Abstract

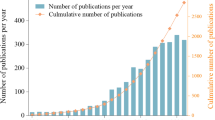

Various alternatives have been exploited to produce biofuels economically and to reduce the environmental impacts with sustainable biowaste management . Lipids are valuable energy rich compounds that has the potential to replace conventional fossil fuels through the production of biofuels . Oleaginous microorganisms contain significant amount of microbial lipids consisting of special fatty acids with varied applications as food additives and nutraceuticals . Biofuels produced from microbial lipids as a third generation feedstock are a promising substitute for fossil fuels and animal fats or vegetable oils . However, the development and scalable production of biofuels from microbial lipids is yet to be commercialized and intensive research is required to evaluate the lipid extraction approaches for optimum biofuel production. In this chapter, we describe the sources of microbial lipids, factors that affect the microbial lipids production, technologies for microbial lipids conversion into biofuels . Alternative and innovative techniques for biofuel production and the life cycle impact of biofuel production from microbial lipids are also discussed.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The continuous use of fossil fuels has led to the tremendous increase in atmospheric CO2 and associated global warming trends and other related environmental issues. These issues have clearly exaggerated energy security, alongside soaring oil prices and climate change. With the increase use of petroleum or fossil fuel based hydrocarbons for energy supply, the gap between demand of crude oil and supply from indigenous sources is expected to increase over the years [1]. This has created the need for energy alternatives that would reduce the dependence on fossil fuels. Besides that, fuels derived from renewable sources are undoubtedly one of the top alternatives to divert from the reliance of petroleum fuels [2, 3]. Renewable and non-polluting biomass energy has received increasing attention from industries as well as academic community.

Biofuels like biodiesel can be produced from feedstock such as canola oil, palm oil, soybean oil, rapeseed oil and sunflower oil. Soybean and rapeseed are common feedstocks for biofuel production in America and Europe, respectively. Countries like Malaysia and Thailand have a surplus of palm crops and can generate large amounts of palm oil for biodiesel production [4, 5]. Many vegetable oil can be converted to renewable fuels, they are favorable due to their environmental benefits and sustainability. The esters from vegetable oils are good substitutes for diesel as they do not require any modification in the current automobile engine design and contain high energetic yields [6]. Fatty acids with longer chain length can also produce biodiesel with high cetane number and reduced nitrogen oxide emissions. It is possible to improve the properties of biodiesel through genetic engineering, where modification of the parent oil could lead to an enriched fuel with certain fatty acids for improved fuel properties.

The development of biofuels with dedicated energy drops like Jatropha and soybean have raised many controversies, including land use changes and competition with food crops for agricultural resources. Biodiesel derived from oilseed or animal fats is currently not able to meet the realistic demand as they can cover only a small fraction of the transport fuel requirements. The infeasibility of these sources become more apparent as large areas of land is needed for the production of oilseed crops and animal feed [7, 8]. Therefore, it is essential to search for new feedstocks which are economically competitive, renewable and can be produced in large quantities without complicated processing. Moreover, the feedstock should provide environmental benefits over fossil fuel sources and do not compete with food crops production. Microbial lipids satisfy these criteria as they can be produced cost-effectively and hence, they have generated interest due to their ability to lessen the global crude oil and greenhouse gas crisis. Lipids are ubiquitous in all living organisms, which form the permeable membranes of cells and organelles as a lipid bilayer. The cultivation of lipid rich microorganisms could be independent from climatic constraints and can valorize industrial wastes by using them as substrates [9]. However, the broad commercialization of microorganisms-derived biofuel is yet to be accomplished due to techno-economic constraints in the downstream processing and mass cultivation [10].

Microalgae can be considered as the ideal feedstock for the production of biodiesel for the following reasons [3, 7, 8, 10]:

-

i.

Microalgae are unicellular with simple nutritional requirements, they grow easily in varied climatic conditions and habitats, thus providing a high biodiversity.

-

ii.

They have high photosynthetic efficiency compared to terrestrial plants, and certain microalgae are able to tolerate very high concentrations of CO2 and can be used for carbon sequestration. The carbon footprint in biofuel production can be reduced.

-

iii.

Microalgae can assimilate nutrients like nitrogen and phosphorus from wastewater, hence wastewater can be used for biomass production and concomitant bioremediation.

-

iv.

Microalgae can adsorb heavy metals in solution, and can be used for heavy metal removal and reduce environmental pollution .

-

v.

Microalgae are rich in high value compounds like polyunsaturated fatty acids , pigments, and proteins that has applications in pharmaceutical and nutraceutical industries.

-

vi.

Microalgal biomass has diverse applications in human health and nutrition, aquaculture feed, animal feed and with the energy rich compounds like carbohydrates and lipids, they can be used as a sustainable feedstock for biofuel production.

Substantial efforts have been taken for the development of high density cultivation processes in commercializing microalgal biomass production. Two examples of these processes are (i) Utilizing the metabolic potential of microalage and (ii) innovative cultivation systems designed for high cell density cultivation of microalgae . The metabolic pathways depend on the requirement of light and carbon sources for growth and cell division and can be divided into three types, namely photoautotrophy, heterotrophy and mixotrophy [11]. Photoautotrophy is the simplest cultivation system with sunlight and CO2, generally uses an open pond system and is relatively simple to operate with low cost. Heterotrophic cultivation can utilize a wide source of organic carbon to reduce the overall cost of biofuel produced. For the cultivation systems design, the choice between an open or closed style plays a major role in affecting the efficiency of large scale biofuel production. Open ponds systems can simulate the growth environment in its natural behavior while closed system like photobioreactor which are constructed specifically for the cultivation processes provide uniform and optimal growth conditions for the culture .

Many oleaginous species have the ability to metabolize pentoses, revealing the potential of producing triacylglycerol (TAG) from lignocellulosic biomass and other cheap materials [12]. The cost of microbial oil production may be currently higher compared to vegetable oil , however, the techno-economics of the production processes can be significantly improved with various methods. The costs of biofuel production can be reduced with further developments in using lignocellulose-based carbohydrates as a feedstock. Besides that, the utilization of the by-product from the microorganisms’ cultivation for value-added products may also improve the economic potential. Optimization of the operating processes could help attain higher lipid productivity and better cellular lipid content [13].

2 Microbial Lipids as a Potential Resource for Biofuels

The potential feedstocks that may be used as raw materials for biofuel production has been widely extended due to the recent technological advantages in the related areas. Microorganisms , because of their ubiquitous nature, is a potential source for a variety of valuable compounds that can serve as feedstock for biofuel production (Table 1). Microorganisms offer numerous benefits in the environmental, economic and energy security outlook when used for the production of biofuels (Fig. 1). The cultivation of microbes for a desirable product is an age old process and all the techniques have been established for major industrial microorganisms like E. coli, the ethanol fermenting yeast Saccharomyces and the anaerobic Clostridia for Acetone-butanol-ethanol (ABE) fermentation . They can be cultivated with relatively less labor, regardless of the climate or season, can be easily scaled up and contains much higher yield of lipids compared to plants [14]. Using microorganisms to produce biofuels will also not compromise the production food and other products derived from crops. Oleaginous microorganisms , that mainly comprises of bacteria, algae, yeast and molds, are defined as microbes with lipid content exceeding 20% of the cellular biomass content. Lipids produced by oleaginous microorganisms have fatty acid compositions which are similar to that of vegetable oils and this shows great potential for biofuels production.

