Abstract

. This paper presents the study on GSCM practices in SMEs in Pune region (India). The components for the study (survey) were based on the literature review and also from the feedback received from the academicians and executives from the corporate world. From the survey, it was found that the adoption of GSCM practices in SMEs was still in the early stage. The environmental sustainability awareness was very low among the customers. The legislation and regulatory framework is also lagging in promoting the sustainability of the environment. Data analysis results revealed that vendor–vendee relationship has positive impact on sustainability of product design and the logistics, which further was positively related to economic performance and competitiveness of the organization. This study was conducted with 120 manufacturing industries under SMEs category. AMOS, a statistical software, which stands for Analysis of Moment of Structures is used for structural equation modeling and path analysis, and confirmatory factor analysis was used to measure the overall respondents view on sustainable supply chain management.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Green supply chain management (GSCM)

- Environmental sustainability

- SMEs

- Structural equation modeling (SEM)

1 Introduction

The supply chain is a chain of activities which starts from customers and end with customers. Through the chain flows all the raw materials and finished products, information and all the transaction processes. Handfield and Nicholas [1] define supply chain and SCM as the Supply Chain encompasses all the activities associated with the flow and transformation of goods from the raw material stage (extraction), through to the end user, as well as the associated information flows. Material and information flow both up and down the supply chain. Supply chain management (SCM) is the integration of these activities through improved supply chain relationships, to achieve a sustainable competitive advantage. Now, the supply chain includes collaboration from customers, agents, and from suppliers. With government legislations and regulations and customer’s awareness, industries have started the integration of environmental factors throughout their firms. Now, the industries have started shifting toward eco-friendly supply chains by the integration of green technologies into their production process activities through product design and development, manufacturing, and distribution processes. All these together led to the incorporation of Extended Production Responsibility (EPR), which further led to the evolution of green supply chain management (GSCM) [2].

The strategy of green supply chain management is to minimize the adverse effect of the firm and their supply chain network on the environment with respect to change of climate, pollution control, and non-renewable resource constraints. Thus, GSCM integrates supply chain management activities for reducing the environmental impact during the whole product life cycle management [3]. The objective of the GSCM is to improve the flow of material by adding value and controlling the material flow, capital, information, and work. Also it includes providing good quality products or services to the customers at the lowest possible cost and environmental impact [4]. Three issues are important to the environmental management and sustainability. They are as follows [5]:

-

(i)

Inclusion of environmental aspect in an integrated supply chain management for the production of goods.

-

(ii)

Integration of innovations of modern technology for the ecologically beneficial outcomes throughout the supply chain activity.

-

(iii)

The larger participation of industrial actors for the environmental management of industrial production, in order to strengthen the capacity building on environment management governance.

Review of extant literature on green supply chain management has shown that there is an important link between supply chain management decisions and green supply chain [6]. For some of the firms, these new greener perspective will be in more transformative, which leads to fresh thoughts, newer markets, with profitability and increased values. And for some others, the focus on environmental aspect will emerge gradually and modestly as their critical element of their corporate strategy [7]. With the passing of time, these companies may find long-term sustainable benefit for being greener but not overnight gains. For most of the large-scale and heavy industries, these gains are very closer to be assured. But very surprisingly, the smaller organizations also found the benefits [8]. The framework of a green supply chain with forward and reverse activities is shown in Fig. 1.

Figure 1 explains the forward as well as reverse activities of green supply chain management. The forward activities include purchasing, engineering (Design), production (Manufacturing), and product distribution to the end-user (Distribution). The backward activities include inspection, sorting, and disassembly for reprocessing, reusing, and redesigning which is done mainly for the demand in primary as well as secondary markets.

2 Materials and Methods

The sample size of the study is determined by using the formula (Slovin’s formula) given below (1). Slovin’s formula is used when nothing about the behavior of a population is known at all.

where n—Sample size, N—Population size = 500, e—Error of acceptance = 8% Power = 80%, Type I error (level of significance) = 5%.

According to Slovin’s formula, the minimum sample size to be studied in the study is 120. Stratified random sampling (n = 120) was carried out to collect data from small and medium enterprises (SME’s) of Pune region in Maharashtra state (India). Out of these, 110 industries are small scale and ten industries are medium scale. All the factors of green supply chain management such as legislation and regulation (LR), green purchasing (GP), eco design (ED), green logistics (GL), reverse logistics (RL), environmental performance (EP), and supply chain performance (SCP) are given due consideration in the questionnaire. All the variables will be measured by the participant’s responses based on the five-point Likert- scales (1 stand for strongly disagree and 5 stands for strongly agree). Data collection was done by personally visiting the SME’s and through sending the questionnaire forms through emails. Out of the 200 questionnaires distributed, 120 responses were obtained back from the respondents of SME’s. Thus, the response rate of 60% is achieved.

