Abstract

Water is one of the crucial components for the existence of life on our planet. This gift of nature has several usages and applications. One can see a clear implication of water availability on industries, civilization, livelihood, etc. Though a plethora of water is available, however, not all of it is of direct use; only 2.6% of total available water is freshwater and of that only 1% is in human reach. Unfortunately, that little amount is also prone to several impurities, mainly because of human activities. Indian ministry of water resources, United Nations, UNICEF and several other organizations reported on the ignorance of environmental norms pertaining to water discharge by many industries and organizations. All such ignorance somehow enhances water scarcity. The investigation of active solar desalination system working in dynamic mode is one of the best considerations to lessen the water scarcity problem. This work focuses on energy metrics scrutiny of basin type double slope active solar desalination systems, and these solar desalination systems have been judged against each other on the grounds of energy metrics.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The reducing figures for availability of water can be seen through the data regarding the parameter of annual per capita of water availability. A decrement of 6042–1545 m3 within a time phase of 1947–2011 has been found; recent surveys show that this data will keep on decreasing and will approximately reach a figure of 1140 m3 by the end of year 2050 [1]. All these data suggest nothing but a huge threat of freshwater scarcity which our world will face in the upcoming years. So, to counter these problems, researchers have come across several technologies, but most of them are based on conventional sources of energy and are very energy intensive. Solar distillation is one of the best alternatives as it requires less energy and is based on renewable sources of energy which makes it eco-friendly. In order to make this system better and better and to enhance its performance, researchers have come up with several different designs. Zaki et al. [2] were the first ones to report on the dynamic behavior of the solar still under natural circulating conditions. Rai and Tiwari [3] and several other researchers have proved that by integrating several other external devices to the still in order to design an active still by manipulating the parameter of temperature difference between condensing glass and vapor. So, after coming across such several designs of solar stills, it is very crucial to have examining criteria so as to judge these different designs and compare them on different grounds. So, the aim of this paper is to compare double slope active state solar desalination system coupled with different collectors like flat plate collector (FPC), compound parabolic concentrator collector (CPC) and evacuated tubular collector (ETC) on the ground of energy matrices for generating an insight regarding comparative performance of various assemblies.

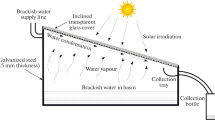

2 Active State Solar Still

In order to produce freshwater from brackish/saline water, a simple natural phenomenon of hydrological cycle (a basic principle working behind rainfall) is being used by several man-made desalination systems. Producing freshwater from saline water involves removal of salts and unwanted material from it which requires energy [4]. Heat as a form of energy is being supplied to a brackish or saline water in order to attain a phase change of that saline water so as to gain freshwater. Active state solar still is nothing but an idea to boost the performance of solar desalination system by supplying additional heat using collectors so that rate of evaporation can be enhanced and hence enhanced freshwater production. Under forced circulation, water is pumped by a DC motor assembled in the system so as to overcome the pressure drop and maintain an optimum flow. Thus, by maintaining the flow, the temperature of the water rises, and in turn, it gives rise to the difference in temperature between condensing glass cover and water surface. As temperature difference acts as a potential for heat flow, with the enhancement in temperature difference, heat transfer between water surface and glass cover rises which helps the assembly to generate distillate at a faster rate. In the case of active solar desalination system, collectors receive solar energy from sun and provide heat to the circulating water so as to enhance its temperature. Besides solar collectors, several other external sources could be utilized like heat exchangers, fins, nanoparticles, etc. Energy received by solar collectors could be utilized by PV module, if photovoltaic (PV) module gets mounted on the collectors. This PV module can in turn convert the energy obtained from solar intensity impinging on the surface into high-grade energy. Thus, direct current (DC) motor rather than to take power from the grid could utilize this electrical energy generated from solar energy by PV module. This idea of PV module was first represented by Kern and Russel [5]. His idea helped this technology to attain a tag of self-sustained machine.

