Abstract

The investigation and development of micro/nano biosytem requires a sealed fluidic platform to separate, mix or control the flow of liquids and bio samples as well as a biochemical surface processing to selectively capture or repel biospecies. The first part of this chapter reviews the main techniques used for the fabrication of microchannels, reservoirs, pillars,… in various substrate materials. This includes direct machining techniques such as mechanical cutting, lithography and electroforming, as well as various replication techniques such as PDMS or UV curable resin casting, hot embossing and overall injection molding that is compatible with mass production. The second part describes the recent advances in the development of functionalized surfaces and their applications in biochips. First a focus is put on bioreceptors immobilization and a brief presentation of bioreceptors (antibodies and aptamers) is included. Next the polymers employed against plasmatic proteins fouling are reviewed and finally the surface chemistry preventing bacteria attachment is presented. The two approaches leading to bacteria repelling or killing, depending on the polymers employed, is discussed. The last chapter part is devoted to a critical analysis of bonding and welding techniques proposed to seal fluidic platforms.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Microfabrication

- Machining processes

- Microfluidics platforms

- Bacteria

- Proteins

- Antifouling

- Self-assembled monolayers

3.1 Introduction

Basically, the full fabrication of micro/nano biosystems requires the mastering of three main steps which are covered in this chapter: manufacturing of the micro/nano fluidics system with its internal elements, surface biofunctionnalization to selectively capture or prevent attachment of biospecies, and packaging to seal and protect the fluidic system. These three steps are not necessarily consecutive and additional processing steps are often required for fluidic connections and, in fully integrated systems, for fluid injection with micropumps, for fluid control with microvalves and for sensors integration. The different types of microvalves and micropumps will be described in the first part of Chap. 4 and sensing/actuation techniques by mechanical, optical, electrical and magnetical ways are detailed in the following chapters of this book.

The choice of fabrication and surface functionalization technologies depends on many factors such as the substrate material used (polymer, glass, silicon, paper,…), the targeted application and its environment (ex vivo, in vivo, in vitro), the level of integration and of autonomy (portable systems), the technology readiness level (going from basic principles to real application product), the targeted cost, the need or not to get a disposable, re-usable, biocompatible and/or biodegradable system, etc.… Consequently, a very broad range of techniques have been developed and will be developed in the future for the micro/nanofabrication and biofunctionnalization of micro/nano biosystems. An exhaustive description is impractical but this chapter provides a critical analysis and a description of recent advances for a large selection of them.

Concerning microfabrication, this chapter will describe the main direct machining and replication techniques, their issues and some solutions. The subchapter on biofunctionnalization will first present bioreceptors and their immobilization on a surface, will then review polymers for plasmatic proteins fouling and will finally present surface chemistry that can be used to repel or kill bacteria. The last part of this chapter will discuss the different bonding or welding techniques that can be applied to the sealing of fluidic devices.

3.2 Micro/Nano Fabrication for Fluidic Devices (Yeong-Eun Yoo)

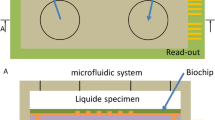

Nano or micro-fluidic platform for bio-chip or lab-on-a-chip consists of various fluidic elements such as channels, pillars, reservoirs, etc. in nano or micro-scale for separation, mixing, or controlling the flow of the samples. The various functions and performance of these micro-fluidic devices are determined significantly by the characteristics of the fluidic elements. Therefore, it is important to fabricate the various micro/nano structures on the fluidic platform for bio-chip or lab-on-a-chip.

As shown in Fig. 3.1, a basic fluidic platform can simply be thought of as having two parts: a plate with fluidic elements on the surface (a fluidic plate) and a plate to cover the fluidic plate (a cover plate). It may not often be clear to distinguish the fluidic plate from the cover plate, because both can have fluidic elements depending on the design of the device, or it may consist of several elements (Fig. 3.2).

The fabrication processes for micro/nano fluidic elements can be generally grouped into either direct machining of the structures on a workpiece or replicating the structures from a previously fabricated template.

The direct machining process includes mechanical cutting or forming, laser machining and chemical etching along with UV lithography for materials such as metal, silicon, glass, plastic or ceramic depending on the process. Replication processes include the following: (1) casting process using thermoset resins like PDMS or UV curable resins like photo-resist, (2) hot embossing process on thermoplastic substrate, (3) injection molding using thermoplastic materials such as COC (cyclic olefin copolymer), PMMA (polymethylmethacrylate) or PC (polycarbonate). All these replication processes can fabricate the same structures or devices repeatedly.

3.2.1 Direct Machining Process for Nano/Micro Fluidic Device

The direct machining process may be efficient to see the feasibility of the fluidic system at the early stage of development from the view point of the cost or lead time etc. because there is no need on replication process which requires additional tooling, casting, embossing or molding process. Depending on the shape and size of the structure, the area for process, the material of the workpiece, etc., various direct machining processes are currently available for micro/nano structures and one of them can be applied. In this chapter, several direct machining processes will be reviewed briefly for fabrication of micro/nano structures.

3.2.1.1 Mechanical Cutting Process

Micro-shaping and micro-milling are representative mechanical cutting processes for machining micro-structures. Micro-shaping is efficient to machine micro-groove type of structures straight or circularly by reciprocation or turning of cutting tool or workpiece (Fig. 3.3). The groove can be machined to be order of 1 µm both in width and depth while the ridge between grooves can be machined in order of 1 µm in width, but tens of microns in depth depending on the shape of the groove. Although the micro-shaping is very efficient process for micro-groove, it is generally not available for the fluidic channel-like structures of irregular shape or path as shown in Fig. 3.4.

A schematic for shaping of micro-groove with cutting tool (left) and a photo of micro diamond cutting tool [3] (with permission of Springer)

Images of fluidic channel in irregular shape or path [4] (with permission of Elsevier)

The fluidic channel of irregular shape or path not straight as in Fig. 3.4 can be machined through micro-milling process using a rotating cutting tool (Fig. 3.5), which is available to cut the channel-type structures as small as several tens of micrometer or embossed structures even in order of few micrometers [5, 6].

Photos for a micro-milling process b a micro-channel machined by micro-milling [7] (with permisiion of Creative Commons)

Micro-milling depends on cutting speed or spindle speed, feed rate, depth of cut etc. as process parameters. The quality of the surface and surface structures micro-milled is also affected by tool design (Fig. 3.6) such as cutting-edge radius, rake angle, helix angle of the flute, number of flute, etc. The optimal conditions on process or tool may be quite different for the micro-milling process due to reduced mechanical stiffness of the micro-milling tool, comparable size of the cutting-edge radius or grain of the workpiece material to the depth-of-cut, etc. Extensive researches on micro-milling have been reported [7,8,9,10,11,12,13,14]. In terms of the dimension of structure to be machined, the mechanical machining may be limited by the size of the cutting tool. Some commercial micro-milling cutting tools are available currently around 25 µm, therefore the fluidic channel less than 25 µm approximately is hard to machine directly on the device. The limit of the dimension of surface structure, however, may become smaller for embossed or positive surface structures if the cutting area is larger than the cutting tool (Fig. 3.7). The positive surface structures on the workpiece as in Fig. 3.7b may be damaged by the interaction with the cutting tool [5, 6]. This may limit the dimension of the embossed surface structures to be machined. Fluidic channels smaller than the machining limit can be fabricated by replicating the surface structures using polymeric resin based on the embossed surface structures machined on a workpiece.

Mechanical machining process can be used for various materials such as brass, copper, carbon steel or plastic. One of the advantages of the mechanical machining process is that it can machine various surface structures directly on durable materials like metal, which is crucial to mass production of polymeric device by replication process such as injection molding. Also using the mechanical cutting process, the cross-section of the structures can be designed to have more diverse shapes or wider range of slope for the vertical wall. Moreover, the vertical wall of structure machined mechanically has generally positive slope, which is an advantage for easy releasing of the replica during the replication process (Fig. 3.8).