2.1 Sources of Microbial Lipids from Oleaginous Microorganisms

Oleaginous microorganisms belonging to different families such as algae, bacteria, yeast and fungi are able to generate neutral lipids under certain cultivation conditions. Of these, eukaryotic microorganisms like yeasts and microalgae can synthesize and store triacylglycerol (TAG) in their cell when subjected to nutrient derivation in the form of nitrogen limitation. In microalgae, under nitrogen limiting conditions and the continued availability of carbon, cell growth is arrested because of the limited availability of nitrogen for the synthesis of proteins that are responsible for cell division. And nitrogen deprivation leads to the activation of deaminases that particularly act on AMP. Reduction in the cellular and mitochondrial AMP can result in the reduced activity of isocitrate dehydrogenase, and hence citric acid is accumulated, which is then exported to cytosol and converted to acetyl CoA [21]. Acetyl CoA is the major precursor of fatty acid synthesis and hence in nitrogen limiting conditions the metabolized carbon is continuously funneled into lipid synthesis in eukaryotic oleaginous microorganisms . Since lipids are the most reduced forms of carbon, they also need an uninterrupted supply of reducing equivalents like nicotinamide adenine dinucleotide phosphate (NADPH). For the synthesis of one mole of a C18 fatty acid, 16 mol of NADPH is required [22]. The required NADPH is continuously supplied by the TCA cycle via the activity of the malic enzyme or the pentose phosphate pathway [23]. The lipids thus stored serve as an energy source or as precursors of fatty acid synthesis required for cell growth and metabolism after rejuvenation. Hence eukaryotic oleaginous microorganisms are capable of accumulating neutral lipids or TAGs from 40–80% of their biomass [21]. Bacteria generally accumulate polyhydroxy alkonates as lipid reserves and polyhydroxy butyrate is the major PHA to be synthesized and stored and is also mainly studied in the bacteria Bacillus. Certain bacteria like Mycobacterium sp., Rhodococcus sp., Streptomyces sp., Acinetobacter sp., Nocardia sp., Gordonia sp., Micromonospora sp., and Dietzia sp. are capable of accumulating TAGs or neutral lipids [24]. Neutral lipids or TAG accumulation in bacteria is modulated by enhanced activities of phosphatidate phosphatase (PAP) and AcylCoA:Diacyglycerol acyltransferase (DGAT) that converts the fatty acid palmitic acid to TAG, and with reduced β-oxidation of fatty acids by the activity of the transcriptional regulator FadR [25]. Table 2 indicates that bacteria have lower lipid content (20–40% of dry biomass) compared to the other microorganisms. Nevertheless, bacteria have a very high growth rate, such that it can achieve a huge biomass production in about 12–24 h, and the culturing method for bacteria growth is relatively simple. Most bacteria are not oil producers, though there are some types of bacteria which can synthesize high amounts of fatty acids (up to 70% of the cellular dry weight ) from simple carbon sources [26]. The extraction of complicated lipoids from bacteria is difficult and hence less significance is placed on the use of oleaginous bacteria as a raw material for the production of biofuels. With the extended knowledge of lipid accumulation in both prokaryotes and eukaryotes, it is believed that algal lipids has the highest chance to be the alternative biodiesel source compared to yeasts and bacteria, because of their economic production potential and increased accumulation of TAGs, next only to oleaginous yeasts whose production costs should be sustained by alternative cheap carbon sources [27]. Microalgae can grow very rapidly and many of its species contain high amount of oil. This oil content may exceed 80% of its dry biomass weight and its biomass doubling time during exponential growth can be as short as 3.5 h [28]. The oleaginous microalgae and yeasts can grow and accumulate significant amounts of lipids and their maximum achievable lipid content can alter immensely among different species and individual strains [29]. Table 2 shows the potential microorganism for microbial oil production.

The oil productivity depends on the growth rate of the algal strain and oil content of the biomass . Microalgae with high oil content and productivities are highly sought after for producing biofuels . On the other hand, yeasts and fungi are favorable microorganisms as an alternative oil resource as they typically contain intracellular lipid as high as 70% of their biomass dry weight. Oleaginous yeast Crptococcus curvatus is extremely efficient and can accumulate lipids up to 60% on a dry weight basis. Oleaginous yeasts and molds can also accumulate triacylglycerols that are rich in polyunsaturated fatty acids [31]. Certain species of yeasts are known for their ability to produce large quantities of microbial lipids due to their capability to obtain a high dry biomass and high cellular lipid content. Furthermore, a recent report has shown that the filamentous fungus Mucur circinelloides has potential as a feedstock for biodiesel production. This microbial lipids showed a high content (>85%) of saponifiable matter and adequate fatty acid content for biodiesel production. High purity of fatty acid methyl esters (FAME) was produced and the direct transformation of fungal biomass to biodiesel without an intermediate lipid extraction step was made possible [32]. This strengthens the potential of oleaginous yeasts and fungi as an alternative for biofuels production. The lipids extracted from oleaginous microorganisms also consists of a wide variation of lipid classes, such as acylglycerides, phospholipids, glycolipids , free fatty acids (FFA), lipoproteins, and sterols. These lipid classes will have different physico-chemical properties which can be observed during extraction [2]. Table 3 shows the content of various lipids in cell biomass from the oleaginous microorganisms.

2.2 Microbial Lipids Production from Renewable and Waste Materials

For cost effective biofuels production with microbial lipids , it is essential to reduce production costs and valorize wastes by recycling resources such as spent cell mass, water and nutrients. Lipids are intracellular products and the technology involved for the production of microbial lipids usually produces significant amounts of cell mass by-products, which contain nutrient, proteins , polysaccharides and other trace elements. Besides that, wastewater contains residual nutrients and elements which can be recycled to increase the efficiency of the microbial lipid technology [30, 41]. Biodiesel production commonly involves three processes which are drying of the biomass, lipid extraction and transesterification . Recently, the use of direct transesterification has been reviewed, as fatty acids in the lipid rich biomass can undergo transesterification without a lipid extraction step. This would result in the reduction of processing time and lessen the solvent needed for biofuel production.

The growth of microorganisms and the production of microbial lipids could also be supported by fermentation material like food waste. Food wastes are unconsumed food and food residues from residential areas or commercial businesses. They contain protein, lipids , lignin, carbohydrate and organic acids, which are promising sources of nutrients for the fermentation process and valuable raw material for various biotechnological products. With the use of yeasts, some low-cost fermentation substrates can be converted into bio-lipids. This indicates that recycling food wastes as a low-cost fermentation substrate for yeast cultivation is feasible for biological lipid production [42]. Furthermore, lignocellulosic materials and organic wastes are suitable carbon sources for producing biofuels due to its high availability and low impact on food prices. The cellulosic biomass will be converted into simple sugars and these sugars are subsequently converted into biofuels. Nonetheless, pre-treatment steps are needed and it may be quite energy intensive as the usage of hazardous chemicals or large amount of enzyme during the hydrolysis step is required. The pre-treatment step is necessary to reduce the recalcitrance of lignocellulosic material and this is done by partially breaking the recalcitrant structure [43].

Cheirsilp and Louhasakul [44] studied the cultivation of oleaginous yeast Yarrowia lipolytica with industrial wastes like serum latex, palm oil mill effluent and crude glycerol to evaluate their abilities to grow and synthesize lipid from the wastes. Different types and mixtures of wastes were also analyzed to reduce the nutrients requirements. It was found that the yeasts could grow and produce lipids from various types of wastes, yielding a relatively high amount of lipid (1.6–1.7 g/L) and high lipid content (48–61%) based on their dry cell mass [44]. Furthermore, in a study by Poli et al. [45], two industrial wastes have been tested as the carbon and nitrogen sources for Y. lipolytica QU21 cultivation. The wastes are crude glycerol from a biodiesel industry and fresh yeast extract from brewery waste. Enhanced biomass production was observed in crude glycerol waste due to the impurities present. The additional amounts of peptides and proteins provided are beneficial as nitrogen sources for yeasts and yeast was found to adapt, grow and accumulate lipids rapidly on a large variety of wastes [45]. The optimum carbon to nitrogen ratio is also significant to enable cells to initiate lipid storage, and the use of crude glycerol for conversion was attractive for increasing the productivity of biofuels.

Microalgal cultivation in photoheterotrophic mode does not need any added organic carbon source and the carbon is supplied as inorganic CO2 or soluble carbonates. Industrial exhaust gases or flue gases are rich in CO2 and can be used as a carbon source for the photoautotrophic cultivation of microalgae . Kao et al. cultivated a Chlorella sp. MTF-15 on three different flue gases in both indoor and outdoor cultures and the growth, biomass and lipid productivities were examined [46]. The microalgal strain could efficiently utilize CO2, SOx and NOx present in the flue gas and a lipid accumulation of up to 35% was observed. Growth rate and lipid production were 0.827/d and 0.961 g/L, respectively [46]. The experiments were performed on site of a steel factory in Taiwan, making carbon capture feasible with microalgal cultures. Similarly, Scenedesmus obliquus was grown on flue gas for carbohydrate and lipid accumulation, and maximum biomass production was obtained at 14% flue gas [47]. The growth rate, lipid productivity and carbohydrate productivity were 1/d, 9.9 mg/L/d and 10.3 mg/L/d respectively [47]. Thus, flue gas is a potential source of inorganic carbon for the photoautotrophic cultivation of microalgae . However, in heterotrophic cultivation of microalgae, organic carbon can be assimilated into biomass, resulting in high biomass and lipid productivities. And as a cost cutting measure, various waste resources rich in organic carbon like sugarcane bagasse [48], palm oil mill effluent [49], anaerobic digestate [50], lignocellulosic biomass like rice straw [51] and biodiesel derived crude glycerol [52] has been successfully used for the cultivation of various microalgae. Rice straw was saccharified by the combination of gamma irradiation, alkali treatment and enzyme hydrolysis, which was then used for the cultivation of Chlorella protothecoides. A biomass concentration and fatty acid methyl ester concentration of 6.51 g/L and 2.95 g/L respectively [51]. Sugarcane bagasse hydrolysed by combined acid and enzymatic treatment and it was shown that better biomass and lipid productivity was obtained by fed batch fermentation. Biomass and lipid productivity were 24 g/L and 1.19 g/L/d respectively [48]. It was shown that the metabolism of pentoes via the pentose phosphate pathway (PPP) supported lipid production much better than the metabolism of glucose by glycolysis. As discussed earlier, the PPP pathway is a source of NADPH which is much needed for the synthesis of lipids . The utilization of waste materials as a nutrient source for the production of microbial lipids and further production to biofuels is a promising platform for the effective transformation of renewable and waste materials. The combination of different wastes rich in different nutrients can improve the economics of large scale lipid production, and the main success factor lies in the selection of microbial strains with high efficiency for lipid production.

