Abstract

The glycoside hydrolase-catalyzed polycondensation of activated glycosyl monomers such as glycosyl fluorides and polyaddition of sugar-oxazoline monomers have been reviewed. Various kinds of oligo- and polysaccharides including natural cellulose, xylan, chitin, hyaluronic acid, and specifically modified functional polysaccharides have successfully been prepared by this methodology. Based on the formation of metastable cellulose I by the enzymatic polymerization of β-cellobiosyl fluoride monomer catalyzed by cellulase, a new concept of “choroselective polymerization” for the control in high-order molecular assembly during polymerization was proposed.

The use of sugar oxazolines as a glycosyl monomer with a distorted conformation allowed the polymerization to proceed only in the direction of the product polysaccharides while suppressing hydrolysis. Sugar oxazolines which possess higher potential energy compared with the conventional glycosyl donors enabled us to produce various N-acetylglucosamine-containing polysaccharides such as chitin, hyaluronic acid, and chondroitin. A new concept of “transition state analogue substrate” (TSAS) has been introduced to polymerization chemistry.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Glycoside hydrolase

- Functional polysaccharide synthetic cellulose

- Choroselective polymerization

- Glycosyl fluoride monomer

- Artificial chitin

- Sugar-oxazoline monomer

- Transition state analogue substrate (TSAS)

2.1 Introduction

Polysaccharides are one of the naturally occurring three major biomacromolecules, together with proteins and nucleic acids, that play important roles, such as structural materials (e.g., cellulose, chitin, and hyaluronic acid) and energy storage (e.g., amylose and glycogen), in living body. Recently, polysaccharide-governed immune response and their potential for clinical use have also been identified [1]. Accordingly, the synthesis of polysaccharides is of keen interest to reveal structure-function relationships and to prepare bioactive and biodegradable materials for research and commercial applications. However, because of the strict requirement for complete regio- and stereoselective glycosidic bond formation between saccharide monomers (Fig. 2.1a and b), synthesis of polysaccharide has long been one of the most challenging yet important topics in macromolecular science [2]. While the automated synthesizers of polynucleotides (DNA, RNA) and polypeptides have already been developed and commercially available, chemical approaches toward polysaccharides which rely upon multiple protection and deprotection steps are inherently limited in scopes [3]. Hence, enzymatic reaction, which requires no protecting groups and proceeds basically in aqueous media, has become an attractive alternative to the conventional synthesis from the viewpoint of green and sustainable chemistry.

In nature, polysaccharides are biosynthesized by the action of glycosyltransferases (GT family, EC 2.4) using sugar nucleotide phosphates as monomers [4]. The employment of these glycosyltransferases for polysaccharide synthesis is, however, currently limited due to their low solubilities, low expression efficiencies, and consequently high cost [5]. In comparison to these glycosyltransferases, another class of enzyme, glycoside hydrolases (GH family, EC 3.2.1), is considerably inexpensive due to the production on an industrial scale and has gained attention for practical synthesis of oligo- and polysaccharides [6,7]. This chapter reviews the glycosidase-catalyzed polymerization toward naturally occurring polysaccharides as well as nonnatural polysaccharide derivatives.

2.2 General Introduction of Glycosidases

Hydrolases (EC 3) are naturally occurring macromolecular organic catalysts that cleave the bond between part A and part B of the substrate A-B in the presence of water. In general, water (H2O) is divided to H+ and OH− and distributed to the part A and part B, respectively, affording A-OH and B-H (acid-base reaction). According to the principle of microscopic reversibility, hydrolases can catalyze not only hydrolysis but also the reverse reaction (A-OH + B-H → A-B + H2O) through the same transition state (dehydrative condensation).

Glycosidases (GHs) (also called glycoside hydrolases) are a class of hydrolases that degrade sugar chain by cleaving the glycosidic linkages (Scheme 2.1). Glycosidase-catalyzed synthesis of oligosaccharides by the reverse reaction of hydrolysis using a free sugar as glycosyl donor is a well-known method in the food industry. However, this approach suffers from relatively low yields because the equilibrium is greatly shifted to the direction of thermodynamically stable hydrolyzates.

Therefore, the synthesis of oligo- or polysaccharides by using the reverse reaction of hydrolysis (equilibrium-controlled synthesis) must be done under special reaction conditions to construct a glycosidic bond effectively. The position of the equilibrium can be shifted toward the product by increasing substrate concentration, decreasing the amount of water, and removing the final product from the reaction system, for example, by precipitation or by extraction. However, the yield of polysaccharides would normally be low even if the reaction was carried out under a high substrate concentration, which can be explained by the large negative values of standard Gibbs energy formation of hydrolysis.

The addition of organic solvent or the operation of an enzymatic reaction in organic solvents can enhance the dehydrative condensation toward the products by decreasing the amount of water. However, it is not recommended from the viewpoint of green polymer chemistry to use organic solvents that may increase the environmental stress of the synthetic process. The removal of the products by precipitation or extraction would also require special equipment such as packed columns with activated charcoal for absorption of the resulting products.

On the other hand, glycosidase-catalyzed glycosidic bond formation can be performed under kinetically controlled conditions by using the transglycosylating activity of glycosidases [8] One solution is to introduce a leaving group X into the anomeric center of glycosyl donors. By replacing the reducing hemiacetal end with an appropriate leaving group X, a variety of activated glycosyl substrates can be designed and chemically prepared for glycosidase-catalyzed polymerization (Scheme 2.2). By introducing an electronically negative group X, the partial charge (δ +) on the anomeric carbon is increased, and the nucleophilic attack of a hydroxy group of another monosaccharide unit occurs smoothly. In these reactions, the by-product is not H2O but HX. Polysaccharides of definite structures are produced by repeating a regio- and stereoselective glycosylations between saccharide units.

Glycosyl fluorides, sugars whose anomeric hydroxy group is replaced by a fluorine atom (Scheme 2.2, X = F), are interesting sugar derivatives because fluorine has the smallest covalent radius among all elements [9]. Since glycosyl fluorides were found to be recognized by glycosidase [10], numerous studies on the interaction between glycosyl fluoride and enzymes have been reported [11]. From the viewpoint of organic chemistry, the use of fluorine as a leaving group has the following advantages. First, the size of fluorine atom is small enough to be incorporated in the catalytic site of glycosidases. Second, among glycosyl halides, only glycosyl fluorides are stable in an unprotected form due to the large bond-dissociation energy of the C-F bond, which is necessary for most enzymatic reactions to be carried out in aqueous media.

The higher efficiency of using glycosyl fluorides can be rationalized by considering the number of lone pairs on the fluorine atom. The conventional O-glycoside donors such as p-nitrophenyl (pNP) glycosides have two lone pairs on the anomeric oxygen atom (Fig. 2.2b), whereas the anomeric fluorine atom possesses three lone pairs (Fig. 2.2a). Furthermore, there is a potential risk for the lone pairs on the anomeric oxygen of pNP derivatives not to be protonated by an acidic amino acid side chain effectively, because the position of the lone pairs may not be oriented in the proper position when influenced by the location of the bulky pNP moiety in the active site of the enzyme. The position of the lone pairs on the fluorine atom has considerable flexibility, which contributes to an efficient protonation from the acidic amino acid side chain in the active site of the enzyme. The selection of glycosyl fluorides as glycosyl donors for glycosidase-catalyzed transglycosylation is quite reasonable, taking their stability and reactivity into consideration.

In general, the preparation of p-nitrophenyl glycosides or glycosyl fluorides requires a multistep process including the protection of all of the hydroxy groups; the regioselective introduction of a bromine or chlorine into the anomeric center under acidic conditions; the nucleophilic substitution of these halogen atoms by, for example, p-nitrophenol or fluoride anion; and the removal of the protecting groups [12] (Scheme 2.3). Recently, the dimethoxytriazinyl (DMT-) glycosides have been developed as a one-step preparable glycosyl donor for glycosidase-catalyzed transglycosylation from the viewpoint of green chemistry where the use of organic solvents and reagents has drastically been reduced (Scheme 2.3) [13].

Glycosidases show perfect stereoselectivity in transglycosylation reactions, giving rise to only one isomer (either of α-isomer or β-isomer) because the formation of the undesired isomer is impossible due to steric hindrance caused by the wall of amino acid residues in the active site of the enzyme. For example, in case of β-glucosidase, the attack of the hydroxy group of a glycosyl acceptor takes place from the β-face of the pyranose ring, leading to stereoselective formation of a β-glycosidic bond.

Glycosidase-catalyzed hydrolysis occurs with either retention or inversion mechanism (Scheme 2.4) [14]. The inverting glycosidases follow a direct displacement reaction in which two carboxylic groups in the active site act simultaneously as an acid and as a general base (Scheme 2.4a). The acid (carboxylic acid) protonates a lone pair on the leaving group X, while the base (carboxylate anion) activates the incoming water leading to a hydrolyzate with inversion of configuration. According to this mechanism, α-type hydrolyzates are obtained starting from β-type glycosides. The hydrolysis catalyzed by retaining enzymes undergoes through a double-displacement process involving a glycosyl-ester intermediate (Scheme 2.4b). Firstly, the nucleophilic residue of enzyme attacks the anomeric center concomitant with protonation of the leaving group X by the acid residue. This results in the cleavage of the C-X bond, forming the glycosyl-enzyme intermediate. The anomeric center of this intermediate is then attacked by water, with assistance from the same acid/base residue. This leads to a product with the same anomeric configuration of the substrate.

