolytic enzymes irreversibly (Tarasov et al. 2018; Valdés et al. 2020). Therefore, an effective pretreatment method is required for the disruption of lignin-cellulose matrix and reducing enzyme adsorption to lignin complex for the subsequent valorization of lignocellulosic biomass to valuable products like biofuels.

13.5.2 Pretreatment of Lignocellulosic Biomass

The recalcitrance of lignocellulosic biomass makes its hydrolysis ineffective. Therefore, pretreatment is needed to degrade the crystalline structure and to separate these polymers, thus making each of the polymers available for enzymatic hydrolysis. Particle size reduction by milling, grinding, and extrusion before pretreatment efficiently deconstructs lignocellulosic biomass with an increased rate of hydrolysis (size threshold depends on the lignocellulosic feedstocks). Various methods of pretreatments like physical (mechanical comminution, extrusion, pyrolysis, and pulsed electric field), chemical (alkali pretreatment, acid pretreatment, ozonolysis, and organosolv process), physiochemical process (steam explosion, ultrasound treatment, CO2 explosion, liquid hot water treatment, ammonia fiber expansion, oxidative pretreatment, and wet oxidation), thermochemical process, and biological pretreatment (fungal or bacterial) are used. An effective pretreatment should be cost-effective, should remove lignin portion without degrading cellulose and hemicelluloses layers, should produce minimum inhibitory compounds, should be low energy demanding, and should be ecofriendly and safe to use. Chemical pretreatments are the most commonly used technique for lignocellulosic deconstruction.

13.5.2.1 Physical Methods

Mechanical comminution and pyrolysis are the commonly used physical methods of pretreating lignocellulosic biomass. In mechanical comminution, the size and crystallinity of biomass are reduced by the combination of chipping, milling, and grinding (Cadoche and López 1989). In pyrolysis, cellulose is decomposed by exposing the biomass to high temperature (>300 °C) (Kilzer and Broido 1965).

13.5.2.2 Chemical Methods

13.5.2.2.1 Acid Pretreatment

Acid pretreatment (with hydrochloric acid, sulfuric acid, phosphoric acid, and acetic acid) solubilizes hemicellulose and reduce cellulose through disruption of hydrogen and covalent bonds in the lignocellulosic complex. This process hydrolyzes hemicellulose especially xylan into its monomers. Acid pretreatment is found to be suitable for the disruption of lignocellulose complex in agriculture residues and hardwood species. Pretreatment with concentrated acids results in effective hydrolysis releasing a high concentration of simple sugars. However, the use of concentrated acids partially degrades hemicellulose into furfural, hydroxymethyl furfural, and other organic acids whose presence in the hydrolysate inhibits the fermentation process (McMillan et al. 1994). Therefore, a two-stage acid pretreatment method has been proposed, wherein the extraction of hemicellulose is done with less concentrated acid in the first phase followed by high concentrated acid in the second phase for cellulose destruction. But using concentrated acids necessitates the use of corrosion-resistant equipment, thus increasing the cost and also possesses safety issues. Pretreatment with dilute acids, on the other hand, is less aggressive, economical, more environmentally friendly, and generates fewer inhibitory compounds (furfural and HMF). However, pretreatment with dilute acid requires a higher temperature than that required for concentrated acids (Solarte-Toro et al. 2019; Singh et al. 2015). The dry dilute acid method has been used as an alternative to the wet acid method (concentrated and dilute acids), wherein both the biomass and product are solid. Dry biomass is impregnated with acid for efficient adsorption. Comparable assimilable sugar yields with reduced amounts of inhibitory compounds can be obtained with the dry dilute acid method (He et al. 2014).

13.5.2.2.2 Alkali Method

This method of pretreatment is carried out by the addition of bases like NaOH, KOH, and Ca(OH)2 to the lignocellulosic biomass. In this process, the internal surface area of the biomass is increased by swelling the biomass, reduces the degree of polymerization, crystallinity, and breaks the lignin carbohydrate complex. Ester and ionic bonds interlinking hemicellulose and other components are saponified thereby increasing the porosity of the lignocellulosic complex (Tarkow and Feist 1969). Alkali pretreatment is found to be effective with biomass with low lignin content compared to those with high lignin content (Singh et al. 2015; Xu and Sun 2016). Alkali pretreatment resulted in the highest recovery of cellulose (59.66) and hemicelluloses (28.34) from corn cob (Sharma et al. 2017), 92.5% delignification, and 81.5% w/w cellulose yield in paddy straw (Kobkam et al. 2018). The main advantage is its low cost and mild operation conditions. But the process results in the formation of salts that are difficult to remove, and the reaction time is also longer.

13.5.2.2.3 Ozonolysis

Ozonolysis is used for the efficient degradation of lignin at room temperature and pressure. Yield from enzymatic hydrolysis has been shown to increase after pretreating the biomass with ozone. While lignin is efficiently removed, hemicellulose is only partially degraded in this process. Ozonolysis does not lead to the production of any inhibitor compounds during the pretreatment. However, this method requires large quantities of ozone, thus making ozonolysis expensive (Vidal and Molinier 1988).

13.5.2.2.4 Oxidative Delignification

In this method, peroxidase enzyme is used to decompose lignin in the presence of hydrogen peroxide. Solubilization of 50% lignin and hemicellulose was achieved with 2% hydrogen peroxide within 8 h at 30 °C. Glucose yield with enzymatic hydrolysis of cellulose after pretreatment was also found to be increased with oxidative delignification (Azzam 1989).

13.5.2.2.5 Organosolv Pretreatment

In this method, organic solvent (ethanol, methanol, glycerol, phenol, acetone, formic acid, and acetic acid) is added to the lignocellulosic biomass to separate lignin from cellulose. Solid phase with cellulose, hemicellulose, and liquid fraction with lignin is obtained at the end of pretreatment (Borand and Karaosmanoğlu 2018). Excision of O-aryl bonds of lignin with carbohydrates occurs during solvent treatment resulting in the dissolution of lignin along with organic solvent. This process also generates acetyl compounds which help in the autohydrolysis of hemicellulose and cellulose. Organic solvents can be recovered and reused. The main disadvantage of this process is the generation of several inhibitor compounds (guaiacol, vanillin, vanillic acid, syringaldehyde, syringic acid, and ferulic acid) (Zhao et al. 2009).

13.5.2.3 Physicochemical Method

13.5.2.3.1 Steam Explosion Pretreatment

Steam explosion, a physicochemical method, is a very energy efficient method (Conde-Mejía et al. 2012). In this process, the biomass is first exposed to saturated steam at high temperature (162–260 °C) and pressure (5–50 atm) for a short interval of time. The steam expands into the lignocellulose matrix as the pressure is reduced gradually, thus separating the cellulose fibers and thus disrupting the cell wall. This process also generates acetyl compounds that auto-hydrolyze hemicellulose (Grous et al. 1986). This method generates less inhibitory compounds than acid and alkali methods. Steam explosion is less effective in softwood species with less content of acetyl groups. Acid compounds can be used as a catalyst in such cases to improve cell wall deconstruction, but it leads to the generation of fermentation inhibitor compounds (Singh et al. 2015).