2.3 Factors Affecting Microbial Lipids Production

Microalgae which are capable of producing large amounts of lipids and hydrocarbons are a promising alternative feedstock for the next generation of biofuels . They can be cultivated using relatively cheap resources like sunlight and carbon dioxide (CO2) from flue gases as mentioned earlier and have higher lipid content with rapid growth rate. However, the lipid accumulation and cell growth in algae under phototrophic conditions are influenced by various factors, which include light intensity , dissolved oxygen concentration, pH , carbon dioxide fraction, presence of organic carbon sources and concentration of nutrients such as iron, nitrogen, phosphorus and silicon [39, 53, 54]. Apart from that, key parameters such as cellular lipid content, lipid productivity and biomass productivity should be improved to enhance the economic feasibility of algal oil production, though it is apparent that algae species with high oil content tends to grow more slowly, resulting in low rates of oil production [55].

Light is essential for cell growth and the specific cell growth rate increases with increasing photon irradiation flux. The excess photonic energy will dissipate as heat and this may lead to the photo inhibition of cellular functions [56]. To overcome this, proper design of bioreactors are selected to elevate the higher limit of photonic flux. The use of low methanol concentrations could also lead to an improvement of phototrophic growth of algae by increasing photosynthesis and algae respiration rates. This indicates that algae grown in a low light exposure condition will have a higher total lipids content compared to algae exposed to higher light intensity [57]. The CO2 fraction in sparging gas also plays a major role on the cell growth and lipid accumulation as it affects the medium pH and the availability of bicarbonates as carbon source for the cells. Several studies reported that increasing the CO2 fraction in sparging air could increase the maximum limit of cell concentration and promote the rapid growth of cells. However, further elevations on the CO2 fraction completely inhibited cell growth in many cases as the concentration of CO2 above 5% (v/v) would reduce cell growth [58,59,60]. This has led to development of pre-adaptation of cells to higher CO2 conditions and the use of high inoculums levels to overcome the CO2 toxicity. The use of pure carbon dioxide in the sparging medium had shown unfavorable pH changes and growth inhibition and hence, they were replaced with sparging with ambient air and adjustment of pH for successful cultivation of the algal culture.

The growth of algae was also found to improve at the temperature range of 25–35 °C. Reports have stated that the biomass production increased at temperature of 30 °C, though the lipid content of certain species tends to decrease at higher temperatures [61, 62]. Heterotrophic cultivation using carbon sources was introduced to overcome the difficulty of delivering optimal photonic energy to cells in photoautotrophic growth conditions. High lipid yield and high biomass production were observed when heterotrophic algae were placed in low light conditions and supplied with organic carbon instead of CO2 [63]. Another type of growth is the mixotrophic growth, which utilizes a mixture of different source of energy and carbon, and undergoes two distinctive processes within the cell: photosynthesis and aerobic respiration. This type of growth resulted in several fold increase of maximum cell density and specific growth rates [11]. The nitrogen and phosphorus limitation in the medium also enhances lipid production in algae cells. Many strains of algae was found to contain higher lipid content when cultivated in low-nitrogen medium [64]. The cessation of cell division may occur as a result of nitrogen depletion, but if carbon metabolism continues, the conversion of carbon to lipid will divert as described previously [65]. Apart from that, the nature of nitrogen sources may also affect the algae cell growth and lipid productivity [66]. This is likely to cause variation in the total fatty acid content in algae while the biochemical composition of algae is influenced greatly by the growth phase.

Certain oleaginous fungi can accumulate as much as 80% of their biomass as lipids. The lipids in fungi are mainly affected by the carbon source, temperature , pH , nitrogen source and agitation. Molds are often cultivated as they produce high concentrations of γ-linolenic acid (GLA) and arachidonic acid (AA), which is favorable for the production of biofuels [67]. High oil yields could be obtained with prolonged fermentation times, which are common in single cell oil fermentation processes. Prolonged fermentation are carried out under nitrogen limitation, redirecting the carbon flux of metabolic pathways towards lipid accumulation [68]. In Cunninghamella echinulata and Mortierella isabellina, the fatty acid content of the microbial oil produced was not significantly affected by the carbon source used, however, the production of these fatty acids in the cells is associated with the age of the mycelia. The highest fraction of these fatty acids can be found in young mycelia, while fully grown mycelia showed lower content as the cells have aged [69]. However in general, the type of carbon source can strongly affect the production and fatty acids content in lipids of fungi. The use of various carbon sources may result in variation in the lipid and GLA content. Since each carbon source would be utilized as a substrate by a different metabolic pathway , the resultant metabolites will contribute to the variations in fatty acids content.

Oleaginous yeasts has a TAG fraction which is similar to that of plant oils, they also have a high oil content and fast growth rate. Yeast can grow on various carbon sources like glucose, mannose, glycerol, xylose, arabinose and other agriculture residues. Most oleaginous yeast accumulate lipids up to 40% of their dry weight and it can increase up to 70% under nutrient-limiting conditions [65]. Many studies were conducted on the use of glycerol as a carbon source, resulting in highs yields and enhanced lipid production. However, different yeast strains might have higher potential of lipid accumulation in different mediums. The supply of excess carbon sources as well as the limiting of certain nutrients in a medium can also help increase the lipid production. Lipid production in yeast is strongly influenced by the aeration, carbon to nitrogen ratio, temperature , pH and inorganic salts [70]. At high temperatures, the cellular lipid content and production can be high with low degree of fatty acid unsaturation, and the composition of the fatty acids might vary as a result of the increased temperature. Moreover, a higher carbon to nitrogen ratio yields higher lipid content [71]. Many strains of yeast requires a high carbon to nitrogen ratio to accumulate large amount of lipids.

Bacteria can exhibit high cell growth rates under simple cultivation methods. Their cellular composition and structure vary depending on the microorganism and the carbon source used. Actinomycete group of bacteria are able to accumulate high amounts of intracellular fatty acids of up to 70% of the cell dry weight from simple carbon sources like glucose under growth-limiting conditions [29, 72]. The accumulation takes place usually at the stationary phase of growth, which is when the proteins are not being synthesized. However, not all bacteria can accumulate large amount of fatty acids, they usually produce complex lipoids for energy storage and stored them as insoluble inclusions in the cytoplasm when excess carbon sources are available [73].

3 Conversion of Microbial Lipids to Biofuels

Recently, microbial lipids -derived biofuels are found to contain equivalent qualities with derivatives of fossil fuels. Biofuels are produced from microbial lipids through different conversion processes. Some conventional processes to produce biofuels are transesterification , esterification and anaerobic digestion . These processes are optimized to obtain the maximum yield of biofuel from microbial lipids through manipulating the operating parameters. In order to achieve high yields of biofuels , the lipid accumulation in the feedstock is the key factor. Microbial lipids within the oleaginous microorganisms are categorized as wax esters (WEs), free fatty acid (FFA), TAG and polyhydroxyalkanoates (PHAs). WEs are esters that consist of long chain fatty alcohol and fatty acid. The special properties of WEs resulted in diverse applications of WEs such as lubricants, polishes, coatings and printing inks. However, TAG and PHAs are the favorable lipids in biodiesel production compared to WEs. This is due to the need of the conversion of lipids into a less viscous form to be used in common internal combustion engines. FFA has always been a concern in biodiesel production. The presence of FFA during the conversion process leads to the formation of soap. Therefore, pretreatment has to be performed for removing or reducing the existence of FFA in biofuel production.

In the biofuel production process, the transesterification of TAG will form fatty acid alkyl esters (FAAE) and the esterification of PHAs will form hydroxyalkanoate methyl esters (HAMEs), which could serve as fuel additives as well. Transesterification is a process of reacting triglyceride, which is found in microbial lipid, with an alcohol to produce esters (biodiesel) and glycerol as the products. The common alcohols used are methanol and ethanol that will lead to the formation of fatty acid methyl esters (FAME) and fatty acid ethyl esters (FAEE), respectively. On the other hand, the esterification process will lead to the formation of esters and water by reactions of the alcohol with an acid. The formation of HAMEs can be obtained by using methanol in the esterification of PHAs. Besides that, the anaerobic digestion is an established process applied for biogas production from wastewater or sludge. The biofuels recovery from wastewater and sludge under anaerobic condition are favorable as the bacteria will breakdown the organic matter in the wastewater or sludge to produce biogas .