The summary of demographic features of the respondents indicates 91.7% (n = 110) of SMEs that participated in the survey are small-scale industries, 8.3% (n = 10) were medium-scale industries. The working style of the organization includes traditional management, 21.7% (n = 66), modern management, 30% (n = 36), and combination, 48.3% (n = 38). 28.3% (n = 34) respondents were diploma qualified, 33.3% (n = 40) respondents were graduates, 20% (n = 24) respondents were post graduates, and the remaining 18.4% (n = 22) were other categories. With regard to respondent’s designations, 50% (n = 60) were the owners of SMEs, 18.3% (n = 22) were managers, 23.3% (n = 28%) were senior managers, and the remaining 8.4% (n = 10) were in charges. As regards quality certifications (ISO-9000), 61.7% (n = 74) were certified SMEs, with environmental certifications (ISO-14001), 20.8% (n = 25) were certified SMEs, and 17.5% (n = 21) implemented environmental management systems (EMS) in their organizations.

The entire statistical analysis was done using Statistical Package for Social Sciences (SPSS, AMOS version 22.0, IBM, USA) for MS Windows. Structural equation modeling as implemented in AMOS is used to test the proposed model on impact of GSCM on environmental performance and supply chain performance (EP and SCP).

2.1 Hypothesis Setting

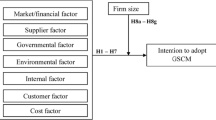

The hypotheses are formulated based on the objectives of the study:

-

H1: Medium-scale enterprises are more likely to adopt green purchasing (GP) practices than small-scale enterprise. H2: There is a significant difference between mean ranks of dimensions of GSCM (LR, GP, ED, GL, and RL). H3: Legislation and regulation (LR) is positively related to environmental performance (EP). H4: Green purchasing (GP) practices are positively related to environmental performance (EP). H5: Green logistics (GL) is positively related to environmental performance (EP). H6: Reverse logistics (RL) is positively related to environmental performance (EP). H7: Eco-friendly design (ED) collaboration in SME’s is positively related to environmental performance (EP). H8: There is an interrelationship between various dimensions of GSCM (LR, GP, ED, GL, and RL), environmental performance (EP) and supply chain performance (SCP) (Fig. 2).

Structural equation modeling (SEM) is one of the multivariate statistical modeling tools which are widely used to investigate the independent determinants of the outcome variables of interest. Its estimation techniques, modeling capacities, and spectrum of application are expanding rapidly day by day. It is also used to study the relationships among latent constructs indicated by multiple measures. It is also applicable to experimental and non-experimental data, as well as cross-sectional and longitudinal data. In general, SEM analysis goes through the steps of model specification, data collection, model estimation, model evaluation, and possible model modification.

3 Results and Discussions

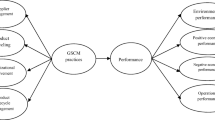

From Fig. 3 and Table 1, the variables used for structural equation model are given below:

Observed or endogenous variables | Unobserved, exogeneous variables |

|---|---|

Legislation and Regulation (LR) | e1: Error term for Legislation and Regulation (LR) |

Green Purchasing (GP) | e2: Error term for Green Purchasing (GP) |

Eco-friendly design (ED) | e3: Error term for Eco-friendly design(ED) |

Green logistics (GL) | e4: Error term for Green Logistics (GL) |

Reverse logistics (RL) | e5: Error term for Reverse Logistics (RL) |

Environmental Performance (EP) | e6: Error term for Environmental Performance |

Supply chain performance (SCP) | e7: Error term for SCP (Supply chain Performance) |

GSCM |

Variable details

Number of variable in the model: 15 | Number of observed Variables: 7 |

Number of unobserved variables: 8 | Number of Exogenous variables: 8 |

Number of Endogenous variables: 7 |

In this study, a SEM model was tested and developed by exploring the relationship between GSCM, EP, and SCP. The absolute fit of the dataset for the model test confirms that the model is stable. From the model, it is found that LR, GP, ED, and RL play an important role during the implementation of GSCM with the improvement in EP and SCP.

From Table 1 and Fig. 3, the below interpretation has been made.

For legislations and regulations (LR); the unstandardized coefficient of GSCM is 2.385 which indicates that there will be little or partial effect of LR on GSCM, and the other variables are constant (fixed or adjusted.) The positive sign indicates positive effect. There will be increase of LR score by 2.385 which means that LR increases by 2.385 for each increase in GSCM score. The value of co-efficient is significant at 5% level.

