Abstract

In the last two decades, fundamental and application-driven research on microfluidics and bio-micro-electro-mechanical systems (BioMEMS) has flourished in academia and industries and has begun to make impact on medicine and bio-sciences. Packaging of these systems is an integral if not critical part of the device/system design and function. Because the applications and the designs of the chips are wide ranging, it is difficult to achieve a universal packaging scheme that meets the requirements of all applications. Instead, research and manufacturing practices of each type of biochip have come up with specialty techniques. This chapter will review these techniques in the specific contexts of the chip applications, as well as materials requirements. In addition, we will highlight common and advanced practices and point out research needs in these areas.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Packaging

- Lab-on-a-chip

- BioMEMS

- Microfluidics

- Medical diagnostics

- Chip-to-world connection

- Biocompatibility

- Surface modification

- Interface

- Integration

- Fluidic interconnect

- Electrical interconnect

- Optical transparency

- Disposable

- Point-of-care diagnostic

- Sample preparation

- Fluid handling

- Soft lithography

- Large-scale integration

- Microfabrication

1 Introduction

In recent years, applications of lab-on-a-chip, microfluidics, and bioMEMS devices have ranged from basic research on macromolecules (e.g., DNAs and proteins), cells, tissues, and organisms to clinical applications (e.g., blood analysis, disease diagnosis, and drug delivery). The device design and the final packaging of the devices demand two very important aspects of compatibility. First, the fabrication processes and sequences of all components (including device or reagents) need to be compatible with each other. Second, the devices and their packaging need to be biocompatible, whether it is referring to minimizing sample contamination, optimizing sample interaction with device/packaging materials, or eliminating immune responses to implanted devices. Therefore, in designing these biochips, one has to consider not only the functionalities but also the packaging scheme with the final product and the environment in which it will be used.

This chapter is organized to address packaging issues in a variety of applications, packaging schemes that are commonly used, the types of interfaces one needs to think about (e.g., interface with the outside environment and interface between devices), and the materials of choice and their modifications. In designing a good packaging scheme, one needs to strategize in terms of constraints and a series of trade-offs. No packaging scheme is universal, and there exist many options. Depending on how the devices are designed and how they are intended to be used, the packaging scheme can be very different, and aspects that have smaller design space (miniaturization) need to be considered first. For example, if an implantable device needs to be packaged, the most important aspect is the biocompatibility; next, one needs to consider where the device is to be implanted and then match the mechanical properties of the tissues and consider all the geometrical constraints. More than often, the infrastructure that is available to manufacture the devices and the packaging will also put constraints on selecting the processes. For industrial applications, overall cost is likely an important parameter.

This chapter aims to point out some standard solutions and research opportunities in bioMEMS packaging and will refer to many primary research articles for detailed information on existing technologies.

2 Packaging Schemes Based on Application

2.1 Portable and Point-of-Care (POC) Diagnostics and Analysis

Owing to their small size, bioMEMS are ideal platforms upon which to design portable and point-of-care (POC) diagnostics and analytical systems. Portability is an essential consideration in the design and packaging of systems intended for use in resource-poor or similarly challenging environments. These environments lack the infrastructure of typical “developed-world” clinical laboratories, which provide stable electrical power, cleanliness, refrigeration, and highly trained personnel. Interest in developing bioMEMS-based portable analytical systems originated in the 1990s from the US Defense Advanced Research Projects Agency (DARPA), seeking to enhance chemical and biological weapons detection and to improve battlefield medical care. More recently, interest from both governmental and charitable organizations has led to significant investments in developing portable diagnostics to avert epidemics in poor and remote geographies [1, 2].

The design and packaging of portable diagnostic systems must satisfy a challenging set of requirements. Such requirements include (i) small size and weight, (ii) full integration of necessary functions (unit operations), (iii) low power consumption, (iv) easy operation by potentially non-skilled personnel, (v) functionality in wide temperature ranges, (vi) ruggedness and mechanical protection, (vii) protection from dust or other contaminants, and (viii) low cost.

The packaging schemes that have emerged to address the above requirements can be grouped into two broad categories. The first category focuses upon integrating as many functions as possible onto a single chip in order to maximize portability. The second category consists of systems that are partitioned into two components: (i) a disposable chip (or cartridge) and (ii) a readout machine (or scanner). The cartridge is inserted into the scanner, read and analyzed, and then discarded. Both the integrated and partitioned categories are discussed in the following sections.

2.1.1 Integrated BioMEMS Packaging Schemes

Integrating functions onto a single bioMEMS device are the central aim for packaging diagnostic systems when size and weight are the most important criteria. Basic functions in a typical diagnostic system include fluid handling (i.e., pumping and mixing), reagent storage, species separation and concentration, and detection. Today, diagnostic chips that integrate all necessary functions are rare. In most cases, the devices are designed with a specific function in mind.

The major challenges in portable chip-scale integration involve fluid handling, detection, and electrical power. Fluid pumping for analytical purposes has traditionally been carried out using macroscale machines (i.e., peristaltic, syringe pump). Likewise, analyte detection is normally accomplished using complex optical or spectroscopic techniques that require bench-top equipment, which are usually expensive and bulky. In such forms, both functions require power sources that exceed the latest capabilities of portable batteries. To circumvent these challenges, integrated biochips must often rely upon passive fluid transport mechanisms (e.g., capillary action) and simplified “yes/no” detection readouts for portable diagnostics.

Immunochromatographic Test Strips

The classic example of integrated, portable diagnostic devices is immunochromatographic strip (ICS) tests. ICS tests are packaged with a strip of fibrous material that is divided into a sample pad, conjugation/labeling region, and detection zone. The strip is contained in a plastic casing with access windows over the sample pad and detection zone. Fluid samples are transported along the strip via capillary action through the pores and channels in the fibrous material and are bound to an antigen (or by an antibody) as they pass through the labeling region. Typically, a dye is labeled to the analyte, allowing for easy visual readout by the operator. ICS tests have been successfully deployed “in the field” for over 10 years to diagnose infectious agents like diphtheria toxin [3] and various sexually transmitted diseases [4,5,6]. The ICS packaging scheme is advantageous because it does not include any active power source. In addition, materials and reagents are off-the-shelf, inexpensive, and compatible with high-volume production methods.

The primary drawback of ICS design is its relatively crude “yes/no” readout mechanism (although visual readouts can also be an advantage if the operator is non-skilled). Paper-based microfluidic systems are being developed that provide colorimetric readout of digital images [7,8,9]. Such systems are comprised of a paper sheet that is embedded with a photoresist pattern that guides sample fluid into different detection zones. Each zone contains different labels for parallel diagnoses. Paper-based systems exhibit the same packaging advantages as ICS systems. However, the image acquisition is performed using a digital camera, which reduces the degree of integration but increases the precision of the measurement due its semi-quantitative nature. For both ICS and paper-based microfluidics, this simple packaging scheme is compatible with the economic requirement of the applications.

Electrical Detection

In order for portable diagnostics to provide fully quantitative measurements, researchers are investigating ways to miniaturize sophisticated detection components and package them on-chip. The most actively researched techniques are electrical, mechanical, and optical. To achieve electrical detection on-chip, conductive electrodes are integrated into the flow path of the sample fluid. The electrodes are typically metallic and are sometimes functionalized with molecular probes or modified with a selective membrane. The simplest packaging configuration for electrical detection is to pattern electrodes on a planar substrate, which is interfaced with another substrate that contains the sample flow path (Fig. 12.1). Several examples of this configuration exist, most notably for glucose and urea detections [10, 11], where a current or a potential is measured as a result of redox (reduction and oxidation) reactions on the substrate. A similar packaging configuration enables ICS test strips to give fully quantitative outputs using screen-printed, disposable electrodes that couple to quantum dot labels [12]. Also, highly sensitive and reversible electrical detection of antibodies has been demonstrated using silicon nanowires grown on an oxidized silicon surface and coupled to a polydimethylsiloxane (PDMS) flow channel [13, 14]. The challenge is that often sensitive off-chip electronics are needed to detect minute changes in current or potential.