Microbial lipids extracted from oleaginous microorganisms are converted into biofuels through two types of conversion processes: one-step process or multi-stage process. In one-step process, energy intensive cell disruption and lipid extraction steps are usually avoided and the biomass is directly subjected to the fuel production process. This process often is more beneficial in the economic perspective, as the process duration is shorter and reduces the use of harsh chemicals resulting in less environmental impact. Hence, one-step process tends to be a more environmental friendly conversion process compared to multi-stage process. However, the microbial lipid yields, quality of biofuel and overall lipid productivity have to be considered in order to obtain comparable final products from conventional methods. Multi-stage process is performed by converting microbial lipids to biofuels in two or more processes simultaneously or sequentially, converting microbial lipids to biofuels. The advantages and disadvantages between single stage and multi-stage conversion process are yet to be weighed out by researchers for the optimum biofuel production method.

3.1 Technologies for Converting Microbial Lipids to Biodiesel

Biodiesel is a “drop-in” type of biofuel that can be utilized in most of the automotive industry without changing the standard diesel engines. The conventional process in biodiesel production is to perform the extraction of accumulated microbial lipids within the feedstocks followed by the transesterification process. The products of transesterification, namely FAMEs and FAEEs, are known as biodiesel as well. Additional of a catalyst is required in transesterification besides an alcohol. The transesterification process includes catalytic transesterification and enzymatic transesterification. The difference between these transesterification processes is the use of catalysts. The common transesterification catalyst for catalytic transesterification is chemicals such as acid or a base while the catalyst for enzymatic transesterification is the biological catalyst lipase [74, 75]. The conventional process for biofuel production by using catalytic transesterification is shown in Fig. 2.

Conventional process for biofuel production by catalyzed transesterification [76]

The catalyst used in the process could be either homogenous or heterogeneous catalysts. Transesterification reaction is shown as Eq. 1:

Among the types of transesterification processes mentioned above, base catalyzed transesterification is an established process and is widely used in the industrial production of biodiesel. Strong base chemicals such as sodium hydroxide (NaOH) and potassium hydroxide (KOH) are common catalysts for base catalyzed transesterification [77]. This is due to the relatively low cost of raw materials and high biodiesel productivities [78]. In addition, a comparable yield of biodiesel with conventional petroleum-based diesel could be obtained from base catalyzed transesterification within a few hours [79]. The short duration of catalyzed reaction, high conversion yield, requirement of low operating temperature and pressure (i.e. ambient pressure and low temperature) have made base catalyzed transesterification the most economical process in biodiesel production. However, the microbial lipids that contain high composition of FFA will be required to undergo a pre-treatment process before proceeding to transesterification. This is to avoid the saponification reaction that occurs when FFA reacts with NaOH as shown in Eq. 2:

This reaction is not favorable as the yield of esters will decrease with the increase in soap formation and the soap formed will inhibit the separation of esters and glycerol [80]. Furthermore, this reaction also lowers the efficiency of catalyst due to competitive and futile binding of FFA with the catalyst. This resulted in the requirement of higher amount of catalyst and thus, a higher operation cost. Besides FFA, water within the microbial lipid or water formed from the saponification reaction is another concern in transesterification . The water molecules tend to hydrolyze the triglyceride into diglycerides and FFA by hydrolysis. The removal of glycerol, catalyst and impurities such as soap are essential after transesterification process to obtain biodiesel . The saponification compounds contain alkaline metal which may result in the higher ash content in biodiesel and cause problems in the engines. The deactivation of the catalytic converter or the corrosion of motor may occur due to the alkaline metal [78].

When the FFA content in lipid is higher than 1%, acid catalyzed transesterification is used to overcome the wasteful saponification reaction [78]. This type of transesterification has been intensively studied for the benefits of avoiding soap formation and possessing feedstock with residual moisture. The moisture remaining in low cost feedstock is acceptable in acid catalyzed transesterification and the final product would be clear of impurities [81]. The disadvantages of acid catalyzed transesterification are longer reaction time and the requirement of higher molar ratio of catalyst to oil. The operating conditions of acid catalyzed transesterification are more critical than base catalyzed transesterification. Operating cost are usually higher as the highly corrosive catalysts utilized during the process will damage the reactor. A large amount of wastewater will be generated to neutralize the remaining acid catalysts in the system as well. Therefore, most of the biodiesel productions in industries convert lipids into biodiesel by base catalyzed transesterification. So for acid catalyzed process, intensive studies were performed to overcome the barriers. Some strong common acids such as sulfuric acid, hydrochloride acid, and boron trifluoride were used. Most of the studies conducted have utilized methanol with the presence of catalysts (acid or base) with high yields of biodiesel, in the range of 80–98% purity can be obtained as the end product [32, 82, 83]. However, lower productivity of biodiesel could be observed for microbial lipids from certain feedstock, which range from 49 to 66% purity [84, 85]. The choice of catalysts is important as the biodiesel yield vary with the type of catalyst used as studied by Vicente et al. [32]. At the same time, higher operating temperature for the acid catalyzed transesterification is favored compared to low operating temperature, which results in lower ester yield from the microbial lipids [32].

The products from transesterification, FAMEs or FAEE, are analyzed by gas chromatography with flame ionization detector. The temperature of flame ionization detector is controlled at a high temperature of around 250–260 °C during the analysis [86, 87]. The used catalysts may be recycled for next conversion process in order to reduce the operating cost. Besides, the conversion process from lipid to biodiesel , especially for microalgae -based biodiesel, is found to be influenced significantly by several factors such as catalyst loading, types of catalyst, temperature and stirring rate [86]. The reaction time for transesterification of microalgal lipids might vary, ranging from 1 to 48 h, and is different in each study [32, 83, 86, 88]. The biodiesel products are separated from glycerin by allowing the biodiesel to settle down for at least 24 h and biodiesel forms the top layer with glycerin at the bottom. The glycerin is drained off to obtain biodiesel by decantation. For purification, biodiesel is washed by warm distilled water and dried before calculating their exact percentage extracted from the microbial lipids . Biodiesel is dried with anhydrous CaCl2 and heated at 50 °C. After that, the volume of clean dry biodiesel is determined and prepared for analysis.

3.2 Alternative Pathways for the Conversion of Microbial Lipids to Biofuels

The conventional methods in producing biofuel by microbial lipids were explained in detail in the Sect. 3.1. The usage of enzymes as catalysts in transesterification have been considered and studied. Extensive investigations have also been performed by using lipase as the catalyst in transesterification . Lipase is a common enzyme that is produced by all living organisms and a good choice for transesterification. The compatibility of lipase with various raw materials and reusability have showed that it has high potential as a catalyst in transesterification [89]. Lipase as biocatalysts has overcome the difficulty faced by acid and based transesterification, which is the high energy consumption for multi-step purification and wastewater treatment in order to obtain the final product [90]. However, certain drawbacks are observed by using lipase as catalyst. For example, the reaction rate of enzyme catalyzed transesterification is slower compared to acid or base catalyzed transesterification. In addition, the cost of enzyme is comparatively higher than the cost of common acid or base. The usage of enzyme will directly increase the operating cost of whole process.

Most of the lipase utilized as biocatalysts are obtained from microbes, which have comparatively higher yield than the lipase extracted from animal and plants. Lipase to be used as catalysts are available in three forms: extracellular lipase, intracellular lipase and immobilized lipase. Extracellular lipase is the lipase extracted or purified from microbial fermentation broths and these are hydrolytic enzymes secreted by the cells. Microbial lipase is normally produced through submerged fermentation or solid state fermentation . The increased market price of microbial lipase is high due to the need of a high degree of purity that is required as a biocatalyst. Furthermore, the high cost of purification of enzymes is one of the difficulties in commercializing enzymatic transesterification . The purification steps depend on the source of the lipase and the structure [90]. The intracellular lipase used in the transesterification process is the metabolic or cytosolic lipase present inside the cells. Whole cell biocatalysts are microbial cells that are used as catalyst in transesterification. This method is relatively inexpensive compared to pure enzymes and the additional enzyme extraction steps has been eliminated. In order to increase the reaction rate of transesterification, immobilized lipase was introduced. Instead of free enzyme, whole microbial cells with intracellular lipase are immobilized in porous biomass particles and can be directly used as a biocatalyst [90].