3.2.1.2 UV Lithography

Based on the reaction of the photo-resist(PR) when exposed to the UV light or E-beam, the PR layer coated on silicon or glass substrate can be patterned intrinsically by UV light exposure through a pattern mask or direct writing of E-beam. The smooth PR layer turns into a structured layer with channels, pillars or chambers etc. by a developing process through which the PR is removed as patterned. Depending on the PR type, negative or positive, the PR is removed from different region (Fig. 3.9). For negative PR, the exposed region remains through the developing process because the negative PR becomes more stable by cross-linking reaction when being exposed to UV light or e-beam. For the positive PR, the exposed region is removed after developing due to the degradation during exposure. A transition region exists between the exposed and unexposed region due to chemical diffusion, optical diffraction or reflection, etc. The minimum dimension of the structure fabricated depends on the size of the transition region, which is determined by contrast of the photo-resist. The surface structures obtained after developing process can be used as a barrier layer to etch surface structures selectively on silicon or glass substrate, etc., a platform for fluidic device or a master to fabricate Ni-stamper used for injection molding.

Dry or wet etching process can be applied to fabricate the structures on the hard materials such as silicon, glass or metal using the PR pattern as a barrier. The cross-sectional shape of the structure is determined by the anisotropy of the process and material. As shown in Fig. 3.10, through wet etching of Si-wafer using a barrier layer with a square opening in several micrometers, the Si-wafer is etched to have a negative pyramid in order of micrometers with 70° of slope approximately rather than being etched into hemispherical structure due to the anisotropic crystal direction. The dry etching is an anisotropic process because a reactive gas impinges generally in normal direction to the substrate, so a highly anisotropic structure like deep channel or hole with straight vertical wall can be fabricated (Fig. 3.11).

Although the surface structures may be fabricated directly on a device itself via the processes mentioned above, they can also be fabricated with additional processes on a master or template to replicate the structures repeatedly using polymeric materials. The Figs. 3.12 and 3.13 show one of processes for fabricating Ni stamper which is a typical durable nano/micro pattern template for injection molding. A PR master is fabricated first via UV lithography process using either of positive PR or negative PR and then Ni stamp is fabricated using nickel electroforming process explained in next section. From the viewpoint of the injection molding, the slop of side wall of the surface structure like channel is important because it affects greatly the productivity of the injection molding process or it even determines whether the structure can be injection molded or not. The channel of the PR master may have negative or positive slope of vertical wall depending on the PR type and the conditions for exposure to UV light because the PR is affected differently along the thickness direction due to the decrease of the UV light intensity, the diffusion of cross-link initiator, light scattering in the PR layer or reflection of the light on the substrate [15]. For example, the wider exposure along the depth due to reflection or scattering of the UV light at the bottom of the PR layer may cause negative slope of side wall with wider channel at the bottom. The negative slope of side wall may cause little issue for device itself. For master or stamp for replication, however, the negative slope results in severe failure during the fabrication due to locking on the stamper of the replica. The channel on the silicon or the glass substrate fabricated by dry etching may also have same negative slope of the side wall (Fig. 3.14). In addition to this, the dry-etched side wall has undulation in the depth direction and this undulation can also cause releasing issue of replica from the master or stamper (Fig. 3.14).

3.2.1.3 Ni Electroforming Process

The pattern master fabricated on silicon or glass wafer cannot be directly used for injection molding process due to the high pressure (higher than tens of MPa) and high temperature (higher than 200 °C) during the injection molding process. Nickel electroplating using a silicon, glass or PR pattern master is a process to fabricate a durable master (called Ni-stamper) for nano/micro surface structures which generally cannot machined directly on a metal workpiece. Ni-electroforming is a process depositing nickel layer on the pattern master by redox reaction. As in Fig. 3.15, the pattern master, as a cathode, coated with conductive seed layer typically over 100 nm of thickness and a nickel anode are dipped in electrolyte. Then Ni layer starts to grow on the pattern master by redox reaction and replicate pattern from the master. Ni layer can grow until it reaches the target thickness generally between 0.3 and 1.0 mm for sufficient stiffness during the injection molding process.

3.2.2 Fabrication the Fluidic Device Using Replication Process

For mass production or multiple fabrication of the nano or micro fluidic device, a replication process like casting or molding using polymeric material are required. Three types of polymeric materials including thermoplastic, thermoset and UV curable resin can be used for fabrication of the fluidic device based on replication process. Depending on these materials, several replication processes can be used such as PDMS casting, UV curable resin casting, hot embossing or injection molding using thermoplastic resin. In this chapter, these casting, embossing and injection molding processes are reviewed

3.2.2.1 PDMS(Polydimethylsiloxane) Casting

PDMS is in liquid phase with low viscosity at room temperature, but it starts to solidify when being mixed with curing agent and the temperature is raised. PDMS is a material most widely used to fabricate a micro-fluidic device due to its low viscosity, low surface energy, good elasticity and very simple casting process. As shown in Fig. 3.16, the casting process with PDMS consists of mixing PDMS and curing agents, eliminating bubble, coating, curing and releasing the PDMS replica from the pattern master [16, 17]. The casting process can be done with ease in a laboratory without any complicate apparatus or process expert. Due to its low viscosity in liquid state and good elasticity in solid state, PDMS can fill the micro-structures well in the coating process and be released easily after being cured from the template. Moreover, the PDMS is excellent for sealing the fluidic channel of the device due to its good adhesion to many materials such as silicon, glass or plastic after oxygen plasma treatment which results in increasing of free radicals on the surface [18]. Also, it is convenient to apply interconnection port or tube for sample delivery or interfacing with other device because it is easy to punch a hole out or insert a port into the PDMS substrate [19,20,21,22].

As mentioned in this section, the PDMS casting process has many merits for micro-fluidic device fabrication at an early stage of development in laboratory. This casting process using PDMS, however, is only for fabrication of small number of device due to its poor productivity, durability or reproducibility, etc. The PDMS casting process requires quite long cycle time, typically longer than tens of minute. In addition, The PDMS replica tends to deform easily due to its low mechanical modulus and has less dimensional accuracy due to its relatively large shrinkage rate during the curing process.

3.2.2.2 UV Curable Resin Casting

UV curable resin can also be used for replicating the nano or micro-structures with supporting substrate. In terms of replication of nano or micro-structures and productivity, UV curable resin may have a good potential because it fills the structures easily due to its low viscosity and is cured very quickly when being exposed to UV light. A casting process may consist of resin coating on a transparent plastic film or substrate, embossing the structures using pattern master, curing by UV exposure and releasing from the master (Fig. 3.17). As an alternative process, the UV curable resin can be coated on the pattern master first and a transparent film or plate is laminated on the coated layer followed by curing and releasing. For replication of micro/nano structures, at least, one of the structures master or the substrate for pattern layer of the replica should be transparent to the UV light for curing the resin.

3.2.2.3 Hot Embossing

The hot embossing is a process that replicates nano or micro-structures from the master to thermoplastic substrate by heating the substrate over glass transition temperature (Tg), pressing, cooling and releasing (Fig. 3.18). The hot embossing process has a good potential for replicating high-aspect-ratio of nano or micro-structures precisely on a plastic substrate [23, 24]. The drawback of the hot embossing process is its low productivity due to the long cycle time over tens of minutes for heating and cooling mostly. The poor productivity of the hot embossing process refrains this process from being used for the device requires a large scale of production.

3.2.2.4 Injection Molding

As the demand for mass production of the devices employing micro/nano structure increases, those devices are needed to be manufactured by injection molding process. The injection molding is a representative mass production process for plastics due to its excellent productivity with very short cycle time typically less than a minute or even several seconds for some commercial products. Injection molding process consists of four steps: filling, packing, cooling and releasing (Fig. 3.19). In the filling step, the polymer melt is injected into the mold cavity, where a stamp or a master is installed on the surface, and fills the intaglio structure on the stamp. In the releasing step, the injection-molded plate with micro/nano surface structures is mechanically released from the stamp after being solidified through cooling step. Because the polymer melt is hot (usually at least 200 °C) and the surface of the mold or stamp is relatively cold (usually less than 100 °C), the hot polymer melt starts to be cooled and solidified rapidly from the skin layer after it is injected into the mold cavity to contact the mold surface (Fig. 3.20). The rapid cooling and solidification of the melt from the skin layer makes it very difficult to replicate the surface micro/nano structures, especially in the case of a high aspect ratio of structure (Fig. 3.20).

In addition to this incomplete filling of the hot melt, deformation or fracture of the micro/nano structures during the releasing step is another critical issue for injection molding of a device employing micro/nano structures. This deformation issue at the releasing step is caused by an interference between the stamp and plastic structures (Fig. 3.21). These two issues, incomplete filling and deformation of the structures, are most concerns in applying the injection molding for mass production of the device with micro/nano structures and have been studied by many research groups.