Electrodes used for sensing are deposited on the surface of the device, with the sensing portion protruding into the fluidic components. Packaging materials compatible with the manufacturing requirements have to be chosen. For example, if the device is to be polymer based, deposition of metal electrodes will be complicated and will require modification of the polymer

Mechanical Detection

On-chip mechanical detection has been achieved using a two-substrate packaging scheme similar to electrical detection. Mechanical detection has been demonstrated using micro- and nanoscale cantilever beams that are machined from bulk silicon using MEMS fabrication techniques and functionalized with the appropriate capture probes [15, 16]. A change in the surface stress or resonance frequency of the cantilever indicates binding of biological species. The cantilever’s mechanical output is then measured in two ways: (i) optically, by tracking the change in location of a laser beam reflected off the cantilever or (ii) electrically, by coupling a piezoresistive element to the edge of the beam. As a result, cantilever detectors must be packaged in a manner that can interface to optical components or electrical leads, respectively. Specifically, optical detection would require a viewing aperture with a transparent substrate (and laser beam alignment and position detection), while electrical detection would require attachment of leads to bond pad arrays (Fig. 12.2).

Mechanically based bio-detection via cantilever beams requires optical and electrical access in packaging. (a) A stress-based cantilever functionalized with capture probes is exposed to fluid containing a ligand of interest; attachment of the ligand causes the beam to deflect, changing the angle of reflected light. DNA hybridization and protein–protein interactions have been reported using stress-based methods [17, 18]. (b) A resonance-based cantilever responds by changes in resonance frequency due to changes in mass as ligand attaches to capture probes [19, 20]; piezoelectric actuation requires electrical leads and interconnects in packaging.

Because of such additional components, portable and fully integrated cantilever- based diagnostic systems have yet to be realized. However, a major advantage of cantilever-based detection, which is the ability to detect molecules without attaching optical (e.g., fluorescent) labels to the molecules themselves, motivates continuing research. Label-free, stress-based detection has been demonstrated with DNA and proteins [17, 18, 21, 22]. In addition, resonance-based detection has been demonstrated with cells [20] and viruses [19]. A particularly novel resonator is configured so that the sample flows through a microchannel in a hollow cantilever, which enables sub-femtogram measurement resolution [23, 24]. High sensitivity is made possible by packaging the cantilever and drives electrode under high vacuum in a hermetically sealed cartridge. Such innovation in both fabrication and packaging is a good example of collaboration between academia (MIT) and industry (Innovative Micro Technology, Inc. and Affinity Biosensors). Although some progress has been made in this area in miniaturizing and integrating the detection modules, most mechanical detection chips still require some off-chip components (i.e., optics). This area therefore remains an active research area for miniaturization.

Optical Detection

The miniaturization and integration of optical detection on-chip is also an active area of research. Packaging schemes vary dramatically, depending on which optical components are deemed critical for integration. The most basic approach is to attach a separate module containing a miniaturized excitation source and photodetector directly to a chip containing the appropriate flow network. Although it is not true chip-scale integration, the modular approach confers advantages with respect to flexibility and convenience, while maintaining acceptable (though not ideal) size and weight. Such an approach has been successfully employed to couple a glass capillary electrophoresis chip to a light-induced fluorescence (LIF ) module to detect protein biotoxins (i.e., ricin, botulinum toxin) without preconcentration [25].

A similar modular approach assembles a miniature diode laser, sample well plate, and detection chip. The use of a self-contained detection chip in lieu of a full-size camera makes the assembly better suited for field use, and diffractive optics split the excitation beam into 16 channels, resulting in parallel analysis of 16 corresponding wells. The chip-to-plate approach is shown to detect low concentrations of Bacillus globigii, a surrogate marker for Bacillus anthracis, utilizing ELISA signal amplification to compensate for the detection chip’s limited sensitivity [26].

True on-chip integration of optical components has been achieved on a limited basis. The concept of a “microscope-on-a-chip,” integrating miniature lenses and complementary metal oxide semiconductor (CMOS) detectors on-chip, has been investigated [27]. Optical fibers micromachined with angled grooves have been embedded underneath microfluidic chips to guide excitation beams into multiple flow channels simultaneously [28]. Similarly, optical fibers have also been directly inserted into waveguides patterned in photoresist (SU-8, a multifunctional epoxy negative photoresist, manufactured by MicroChem Corp.) [29].

Using soft lithography, the fabrication of several optical components, such as beam splitters, lenses, and prisms, has been shown [30]. Moreover, integrated circuit (IC) fabrication techniques have been utilized to produce monolithic light- emitted diodes (LEDs), photodetectors, and optical fibers [31]. From a packaging standpoint, this represents a high degree of integration, uniting the excitation source, waveguides, and detectors onto a single silicon chip that is attached to a PDMS microfluidic flow channel. In a similar display of high integration, optical waveguides in photoresist, an optically pumped dye laser, and photodiodes embedded in silicon have been integrated on-chip [32]. On-chip optical integration is a large and diverse field [12, 33]. Nevertheless, the field is still in its infancy, providing few portable packages for diagnostic applications today.

Other Components

The portability of diagnostic devices has been improved by the integration of other components, such as vapor barriers to prevent the evaporation of fluids from microfluidic systems constructed from gas-permeable elastomers [34]. Also, on-chip diaphragm-based pumps and valves, which rely upon thermal actuation from resistive losses from adjacent electrodes, have been integrated into a portable polymerase chain reaction-capillary electrophoresis (PCR- CE) system [35]. Furthermore, the storage and release of reagents on-chip has been addressed by the integration of torque-actuated screw valves, which eliminates the necessity for electrical power when closing or opening microfluidic flow paths [36].

Integration Outlook

Although the full integration of all essential functions onto a single chip has not been realized, some devices have come very close to being total analysis system “on a chip” [37,38,39]. As previously discussed, fluid handling, detection (i.e., electrical, mechanical, optical), and electrical power are the major challenges in developing a fully integrated device. In addition, stored reagents could also add to the bulk of a diagnostic chip. The trade-off one makes as more functions are integrated on-chip is that detection sensitivity typically decreases. In addition, the cost per chip increases. Because of these limitations, the idea of inserting a simple and disposable diagnostic chip into a separate scanner box could provide a workable compromise between portability and performance.

2.1.2 Portable BioMEMS Chip in Tandem with a Readout Box

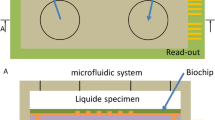

By partitioning a portable diagnostic system into a disposable chip and a scanner, not only can high performance be provided, but also cleaning and per-test costs are reduced. From the design standpoint, a major task is to decide what mix of functions will be located on the disposable chip versus on the reader. Careful consideration will result in functions that are located in a manner that maximizes the combined benefit of detection sensitivity, ease of use (during testing and maintenance), and low cost. From there, packaging can be developed that properly interfaces the chip to the reader and the reader to the operator. Figure 12.3 illustrates the concept of the partitioned approach.