Glycosidases are classified into exo-type enzyme and endo-type enzyme. Exo- and endo- refer to the ability of a glycoside hydrolase to cleave a substrate at the end or the middle of a chain [15]. Exo-type glycosidases have a pocket in their catalytic site and are used for enzymatic syntheses of glycosides having a small size (Fig. 2.3a). Endo-type glycosidase, whose shape at the catalytic domain looks like a cleft, shows high catalytic activity for enzymatic syntheses of polysaccharides (Fig. 2.3b).

(a) Exo-type glycosidases have a pocket in their catalytic site. (b) Endo-type glycosidases have a cleft where both a glycosyl donor and a glycosyl acceptor are strictly recognized by the corresponding −1 subsite and + 1 subsite, respectively. (Reprinted with the permission from Ref. [17]. Copyright 2016 American Chemical Society)

The formation of only a single isomer can be realized perfectly regardless of the class of enzyme employed; both exo-type and endo-type glycosidases catalyze a completely stereoselective glycosylation, whereas the regioselectivity of enzyme-catalyzed reactions depends on the class of glycosidase. Exo-type glycosidase normally displays lower regioselectivity toward an acceptor, giving rise to a mixture of regio-isomers (Fig. 2.3a) [16]. In the case of endo-type glycosidases, higher regioselectivity can be achieved. Since both the reducing end of the glycosyl donor and the nonreducing end of the glycosyl acceptor are strictly recognized by the −1 subsite and +1 subsite of endo-type glycosidases, respectively, the hydroxy group that will be incorporated into the resulting glycosidic bond can be located in a suitable position at the +1 subsite of the enzyme to attack the anomeric center located in the −1 subsite (Fig. 2.3b). Consequently, perfect regioselectivity can be guaranteed concerning the resulting glycosidic bond. This is one of the main reasons why endo-type glycosidases have been extensively used as catalysts for synthesis of polysaccharides where perfectly controlled glycosylation reactions must occur repeatedly.

Taking the characteristics of both glycosyl donor and hydrolase into consideration, the combined use of a glycosyl fluoride as monomer and an endo-type glycosidase as catalyst has now become one of the most favorable methods to achieve a polysaccharide synthesis [18]. Finding an appropriate combination of a glycosyl fluoride and an enzyme catalyst is, therefore, key in designing a method for preparation of polysaccharides. For the purpose of finding the best combination of glycosyl fluoride donor and the corresponding glycosidase, a novel enzyme assay for screening glycosidases has been developed by using glycosyl fluorides as enzyme substrates [19]. The method is based on the color change caused by the complex formation of fluoride ion liberated as the result of hydrolysis of glycosyl fluoride and lanthanum-alizarin complexone (La3+-ALC). The assay has a much higher sensitivity compared with the conventional methods using p-nitrophenyl glycoside as a screening substrate. According to this enzyme assay screening method, it is possible to find a suitable combination of glycosyl fluoride donor and the corresponding hydrolase by employing the glycosyl donor itself for an enzymatic transglycosylation.

Although the activated sugar units can be polymerized successfully under the repeated glycosidase-catalyzed transglycosylation, in all cases product hydrolysis severely limits conversion. To overcome this problem, enzyme engineering has been implemented to enhance the transglycosylation activity of glycosidase and simultaneously attenuate hydrolysis [20]. Random or site-directed mutations combined with directed evolution have significantly improved the transglycosylation/hydrolysis (T/H) activity ratio of glycosides [21]. In the late 1990s, a new class of glycosidase mutants was introduced in which the active sites of the enzymes are modified such that they lose the ability to hydrolyze their transglycosylation product, thereby driving the reaction in the synthetic direction [22]. These mutant glycosidases, termed “glycosynthases,” are rendered hydrolytically incompetent through the replacement of the nucleophilic residue (aspartic or glutamic acid) with an alternative unreactive amino acid (e.g., alanine). These glycosynthases can perform neither hydrolysis nor transglycosylation on the native substrates. However, when used in conjunction with an activated donor having the opposite anomeric configuration to that of the native substrate, glycosidic linkages may be formed (Fig. 2.4). Donors of this configuration mimic the glycosyl enzyme intermediate and take advantage of the vacant cavity created by mutation of the nucleophile. Without risk of hydrolysis, glycosynthases are the ideal tool for the efficient production of oligo- and polysaccharides.

In the following sections, enzymatic polycondensation reactions catalyzed by glycosidases are described according to the nature of catalyst enzymes.

2.3 Cellulase

2.3.1 Enzymatic Polymerization of Cellobiosyl Monomers Catalyzed by Cellulase

Cellulose, which is the most abundant organic compound on earth, has a linear structure of a β(1 → 4)-linked D-glucose repeating units. It is one of the three major structural components of the primary cell walls of green plants, along with hemicellulose and lignin. In nature, cellulose is biosynthesized by the polycondensation of uridine diphosphate glucose (UDP-glucose) catalyzed by cellulose synthase mainly at the plasma membrane of plants.

In spite of the importance of cellulose, an in vitro chemical synthesis of cellulose had not been achieved in the first challenge of the task in 1941; the in vitro cellulose synthesis has been a central problem in polymer chemistry [23]. In 1991, the first in vitro synthesis of cellulose was achieved via the polymerization of β-cellobiosyl fluoride monomer catalyzed by cellulase from Trichoderma viride, an extracellular hydrolase of cellulose (Table 2.1, entry 1) [24,25,26]. Cellulase catalyzed the in vitro glycosidic bond formation, producing “synthetic cellulose” having a perfectly controlled β-(1 → 4) glycosidic structure. During the polymerization, the glycosidic linkage-forming reaction was repeated, and hence, the cellobiosyl moiety behaved as a glycosyl monomer. Thereafter, hydrolytically inactive mutants of glycosidase (glycosynthase) were developed to improve the transglycosylation yields [22,27]. The mutant enzyme from Humicola insolens was capable of transferring disaccharides from α-cellobiosyl fluoride, giving rise to cellulose in good yield (Table 2.1, entry 2). As an alternative of cellobiosyl fluorides, one-step preparable glycosyl monomer having the 4,6-dimethoxy-1,3,5-triazin-2-yl (DMT) leaving group at the anomeric position was developed (Table 2.1, entry 3), where both the glycosyl monomer synthesis and the subsequent polymerization can be achieved in aqueous media without any protection and deprotection steps [28]. Recently, a nonaqueous polycondensation with nonactivated disaccharide monomer under the catalysis of a cellulase-surfactant complex in dimethylacetamide (DMAc)/LiCl was demonstrated to afford cellulose as white powders (Table 2.1, entry 4) [29,30]. The DP value was high (over 100), but the product yield was low (<5%). This is a typical example of classical dehydrative polycondensation, affording water as a by-product.

One of the most interesting differences between this enzymatic polymerization and the polymerization via biosynthetic path is that the cellulase-catalyzed polycondensation used a cellobiose derivative as a monomer, rather than a glucose derivative, taking the symmetry of cellulose crystal into consideration. The smallest unit of the cellulose repeating unit structure is “cellobiose” because cellulose has a twofold screw axis due to the two kinds of intramolecular hydrogen bonds between C3-OH with endocyclic oxygen and C6-OH with the C2-OH (Fig. 2.5). It was postulated that cellobiose moiety would be a preferable substrate since it could be recognized by the catalytic site more strongly than a glucose derivative. Furthermore, from the viewpoint of supramolecular interaction between the substrate and amino acids, disaccharide substrates are preferable for the processive movement of chain elongation along the cleft of cellulase. In fact, it is to be noted that disaccharide fluoride monomers were widely used, and the disaccharide structure was confirmed effective [27,31]. A monosaccharide fluoride was not a good substrate for the polysaccharide synthesis [32].

The characteristic feature of synthetic cellulose formation in vitro is that a single glucan chain elongates by interacting with other growing glucan chains. These dynamic events via a nonbiosynthetic path can be realized only by the enzymatic polymerization technique where unprotected glucan chains propagate in aqueous media. These dramatic phenomena prompted us to consider a polymer-polymer interaction during polymer chain elongation in addition to the conventional monomer-polymer interaction, monomer-catalyst interaction, and polymer-catalyst interaction in the field of supramolecular chemistry [33].

Cellulose forms typically two types of allomorphs of high-order molecular structure through self-assembly. One form is the thermodynamically metastable cellulose I, in which cellulose chains are aligned in parallel. Another form is the thermodynamically stable antiparallel cellulose II. Notably, naturally occurring cellulose forms the less stable cellulose I crystalline structure. In vitro, crystalline structure of cellulose synthesized via cellulase-catalyzed polymerization was of the cellulose II structure with crude enzyme [34] and of cellulose I structure with purified enzyme. Metastable cellulose I could be formed due to a kinetically controlled process [35,36]. This was the first example of cellulose I formation via a nonbiosynthetic pathway. Such a control in high-order molecular assembly during polymerization was not reported before; therefore, a new concept of “choroselective polymerization” was proposed [37]. The term “choros” has its origin in a Greek word which means “space.”