For incomplete filling problem, many researches have been continued to optimize the process or mold design to fill the micro/nano structures on mold surface completely with melt before the melt solidifies. Considering the key parameters for melt filling process such as melt temperature, mold temperature, injection speed and packing pressure, replication of the micro/nano structure is generally known to enhance under conditions of higher melt temperature, higher mold temperature, faster injection speed and higher packing pressure. Higher temperature of melt or mold delays the solidification of the polymer melt, which allows the melt to fill the tiny structures on the mold. Faster injection makes the melt to fill the surface structure more quickly before being solidified too. Higher packing pressure can make the melt to flow into the surface structures even after being solidified slightly. For smaller or higher aspect ratio of structures, higher temperature, higher pressure or faster injection speed are generally required to replicate the structures better. These conditions, however, result in some negative effects such as longer cycle time or warpage of the substrate. For some micro/nano structures, it may be almost impossible to replicate the structure to the edge or corner precisely by optimizing conventional injection molding process using a mold set to a constant temperature during the process (Fig. 3.22). To overcome this issue, vario-themal injection molding processes, called rapid heat-and-cool injection molding process [25,26,27], are adapted for some devices with micro/nano structures [24, 28, 29]. In the vario-thermal injection molding process, the mold is heated up to the glass transition temperature of the molding material or higher temperature for filling step and cooled down below conventional mold temperature, for example 70 °C in case of PMMA, for cooling and releasing step. The key technology of the vario-thermal injection molding process is to heat up and cool down the mold very quickly to maintain the productivity of conventional injection molding process. Since the thermal mass of the mold is quite large, it takes too long time to heat up and cool down the entire mold system. So many molds for vario-thermal process employ a mold design isolating the surface with structures of the cavity thermally by separating the thin layer of the surface from the mold base [24, 25, 29], applying insulation layer beneath the surface or flow channels for heating and cooling close to the surface, etc. In Figs. 3.22 and 3.23, some injection molding results for micro/nano structures are shown using vario-thermal injection molding process.

Injection molded high aspect ratio of nanostructures using vario-thermal injection molding process [24]

Another advantage of injection molding is that various commercial materials are available to meet diverse requirements for the device in terms of mechanical, chemical or optical performance. PMMA, PC, PS and COC are used mostly for injection molding of a plastic nano or micro-fluidic device, but other thermoplastic resins for injection molding and their variations are also available.

Based on injection molding, the device can be designed and fabricated to have many functional elements such as port for tubing, load-bearing structures like rib or body, structures for assemble like welding bid, hole for bolting, snap-fit, etc. in addition to nano or micro-structures (Fig. 3.24).

Considering these advantages along with excellent productivity and cost competitiveness, the injection molding process is most promising manufacturing process for commercialization of nano or micro-fluidic devices.

3.3 Surface Biofunctionalization Engineering for Bioreceptors and Antifouling Coatings (Claire Smadja and Mehdi Ammar)

3.3.1 Introduction

Biomolecules immobilization on solid supports is of paramount importance for biochip applications. Immobilization can be achieved by covalent immobilization, physical adsorption, and entrapment within polymer matrices or non-covalent attachment via intermediate biomolecular species. However, when analyzing complexes mixture such as blood, plasma or serum, unwanted interferences related to nonspecific adsorption of analytes occurred. To avoid this effect, coating allowing bioreceptors immobilization while reducing dramatically fouling phenomenon could be proposed [30].

The ultrasensitive biosensing methods are also combined to a high specificity provided by antibodies grafting. So far, the issue of self-deposited functionalization has been seldom addressed because of the absence of generic techniques allowing molecular diagnosis at the nanoscale. Therefore, a controlled and adaptive chemical preparation of the sensing surfaces is important for the bio-functionalization step. Modification of solid substrates by deposition of organic monolayers with controlled architecture [31, 32], such as thiols on gold, carboxylic acids on alumina or alkanes on silicon and silica are a subject of growing interest.

Therefore, several groups proposed a variety of functionalized surfaces coated to avoid fouling from complex media. Several techniques based on self-assembled monolayers (SAMs) are widely used as coating for proteins grafting but also to obtain anti-fouling properties towards proteins or bacteria. Poly[ethylene glycol] and its derivatives have been widely employed [30, 33]. In addition, advances in polymers synthesis lead to a novel class of non-fouling materials, including brushes of hydrophilic electro-neutral polymers [30, 33,34,35].

This chapter focuses on recent advances in the development of functionalizable surfaces and their applications in biochips. Several types of coating materials will be described. In the first part of this review, we will focus on bioreceptors immobilization. This section also includes a brief presentation of the bioreceptors (antibodies and apatmers). The next section reviews the coating anti proteins fouling. In this section, we also described results concerning fouling resistance against models plasmatic proteins and blood plasma or serum. The last section relied on functionalized antifouling coatings towards bacteria. This section includes several works on applications in this field. Different coating allowing antifouling against bacteria such as Pseudomonas aeruginosa, Staphylococcus aureus, Enterococci and Escherichia coli will be presented.

3.3.2 Immobilization of Bioreceptors

3.3.2.1 Biorecognition Elements

Antibodies. Immunoglobulines are the most widely used biorecognition element. They are produced by B cells for defensive immune response when exposed to foreign organisms [36]. Antibodies are Y-shaped immunoglobulins weighing approximately 150 kDa (Fig. 3.25). Each arm of an antibody contains a pair of antibody heavy (~55 kDa) and light (~25 kDa) chains that are connected by interchain disulfide bonds. An antibody can be divided into two distinct regions, variable (located at the top of the Y) and constant (located at the bottom of the Y) regions. An antigen binds to the paratope, variable region, of an antibody that is located at the top of the Y in a region [36].

Antibody structure (http://www.biology.arizona.edu/immunology/tutorials/antibody/structure.html)

Nucleic acids. DNA and RNA aptamers can be also used for the detection of proteins analytes [37]. The aptamer corresponds to a single strands nucleic acid that forms a 3-dimensional structure interacting specifically with a target via intricated mechanisms i.e. van der Waals, hydrogen bonding and electrostatic interactions.

3.3.2.2 Self-assembled Monolayers [SAMs] for Biochemistry

Self-assembled monolayers are ordered molecular assemblies of different organic materials (Fig. 3.26). SAMs are performed by simply immersing a substrate into a solution of the surface-active material. The driving force for the spontaneous formation of the 2D assembly includes chemical bond formation of molecules with the surface and intermolecular interactions. SAMs provide the needed design flexibility, both at the individual molecular and at the material levels, and offer a vehicle for investigation of specific interactions at interfaces, and of the effect of increasing molecular complexity on the structure and stability of two-dimensional assemblies.

Reprinted with permission from [38]

Self Assembled Monolayers universal protocol.

In contrast to ultrathin films made by, for example, molecular beam epitaxy (MBE), and chemical vapor deposition (CVD), SAMs are highly ordered and oriented and can incorporate a wide range of groups both in the alkyl chain and at the chain terminal. For example, Self-Assembled Mono-layers (SAM) of organosilicon are currently used for coating glass slides, enhancing the biocompatibility of the surface and protecting proteins from denaturation during the immobilization step. In fact, maintaining protein conformations not only determine their tri-dimensional structure but also bioactivity and ability to interact with antigens, antibodies or substrates. The SAM technique is applied to interdisciplinary areas, and is widely engaged in research at the interface of chemistry with biorecognition.

3.3.2.3 Bioreceptors Attachment

Many biological and medicals applications, such as biochip, labchip and biosensors involved proteins—proteins or proteins ligand interactions. Attachment of biomolecules on different surfaces is therefore of paramount importance for micro-device development. Biomolecules could be immobilized on a large range of substrates; from carbone nanotubes, silicon, semiconducting polymers, magnetic nanoparticles [39]. In these surfaces, the biological properties of the proteins must be maintained. In the context of lab on chip or biosensors development, the aim is to detect target molecules (e.g. biomarkers) at low level in highly complex media such as human serum, plasma or urine. Therefore, for biosensing and lab-chip applications the proteins immobilized (e.g. antibodies) on surfaces, should meet the following criteria; (i) accessibility of the active site, (ii) an homogeneous surface coverage, (iii) stability of the grafting. In addition, proteins should be attached onto surfaces without affecting conformation and function to maintain their biological activity [32]. A large variety of immobilization techniques are proposed nowadays which are mainly based on three mechanisms: physical, covalent, and bioaffinity immobilization.