A bioMEMS chip used in tandem with a scanner. Functions are partitioned between the disposable chip and scanner box, thereby optimizing critical factors (i.e., cost, detection sensitivity, portability) [2]. Interconnect between the two elements, as well as scanner maintenance, is an additional packaging consideration

A champion of the partitioned design concept is the Yager Research Group at the University of Washington. Its development of a disposable diagnostic card for saliva testing is an insightful case study [2, 40]. Most active functions, such as fluid pumping and surface plasmon resonance [41] excitation and detection, are located on the scanner. Functions located on the chip, which include sample preconditioning, mixing, and assaying, are specifically designed to be passive in nature. For instance, the mixing region relies upon chaotic mixing that is induced by herringbone structures as fluid flows through the channel. Also, the diffusion of small molecules across the interface of two laminar flow streams (buffer and sample) is utilized to precondition the sample before assay. Such a preconditioning approach cleverly removes the necessity for less portable preconditioning methods (e.g., centrifugation). The chip (roughly 4 inches by 2 inches in size) consists of a PDMS slab containing the flow channel network that is bonded to a glass slide, which is gold-coated and functionalized for antibody capture. Rubber gaskets (O-rings) are embedded into the fluidic inlet/outlet ports to facilitate connection with off-chip pumps and other active elements.

A similar partitioned package, consisting of a microfluidic chip whose channels are loaded with polyacrylamide gel, has been used to perform electrophoretic immunoassays to measure the concentration of the protein MMP-8 from a saliva sample [42]. The glass chip is inserted into a portable scanner containing a user interface , miniature high-voltage power supply, data acquisition, and software control. Although some sample preparation and fluorescence imaging was performed with standard laboratory equipment, the system proves the principle of a modular, point-of-care microfluidic assay for a clinically relevant disease marker. The choice of glass also minimizes work that has to be performed for surface modification and ensures optical compatibility for the readout.

The partitioned design strategy is being pursued in other contexts also [43]. A capillary electrophoresis (CE) chip for the separation and detection of organophosphate nerve agents has been demonstrated as a chemical weapon detector [44]. The glass chip contains a CE channel coupled to a screen-printed carbon electrode for amperometric detection. The scanner houses the electrochemical detector, reference/counter electrodes, and buffer/sample reservoirs. A portable, highly parallel SPR system has also been developed for chemical weapons detection [45]. The system is based on the Texas Instruments’ Spreeta sensing chip, which contains three LEDs and a diode array detector. The sensing chips are inserted into a control box that houses the power supply, LCD touch screen display, custom electronic board, and fluidic elements, such as pumps and valves. Each chip is replaced via a snap-in mechanism that mates it to a silicone flow cell. The combination of eight chips, each having three channels, enables the simultaneous monitoring of up to 24 analytes.

Yet another embodiment of the tandem strategy utilizes a cartridge in which cells are cultured and stimulated for use as a cell-based biosensor [46]. The cartridge is made of a CMOS silicon chip bonded to a PDMS slab patterned with cell chambers. Circuitry on the CMOS chip enables temperature control and electrophysiological sensing with microelectrodes. The cartridge interfaces with a handheld electronic reader that monitors the action potential (AP) activity of cardiomyocytes within the cell chambers. The system has successfully monitored the AP response of cells to different biochemical stimulation under conditions outside the laboratory (desert field testing).

2.1.3 Outlook for Portable Diagnostics

Portable diagnostic and analysis systems have the potential to dramatically improve the health of people in the poorest, most remote areas in the world, especially with respect to infectious diseases. Moreover, the benefits of portability will undoubtedly contribute to the ease and decentralization of disease management in the developed world as well. One could imagine patients wearing portable diagnostic devices that monitor their response to drugs for screening or dose titration purposes, which would be a critical step toward realizing the concept of “personalized medicine” [47, 48].

The major challenges facing packaging, as previously discussed, are function integration and partitioning between disposable and non-disposable components. Another challenge is cost. Virtually all prototype devices today have been fabricated out of relatively expensive base materials, such as glass, silicon, or PDMS . Furthermore, their fabrication processes may not be ideal for mass production, unlike thermoplastics that can be hot-embossed or injection-molded, which makes them disposable. For example, a microfluidic immunosensor made of embossed plastic has recently been applied to monitor cardiac inflammation markers from human serum [49]. On the other hand, some applications have stringent materials requirements that disqualify some plastic materials; hence, glass and PDMS continue to serve in many areas as the materials of choice.

Besides the device components, the packaging of reagents presents an additional challenge to system portability. To reduce bulk and transportation costs, reagents would ideally be packaged in dry form and reconstituted into solution at the point of care. In situations where the reagent can neither be dried nor reconstituted with local solvents to maintain activity (e.g., antibodies), the reagent solution must typically be packaged off-chip due to inadequate space within the miniscule volume of the on-chip microfluidic network. To address this, the use of plastic clinical tubing as a reagent cartridge has been investigated [50]. Plugs of different reagents are sequentially loaded into a tube and spaced by air. Similar packaging may enable reliable transport of valuable, ready-to-use solutions in portable diagnostic systems.

2.2 Implantable Devices

In the recent years, MEMS technology has become popular in the medical field due to its many advantages over traditional technologies. BioMEMS chips are highly functional, versatile, and power efficient and can be fabricated much smaller than other implantable systems. Furthermore, since bioMEMS fabrication processes originate in the IC industry, the infrastructures of the fabrication are well established, and these techniques are reasonably well developed and standardized [51]. Therefore, it is no surprise that many implantable devices that primarily use IC fabrication technologies, such as wireless pressure sensors [52], subcutaneous drug delivery chips [53], and glucose sensors [54, 55], have been and are being developed and commercialized.

The major packaging challenges for implantable MEMS devices include but are not limited to biocompatibility and size considerations. Another consideration is matching the mechanical properties and sometimes optical properties of the surrounding tissue. Implantation is an invasive process and triggers a healing and immune response from the body. Not only do implants have to be designed to minimize the immediate and long-term immune response, but they are also required to be non-toxic to the surrounding tissue. For this purpose, various packaging methods, materials, and protective coatings are available.

These designs must be developed with the miniaturization requirement in mind. They need to add as little volume or length to the device as possible and have to be adaptable to the specific tissue environment and their applications. For example, ocular implants need to be small enough for implantation through hypodermic needles, flexible enough to not cause irritation to the patients, and to match the mechanical properties of the surrounding tissues, but mechanically sturdy enough to survive the implantation process. The latter is particularly critical because inadequate protection during implantation can cause a complete loss of device functionality [56]. This section will review some successful strategies for implantable devices with these considerations in mind.

2.2.1 Drug Delivery Devices

Packaging for drug delivery devices is highly dependent on the duration of the intended delivery applications. Short- or intermediate-term delivery can be achieved through oral or subcutaneous administration, whose packaging requirement is minimal, typically involving encapsulating drugs in microbeads or delivery through various types of microneedles [57,58,59,60]. However, for long-term controlled delivery, bioMEMS devices seem to be most suitable: these devices can be designed to be highly functional; in addition, if proper packaging is designed, the drug reservoirs for controlled delivery can be made refillable [61].

A highly efficient and reliable controlled-release biochip design for implantation was introduced by Santini et al. [62]. The release of drug occurs from an array of wells covered by a gold thin-film membrane, which is electrochemically dissolved during the time of release (Fig. 12.4a). The reservoirs are fabricated using standard wet-etch MEMS technology in silicon wafers. The gold membrane covering the wells serves simultaneously as an electrical component and as a protective layer for the content of the reservoirs. The gold membrane is chemically stable and mechanically able to resist pressures exerted by the tissue and interstitial fluids [62]. Applying proper voltage to the anodic membrane leads to the dissolution of the membrane. This process is dependent on the presence of chlorine ions (Cl−) in bodily fluids.

