Abstract

Microbial lipid produced using yeast fermentation with inexpensive carbon sources such as lignocellulosic hydrolyzate can be an alternative feedstock for biodiesel production. Several inhibitors that can be generated during acid hydrolysis of lignocellulose were added solely or together into the culture medium to study their individual inhibitory actions and their synergistic effects on the growth and lipid accumulation of oleaginous yeast Rhodosporidium toruloides. When the inhibitors were present in isolation in the medium, to obtain a high cell biomass accumulation, the concentrations of formic acid, acetic acid, furfural and vanillin should be lower than 2, 5, 0.5 and 1.5 g/L, respectively. However, the synergistic effects of these compounds could dramatically decrease the minimum critical inhibitory concentrations leading to significant growth and lipid production inhibitions. Unlike the above-cited inhibitors, sodium lignosulphonate had no negative influence on biomass accumulation when its concentration was in the range of 0.5–2.0 g/L; in effect, it was found to facilitate cell growth and sugar-to-lipid conversion. The fatty acid compositional profile of the yeast lipid was in the compositional range of various plant oils and animal tallow. Finally, the crude yeast lipid from bagasse hydrolyzate could be well converted into fatty acid methyl ester (FAME, biodiesel) by enzymatic transesterification in a tert-butanol system with biodiesel yield of 67.2% and lipid-to-biodiesel conversion of 88.4%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, biodiesel production has attracted much interest because of its biodegradable characteristics and, reduced levels of combustion products such as particulates, carbon monoxide, sulfur oxides, hydrocarbons and soot relative to conventional diesel fuel [1, 2]. However, in China the primary biodiesel production hindrance is the feedstock shortage bottleneck. Some microorganisms can quickly synthesize lipids consisting mainly (more than 80%) of triglycerides and accumulate them intra-cellularly. It appears that using microorganisms for lipids production provides a promising alternative to tackle biodiesel feedstock supply. In effect, compared with other vegetable oils and animal tallows, production of microbial oil has many advantages such as short life cycle, less labor required, reduced sensitivity to venue, season, and climate, and scaling-up facilitation [3]. Nevertheless, yeast lipid production from glucose is more costly than that of vegetable oils, unless much cheaper carbon sources are employed. Although fatty wastes such as animal waste fats, tallow derivatives, lards, waste cooking oils and fats, and grease-containing waste waters can be used as carbon substrates to produce lipid-rich biomass and other added-value compounds [4], in the present work we dwell on microbial lipid production from lignocellulosic biomass, which is also much cheaper than waste oil.

Lignocellulosic biomass, which mainly consists of cellulose, hemicelluloses and lignin, is the most abundant organic material in the natural world. The former two polymers are carbohydrates and can be hydrolyzed into monosaccharides that can be used as a carbon source for yeast lipid production. Dilute acid hydrolysis has been proven to be a fast and inexpensive method for producing sugars from lignocellulosic biomass [5]. It has the advantage of not only solubilizing hemicelluloses but also converting the solubilized hemicelluloses to fermentable sugars [6]. However, one problem associated with dilute acid hydrolysis is the formation of toxic compounds such as furfural, aliphatic acids, and phenolic compounds, all of which exhibit strong inhibition to microorganism growth [7]. Therefore, a better understanding of the aforementioned inhibitors and how to mitigate their negative effects is crucial [8]. For cellulosic ethanol production, the effects of the inhibitors formed during acid hydrolysis of biomass on the growth of Saccharomyces cerevisiae and ethanol production have been well investigated [8–11]. It was found that S. cerevisiae can survive at external pH higher than 4.5 and maximum concentration of undissociated acetic acid of <5 g/L [12]. Nigam (2001) found that a furfural concentration of 0.25 g/L in the fermentation medium did not reduce ethanol yield and productivity, while 1.5 g/L concentration interfered with microorganism respiration and growth [13]. Parajó et al. [14] reported that xylose metabolism of S. cerevisiae from wood hydrolyzate was totally or partially inhibited by vanillin at concentrations of 5 or 3.7 g/L, respectively. These microorganisms have different resistances to different inhibitors. In other words, if an inhibitory behavior is understood, then the fermentation strategy can be designed to perform an effective detoxification process, which can help to optimize sugar recovery and removal of toxic compounds.