3.3.2.4 Physical Adsorption

Physical adsorption is one of the simplest methods [40, 41]. Proteins can adsorb on surfaces via weak interactions, mainly ionic interactions, hydrogen bonds, hydrophobic and polar interactions. Although physical adsorption provides several advantages such as method simplicity, the risk is to obtained heterogeneous layer with proteins randomly oriented, considering that each molecule can form many contacts in different orientations for minimizing repulsive interactions with the substrate and previously adsorbed proteins [32]. In addition, conformational changes, reducing thereby proteins biological activity could also occur [39] (Fig. 3.27).

Reprinted with permission from [39]

Differences between random a and oriented b proteins.

3.3.2.5 Non Site Specific Covalent Immobilization

In this approach, bioreceptors are covalently bound to the immobilization support through accessible functional groups of exposed amino acids. Covalent bonds are mostly formed between side-chain exposing functional groups of proteins with chemical modified supports [e.g. Self-assembled monolayers (SAM)], resulting in an irreversible binding and producing a high surface coverage [32]. In addition, the immobilization process should be performed under physiological conditions to avoid proteins denaturation during their coupling on the chemically modified surfaces [39]. Chemical binding via side chains of amino acids is often random, since it is based upon residues present at the proteins surfaces. The most widely used chemical groups are amines and thiols that are both good nucleophiles. Carboxylic groups can be activated to renders them reactive towards nucleophiles.

Amine chemistry. Lysine residues are the amino acids the most commonly involved for covalent grafting since they are frequently located on the proteins surfaces [39, 42]. N-Hydroxysuccinimide [NHS] is the most frequently used agent for the coupling between protein and surfaces, forming stable amide bonds (Fig. 3.28). This method has been successfully employed to graft antibody directed against Alzheimer diseases biomarkers, amyloid peptides, on silicon surfaces silanized by octenyl trichlorosilanes (OTS) (Fig. 3.28). A step of oxidation permit to emerge carboxylic groups. The optimized protocol rends possible to perform an immunoassay allowing thereby a sensitive detection of amyloid peptides on these surfaces. In this work, the carboxyl functionalized surface has been activated by 1-ethyl-3-(3-dimethylpropyl) carbodiimide (EDC)/sulfo-NHS for coupling with the monoclonal antibodies directed against Aβ 1–42 [43].

Reprinted with permission from [42]

Schematic representation of the 7-octenyltrichlorosilane grafting reaction on silicon and immobilization of proteins on emerged COOH groups.

Thiol chemistry. This methods required cysteine which is the unique aminoacids containing a thiol group. Since cysteines are not as abundant as lysines, proteins are less prone to random orientation rendering cysteine interesting for immobilization on sensor surfaces for instance [32].

Carboxyl chemistry. Immobilization via carboxyl groups is also interesting opportunity considering the fact that aspartic and glutamic acid represent the major fraction of surface exposed groups on proteins. The coupling reaction could also involve EDC/Sulfo-NHS chemistry (Fig. 3.29).

Reprinted with permission from [39]

Immobilisation anbtibodies via the amine groupe on N-hydroxysuccinimide (NHS) modified surfaces.

3.3.2.6 Site Specific Immobilization Strategies

To provide a better control of the protein orientation during the immobilization process, different site-specific immobilization techniques have been proposed. This approach could also be divided in noncovalent and covalent strategies.

Site specific and non-covalent immobilization

Most of these approaches exploit complementary affinity interactions between biomolecules. They rely on specific interactions occurring in biological process [39] such as biotine/streptavidin interactions or Protein A or G towards antibodies.

Polyhistidine. This method is based on affinity between polyhistidine and divalent metal cations such as Ni2+, Cu2+ and Zn2+. Recombinant proteins exhibiting a (His]6 tag at the C- or N-terminus can be immobilized on metal treated surfaces via a chelating agent such as nitriloacetic acid (NTA). This immobilization is reversible (Fig. 3.30). This strategy has been employed to develop an electrochemical biosensor, by immobilizing horse heart Cytochrome c on gold electrode surface [44].

Reprinted with permissions from [45]

Immobilization of a protein-His-Tag via NTA complex.

Biotin-(strept)Avidin interaction. This approach relies on one of the strongest noncovalent bonds. The specificity of the interaction allows uniform orientation of immobilized proteins. It is based on the interaction between strept(avidin) and biotin (Fig. 3.31). An example of application is given by Xia et al. [46]. They have developed a sensor surface, by immobilizing antibodies directed against Alzheimer using Biotin-(strept)]Avidin interaction. This non-covalent bonding permits repeated SPR measurements on the same surface and thereby improves the reproducibility of the methods and enhances the sample throughput. They have been able to measure Alzheimer disease biomarkers (amyloid peptides) in cerebrospinal fluid (CSF) samples from AD patients.

Reprinted with permission from [47]

a Streptavidine, b biotin, c immobilization of a protein relying on biotinstreptavidin interaction.

Protein A/Protein G-mediated Immobilization. The immobilization of antibodies by use of protein A/protein G relies on the specific interaction with the constant region [Fc Fragment] of the antibodies. Using this immobilization method ensures that the binding site of the antibody, located on the Fab variable region, remains available for specific antigen capture [32].

DNA-Directed Immobilization. This strategy has been developed to convert DNA arrays into protein arrays using DNA hybridization. In this method, the complementary DNA conjugates to protein will be immobilized by specific interaction between the DNA grafted on the microarray and the DNA-protein conjugate. However, it is important to note that the incorporation of oligonucleotides into large proteins is still poorly developed [32].

Site specific and covalent immobilization

Click chemistry. In order to control an oriented and covalent coupling of a protein to a substrate, a unique chemical group or sequence could be introduced in the protein at a site-specific location. Several bio-orthogonal chemistries can lead to an oriented covalent immobilization of proteins. In this context, the ‘click chemistry’ concept becomes very popular. This chemistry rely on; (i) mild reaction conditions, (ii) insensitivity to oxygen and water, (iii) ability to use water as reaction medium, and the formation of a stable product under physiological conditions. In recent years several works include, copper or ring-strain catalyzed azide—alkyne cycloadditions, Staudinger-ligations, Diels—Alder cycloadditions, thiol—ene additions, and oxime formation [48].

Targeting the Carbohydrate Moiety. Many glycoproteins, including antibodies, hormones, and enzymes, can be immobilized through their carbohydrate moiety without affecting their biological activity, since the carbohydrate region is generally located in areas not involved in specific activity. Moreover, coupling of antibodies via carbohydrate moiety, located on the Fc region, was proven to enhance steric accessibility of the binding sites [32, 49].

3.3.3 Coatings for Proteins Anti Fouling

In this chapter, we will present the key strategies for preparing antifouling coating. Proteins solution containing fibrinogen or bovine serum albumin [BSA] or lysozyme are often employed to evaluate the antifouling properties of the coating. However, it is also important to evaluate the resistance toward highly complex mixture such as blood, plasma or human serum.

3.3.3.1 Poly(Ethylene Glycols) PEG and Poly[Ethylene Oxide] PEO Based Coating

PEG is one of the most widely used polymers to prevent proteins adsorption. The antifouling properties of PEG have been widely reported in the literature [50]. A range of groups have shown that by independently varying the molecular weight and chain density of PEG layers the protein resistance can be tuned accordingly. Indeed, a decrease of proteins adsorption is observed by increasing the grafting density or the chain length [30, 51, 52]. Layers with increasing grafting density pass from a single grafted chain (mushroom) regime to a brush regime with deformed polymer coils [30]. The effects of the polyethylene glycol (PEG) density, chain length, on proteins adsorption have been studied by using a complex mixture of proteins (lysozyme, human serum albumin (HSA), IgG and lactoferrin). For shorter chains a high density of PEG surface attachment sites is required to prevent proteins adsorptions. If the initial density of functional groups is low, the PEG chains should be longer to obtain a protein resistance effect. The development of PEG coatings by attachment of PEGs from aqueous solution onto an amine interlayer (or an alternative equivalent amine base layer) provides a more convenient and versatile route for the fabrication of protein resistant PEG coatings [53]. High molecular weight PEG molecules grafted on SiO2 surfaces showed adsorption resistance of proteins from human serum evaluated with two different techniques: ellipsometry and QCM-D.