13.5.2.3.2 Ammonia Fiber Explosion (AFEX)

In this method, the biomass is treated with liquid ammonia (1.2 kg of liquid ammonia for 1 kg of lignocellulosic biomass) at high temperature (90 °C) and for a short period (30 min), after which the pressure is reduced rapidly. The AFEX method is not efficient for biomass with high lignin, and hemicellulose is not solubilized significantly with this method. However, this method does not require a small particle size and does not produce inhibitor compounds (Holtzapple et al. 1991).

13.5.2.3.3 CO2 Explosion

This method works by increasing the hydrolysis rate with carbonic acid generated from carbon dioxide. But the yields of hydrolysis are low when compared to that achieved with ammonia fiber explosion methods and steam explosion. However, pretreatment of lignocellulosic biomass with CO2 explosion does not result in the formation of fermentation inhibitor compounds (Zheng et al. 1998).

13.5.2.4 Biological Pretreatment

Microorganisms or biocatalysts from microbes are used to open the cell wall matrix in this method of pretreatment. White-rot, brown-rot, and soft-rot fungi and actinomycetes can be used to degrade lignin and hemicellulose components of waste plant biomass. White-rot fungi target lignin, whereas brown-rot fungi degrade cellulose (Hatakka 1983). White-rot fungi have been reported with enzymes degrading lignin, cellulose, and hemicellulose polymers. Phanerochaete chrysosporium is the well-studied white-rot fungi with lignin-degrading property. P. chrysosporium has been shown to produce lignin-degrading enzymes like manganese-dependent peroxidases and lignin peroxidases (Boominathan and Reddy 1992). Actinomycetes were also investigated for their ability to degrade lignin. Small laccases similar to fungal laccases were shown to affect lignin degradation in Streptomyces coelicolor, Streptomyces lividans, Streptomyces viridosporus, and Amycolatopsis sp. (Saritha et al. 2013; Majumdar et al. 2014). The requirement of longer duration, specific growth conditions, and aseptic environment makes it less preferable for industrial-scale operation. A combination of biological methods with a common pretreatment method can be advantageous in the deconstruction of the lignocellulosic cell wall matrix.

13.5.3 Conversion of Biomass into Fermentable Sugars

Since most of the oleaginous yeasts lack cellulolytic activity, the pretreated lignocellulosic biomass should be hydrolyzed before the fermentation process. This process depolymerizes cellulose and hemicellulose into hexose and pentose monomers which can be assimilated by oleaginous yeasts into biolipids/single cell oil. Enzymatic hydrolysis is advantageous at mild process conditions compared to acid and alkaline hydrolysis. Microorganisms like bacteria and fungi are endowed with the abilities to produce hydrolytic enzymes for depolymerizing lignocellulosic biomass. Bacterial genera, Bacillus, Clostridium, Ruminococcus, Microbispora, Cellulomonas, Erwinia, Bacteriodes, Thermomonospora, Acetovibrio, and Streptomyces, have been reported to produce cellulolytic enzymes. Among the cellulolytic fungi (Phanerochaete chrysosporium, Aspergillus, Sclerotium rolfsii, Schizophyllum, Trichoderma, and Penicillium), Trichoderma has been widely used for the cellulase production (Duff and Murray 1996). Cellulases are a group of enzymes that includes endoglucanase, exoglucanase/cellobiohydrolase, and β-glucosidase. Endoglucanase is active against amorphous regions/less crystalline regions and creates new free chain ends which are then attacked by other enzymes. Exoglucanase attacks crystalline cellulose and generates glucose/cellobiose units. Finally, β-glucosidase hydrolyzes cellobiose to monomer sugars like glucose. Other accessory enzymes attacking hemicellulose, glucuronidase, acetylesterase, β-xylosidase, glucomannanase, galactomannanase, and xylanase act synergistically with cellulase enzymes and convert cellulose-hemicellulose into assailable free sugars (Singh et al. 2015; Fan et al. 2012; Sternberg 1976). The rate of hydrolysis can be improved by increasing the concentration of cellulase. Usually, in laboratory, cellulase is used at the dose of 10 FPU/g cellulose for high monomer (glucose) yield in 48–72 h of reaction time (Gregg and Saddler 1996). Irreversible adsorption of cellulase to cellulose and lignin deactivates the enzyme which can be minimized by the use of surfactants (Tween 20, 80, cationic Q-86 W, antihole 20BS, polyoxyethylene glycol, Emulgen 147, and anionic Neopelex F-25) in enzymatic hydrolysis (Wu and Ju 1998; Park et al. 1992; Ooshima et al. 1986; Helle et al. 1993). Cellobiose and glucose, which are the end products of hydrolysis, inhibit the activity of cellulase. High loading of enzymes, removal of hydrolysis products formed during hydrolysis, and supplement of β-glucosidases during the reaction can minimize the inhibition of cellulase by end products. From the reaction mixture, cellulases can be recovered and reused for the next batch of hydrolysis (Kumar et al. 2017). But the efficiency of hydrolysis decreases gradually with each step of recycling (Ramos et al. 1993).

13.5.4 SCO Production with Oleaginous Yeasts from Lignocellulosic Hydrolysate

Various waste products and lignocellulosic hydrolysates have been used by researchers for single cell oil production from oleaginous yeasts (Table 13.2). SCO was produced with 45% lipid yield from Endomycopsis vernalis with sulfite waste liquor as a carbon source by Lindner in 1922. Lignocellulosic hydrolysate contains hexoses like glucose, galactose, and mannose and pentoses like xylose and arabinose. Hexoses can be readily utilized by all microorganisms, but the utilization of pentoses which constitute a significant portion of hydrolysate is essential for the complete valorization of lignocellulosic biomass into single cell oil. Various oleaginous yeast strains have been reported with the ability to use both these hexoses and pentoses as carbon sources for lipid accumulation. Therefore, xylose- and pentose-utilizing oleaginous yeast isolates possess an advantage for the economical production of SCO from lignocellulosic biomass.

High biomass loading during saccharification leads to a higher level of inhibitor compounds having an inhibitory effect on fermenting microbes and subsequent reduction in lipid yield. Greater biomass loading also results in lower sugar yield due to feedback inhibition in enzymatic hydrolysis and subsequent reduction in lipid yield.

Lipid production by oleaginous yeasts from lignocellulosic biomass can be proceeded after pretreatment by three processes—SHLP (separate hydrolysis and lipid production), SSLP (simultaneous saccharification and lipid production), and CBP (consolidated bioprocessing). Separate hydrolysis and lipid production is commonly used, wherein lipid production is carried out in hydrolysate after saccharification by hydrolytic enzymes. The main disadvantage of SHLP is the feedback inhibition of hydrolytic enzymes by the end products. Simultaneous saccharification and lipid production can resolve the problem of feedback inhibition, wherein saccharification and lipid production is carried out simultaneously. However, it requires the use of thermotolerant microorganisms for fermentation since enzymatic hydrolysis requires the optimal temperature of 50 °C, but the optimal temperature for most oleaginous yeasts for fermentation is ≤30 °C. SSLP was demonstrated with Cryptococcus curvatus at 37 °C and regenerated corn stover as the substrate. The lipid yield of 6 g L−1 was obtained with 5% substrate loading after 48 h. Consolidated bioprocessing is extensively used in bioethanol production from lignocellulosic biomass, wherein enzyme production, carbohydrate hydrolysis, and fermentation/lipid production are integrated into one process. Isolation of natural populations of cellulolytic oleaginous yeast strains or genetic engineering of oleaginous yeasts for production of extracellular cellulolytic enzymes will pave the way for inexpensive and rapid lipid production from lignocellulosic biomass (Gong et al. 2013). Consolidated bioprocessing with genetically engineered cellulolytic yeast Yarrowia lipolytica was attempted with 12 gL−1 cellulose consumption and 14% lipid accumulation (Guo et al. 2018).