2.1 Active State Double Slope Solar Desalination Unit Attached with Series Connected N Alike PVT-CPC Collectors (Case (i))

CPC is a solar water collector which is integrated into the assembly of solar still in order to provide heat to the circulating water. Impure water present in the basin of the still is allowed to circulate throughout the assembly, by the virtue of DC motor in this case. When impure water enters CPC during circulation throughout the assembly, it gains some heat from the collector. Now, the end of the collector is connected to the entry of the basin, so after gaining the heat from collector, water again joins the basin and gives the effect of rise in the temperature of basin water. The design of the CPC water collectors was presented by Renold Winston and was further developed by Watter Welford by the 1970s. CPCs are able to focus a wider region of the sky on the surface of receiver and do not require much tracking and thus are enormously attractive in nature. Atheaya et al. [6] proposed the design of the integration of CPC with PV module. There are several ways to arrange PV module on the CPC collector; different arrangements are required for different requirements of operation. PV module can cover the surface of the collector either fully or partially. In partially covered arrangements, percentage coverage of PV module on the collector could also vary like 25, 50%, etc. An appreciable amount of work was done by Tripathi et al. in analyzing such arrangements and gave a conclusion that the water temperature can be increased by connecting the N-photovoltaic thermal (PVT) CPC in series [7]. The idea of coupling series connected N-PVT-CPCs with basin type double slope solar desalination unit shown in Fig. 1 was given by Singh and Tiwari [8]. The outlet of the solar desalination unit is connected to the inlet of the 1st PVT-CPC collector, so, by the virtue of DC motor driven by the PV module, water gets circulated and after leaving the basin, it first enters the 1st collector. There, it collects heat from collector and then leaves to enter the 2nd collector as the outlet of 1st collector is attached to the inlet of the 2nd collector. The inlet and outlet of the collectors are connected in this manner because the whole PVT-CPC collectors are arranged in series so as to maximize the basin water temperature. So after gaining heat from all the collectors of the series, water returns back to the basin with an increased temperature. When it joins the water present in the basin, then a thermal equilibrium gets created which in turn enhances basin water temperature. All the necessary measures are taken so as to minimize the heat loss and vapor loss. A layer of glass wool having 0.01 m thickness is applied at the bottom and side of the basin, absorbers are provided and pipes get insulated to ensure that heat loss must be minimized. To ensure the receiving of maximum annual solar radiation, an inclination of 30° with the horizontal is provided to the PVT-CPC collectors. The transparent glass which acts as a condensation base and glazing for the still is also provided an inclination of 15° to maximize effective area. Receiver area of the collector is half the aperture area. Basin is also painted with black color so as to absorb the heat and then transfer the heat to water. A hole is also provided at the bottom of the still for cleaning the basin. So after gaining a maximum temperature, water gets evaporated and converted into vapor. This vapor then rises up and strikes the glass cover. Because of the temperature difference between vapor and glass cover, vapor gets condensed after releasing its latent heat. This condensate is now the potable water which we call distillate. This distillate then drops down to the container present on the sideline.

Double slope solar desalination unit integrated with N alike PVT-CPCs [8]

2.2 Active State Double Slope Solar Desalination Unit Attached with Series Connected N Alike PVT Flat Plate Collectors (NPVTFPCs) (Case (ii))

Just like CPC, FPC is also a solar water collector which is integrated into the solar still in order to provide heat to the circulating water. If parabolic surface is removed from CPC, the collector becomes FPC as shown in Fig. 2. There is not much of a difference between the still integrated with CPC and still integrated with FPC regarding the working. Usually, solar collectors are arranged in parallel to obtain higher amount of fluid per unit time at lower temperatures and are arranged in series to obtain low amount of fluid per unit time at high temperature. Here, the collectors are connected in series so as to gain low discharge at high temperature. All the specifications regarding different components of the still and collector are encountered exhaustively in Singh et al. [9]. Just like in the still integrated with CPC, here also the water gathers the heat by circulating (by the virtue of DC motor driven by electrical energy from PV module) through the collectors which are connected in series and returns back to the basin to increase the temperature of the water. All boundaries and gaps are sealed; pipes were made insulated so as to minimize heat loss and vapor loss. Collectors are kept in such a way that it faces south, and an inclination of 30° is provided to them with respect to horizontal. Solar desalination unit is also kept in such a way that it is oriented along east–west. It is done to maximize the incident solar intensity. A layer of black paint is provided inside surface of the basin to absorb the heat and then transfer that heat to the water present in the basin so as to enhance its temperature. After all such efforts, water gets evaporated and its vapor then loses its latent heat to condense and form the distillate. This distillate then gets drops down in the container placed on the sidelines of the still. Singh et al. [9] studied experimentally double slope solar desalination system integrated with two collectors in which some portion of only one collector was covered with PV panel to generate self-sustainability in the system. This system is illustrated in Figs. 2 and 3.