In another work, silane-PEGs with either carboxylic acid (silane-PEG-COOH, SPC) or biotin have been grafted on stainless steel surfaces (Fig. 3.32) [54]. Stainless Steel is a commonly used metal in industrial and medical settings, where it becomes exposed to organic and biological agents that may result, for example, in biofouling and microbial-induced corrosion. In this work the silanes-PEGs formed less than 10 Å thick overlayers with close to 90% surface coverage. Recently, it has been demonstrated that a coating by PEO stearate on a Dyneon THV microchip prevents the adsorption of proteins such as BSA and trypsin inhibitor and allow their analysis by electrokinetic mode [55].

Reprinted with permission from [54]

Schematic illustration of silane-PEG-modified Stainless Steel. a silane-PEG-COOH overlayer resists non-specific biofouling of both bacteria and proteins. b silane-PEG-biotin overlayer enables selective functionalization of SS via avidin-biotin bridges.

Another approach rely on amphiphillic triblock PEO-bl-PPO-bl-PEO copolymers consisting of central hydrophobic propylene oxide (PPO) segment flanked by two hydrophilic PEO chains has been also evaluated on gold surfaces by SPR. An ultra-low adsorption of single protein solutions of fibrinogen, BSA, and complex mixtures of proteins has been obtained [56]. The same effect has been observed on stainless steel surface coated with the triblock copolymer a poly(ethylene oxide)-poly(propylene oxide)-poly(ethylene oxide) (PEO-PPO-PEO). The non-specific biofouling of fibronectine and biotine is reduced by 70%. Similar reductions in protein adsorption have been reported, for example, by Yang et al. [57] and Harder et al. [58]. Y. Yang and his colleagues coated stainless steel surface with a poly(ethylene oxide)-poly(propylene oxide)-poly(ethylene oxide) (PEO-PPO-PEO) triblock copolymer, and showed that the coated stainless steel surfaces were capable of significantly reducing the adsorption of bovine serum albumin (BSA) [57]. Another triblock copolymer structures composed by a central polypropylene sulfide flanked by two external PEG chains (PEG-bl-PPS-bl-PEG) grafted on gold surface exhibit anti-proteins adsorptions towards highly complex media such as human serum measured by SPR [59] (Figs. 3.22 and 3.33).

Reprinted with permission from [60]

Molecular structure of two variants of sulfur-based poloxamer analogues (PEG-bl-PPS-bl-PEG triblock copolymers).

Another type of multidentate copolymeric has been proposed (Fig. 3.34). They are composed by three different monomers that have been randomly copolymerized in order to obtain a macro- molecule bearing grafted PEG side chains and providing a non-fouling property when exposed to human serum [61].

Reprinted with permission from Ref. [60]

Molecular structure of the PEG-polyalkyl phosphonate terpolymer.

3.3.3.2 Oligo[Ethylene Glycols] SAMs Based Coating

Regarding OEG-Sam coating the typical structure is R1-(CH2)n-R2. R1 is an hydrophilic moiety at the ω-position, (CH2)n is a nonpolar alkane chain and R2 is a group on α-position that is chemically reactive to substrate. Chapman et al., pioneered research on proteins adsorption [i.e. fibrinogen, a large (340 kD) blood plasma proteins and lysozyme, a small protein (14 kD), onto ω-functional SAMs. They showed that the best results were obtained when functional groups share the following properties: containing polar functional groups, incorporating hydrogen bond accepting groups without any hydrogen bond donating groups, and having no net charge [62]. The same groups has also evaluated the ability of SAM to resist to model protein adsorption such as fibrinogen, RNase, lysozyme and carbonic anhydrase, when incorporating oligo(ethylene glycols) (EG) groups into alkenethiols. [63]. The results obtained showed that by incorporating oligomer of EGn groups [n = 6], the mixed SAM completely resist to model proteins adsorption. The surface inertness towards proteins could be due to a reduction of the number of hydrogen bond donors.

3.3.3.3 Zwitterionic SAMs Based Coating

Zwitterionic-based materials, such as phosphoryl choline, phosphobetaine, sulfobetaine, and carboxybetaine-based polymers or surfaces have been shown to greatly reduce nonspecific protein adsorption. To explain their repellent activity towards proteins, the hypothesis is that zwitterionic surfaces interact with water molecules creating thereby a hydration layer. This layer prevents protein adhesion on the surface. Several studies demonstrated the resistance of phosphorycholine (PC) SAM to proteins adsorption [64, 65]. In this work protein adsorption has been investigated on gold chip terminated by PC-SAMs by an SPR sensor. The results showed a dramatic decrease of two model proteins adsorption; Fibrinogen and BSA. A recent study, investigated polyurethane membranes modified with zwitterionic polymers such as 2-methacryloyloxyethyl phosphorylcholine (PU-MPC) showed a significant reduction of plasmatic proteins adsorption (Fig. 3.35) [66].

Reprinted with permission from [66]

Reduction of proteins adsorption after coating with zwitterionic polymers, methacryloyloxyethyl phosphorylcholine (PU-MPC).

Recently, brushes produced by the copolymerization, on Si3N4 surfaces, of a standard zwitterionic sulfobetaine monomer have demonstrated their antifouling properties towards fibrinogen (Fig. 3.36) [67]. In this study, they showed a proof of principle with biotin-functionalized brushes on Si3N4 that combine excellent antifouling properties toward fibrinogen with specific avidin binding (Fig. 3.37). The avidin binding could allow in the next step bioreceptors attachment.

Reprinted with permission from [67]

Standard Monomer of a standard zwitterionic sulfobetaine.

Reprinted with permission from [67]

Schematic representation of functional antifouling polymer brushes as obtained from the copolymerization of a clickable monomer with a standard SB monomer.

Zwitterionic SAM carboxybetaine methacrylate and acrylamide surfaces have also demonstrated by surface plasmon resonance (SPR) measurements their ability to reduce fibrinogen from buffer solution [68] and BSA from undiluted human blood plasma [69] non-specific adsorption. In addition, it has been possible to develop an antibody-functionalized poly carboxybetaine acrylamide gold surface platform to detect a biomarkers of carcinoma, Activated leukocyte cell adhesion molecule (ALCAM), in blood plasma using a sensitive surface plasmon resonance (SPR) sensor [69].

3.3.4 Anti Bacterial Coatings

Biomedical device-associated infection by bacteria is one of the most common and problematic complications faced worldwide [70]. Numerous epidemiological studies have shown that the most common bacteria causing hospital infections are Pseudomonas aeruginosa, Staphylococcus aureus, Enterococci and Escherichia coli [71, 72].

Bacteria could be considered as living colloids that interact easily with surfaces. This is due to their small size, low density, surface charge, and variable degrees of cell surface hydrophobicity. Their adhesion in surfaces could leads to a growth and production of an extracellular polymeric matrix and eventually to biofilm. Within this biofilm bacteria are more resistant to usual treatments by antimicrobial agents, which in turn increase health problems. Therefore, it is of paramount importance to prevent or control microbial attachment in the surface to avoid proliferation of adherent bacteria and biofilm formation. To prevent pathogenic biofouling on surfaces specific surface chemistries could be employed. The bacteria adhesion is influenced by the hydrophobicity and the charge of the external membrane of bacteria but also by the physico-chemical properties of the materials and its topography. Therefore, to prevent bacteria adhesion in surfaces by modifying surface chemistry two approaches could be proposed; repel or bacteria killing (Fig. 3.38). Repelling prevent bacteria attachment by steric hindrance or charged anionic polymers leading thereby to a repulsive electrostatic force between the negatively charged bacteria and the surface.

Reproduced with permissions from [77]

Repelling and killing bacteria surfaces.

Killing surface could be prepared by using polymers interacting with the bacteria membrane and cause its disruption or inactivate microbial cell activity [73,74,75]. Another approach relies on the incorporation of antibiotics on the polymers [76].