Implantable drug release devices. (a) Basic design schematic of the device design by Santini et al. Prior to release, gold membranes form protective caps for drug compartments etched into the device. Once current is applied to the membrane, the gold forms soluble salts with Cl− ions from the environment, dissolving the membrane and releasing the drug. Coating for protection and passivation can be applied. (b) Concept drawing of a drug release system combining active sensing technology and controlled drug release, contained within an implantable protective shell. Concept adapted from research by MicroCHIPS and ChipRx

Soluble salts of gold form due to the applied potential and the presence of Cl−, and instead of which dissolve into the surrounding fluid. Santini et al. established that these salts are biocompatible and are present in very low concentrations after the dissolution of the gold metal [63]. Because silicon is the structural material for the chip, the device overall is suitable for implantation. To protect the metallic components of the chip further from the interstitial fluids, SiO2 is deposited as a protective coating for the device.

This technology is being further developed for commercial application by MicroCHIPS [64]. The aim is to couple the release of drug to sensor devices for improved release timing and schemes. As such, a microchip packaged with a sensor array and a power source would regulate the release of drugs from the reservoirs [53] (Fig. 12.4b). A modified version of the approach, which relies on re-sealable compartments, is being investigated by ChipRx [64]. This technique could prove useful in limiting the size requirement for larger amounts of drugs through the use a single refillable compartment. While silicon is a chemically and mechanically robust material and is usually easy to be rendered biocompatible, one drawback of silicon-based devices is that these devices may not be suitable for other drug delivery formats that require soft and flexible surface materials, such as ocular drug delivery. New approaches and new materials need to be considered.

2.2.2 Ocular Implants

Li et al. [61, 65] developed a drug delivery device enclosed in silicone rubber for ocular drug delivery (Fig. 12.5a). The soft material protects a two-part chip – a reservoir and a delivery chip; the refillable drug reservoir is bound to the delivery chip during the packaging process. The packaging is comprised of a silicone rubber outer surface molded to fit the curvature of the eye, which is filled with paraffin wax and encloses the delivery chip, provided that the chip is small compared to the eye. The advantage of this approach is that the device is completely enclosed in the flexible and biocompatible material [61, 66]. Furthermore, since the enclosure is made of flexible material, the reservoir can be punctured by a needle and refilled with drug, after which the silicone rubber seals itself [61]. This already efficient packaging could be further improved through various surface modification technologies. Integration of traditional IC or MEMS components is also made possible with flexible polymeric packaging [67,68,69]. The chip device can thus be fabricated from the required or desired material and packaged for flexibility. Another option is to design a hard-shell packaging scheme, which must minimally interfere with the tissue in the eye [70, 71].

Examples of devices for ocular implantation. (a) Example of an ocular drug delivery device fabricated with a soft silicone rubber shell for minimal eye irritation is designed by Li et al. [61, 65]. The base is molded to conform to the curvature of the eye. The reservoir can be refilled by puncturing the rubber reservoir cap, which re-seals itself after the procedure. The protective silicone rubber is a soft and biocompatible material and thus suitable for implantable devices. (b) The light sensor is separated from the retinal stimulator in this ocular implant. Only the stimulation chip is implanted in the eye, while the light sensor or camera is worn on the outside. This allows for minimal invasiveness, especially if the implanted chip is made from soft and flexible biocompatible materials

Another type of ocular implant is the retinal stimulation device (Fig. 12.5b). The purpose of this implant is to stimulate the ocular nerve in diseases caused by photoreceptor degeneration. These implants incorporate image sensors and electrode stimulators to facilitate image capture and nerve stimulation, which renders the chip more complex [69]. Because of the electrical components, CMOS fabrication technology is used to produce the device components. Typically all of the components are fabricated on a highly flexible silicon substrate. The silicon substrate between these components is then thinned, leading to an overall flexible device [69].

Monolithic integration of all parts for ocular implant devices can be advantageous in terms of simpler design because of the electrical connectivity and signal transduction among the sensing, stimulation, and electronics components. However, this monolithic scheme comes with the price of having larger devices. The alternative is then to reduce the number of components in the system to be implanted. In the case of ocular implants, image sensors/CMOS cameras can be worn on the outside, while only a signal receiver and the stimulation chip (with its electrodes) need to be implanted. In one packaging scheme, the implanted components are then coated with Parylene-C to form a biocompatible protective layer [67, 68] where the device is fabricated on a flexible (but not necessarily biocompatible) substrate, such as polyimide [68].

Hard-shell protection for the implanted device is also an option. Since the shell is not flexible, its shape and size should be minimally invasive to the eye. Tube-like capsules can be fabricated from glass, ceramics, metals, or silicon, all of which must be hermetically sealed to the device [71]. This method has been pursued by BION™ implants. These implants incorporate circuitry, a power source, and other functional parts within a hermetically sealed tantalum tube [70]. The rugged yet biocompatible tube is small enough to be implanted through a needle.

2.2.3 Neural Interface Implants

Some of the most common neural interfaces include pacemakers, neural probes, brain stimulators, and cochlear implants [72, 73]. The connection to the nervous tissue usually occurs through electrodes implanted into the brain tissue and in the vicinity of neurons and their processes. These electrodes are commonly organized into arrays such as the Michigan probe array and Utah array [74,75,76]. Both of these are variations of arrays of long silicon multi-electrode probes (Fig. 12.6) and are commonly coated with silicon nitride (SiN), silicon dioxide (SiO2), or gold [73] to improve biocompatibility.

Device details and packing of typical neural probes. (a) Microfabricated neural probes are usually mechanically mounted on and electrically connected to a circuit board. The probes are inserted into brain tissues for recording of neural activities. (b) These microfabricated probes can include either a single probe head or multiple parallel probe heads. (c) The tip of the probes can incorporate both metal electrode leads and fluid delivery ports. Materials to render the devices biocompatible or to include additional drug delivery capabilities (not drawn)

Besides silicon, which is mechanically rigid and easy for insertion during surgery, other materials are used to create flexible arrays. Common choices include polyimide, benzocyclobutene, and Parylene. Some of these devices also include microfluidic channels for delivery of drugs to discourage scar tissue buildup for long-term recording and stimulation of the electrodes. In most arrays (stiff or soft), it is common to coat the surfaces with (i) poly(ethylene glycol) (PEG) films to minimize protein adsorption and (ii) drug eluting coatings [73]. The latter is achieved by using amphiphilic hydrogel particles that are capable of releasing drugs over time. One challenge of incorporating these particles into the coating is the choice of polymers, which need to be stable and biocompatible over time and also giving the desired drug release profile. Modification of the surfaces to increase porosity may also be used to reduce cell adhesion, which may be especially useful in preventing isolation and preserving functionality of probes [73].

Tokuda et al. [77] developed a general neural interface based on a multi-chip system similar to the segmented ocular implant described above. Several interconnected unit chips equipped with stimulating and recording electrodes can be implanted as a thin sheet. Due to the small size of each chip and flexible interconnects, the array can be bent and extended. However, for added mechanical protection, the chips are anchored on a polyimide film and covered with epoxy resin, which protects the body of the chip while leaving the electrodes exposed [77].

As was the case with ocular implants, hard-shell enclosures may be used with neural interface implants. Biocompatible materials such as titanium could be used to manufacture the shell. The shell has to be hermetically sealed, which can be achieved through the use of medical-grade epoxy, which also provides additional shock absorption for the circuitry [78].

2.2.4 Cardiovascular Implants

Stents

Though stents are not typically considered bioMEMS devices, packaging technologies for stents can be applied to MEMS devices designed to interact with the cardiovascular system. The cardiovascular system is very sensitive to disturbances, and the presence of foreign objects can lead to problems such as intimal hyperplasia, or thickening of the blood vessel wall due to injury, and blood coagulation.