The self-assembling process of synthetic cellulose during crude cellulase-catalyzed polymerization was investigated in detail in real time and in situ by a combined small-angle scattering (SAS) methods, together with wide-angle X-ray scattering (WAXS) and field-emission scanning electron microscopy (FE-SEM). The aggregation of the synthetic cellulose was observed and associated with characteristic lengths larger than 200 nm in aqueous media. Further, cellulose molecules created at each active site of enzymes associate themselves around the enzyme associations into cellulose aggregates having surface fractal dimensions D s, increasing from 2 (smooth surface) to 2.3 (rough surface with fractal structure) as the reaction progressed, extending over a surprisingly wide length scale ranging from ~30 nm to ~30 μm with three orders of magnitude. The construction of this unique self-assembly can be explained by an extremely large number of cellulose molecules repeatedly created at the active site of cellulase [38,39].

Concerning the enzyme catalysts responsible to the polymerization of β-cellobiosyl fluoride, many kinds of cellulases (EC 3.2.1.4) have the possibility of possessing the glucan chain-elongating ability. One of these is endoglucanase II (EGII) from Trichoderma viride. EGII is composed of three functional domains: the cellulose-binding domain (CBD), the linker, and the catalytic domain. In the hydrolysis, CBD first binds the crystalline part of cellulose, and then the catalytic domain catalyzes the hydrolysis of cellulose molecules, the linker domain linking these two domains. Using biotechnology, two types of enzymes were prepared from yeast, the one having all domains (EGII) and the other having only catalytic domain lacking CBD and the linker domain (EGIIcore) [40] (Fig. 2.6a and b. Very interestingly, both enzymes showed high polymerization activity for β-cellobiosyl fluoride, giving synthetic cellulose. With progress of time, the produced cellulose gradually disappeared with EGII-induced hydrolysis; however, the cellulose degradation is resisted in the polymerization solution with EGIIcore. These results suggest that the CBD plays an important role for the hydrolysis of the product, but not for the polymerization. The polymerization needs only the function of the catalytic domain.

Another mutant EGII having two sequential catalytic core domains (EGII(core)2) was prepared (Fig. 2.6c) [41]. This mutant EGII(core)2 catalyzed polymerization of β-cellobiosyl fluoride faster than EGIIcore, affording large spherulites. The resulting large spherulites were composed of platelike crystals radiating from the center of the spherulites. On the other hand, fibrous cellulose was produced from cross-linked mutant EGII(core2H) (Fig. 2.6d) having two hexameric histidine residues (His-tags) in total on both enzyme chain terminals [42].

The cross-linking molecule used is bisNTA (Fig. 2.7a), which has two nitrilotriacetic acid (NTA) moieties on both terminals of poly(ethylene oxide). The NTA moiety is one of the most utilized ligands which is known to interact with oligo-histidine residues (His-tag) through transition metal ions such as Ni [43]. EGII(core2H) mutant enzymes were cross-linked with the help of Ni ions through bisNTA. Using the cross-linked EGII(core2H) as a catalyst for enzymatic polymerization of β-cellobiosyl fluoride, the polymerization proceeded extremely fast, and the fibrous cellulose with high molecular weight was produced. Taken together, the configuration of enzymes in vitro synthesis of cellulose seems to influence the morphology of synthetic cellulose as is the case of in vivo synthesis. To obtain an in-depth understanding of in vitro synthesis of cellulose with regard to geometry of the mutant enzymes, EGII(core)2 was immobilized on gold, and its hydrolytic activity [44] and polymerization activity were analyzed [45]. The linker molecules (NAT-SH) (Fig. 2.7b) with thiol at one end and NTA at the other were self-assembled on gold, and EGII(core)2 having a His-tag was immobilized on the self-assembled monolayer (SAM) via Ni ion. The hydrolytic activity of the immobilized EGII(core)2 was nearly the same on either anchor molecule. The immobilized EGII(core)2 apparently retained the inherent hydrolytic activity similar to free EGII(core)2. The local high concentration of EGII(core)2 on gold probably promoted successive hydrolysis of the transient products, leading to high hydrolytic activity despite immobilization. Two kinds of the mutant enzymes, EGII(core)2 and EGII(core2H), were immobilized on the NTA-SAM. The crystallinity of the synthesized cellulose by the immobilized EGII(core)2 was higher than that by free EGII(core)2. The crystallinity of the synthesized cellulose by the immobilized EGII(core2H) was particularly high that can be attributed to the high density with the horizontally immobilized EGII(core2H) on the flat gold substrate. The well-oriented endoglucanase should help in the crystallization of synthesized cellulose. EGII(core2H) was piled up on gold via NTA-Ni-His-tag linkage (Fig. 2.7c), where EGII(core2H) was cross-linked with each other in the vertical direction on gold substrate [46]. The highly crystalline cellulose was synthesized also by this cross-linked enzyme on gold substrate because of high local concentration of EGII(core2H) (Fig. 2.7d).

Chemical structure of (a) BisNTA; (b) NTA-SH; (c) complex formed with NTA, Ni, and His-tag; (d) schematic illustration of cross-linked enzymes, immobilized enzyme on gold substrate, and cross-linked and immobilized enzymes. (Reprinted with the permission from Ref. [17]. Copyright 2016 American Chemical Society)

2.3.2 Enzymatic Polymerization of Other Saccharide Monomers Catalyzed by Cellulases

Xylan is one of the most important components of hemicelluloses in plant cell walls. The backbone of naturally occurring xylan is a polycondensation product of xylose through a β-(1 → 4) glycosidic bond. β-Xylobiosyl fluoride monomer was polycondensed by the action of cellulase enzyme. The polymerization proceeded in a mixed solvent of acetonitrile/buffer (pH 5.0) to give a synthetic xylan having β-(1 → 4) glycosidic linkage, with a Mn of 6.7 × 103 corresponding to the DP value of ∼23 (Table 2.2, entry 1) [47]. The resulting xylan has the same structure as natural xylan extracted from esparto grass [48].

As an analogous substrate to β-cellobiosyl fluoride, S-linked β-cellobiosyl fluoride was polymerized by cellulase from Trichoderma viride to produce oligosaccharides having an O-glycosidic bond and S-glycosidic bond alternatingly (hemithiocellodextrins) (Table 2.2, entry 2) [49]. Tetra-, hexa-, octa-, and decasaccharides were isolated from the reaction mixture in 4.5, 7.5, 5.7, and 5.0% yields, respectively.

The development of cellulose-based materials necessitates a precise control of regioselectivity and degree of substitution. However, chemical structures constructed by a polymer reaction are not precisely controlled because such modifications normally give a mixture of randomly substituted polysaccharides. An alternative method for the construction of a modified polysaccharide with well-defined structure is to polymerize a modified saccharide monomer. Based on this strategy, cellulase-catalyzed polymerization with O-substituted β-cellobiosyl fluoride monomers was demonstrated.

The 6-O-methyl-β-cellobiosyl fluoride (R1 = Me, R2 = H) was found to be recognized by cellulase and polymerized, giving rise to the corresponding alternatingly O-methylated cellulose derivative (Table 2.2, entry 3) [50,51]. The Mn of the product was 3.9 × 103, corresponding to n ~7. In comparison with 6-O-methyl derivative, 6′-O-methyl-β-cellobiosyl fluoride gave oligomers like tetrasaccharide. The cellulase-catalyzed polycondensation of the other methylated β-cellobiosyl fluoride derivative, 2′-O-methyl-β-cellobiosyl fluoride, also took place in a mixed solvent of acetonitrile/acetate buffer (pH 5.0) to produce an alternating 2′-O-methylated cellulose derivative (Table 2.2, entry 3) [52]. These results show that the 6-OMe group and 2′-OMe group of the cellobiose moiety do not have large steric hindrances for the substrate recognition.

A synthetic strategy for hybrid-type oligosaccharides and polysaccharides having an alternating structure composed of two monosaccharide units has been developed by chemoenzymatic procedures [53]. Because of the wide spectrum in substrate recognition of glycoside hydrolases, synthesis of unnatural polysaccharides composed from different two polysaccharide components could be achieved [54]. Such polysaccharides (hybrid polysaccharides) are difficult to synthesize via the biosynthetic path or by the conventional chemical synthesis.

Synthesis of cellulose-mannan hybrid polysaccharide was performed by the enzymatic polymerization of Man-β-(1 → 4)-Glc-β-fluoride (Man: mannose) catalyzed by cellulase from Trichoderma reesei (Table 2.2, entry 4) [52]. The MALDI-TOF mass spectrum indicated that the water-insoluble fraction in the products was composed of oligosaccharides up to hexadecasaccharide.