3.3.4.1 Polymers for Bacteria Repelling

For Bacteria repelling surfaces that are coated with non-charged hydrophilic polymers the reduced attachment of bacteria could be due to a steric hindrance phenomenon [78]. The most widely described repelling polymers is the poly(ethylene glycol) (PEG). The bacteria repelling by PEG could be explained by several hypothesis such as; hydrophilicity, high polymer flexibility, large excluded volume, steric hindrance effect [53]. It has also been demonstrated that the longer is the PEG chain the higher is the resistance of the bacterial attachment [79]. PEG molecules bearing terminal hydroxyl, amino and sulfonates groups were tested against Escherichia Coli (E. Coli) and Staphyloccus Epidermidis (S. Epidermidis). Results obtained showed that the best repelling effect is obtained for both bacteria with PEG- terminated by sulfonates [79].

Several authors also obtained a significant reduction of bacteria adhesion (70 to 95%) with poly[ethyleneterephtalate] (PET) surfaces modified by poly[ethylene oxide] (PEO) [80]. Glass and silica surfaces have also been modified with a covalent grafting of PEO brush. They showed that for the most hydrophobic strain the repelling is less effective [81, 82]. Thus, a dramatic reduction of attachment was obtained with S. Epidermidis, S. Aureus, S. Salivarius and E. Coli. Other materials that reduce bacterial adhesion are based on surfactants such as hydroxyapatite and chitosan or biological molecules such as albumin and heparin. Friedman and co- workers coated TiO2 surfaces with BSA using carbodiimide chemistry. A recent study performed on titanium surfaces sprayed with calcium phosphate incorporating silver showed a strong reduction of E. Coli and S. Aureus attachment [83] (Fig. 3.39).

Reprinted with permission from [83]

SEM images of E. Coli and S. Aureus (c and h) when silver (Ag) is incorporated into calcium phosphate coatings on Titanium.

3.3.4.2 Polymers for Bacteria Killing

Killing surfaces could be obtained with cationic polymers. These polymers are able to interact with bacteria surfaces leading to their disruption [73].

Non-natural cationics polymers

The first study has been proposed by Klibanov and coworkers. They developed antimicrobial surfaces which involve a covalent coating of amino-modified glass slides with long hydrophobic polycationic chains i.e. poly(4-vinyl-N-alkylpyridinium bromide). These derivatized surfaces become bactericidal since they kill up to 99% of deposited bacteria such as Tiller et al. [84]. The bactericidal mechanism of the surface-attached polycationic chains probably involves their penetration into the bacterial membranes, leading to cell damage and death [85].

Another approach to provide antimicrobial properties to medical device surfaces involves their silanization with quaternary ammonium-containing silane agents. Microfibrillated cellulose surfaces have been modified with alkoxysilane octadecyldimethyl [3-trimethoxysilylpropyl]-ammonium chloride rendering the material highly microbiocidal [86]. The quaternary ammonium functionalized surfaces have a high positive surface charge exerting thereby a strong adhesive force on negatively charged bacteria, presumably causing membrane leakage and cell death [87,88,89]. These surfaces have been tested for antibacterial activity against S. Aureus, E. Coli and P. aeruginosa. Results obtained showed that more than 99% of S. aureus or E. coli bacteria initially exposed to the material were killed after a 24 h contact. The killing efficiency of these surface was found to be smaller toward P. aeruginosa [95%] compared to E. coli and S. aureus. A similar approach has been described recently when glass was modified by triethoxysilane terminated with a quaternary ammonium [90]. In this study, bacterial suspensions of S. Aureus or E. coli were sprayed at coated and uncoated slides. After 24 h, the number of colonies for both strains decreased; 92% and 71% for S. aureus and E. coli respectively.

Another important class of polymeric biocides is based on quaternary ammonium compounds. Recently, new random copolymers, where rather small fractions of reactive units such as carboxyl groups or epoxides are copolymerized with quaternary ammonium biocidal units, covalently attached or electrostatically bound onto the polymeric chains. Two series of copolymers, poly(4-vinylbenzyl chloride-co-acrylic acid), P(VBC-co-AAx), and poly(sodium 4-styrenesulfonate-co-glycidyl methacrylate), P[SSNa-co-GMAx], were synthesized via free radical copolymerization and further modified by the incorporation of biocidal units either covalently (4-vinyl benzyl dimethylhexadecylammonium chloride) or electrostatically bound (cetyltrimethylammonium 4-styrenesulfonate, SSAmC16). Antimicrobial tests also revealed that the cross-linked membranes presented strong antimicrobial activity against S. aureus and P. aeruginosa [91]. Another study showed that hydrophilic monomer acrylic acid (AA), at low contents, with the covalently attached bacteriostatic group vinyl benzyl dimethylhexadecylammonium chloride (VBCHAM) in the copolymer P(AA-co-VBCHAM88), resulted in a high bacteriostatic activity against P. aeruginosa and E. faecalis (6 log reduction in certain cases) [92]. This performance of the coating materials, evidencing their strong antimicrobial activity suggests that such materials are promising for antimicrobial applications [93].

Natural cationics polymers

Chitosan is a polycationic polymer that can be employed alternatively to the non-natural polycationic polymers described above. Because of its non-toxicity, biodegradability, biocompatibility and antibacterial activity chitosan has attracted attention for application in the food and pharmaceutical industries [78]. Chitosan is the N-deacetylated derivative of chitin. Chitosan inhibits the growth of a wide variety of bacteria, including E. Coli and S. Aureus [94]. The exact mechanism of the antimicrobial action of chitin, chitosan, and their derivatives is still unknown, but it has been suggested that an interaction between positively charged chitosan molecules and negatively charged bacteria cell membranes could occur leading thereby to membrane disruption [94].

Because of their practical importance, microbiological applications of zwitterionic polymers and their derivatives have been studied in depth in recent years, resulting in new mechanistic understandings and novel molecular designs. Recently, a coating by chitosan–iron oxide on graphene oxide nanocomposite hydrogel has been developed. The chitosan–iron oxide coated graphene oxide nanocomposite hydrogel films displayed significant antimicrobial activities against both Gram-positive and Gram-negative bacterial strains, such as methicillin-resistant Staphylococcus aureus, Staphylococcus aureus, and Escherichia coli, and also against the opportunistic dermatophyte Candida albicans [95].

3.3.4.3 Nanostructured Surfaces

Somme recent development showed that nanostructured surfaces could prevent surface colonization by bacteria. A recent work demonstrated the ability of a highly ordered arrays of surface nanopillars from cicada wing surface elicits bacterial membrane disruption (Fig. 3.40) [96, 97].

Reprinted with permission from [96]

Scanning electron micrograph of the upper surface of the forewing, at 25,000 × magnification. The surface consists of an array of nanoscale pillars, with approximately hexagonal spacing. Scale bar is 2 μ m.

3.3.5 Conclusion

To develop lab on chip or sensor, it is of paramount importance to control proteins immobilization in order to obtain the best bio-functionalized surface in term of grafting density and bioreceptors orientation. A large variety of immobilization techniques has been described in this chapter. However, the most widely used approach for the immobilization of bioreceptors, to optimize biorecognition and resist to non-specific grafting (antifouling), is covalent attachment. For specific proteins attachment, the SAM technique is majority used directly or indirectly on the host substrate. To reach a high sensitive bioactive surface, all the steps for SAM protocols need to be extensively characterized, to optimize the efficiency of the biografting, and the reproducibility finely evaluated. In parallel, many developments of functionalizable antifouling coatings towards proteins and bacteria have been proposed. We demonstrated in this review the large variety of surface chemistry developed from polyethylene glycol to self-assembled monolayers (neutral or zwitterionic) to prevent unspecific adsorption. For antibacterial surfaces, similar surface chemistry is proposed. However, two different purposed could be attained; repel or bacteria killing. Repelling prevent bacteria attachment by steric hindrance or charged anionic polymers. Killing surface could be prepared by using polymers interacting (electrostatic interactions) with the bacteria membrane and cause its disruption or inactivate microbial cell activity. At least a recent and promising alternative has been proposed by designing nano-structured surface with nanopillars may be a promising route to minimize bacterial contamination/infection.

3.4 Packaging Technologies for Fluidics and Biodevices (Yeong-Eun Yoo)

3.4.1 Introduction

In Sect. 3.2, several fabrication processes are described for micro/nano structures like channels or pillars using various materials. These fabricated micro/nano structures are open along the structures on the substrate, so a capping process with a cover plate is needed to seal the open structures to deliver the fluidic samples without overflow or leakage. Sealing the surface structures like fluidic channels or chambers depends on the size and shape of the structures, materials of the parts, bonding strength required, etc.

