Abstract

In this research, it is aimed to study different barriers related to green supply chain management practices of the Indian Rubber Industries, i.e., for both small and medium enterprises (SMEs) and large-scale industries, as there are numerous barriers which hinder the adoption and practices of green business practices. For that persistence, a contextual relationship among the identified barriers has been found out. The objective of current research work is to create a model by considering different barriers of GSCM and evaluate them using structural equation modeling (SEM). To validate the developed model, data has been collected from the relevant sources and hypotheses have been developed to check the robustness, and then, the SEM approach has been applied to validate the developed model.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Green supply chain management (GSCM)

- Structural equation modeling (SEM)

- Rubber industries

- Small and medium enterprises (SMEs)

1 Introduction

In today’s era, the major global problem arising is environmental degradation. Due to the upsurge in the raw material and energy consumption, natural resources are depleting at a very rapid rate. Moreover, pollution and waste production have also been increased significantly. Therefore, concurrently, there are twin challenges for the industries viz. competitive and environmental demands. The concept of GSCM is thus generated due to the alarming environmental issues and emerging economic opportunities. The assimilation of environmental concerns and the values of SC give rise to GSCM [1].

In the last two decades, most of the multinational industry and SME are turning toward GSCM for the sake of alarming environmental conditions. The demand for GSCM has risen nowadays as public awareness, environmental, economic or governmental reasons. But it is not an easy assignment. To make a model of various interrelated barriers to implement GSCM in Indian Rubber Industries and then validate that model using SEM is the main objective of this research.

1.1 Motivation

GSCM is a very good practice to be done for dealing with and minimizing the environmental issues that we are facing today. The boundary of GSCM is dependent on the researcher's goals and the problems which are at tips similar to the concept of SCM. The very initial green SC came into the framework by Kelle and Silver’s [2]. Apart from the operations perspective, considerable work has been done to facilitate the GSCM implementation in the industries at various stages by analyzing the barriers for the implementation of GSCM. GSCM activities are constrained on part of the suppliers by their unwillingness to support and lack of attentiveness. The outdated mindset of the supplier firm is the main key, which reflects suppliers’ and the total network interests as being. Government guidelines can inspire or depress the acceptance of alterations.

Customers, investors and non-governmental organizations can be treated as external drivers. Rao [3] explored the idea of GSCM by empirical survey initiative in the Philippine context.

2 Review of the Literature

2.1 Supply Chain (SC)

SC is the progress of products as they move from their source to the end customer. Regularly, a SC is additionally depicted by the term worth chain, which mirrors the concept that worth is included along the chain.

2.2 Green Supply Chain Management (GSCM)

To minimize or reduce waste in the form of energy, emission, dangerous solid and waste chemicals is the main aim of GSCM. The addition of the ‘green’ component to SCM includes addressing the influence and connection between SCM and the natural environment [4, 5].

The main aim of the organizations is to adopt GSCM practices to enhance their environmental and financial performance [6, 7].

2.3 Structural Equation Modeling (SEM)

For testing and estimating the fundamental relationship, SEM approach is used by a combination of statistical data and qualitative triggered assumptions. Unlike other methods, number of variables and limitations are not a case for SEM; hence, it is considered as the best approach. Jiang et al. [8] presented a new Bayesian nonlinear SEM approach for the hierarchical valuation of dynamic systems, considering uncertainty in predicted and measured time series. The proposed model and assumptions were validated using SEM. Although the SEM approach has been used by researchers for numerous problems, the application of SEM to model a GSCM barrier system has been found to be very limited. The application of SEM to a GSCM barrier model has not been found in more practices. This research study was initiated in this context (Fig. 1).

3 Problem Description

Due to environmental issues, GSCM finds a great need in society. For that purpose, to study the hindrances or barriers that organizations are facing in the implementation of GSCM is the main objective of this research. For that, firstly, we should know about which barriers are influencing the SC. In view, a lot of pollution is caused by disposing of the waste rubber as they are burned after use which causes a lot of smoke and pollution. So, there is an utmost need to reduce the wastes of rubber. For that, recycling of rubber should be done. For that purpose, rubber industries are chosen for reference. In this research, it aims to find the barriers which cause hindrances in the rubber industry and then to validate these barriers using SEM.

3.1 Research Methodology

The objective of this research is to create a model by considering different barriers of GSCM and evaluate them using structural equation modeling (SEM). For this, barrier is identified which hinders rubber industries to adopt GSCM using survey and expert opinion. Then, hypothesis has been developed relating to these barriers. Data was collected using questionnaire-based survey and was analyzed using SEM, and then, validation of hypothesis has been done. The result thus obtained will show that the validated hypothesis will influence the system and vice versa.