Stents often suffer from restenosis or the re-narrowing of the blood vessel wall, rendering them not functional. To prevent restenosis, various protective coatings have been developed, with the goal to provide a biocompatible interface , which passively or actively limits vessel wall thickening or fouling. TiNOx films can be deposited by physical vapor deposition (PVD); tuning the ratios of nitrogen to oxide allows for control of electrical properties of the film [79]. Polymeric coatings are also often used to provide a protective function. Drugs to prevent restenosis and hyperplasia are often contained in the polymer matrix and eluted from the matrix after the implantation [80, 81]. Although the type of drug may vary, the coating procedure generally relies on the application of a thin layer of polymer–drug mixture in solvents (e.g., by dip coating). Some of common polymers used for this purpose include methyacrylate and ethylene-based polymers [81].

Stents can also be implanted in combination with a pressure sensor to monitor the success of the implantation procedure [52]. CardioMEMS Inc. has developed a capacitance-based sensor enclosed in flexible polymers (Fig. 12.7). The capacitance change of the sensor can be correlated to deflection of the capacitor component from which pressure data can be calculated. The sensor is constructed from ultra- flexible alloys for additional flexibility. Pressure-related data are obtained wirelessly from an external readout machine. Communication between the devices is achieved through an energizing radio frequency (RF) signal sent by the readout machine. The signal is coupled to the sensor via magnetic coupling and induces a current in the sensor, which vibrates at a specific frequency depending on the applied pressure. The readout machine receives the response from the sensor through magnetic coupling and determines pressure based on the frequency of the sensor [82]. In this case, the packaging materials should not interfere with the RF signals.

CardioMEMS wireless pressure sensor. The sensor is implanted inside an aneurism along with the stent. Pressure measurements are obtained using an external readout module. This module sends out RF signals, which energize the LC circuit on the implanted device, including a pressure sensor. The sensors resonant frequency is determined through a series of RF signals with different frequencies; the module receives data through magnetic coupling. Once the resonant frequency has been determined, the pressure reading can be calculated. Packaging for this device not only needs to be biocompatible but also to pose minimal interference to the incoming and outgoing signals

Pacemakers

Pacemakers are electrical devices that interact with the cardiovascular system and the nervous system. Although typically not considered as MEMS devices, they are sometimes interfaced with MEMS devices and have successful packaging schemes that implantable MEMS devices can borrow. Packaging schemes for different components of pacemaker devices face the challenge of different requirements. Typically the power source and control mechanism can be housed in traditional enclosures manufactured from titanium [83], PDMS , to a myriad of other materials. However, packaging of the pacemaker leads has to be treated separately.

Pacemakers are packaged to minimize the required pacing current and the polarization of the lead, to protect the lead from damage, and to reduce the inflammatory response around the lead. The packaging schemes are similar to that of stents; for example, protective polymeric sheaths, such as polyether polyurethane sheaths, are further covered by silicone rubber sheaths [84,85,86]. As was the case with stents, these sheaths may elute drugs, such as steroids, to prevent inflammatory response [84, 85].

2.2.5 Implantable Biosensors

Glucose Sensors

Continuous glucose measurement is critical in monitoring the well-being of diabetes patients. A myriad of glucose measurement techniques is available for subcutaneously implantable glucose sensors. In these techniques, blood sugar can be measured through changes in fluorescence of a glucose sensitive system [87], output current in electrochemistry [54], or changes in viscosity [55]. Since each of these methods relies on different chemical and/or physical principles, packaging schemes must be fitted to reflect the different demands.

Encapsulation of fluorescently sensitive systems, whether they are housed on-chip or in microparticles, can be achieved through coating by PEG hydrogels [87]. To obtain a flexible sensor, which can be worn or implanted, biocompatible polymers can be used [54]. Flexible polymers are particularly useful if bendable electrodes are used in a current-sensing-based device. Bioinert polymers, such as PDMS and dimethylacrylamide (DMA), may be combined with other types of polymers for additional functionality, such as increased permeability of small molecules [54]. Biocompatible rigid sensor enclosures can also be manufactured from materials such as silicon, glass, or medical-grade epoxy [55] to reduce the risk of immune response.

Pressure Sensors

MEMS-based minimally invasive pressure sensors can be used to monitor intraocular, intracranial, and cardiovascular pressures [52], each being of great interest to parts of the medical community [88]. Although the designs may differ, these sensors are generally fabricated using CMOS technology and enclosed in silicon [89,90,91]. The overall device may be further coated with deposited silicon nitride or silicon oxide layers.

As with other implantable devices, pressure sensors can also be coated with a polymer film for protection during the implantation process and normal operation. One such example is the use of Parylene-C as a protective membrane for ocular implants, which can be deposited through CVD processes at room temperature [92]. The polymer package may be further treated to reduce bubble formation on the surface through oxygen plasma roughening [92].

Communication between the sensors and the outside world must be considered in the packaging scheme. For example, ocular pressure sensors can be observed directly through the tissue of the eye, since this tissue is mostly transparent. Choosing transparent packaging such as biocompatible polymers will thus enable readouts by direct observation [93]. However, this option is not available for sensors implanted in non-transparent tissue, such as the CardioMEMS sensor described previously. For deep tissue implants, other readout methods are required, such as the RF-based method.

2.3 BioMEMS Packaging for Clinical Applications

BioMEMS technology is rapidly gaining attention in the clinical field due to its high versatility and broad range of functions. The most common bioMEMS uses can be divided into two broad categories: (i) analytical tools and (ii) components of medical devices, such as endoscopes or catheters. Section 12.2.2 reviews many implantable devices. This section will include additional devices used in medical diagnostics. Analytical devices used in the laboratory environment share designs common with point-of-care diagnostic devices, with some key differences in packaging schemes. The major difference is rooted in the availability of off-chip analytical technology and a clean and protected processing environment in the laboratory. Many of these devices are a direct miniaturization of existing conventional macroscopic assays. Even though all sample modification and processing occur on chip, analysis of the results can be performed off-chip [94] without exposure to an interfering environment. Hence, the challenge for packaging schemes lies in providing ease of interfacing to external instruments and primarily a high level of re-usability of bioMEMS devices.

Enzyme-linked immunosorbent assay (ELISA) devices are a prime example of the common device design. ELISA chips utilize antibody–antigen interactions to detect the presence of specific molecules in the analyte fluid. The sample is pumped through the chip resulting in (i) bonding of specific analyte to a localized protein or enzyme and (ii) changes in chemiluminescence, from which presence of the desired analyte can be inferred. The change is observed by an external camera [94] or on a microscope and processed on a computer. Analogous designs may include a sensor array and wireless transmitters to gather signals and relay them to the final analysis system [95]. Packaging schemes for these types of devices do not face biocompatibility issues but must allow for interfacing the chip to the outside world. This most commonly occurs in the fluidic, optical, and electrical domains, since analytes are introduced in solution and signal gathering occurs through imaging or microelectrode sensing.

Polymerase chain reaction (PCR) chips are also heavily used in the medical field when genetical analysis is required. PCR chips can be manufactured using typical MEMS materials such as silicon, glass, epoxy, SU-8 (an epoxy negative photoresist, MicroChem Inc.), PDMS , poly(methyl methacrylate) (PMMA), poly(ethylene terephthalate) (PET or PETE), and common fabrication processes [96, 97]. These devices operate on fluids, making use of standard microfluidic approaches for pumping, mixing, and flow control. As such, their packaging must allow for easy sample introduction and removal of product. However, reuse of PCR chips (or similar biological or medical analytics devices) is complicated due to risk of contamination from previous samples [96]. This risk is minimized through the use of various cleaning and packaging schemes. Prakash et al. use a removable silane coating in a glass-based device to prevent cross-contamination. A silane layer is first applied to improve the hydrophilicity of internal channels for PCR. After the reactions, the silane is stripped and reapplied for a new run [96]. This method or its analogs for different coatings may improve the re-usability of bioMEMS devices used in the clinical environment. PCR chip packaging is further discussed in Sect. 12.2.4.1.