Cellulose-chitin hybrid polysaccharide has also been synthesized based on the same concept [55]. GlcNAc-β-(1 → 4)-Glc-β-fluoride monomer was designed and prepared and polymerized by the action of cellulase (GlcNAc: N-acetylglucosamine) (Table 2.2, entry 5). These results clearly show that the −2 subsite and +1 subsite of cellulase can accept even a nongluco-type monosaccharide unit like GlcNAc efficiently.

Although the enzymatic glycosylation of glycosyl fluoride monomers has become a general strong synthetic method for polysaccharide synthesis, the preparation of glycosyl fluorides requires several steps, including protection of the hydroxy groups, activation of the anomeric center by introducing chlorine or bromine, nucleophilic replacement by fluorine as a leaving group, and the removal of the protecting groups (Scheme 2.3). These procedures eventually lower the total yields of the glycosyl donor syntheses. In addition, in case of oligosaccharide donors, the cleavage of the inner glycosidic bonds occurs during the process of glycosyl donor synthesis, affording a mixture of oligosaccharide donors with different molecular weights [56]. These demerits of the conventional glycosyl donor synthesis have hampered the application of enzymatic glycosylation to complex target molecules.

One-step preparable glycosyl donors, 4,6-dimethoxy-1,3,5-triazin-2-yl glycosides (DMT-glycosides), have been developed for enzymatic polymerization. A cellotetraose-backboned heptasaccharide (XXXG) and a nona-saccharide (XLLG) have directly been converted to the corresponding DMT-β-XXXG and DMT-β-XLLG, respectively, by the action of 4-(4,6-dimethoxy-1,3,5-triazin-2-yl)-4-methyl morpholinium chloride (DMT-MM) [57]. Note that the letter X represents a glucopyranose residue that is substituted with a xylopyranose through an α-1,6 glycosidic bond, the letter G represents a nonsubstituted glucopyranose residue, and the letter L represents a glucopyranose residue that is substituted with a galactopyranose β-(1 → 2) xylopyranose through an α-(1 → 6) glycosidic bond. The resulting activated oligosaccharide derivatives were found to polymerize catalyzed by an endo-β-1,4-glucanase as catalyst. The polymerization took place in a complete regio- and stereoselective manner, affording nonnatural polysaccharides having a XXXG-repeating unit and a XLLG-repeating unit, respectively, in the main chain (Table 2.2, entry 6).

2.4 Xylanase, 4-Glucanohydrolase, and Amylase

A cellulose-xylan hybrid polysaccharide has been prepared [58]. There are two possible candidate monomers: Glc-β-(1 → 4)-Xyl-β-fluoride (Table 2.3, entry 1) and Xyl-β-(1 → 4)-Glc-β-fluoride (Table 2.3, entry 2). Both monomers were polymerized by xylanase (EC 3.2.1.32) enzyme catalyst, giving rise to the corresponding cellulose-xylan hybrid-type polysaccharides.

Polysaccharides composed of glucose residues linked through β-(1 → 3)-glycosidic linkages, i.e., (1 → 3)-β-glucans, such as curdlan, laminarin, and schizophyllan, are found in nature. They have increasingly attracted much attention because of their high immune properties and anticancer activities [59]. A 1,3-1,4-D-glucan 4-glucanohydrolase from Bacillus licheniformis has been shown to catalyze the polycondensation of β-laminaribiosyl fluoride (Glc-β-(1 → 3) -Glc-β − fluoride) and to lead to alternating 1,3-1,4-β-D-glucotetraose and 1,3-1,4-β-D-glucohexaose in low yields [60]. Thereafter, the mutated glucan endohydrolase E231G was prepared, and the polymerization of α-laminaribiosyl fluoride by this mutated enzyme was performed in a mixed solvent of acetonitrile/acetate buffer (pH 5.0) to produce (1 → 3)-β-glucan with DPs of 28–44 (Table 2.3, entry 3) [61]. The catalysis of this mutated enzyme was extended to the polymerization of 3-thio-laminaribiosyl fluoride, giving rise to the corresponding polysaccharide with DPs of 6–18.

Malto-oligosaccharides are glucose oligomers linked through α-(1 → 4) glycosidic bonds. An activated substrate of α-D-maltosyl fluoride was designed and prepared as a glycosyl monomer based on the double-displacement transfer mechanism of α-amylase (EC 3.2.1.1), and its polymerizability has been investigated. The reaction was carried out in a methanol-phosphate buffer, affording amylose oligomers up to heptasaccharide (Table 2.3, entry 4) [62].

2.5 Glycosidase Catalysis for Ring-Opening Polyadditions

Addition reactions are organic transformations where two or more molecules combine to form larger adducts without liberating any small molecules like H2O and HX. The glycosidase-catalyzed polyaddition reaction is regarded as a repeating multistep process of an addition reaction of one of the hydroxy groups in a glycosyl monomer to the anomeric center of another monomer [6].

In principle, it is impossible to construct dehydrated skeletons like O-glycosidic bonds through an addition reaction because the concept of elimination of H2O or HX is not included in any addition reactions. Therefore, to design a glycosylation based on an addition reaction, the use of a glycosyl donor having an already dehydrated moiety like an unsaturated bond or a heterocycle is indispensable.

A general scheme of enzymatic addition glycosylation consists of the following two reactions (Scheme 2.5): (1) an intramolecular dehydration of a native sugar (Scheme 2.5, left) to produce activated glycosyl donor containing a heterocyclic moiety Z (Scheme 2.5, center) and (2) addition of glycosyl acceptor catalyzed by an enzyme, affording the corresponding addition product (Scheme 2.5, right). By using such kind of already dehydrated glycosyl donor, the construction of a dehydrated moiety through an addition reaction becomes possible. Meanwhile, this intramolecularly dehydrated glycosyl donor having higher potential energy can promote the reaction effectively in the direction of product under kinetically controlled conditions. Since the glycosyl donor possesses an intramolecularly dehydrated structure, the reaction proceeds smoothly via a nucleophilic attack of one of the hydroxy groups in the glycosyl acceptor to the anomeric carbon atom of the glycosyl donor, accompanying a ring opening, without liberating any small molecules. This is a typical example of addition reactions where the O− and the H+ from the OH in the glycosyl acceptor bind to glycosyl donor’s anomeric carbon and the heteroatom unit Z, respectively.

Actually, an addition of water to a reactive intermediate having a heterocycle moiety was proposed for hydrolysis of chitin, a β-(1 → 4)-linked polysaccharide composed of N-acetylglucosamines, catalyzed by chitinases (EC 3.2.1.14). Specifically, the glycosidic oxygen is protonated by one of the carboxylic acid residues immediately after the recognition of chitin at the catalytic domain. The carbonyl oxygen of C-2 acetamido group in a chitin unit at the donor site attacks the anomeric carbon from α-side to form an oxazolinium ion transition state stabilized by the other carboxylic acid residue, and the glycosidic linkage is cleaved completely (substrate-assisted catalysis) [63]. A nucleophilic attack by a water molecule from β-side induces the opening of the oxazoline ring, giving rise to the hydrolyzate (Fig. 2.8a).

Proposed mechanism for (a) hydrolysis by neighboring group participation and (b) ring-opening addition of sugar oxazoline in the catalytic site of chitinase. Note that two acidic amino acids synergetically act as proton donor and proton acceptor [2]

Sugar oxazolines, which are the intramolecularly dehydrated derivatives of 2-acetamido-2-deoxy sugars (Z = -N=C(CH3)-O- in Scheme 2.5), are potentially useful glycosyl donors for enzymatic glycosylation by addition reaction because the oxazoline ring can be opened by the attack of a hydroxy group at the anomeric position, regenerating an N-acetylglucosaminide moiety. The reasoning for using oxazoline derivatives can be shown in the retro-synthetic analysis of an N-acetylglucosaminide unit [63]. First, the sugar oxazoline is recognized and simultaneously protonated by the carboxylic acid residue to form the corresponding oxazolinium ion. Then, the hydroxy group of acceptor attacks the anomeric carbon from β-side to induce the ring opening, giving a new β-type O-glycosidic linkage (Fig. 2.8b). The key point for the ring-opening addition is the similarity in the structure of sugar oxazoline and the oxazolium transition state. The pH value for the optimal condition of the hydrolysis reaction was reported to be 8.0 [64]. However, the ring-opening addition took place even under the weak alkaline conditions at around pH 10–11 while simultaneously suppressing the hydrolysis of the product [65].

Another advantage of using sugar oxazolines is that the transglycosylation proceeds smoothly due to its lower activation energy. Sugar oxazolines are bicyclic molecules having a distorted structure where a six-membered pyranose ring and a five-membered oxazoline ring are fused sharing the anomeric and C-2 positions. Sugar oxazolines possess higher potential energy compared with the conventional glycosyl donors such as p-nitrophenyl glycoside. Consequently, the activation energy between the TSAS donor and the product of glycoside becomes much smaller than the case of using the conventional glycosyl donor (Fig. 2.9). Therefore, the glycosylation reactions proceed efficiently even when a chitinase with low activity is employed. It should be noted that the use of sugar oxazolines as a transition state analogue substrate (TSAS) allows the reaction to proceed only in the direction of the glycosylation reaction while suppressing hydrolysis of the product.