Setup of double slope solar desalination unit integrated with two FPCs [9]

Double slope solar desalination unit integrated with N-ETCs [10]

2.3 Active State Double Slope Solar Desalination Unit Integrated with Series Connected N-ETCs (Case (iii))

Here, in this assembly shown in Fig. 3, the proposed system has a solar desalination unit coupled to N alike ETCs arranged in series. A series assembly is preferred here so as to obtain high basin water temperature rather than a parallel assembly. Each ETC is comprised of an inner copper tube and an outer evacuated co-axial tube. The outer evacuated co-axial tube is comprised of two glass tubes, in between of which a vacuum space is created. This vacuum space is created just to drop down the ways of heat transfer to radiation only, as conduction and convection cannot take place without medium. Water flows through the inner tube of the ETC. All the specifications regarding different components of ETC and still are given by Singh and Al-Helal [10]. As these ETCs are connected in series, inlet of one ETC is connected to the outlet of its previous ETC in the series. Inlet of the first ETC of the series is connected with the outlet of the basin from where the water circulates to the whole system by virtue of a DC motor which could be powered by either the gird or the PV modules. Rest of the working is same as that of the previous stills discussed above.

3 Energy Metrics

Energy matrices are the analysis parameters to give us the performance of the technology and help us to judge the technology on the grounds of its uniqueness or its drawbacks etc. It is a very prudent aspect regarding all the technologies especially the one which is based on renewable energy. The technology is of no use if the amount of energy/exergy generated by that technology during its lifetime is less than that of its embodied energy (energy/exergy which is being used to develop that technology). Energy metrics consist of several analytical parameters like energy payback time (ET), energy production factor (EP) and life cycle conversion efficiency (LCCE). These factors represent nothing but a comparison between energy required for manufacturing the whole setup and energy produced by that setup, which in turn become the determining factor of the technological and economical success of that particular setup [11]. Embodied energy is the total (direct or indirect) energy which is consumed for generating an element or set up. As a better economic approach, whether the study is being on theoretical or experimental grounds, the embodied energy and payback time should be as low as possible. To keep this payback time low, PVT modules, water pumps, etc. are used for enhancing the performance by better heat transfer.

3.1 Energy Payback Time (ET)

This parameter is mathematically expressed as the ratio of the embodied energy (EBE) to annual energy output (AO), so as to compare both of them with respect to each other. This parameter represents the period of time required by the setup in order to return that much amount of energy which is being consumed to generate that setup (embodied energy). The net annual energy output is being represented by the addition of net thermal energy output and net thermal energy which is equivalent to the electrical energy output by PV module. Equation (1) represents the total energy output of distillation unit.

here ‘(Pm − Pu)’ represents the net annual electrical energy output by PV module. For converting this high-grade energy into low-grade energy, i.e., thermal energy, it is being divided by 0.38 [12]. Mathematically, Eq. (2) represents energy payback time with respect to energy (ET(e)) and Eq. (3) represents (energy payback time with respect to exergy (ET(ex)).

3.2 Energy Production Factor (EP)

The inclusive performance of a solar distillation system is being represented by the virtue of an energy metrics parameter, i.e., EP. Mathematically, EP is nothing but the reciprocal of ET. So, we can conclude that EP is inversely proportional to ET. As we have discussed, a better system has a lower ET. Thus, for a better performance of solar stills on both economic and technological ground the value of EP must be higher. Equations (4) and (5) represent EP on the basis of energy and exergy respectively for active solar distillation units [11].

here AXO stands for the exergy output in a year.

3.3 Life Cycle Conversion Efficiency (LCCE)

This energy metrics parameter represents how efficient the system is in converting the input of solar energy into the net output energy throughout its lifetime period. Higher the efficiency of the system, higher will be the capability of the system to get maximum output energy from the input energy. Ideal LCCE value of the system should be unity, i.e., an ideal system possesses the capability to convert the total input energy into output energy. Idea of LCCE parameter was given by Tiwari and Mishra [11]. Mathematically, Eqs. (6) and (7) represent LCCE on the grounds of energy and exergy, respectively.