Microfluidic-based bioMEMS chips are also used for analysis of human blood [98, 99]. The purpose of these devices is to separate specific molecules or cells from the sample for analysis or transfusion. For example, microfluidic devices can be used to remove leukocytes from blood before it is received by the patient to minimize the immune response. Micronics, Inc. has designed a microfluidic device to work in tandem with a readout machine for the purpose of blood (and even urine) analysis [99]. The analysis occurs on a microfluidic card designed to perform all functions related to sample manipulation. The card is placed into a manifold, which allows the card to interact with a computerized pumping and control mechanism. The system can then automatically perform an analysis of the sample included in the card. The packaging for this system must ensure that the card interacts with the control device. Thus, proper precautions have to be taken, especially at the card–manifold interface , where leaking can occur.

Unlike stand-alone bioMEMS devices, packaging schemes for bioMEMS components of medical tools, such as endoscopes [100], are heavily influenced by the tool design and its application. Packaging has to allow for incorporation into the overall apparatus without inhibiting function. Since there are no general device types, no general packaging schemes exist for this application. Rather, each device or chip must be integrated into the complete system with specific considerations for that system.

2.4 General Research for the Life Sciences

Whether a research laboratory is academic or industrial, it is undoubtedly in need of data of higher quality, greater throughput, and potentially newer forms. To address these unmet needs, bioMEMS-based research devices are being developed to offer (i) greater sensitivity and lower noise; (ii) higher throughput, automation, and standardization; and (iii) new functional capabilities.

The packaging schemes for research bioMEMS are diverse and non- standardized. This diversity spans both academic and industrial systems and is due in part to the relative youth of the bioMEMS field. The following subsections will highlight general packaging strategies and considerations for four of the most actively researched applications: PCR–CE analysis, microarrays, microfluidic large-scale integration (MLSI), and cell culture.

2.4.1 Genetic Analysis via PCR and CE

The analysis of DNA and RNA is fundamental to the life sciences. One of the most widely used methods for such analysis is the polymerase chain reaction (PCR). The PCR process amplifies minute amounts of nucleic acids by subjecting a sample solution to a sequence of temperature cycles. PCR is one of the first applications for which biochips have been designed and where integration of different functionalities is demonstrated and therefore is a good example for packaging considerations (Fig. 12.8). The advantages of miniaturized PCR include shorter cycle times, reduced reagent consumption, lower fabrication costs, and reduced contamination.

Examples of different types of PCR systems. (a) In a flow-through system, a syringe pump/injector drives the fluid through the device. The fluid is heated in a cyclic fashion for the PCR to occur, and the result, such as an increase in fluorescence, is observed at the end. Packaging for flow-through systems has to allow for connecting the syringe pump and including inputs for valve control and a source of heat to run the PCR and a transparent area for microscopy. (b) Batch PCR systems do not require an input for a syringe pump, but all other components of the packaging scheme need to be present, such as a heating pad, flow control, and transparent packaging for imaging purposes

Materials

One of the most important factors to consider in the packaging of PCR chips is material selection. First, the choice of material will dictate its thermal conductivity, which in turn affects the device’s temperature cycling rate and overall throughput. Second, optical transparency must be considered, as less transparent materials may limit the device’s utility for real-time optical detection of amplification products. Third, the binding affinity of sample molecules to the material will determine whether the inner surface of the reaction chamber requires a passivation coating. Finally, adequate chemical resistance and dimensional stability are required for cleaning steps and temperature cycles, respectively. One should bear in mind that the factors just discussed are by no means an exhaustive list. For example, cost and manufacturability may also be important.

PCR biochips have been manufactured in silicon, glass, and various polymers. A thorough review of PCR chip technology is by Zhang et al. [97], which among other things includes a detailed list of materials used in PCR chips. In recent years, polymers have gained the most interest due to the potential for very low cost for both raw materials and fabrication. Notable polymers are embossed polycarbonate [101, 102], embossed PMMA [103], and compression-molded poly(cyclic olefin) [104]. Also, hybrid PCR chips constructed out of two base materials have also been investigated. Silicon–glass [105, 106], polymer–silicon [107], and polymer–glass [108, 109] chips have also been realized for various applications.

Temperature Cycling and Heating

Another factor in PCR chip packaging is the choice of heating elements. Thin-film electrodes have been integrated on-chip out of platinum [110], other metals, and doped polysilicon [111]. Indium tin oxide (ITO) thin film has also been used due to its optical transparency [112]. The advantage of thin-film electrodes is the small thermal mass of the integrated chip and rapid heating. This comes at the cost of a more complex fabrication process and the risk of sample contamination due to electrode degradation.

External heating strategies have also been employed. For example, Peltier-based thermoelectric heating plates have been attached to PCR chips [113,114,115]. To achieve intimate thermal contact, a layer of material with high thermal conductivity, such as mineral oil [113, 116] or metal [117], is placed at the interface between the Peltier heater and PCR chip. Peltier heaters are a reliable and modular temperature cycling method. However, their large thermal mass makes it difficult for a single Peltier heater to achieve an adequate ramp rate; as a result, two or more heaters must sometimes be packaged above and below the chip [113, 116, 118]. Other external heaters, such as commercial thin-film resistors [104] and resistive heater coils [119, 120], have been utilized.

PCR heating is also achieved without direct physical contact between the chip and the heat source. This scheme makes the fabrication process simpler. Examples of non-contact heat sources are hot/cold air streams [121, 122], infrared (IR) radiation [123,124,125], and lasers [126]. When non-contact heating methods are employed, the package must provide good contact and thermal conductivity to the chip. In addition, thermal insulation is also important in IR heating, where heat should not be easily lost to the surroundings.

Flow Control

In flow-through PCR systems, where the sample undergoes temperature cycles by flowing past a series of heating zones, a fluid pump must be included in the system. Syringe pumps [127] and peristaltic pumps [128] are examples of flow drivers. In such cases, the pump and PCR chip are separate modules within the entire package. In a few cases, the flow driver has been integrated into the chip itself. Miniaturized peristaltic pumps have been integrated [129]. Also, electrokinetic pumping driven by on-chip electrodes has been used [37]. In these flow delivery schemes, sealing of fluids and interfaces between the chip and the macro-world needs to be considered.

CE and Integration of Other Functions

Capillary electrophoresis (CE) benefits from miniaturization through dramatically increased separation efficiency. One noteworthy innovation in CE packaging is a radial array CE system, which utilizes a laser-excited rotary confocal scanner with four color detection channels, enabling the simultaneous analysis of 96 samples [130]. Moreover, PCR and CE are commonly integrated onto a single chip [37, 43, 104, 108, 113, 116, 131, 132]. By packaging PCR and CE together on-chip, sample handling and risk of contamination are minimized, sensitivity increases, and large-scale parallelization becomes possible. In addition, fluids can be driven by electrokinetic means, thereby obviating the need for an external pump.

The integration of sample preparation and PCR–CE onto a single chip is a less developed endeavor. Sample preparation includes cell separation, isolation, washing, and lysis. Attempts at integrating sample preparation steps include on- chip cell capture and lysis using immunomagnetic beads [38], as well as cell separation using dielectrophoresis [100, 133], or DEP coupled with field flow fractionation (DEP-FFF) [134]. Despite such efforts, sample preparation largely remains an off-chip operation; therefore, major opportunities exist for higher-speed and lower-sample consumption if sample preparation is integrated into a single-chip package.