Taking the abovementioned requirements for glycosyl donor and enzyme catalysts into consideration, the use of sugar oxazolines as monomers and endo-type glycosidases that can act as a substrate-assisted catalysis has now become the most promising combination to achieve synthesis of N-acetylglucosamine-containing polysaccharides. In the following sections, several enzymatic polyaddition reactions catalyzed by N-acetylglucosaminidases will be introduced.

2.6 Chitinase

2.6.1 Enzymatic Polymerization of Chitobiose Oxazoline Monomer Catalyzed by Chitinase: Artificial Chitin

Chitin is a β-(1 → 4)-linked N-acetyl-D-glucosamine (GlcNAc) polysaccharide that can be biosynthesized by the polymerization of UDP-GlcNAc as substrate monomer with chitin synthase [66]. Chitosan is an N-deacetylated product of chitin. Chitin is one of the most abundant and widely found polysaccharides in the animal field. Chitin and chitosan show excellent characteristics of biodegradability, biocompatibility, and in particular low immunogenicity.

In 1995, the first in vitro synthesis of chitin was accomplished via ring-opening polyaddition of a chitobiose oxazoline monomer catalyzed by chitinase and published in 1996 (Fig. 2.10) [65,67,68,69,70]. The reaction occurs as a ring-opening polyaddition mode and is promoted under weak alkaline conditions (pH 9.0–11.0). The yield of “artificial chitin” in these works was almost quantitative because the resulting chitin was not hydrolyzed by the chitinase catalyst due to its lower hydrolytic activity under alkaline conditions. The DP value of synthetic chitin was evaluated as 10–20, depending on the reaction conditions [2].

Chitinase-catalyzed ring-opening polyaddition of chitobiose oxazoline and electron microscopy of the resulting artificial chitin. (Reprinted with the permission from ref. [70]. Copyright 2000 American Chemical Society)

The organization process of crystalline chitin during the chitinase-catalyzed polyaddition of chitobiose oxazoline monomer was monitored by using phase-contrast and polarization microscopy in combination with SEM and TEM (Fig. 2.10) [70]. Under reaction conditions of pH 10.5 and 30 °C, 25 h was required for the complete consumption of the disaccharide monomer. During the first 30 min, a small number of rectangular platelike solids were observed whose width, height, and length of the plates were 25, 10, and 50 nm to 1 μm, respectively. The electron microdiffraction of the resulting plates clearly showed that the products were the thermodynamically stable form of chitin crystal, α-chitin. Therefore, single-crystalline plates of α-chitin were formed, in which polysaccharide chains packed antiparallel and formed intra- and intermolecular hydrogen bonds. The crystal plates grew and stacked on each other as time elapsed (ca. 3 h) and shaped into ribbons, followed by the formation of bundle-like assemblies. After 25 h, the texture of the synthetic chitin spherulites was observed by SEM that revealed the diameters of these spherulites to be 20–50 μm.

A direct method for synthesis of sugar oxazolines from the corresponding N-acetyl-2-amino sugars in aqueous media has been developed with chloroformamidinium-type dehydrating reagents (e.g., DMC. 2-chloro-1,3-dimethylimidazolinium chloride; CDMBI, 2-chloro-1,3-dimethyl-1H-benzimidazol-3-ium chloride) [71,72]. This method was applied to one-pot regio- and stereospecific synthesis of chitoheptaose ((GlcNAc)7) by using chitopentaose ((GlcNAc)5) and chitobiose ((GlcNAc)2) as starting materials. The key intermediate, 1,2-oxazoline derivative of (GlcNAc)5, was transglycosylated to a (GlcNAc)2 acceptor catalyzed by a mutant chitinase with lower hydrolyzing activity [73].

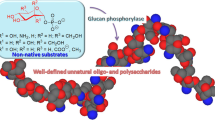

2.6.2 Chitinase-Catalyzed Synthesis of Unnatural Oligo- and Polysaccharides

Several artificial disaccharide oxazoline derivatives have been designed as substrates for chitinase-catalyzed synthesis of unnatural oligo- and polysaccharides (Table 2.4). The stepwise elongation of the GlcNAc unit, which was performed via the combined use of chitinase and β-galactosidase catalysis, was demonstrated. Chitinase-catalyzed transglycosylation by using N-acetyllactosamine (LacNAc) oxazoline as glycosyl donor and a chitooligosaccharide as glycosyl acceptor allowed the synthesis of unnatural chitooligosaccharides having a galactose unit at the nonreducing end. Repetition of sequential manipulations using chitinase and β-galactosidase has made it possible to produce chain-length-controlled chitooligosaccharides (Table 2.4, entry 1) [74,75]. Interestingly, in the absence of the glycosyl acceptor, N-acetyllactosamine oxazoline was polymerized by chitinase, giving rise to novel oligosaccharides having the β-(1 → 4)-β-(1 → 6)-linked repeating unit in the main chain (Table 2.4, entry 2) [76]. The DP of the resulting oligosaccharides was up to 5 based on the disaccharide. This was the first example of enzymatic glycosylation forming β-(1 → 6)-glycosidic linkage by chitinase catalysis.

Cellulose-chitin hybrid polysaccharide having an alternating Glc and GlcNAc was obtained by the enzymatic polymerization of Glc-β-(1 → 4)-GlcNAc oxazoline monomer catalyzed by a chitinase (Table 2.4, entry 3, R1 = CH2OH, R2 = OH) [55]. Despite the high crystallinity of both cellulose and chitin homopolymers, the resulting cellulose-chitin hybrid polysaccharide showed no crystalline structure. Similarly, xylan-chitin hybrid polysaccharide having an alternating Xyl and GlcNAc was prepared from Xyl-β-(1 → 4)-GlcNAc oxazoline monomer catalyzed by a chitinase (Table 2.4, entry 3, R1 = H, R2 = OH) [77]. The resulting polysaccharide was water-soluble, and its molecular weight was larger than 1.0 × 104. Chitosan-chitin hybrid-type polysaccharide having a regular alternating sequence of GlcNAc and GlcN was synthesized (Table 2.4, entry 3, R1 = CH2OH, R2 = NH2) [78].

Substituted chitin derivatives were also prepared; 3-O-methyl-chitobiose oxazoline (Table 2.4, entry 4, R1 = Me, R2 = R3 = R4 = H) or 3′-O-methyl-chitobiose oxazoline (Table 2.4, entry 4, R3 = Me, R1 = R2 = R4 = H) gave products of lower degree of polymerization [79]. 6-O-Carboxymethylated chitobiose oxazoline (Table 2.4, entry 4, R2 = CH2COONa, R1 = R3 = R4 = H) and 6′-O-carboxymethylated chitobiose oxazoline (Table 2.4, entry 4, R4 = CH2COONa, R1 = R2 = R3 = H) were polymerized by a chitinase, indicating that the introduction of a carboxymethyl group at 6 or 6′ position did not affect the recognition for chitinase [80,81]. Similarly, fluorine-substituted chitobiose oxazoline derivatives at the C-6 and/or C-6′ position could be polymerized by the chitinase catalyst, giving rise to white precipitates of structurally well-defined fluorinated chitins (Table 2.4, entry 5, R1 and/or R2 = F, R3 = Ac) [82,83]. Chitinase-catalyzed polymerization of a TSAS monomer bearing a bulky N-sulfonate group at the C-2′ position proceeded homogeneously, due to a good solubility of the resulting polysaccharide (Table 2.4, entry 5, R1 = R2 = OH, R3 = SO3Na) [84]. Chitinase from Serratia marcescens provided a polysaccharide of Mn = 4180. With copolymerization of N-acetylchitobiose oxazoline monomer with N,N′-diacetylchitobiose oxazoline monomer, a tailor-made synthesis of a chitin derivative with controlled deacetylated extent ranging from 0% to 50% was achieved (Table 2.4, entry 6) [85].

2.7 Hyaluronidase

2.7.1 Hyaluronidase-Catalyzed Synthesis of Hyaluronan and Chondroitin

Hyaluronidase (EC 3.2.1.35–36) is an endo-type glycoside hydrolase, which hydrolyzes β-(1 → 4) glycosidic linkage between GlcNAc and GlcA (glucuronic acid) of hyaluronic acid. The hydrolysis mechanism of hyaluronidase is considered similar to that of chitinase due to the presence of GlcNAc at the −1 site of the catalytic center [86,87]. Therefore, based on the concept of a “transition state analogue substrate” (TSAS) monomer proposed first in the synthesis of chitin [65], GlcA-β-(1 → 3)-GlcNAc oxazoline was designed as a monomer for enzymatic polymerization catalyzed by hyaluronidase (Scheme 2.6a). The polymerization afforded the hyaluronic acid (HA) with a high molecular weight Mn value of 1.74 × 104 in more than 50% yields [88]. HA is present in almost all biological fluids and tissues. In clinical medicine, it is used as a diagnostic marker for many diseases, including cancer, rheumatoid arthritis, and liver pathologies, as well as for supplementation of impaired synovial fluid in arthritic patients by means of intra-articular injections. It is also used in certain ophthalmological and otological surgeries and cosmetic regeneration and reconstruction of soft tissue [89].