The wet biomass of Chlorella vulgaris ESP-31 with 63% lipid content was successfully converted to biodiesel by transesterification with immobilized Burkholderia lipase [91]. The wet microalgal biomass without lipid extraction (70% water content) showed better results than lipid extracts, with a biodiesel conversion efficiency of 97.3% and the lipase could be reused for six continuous cycles [91]. And it was shown that for direct transesterification of wet microalgal biomass with lipases, the lipid content of the biomass determines the biodiesel conversion efficiency and hence a microalgal biomass with high lipid content is preferable [86]. The oleaginous yeast Rhodosporidium toruloides was cultivated in detoxified sugarcane bagasse hydrolysate with a lipid content of 52.5%. When the lipids were extracted and subjected to transesterification with commercial lipases in a tert-butanol system, biodiesel yield of 88.4% was observed [74]. The immobilization of lipase in iron-nanoparticles could help in easy removal of lipases after the reaction with a magnet and it was found that the reaction efficiency remains unchanged for at least 4 cycles [86]. In the transesterification of microalgal lipids from Tetraselmis sp., enzyme catalyzed transesterification achieved 5 folds higher biodiesel conversion yield compared to alkali catalyzed transesterification [92].

The alcoholysis process which uses methanol to produce biodiesel is also known as methanolysis. This process is commonly used in plastic recycling by converting polyesters into monomers. The direct methanolysis method is more advantageous than conventional methods as oil extraction and cell disruption can be eliminated prior to methanolysis. The study of Thliveros et al. [79] investigated the microbial biodiesel production with different types of methanolysis: direct base catalyzed methanolysis, direct acid catalyzed methanolysis and a conventional method with cell disruption, oil extraction and acid-catalyzed esterification. Among these methods, highest yield of FAME was obtained with direct base-catalyzed methanolysis compared to the others and lowest yield of FAME was produced in the conventional method [79]. Methanolysis is performed under atmospheric pressure with temperatures ranging from 40 to 70 °C. Vigorous stirring of the mixture is required to dissolve the base or acid catalyst completely in methanol. In direct methanolysis, the dried microbial biomass is added after thorough mixing of methanol and catalyst.

3.3 Improved Pathways for the Conversion of Microbial Lipids

The conventional biodiesel production with pre-treatment to extract microbial lipid prior to transesterification have been investigated in numerous studies. Yet, biodiesel produced by conventional transesterification requires longer time and it is a multi-step process. Direct transesterification of the biomass is an excellent option for efficient conversion of microbial lipids to biodiesel . Direct transesterification is a simplified and improved pathway in yielding biodiesel. Direct transesterification is similar to direct methanolysis, where the microbial lipids still inside the whole microbes are directly converted into biodiesel without lipid extraction . Figure 3 shows the flowchart of both direct and indirect transesterification.

Flowchart of direct and indirect transesterification process of biofuels [44]

The microalga Nannochloropsis sp. CCMP1776 was cultivated outdoors in tubular photobioreactors and the lipid content was 50% and the dried biomass had a moisture content of about 8–10%. This biomass was subjected to direct transesterification with supercritical methanol (250 °C, 8% w/v methanol, 25 min) and microwave assisted transesterification. Biodiesel conversion efficiency and FAME yield was higher in supercritical methanol method with FAME yield of 84.5% and the biodiesel obtained was stable and pure. With the microwave assisted method, 80.3% FAME was obtained, but the energy consumed was considerably less, it was only 250 kJ compared to 600 kJ in supercritical methanol. So, for large scale purposes, microwave assisted transesterification could be a viable option [93]. The wet biomass of the oleaginous yeast C. curvatus with a total lipid content of 42% was subjected to microwave assisted direct transesterification with methanol and KOH as a catalyst. The reaction conditions as optimized by statistical design are as follows: methanol biomass ratio of 50:1, 5% KOH, 80% water, 2 min reaction time and stirring at 966 rpm. The biodiesel yield reached 92% after two rounds of reaction with 63.88% FAME content [94]. Cheirsilp and Louhasakul’s (2013) study has investigated the transesterification of yeast lipid into fatty acid methyl ester (FAME) [44]. The cells were subjected to conventional acid catalyzed transesterification, transesterification with dried biomass and direct transesterification of wet biomass. The production of FAME is found to be highest for direct transesterification with high methanol molar ratio (167:1 and 209:1) in 1 h reaction but the reverse reaction of FAME to monoglyceride was observed at 6 h reaction time. However, at high methanol molar ratio, the highest amount of FAME was produced with transesterification of dried biomass at the reaction time of 6 h without any reverse reaction. These methods have proved to be more efficient than the conventional methods (lipid extraction followed by transesterification) and have showed great potential in cost reduction of biodiesel production. Table 4 shows the transesterification of various lipids .

4 Life-Cycle Assessment

Life-cycle assessment (LCA) is a systematic framework for evaluating the implications of products, processes and activities involved in the production of a particular product towards environmental damages. LCA uses specific metrics through life-cycle impact assessment that can be assessed to determine the effect on the environment. The development towards life-cycle based metrics for biofuel policies also extends the sustainability criteria to non-greenhouse gas related projects and is a very effective tool to compare alternative energy routes in terms of environmental impact and indirect natural sources costs towards various services and commodities. LCA has been widely conducted to estimate the life-cycle impact of various biofuels produced from different feedstocks. It includes the entire life cycle of the fuel production process from the collection of feedstock to the combustion of biofuels . Life cycle assessment has shown that first generation biofuels, which are fuels derived from sources such as sugar, starch, animal fats and vegetable oil , provided little to no benefit regarding greenhouse gas (GHG) reductions compared to petroleum fuels. It was expected that second generation biofuels , which are fuels derived from non-food feedstock such as lignocellulosic materials , would be able to achieve better GHG reductions as well as avoid sustainability issues. However, great variability and uncertainty has been displayed by the LCA of this second generation biofuels, hence creating an inconclusive analysis [105].

Oleaginous microorganisms such as microalgae have high growth rates and photosynthetic efficiencies, which makes it potentially advantageous over conventional terrestrial biofuel feedstock. In addition, algae has high lipid content and can use non-arable land for cultivation. Microalgae cultivation has been compared with conventional crops from a life-cycle perspective, the results indicated that conventional crops had lower environmental impacts, greenhouse gas emissions , water and energy use [106]. Algae performed more favorably in the aspects of total land area used and eutrophication potential. Studies on crops such as canola, corn or switchgrass resulted in less GHG emissions compared to that of algae. This suggests that algae requires more fossil-based carbon to produce the equivalent amount of bioenergy . However, significant developments are being made in algae cultivation to increase the feasibility of biofuel production. The direct nutrient discharge from algae ponds and the resultant eutrophication improved as engineered ponds were used and this allows better runoff control compared to that of terrestrial cultivation. It is essential to establish and maintain the infrastructure for algae cultivation and conversion as the efficient land use for algae cultivation will be beneficial for the transportation energy system [107].

Besides that, life-cycle assessment on the effects of nitrogen supply and oil extraction technologies showed promising results in the fossil energy ratio of algal biofuel production. The life-cycle fossil energy ratio describes the ratio of energy output to fossil energy consumption [108]. This factor is important for life-cycle analysis to evaluate the depletion of non-renewable resource as well as in terms of pollution to the environment. It was found that nitrogen deficiency successfully elevated the oil content and productivity of algae. Moreover, the extraction of oil directly from wet algae with subcritical solvents can efficiently enhance the life-cycle fossil energy ratio of algal biomass compared to extraction from dried biomass . Several other factors which affect the life cycle fossil energy ratio includes the esterification efficiency, heat value or calorific value of algae, ratio of algal residue and algae cultivation water recycling rate. Different life-cycle stages of the utilization of algal biomass for the production of biofuels are presented in Fig. 4: Life-cycle stages of bioethanol, biomethane and biodiesel production from algal biomass. The cultivation of microalgae requires considerable amount of freshwater, hence, this leads the necessity for the quantification of water footprint and nutrient usage for microalgae biofuel production. It was shown that using seawater or wastewater with recycling for the cultivation of microalgae could significantly reduce the freshwater usage by as much as 90% [109, 110]. The usage of nutrients such as phosphorus, potassium, nitrogen, magnesium and sulfur can also be reduced by approximately 55% with harvest water recycling.