For mass production of device based on fluidic channel, injection molding using thermoplastic resin may be the most competitive process due to its excellent productivity, good dimensional accuracy and low cost, etc. Although injection molding process is now available for plastic substrate with nano or micro-structures on its surface, sealing the fluidic channel is still a big hurdle.

The major goal of sealing the fluidic channel is to bond the substrates hard, hermetically but still precisely to avoid deforming the channel. For the bonding of two substrates to seal the fluidic channel, the substrate mostly needs to be altered chemically or mechanically on the surface. Heating or applying a solvent softens the substrate especially in the skin region (Fig. 3.41), which results in inter-diffusion of the material and bonding at the interface of the substrates.

A dry or wet adhesive may be used between the substrates for sealing. This adhesive bonding might be simple and fast to use, but have some issues like clogging by overflow of the adhesive during the coating or pressing process, misalign of the adhesive layer to the channel substrate or leakage path formed by porous structures in the adhesive layer (Fig. 3.42).

Clamping two substrates mechanically is another method for sealing of the fluidic channel device as shown in Fig. 3.43. It looks quite simple conceptually, but it is not easy to seal the fluidic channel hermetically due to the deformation of the substrate caused by point load for clamping.

Generally, more heating, solvent or adhesive is applied, higher strength of bonding can be obtained, but the surface structures are more deformed. The structures order of millimeters may not be affected significantly by the small amount of deformation or change at the interface (Fig. 3.44a). In case of sealing the structures less than hundreds of micrometers, however, the deformation or interference on the structures may be comparable to or even larger than the scale of the structure itself (Fig. 3.44b). This significant influence on the channel requires that a very precisely controlled bonding method be used to enhance the bonding strength and the dimensional stability of the micro-structures at the same time, especially for polymeric substrates.

Beside the issues mentioned above, restriction on heat, mechanical stress, UV radiation or solvent during the sealing process are additional issues on sealing of fluidic channel especially for devices employing biomaterials. Most biomaterials like antibody, other proteins or lipid are degradable or susceptible to losing their functionality when exposed to thermal, chemical or mechanical stress, UV radiation etc. Considering most bonding require at least one of processes such as heating, solvent treatment, pressing or UV exposure processes, it should be designed very carefully not to damage the biomaterials.

Although diverse sealing methods have been proposed for nano or micro-fluidic device, it is still challenging task for many cases. In this chapter, some sealing methods are reviewed mainly based on typical bonding processes for plastics such as thermal bonding, adhesive bonding, ultra-sonic welding and solvent bonding. A sealing by direct contact using PDMS, which is mostly used in laboratory, is reviewed briefly.

3.4.2 Sealing by Direct Contact Based on PDMS

PDMS is one of the materials widely used for packaging of micro-fluidic device because it can contact the other surface conformally due to its low elastic modulus, typically less than 1 MPa [18], and provides consequently good sealing even through solid to solid contact. The bond strength for PDMS device depends on the characteristics of the PDMS such as the mixing ratio of the curing agent or the degree of cure [16, 98]. Higher mixing ratio of the curing agent makes the PDMS have lower elastic modulus and contact the other surface more conformally, which results in better adhesion. The partially cured PDMS can also contact the other surface better because the incompletely cured PDMS has lower elastic modulus compared to the fully cured one. Although PDMS/PDMS or PDMS/other surface can bond together well reversibly, PDMS’s or PDMS and some materials can also bond irreversibly when the surface is modified by surface treatment such as oxygen plasma. The oxidized surface of PDMS by exposing to oxygen plasma has silanol groups (Si–OH) temporarily, less than 30 min approximately in the air, and can form covalent siloxane bonds (Si–O–Si) when facing two surfaces tightly before silanol groups disappear [99, 100]. The PDMS and Si-based materials can also form covalent bond when the surface is oxidized by exposing to oxygen plasma [16, 98, 100, 104].

3.4.3 Adhesive Bonding

Bonding with an adhesive is one of general methods for sealing the fluidic channel. For this bonding method, the two parts are bonded through a 3rd material such as thermoset resin, UV curable resin or thermoplastic resin. The adhesive is coated to thin layer usually on the flat surface and cured or solidified after facing to press two substrates. The adhesive layer is cured or solidified in different ways depending on the material. The thermoset adhesive such as epoxy resin or thermo-reactive polymers is cured by heating up to curing temperature of the resin [101]. The UV curable resin is cured by UV light with appropriate wavelength to the resin much faster than the thermoset resin. These thermoset and UV curable resin are mostly liquid during the process to be coated on a substrate with a simple process. The thermoplastic adhesive layer previously coated on the substrate like thermoplastic film is heated up over the glass transition temperature of the adhesive and cooled down for re-solidification after facing and pressing two substrates. In general, the glass transition temperature of the thermoplastic adhesive is lower than of the substrate to reduce the deformation of the substrate or fluidic channel during the bonding process. The bonding process using adhesive is relatively simple, but one of the issues is to maintain the channel dimension precisely. The adhesive layer coated on a part is squeezed to flow by a compressive force on the layer for bonding. The squeezing flow of the adhesive during the bonding process may result in overflow into the micro-channel and blocking or narrowing the channel (Fig. 3.42). This blocking or narrowing the channel may depend on the thickness of the adhesive layer, channel size, viscosity of the adhesive, the design of the channel array or the surface structure, etc. Some solutions to reduce this blocking problem by the overflow have been proposed such as employing additional guiding channel for overflow adhesive [102].

3.4.4 Sealing Fluidic Channel by Thermal Bonding

For bonding two thermoplastic substrates directly without additional materials like adhesives, the substrates should be heated up to be softened and pressed after facing target surfaces to enhance the inter-diffusion at the interfacing zone of the mating surfaces. The bonding strength and sealing performance enhance as the substrate is heated to higher temperature and pressed with higher pressure. The dimensional stability of the fluidic channel and the substrate, however, is influenced negatively due to the larger deformation caused by lower modulus of the material at higher temperature and higher stress. The deformation of the fluidic channel or substrate and bonding strength increases for a same pressing condition as the temperature of the substrate increases and consequently the modulus of the thermoplastic decreases. Low temperature of substrate and low pressing pressure usually results in good dimensional stability, but poor bonding strength. High temperature and high pressing pressure usually results in poor dimensional stability, but good bonding strength. Some studies tried to enhance the dimensional stability and bonding strength at the same time by balancing the temperature for the substrate and pressure for pressing. Some other methods have tried to enhance the bonding strength, sealing performance and dimensional stability such as matching thermoplastic substrates with different glass transition temperature (Tg), modifying the substrate to have varying Tg through thickness or activating the surface of the substrate to have functional chemical groups [103, 104].

It may be a good match to use a high Tg of fluidic channel substrate and a low Tg of cover plate with lower Tg for good dimensional stability and bonding strength when the temperature for the bonding process is set to between the glass transition temperatures of the fluidic channel substrate and the cover plate (Fig. 3.45).

The thermoplastic substrate can be pre-softened or have lower Tg at the skin layer by solvent, UV radiation or plasma treatment on the surface [103, 105], which may cause degradation of the polymer (Fig. 3.46). The thickness of low Tg layer by these treatments is reported to be very thin, 50 nm for example [105]. Using the substrate with thin low Tg or pre-softened layer on the surface, the process temperature can be set to near low Tg to restrict the deformation within skin layer, which may be negligible for the channel, without bulk deformation of the fluidic channel or substrate itself. The bonding strength for this bonding configuration still can be enhanced significantly due to the active diffusion in the softened low Tg layer even at low temperature and higher pressing pressure considering the high modulus of bulk substrate and the channels [106].

Surface modifications to have functional group such as −COOH or −NH3, etc. by chemical reaction or plasma treatment also have been studied to enhance affinity of the two surfaces and bonding strength consequently. Some studies reported that the bonding strength enhanced compared to bare substrates, but not as much as bonding with softened skin layer by solvent exposure, etc. [104, 105].

As shown in Fig. 3.47, materials such as metal or carbon absorbing irradiation energy by laser or microwave and releasing heat are applied in skin region of the substrates to soften the skin region preferentially [107].