Based on the method of pretreatment and hydrolysis, toxic lignocellulosic degradation byproducts may be produced. These include acetic acid, furfural, hydroxymethyl furfural, formic acid, and vanillin. These degradation compounds can inhibit cell growth and subsequent fermentation. Furfural was found to be the most toxic among the other degradation compounds. A decrease in the yeast biomass weight and lipid yield of Cryptococcus curvatus by 78.4% and 61% for glucose and 72% and 59.3% for xylose, respectively, was reported in the presence of furfural (1.0 g L−1) (Yu et al. 2014a). The generation of inhibitory compounds necessitates detoxification of hydrolysate which may further increase the cost of the whole production process. The selection of oleaginous yeast with high tolerance to inhibitory compounds or the ones capable of utilizing lignin degradation compounds as a carbon source is therefore a good tactic for lipid production from lignocellulosic hydrolysates. A fed-batch lipid production from Trichosporon cutaneum was performed with 4-hydroxybenzaldehyde as the sole carbon substrate. The lipid yield obtained was 0.85 g L−1 (0.039 g/g of 4-hydroxybenzaldehyde) (Hu et al. 2018). An inhibitor degradation study was undertaken, wherein the biodegradation of inhibitors was examined by providing each inhibitor as the solitary carbon source. It was found that furfural, hydroxymethyl furfural, 4-hydroxybenzaldehyde, vanillin, and syringaldehyde were converted to corresponding nontoxic acid—furoic acid, HMF acid, 4-hydroxybenzoate, vanillate, and syringate—by Trichosporon cutaneum. The enzymes involved in the biodegradation of inhibitors were found to be alcohol dehydrogenases, aldehyde reductases, aldehyde dehydrogenases, salicylaldehyde dehydrogenase, D-lactaldehyde dehydrogenase, aminoadipate-semialdehyde dehydrogenase, betaine aldehyde dehydrogenase, semialdehyde dehydrogenase, alcohol oxidase, vanillyl alcohol oxidase, glucose oxidase, and choline oxidase (Wang et al. 2016). Phenolic aldehyde from lignin was also used as the only carbon source for SCO production by Trichosporon cutaneum. Resistance to inhibitors was demonstrated in Rhodosporidium toruloides. The study conducted showed that the presence of inhibitory compounds does not have a profound effect in the distribution of major fatty acids of Rhodosporidium toruloides—palmitic acid (C16:0), stearic acid (C18:0), and oleic acid (C18:1) (Hu et al. 2009). High recalcitrance of lignin makes it difficult to valorize it into valuable bioproducts. However, aromatic metabolic pathways for metabolizing lignin-related aromatic compounds have been found in certain oleaginous yeast species. Products of this aromatic metabolism include acetyl Co-A which is a precursor for fatty acid synthesis thus leading to the conversion of lignin-related aromatic compounds into lipids (Yaguchi et al. 2020).

13.6 Genetic Engineering for Enhanced SCO Production from Oleaginous Yeasts

Under the conditions of excess carbon and limited nitrogen conditions, non-oleaginous microbes accumulate excess carbon as polysaccharides like glycogen, whereas oleaginous yeast accumulates excess carbon as intracellular lipids.

Two different approaches are generally used for the improvement of the wild microbial strains for enhanced single cell oil production. The first is to improve the metabolic pathways of lipid biosynthesis in oleaginous yeasts, and the second is to recombine fatty acid synthesis genes from oleaginous yeasts into non-oleaginous yeasts or other microbes (Saccharomyces cerevisiae and Escherichia coli). Approaches used for metabolic engineering to enhance the lipid yield include overexpressing the enzymes involved in fatty acid and TAG (triacylglycerol) biosynthesis pathway, regulation of enzymes related to TAG biosynthesis, and inhibition of lipid catabolism (Fig. 13.3). Key lipid biosynthesis genes identified are ATP-citrate lyase (ACL), acetyl Co-A carboxylase (ACC), diacylglycerol acetyl transferase (DGAT), glycerol 3-phosphate dehydrogenase, glycerol 3-phosphate acyl transferase (GPAT), and acetyl Co-A synthetase (ACS) (Liang and Jiang 2013). A two-fold increase in lipid content in Yarrowia lipolytica was achieved by the overexpression of the key enzyme ACC 1 (acetyl Co-A carboxylase). An increase in lipid content by 41% in Yarrowia lipolytica was achieved by simultaneous co-expression of ACC 1 and DGA 1 (acetyl Co-A carboxylase and diacylglycerol acetyl transferase) by combining both the genes in a gene construct (Tai and Stephanopoulos 2013). A three-fold increase in lipid yield has been achieved by redirecting the carbon flux towards TAG biosynthesis by deletion of GUT 1 (glycerol 3-phosphate dehydrogenase) (Beopoulos et al. 2008). Ester synthesizing genes can be introduced into non-oleaginous yeasts for fatty acid esters production from carbohydrates. This approach results in the direct biodiesel production from raw material rather than lipid production (Kalscheuer et al. 2006; Schmidt-Dannert and Holtzapple 2011). Enzymes not directly involved in lipid biosynthesis like malic enzyme and ATP:citrate lyase (ACL) also influence the lipid yield. Malic enzyme supplies NADH for fatty acid synthase (FAS) and desaturases. ACL catalyzes the citrate to acetyl-CoA conversion and is the key enzyme in oleaginous microorganisms. Besides genetic modification approach for high lipid yield, engineering for other desirable characteristics like simultaneous/co-utilization of various sugars (like glucose and xylose), lipid production at high temperature thus facilitating for simultaneous saccharification and fermentation after pretreatment of lignocellulosic biomass, and resistance to inhibitor compounds generated from various pretreatment approaches of lignocellulosic biomass could lead to economical and sustainable single cell oil production.