Among the well-known oleaginous yeasts, Rhodosporidium toruloides is a promising one with industrial application potential. The lipid accumulation of this yeast has been well investigated with glucose [15] and/or xylose [16] as carbon source in batch [15] or fed-batch fermentation [17]. This yeast also can accumulate lipid under phosphate-limited [18] or sulfate-limited conditions [19]. However, unfortunately if the biomass hydrolyzate is not detoxificated, this yeast could not use it as a carbon source for growth. On the other hand, lipid cannot be optimally accumulated intracellularly unless the yeast can substantially grow on the medium. Therefore, cell growth is the prerequisite and limiting factor to microbial oil production. Besides, microbial lipid concentration is increased with cell biomass given the intracellular nature of lipid accumulation. Therefore, understanding the inhibitory mechanisms and dynamics of the each inhibitor on cell biomass accumulation is very important. Hu et al. [20] studied the effects of several biomass hydrolysis by-products on the growth and lipid content of R. toruloides Y4. However, the tested concentration ranges of the inhibitors in their study were not wide enough. For instance, the maximum acetic acid concentration investigated in their study was 120 mM (7.2 g/L); however, we found that the yeast actually could tolerate acetic acid concentration of as high as 15 g/L. Secondly, the effect of lignin degradation product with higher molecular weight was not included in their study. Thirdly, the time courses of cell growth and sugar consumption were not given, so the dynamic process of cell growth was not clear. Therefore, the objective of this article is to investigate the effects of some toxic compounds (formic acid, acetic acid, furfural, lignin derivatives) in broad concentration ranges on cell growth and lipid accumulation of the oleaginous yeast to provide data to further investigate the production of microbial lipid with lignocellulosic hydrolyzates as a carbon source.

Materials and methods

Materials, chemicals and reagents

The biomass material used for the production of hydrolyzate was sugarcane bagasse, whose main chemical components were as follows: 41.5 ± 0.8% glucan, 25.4 ± 0.4% xylan, 2.2 ± 0.1% araban, 5.5 ± 0.2% acetyl group, 23.1 ± 0.5% klason lignin and 1.5 ± 0.2% acid-soluble lignin.

The chemicals and reagents used in the experiments mainly included 88 wt% formic acid, glacial acetic acid, furfural, vanillin, sodium lignosulphonate (SL), methanol and ethanol, all of which were analytically pure and purchased locally. 88 wt% formic acid and furfural were produced by Guangdong Xilong Chemical Co., Ltd. Glacial acetic acid, methanol and ethanol were produced by Beijing Chemical Works. Vanillin was produced by Tianjin Kermel Chemical Reagent Co., Ltd. Sodium lignosulphonate was produced by Tokyo Kasei Kogyo Co., Ltd. The standard compounds used for HPLC calibration were purchased from Sigma-Aldrich (Shanghai agent).

Dilute acid hydrolysis of sugarcane bagasse

The lignocellulosic biomass used for fermentable sugars production was sugarcane bagasse. It was hydrolyzed with 1% sulfuric acid (w/w) at liquid-to-solid ratio of 10:1 (L/kg) at 121 °C for 2 h in a 5-L stainless autoclave with mechanical stirring. After hydrolysis, the mixture was filtered and the filtrate was analyzed for sugar concentrations. The results showed that the sugars in the hydrolyzate mainly consisted of glucose, xylose and arabinose, with their mass ratio of about 1:10:1. Total sugar yield was about 0.21 g sugar/g bagasse. Formic acid, acetic acid, furfural and acid-soluble lignin were also detected in the hydrolyzate, but no 5-hydroxymethylfurfural (5-HMF) was detected probably due to the mild hydrolysis condition employed in the present work.