In a typical thermal bonding process by heating and pressing, the substrates are heated from the other surface of the facing surface while the skin region on the facing surface is needed to be softened. This configuration for bonding in the press results in excessive heating on the back surface of the substrate (Fig. 3.48). If the bonding surface is set to required temperature, then the back surface of the substrate will have higher temperature and severe deformation. This will become worse for a thicker substrate or a substrate with lower thermal conductivity. As an alternative process, heating the substrate from the facing surface may be effective approach to heat and soften the skin region locally (Fig. 3.49).

3.4.5 Solvent Bonding

When a thermoplastic substrate is exposed to a solvent, the substrate becomes softened from the surface under treatment and the mating substrates are bonded by pressing thereafter under a certain pressure. The bonding based on solvent may be efficient in dimensional stability of the fluidic channel and bonding strength because the solvent may soften only the limited skin region if the process and solvent involving are controlled properly. For optimization of solvent bonding, the thermoplastic material and solvent should be selected carefully first because the thermoplastics react differently depending on the solvents and its concentration. For example, Acetone dissolves PMMA (Poly (methyl methacrylate)) quite well but not COC (Cyclic Olefin Copolymer). The softening also depends on the phase of the solvent (liquid or vapor), exposure time or temperature when applied to the surface. If a thermoplastic substrate is exposed to a reactive solvent to the thermoplastic in liquid phase for long time, the substrate may be softened too deeply, resulting in severe deformation during the pressing process. When the surface of the fluidic channel is exposed to the solvent, the fluidic channel might be clogged due to the swelling of the channel surface by the solvent and this clogging may become worse for the channel in smaller scale [108]. The bonding processes using solvent have been studied in various way to enhance the dimensional stability and bonding strength. To prevent channel deformation due to excessive solvent, a solvent less reactive with the substrate was selected to avoid softening the substrate too much [105]. In the other study [109], cyclohexane vapor was used to reduce the penetration of the solvent into the COC(Cyclic Olefin Copolymer) substrate and deformation consequently. Additional DUV exposure thereafter induces a cross-linking reaction in the softened layer at the interface which results in higher bonding strength. The fluidic channel was filled with sacrificial material like wax before being exposed to solvent not to contact with solvent [110]. After bonding two substrates, the wax was eliminated through the channel by heating the substrates over melting temperature of the wax.

Another issue on solvent bonding is chemical contamination because the biological substances in the fluidic channel may lose their functionalities due to the solvent [111].

3.4.6 Ultrasonic Welding

Ultrasonic welding is one of bonding processes widely used for plastic parts. Ultrasonic welding uses high frequency vibration (15 ~ 70 kHz, typically 20 kHz for plastic welding) generated by piezoelectric transducer and transmitted to the target part via booster and horn. The ultrasonic welding equipment consists of a generator, a converter (piezoelectric transducer or similar one), a booster and a horn as shown in Fig. 3.50.

Some configurations of 27, 40 and 67 kHz longitudinal vibration systems for ultrasonic plastic welding machine [112]

The transmitted vibration energy to the workpiece is concentrated into a structure, called welding bid, for localized melting at the contact point (Fig. 3.51). The welding bid is usually designed to have sharp edges to contact counterpart at only restricted areas and to be melted locally by friction or plastic deformation of the welding bid. The size and shape of the welding bid are designed by considering the thickness of welding layer or the volume for melt at the interface with the counterpart for welding. Typical size of the welding bid for conventional plastic part is in the order of hundreds of micro-meters, but this is too large for direct welding on micro-structure (Fig. 3.52).

For many micro-fluidic devices, many of flow channels are less than a hundred of micro-meter but the land or ridge for the channels is larger than a millimeter. Therefore, for most ultrasonic welding structure for micro-fluidic, the welding bid contacts the macro region to be welded and cover the micro-channels. If the ridge of the channel is too small to apply welding bid in order of hundreds micrometer, then the welding bids are required to be applied to other regions, practically apart from the channels, on the device (Fig. 3.53). In this case, the channels are sealed by mechanical contact between the channel ridge and cover plate, which may cause leak in case of incomplete contact due to a deflection of the plate or difference in height of the ridge, etc. As shown in Figs. 3.51 and 3.53, too large welding bid results in a thick melting layer and consequently larger channel or gap between the cover plate and the ridge. Too small welding bid may result in insufficient bonding strength or channel collapse due to severe deformation of the ridge.

References

Y. Shang, Y. Zeng, Y. Zeng, Integrated microfluidic lectin barcode platform for high performance focused glycomic profiling. Sci. Rep. 6, 20297 (2016)

E. Primiceri, M.-S. Chiriaco, R. Rinaldi, G. Maruccio, Cell chips as new tools for cell biology—results, perspectives and opportunities. Lab Chip 13, 3789 (2013)

L.N. Abdulkadir, K. Abou-El-Hossein, A.I. Jurmare, P.B. Odedeyi, M.M. Liman, T.A. Olaniyan (2018) Ultra-precision diamond turning of optical silicon-a review. Int. J. Adv. Manuf. Technol. Published online: 20 January 2018 (2018)

J. Nestler, A. Morschhauser, K. Hiller, T. Otto, S. Bigot, J. Auerswald, H.F. Knapp, J. Gavillet, T. Gessner, Polymer lab-on-chip systems with integrated electrochemical pumps suitable for large-scale fabrication. Int. J. Adv. Manuf. Technol. 47, 137 (2010)

P. Li, D. Zdebski, H.H. Langen, A.M. Hoogstrate, J.A.J. Oosterling, R.H. Munnig Schmidt, A.M. Allen, Micromilling of thin ribs with high aspect ratios. J. Micromech. Microeng. 20(11), 115013 (2010)

D.L. Zariatin, G. Kiswanto, T.J. Ko, Investigation of the micro-milling process of thin-wall features of aluminum alloy 1100. Int. J. Adv. Manuf. Technol. 93, 2625 (2017)

E.G. Mintegi, Micromilling technology: a global review. (2017). https://www.slideshare.net/endika55/micromilling-technology-a-global-review. Accessed 17 July 2017

E. Kuram, B. Ozcelik, Micro milling, in Modern Mechanical Engineering, Materials Forming, Machining and Tribology, zd. by J.P. Davim (Springer, Berlin Heidelberg, 2014) p. 325

D.J. Guckenberger, T.E. de Groot, A.M.D. Wan, D.J. Beebe, E.W.K. Young, Micromilling: a method for ultra-rapid prototyping of plastic microfluidic devices. Lab Chip 15, 2364 (2014)

X. Cheng, Z. Wang, K. Nakamoto, K. Yamazaki, A study on the micro tooling for micro/nano milling. Int. J. Adv. Manuf. Technol. 53, 523–533 (2011)

H. Weule, V. Hüntrup, H. Tritschler, Micro-cutting of steel to meet new requirements in miniaturization. CIRP Ann. 50(1), 61 (2001)

X. Liu, R.E. DeVor, S.G. Kapoor, An analytical model for the prediction of minimum chip thickness in micromachining. J. Manuf. Sci. Eng. 128(2), 474 (2006)

E. Vazquez, C.A. Rodríguez, A. Elías-Zúñiga, J. Ciurana, An experimental analysis of process parameters to manufacture metallic micro-channels by micro-milling. Int. J. Adv. Manuf. Technol. 51, 945 (2010)

T. Wu, K. Cheng, R. Rakowski, Investigation on tooling geometrical effects of micro tools and the associated micro milling performance. Proc IMechE Part B: J Eng. Manuf. 226(9), 1442 (2012)

J. Steigert, S. Haeberle, T. Brenner, C. Müller, C.P. Steinert, P. Koltay, N. Gottschlich, H. Reinecke, J. Rühe, R. Zengerle, J. Ducree, Rapid prototyping of microfluidic chips in COC. J. Micromech. Microeng. 17, 333–341 (2007)

J.C. McDonald, G.M. Whitesides, Poly(dimethylsiloxane) as a material for fabricating microfluidic devices. Acc. Chem. Res. 35(7), 491 (2002)

A. San-Miguel, H. Lu, Microfluidics as a tool for C. elegans research, WormBook, ed. The C. elegans Research Community, WormBook (2013)

M.A. Eddings, M.A. Johnson, B.K. Gale, Determining the optimal PDMS-PDMS bonding technique for microfluidic devices. J. Micromech. Microeng. 18(6), 067001 (2008)