The integration of detection systems on-chip is in a similarly early stage of development. PCR products are typically detected optically using laser-induced or other fluorescence methods. Optical excitation sources and emission detectors (e.g., mercury lamps and CCD cameras, respectively) are sophisticated and bulky instruments usually located off-chip. Using these systems, an integrated PCR–CE chip must be optically transparent and have an unobstructed observation path. Efforts to integrate detection on-chip are limited. For instance, photodiodes have been coupled to PCR chambers via integrated optical fibers, with the excitation source remaining off-chip [135].

2.4.2 Microarrays

Microarray technology is considered one of the first realizations of truly high- throughput biological analysis [136]. A microarray is a grid-like arrangement of micrometer-scale spots on a planar substrate. Each spot is a surface-deposited cluster of molecules known as capture probes. The two most common types of microarrays are DNA and protein arrays. The capture probes on DNA microarrays are either single-stranded oligonucleotides or complementary DNA (cDNA), whereas the capture probes on protein microarrays could by definition be one of many different types of proteins, including enzymes, antibodies, peptides, or protein complexes. When a sample solution containing DNA, RNA, or proteins (a.k.a. the target) is incubated with the array, the target molecules bind to the capture probes of the spots on the array to varying degrees. Binding and capturing are facilitated (i) by hybridization between complementary DNA–DNA or DNA–RNA sequences or (ii) by protein–protein or protein–DNA interactions. Fluorescent labeling of the target probes enables the researcher to optically detect the presence and/or interactions of thousands of different target probes simultaneously on a single array.

The emergence of microarrays can be attributed to a serendipitous merger of precision robotics, microelectronics fabrication, biology, and chemistry over a decade ago. Today, a wide variety of microarrays is commercially available from several manufacturers (e.g., Affymetrix Inc. and Nanogen Inc.). Microarrays are used for both basic and applied purposes, including gene expression analysis, mutation analysis, protein function studies, drug development, diagnostics, and forensics. Recent reviews offer a detailed discussion of current and future applications [137,138,139,140,141].

General Packaging and Fabrication

The typical packaging scheme for a commercial microarray consists of a glass or quartz substrate that is encased by a card-like plastic cartridge. The substrate acts as a rigid support upon which the capture probe array is patterned and subsequently read. To facilitate the attachment of capture probes, the surface of the substrate must be pre-treated or otherwise modified (not discussed here) [136]. Furthermore, the substrate in the optical path is required to be transparent and minimally autofluorescent so as not to interfere with the probes’ fluorescence signals.

The capture probe array is patterned using one of many techniques, including an in situ photolithographic synthesis or an electric field-mediated attachment (for DNA arrays), as well as robotic spotting or microstamping (for protein arrays) [136, 142].

Cartridge

The cartridge serves a number of purposes: (i) protecting the substrate from mechanical damage, (ii) forming an enclosed reaction chamber and flow path, and (iii) interfacing the substrate with external supporting equipment. An enclosed reaction chamber is beneficial because it lowers the usage of sample/wash buffers and prevents the evaporation to the external environment; the enclosure also permits straightforward connection to external fluid ports (which in turn link with pumps, sample, and waste) and eases handling by the operator. Rubber septa/gaskets are embedded at the inlets to the cartridge to interface with external fluid connections, forming a leak-free re-sealable fluid port. Also, the cartridge must have a viewing window for optical interrogation of the array in addition to a shape that facilitates easy loading and automated processing in a scanning system.

Supporting Infrastructure

The microarray package is supported by a substantial collection of bench-scale equipment. This includes a fluidic module (i.e., pumps and reservoirs for samples, buffers, and waste), scanning system and housing, computer, and equipment for sample preparation (e.g., PCR, fluorescent labeling) [143]. The scanning system contains the excitation source, such as laser or mercury lamp, and the emission detector, such as photomultiplier tube (PMT) or charge-coupled device (CCD).

Integrated Packages

The footprint, complexity, and sample usage of the total microarray system can be reduced by miniaturizing and packaging elements of the supporting infrastructure into the cartridge. In one instance, sample preparation, including PCR and target labeling, was integrated with the array on a single chip that is less than the size of a credit card [144]. The chip interfaced with 10 buffer connections, three Peltier heater–coolers, and over 100 gas pressure lines to actuate on-chip valves. Functionality of the chip was demonstrated by detecting mutations from a low copy sample of RNA. Another device was demonstrated to have even greater upstream integration by including cell capture and lysis, as well as PCR and DNA hybridization, on a single chip [38]. In this setup, no external pressure sources were required, as fluid pumping was provided by thermoelectrically actuated on-chip valves. In addition, the hybridization was detected using an integrated electrochemical sensor. Although the chip’s resolution and sensitivity are less favorable in comparison with that of optical arrays, the simplicity to detect the presence of bacteria from a sample of whole blood was an advantage.

The integration of new functions can also make dramatic improvements in performance. A notable example is the desire to speed up hybridization. Under normal circumstances, hybridization is driven solely by molecular diffusion of targets to the capture probes, which could take many hours. In one device, the target solution was oscillated by an on-chip pump, thereby introducing convection to the fluid and increasing the hybridization rate many times over [145]. Cavitation microstreaming, which mixes fluids by vibration, has also been integrated on-chip and shows a fivefold increase in hybridization [38, 146]. Because DNA molecules are charged, it is also possible to use electrical field to increase the mass transfer of the target molecules to the surface. The packaging of any of these flow devices would require somewhat more complex schemes, where a pump, a piezo-actuator, or electrical leads need to be accommodated.

Integration Outlook

Naturally, higher integration will lead to more interconnect-related challenges in the package, particularly for electrical and fluidic interconnects. In addition, the increasingly commercial nature of the microarray field will demand fabrication processes and raw materials of lower cost. The use of polymer substrates that are amenable to high-volume manufacturing (i.e., embossing, injection-molding) may bring the end results closer to both goals [147,148,149]. The integration of new functions and materials, while introducing short-term challenges, will likely lead to higher performance and more economical microarray packages [150].

2.4.3 Microfluidic Large-Scale Integration

Microfluidic large-scale integration (MLSI) is a term describing microchips that possess a dense arrangement of fully integrated valves, channels, and chambers [151]. Invented by researchers in Stephen Quake’s group, the enabling technology for MLSI is a miniaturized, elastomeric valve that is fabricated monolithically into the microfluidic network of the device using soft lithography [152] and thermal bonding [153]. Such valves are used to perform fluid handling operations, such as pumping and mixing, and to isolate chambers (or sections) of a device from fluid flow.

Out of all bioMEMS platforms, the layout and packaging of MLSI devices are most analogous to that of microelectronic integrated circuits (ICs). In MLSI, multiple layers of channels, chambers, and valves are stacked upon each other in a grid-like configuration that is reminiscent of the multilayer architecture comprised of metal lines, transistors, and gate electrodes found in ICs. Moreover, fluidic interconnections between MLSI inlets (or outlets) and external tubes are accomplished by rows of densely packed, hollow metal pins positioned in a manner that resemble the bond pads and vias at the edge of ICs (Fig. 12.9).

An illustration of a MLSI system. The MLSI chip is mounted to a microscope stage for optical interrogation. The chip is comprised of an elastomeric block, patterned with a microfluidic network, which is bonded to a glass substrate. Rows of hollow L-shaped pins connect the on-chip network to external tubing. A magnified view shows a portion of the multilayer architecture that enables the construction of monolithic valves and dense arrays. MLSI systems typically require extensive off-chip infrastructure, including solenoid valves, a pressure source, and computer control

The applications of MLSI are diverse. The detection of mRNA from single cells [154], synthesis of precious reagents [155], and realization of a non-fouling bacterial chemostat [156] are a few questions that have been addressed by exploiting the highly integrated nature of MLSI. In addition, commercial MLSI systems are currently used as tools for protein crystallization screening and genetic analysis [157,158,159,160].