Detoxification of bagasse hydrolyzate

The hydrolyzate was first evaporated under reduced pressure at 70 °C, followed by pH adjustment with lime to 2.0. The solid was filtered and the filtrate was further treated with 3% activated charcoal at 80 °C for 50 min. After activated charcoal filtering, the filtrate was then neutralized with lime to pH 6.0 followed by filtration. The obtained liquid was analyzed for sugar concentrations and stored at 4 °C before use.

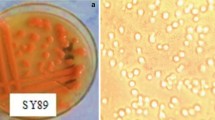

Organism and culture medium

The oleaginous yeast used in the experiments was R. toruloides AS 2.1389, which was purchased from China General Microbiological Culture Collection Center (CGMCC). The yeast was maintained at 4 °C on yeast extract peptone dextrose (YEPD) slope containing: 20 g/L glucose, 10 g/L peptone, 10 g/L yeast extract, and 20 g/L agar. To prepare the inocula, the organism was pre-cultured for 24–30 h in the medium containing 20 g/L glucose, 10 g/L peptone and 10 g/L yeast extract at 30 °C and 200 rpm in an air-bath shaker until the optical density (OD) at 620 nm was 15–17. Batch fermentation experiments for investigating the effects of inhibitors on yeast growth and lipid accumulation were conducted in 500 ml flasks containing 100 ml nitrogen-limited liquid medium. The concentrations of the nutrients are as follows: 70 g/L total sugar (with the weight ratio of glucose:xylose:arabinose being 1:10:1 based on the sugar composition of sugarcane bagasse hydrolyzate), 0.1 g/L (NH4)2SO4, 0.75 g/L yeast extract, 0.4 g/L KH2PO4, and 1.5 g/L MgSO4·7H2O. Certain amounts of inhibitors [formic acid, acetic acid, furfural and lignin derivatives (sodium lignosulfonate and vanillin)] were added solely or together into the medium. The pH value of the liquid medium was then adjusted to 6.0. Followed by sterilization at 115 °C for 15 min, 10 ml inocula were added to the medium and the culture was conducted at 30 °C in an air-bath shaker at 200 rpm for 5–6 days. The medium without addition of any toxic compound was used as a control sample. For each batch of fermentation, control experiments were simultaneously performed.

For lipid production with detoxified sugarcane bagasse hydrolyzate as a carbon source, the experiments were performed in 5-L fermentors with 4 L culture volume. pH was maintained at 6.0 by feeding 40 wt% NaOH. Dissolved oxygen was controlled at 20–30% saturation by automatic adjustment of stirring speed with 1.1 vvm aeration.

Sugar and inhibitors analysis

The yeast cell biomass was estimated by measuring the OD at 620 nm. A standard curve between OD and oven-dried biomass concentration (g/L) was performed previously. The quantitative analysis of glucose, xylose, arabinose, acetic acid, formic acid and furfural was performed with a Shimadzu10AVP HPLC system (Shimadzu Corp., Japan) equipped with a RID-10A refractive index detector, Aminex HPX-87H column (300 × 7.8 mm, Bio-Rad, USA) at 65 °C. 5 mM H2SO4 was used as the eluent at 0.8 ml/min.

Lipid extraction and fatty acid composition analysis

Total crude lipid was extracted by acid-heating procedure with mixture of chloroform and methanol as extractant [21]. Crude lipid content was expressed as gram of lipid per gram of dry biomass. For determination of fatty acid compositions, the crude lipid was first converted to fatty acid methyl ester (FAME) with excess methanol in a tert-butanol system under the catalysis of excess loading of immobilized lipase (NS 435 and NS 40044, produced by Novozymes). The obtained FAME was then analyzed with GC-14B gas chromatography (Shimadzu, Japan) equipped with a CP-FFAP CB capillary column (25 m × 0.32 m × 0.30 μm, Agilent, USA). Heptadecanoic acid methyl ester was used as internal standard. The column temperature was kept at 180 °C for 0.5 min and heated to 250 °C at 10 °C/min, and then kept for 6 min. The temperatures of the injector and detector were set at 245 and 260 °C, respectively.