3.2 Identification of GSCM Barriers

GSCM is a very good practice to be done for dealing with and minimizing the environmental issues that we are facing today. Many researchers contribute to this topic, and they had found barriers related to different kinds of industries, namely plastic, manufacturing, automobile, etc. (Table 1).

3.3 Methodology

Firstly, the research hypothesis was prepared based on the barriers related to the implementation of GSCM in the rubber industry. Then, a questionnaire was prepared to keep in mind the exhaustive and extensive factors in order to get the awareness of the industry regarding GSCM. The data attained from the responses to the questionnaire was analyzed using SEM with the help of LISERAL software.

3.4 Research Hypothesis

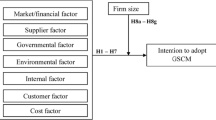

According to the available literature, the hypothesis has been synthesized considering the barriers to the implementation of GSCM in mind. Each major barrier found by the literature gives augmentation to each hypothesis as follows:

H1: Lack of top management support has a positive relationship with GSCM and they hinder in GSCM practices.

H2: Inability or unwillingness to share information has a positive relationship with GSCM and they hinder in GSCM practices.

H3: Inability or unwillingness to share risk and rewards has a positive relationship with GSCM and they hinder in GSCM practices.

H4: Inflexible organizational system and processes has a positive relationship with GSCM and they hinder in GSCM practices.

H5: Communication gap between management and shop floor workers has a positive relationship with GSCM and they hinder in GSCM practices.

H6: Unawareness of customers has a positive relationship with GSCM and they hinder in GSCM practices.

H7: Lack of training of workshop floor workers has a positive relationship with GSCM and they hinder in GSCM practices.

H8: Incapable of achieving the exact design standard has a positive relationship with GSCM and they hinder in GSCM practices.

H9: Lack of financial supports has a positive relationship with GSCM and they hinder in GSCM practices.

H10: Cost implications have a positive relationship with GSCM and they hinder in GSCM practices.

H11: High initial capital cost has a positive relationship with GSCM and they hinder in GSCM practices.

H12: High cost in managing hazardous wastes has a positive relationship with GSCM and they hinder in GSCM practices.

H13: Administrative and financial burden of tax has a positive relationship with GSCM and they hinder in GSCM practices.

H14: Market competition and uncertainty have a positive relationship with GSCM and they hinder in GSCM practices.

H15: Market lack of government support systems has a positive relationship with GSCM and they hinder in GSCM practices.

H16: Lack of demand for GSCM has a positive relationship with GSCM and they hinder in GSCM practices.

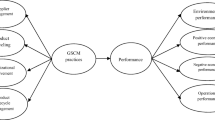

Then, for importance and the scale of each measure, the factor loading of each measure on GSCM is verified, irrespective of the sign will give the influence of that barrier of GSCM. These values are used for arriving at the relative weight of attributes. To bring out the above process, the SEM model with LISREL symbolization can be established by assuming the connection between the observed variables and their underlying factors. Using LISREL notations, the hypothesized conceptual models are presented.

We can summarize its configuration by writing the series of Equations/statements.

The equations for model factor structure are as:

And vector form of the above equations can be written as:

Also, summarization of the above lower-order structure can be:

where model factor loadings are \(\Lambda\) the and error terms measurement is ε; thus, relative influence or weight of attributes on barriers can be established by SEM.

The achieved results from LISREL for the model are depicted in Fig. 2

4 Results and Discussion

According to the results obtained from the model demonstrates optimistic values for the entire path coefficient; at p < 0.05, all the t-values of the variables are statistically important. Thus, according to Table 2, the structural model supports all the 16 hypotheses of the projected model. The influence of all the listed barriers for GSCM has been proved by hypotheses H1, H2, H3, H4, H5, H6, H7, H8, H9, H10, H11, H12, H13, H14, H15 and H16. So, the projected model explicated a substantial percentage of variance in the barriers of GSCM. Thus, the SEM model confirms the consistency of the proposed model and achieves an acceptable level.

5 Conclusion

In the research, SEM approaches were proposed to implement green SC in the Indian rubber industry. This research is focused on the empirical validation of a real working environment using the SEM approach. SEM examines a set of associations between one or more independent variables (IV) and one or more dependent variables (DV). Here, a model is presented for which all the barriers are validated using SEM. This model validated the hypothesis made for the barriers, and it gives the right path for the industries to work on. The Cronbach’s alpha value demonstrates the reliability standard, which is greater than 0.96 for all criteria.

6 Managerial Implications

Researchers are confronted to provide a guide for selecting the technique that is both theoretically well originated and almost operational to crack the real problems. Result obtained shows that the barriers are hindering the supply chain performance for rubber industries. Suggested framework provides the barriers which are influencing the GSCM practices. This research provides an in-depth study of barriers and their implication on supply chain performance. Managers and decision makers are required to implement GSCM keeping the above-mentioned barriers in mind.