13.7 Fatty Acid Composition and Application of Lipids from Oleaginous Yeasts

The fatty acid profile of oleaginous yeast varies with the species, strain, substrate used, and culture conditions. The common fatty acids in diacyl and triacylglycerols accumulated by oleaginous yeast includes myristic acid (C14:0), palmitic acid (C16:0), stearic acid (C18:0), oleic acid (C18:1), and linoleic acid (C18:2) (Sagia et al. 2020; Patel et al. 2014; Patel et al. 2015). The fatty acid composition of the single cell oil determines the potentiality of biodiesel to be used in diesel engines. Higher octane number and a lower degree of unsaturation are essential for better ignition and stability. EU (European Union) has set a limit for iodine value, which measures the degree of unsaturation as 120 g I2/100 g (Knothe 2006). Oleaginous yeasts like Trichosporon fermentans and Rhodotorula glutinis have been reported to produce single cell oil from lignocellulosic hydrolysate with iodine values within the threshold limit (Hoekman et al. 2012). High saturated fatty acids increase the shelf life of biodiesel, whereas unsaturated fatty acids determine the cold flow plugging property of biodiesel. An optimum ratio of saturated to unsaturated fatty acids is necessary for kinematic viscosity and oxidative stability of biodiesel. The cold flow plugging property (CFPP) determines the low-temperature operability of the biodiesel. CFPP is defined as the lowest temperature at which biodiesel (20 ml) flows through a wire mesh screen in 60 seconds under vacuum. Biodiesel solidifies and blocks the engine once the CFPP is reached. Several oleaginous yeasts have been reported with CFPP within the threshold limits of CFPP set by EU (≤5/≤−20). Oxidative stability of the biodiesel increases its shelf life. Oxidative stability is inversely proportional to the number of double bonds in the cis configuration. Linolenic acid (18:3) is highly prone to auto-oxidation, and therefore, a limit of 12% linolenic acid is set by EU (Knothe 2006; Patel et al. 2016). Oleaginous yeasts like Yarrowia lipolytica, Trichosporon cutaneum, Rhodosporidium toruloidies, and Lipomyces starkeyi have been shown to produce SCO from lignocellulosic hydrolysates with physical properties suitable for biodiesel application in diesel engines (Patel et al. 2016).

13.8 Possibilities for Improved Profitability from SCO Production

Oleaginous yeast can be co-cultured with microalgae for enhanced biomass and lipid yield. Microalgae provide oxygen for heterotrophic yeast, and yeast supplies carbon dioxide for autotrophic microalgae thus minimizing the requirement for mechanical aeration. Enhanced lipid yield and biomass were achieved with the synergistic association of microalgae (Chlorella vulgaris) with yeast (Rhodotorula glutinis) compared to pure cultures (Zhang et al. 2014).

In addition to lipid production, oleaginous yeast can also be used for the synthesis of other value-added chemicals like β-carotene, torularhodin, and torulene. Carotenoids exhibiting provitamin A was shown to be produced by the oleaginous yeast Rhodotorula glutinis (Chaturvedi et al. 2018). Oleaginous yeast is also reported to produce enzymes like phenylalanine ammonia lyase (for aspartame production), invertase, α-L-arabinofuranosidase, tannase, and pectinase (Cui et al. 2015; Kot et al. 2016; Taskin 2013).

13.9 Conclusion

Biodiesel has been currently produced with high-cost vegetable oils. Lipids from oleaginous yeast have been confirmed as a potential alternate feedstock to vegetable oil for biodiesel production. Therefore, the use of oleaginous yeasts for microbial lipid production is a promising way for biodiesel production and to combat the energy crisis. Abundant and nonedible lignocellulosic biomass can be used as a low-cost raw material for single cell oil production, thus making biodiesel production sustainable, economical, and renewable. However, the recalcitrance of lignocellulosic biomass necessitates pretreating the biomass which results in the production of various inhibitor compounds. Selection and improvement of oleaginous yeast isolates with high lipid yield, biomass yield, osmotolerance, inhibitor resistance, SCO production at high temperature, and low pH make the process highly advantageous over vegetable oil production. Optimization, scale-up, and technological advancements in the sustainable conversion of lignocellulosic biomass into SCO by oleaginous yeasts can help to meet the increasing energy demand by the increasing population.

References

Almeida JRM, Bertilsson M, Gorwa-Grauslund MF, Gorsich S, Lidén G (2009) Metabolic effects of furaldehydes and impacts on biotechnological processes. Appl Microbiol Biotechnol 82(4):625–638. https://doi.org/10.1007/s00253-009-1875-1

Angerbauer C, Siebenhofer M, Mittelbach M, Guebitz GM (2008) Conversion of sewage sludge into lipids by Lipomyces starkeyi for biodiesel production. Bioresour Technol 99(8):3051–3056. https://doi.org/10.1016/j.biortech.2007.06.045

Ayadi I, Belghith H, Gargouri A, Guerfali M (2018) Screening of new oleaginous yeasts for single cell oil production, hydrolytic potential exploitation and agro-industrial by-products valorization. Process Saf Environ Prot 119:104–114. https://doi.org/10.1016/j.psep.2018.07.012

Azzam AM (1989) Pretreatment of cane bagasse with alkaline hydrogen peroxide for enzymatic hydrolysis of cellulose and ethanol fermentation. J Environ Sci Health Part B 24(4):421–433. https://doi.org/10.1080/03601238909372658

Bauer F, Hulteberg C (2013) Is there a future in glycerol as a feedstock in the production of biofuels and biochemicals? Biofuels Bioprod Biorefin 7(1):43–51. https://doi.org/10.1002/bbb.1370

Beopoulos A, Mrozova Z, Thevenieau F, Le Dall M-T, Hapala I, Papanikolaou S, Chardot T, Nicaud J-M (2008) Control of lipid accumulation in the yeast Yarrowia lipolytica. Appl Environ Microbiol 74(24):7779. https://doi.org/10.1128/aem.01412-08

Bialy HE, Gomaa OM, Azab KS (2011) Conversion of oil waste to valuable fatty acids using oleaginous yeast. World J Microbiol Biotechnol 27(12):2791–2798. https://doi.org/10.1007/s11274-011-0755-x

Boominathan K, Reddy CA (1992) cAMP-mediated differential regulation of lignin peroxidase and manganese-dependent peroxidase production in the white-rot basidiomycete Phanerochaete chrysosporium. Proc Natl Acad Sci U S A 89(12):5586. https://doi.org/10.1073/pnas.89.12.5586

Borand MN, Karaosmanoğlu F (2018) Effects of organosolv pretreatment conditions for lignocellulosic biomass in biorefinery applications: a review. J Renew Sustain Energy 10(3):033104. https://doi.org/10.1063/1.5025876

Boulton CA, Ratledge C (1980) Regulatory studies on citrate synthase in Candida 107, an oleaginous yeast. Microbiology 121(2):441–447. https://doi.org/10.1099/00221287-121-2-441

Boulton CA, Ratledge C (1981) Correlation of lipid accumulation in yeasts with possession of ATP: citrate lyase. Microbiology 127(1):169–176. https://doi.org/10.1099/00221287-127-1-169

Cadoche L, López GD (1989) Assessment of size reduction as a preliminary step in the production of ethanol from lignocellulosic wastes. Biol Wastes 30(2):153–157. https://doi.org/10.1016/0269-7483(89)90069-4

Calvey CH, Su Y-K, Willis LB, McGee M, Jeffries TW (2016) Nitrogen limitation, oxygen limitation, and lipid accumulation in Lipomyces starkeyi. Bioresour Technol 200:780–788. https://doi.org/10.1016/j.biortech.2015.10.104

Canonico L, Ashoor S, Taccari M, Comitini F, Antonucci M, Truzzi C, Scarponi G, Ciani M (2016) Conversion of raw glycerol to microbial lipids by new Metschnikowia and Yarrowia lipolytica strains. Ann Microbiol 66(4):1409–1418. https://doi.org/10.1007/s13213-016-1228-0