Biodiesel preparation by transesterification of extracted crude lipid

Biodiesel preparation from the crude lipid was conducted by lipase-catalyzed transesterification in a solvent system developed previously in our laboratory [22]. Specifically, 8.0 g crude lipid and 1.42 g methanol were dissolved in 6.0 g tert-butanol solvent. Then 3 wt% (based on lipid) immobilized lipase NS40044 (produced by Novozymes) and 4 wt% (based on lipid) NS 40042 (produced by Novozymes) were added to the mixture. The reaction was then pursued in an air-bath shaker at 45 °C and 190 rpm for 48 h. 1.2 g methanol was added after the 10th hour. After reaction, biodiesel (FAME) was analyzed using gas chromatography per the aforementioned description. To quantify the efficiency of biodiesel production, two objective functions, namely biodiesel yield and lipid-to-biodiesel conversion, are, respectively, defined as follows:

Results and discussion

Effect of formic acid

Formic acid concentration was varied from 0 to 8 g/L. The time courses of cell biomass and sugar concentrations are shown in Fig. 1. It was observed that cell growth inhibition was increased with formic acid concentrations. R. toruloides growth was apparently lagged in the presence of formic acid concentration higher than 6 g/L, but the yeast still could grow after 90 h of incubation. When formic acid concentrations were 2 and 4 g/L, corresponding biomass concentration were decreased by 25 and 40%, respectively. Glucose was found to be quickly consumed followed by consumption of xylose. Arabinose was not utilized by the strain. It has been known that undissociated weak acids are liposoluble and can diffuse across the plasma membrane. The growth-inhibiting effect on microorganisms has been proposed to be due to the inflow of undissociated acid into the cytosol [7]. According to the experimental data, formic acid concentration should be lower than 2 g/L when no other toxic compound is present in the medium to obtain a satisfactory biomass accumulation.

Effects of formic acid on time courses of cell biomass concentration and sugar consumption: filled squares, open squares control; filled circles, open circles 2 g/L formic acid; filled triangles, open triangles 4 g/L formic acid; filled inverted triangles, open inverted triangles 6 g/L formic acid; filled diamonds, open diamonds 8 g/L formic acid; solid symbols for biomass and xylose concentration; open symbols for glucose concentration

Effect of acetic acid

Acetic acid is generated by the hydrolysis of the acetyl groups on hemicelluloses and is commonly observed along with the release of xylose [23]. It is one of the most important inhibitors when using lignocellulose hydrolyzate for production of fermented products. The toxicity of acetic acid varies according to the cultivation conditions employed in the fermentative process [8]. Figure 2 shows the biomass accumulation and sugar consumptions with different acetic acid concentrations. The cell growth was inhibited at acetic acid concentration higher than 10 g/L. Cell biomass concentrations were decreased by 15.6 and 50%, respectively, when acetic acid concentrations were 5 and 10 g/L. Complete inhibition was observed when acetic acid concentration was set to 20 g/L. Although the accumulation of cell biomass was decreased with the increase of acetic acid concentration, glucose was also found to be utilized quickly. However, arabinose was still not utilized by this microorganism at any controlled acetic acid concentration. Being similar to the inhibitory action of formic acid, acetic acid inhibition depends on the concentration of its undissociated form, which is a function of both concentration and pH. At acidic pH, acetic acid can diffuse into cell cytoplasm, where it dissociates and lowers the intracellular pH, resulting in uncoupled energy production and impaired transport of various nutrients along with increased ATP requirements. In effect, with increasing acid concentration, the corresponding ATP demand increases accordingly. Once ATP demand surpasses a certain limit, the acid provokes significant inhibition of the fermentation process. The sensitivity of yeasts to acetic acid also depends on the microorganism considered [7, 24]. However, it was interesting to find that acetic acid was continually consumed by the strain during the fermentation when its concentration was below the total inhibition concentration. All of the added acetic acid was consumed after fermentation for 72 h when initial acetic acid concentration was lower than 15 g/L. The experimental results showed that this yeast had a strong ability to endure acetic acid; hence, acetic acid is not the most serious inhibitor for R. toruloides. In particular, according to the experimental results, to obtain a high biomass accumulation, the acetic acid concentration should be lower than 5 g/L when it was solely present in the medium.