A comparative LCA study of algal biodiesel production was carried out by Lardon et al. to assess the energetic balance and potential environmental impacts of the whole process chain, from biomass production to biodiesel combustion. Two different culture conditions (nominal fertilizing and nitrogen starvation) and two extraction methods (dry and wet) were analyzed and the best scenario was compared with first generation biodiesel [111]. All the equipment for cultivation showed high energetic consumption. However, it is worth noting that both fertilizers and energetic requirements were lower for the low nitrogen culture condition. The use of wet oil extraction also reduced the energy requirements but had lower extraction efficiency. Several factors were selected from a whole set of impacts to evaluate the potential effects on human health, ecosystem quality and resource usage. The production steps were categorized into several groups to examine the contribution of the process chain to different impacts, where each impact is standardized with the worst situation for evaluation. It was found that a low nitrogen condition with wet extraction method always showed lower impacts. Besides that, the comparison of algal biodiesel with other fuels showed very low impacts for eutrophication, land use and human toxicity effects, which can be attributed to better control of fertilizers as well as the absence of pesticides [111]. Nevertheless, algal biodiesel was not deemed favorable in terms of global warming, ozone depletion and mineral resources as it requires large amount of heat and electricity.

Growing algae using carbon dioxide flue gases from various power stations has also been regarded as a possible GHG capture mechanism. However, this mechanism does not gain any carbon credits as the algae-derived fuel would eventually be burnt and the captured carbon would return to the atmosphere. The carbon credit arises from the fact that biofuel availability replaces the utilization of fossil fuels. Similar case can be observed for electricity production, such that carbon credits are obtained from the use of algal biomass instead of coal or gas for electricity production [112]. A study by Jorquera et al. [113] showed that the energy return of algae grown using ponds was greater than unity while algae grown using photo-bioreactors were less than unity. A higher ratio of illuminated area to cultivation volume was needed for photo-bioreactor systems compared to open ponds, but in order to generate the same amount of biomass, an area twice as large as the photo-bioreactor was needed for the pond system. The water consumption in the pond was also about 16 times higher than that required for the photo-bioreactor [113]. Furthermore, the commercial scale production of algal biofuel needs much consideration in terms of economic aspects. At present, the economical complication of producing biofuels shows greater uncertainty than the GHG emissions. To make algal fuels profitable, a higher production rate is necessary as a lower production rate would result in an expensive final product and would not be cost competitive with fossil fuels. This situation should relatively improve with the technological advances in algal biofuels production and the rise of crude oil price due to its continuous depletion.

The improvements made on oil extraction techniques could directly impact the sustainability of biofuel production, where almost 90% of the process energy is reserved for lipid extraction . For example, the drying of biomass for lipid recovery can be improved with alternative methods that are less energy consuming. A more secure control on the energy consumption could very well reduce numerous impacts and this will lead to better overall environment performance compared to other biofuels. With additional research on the optimization of growth conditions for oleaginous microorganisms , along with industrial scale research, biofuels from microbial lipids could be produced with low capital costs and eventually commercialized.

5 Challenges and Future Perspectives

Many of the recent investments in green fuels are steering the market attention towards the production of algal biofuels and development of outstanding production systems. The major requirements for producing biofuels from microbial lipids is the large-scale cultivation and harvesting systems, and the challenge rests on the ability to reduce the cost per unit area. Apart from that, a large amount of land is needed to grow oil crops and this may lead to the clearing of rainforests for the purpose of monoculture plantations [114]. Besides that, the strong interest in sustainable biofuel production requires industrial processes to exploit new genetically modified microbial strains with enhanced photosynthetic efficiency, increased growth rate and biomass production. Other desirable features in microalgal biofuel system would be: increased oil content and productivity and enhanced temperature tolerance aiding in outdoor cultivation. Microalgal biotechnology has improved greatly in the recent past and well defined genetic tools for gene silencing and heterologous protein expression are available for model microalgae . These are the upstream processes in arriving at a particularly robust strain with high biomass and lipid productivity. Cultivation of the strain under optimal conditions, with efficient process control and aided by process engineering strategies will greatly enhance the biomass production potential. Valorization of wastes like flue gases, wastewater or carbon rich waste and lignocellulosic biomass can be applied for the photoautotrophic or heterotrophic cultivation of microalgae, thereby cutting cultivation costs.

Further efforts on oil rich microbial biomass production should concentrate on the cost reduction for small and large scale systems as the feasibility of producing viable biofuels is dependent on the efficiency, cost structure and ease of scale up [115]. Biofuels from microbial lipids could play a major role in the future energy systems and this will be realized through a defined set of technology breakthroughs, based on the development of the optimum utilization of algal biomass for commercial biofuel production. Moreover, the life cycle assessment of algal biofuels concerning the environment benefits and impacts should be used for as a guide for decisions on the operation and technology sides. Lastly, the possibilities of producing high-value co-products from the biomass residues after the extraction of microbial lipid should be considered. These biomass residues can be used in different applications like food, medicine, agriculture and this could well save raw material costs, reduce waste amount as well as GHG emissions. The utilization of wastes and residues from the microorganisms will contribute tremendously to the sustainability and market competitiveness of the biofuel industry.

6 Conclusion

In conclusion, the biofuels from microbial lipids have shown great potential as a replacement for petroleum-based fuels. The nature of lipids varies in each microbe, like yeasts, molds, bacteria and microalgae and they can serve as feedstock for the production of different biofuels. Microbial lipids can be obtained with existing infrastructure which will greatly improve the economics of biofuel production and reduce the dependency on fossil fuels. The feedstock for biofuel production should be chosen with prudence, which can be produced economically with high lipid content. The lipid content of the microbial biomass is affected by the nutritional status of the medium and is also modified by certain environmental stress. The current technologies discussed in this chapter will provide sufficient information to design a biofuel production facility which is comparable to petroleum based fuels in an economic perspective. The limitation of nitrogen and the choice of oil extraction methods for algae cultivation have significantly lowered the eutrophication potential of the effluent as described in the life cycle assessment. Challenges in commercializing microbial lipids based biofuels such as high production cost, large-scale cultivation and harvesting systems are being overcome in order to commercialize biofuel production.

References

Khan SA, Rashmi Hussain MZ, Prasad S, Banerjee UC (2009) Prospects of biodiesel production from microalgae in India. Renew Sustain Energy Rev 13(9):2361–2372

Dong T, Knoshaug EP, Pienkos PT, Laurens LML (2016) Lipid recovery from wet oleaginous microbial biomass for biofuel production: a critical review. Appl Energy 177:879–895

Brennan L, Owende P (2010) Biofuels from microalgae—a review of technologies for production, processing, and extractions of biofuels and co-products. Renew Sustain Energy Rev 14(2):557–577

Srivastava PK, Verma M (2008) Methyl ester of karanja oil as an alternative renewable source energy. Fuel 87(8):1673–1677

Sarin R, Sharma M, Sinharay S, Malhotra RK (2007) Jatropha-Palm biodiesel blends: an optimum mix for Asia. Fuel 86(10):1365–1371

Pinto AC, Guarieiro LLN, Rezende MJC, Ribeiro NM, Torres EA, Lopes WA, De Pereira PAP, De Andrade JB (2005) Biodiesel: an overview. J Braz Chem Soc 16(6B):1313–1330

Chisti Y (2008) Biodiesel from microalgae beats bioethanol. Trends Biotechnol 26:126–131

Chisti Y (2007) Biodiesel from microalgae. Biotechnol Adv 25(3):294–306

Li Q, Du W, Liu D (2008) Perspectives of microbial oils for biodiesel production. Appl Microbiol Biotechnol 80(5):749–756

Wu X, Ruan R, Du Z, Liu Y (2012) Current status and prospects of biodiesel production from microalgae. Energies 5(8):2667–2682

Chojnacka K, Noworyta A (2004) Evaluation of Spirulina sp. growth in photoautotrophic, heterotrophic and mixotrophic cultures. Enzyme Microb Technol 34(5):461–465

Papanikolaou S, Chevalot I, Komaitis M, Marc I, Aggelis G (2002) Single cell oil production by Yarrowia lipolytica growing on an industrial derivative of animal fat in batch cultures. Appl Microbiol Biotechnol 58(3):308–312

Chang YH, Chang KS, Lee CF, Hsu CL, Huang CW, Der Jang H (2015) Microbial lipid production by oleaginous yeast Cryptococcus sp. in the batch cultures using corncob hydrolysate as carbon source. Biomass Bioenergy 72:95–103

Rittmann BE (2008) Opportunities for renewable bioenergy using microorganisms. Biotechnol Bioeng 100(2):203–212

Muniraj IK, Uthandi SK, Hu Z, Xiao L, Zhan X (2015) Microbial lipid production from renewable and waste materials for second-generation biodiesel feedstock. Environ Technol Rev 2515:1–16

Wackett LP (2011) Engineering microbes to produce biofuels. Curr Opin Biotechnol 22:388–393

Wackett LP (2008) Microbial-based motor fuels: science and technology. Microb Biotechnol 1(3):211–225