93% of the total annual solar energy represents annual solar exergy, and this concept was given by Petela [13]. Here, n stands for life of the system, and AS stands for solar energy in a year.

4 Discussions

The variation of energy metrics for different systems is shown in Fig. 4. From Fig. 4, it is seen that the energy payback time on the ground of energy as well as exergy is minimum for case (iii). The main reason its occurrence was found to be contributed by the lack of presence of convection loss in the case of ETC which in turn happens due to the presence of vacuum between tubes which result in higher energy as well as exergy output and hence lower ET. Life cycle conversion efficiency is far away dissimilar from the efficiency. The evaluation of LCCE takes into consideration the whole life of the solar desalination system under study. The value of LCCE on the basis of energy as well as exergy is highest for case (iii) due to the fact the lower losses occur in the case of ETC due to the absence of loss through convective heat transfer mode.

5 Conclusions

The comparative study of active double slope solar desalination systems has been conducted on the ground of energy metrics. From the present study, one can conclude that ET on the ground of exergy as well as energy is minimum for case (iii) followed by cases (ii) and (i) in succession. The life cycle conversion efficiency on the ground of energy as well as exergy is uppermost regarding case (iii) followed by cases (ii) and (i) in succession.

6 Recommendations

The theoretical scrutiny of double slope solar desalination system integrated with N alike collectors under optimized condition has been conducted. They have not been validated experimentally. So, one should validate the result experimentally before installing it on commercial level.

References

UNICEF-WHO (2015) Progress on sanitation and drinking water. Update and MDG assessment, pp 1–90

Zaki GM, Dali TEl, Shafie HEl (1983) Improved performance of solar still. In: Proceedings of the first Arab international solar energy conference, Kuwait, pp 331–335

Rai SN, Tiwari GN (1983) Single basin solar still coupled with flat plate collector. Energy Convers Manage 23(3):145–149

Mohameed QH, Fawzi B (2008) Solar thermal desalination technologies. Desalination 220:633–644

Kern EC, Russell MC (1978) Combined photovoltaic and thermal hybrid collector systems. In: Proceedings of the 13th IEEE photovoltaic specialists, 5–8 June 1978, Washington DC, USA, pp 1153–1157

Atheaya D, Tiwari A, Tiwari GN, Al-Helal IM (2015) Analytical characteristic equation for partially covered photovoltaic thermal (PVT) – compound parabolic concentrator (CPC). Sol Energy 111:176–185

Tripathi R, Tiwari GN, Al-Helal IM (2016) Thermal modelling of N partially covered photovoltaic thermal (PVT) - compound parabolic concentrator (CPC) collectors connected in series. Sol Energy 123:174–184

Singh DB, Tiwari GN (2016) Effect of energy matrices on life cycle cost analysis of partially covered photovoltaic compound parabolic concentrator collector active solar distillation system. Desalination 397:75–91

Singh G, Kumar S, Tiwari GN (2011) Design, fabrication and performance of a hybrid photovoltaic/thermal (PVT) double slope active solar still. Desalination 277:399–406

Singh DB, Al-Helal IM (2018) Energy metrics analysis of N identical evacuated tubular collectors integrated double slope solar still. Desalination 432:10–22

Tiwari GN, Mishra RK (2012) Advanced renewable energy sources. Royal Society of Chemistry Publishing House, UK. ISBN 978-1-84973-380-9

Huang BJ, Lin TH, Hung WC, Sun FS (2001) Performance evaluation of solar photovoltaic/thermal systems. Sol Energy 70(5):443–448

Petela R (2003) Exergy of undiluted thermal radiation. Sol Energy 86:241–247

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sharma, A., Dwivedi, V.K., Singh, D.B. (2020). Comparative Study of Basin Type Double Slope Active Solar Stills Based on Energy Metrics. In: Kumar, H., Jain, P. (eds) Recent Advances in Mechanical Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-1071-7_54

Download citation

DOI: https://doi.org/10.1007/978-981-15-1071-7_54

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-1070-0

Online ISBN: 978-981-15-1071-7

eBook Packages: EngineeringEngineering (R0)