Effects of acetic acid on time courses of cell biomass concentration and sugar consumption: filled squares, open squares control; filled circles, open circles 5 g/L acetic acid; filled triangles, open triangles 10 g/L acetic acid; filled inverted triangles, open inverted triangles 15 g/L acetic acid; filled diamonds, open diamonds 20 g/L acetic acid; solid symbols for biomass and xylose concentration; open symbols for glucose concentration

Effect of furfural

During hydrolysis, pentose sugars can be degraded into furfural, a toxic compound that, depending on its concentration in the fermentation medium, can inhibit cells affecting the specific growth rate and cell biomass yield and cell biomass yield per ATP [7]. Furfural has been known to be highly toxic to the growth and fermentation of microorganisms for ethanol production [25, 26]. As shown in Fig. 3, furfural displayed stronger inhibitory power than formic and acetic acids, indicating that the yeast R. toruloides was highly sensitive to furfural. The biomass accumulation was decreased by 60% at a furfural concentration of 1.0 g L−l. Increasing its concentration caused more important decrease of cell accumulation. It was also found that glucose could still be utilized in the first 48 h fermentation, while the xylose consumption was strongly inhibited. Therefore, cell biomass did not further increased after the 48th hour. Given the above, it comes that experimental results illustrate that furfural concentration should be as low as possible to eliminate its inhibition of biomass accumulation.

Effects of furfural on time courses of cell biomass concentration and sugar consumption: filled squares, open squares control; filled circles, open circles 1.0 g/L furfural; filled triangles, open triangles 1.5 g/L furfural; filled inverted triangles, open inverted triangles 2.0 g/L furfural; filled diamonds, open diamonds 2.5 g/L furfural; solid symbols for biomass and xylose concentration; open symbol for glucose concentration

Effect of lignin derivatives

A large variety of compounds (aromatic, polyaromatic, phenolic, and aldehydic) are released from lignin during hydrolysis of lignocellulosic materials, which are known as acid-soluble lignin or lignin degradation products. These compounds are always strong inhibitors to microorganisms’ growth. To investigate the effects of lignin and its derivatives on the growth of R. toruloides, sodium lignosulphonate and vanillin were added to the liquid medium as model inhibitors. Compared with vanillin, sodium lignosulphonate had a much higher molecular weight (usually higher than 2000). In addition, the objective of this experiment is also to compare the toxicity of macromolecular lignin and its degradation products on cell growth. As shown in Fig. 4, sodium lignosulphonate with concentration of 0.5–2.0 g/L had no negative effect on biomass accumulation; instead it was found to enhance cell growth. Further replicate experiments also confirmed the enhancement of cell growth. According to the experimental results, cell biomass concentration was increased by 10% when 1.5 g/L sodium lignosulphonate was added. It has been known that sodium lignosulphonate is a good surfactant, which might have positive influence on microbial growth. Taoka et al. [27] found that addition of Tween 80, a non-ionic surfactant, to the culture medium significantly enhanced the growth and lipid accumulation of Thraustochytrium aureum ATCC 34304. It indicates that surfactant can indeed promote cell growth. However, exact mechanisms should be further investigated in future work.