Hyaluronidase is known to be an in vivo hydrolysis catalyst of chondroitin (Ch), cleaving its β-(1 → 4) glycosidic linkage. An oxazoline derivative of GlcA-β-(1 → 3)-GalNAc was synthesized, and its polymerization was examined using a hyaluronidase catalyst (Scheme 2.6b) [90]. The corresponding nonsulfated chondroitin of the Mn value of 5.0 × 103 was obtained.

Monomers bearing various substituents at the 2-position (2-vinyl, 2-ethyl, 2-n-propyl) were prepared for the production of unnatural HA and Ch bearing the corresponding N-acyl groups (Scheme 2.7a and b). Polymerization proceeded successfully with the catalysis of PH-20 HAase, which facilitates penetration for the sperm through the hyaluronan-rich matrix of the oocyte [87].

Chondroitin sulfate is an important structural component of cartilage and provides much of its resistance to compression. Along with glucosamine, chondroitin sulfate has become a widely used dietary supplement for the treatment of osteoarthritis [91]. A structurally well-defined synthetic chondroitin sulfate has been prepared using the hyaluronidase catalyst (Scheme 2.7c) [92]. Among three oxazoline monomers sulfated at C4, C6, and C4 + C6, the monomer sulfated at C4 gave the chondroitin sulfate in good yields. The resulting synthetic chondroitin sulfate has the sulfonate group exclusively at C-4 of the GalNAc unit; the purity of the synthetic ChS-A 100% is to be compared with that of natural ChS-A ∼ 80%. The Mn value ranged from 4.0 × 103 to 1.8 × 104.

2.7.2 Unnatural Hybrid-Type Glycosaminoglycan Synthesis

The use of PH-20 HAase enabled the production of various polysaccharides with well-defined structure through the homopolymerization of sugar-oxazoline monomers. These results imply the possibility of cross reactions, that is, copolymerization of the monomers. First, HA monomers with different substitutes at C2 were copolymerized, affording the corresponding HA1-co-HA2 products (Fig. 2.11) [93].

Furthermore, hybrid glycosaminoglycans of hyaluronan-chondroitin (HA-co-Ch) and hyaluronan-chondroitin 4-sulfate (HA-co-Ch4S) can be obtained by enzymatic polymerization using a hyaluronidase catalyst (Fig. 2.11) [94]. N-Acetylhyalobiuronate (GlcA-β-(1 → 3)-GlcNAc)-derived oxazoline was copolymerized with N-acetylchondrosine (GlcA-β-(1 → 3)-GalNAc)-derived oxazolines by the hyaluronidase catalysis at pH 7.5 and 30 °C, giving rise to the corresponding copolymer with a Mn = 7.4 × 103 in 50% yield. Hyaluronidase-catalyzed copolymerization of monomer with N-acetylchondrosine oxazoline having a sulfate group at C4 on the GalNAc moiety produced the corresponding copolymer with a Mn = 1.4 × 104 in 60% yield. The copolymer compositions can be controlled by varying the comonomer feed ratio.

Hyaluronidase catalyzes multiple enzymatic polymerizations with controlling regio- and stereoselectivity perfectly. This behavior, that is, the single enzyme being effective for multireactions and retaining the enzyme catalytic specificity, is unusual, and hence, hyaluronidase can be considered to be a “supercatalyst” [93].

2.8 Keratanase

Keratanase II obtained from Bacillus sp. Ks36 has been used for the enzymatic polymerizations. Even though the details of the enzyme are still unknown, similar ones obtained from Bacillus circulans KsT202 have been reported [95]. The enzyme was shown to hydrolyze keratan sulfate between the 4GlcNAc-β-(1 → 3)-Gal structure [96].

Keratan sulfate (KS) is in the class of glycosaminoglycans, which have repeated sulfated disaccharide structures of β-(1 → 3)-linked Gal-β-(1 → 4)-GlcNAc. Besides acting as a constitutive molecule of the extracellular matrices, KS also plays a role as a hydrating and signaling agent in the cornea and cartilage tissues. Inasmuch as KS is widely explored in the pharmaceutical industry [97], C-6 sulfated and C-6, 6′ disulfated Gal-β-(1 → 4)-GlcNAc oxazoline monomers have been designed for polymerizations using keratanase II. These two sulfated monomers were polymerized by keratanase II (3.2.1.103), producing the corresponding keratin sulfate oligosaccharides (Scheme 2.8) [98]. Notably, keratanase II catalyzed transglycosylation to form a β-(1 → 3)-glycosidic bond and required the 6-sulfate group in the GlcNAc residue. The information on the catalytic site of keratanase II of KsT202 was further obtained by the examination of the reaction specificity using 6-O-sulfonato-Lewis X and its oxazoline derivative as a glycosyl acceptor and donor, respectively. The active site should be constituted as a cleft structure having a steric hindrance around the (+3)(+4) subsites [99].

2.9 Perspective

Enzymatic polymerization that utilizes glycoside hydrolases as catalysts is a promising method not only for synthesis of natural polysaccharides but also for the construction of artificial polysaccharide backbones having definite structures. A variety of monosaccharides (Ⓐ or Ⓑ), disaccharides (Ⓐ-Ⓑ or Ⓐ-Ⓑ), or even larger oligosaccharides are available as refined raw materials from the naturally occurring polysaccharide biomass (Fig. 2.12a). These refined raw materials can be converted to activated glycosyl monomers (Ⓐ-Ⓑ* or Ⓐ-Ⓑ*) via the classical organic reactions with protection and deprotection of the hydroxy groups or the direct anomeric activation methods. The resulting glycosyl monomers are then polymerized by the action of glycoside hydrolases, giving rise to the corresponding polysaccharides having definite structures (Fig. 2.12b). According to this methodology, it has become possible to achieve a process of low environmental impact for production of various natural polysaccharides or functional polysaccharides.

Since the first in vitro synthesis of cellulose was reported by S. Kobayashi et al. in 1991, various kinds of bioactive and structurally complex polysaccharides have successfully been prepared by the enzymatic polymerization of activated glycosyl monomers. Furthermore, recent progress in biotechnology has made it possible to overcome the problems caused by the hydrolysis of the products by wild-type glycosidases; mutated enzymes called glycosynthases were developed with the help of advanced enzyme engineering such as the site-directed mutation and site-directed evolution technologies.

The enzymatic polymerization catalyzed by glycoside hydrolases are environmentally friendly process because it utilizes a protein, naturally occurring biomacromolecule, whose production requires no strong acid/base or harsh conditions. It is expected that the production of polysaccharides from biomass-derived saccharide monomers catalyzed by glycoside hydrolases will greatly contribute to the future innovation of polymer materials that have been difficult to produce by conventional methodologies, including classical synthetic reactions that have high environmental stress.

References

Trianabos AO (2000) Polysaccharide immunomodulators as therapeutic agents: structural aspects and biologic function. Clin Microbiol Rev 13:523–533

Kobayashi S (2007) New developments of polysaccharide synthesis via enzymatic polymerization. Proc Jpn Acad Ser B Phys Biol Sci 83:215–247

Xiao R, Grinstaff MW (2017) Chemical synthesis of polysaccharides and polysaccharide mimetics. Prog Polym Sci. https://doi.org/10.1016/j.progpolymsci.2017.07.009

Taniguchi N, Honke K, Fukuda M (eds) (2002) Handbook of glycosyltransferases and related genes. Springer, Tokyo

Kittl R, Withers SG (2010) New approaches to enzymatic glycoside synthesis through directed evolution. Carbohydr Res 345:1272–1279

Kobayashi S, Makino A (2009) Enzymatic polymer synthesis: an opportunity for green polymer chemistry. Chem Rev 109:5288–5353

Shoda S, Kobayashi A, Kobayashi S (2015) Production of polymers by white biotechnology. In: Coelho MAZ, Ribeiro BD (eds) White biotechnology for sustainable chemistry. Royal Society of Chemistry, Cambridge, pp 274–309

Rye CS, Withers SG (2000) Glycosidase mechanisms. Curr Opin Chem Biol 4:573–580

Kerr AK (1995) CRC handbook of chemistry and physics. CRC, Boca Raton

Barnett JEG, Jarvis WTS, Munday KA (1967) The hydrolysis of glycosyl fluorides by glycosidases. Biochem J 105:669–672

Hehre EJ, Brewer CF, Genghof DS (1979) Scope and mechanism of carbohydrase action – hydrolytic and non-hydrolytic actions of β-amylase on α-maltosyl and β-maltosyl fluoride. J Biol Chem 254:5942–5950

Yokoyama M (2000) Methods of synthesis of glycosyl fluorides. Carbohydr Res 327:5–14

Tanaka T, Noguchi M, Watanabe K, Misawa T, Ishihara M, Kobayashi A, Shoda S (2010) Novel dialoxytriazine-type glycosyl donors for cellulase-catalysed lactosylation. Org Biomol Chem 8:5126–5132

Koshland DE (1953) Stereochemistry and the mechanism of enzymatic reactions. Biol Rev 28:416–436

Davies G, Henrissat B (1995) Structures and mechanisms of glycosyl hydrolases. Structure 3:853–859