Chandel AK, Garlapati VK, Singh AK, Antunes FAF, da Silva SS (2018) The path forward for lignocellulose biorefineries: bottlenecks, solutions, and perspective on commercialization. Bioresour Technol 264:370–381. https://doi.org/10.1016/j.biortech.2018.06.004

Chaturvedi S, Bhattacharya A, Khare SK (2018) Trends in oil production from oleaginous yeast using biomass: biotechnological potential and constraints. Appl Biochem Microbiol 54(4):361–369. https://doi.org/10.1134/s000368381804004x

Cherubini F, Ulgiati S (2010) Crop residues as raw materials for biorefinery systems—a LCA case study. Appl Energy 87(1):47–57. https://doi.org/10.1016/j.apenergy.2009.08.024

Chi Z, Zheng Y, Jiang A, Chen S (2011) Lipid production by culturing oleaginous yeast and algae with food waste and municipal wastewater in an integrated process. Appl Biochem Biotechnol 165(2):442–453. https://doi.org/10.1007/s12010-011-9263-6

Christophe G, Deo JL, Kumar V, Nouaille R, Fontanille P, Larroche C (2012) Production of oils from acetic acid by the oleaginous yeast Cryptococcus curvatus. Appl Biochem Biotechnol 167(5):1270–1279. https://doi.org/10.1007/s12010-011-9507-5

Conde-Mejía C, Jiménez-Gutiérrez A, El-Halwagi M (2012) A comparison of pretreatment methods for bioethanol production from lignocellulosic materials. Process Saf Environ Prot 90(3):189–202. https://doi.org/10.1016/j.psep.2011.08.004

Cui J, Liang L, Han C, Lin Liu R (2015) Stabilization of phenylalanine ammonia lyase from Rhodotorula glutinis by encapsulation in polyethyleneimine-mediated biomimetic silica. Appl Biochem Biotechnol 176(4):999–1011. https://doi.org/10.1007/s12010-015-1624-0

Deeba F, Pruthi V, Negi YS (2016) Converting paper mill sludge into neutral lipids by oleaginous yeast Cryptococcus vishniaccii for biodiesel production. Bioresour Technol 213:96–102. https://doi.org/10.1016/j.biortech.2016.02.105

Dionisi F, Golay P-A, Hug B, Baumgartner M, Callier P, Destaillats F (2004) Triacylglycerol analysis for the quantification of cocoa butter equivalents (CBE) in chocolate: feasibility study and validation. J Agric Food Chem 52(7):1835–1841. https://doi.org/10.1021/jf035391q

Duff SJB, Murray WD (1996) Bioconversion of forest products industry waste cellulosics to fuel ethanol: a review. Bioresour Technol 55(1):1–33. https://doi.org/10.1016/0960-8524(95)00122-0

Elfadaly H, El-Naggar N, Marwan E-S (2009) Single cell oil production by an oleaginous yeast strain in a low cost cultivation medium. Res J Microbiol 4:301–313. https://doi.org/10.3923/jm.2009.301.313

Enshaeieh M, Abdoli A, Madani M, Bayat M (2015) Recycling of lignocellulosic waste materials to produce high-value products: single cell oil and xylitol. Int J Environ Sci Technol 12(3):837–846. https://doi.org/10.1007/s13762-014-0687-8

Fakas S, Papanikolaou S, Batsos A, Galiotou-Panayotou M, Mallouchos A, Aggelis G (2009) Evaluating renewable carbon sources as substrates for single cell oil production by Cunninghamella echinulata and Mortierella isabellina. Biomass Bioenergy 33(4):573–580. https://doi.org/10.1016/j.biombioe.2008.09.006

Fan LT, Gharpuray MM, Lee YH (2012) Cellulose hydrolysis. Springer Science and Business Media (3)

Gao Q, Cui Z, Zhang J, Bao J (2014) Lipid fermentation of corncob residues hydrolysate by oleaginous yeast Trichosporon cutaneum. Bioresour Technol 152:552–556. https://doi.org/10.1016/j.biortech.2013.11.044

Gong Z, Shen H, Wang Q, Yang X, Xie H, Zhao ZK (2013) Efficient conversion of biomass into lipids by using the simultaneous saccharification and enhanced lipid production process. Biotechnol Biofuels 6(1):36. https://doi.org/10.1186/1754-6834-6-36

Gong Z, Shen H, Zhou W, Wang Y, Yang X, Zhao ZK (2015) Efficient conversion of acetate into lipids by the oleaginous yeast Cryptococcus curvatus. Biotechnol Biofuels 8(1):189. https://doi.org/10.1186/s13068-015-0371-3

Gregg DJ, Saddler JN (1996) Factors affecting cellulose hydrolysis and the potential of enzyme recycle to enhance the efficiency of an integrated wood to ethanol process. Biotechnol Bioeng 51(4):375–383. https://doi.org/10.1002/(SICI)1097-0290(19960820)51:4<375::AID-BIT1>3.0.CO;2-F

Grous WR, Converse AO, Grethlein HE (1986) Effect of steam explosion pretreatment on pore size and enzymatic hydrolysis of poplar. Enzym Microb Technol 8(5):274–280. https://doi.org/10.1016/0141-0229(86)90021-9

Guerfali M, Ayadi I, Sassi H-E, Belhassen A, Gargouri A, Belghith H (2020) Biodiesel-derived crude glycerol as alternative feedstock for single cell oil production by the oleaginous yeast Candida viswanathii Y-E4. Ind Crop Prod 145:112103. https://doi.org/10.1016/j.indcrop.2020.112103

Guo Z-p, Robin J, Duquesne S, O’Donohue MJ, Marty A, Bordes F (2018) Developing cellulolytic Yarrowia lipolytica as a platform for the production of valuable products in consolidated bioprocessing of cellulose. Biotechnol Biofuels 11(1):141. https://doi.org/10.1186/s13068-018-1144-6

Hatakka AI (1983) Pretreatment of wheat straw by white-rot fungi for enzymic saccharification of cellulose. Eur J Appl Microbiol Biotechnol 18(6):350–357. https://doi.org/10.1007/bf00504744

He Y, Zhang J, Bao J (2014) Dry dilute acid pretreatment by co-currently feeding of corn stover feedstock and dilute acid solution without impregnation. Bioresour Technol 158:360–364. https://doi.org/10.1016/j.biortech.2014.02.074

Helle SS, Duff SJB, Cooper DG (1993) Effect of surfactants on cellulose hydrolysis. Biotechnol Bioeng 42(5):611–617. https://doi.org/10.1002/bit.260420509

Hoekman SK, Broch A, Robbins C, Ceniceros E, Natarajan M (2012) Review of biodiesel composition, properties, and specifications. Renew Sust Energ Rev 16(1):143–169. https://doi.org/10.1016/j.rser.2011.07.143

Holtzapple MT, Jun J-H, Ashok G, Patibandla SL, Dale BE (1991) The ammonia freeze explosion (AFEX) process. Appl Biochem Biotechnol 28(1):59–74. https://doi.org/10.1007/bf02922589