Effects of sodium lignosulphonate (SLS) on time courses of cell biomass concentration and sugar consumption: filled squares, open squares control; filled circles, open circles 0.5 g/L SLS; filled triangles, open triangles 1.0 g/L SLS; filled inverted triangles, open inverted triangles 1.5 g/L SLS; filled diamonds, open diamonds 2.0 g/L SLS; solid symbols for biomass and xylose concentration; open symbols for glucose concentration

Vanillin is generated by the partial breakdown of lignin through the guaiacyl residue and exerts inhibitory effects on microbial growth. The effect of vanillin on cell growth is shown in Fig. 5. It can be seen that the yeast could grow well when vanillin concentration was <1.5 g/L. However, the biomass accumulation was completely inhibited when vanillin concentration was increased to 2.0 g/L, corresponding sugar consumption was also completely ceased. It indicated that phenolic compounds with low molecular weight had a considerable inhibition of the fermentation process. Nevertheless, several different toxic phenolic compounds are generated during lignin degradation depending on pretreatment process. Vanillin was the only one employed as model inhibitor in the present work. It is known that phenolic compounds cause a partition and loss of integrity of biological membranes, thereby affecting their ability to serve as selective barriers and enzyme matrices. In consequence, both cell growth and sugar assimilation are reduced [7]. Therefore, more compounds should be tested to have a thorough understanding of their specific toxicities on cell growth. Nevertheless, the results of this part of research work revealed the fact that the low-molecular-weight degradation products of lignin should be as low as possible to obtain a satisfactory biomass accumulation.

Effects of vanillin on time courses of cell biomass concentration and sugar consumption: filled squares, open squares control; filled circles, open circles 0.5 g/L vanillin; filled triangles, open triangles 1.0 g/L vanillin; filled inverted triangles, open inverted triangles 1.5 g/L vanillin; filled diamonds, open diamonds 2.0 g/L vanillin; solid symbols for biomass and xylose concentration; open symbols for glucose concentration

Comparison of the individual inhibitory effect of the inhibitors on R. toruloides

The above experimental results reveal that the toxicities of the inhibitors on the growth of R. toruloides were strongly dependent on inhibitor characteristics and their concentrations. When the concentration of inhibitor was 2 g/L, the growth of R. toruloides was completely inhibited by vanillin, and 70% inhibited by furfural. Whereas, only a slight inhibition by formic acid was observed at this concentration, and no inhibition was found for addition of acetic acid. For the case that 50% of the cell growth was inhibited, corresponding inhibitor concentrations were about 4 g/L for formic acid, 15 g/L for acetic acid, <1 g/L for furfural and <2 g/L for vanillin, respectively. Furfural and vanillin were highly toxic to R. toruloides, while formic acid and acetic acid were less toxic; however, formic acid showed stronger inhibition than acetic acid. Although the exact mechanisms of these compounds to inhibit the growth of R. toruloides have not been reported by literatures, much has been known on the mechanisms of their inhibition to the yeasts used for ethanol production. For the inhibitory effect of weak acid (formic acid and acetic acid), two mechanisms have been proposed: hypothesis of uncoupling and intracellular anion accumulation. Both mechanisms indicate that weak acid can cause the drop of intracellular pH, leading to decrease of cellular ATP levels (uncoupling theory), or inhibition to the activities of some cellular enzymes (theory of intracellular anion accumulation) [7]. Since the acidity of formic acid is higher than that of acetic acid, formic acid showed stronger inhibition. Moreover, smaller molecular size of formic acid makes it easier than acetic acid to diffuse across the plasma membrane to exert inhibitory effect. Furfural is found to directly inhibit the activities of alcohol dehydrogenase, aldehyde dehydrogenase, pyruvate dehydrogenase and some enzymes involved in glycolysis, and thus affect the specific growth rate and cell-mass yield per ATP [7, 8, 28]. Phenolic compounds, such as vanillin, partition into biological membranes and cause loss of integrity, thereby affecting their ability to serve as selective barriers and enzyme matrices [7]. Therefore, furfural and vanillin showed much higher toxicity than formic acid and acetic acid. However, since different yeasts have different endurance to inhibitors, the exact mechanisms of the inhibitory effects of these compounds deserve further investigation.