Zhang F, Rodriguez S, Keasling JD (2011) Metabolic engineering of microbial pathways for advanced biofuels production. Curr Opin Biotechnol 22(6):775–783

Peralta-Yahya PP, Keasling JD (2010) Advanced biofuel production in microbes. Biotechnol J 5(2):147–162

Antoni D, Zverlov VV, Schwarz WH (2007) Biofuels from microbes. Appl Microbiol Biotechnol 77(1):23–35

Ratledge C (2004) Fatty acid biosynthesis in microorganisms being used for single cell oil production. Biochimie 86(11):807–815

Ochsenreither K, Glück C, Stressler T, Fischer L, Syldatk C (2016) Production strategies and applications of microbial single cell oils. Front Microbiol 7:1539

Ratledge C, Wynn J (2005) Microbial production of oils and fats. Food Biotechnol Second. https://doi.org/10.1201/9781420027976.ch1.17

Wältermann M, Steinbüchel A (2005) Neutral lipid bodies in prokaryotes: recent insights into structure, formation, and relationship to eukaryotic lipid depots. J Bacteriol 187(11):3607–3619

Kosa M, Ragauskas AJ (2011) Lipids from heterotrophic microbes: advances in metabolism research. Trends Biotechnol 29(2):53–61

Alvarez HM, Steinbüchel A (2002) Triacylglycerols in prokaryotic microorganisms. Appl Microbiol Biotechnol 60(4):367–376

Ratledge C, Cohen Z (2008) Microbial and algal oils: Do they have a future for biodiesel or as commodity oils? Lipid Technol 20(7):155–160

Spolaore P, Joannis-Cassan C, Duran E, Isambert A (2006) Commercial applications of microalgae. J Biosci Bioeng 101(2):87–96

Meng X, Yang J, Xu X, Zhang L, Nie Q, Xian M (2009) Biodiesel production from oleaginous microorganisms. Renew Energy 34(1):1–5

Subramaniam R, Dufreche S, Zappi M, Bajpai R (2010) Microbial lipids from renewable resources: production and characterization. J Ind Microbiol Biotechnol 37(12):1271–1287

Kavadia A, Komaitis M, Chevalot I, Blanchard F, Marc I, Aggelis G (2001) Lipid and γ-linolenic acid accumulation in strains of zygomycetes growing on glucose. J Am Oil Chem Soc 78(4):341–346

Vicente G, Bautista LF, Rodríguez R, Gutiérrez FJ, Sádaba I, Ruiz-Vázquez RM, Torres-Martínez S, Garre V (2009) Biodiesel production from biomass of an oleaginous fungus. Biochem Eng J 48(1):22–27

Zheng Y, Li T, Yu X, Bates PD, Dong T, Chen S (2013) High-density fed-batch culture of a thermotolerant microalga chlorella sorokiniana for biofuel production. Appl Energy 108:281–287

Yang F, Long L, Sun X, Wu H, Li T, Xiang W (2014) Optimization of medium using response surface methodology for lipid production by Scenedesmus sp. Mar Drugs 12(3):1245–1257

Chen GQ, Jiang Y, Chen F (2007) Fatty acid and lipid class composition of the eicosapentaenoic acid-producing microalga, Nitzschia laevis. Food Chem 104(4):1580–1585

Yao L, Gerde JA, Lee S-L, Wang T, Harrata KA (2015) Microalgae lipid characterization. J Agric Food Chem 63(6):1773–1787

Fakas S, Galiotou-Panayotou M, Papanikolaou S, Komaitis M, Aggelis G (2007) Compositional shifts in lipid fractions during lipid turnover in Cunninghamella echinulata. Enzyme Microb Technol 40(5):1321–1327

Alvarez HM, Mayer F, Fabritius D, Steinbüchel A (1996) Formation of intracytoplasmic lipid inclusions by Rhodococcus opacus strain PD630. Arch Microbiol 165(6):377–386

Wu S, Hu C, Jin G, Zhao X, Zhao ZK (2010) Phosphate-limitation mediated lipid production by Rhodosporidium toruloides. Bioresour Technol 101(15):6124–6129

Huang X, Shen Y, Luo H, Liu J, Liu J (2018) Enhancement of extracellular lipid production by oleaginous yeast through preculture and sequencing batch culture strategy with acetic acid. Bioresour Technol 247:395–401

Yang X, Jin G, Gong Z, Shen H, Bai F, Zhao ZK (2015) Recycling microbial lipid production wastes to cultivate oleaginous yeasts. Bioresour Technol 175:91–96

Zeng Y, Bian D, Xie Y, Jiang X, Li X, Li P, Zhang Y, Xie T (2016) Utilization of food waste hydrolysate for microbial lipid and protein production by Rhodosporidium toruloides Y2. J Chem Technol Biotechnol

Martínez EJ, Raghavan V, González-Andrés F, Gómez X (2015) New biofuel alternatives: integrating waste management and single cell oil production. Int J Mol Sci 16(5):9385–9405

Cheirsilp B, Louhasakul Y (2013) Industrial wastes as a promising renewable source for production of microbial lipid and direct transesterification of the lipid into biodiesel. Bioresour Technol 142:329–337

Poli JS, da Silva MAN, Siqueira EP, Pasa VMD, Rosa CA, Valente P (2014) Microbial lipid produced by Yarrowia lipolytica QU21 using industrial waste: A potential feedstock for biodiesel production. Bioresour Technol 161:320–326

Kao C-Y, Chen T-Y, Chang Y-B, Chiu T-W, Lin H-Y, Chen C-D, Chang J-S, Lin C-S (2014) Utilization of carbon dioxide in industrial flue gases for the cultivation of microalga Chlorella sp. Bioresour Technol 166:485–493

Ji M-K, Yun H-S, Hwang J-H, Salama E-S, Jeon B-H, Choi J (2017) Effect of flue gas CO2 on the growth, carbohydrate and fatty acid composition of a green microalga Scenedesmus obliquus for biofuel production. Environ Technol 38(16):2085–2092

Mu J, Li S, Chen D, Xu H, Han F, Feng B, Li Y (2015) Enhanced biomass and oil production from sugarcane bagasse hydrolysate (SBH) by heterotrophic oleaginous microalga Chlorella protothecoides. Bioresour Technol 185:99–105

Resdi R, Lim JS, Kamyab H, Lee CT, Hashim H, Mohamad N, Ho WS (2016) Review of microalgae growth in palm oil mill effluent for lipid production. Clean Technol Environ Policy 18(8):2347–2361

Zuliani L, Frison N, Jelic A, Fatone F, Bolzonella D, Ballottari M (2016) Microalgae cultivation on anaerobic digestate of municipal wastewater, sewage sludge and agro-waste. Int J Mol Sci 17(10):1692

Joe M-H, Kim J-Y, Lim S, Kim D-H, Bai S, Park H, Lee SG, Han SJ, Choi J (2015) Microalgal lipid production using the hydrolysates of rice straw pretreated with gamma irradiation and alkali solution. Biotechnol Biofuels 8:125

Chen Y-H, Walker TH (2011) Biomass and lipid production of heterotrophic microalgae Chlorella protothecoides by using biodiesel-derived crude glycerol. Biotechnol Lett 33 (10):1973

Griffiths MJ, Harrison STL (2009) Lipid productivity as a key characteristic for choosing algal species for biodiesel production. J Appl Phycol 21(5):493–507

Wan M, Jin X, Xia J, Rosenberg JN, Yu G, Nie Z, Oyler GA, Betenbaugh MJ (2014) The effect of iron on growth, lipid accumulation, and gene expression profile of the freshwater microalga Chlorella sorokiniana. Appl Microbiol Biotechnol 98(22):9473–9481

Lv JM, Cheng LH, Xu XH, Zhang L, Chen HL (2010) Enhanced lipid production of Chlorella vulgaris by adjustment of cultivation conditions. Bioresour Technol 101(17):6797–6804

Luo HP, Al-Dahhan MH (2004) Analyzing and modeling of photobioreactors by combining first principles of physiology and hydrodynamics. Biotechnol Bioeng 85(4):382–393

Khotimchenko SV, Yakovleva IM (2005) Lipid composition of the red alga Tichocarpus crinitus exposed to different levels of photon irradiance. Phytochemistry 66(1):73–79

Yoo Chan, Jun So-Young, Lee Jae-Yon, Chi-Yong Ahn H-MO (2010) Selection of microalgae for lipid production under high levels carbon dioxide. Elsevier Ltd 101:S71–S74

Chiu SY, Kao CY, Tsai MT, Ong SC, Chen CH, Lin CS (2009) Lipid accumulation and CO2 utilization of Nannochloropsis oculata in response to CO2 aeration. Bioresour Technol 100(2):833–838

de Morais MG, Costa JAV (2007) Biofixation of carbon dioxide by Spirulina sp. and Scenedesmus obliquus cultivated in a three-stage serial tubular photobioreactor. J Biotechnol 129(3):439–445