References

Hall, J.: Environmental supply chain dynamics. J. Cleaner Prod. 8(1), 455–471 (2000)

Kelle, P., Silver, E.A.: Forecasting the returns of reusable containers. J. Oper. Manage. 8(1), 17–35 (1989)

Rao, P.: Greening of the supply chain: an empirical study for SME’s in the Philippine context. J. Asia Bus. Stud. 1(2), 55–66 (2007)

Tyagi, M., Kumar, P., Kumar, D.: Modeling and analysis of barriers for supply chain performance measurement system. Int. J. Oper. Res. 28(3), 392–414 (2017)

Srivastava, S.K.: Green supply-chain management: a state-of-the-art literature review. Int. J. Manage. Rev. 9(1), 53–80 (2007)

Kumar, D., Jain, S., Tyagi, M., Kumar, P: Quantitative assessment of mutual relationship of issues experienced in greening supply chain using ISM-fuzzy MICMAC approach. Int. J. Logistics Syst. Manage. 30(2), 162–178 (2018)

Zhu, Q., Sarkis, J.: Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manage. 22, 150–159 (2004)

Jiang, X., Mahadevan, S., Urbina, A.: Bayesian nonlinear structural equation modeling for hierarchical validation of dynamical systems. Mechan. Syst. Signal Proces. 24(4), 957–975 (2010)

Luthra, S., Kumar, V., Kumar, S., Haleem, A.: Barriers to implement green supply chain management in the automobile industry using interpretive structural modeling technique—an Indian perspective. J. Indus. Eng. Manage. 4(2), 231–257 (2011)

Tyagi, M., Kumar, P., Kumar, D.: Analysis of interaction among the drivers of green supply chain management. Int. J. Bus. Perform. Supply Chain Model. 7(1), 92–108 (2015)

Chen, Y.-S., Lai, S.-B., Wen, C.-T.: The influence of green innovation performance on corporate advantage in Taiwan. J. Bus. Ethics, 67(4), 331–339 (2006)

Roarty, M.: Greening business in a market economy. Eur. Bus. Rev. 97(5), 244–254 (1997)

Jose, P.D.: Getting serious about green. Real CIO World 3(8), 26–28 (2008)

Sharma, S.: Managerial interpretations and organizational context as predictors of corporate choice of environmental strategy. Acad. Manag. J. 43(4), 681–697 (2000)

Klassen, R.D., Whybark, D.C.: The impact of environmental technologies on manufacturing performance. Acad. Manag. J. 42, 599–615 (1999)

Ravi, V., Shankar, R.: Analysis of interactions among the barriers of reverse logistics. Technol. Forecast. Soc. Chang. 72, 1011–1029 (2005)

Zhu, Q., Sarkis, J., Geng, Y.: Green supply chain management in China: pressures, practices, and performance. Int. J. Oper. Prod. Manage. 25(5–6), 449–468 (2008)

Lin, Y., Hills, P., Welford, R.: Extended producer responsibility and eco-design changes: perspectives from China. Corporate Soc. Respons. Environ. Manage. 15, 111–124 (2008)

Hosseini, A.: Identification of green management of system’s factors—a conceptualized model. Int. J. Manage. Sci. Eng. Manage. 2(3), 221–228 (2007)

Mudgal, R.K., Shankar, R., Talib, P., Raj, T.: Greening the supply chain practices: an Indian perspective of enablers’ relationship. Int. J. Adv. Oper. Manage. 2(3), 151–176 (2009)

Mudgal, R.K., Shankar, R., Talib, P., Raj, T.: Modeling the barriers of green supply chain practices: An Indian perspective. Int. J. Logist. Syst. Manage. 7(1), 81–107 (2010)

Tyagi, M., Kumar, D., Kumar, P.: Assessment of CSR based supply chain performance system using an integrated fuzzy AHP-TOPSIS approach. Int. J. Logist. Res. Appl. 21(4), 378–406 (2018)

Lamming, R., Hamapson, J.: The environmental as a supply chain management issue. Br. J. Manage. 7(Special Issue), 45–62 (1996)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Agarwal, S., Tyagi, M., Garg, R.K. (2021). Assessment of Barriers of Green Supply Chain Management Using Structural Equation Modeling. In: Muzammil, M., Chandra, A., Kankar, P.K., Kumar, H. (eds) Recent Advances in Mechanical Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-8704-7_55

Download citation

DOI: https://doi.org/10.1007/978-981-15-8704-7_55

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-8703-0

Online ISBN: 978-981-15-8704-7

eBook Packages: EngineeringEngineering (R0)