Synergistic effect of several inhibitors

The maximum concentration of each inhibitor that a microorganism can withstand cannot be established precisely because inhibition strongly depends on factors such as the type of microorganism, the type of fermentative process employed as well as the number of inhibitors present in the medium, and their synergistic effects [8]. On the other hand, the hydrolyzate always contains several toxic compounds. Zaldivar et al. [29] demonstrated that the toxicity of hemicellulosic hydrolyzates results from the aggregation of several toxic compounds (alcohols, aldehydes, and acids), but not from individual compounds. To investigate the synergistic effect of different inhibitors, an orthogonal experimental design of L9(34) was used for arranging experiments, as shown in Table 1. Four inhibitors (formic acid, acetic acid, furfural and vanillin) with three respective levels were studied. The response variables included biomass concentration, glucose utilization rate, and xylose utilization rate after fermentation for 144 h. It was found that the synergistic effect of these compounds dramatically inhibited the biomass concentration and sugar consumptions. They exhibited apparent inhibitions even at low concentrations with other co-present inhibitors. For example, when acetic acid was solely present in the medium, the cell growth was completely inhibited at a concentration of 20 g/L, and the added acetic acid was increasingly consumed after fermentation for 72 h when initial acetic acid concentration was lower than 15 g/L; however, 2.0 g/L acetic acid could completely inhibit the yeast growth when other inhibitors were co-present (No. 3, 6 and 9 in Table 1). The analysis of orthogonal test results showed that the synergistic effect between formic acid and acetic acid, furfural, and vanillin all had very significant influences (p < 0.01) on biomass concentration and sugar consumptions. Similar synergy was also found for baker’s yeast, P. stipitis, S. cerevisiae, E. coli and some other strains [7, 8, 30]. However, the exact mechanisms for the synergistic effects of the inhibitors and how the synergy affects cell growth should be further investigated. In any case, the experimental results illustrated that a detoxification strategy should be designed to consider not only decreasing inhibitor concentrations but also destroying synergistic effects of the inhibitors to optimize the detoxification process and reduce detoxification cost. For example, furfural is the strongest inhibitor, but its concentration is low in a real dilute acid hydrolyzate, so that a detoxification strategy should be designed to first remove furfural. Simple vacuum evaporation is effective to decrease furfural concentration. In the following step, the concentration of lignin degradation products should be decreased, which can be achieved by active charcoal adsorption. The yeast has a strong endurance to acetic acid. On the other hand, acetic acid concentration is also decreased during vacuum evaporation and neutralization with lime. Therefore, it is not an important inhibitor and can be neglected during detoxification.

Effect of the inhibitors on lipid accumulation and fatty acid composition of the lipid

To compare the effects of the studied inhibitors on fatty acid compositions of lipid, the inhibitors were added solely to the culture medium with each at a concentration of 0.5 g/L. The sample without addition of any inhibitors was used as a control. After 120 h fermentation, lipids were extracted and analyzed. The results are shown in Table 2. For comparison, the fatty acid compositions of refined soybean oil were also determined. It can be seen that formic acid, acetic acid, vanillin and sodium lignosulphonate did not cause any obvious inhibition to yeast growth at concentration of 0.5 g/L. However, furfural displayed significant inhibition. The biomass concentration, lipid content and lipid yield were dramatically decreased when furfural was present. This indicates that furfural is a very strong inhibitor to the growth and lipid accumulation of R. toruloides. Hu et al. [20] also obtained a similar conclusion. It also can be known from Table 2 that addition of sodium lignosulphonate could increase cell biomass concentration and lipid yield, indicating that it can promote the conversion of sugar to lipid.