Shoda S (2001) Enzymatic glycosylation. In: Fraser-Reid BO, Tatsuta K, Thiem J (eds) Glycoscience chemistry and chemical biology, vol II. Springer, Heidelberg, pp 1465–1496

Shoda S, Uyama H, Kadogawa J, Kimura S, Kobayashi S (2016) Enzymes as green catalysts for precision macromolecular synthesis. Chem Rev 116:2307–2413

Kobayashi S, Shoda S (1996) Enzymatic synthesis of polysaccharides: a new concept in polymerization chemistry. In: Kamachi M, Nakamura A (eds) New macromolecular architecture and functions. Springer, Heidelberg, pp 171–180

Shoda S, Shintate K, Ishihara M, Noguchi M, Kobayashi A (2007) Colorimetric assay for evaluating glycosyl fluoride-hydrolyzing activity of glycosidase by using alizarin complexon reagent. Chem Lett 36:16–17

Danby PM, Withers SG (2016) Advances in enzymatic glycoside synthesis. ACS Chem Biol 11:1784–1794

Hancock SM, Vauhgan MD, Withers SG (2006) Engineering of glycosidases and glycosyltransferases. Curr Opin Chem Biol 10:509–519

MacKenzie LF, Wang QP, Warren RAJ, Withers SG (1998) Glycosynthases: mutant glycosidases for oligosaccharide synthesis. J Am Chem Soc 120:5583–5584

Kobayashi S (2005) Challenge of synthetic cellulose. J Polym Sci Part A: Polym Chem 43:693–710

Kobayashi S, Shoda S, Donnelly M, Church SP (1999) Enzymatic synthesis of cellulose. In: Bucke C (ed) Carbohydrate biotechnology protocols, Methods in biotechnology, vol 10. Humana Press, Totowa, pp 57–69

Kobayashi S, Kashiwa K, Kawasaki T, Shoda S (1991) Novel method for polysaccharide synthesis using an enzyme – the 1st in vitro synthesis of cellulose via a nonbiosyntehtic path utilizing cellulase as catalyst. J Am Chem Soc 113:3079–3084

Kobayashi S, Shoda S (1995) Chemical synthesis of cellulose and cello-oligomers using a hydrolysis enzyme as a catalyst. Int J Biol Macromol 17:373–379

Fort S, Boyer V, Greffe L et al (2000) Highly efficient synthesis of β(1→4)-oligo- and -polysaccharides using a mutant Cellulase. J Am Chem Soc 122:5429–5437

Noguchi M, Tanaka T, Ishihara M, et al (2007) Synthesis of artificial cellulose from novel activated glycosides catalyzed by cellulase and related enzymes. In: Abstracts of the 2nd International Cellulose Conference, Tokyo, 22–25 October 2007

Egusa S, Kitaoka T, Goto M, Wariishi H (2007) Synthesis of cellulose in vitro by using a cellulase/surfactant complex in a nonaqueous medium. Angew Chem Int Ed 46:2063–2065

Egusa S, Goto M, Kitaoka T (2012) One-step synthesis of cellulose from cellobiose via protic acid-assisted enzymatic dehydration in aprotic organic media. Biomacrocolecules 13:2716–2722

Faijes M, Imai T, Bulone V, Planas A (2004) In vitro synthesis of a crystalline (1→3,1→4)-β-D-glucan by a mutated (1→3,1→4)-β-D-glucanase from bacillus. Biochem J 380:635–641

Saxena IM, Brown RM, Fevre M et al (1995) Multidomain architecture of β-glycosyl transferases – implications for mechanism of action. J Bacteriol 177:1419–1424

Kadokawa J (2011) Precision polysaccharide synthesis catalyzed by enzymes. Chem Rev 111:4308–4345

Kobayashi S, Shoda S, Lee J et al (1994) Direct visualization of synthetic cellulose formation via enzymatic polymerization using transmission electron-microscopy. Macromol Chem Phys 195:1319–1326

Lee JH, Brown RM, Kuga S, Shoda S, Kobayashi S (1994) Assembly of synthetic cellulose-I. Proc Natl Acad Sci U S A 91:7425–7429

Kobayashi S, Hobson LJ, Sakamoto J et al (2000) Formation and structure of artificial cellulose spherulites via enzymatic polymerization. Biomacromolecules 1:168–173

Kobayashi S, Shoda S, Wen X et al (1997) Choroselective enzymatic polymerization for synthesis of natural polysaccharides. J Macromol Sci, Part A: Pure Appl Chem 34:2135–2142

Hashimoto T, Tanaka H, Koizumi S et al (2006) Chemical reaction at specific sites and reaction-induced self-assembly as observed by in situ and real time SANS: enzymatic polymerization to synthetic cellulose. Biomacromolecules 7:2479–2482

Tanaka H, Koizumi S, Hashimoto T et al (2007) Self-assembly of synthetic cellulose during in-vitro enzymatic polymerization process as studied by a combined small-angle scattering method. Macromolecules 40:6304–6315

Nakamura I, Yoneda H, Maeda T et al (2005) Enzymatic polymerization behavior using cellulose-binding domain deficient endoglucanase II. Macromol Biosci 5:623–628

Nakamura I, Makino A, Sugiyama J et al (2008) Enzymatic activities of novel mutant endoglucanases carrying sequential active sites. Int J Biol Macromol 43:226–231

Nakamura I, Makino A, Horikawa Y et al (2011) Preparation of fibrous cellulose by enzymatic polymerization using cross-linked mutant endoglucanase II. Chem Commun 47:10127–10129

Hochuli E, Döbeli H, Schacher A (1987) New metal chelate adsorbent selective for proteins and peptides containing neighboring histidine residues. J Chromatogr A 411:177–184

Nakamura I, Makino A, Ohmae M, Kimura S (2010) Immobilization of his-tagged endoglucanase on gold via various Ni-NTA self-assembled monolayers and its hydrolytic activity. Macromol Biosci 10:1265–1272

Nakamura I, Horikawa Y, Makino A et al (2011) Enzymatic polymerization catalyzed by immobilized endoglucanase on gold. Biomacromolecules 12:785–790

Nakamura I, Makino A, Ohmae M, Kimura S (2012) Enzymatic polymerization to cellulose by crosslinked enzyme immobilized on gold solid surface. Chem Lett 41:37–38

Kobayashi S, Wen X, Shoda S (1996) Specific preparation of artificial xylan: a new approach to polysaccharide synthesis by using cellulase as catalyst. Macromolecules 29:2698–2700

Croon I, Timell TE (1960) Distribution of substitution in a partially methylated xylan. J Am Chem Soc 82:3416–3418

Moreau V, Driguez H (1996) Enzymic synthesis of hemithiocellodextrins. J Chem Soc, Perkin Trans 1(6):525–527

Shoda S, Okamoto E, Kiyosada T et al (1994) Synthesis of 6- and/or 6′-O-methylated cellobiosyl fluorides: new monomers for enzymatic polymerization. Macromol Rapid Commun 15:751–756

Okamoto E, Kiyosada T, Shoda S et al (1997) Synthesis of alternatingly 6-O-methylated cellulose via enzymatic polymerization of a substituted cellobiosyl fluoride monomer catalyzed by cellulase. Cellulose 4:161–172

Izumi R et al (2009) Synthesis of artificial oligosaccharides by polycondensation of 2′-O-methyl cellobiosyl fluoride and mannosyl-glucosyl fluoride catalyzed by cellulase. In: Kadokawa J (ed) Interfacial researches in fundamental and material sciences of oligo- and polysaccharides. Transworld Research Network, Trivandrum, pp 45–67

Kobayashi S, Sakamoto J, Kimura S (2001) In vitro synthesis of cellulose and related polysaccharides. Prog Polym Sci 26:1525–1560

Ohmae M, Makino A, Kobayashi S (2007) Enzymatic polymerization to unnatural hybrid polysaccharides. Macromol Chem Phys 208:1447–1457

Kobayashi S, Makino A, Matsumoto H et al (2006) Enzymatic polymerization to novel polysaccharides having a glucose-N-acetylglucosamine repeating unit, a cellulose-chitin hybrid polysaccharide. Biomacromolecules 7:1644–1656

Saura-Valls M, Fauré R, Ragàs S et al (2006) Kinetic analysis using low-molecular mass xyloglucan oligosaccharides defines the catalytic mechanism of a populus xyloglucan endotransglycosylase. Biochem J 395:99–106

Tanaka T, Noguchi M, Ishihara M et al (2010) Synthesis of non-natural xyloglucans by polycondensation of 4,6- dimethoxy-1,3,5-triazin-2-yl oligosaccharide monomers catalyzed by endo-β-1,4-glucanase. Macromol Symp 297:200–209

Fujita M, Shoda S, Kobayashi S (1998) Xylanase-catalyzed synthesis of a novel polysaccharide having a glucose-xylose repeating unit, a cellulose-xylan hybrid polymer. J Am Chem Soc 120:6411–6412

McIntosh M, Stone BA, Stanisich VA (2005) Curdlan and other bacterial (1→3)-β-D-glucans. App Microbiol Biotechnol 68:163–173