Packaging and Infrastructure

Although MLSI systems are employed in diverse applications, their design layout and packaging are similar. All MLSI devices are fabricated out of the elastomeric polydimethylsiloxane (PDMS) or a fluorinated elastomer that behaves similarly to PDMS [161], which is both amenable to replica molding and exhibits plastic deformability that is essential for valve operation. The features in MLSI devices are typically configured in an array of modules that share common bussing channels, pumps, or specific unit operations. Also, MLSI systems are almost universally packaged to interface with external optical detection instruments. Therefore, glass slides are used as the device’s support substrate, and inlets/outlets (with accompanying interconnect pins) are located near the edge of the chip to allow for unobstructed viewing.

The off-chip infrastructure consists of a computer-controlled battery of solenoid valves that stand between the chip and a pressure source (i.e., compressed gas tank). Selective actuation of solenoid valves actuates corresponding on-chip valves via pressurization or depressurization. Furthermore, reagents are commonly stored off- chip in vials or syringes.

Outlook

The dense packing and computer control of fluidic components have led to unprecedented parallelization and automation, respectively. However, the extensive off-chip infrastructure and the lack of standardized fabrication and interconnect methods are aspects of ongoing research, which will potentially enable wide applications of MLSI. Strategies to minimize the number of off-chip solenoid valves for a given set of on-chip operations, as well as general design rules, are being advocated [146, 162]. The development of alternative valve actuation techniques could ease implementation by eliminating the need for solenoid valves and bulky compressed gas tanks. For example, bioMEMS chips have been mounted to Braille displays, whose piezoelectric pins slide up and down to actuate on-chip valves [163,164,165]. Similar to pneumatic monolithic valves, when Braille pins slide upward, they deform the PDMS membrane and seal the flow channel directly above them. The tandem package of a chip and Braille display could substantially improve MLSI device portability; however, it may restrict the optical access of the chip. In addition, standardized interconnect strategies are likely being pursued by commercial manufacturers on a proprietary basis [166, 167]. This could lead to the development and acceptance of industry-wide standards in the near future.

2.4.4 Cell Culture and Assay

One of the most promising applications of bioMEMS and microfluidics is the culture and assay of living cells. Microtechnologies possess unique capabilities that can dramatically increase the resolution and content of data from cellular experiments. In addition, experimental parallelization and throughput can be greatly improved [168,169,170].

The maintenance of living entities brings with it additional requirements, which in turn affect the packaging of devices. One requirement is the control of temperature at physiological (or experimentally perturbed) levels. Also, the transport of nutrients to the cells must be provided on a continuous or semi-continuous basis to match the cells’ metabolic rate. Added to that must be the means to monitor the levels of critical nutrients or other culture conditions, such as pH and dissolved gas concentration. Moreover, biocompatibility of the device interior must be assured through appropriate selection of base material, polymer coatings, or adsorption/functionalization with specific biomolecules.

Integration of Functions

One way to accommodate for the additional requirements of cell-based systems is to integrate more functions on-chip. Specifically, many requirements are met by integrating electrical components into the device. Temperature control has been demonstrated by the use of microfabricated indium tin oxide (ITO) electrodes [171, 172]. In addition to being conductive, ITO has the added benefit of being transparent, making it an ideal choice when optical interrogation is required. Also, the on-chip electrochemical generation [173, 174] and measurement [65, 173, 175] of dissolved gas have been demonstrated. Similarly, integrated measurement of pH has been achieved [176]. Moreover, the manipulation and positioning of cells into specific locations within a device has been investigated using dielectrophoresis [177,178,179]. As a consequence of integrating electrical functions on-chip, the packaging of bioMEMS is complicated by the attachment (or bonding) of electrical leads to bond pads at the edge of the chip. External power supplies and driver electronics are also required.

Integration of other functions can be achieved through MLSI or arraying approaches. The culture of stem cells has been demonstrated in an array of cell chambers, each of which was semi-continuously perfused with the necessary growth medium [180]. Fluid handling within the device is performed by integrated valves and pumps, and the corresponding fluid interconnect is achieved via rows of densely packed hollow pins. The pins are in turn connected to a computer-controlled row of solenoid valves that lead to a compressed gas pressure source. Other cell-based bioMEMS with innovative linear [181, 182] and radial [183] arrays avoid reliance upon integrated pumps, which reduces the on-chip complexity. However, this necessitates the use of additional off-chip equipment, such as syringe pumps or rotary motors. These trade-offs need to be evaluated according to the specific needs of the applications.

Optical Interface

One off-chip function that has a great impact upon cell-based device packaging is optical detection. Many assays require very high magnification microscope systems. For instance, the forces exerted by cells as they crawl along a substrate have been measured by observing minute changes in the location of dots embedded in an elastomeric substrate [184] and bending of elastomeric pillars [185]. To manipulate and position cells optically, high-power laser beams are necessary using optical tweezing techniques [186, 187]. BioMEMS for such applications must be fabricated of optically transparent materials, and just as importantly, their thickness must accommodate the short working distance of the high-magnification objectives (Fig. 12.10). Occasionally when there is thermal stress(induced by laser power adsorption by the medium or the cell), one must also provide effective means to dissipate the heat so as to reduce cellular damage.

Optical access to the chip, especially at high magnifications, strongly depends on the chip packing. In transmission mode, both the condenser and the objective need to have access to the chip without hindrance of the fluidic, electrical, and mechanical connectors. The working distance of the lenses is a critical parameter to consider. In fluorescent mode, the objective still needs access to the chip; since no condenser is necessary, the fluidic and electrical connections as well as the mechanical clamping mechanisms can be placed on the open side of the device

3 BioMEMS Chip Interfacing

The previous section covers the specific strategies of packaging in many applications of microtechnologies in biological and medical research and practice. This section reviews two important interfaces in biochip designs: the interface between various components of a microsystem and the chip-to-world interface that is critical to operations and functions of each chip.

3.1 Interfacing On-Chip Components in BioMEMS

The integration of various types of components on a bioMEMS chip can prove challenging if the fabrication methods are incompatible. For example, bioMEMS chips often contain immobilized biomolecules, such as DNA or proteins. The high temperatures required for some of the traditional MEMS fabrication steps easily denature these molecules. For instance, although room temperature deposition has been achieved through ammonia catalysis [188], chemical vapor deposition of SiO2 and SiN commonly occurs at temperatures in excess of 250 °C [189]. Therefore, intermediate protective packaging steps need to be introduced to allow the integration and interfacing of seemingly incompatible components, such as the deposition of biomolecules and CMOS technology.

The order of manufacturing steps becomes part of the packaging scheme if protective packaging or modification of fabrication technology is unavailable or infeasible. The order is especially important in manufacturing of hybrid MEMS chips, such as CMOS/microfluidic chips. CMOS and microfluidic components will generally have to be integrated following separated fabrication steps. Integration of biological functionality such as adhesion of DNA, proteins, or enzymes will have to occur last and in already covered devices.

Lastly, interfacing of different components can be difficult when the materials used for their fabrication are incompatible. For example, common bioMEMS materials, such as PDMS , can be difficult to interface with CMOS technologies. PDMS is a poor substrate for the adhesion of deposited metals due to the low surface energy of PDMS [190, 191]. If PDMS packaging is to be used with CMOS technology, better adhesion between the metallic and polymeric layers must be achieved. Furthermore, due to the elevated temperatures during metal deposition, the PDMS surface can buckle upon cooling and cause uneven surfaces and cracks in the metallic layer. Therefore, sufficient cooling of the PDMS layer during metal deposition is required to minimize this effect [192].

3.1.1 Protecting Biomolecules with Intermediate Packaging Steps and Modification of Manufacturing Methods