Hu C, Zhao X, Zhao J, Wu S, Zhao ZK (2009) Effects of biomass hydrolysis by-products on oleaginous yeast Rhodosporidium toruloides. Bioresour Technol 100(20):4843–4847. https://doi.org/10.1016/j.biortech.2009.04.041

Hu M, Wang J, Gao Q, Bao J (2018) Converting lignin derived phenolic aldehydes into microbial lipid by Trichosporon cutaneum. J Biotechnol 281:81–86. https://doi.org/10.1016/j.jbiotec.2018.06.341

Huang C, Zong M-H, Wu H, Liu Q-P (2009) Microbial oil production from rice straw hydrolysate by Trichosporon fermentans. Bioresour Technol 100(19):4535–4538. https://doi.org/10.1016/j.biortech.2009.04.022

Huang C, Wu H, R-f L, M-h Z (2012) Improving lipid production from bagasse hydrolysate with Trichosporon fermentans by response surface methodology. New Biotechnol 29(3):372–378. https://doi.org/10.1016/j.nbt.2011.03.008

Huang X-F, Liu J-N, Lu L-J, Peng K-M, Yang G-X, Liu J (2016) Culture strategies for lipid production using acetic acid as sole carbon source by Rhodosporidium toruloides. Bioresour Technol 206:141–149. https://doi.org/10.1016/j.biortech.2016.01.073

Huang X-F, Shen Y, Luo H-J, Liu J-N, Liu J (2018) Enhancement of extracellular lipid production by oleaginous yeast through preculture and sequencing batch culture strategy with acetic acid. Bioresour Technol 247:395–401. https://doi.org/10.1016/j.biortech.2017.09.096

Jiru TM, Steyn L, Pohl C, Abate D (2018) Production of single cell oil from cane molasses by Rhodotorula kratochvilovae (syn, Rhodosporidium kratochvilovae) SY89 as a biodiesel feedstock. Chem Cent J 12(1):91. https://doi.org/10.1186/s13065-018-0457-7

Kalscheuer R, Stölting T, Steinbüchel A (2006) Microdiesel: Escherichia coli engineered for fuel production. Microbiology 152(9):2529–2536. https://doi.org/10.1099/mic.0.29028-0

Karatay SE, Dönmez G (2010) Improving the lipid accumulation properties of the yeast cells for biodiesel production using molasses. Bioresour Technol 101(20):7988–7990. https://doi.org/10.1016/j.biortech.2010.05.054

Kilzer FJ, Broido A (1965) Speculations on the nature of cellulose pyrolysis. Pyrodynamics 2:151–163

Knothe G (2006) Analyzing biodiesel: standards and other methods. J Am Oil Chem Soc 83(10):823–833. https://doi.org/10.1007/s11746-006-5033-y

Kobkam C, Tinoi J, Kittiwachana S (2018) Alkali pretreatment and enzyme hydrolysis to enhance the digestibility of rice straw cellulose for microbial oil production. Int J Appl Sci Technol. https://doi.org/10.14416/j.ijast.2018.07.003

Kot AM, Błażejak S, Kurcz A, Gientka I, Kieliszek M (2016) Rhodotorula glutinis—potential source of lipids, carotenoids, and enzymes for use in industries. Appl Microbiol Biotechnol 100(14):6103–6117. https://doi.org/10.1007/s00253-016-7611-8

Kraisintu P, Yongmanitchai W, Limtong S (2010) Selection and optimization for lipid production of a newly isolated oleaginous yeast, Rhodosporidium toruloides DMKU3-TK16. Kasetsart J Nat Sci 44:436–445

Kumar A, Singh S, Tiwari R, Goel R, Nain L (2017) Immobilization of indigenous holocellulase on iron oxide (Fe2O3) nanoparticles enhanced hydrolysis of alkali pretreated paddy straw. Int J Biol Macromol 96:538–549

Li Q, Du W, Liu D (2008) Perspectives of microbial oils for biodiesel production. Appl Microbiol Biotechnol 80(5):749–756. https://doi.org/10.1007/s00253-008-1625-9

Liang M-H, Jiang J-G (2013) Advancing oleaginous microorganisms to produce lipid via metabolic engineering technology. Prog Lipid Res 52(4):395–408. https://doi.org/10.1016/j.plipres.2013.05.002

Lotero E, Goodwin JG, Bruce DA, Suwannakarn K, Liu Y, Lopez DE (2006) The catalysis of biodiesel synthesis. Catalogue 19(1):41–83

Lundin H (1950) Fat synthesis by micro-organisms and its possible applications in industry. J Inst Brew 56(1):17–28. https://doi.org/10.1002/j.2050-0416.1950.tb01516.x

Majumdar S, Lukk T, Solbiati JO, Bauer S, Nair SK, Cronan JE, Gerlt JA (2014) Roles of small laccases from Streptomyces in lignin degradation. Biochemist 53(24):4047–4058. https://doi.org/10.1021/bi500285t

Mast B, Zöhrens N, Schmidl F, Hernandez R, French WT, Merkt N, Claupein W, Graeff-Hönninger S (2014) Lipid production for microbial biodiesel by the oleagenious yeast Rhodotorula glutinis using hydrolysates of wheat straw and miscanthus as carbon sources. Waste Biomass Valori 5(6):955–962. https://doi.org/10.1007/s12649-014-9312-9

McMillan JD, Baker JO, Overend RP (1994) Enzymatic conversion of biomass for fuels production. American Chemical Society, Washington, DC, pp 292–324

Monlau F, Sambusiti C, Barakat A, Quéméneur M, Trably E, Steyer JP, Carrère H (2014) Do furanic and phenolic compounds of lignocellulosic and algae biomass hydrolyzate inhibit anaerobic mixed cultures? A comprehensive review. Biotechnol Adv 32(5):934–951. https://doi.org/10.1016/j.biotechadv.2014.04.007

Ooshima H, Sakata M, Harano Y (1986) Enhancement of enzymatic hydrolysis of cellulose by surfactant. Biotechnol Bioeng 28(11):1727–1734. https://doi.org/10.1002/bit.260281117

Pan X, Gilkes N, Saddler JN (2006) Effect of acetyl groups on enzymatic hydrolysis of cellulosic substrates. Holzforschung 60(4):398–401. https://doi.org/10.1515/HF.2006.062

Papanikolaou S, Chevalot I, Komaitis M, Aggelis G, Marc I (2001) Kinetic profile of the cellular lipid composition in an oleaginous Yarrowia lipolytica capable of producing a cocoa-butter substitute from industrial fats. Antonie Leeu 80(3):215–224. https://doi.org/10.1023/a:1013083211405

Papanikolaou S, Chevalot I, Komaitis M, Marc I, Aggelis G (2002) Single cell oil production by Yarrowia lipolytica growing on an industrial derivative of animal fat in batch cultures. Appl Microbiol Biotechnol 58(3):308–312. https://doi.org/10.1007/s00253-001-0897-0

Park JW, Takahata Y, Kajiuchi T, Akehata T (1992) Effects of nonionic surfactant on enzymatic hydrolysis of used newspaper. Biotechnol Bioeng 39(1):117–120. https://doi.org/10.1002/bit.260390117