Pahl SL, Lewis DM, King KD, Chen F (2012) Heterotrophic growth and nutritional aspects of the diatom Cyclotella cryptica (Bacillariophyceae): Effect of nitrogen source and concentration. J Appl Phycol 24(2):301–307

Converti A, Casazza AA, Ortiz EY, Perego P, Del Borghi M (2009) Effect of temperature and nitrogen concentration on the growth and lipid content of Nannochloropsis oculata and Chlorella vulgaris for biodiesel production. Chem Eng Process Process Intensif 48(6):1146–1151

Xu H, Miao X, Wu Q (2006) High quality biodiesel production from a microalga Chlorella protothecoides by heterotrophic growth in fermenters. J Biotechnol 126(4):499–507

Dean AP, Sigee DC, Estrada B, Pittman JK (2010) Using FTIR spectroscopy for rapid determination of lipid accumulation in response to nitrogen limitation in freshwater microalgae. Bioresour Technol 101(12):4499–4507

Beopoulos A, Cescut J, Haddouche R, Uribelarrea JL, Molina-Jouve C, Nicaud JM (2009) Yarrowia lipolytica as a model for bio-oil production. Prog Lipid Res 48(6):375–387

Rodolfi L, Zittelli GC, Bassi N, Padovani G, Biondi N, Bonini G, Tredici MR (2009) Microalgae for oil: strain selection, induction of lipid synthesis and outdoor mass cultivation in a low-cost photobioreactor. Biotechnol Bioeng 102(1):100–112

Rasheva T, Kujumdzieva A, Hallet JN (1997) Lipid production by Monascus purpureus albino strain. J Biotechnol 56(3):217–224

Wynn JP, Hamid AA, Li Y, Ratledge C (2001) Biochemical events leading to the diversion of carbon into storage lipids in the oleaginous fungi Mucor circinelloides and Mortierella alpina. Microbiology 147(10):2857–2864

Fakas S, Papanikolaou S, Batsos A, Galiotou-Panayotou M, Mallouchos A, Aggelis G (2009) Evaluating renewable carbon sources as substrates for single cell oil production by Cunninghamella echinulata and Mortierella isabellina. Biomass Bioenergy 33(4):573–580

Papanikolaou S, Galiotou-Panayotou M, Chevalot I, Komaitis M, Marc I, Aggelis G (2006) Influence of glucose and saturated free-fatty acid mixtures on citric acid and lipid production by Yarrowia lipolytica. Curr Microbiol 52(2):134–142

Angerbauer C, Siebenhofer M, Mittelbach M, Guebitz GM (2008) Conversion of sewage sludge into lipids by Lipomyces starkeyi for biodiesel production. Bioresour Technol 99(8):3051–3056

Kalscheuer R, Stölting T, Steinbüchel A (2006) Microdiesel: Escherichia coli engineered for fuel production. Microbiology 152(9):2529–2536

Zabeti N, Bonin P, Volkman JK, Guasco S, Rontani JF (2010) Fatty acid composition of bacterial strains associated with living cells of the haptophyte Emiliania huxleyi. Org Geochem 41(7):627–636

Zhao X, Peng F, Du W, Liu C, Liu D (2012) Effects of some inhibitors on the growth and lipid accumulation of oleaginous yeast Rhodosporidium toruloides and preparation of biodiesel by enzymatic transesterification of the lipid. Bioprocess Biosyst Eng 35(6):993–1004

Wahlen BD, Morgan MR, McCurdy AT, Willis RM, Morgan MD, Dye DJ, Bugbee B, Wood BD, Seefeldt LC (2013) Biodiesel from microalgae, yeast, and bacteria: engine performance and exhaust emissions. Energy Fuels 27(1):220–228

Sawangkeaw R, Bunyakiat K, Ngamprasertsith S (2010) A review of laboratory-scale research on lipid conversion to biodiesel with supercritical methanol (2001–2009). J Supercrit Fluids 55(1):1–13

Karatay SE, Dönmez G (2011) Microbial oil production from thermophile cyanobacteria for biodiesel production. Appl Energy 88(11):3632–3635

Hidalgo P, Toro C, Ciudad G, Navia R (2013) Advances in direct transesterification of microalgal biomass for biodiesel production. Rev Environ Sci Biotechnol 12(2):179–199

Thliveros P, Uçkun Kiran E, Webb C (2014) Microbial biodiesel production by direct methanolysis of oleaginous biomass. Bioresour Technol 157:181–187

Leung DYC, Wu X, Leung MKH (2010) A review on biodiesel production using catalyzed transesterification. Appl Energy 87(4):1083–1095

Zhao L, Liu DXW (2007) Effect of several factors on peracetic acid pretreatment of sugarcane bagasse for enzymatic hydrolysis. J Chem Technol Biotechnol 82:1115–1121

Dai C-C, Tao J, Xie F, Dai Y-J, Zhao M (2007) Biodiesel generation from oleaginous yeast Rhodotorula glutinis with xylose assimilating capacity. African J Biotechnol 6(18):2130–2134

Awolu OO, Layokun SK (2013) Optimization of two-step transesterification production of biodiesel from neem (Azadirachta indica) oil. Int J Energy Environ Eng 4(1):39

Liu G-Q, Lin Q-L, Jin X-C, Wang X-L, Zhao Y (2010) Screening and fermentation optimization of microbial lipid-producing molds from forest soils. African J Microbiol Res 4:1462–1468

Amirsadeghi M, Shields-menard S, French WT, Hernandez R (2015) Lipid production by Rhodotorula glutinis from pulp and paper wastewater for biodiesel production. J Sustain Bioenergy Syst 5:114–125

Tran DT, Chen CL, Chang JS (2013) Effect of solvents and oil content on direct transesterification of wet oil-bearing microalgal biomass of Chlorella vulgaris ESP-31 for biodiesel synthesis using immobilized lipase as the biocatalyst. Bioresour Technol 135:213–221

Revellame E, Hernandez R, French W, Holmes W, Alley E (2010) Biodiesel from activated sludge through in situ transesterification. J Chem Technol Biotechnol 85(5):614–620

Montero-rodríguez D, Andrade RFS, Lima RA, Silva GKB, Rubio-ribeaux D, Silva TA, Hélvia WC (2016) Conversion of agro-industrial wastes by Serratia marcescens UCP/WFCC 1549 into lipids suitable for biodiesel. Production 49:307–312

Fjerbaek L, Christensen KV, Norddahl B (2009) A review of the current state of biodiesel production using enzymatic transesterification. Biotechnol Bioeng 102(5):1298–1315

Ghaly AE, Dave D, Brooks MS, Budge S (2010) Production of biodiesel by enzymatic transesterification: review. Am J Biochem Biotechnol 6(2):54–76

Tran D-T, Yeh K-L, Chen C-L, Chang J-S (2012) Enzymatic transesterification of microalgal oil from Chlorella vulgaris ESP-31 for biodiesel synthesis using immobilized Burkholderia lipase. Bioresour Technol 108:119–127

Teo CL, Jamaluddin H, Zain NAM, Idris A (2014) Biodiesel production via lipase catalysed transesterification of microalgae lipids from Tetraselmis sp. Renew Energy 68:1–5

Patil PD, Gude VG, Mannarswamy A, Cooke P, Nirmalakhandan N, Lammers P, Deng S (2012) Comparison of direct transesterification of algal biomass under supercritical methanol and microwave irradiation conditions. Fuel 97:822–831

Cui Y, Liang Y (2014) Direct transesterification of wet Cryptococcus curvatus cells to biodiesel through use of microwave irradiation. Appl Energy 119:438–444

D’Oca MGM, Viêgas CV, Lemões JS, Miyasaki EK, Morón-Villarreyes JA, Primel EG, Abreu PC (2011) Production of FAMEs from several microalgal lipidic extracts and direct transesterification of the Chlorella pyrenoidosa. Biomass Bioenerg 35(4):1533–1538

Johnson MB, Wen Z (2009) Production of Biodiesel Fuel from the Microalga Schizochytrium limacinum by Direct Transesterification of Algal Biomass. Energy Fuels 23(10):5179–5183

Chen C-L, Huang C-C, Ho K-C, Hsiao P-X, Wu M-S, Chang J-S (2015) Biodiesel production from wet microalgae feedstock using sequential wet extraction/transesterification and direct transesterification processes. Bioresour Technol 194:179–186

Chee Loong T, Idris A (2014) Rapid alkali catalyzed transesterification of microalgae lipids to biodiesel using simultaneous cooling and microwave heating and its optimization. Bioresour Technol 174:311–315