For green purchasing (GP), the un-standardized coefficient of GSCM is 2.095, For eco-friendly design (ED), the un-standardized coefficient of GSCM is 2.146, For green logistics (GL), the un-standardized coefficient of GSCM is 1.986, For reverse logistics(RL), the un-standardized coefficient of GSCM is 2.003, For environmental performance(EP), the un-standardized coefficient of GSCM is 2.439, and finally, for supply chain performance(SCP), the un-standardized coefficient of EP is 3.879.

From the structural equation model (SEM) analysis, it is seen that the unstandardized coefficient of environmental performance (EP) is maximum and indicates some partial effect of EP on SCP. And other variables are constant (fixed or adjusted). The positive sign indicates that it has positive effect and the SCP would increase by 3.879 for each increase in EP score.

From Table 2, it is found that the calculated P value is 0.209, which is greater than 0.05; this indicates a perfectly fit model. Goodness of fit (GFI) value and adjusted goodness of fit (AGFI) value are greater than 0.90; this represents a good fit to the sample data.

The calculated comparative fit index (CFI) value is 0.969, which means that it is perfectly fitted, and that root mean square residual (RMR) and root mean square error of approximation (RMSEA) values are less than 0.08 also indicating the perfect fit [9,10,11,12,13].

Decision based on statistical analysis

Null hypothesis (H0) is rejected and alternative hypothesis (H1) is accepted at 5% level of significance (LOS).

4 Conclusion

Among the various dimensions of GSCM, the most influencing dimension is LR, followed by ED, GP, RL, and GL. Green logistics has the minimum influence on GSCM. From this study, one can say that green supply chain management influences environmental performance which in turn has its impact on supply chain performance. The results from this study are helpful for manufacturing organizations for identifying an effective approach toward successful green supply chain management practices in small- and medium-scale enterprises (SMEs).

The GSCM practices are mostly dominated by positively influencing some of the production system performances, particularly with the environmental compliances. The relationship between supply chain performance and the environmental performance in manufacturing sectors of SMEs was being evaluated from this study. The study further concludes that an environmental performance in manufacturing industries (SMEs) in Pune region positively influences the supply chain performances. For future researchers, this study acts a reference source on green supply chain management for SMEs. As the sample size is small (n = 120), it is very difficult to draw the optimistic conclusion. A bigger sample size will be helpful for a detailed cross-sectoral comparison.

References

Handfield RB, Nicholas EL Jr (1999) Introduction to supply chain management. Prentice-Hall, New Jersey

Wang H-F, Gupta SM (2011) Green supply chain management: product life cycle approach. Mc Graw-Hill, New York

Sarkis J (2006) Greening the supply chains. Springer London Limited, UK

Rao P (2002) Greening the supply chain: a new initiative in South East Asia. Int J Oper Prod Manage 22(6):633–655

Berger G, Flynn A, Hines F, Jones R (2001) Ecological modernization as a basis for environmental policy and implications on environmental supply chain management. Innovation 14(1):55–72

Seuring S, Muller M (2008) From a literature review to a conceptual framework for sustainable supply chain management. J Cleaner Prod 16(15):1699–1710

Gao Y, Li J, Song Y (2009) Performance evaluation of GSCM based on membership conversion algorithm. In Proceeding: IEEE international colloquium on computing, communication, control and management

Zhu Q, Sarkis J, Lai K (2007) Initiatives and outcomes of GSCM implementation by Chinese manufacturers. J Environ Manage 85(1):179–189

Hervani AA, Helms MM (2005) Performance measurement for green supply chain management. Benchmarking Int J 12(4):330–353

Cronbach LJ (1951) Coefficient alpha and the internal structure of tests. Psychometrika 16(3):297–334

Nunnally JC (1978) Psychometric theory, 2nd edn. McGraw-Hill, New York

Gopal MH (1970) An introduction to research procedures in social sciences. Asia Publishing House, Bombay

Kothari CR (2004) Research methodology methods & techniques, 2nd edn. New Age International publisher, New Delhi

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Bhagawati, M.T., Venkumar, P. (2020). Evaluation of Green Supply Chain Management Practices in Small and Medium Enterprises in Pune Region. In: Vasudevan, H., Kottur, V., Raina, A. (eds) Proceedings of International Conference on Intelligent Manufacturing and Automation. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-4485-9_29

Download citation

DOI: https://doi.org/10.1007/978-981-15-4485-9_29

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-4484-2

Online ISBN: 978-981-15-4485-9

eBook Packages: EngineeringEngineering (R0)