Viladot JL, Moreau V, Planas A, Driguez H (1997) Transglycosylation activity of bacillus 1,3-1,4-β-D-glucan 4-glucanohydrolases. Enzymic synthesis of alternate 1,3-1,4-β-D-glucooligosaccharides. J Chem Soc, Perkin Trans 1:2383–2387

Hrmova M, Imai T, Rutten SJ et al (2002) Mutated barley (1,3)-β-D-glucan endohydrolases synthesize crystalline (1,3)-β-D-glucans. J Biol Chem 277:30102–30111

Kobayashi S, Shimada J, Kashiwa K, Shoda S (1992) Enzymatic Polymerization of α-D-Maltosyl Fluoride Utilizing α-Amylase as the Catalyst - A New Approach for the Synthesis of Maltooligosaccharides. Macromolecules 25:3237–3241

Tews I, van Scheltinga ACT, Perrakis A et al (1997) Substrate-assisted catalysis unifies two families of chitinolytic enzymes. J Am Chem Soc 119:7954–7959

Wiwat C, Siwayaprahm P, Bhumiratana A (1999) Purification and characterization of chitinase from bacillus circulans No. 4.1. Curr Microbiol 39:134–140

Kobayashi S, Kiyosada T, Shoda S (1996) Synthesis of artificial chitin: irreversible catalytic behavior of a glycosyl hydrolase through a transition state analogue substrate. J Am Chem Soc 118:13113–13114

Merz RA, Horsch M, Nyhlen LE et al (1999) Biochemistry of chitin synthase. In: Jolles P, Muzzarelli RAA (eds) Chitin and chitinase. Birkhauser Verlag, Basel, pp 9–37

Kiyosada T, Takada E, Shoda S et al (1995) Hydrolysis and polymerization of novel monomers containing amino sugar. Polym Prepr Jpn 44:660

Kiyosada T, Shoda S, Kobayashi S (1995) Synthesis of Artificial Chitin by Enzymatic Ring-Opening Polyaddition. Polym Prepr Jpn 44:1230–1231

Sato H, Mizutani S, Tsuge S et al (1998) Determination of the degree of acetylation of chitin/chitosan by pyrolysis gas chromatography in the presence of oxalic acid. Anal Chem 70:7–12

Sakamoto J, Sugiyama J, Kimura S et al (2000) Artificial chitin spherulites composed of single crystalline ribbons of α-chitin via enzymatic polymerization. Macromolecules 33:4155–4160

Noguchi M, Tanaka T, Gyakushi H et al (2009) Efficient synthesis of sugar oxazolines from unprotected N-acetyl-2-amino sugars by using chloroformamidinium reagent in water. J Org Chem 74:2210–2212

Noguchi M, Fujieda T, Huang WC et al (2012) A practical one-step synthesis of 1,2-oxazoline derivatives from unprotected sugars and its application to chemoenzymatic β-N-acetylglucosaminidation of disialo-oligosaccharide. Helv Chim Acta 95:1928–1936

Yoshida N, Tanaka T, Noguchi M et al (2012) One-pot chemoenzymatic route to chitoheptaose via specific transglycosylation of chitopentaose-oxazoline on chitinase-template. Chem Lett 41:689–690

Shoda S, Fujita M, Lohavisavapanichi C et al (2002) Efficient method for the elongation of the N-acetylglucosamine unit by combined use of chitinase and β-galactosidase. Helv Chim Acta 85:3919–3936

Kohri M, Kobayashi A, Noguchi M et al (2006) Stepwise synthesis of chitooligosaccharides through a transition-state analogue substrate catalyzed by mutants of chitinase A1 from bacillus circulans WL-12. Holzforschung 60:485–491

Shoda S, Misawa Y, Nishijima Y et al (2006) Chemo-enzymatic synthesis of novel oligo-N-acetyllactosamine derivatives having a β(1-4)–β(1-6) repeating unit by using transition state analogue substrate. Cellulose 13:477–484

Kobayashi S, Makino A, Tachibana N et al (2006) Chitinase-catalyzed synthesis of a chitin-xylan hybrid polymer: a novel water-soluble β(1→4) polysaccharide having an N-acetylglucosamine-xylose repeating unit. Macromol Rapid Commun 27:781–786

Makino A, Kurosaki K, Ohmae M et al (2006) Chitinase-catalyzed synthesis of alternatingly N-deacetylated chitin: a chitin-chitosan hybrid polysaccharide. Biomacromolecules 7:950–957

Sakamoto J, Kobayashi S (2004) Enzymatic synthesis of 3-O-methylated chitin oligomers from new derivatives of a chitobiose oxazoline. Chem Lett 33:698–699

Ochiai H, Ohmae M, Kobayashi S (2004) Enzymatic glycosidation of sugar oxazolines having a carboxylate group catalyzed by chitinase. Carbohydr Res 339:2769–2788

Ochiai H, Ohmae M, Kobayashi S (2004) Enzymatic synthesis of alternatingly 6-O-carboxymethylated chitotetraose by selective glycosidation with chitinase catalysis. Chem Lett 33:694–695

Makino A, Ohmae M, Kobayashi S (2006) Synthesis of fluorinated chitin derivatives via enzymatic polymerization. Macromol Biosci 6:862–872

Makino A, Sakamoto J, Ohmae M et al (2006) Effect of fluorine substituent on the chitinase-catalyzed polymerization of sugar oxazoline derivatives. Chem Lett 35:160–161

Makino A, Nagashima H, Ohmae M et al (2007) Chitinase-catalyzed synthesis of an alternatingly N-sulfonated chitin derivative. Biomacromolecules 8:188–195

Makino A, Ohmae M, Kobayashi S (2006) Chitinase-catalyzed copolymerization to a chitin derivative having glucosamine unit in controlled proportion. Polym J 38:1182–1188

Stern R, Jedrzejas MJ (2006) Hyaluronidases: their genomics, structures, and mechanisms of action. Chem Rev 106:818–839

El-Safory NS, Fazary AE, Lee CK (2010) Hyaluronidases, a group of glycosidases: current and future perspectives. Carbohydr Polym 81:165–181

Kobayashi S, Morii H, Itoh R et al (2001) Enzymatic polymerization to atificial hyaluronan: a novel method to synthesize a glycosaminoglycan using a transition state analogue monomer. J Am Chem Soc 123:11825–11826

Kogan G, Šoltés L, Stern R et al (2007) Hyaluronic acid: a natural biopolymer with a broad range of biomedical and industrial applications. Biotechnol Lett 29:17–25

Kobayashi S, Fujikawa S, Ohmae M (2003) Enzymatic synthesis of chondroitin and its derivatives catalyzed by hyaluronidase. J Am Chem Soc 125:14357–14369

Baeurle SA, kiselev MG, Makarova ES et al (2009) Effect of the counterion behavior on the frictional–compressive properties of chondroitin sulfate solutions. Polymer 50:1805–1813

Fujikawa S, Ohmae M, Kobayashi S (2005) Enzymatic synthesis of chondroitin 4-sulfate with well-defined structure. Biomacromolecules 6:2935–2942

Kobayashi S, Ohmae M, Ochiai H (2006) A hyaluronidase supercatalyst for the enzymatic polymerization to synthesize glycosaminoglycans. Chem Eur J 12:5962–5971

Ochiai H, Fujikawa S, Ohmae M (2007) Enzymatic copolymerization to hybrid glycosaminoglycans: a novel strategy for intramolecular hybridization of polysaccharides. Biomacromolecules 8:1802–1806

Yamagishi K, Suzuki K, Imai K et al (2003) Purification, characterization, and molecular cloning of a novel keratan sulfate hydrolase, endo-β-N-acetylglucosaminidase, from bacillus circulans. J Biol Chem 278:25766–25772

Kariya Y, Watabe S, Mochizuki H et al (2003) Modification of di- and tetrasaccharides from shark cartilage keratan sulphate by refined anhydromethanolic hydrochloric acid-treatments and evaluation of their specific desulphation. Carbohydr Res 338:1133–1138

Pomin VH (2015) Keratan sulfate: an up-to-date review. Int J Biol Macromol 72:282–289

Ohmae M, Sakaguchi K, Kaneto T et al (2007) Keratanase II-catalyzed synthesis of keratan sulfate oligomers by using sugar oxazolines as transition-state analogue substrate monomers: a novel insight into the enzymatic catalysis mechanism. ChemBioChem 8:1710–1720

Yamazaki Y, Kimura S, Ohmae M (2018) Reaction specificity of keratanase II in the transglycosylation using the sugar oxazolines having keratan sulfate repeating units. Carbohydr Res 456:61–68

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Shoda, Si., Noguchi, M., Li, G., Kimura, S. (2019). Synthesis of Polysaccharides I: Hydrolase as Catalyst. In: Kobayashi, S., Uyama, H., Kadokawa, Ji. (eds) Enzymatic Polymerization towards Green Polymer Chemistry. Green Chemistry and Sustainable Technology. Springer, Singapore. https://doi.org/10.1007/978-981-13-3813-7_2

Download citation

DOI: https://doi.org/10.1007/978-981-13-3813-7_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-3812-0

Online ISBN: 978-981-13-3813-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)