Patel A, Pravez M, Deeba F, Pruthi V, Singh RP, Pruthi PA (2014) Boosting accumulation of neutral lipids in Rhodosporidium kratochvilovae HIMPA1 grown on hemp (Cannabis sativa Linn) seed aqueous extract as feedstock for biodiesel production. Bioresour Technol 165:214–222. https://doi.org/10.1016/j.biortech.2014.03.142

Patel A, Sindhu DK, Arora N, Singh RP, Pruthi V, Pruthi PA (2015) Biodiesel production from non-edible lignocellulosic biomass of Cassia fistula L. fruit pulp using oleaginous yeast Rhodosporidium kratochvilovae HIMPA1. Bioresour Technol 197:91–98. https://doi.org/10.1016/j.biortech.2015.08.039

Patel A, Arora N, Sartaj K, Pruthi V, Pruthi PA (2016) Sustainable biodiesel production from oleaginous yeasts utilizing hydrolysates of various non-edible lignocellulosic biomasses. Renew Sust Energ Rev 62:836–855. https://doi.org/10.1016/j.rser.2016.05.014

Patel A, Arora N, Pruthi V, Pruthi PA (2017) Biological treatment of pulp and paper industry effluent by oleaginous yeast integrated with production of biodiesel as sustainable transportation fuel. J Clean Prod 142:2858–2864. https://doi.org/10.1016/j.jclepro.2016.10.184

Polburee P, Yongmanitchai W, Lertwattanasakul N, Ohashi T, Fujiyama K, Limtong S (2015) Characterization of oleaginous yeasts accumulating high levels of lipid when cultivated in glycerol and their potential for lipid production from biodiesel-derived crude glycerol. Fungal Biol 119(12):1194–1204. https://doi.org/10.1016/j.funbio.2015.09.002

Qin L, Liu L, Zeng A-P, Wei D (2017) From low-cost substrates to single cell oils synthesized by oleaginous yeasts. Bioresour Technol 245:1507–1519. https://doi.org/10.1016/j.biortech.2017.05.163

Ramos LP, Breuil C, Saddler JN (1993) The use of enzyme recycling and the influence of sugar accumulation on cellulose hydrolysis by Trichoderma cellulases. Enzym Microb Technol 15(1):19–25. https://doi.org/10.1016/0141-0229(93)90111-E

Ratledge C (1988) Biochemistry, stoichiometry, substrates and economics. In: Moreton RS (ed) Single cell oil. Longman Scientific & Technical, Harlow, pp 33–70

Robak K, Balcerek M (2018) Review of second generation bioethanol production from residual biomass. Food Technol Biotechnol 56(2):174–187. https://doi.org/10.17113/ftb.56.02.18.5428

Sagia S, Sharma A, Singh S, Chaturvedi S, Nain PKS, Nain L (2020) Single cell oil production by a novel yeast Trichosporon mycotoxinivorans for complete and ecofriendly valorization of paddy straw. Electron J Biotechnol 44:60–68. https://doi.org/10.1016/j.ejbt.2020.01.009

Saritha M, Arora A, Lata (2012) Biological pretreatment of lignocellulosic substrates for enhanced delignification and enzymatic digestibility. Indian J Microbiol 52(2):122–130. https://doi.org/10.1007/s12088-011-0199-x

Saritha M, Arora A, Singh, S and Nain L (2013) Streptomyces griseorubens mediated delignification of paddy straw for improved enzymatic saccharification yields. Bioresour Technol 135:12–17. https://doi.org/10.1016/j.biortech.2012.11.040

Schmidt-Dannert C, Holtzapple EK (2011) U.S. Patent No. 7,897,369. Washington, DC: U.S. Patent and Trademark Office

Sharma A, Nain V, Tiwari R, Singh S, Adak A, Nain PKS, Nain L (2017) Simultaneous saccharification and fermentation of alkali-pretreated corncob under optimized conditions using cold-tolerant indigenous holocellulase. Korean J Chem Eng 34(3):773–780. https://doi.org/10.1007/s11814-016-0334-9

Singh J, Suhag M, Dhaka A (2015) Augmented digestion of lignocellulose by steam explosion, acid and alkaline pretreatment methods: a review. Carbohydr Polym 117:624–631. https://doi.org/10.1016/j.carbpol.2014.10.012

Sitepu IR, Jin M, Fernandez JE, da Costa SL, Balan V, Boundy-Mills KL (2014) Identification of oleaginous yeast strains able to accumulate high intracellular lipids when cultivated in alkaline pretreated corn stover. Appl Microbiol Biotechnol 98(17):7645–7657. https://doi.org/10.1007/s00253-014-5944-8

Soccol CR, Dalmas Neto CJ, Soccol VT, Sydney EB, da Costa ESF, Medeiros ABP, de Souza Vandenberghe LP (2017) Pilot scale biodiesel production from microbial oil of Rhodosporidium toruloides DEBB 5533 using sugarcane juice: performance in diesel engine and preliminary economic study. Bioresour Technol 223:259–268. https://doi.org/10.1016/j.biortech.2016.10.055

Solarte-Toro JC, Romero-García JM, Martínez-Patiño JC, Ruiz-Ramos E, Castro-Galiano E, Cardona-Alzate CA (2019) Acid pretreatment of lignocellulosic biomass for energy vectors production: a review focused on operational conditions and techno-economic assessment for bioethanol production. Renew Sust Energ Rev 107:587–601. https://doi.org/10.1016/j.rser.2019.02.024

Sternberg D (1976) Production of cellulase by Trichoderma. In: Biotechnology and bioengineering symposium, vol 6, p 35

Tai M, Stephanopoulos G (2013) Engineering the push and pull of lipid biosynthesis in oleaginous yeast Yarrowia lipolytica for biofuel production. Metab Eng 15:1–9. https://doi.org/10.1016/j.ymben.2012.08.007

Tanimura A, Takashima M, Sugita T, Endoh R, Kikukawa M, Yamaguchi S, Sakuradani E, Ogawa J, Shima J (2014) Selection of oleaginous yeasts with high lipid productivity for practical biodiesel production. Bioresour Technol 153:230–235. https://doi.org/10.1016/j.biortech.2013.11.086

Tarasov D, Leitch M, Fatehi P (2018) Lignin–carbohydrate complexes: properties, applications, analyses, and methods of extraction: a review. Biotechnol Biofuels 11(1):269. https://doi.org/10.1186/s13068-018-1262-1

Tarkow H, Feist WC (1969) A mechanism for improving the digestibility of lignocellulosic materials with dilute alkali and liquid ammonia. In: Cellulases and their applications, vol 95. Advances in chemistry, pp 197–218. https://doi.org/10.1021/ba-1969-0095.ch01210.1021/ba-1969-0095.ch012

Taskin M (2013) Co-production of tannase and pectinase by free and immobilized cells of the yeast Rhodotorula glutinis MP-10 isolated from tannin-rich persimmon (Diospyros kaki L.) fruits. Bioprocess Biosyst Eng 36(2):165–172. https://doi.org/10.1007/s00449-012-0771-8

Tsigie YA, Wang C-Y, Kasim NS, Diem Q-D, Huynh L-H, Ho Q-P, Truong C-T, Ju Y-H (2012) Oil production from Yarrowia lipolytica Po1g using rice bran hydrolysate. J Biomed Biotechnol 2012:378384. https://doi.org/10.1155/2012/378384

Vajpeyi S, Chandran K (2015) Microbial conversion of synthetic and food waste-derived volatile fatty acids to lipids. Bioresour Technol 188:49–55. https://doi.org/10.1016/j.biortech.2015.01.099

Valdés G, Mendonça RT, Aggelis G (2020) Lignocellulosic biomass as a substrate for oleaginous microorganisms: a review. Preprints.org. https://doi.org/10.20944/preprints202009.0449.v1

Vidal PF, Molinier J (1988) Ozonolysis of lignin—improvement of in vitro digestibility of poplar sawdust. Biomass 16(1):1–17. https://doi.org/10.1016/0144-4565(88)90012-1

Wang Q, Guo F-J, Rong Y-J, Chi Z-M (2012) Lipid production from hydrolysate of cassava starch by Rhodosporidium toruloides 21167 for biodiesel making. Renew Energy 46:164–168. https://doi.org/10.1016/j.renene.2012.03.002

Wang J, Gao Q, Zhang H, Bao J (2016) Inhibitor degradation and lipid accumulation potentials of oleaginous yeast Trichosporon cutaneum using lignocellulose feedstock. Bioresour Technol 218:892–901. https://doi.org/10.1016/j.biortech.2016.06.130

Wang X, Fosse HK, Li K, Chauton MS, Vadstein O, Reitan KI (2019) Influence of nitrogen limitation on lipid accumulation and EPA and DHA content in four marine microalgae for possible use in aquafeed. Front Mar Sci. 6(95). https://doi.org/10.3389/fmars.2019.00095

Wei Y, Siewers V, Nielsen J (2017) Cocoa butter-like lipid production ability of non-oleaginous and oleaginous yeasts under nitrogen-limited culture conditions. Appl Microbiol Biotechnol 101(9):3577–3585. https://doi.org/10.1007/s00253-017-8126-7

Woodbine M (1959) Microbial fat: microorganisms as potential fat producers. Prog Indus Microbiol 1:181–245

Wu J, Ju L-K (1998) Enhancing enzymatic saccharification of waste newsprint by surfactant addition. Biotechnol Prog 14(4):649–652. https://doi.org/10.1021/bp980040v

Wu S, Hu C, Jin G, Zhao X, Zhao ZK (2010) Phosphate-limitation mediated lipid production by Rhodosporidium toruloides. Bioresour Technol 101(15):6124–6129. https://doi.org/10.1016/j.biortech.2010.02.111

Wynn JP, Hamid AA, Li Y, Ratledge C (2001) Biochemical events leading to the diversion of carbon into storage lipids in the oleaginous fungi Mucor circinelloides and Mortierella alpina. Microbiology 147(10):2857–2864. https://doi.org/10.1099/00221287-147-10-2857

Xavier MCA, Coradini ALV, Deckmann AC, Franco TT (2017) Lipid production from hemicellulose hydrolysate and acetic acid by Lipomyces starkeyi and the ability of yeast to metabolize inhibitors. Biochem Eng J 118:11–19. https://doi.org/10.1016/j.bej.2016.11.007

Xu JK, Sun RC (2016) Chapter 19—recent advances in alkaline pretreatment of lignocellulosic biomass. In: Mussatto SI (ed) Biomass fractionation technologies for a lignocellulosic feedstock based biorefinery. Elsevier, Amsterdam, pp 431–459. https://doi.org/10.1016/B978-0-12-802323-5.00019-0

Yaguchi A, Franaszek N, O’Neill K, Lee S, Sitepu I, Boundy-Mills K, Blenner M (2020) Identification of oleaginous yeasts that metabolize aromatic compounds. J Ind Microbiol Biotechnol 47(9–10):801–813. https://doi.org/10.1007/s10295-020-02269-5

Yang Q, Zhang H, Li X, Wang Z, Xu Y, Ren S, Chen X, Xu Y, Hao H, Wang H (2013) Extracellular enzyme production and phylogenetic distribution of yeasts in wastewater treatment systems. Bioresour Technol 129:264–273. https://doi.org/10.1016/j.biortech.2012.11.101

Yu X, Zheng Y, Dorgan KM, Chen S (2011) Oil production by oleaginous yeasts using the hydrolysate from pretreatment of wheat straw with dilute sulfuric acid. Bioresour Technol 102(10):6134–6140. https://doi.org/10.1016/j.biortech.2011.02.081

Yu X, Zeng J, Zheng Y, Chen S (2014a) Effect of lignocellulose degradation products on microbial biomass and lipid production by the oleaginous yeast Cryptococcus curvatus. Process Biochem 49(3):457–465. https://doi.org/10.1016/j.procbio.2013.10.016

Yu X, Zheng Y, Xiong X, Chen S (2014b) Co-utilization of glucose, xylose and cellobiose by the oleaginous yeast Cryptococcus curvatus. Biomass Bioenergy 71:340–349. https://doi.org/10.1016/j.biombioe.2014.09.023

Zhan J, Lin H, Shen Q, Zhou Q, Zhao Y (2013) Potential utilization of waste sweetpotato vines hydrolysate as a new source for single cell oils production by Trichosporon fermentans. Bioresour Technol 135:622–629. https://doi.org/10.1016/j.biortech.2012.08.068

Zhang Z, Ji H, Gong G, Zhang X, Tan T (2014) Synergistic effects of oleaginous yeast Rhodotorula glutinis and microalga Chlorella vulgaris for enhancement of biomass and lipid yields. Bioresour Technol 164:93–99. https://doi.org/10.1016/j.biortech.2014.04.039

Zhao X, Kong X, Hua Y, Feng B, Zhao Z (2008) Medium optimization for lipid production through co-fermentation of glucose and xylose by the oleaginous yeast Lipomyces starkeyi. Eur J Lipid Sci Technol 110(5):405–412. https://doi.org/10.1002/ejlt.200700224

Zhao X, Cheng K, Liu D (2009) Organosolv pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Appl Microbiol Biotechnol 82(5):815–827. https://doi.org/10.1007/s00253-009-1883-1

Zheng Y, Lin H-M, Tsao GT (1998) Pretreatment for cellulose hydrolysis by carbon dioxide explosion. Biotechnol Prog 14(6):890–896. https://doi.org/10.1021/bp980087g

Zhou W, Wang W, Li Y, Zhang Y (2013) Lipid production by Rhodosporidium toruloides Y2 in bioethanol wastewater and evaluation of biomass energetic yield. Bioresour Technol 127:435–440. https://doi.org/10.1016/j.biortech.2012.09.067

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Sajish, S., Singh, S., Nain, L. (2022). Yeasts for Single Cell Oil Production from Non-conventional Bioresources. In: Saini, J.K., Sani, R.K. (eds) Microbial Biotechnology for Renewable and Sustainable Energy. Clean Energy Production Technologies. Springer, Singapore. https://doi.org/10.1007/978-981-16-3852-7_13

Download citation

DOI: https://doi.org/10.1007/978-981-16-3852-7_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-3851-0

Online ISBN: 978-981-16-3852-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)