The major fatty acid compositions of the lipids were found to be C16:0 (palmitic acid), C18:0 (stearic acid), C18:1 (oleic acid) and C18:2 (linoleic acid), which accounted for about 26, 10, 50, and 10% of the total fatty acids, respectively. Oleic acid was the most abundant fatty acid in the lipid. This result was in accordance with that of Hu et al. [20]. However, the linoleic acid content determined in the present work was somewhat higher than that of Hu et al. According to the experimental results, addition of formic acid, acetic acid, vanillin and sodium lignosulphonate did not result in a significant difference of fatty acid compositions. This shows that these compounds did not significantly affect the fatty acid biosynthetic pathway. However, the lipid obtained from furfural-added medium showed some difference. Its saturated fatty acid (palmitic acid and stearic acid) content was decreased, but unsaturated fatty acid (oleic acid and linoleic acid) content was increased. Particularly, oleic acid was increased by 10% compared with that of the control. Hu’s experimental results also reflected this phenomenon when 0.6 mM (0.0576 g/L) furfural was added to the culture medium [20]. It seems that furfural could induce more bio-synthesis of unsaturated fatty acids. The corresponding mechanism should be further studied by metabolic analysis. Compared with refined soybean oil, the yeast lipid had higher palmitic acid, stearic acid and linoleic acid contents, but much lower linoleic acid and linolenic acid contents. However, the fatty acid compositional profile of the yeast lipid was in the range of various plant oil and animal tallow, which showed that the lipid could be used as biodiesel feedstock [31].

Production of yeast lipid with sugarcane bagasse hydrolyzate as carbon source

According to the above experimental results, the yeast could not directly grow on biomass hydrolyzate to accumulate lipid unless the hydrolyzate was detoxified. When sugarcane bagasse was hydrolyzed at 121 °C for 2 h with 1 wt% sulfuric acid at liquid-to-solid ratio of 10:1 (v/w), the concentrations of formic acid, acetic acid, furfural and acid-soluble lignin were determined to be 0.10, 1.12, 0.44 and 0.24 g/L, respectively. However, the fermentable sugar (glucose plus xylose) concentration was only about 20 g/L. According to the aforementioned study results, the yeast displayed high endurance to the toxic compounds when they were present solely. A detoxification strategy thus was designed to reduce the toxic compounds concentrations and destroy their synergistic effects. Vacuum evaporation was first employed to remove nearly all furfural and simultaneously the hydrolyzate liquid was concentrated. The lignin degradation products were further removed using lime neutralization and activated charcoal adsorption, which allowed removing over 90% of the products. After detoxification, the concentrations of acetic acid and acid-soluble lignin were 1.6 and 0.07 g/L, respectively, while formic acid and furfural concentrations were below the detect limit of HPLC. With addition of some nitrogen source and mineral salts, this hydrolyzate was further used as a carbon source for lipid production in a 5 L fermentor. Pure sugars with equal amounts of glucose and xylose were used as control under the same fermentation conditions. The experimental results are shown in Fig. 6 and Table 2. It can be known that the detoxified hydrolyzates were well utilized by the oleaginous yeast for biomass accumulation. The biomass concentration and sugar consumption for hydrolyzate were even higher than those of the control. After 196 h of fermentation the cell biomass concentration and sugar consumption for hydrolyzate fermentation were, respectively, 25.5 and 14% higher than those of the control. Corresponding lipid content and lipid yield were also somewhat higher. This may be explained by the fact that the hydrolyzate contained some protein and microelements, which could promote the yeast growth and lipid accumulation. Xing et al. [32] also found that corn fiber hydrolysate could result in higher biomass concentration than other monosaccharide carbon source (glucose, xylose, mannose or arabinose) when using Mortierella isabellina to produce microbial lipid. This result indicates that the detoxified sugarcane bagasse could be well used by the yeast for growth and lipid accumulation. The fatty acid compositions showed no significant difference for the lipids obtained from hydrolyzate and pure sugar (control) (Table 2).

Compared with some reported results of microbial lipid production with biomass hydrolyzate as carbon source, R. toruloides in present work showed similar or higher lipid yield as shown in Table 3. The results indicate that R. toruloides is a promising strain for microbial lipid production with lignocellulose hydrolyzate as carbon source. However, a detoxification process is required to obtain a high biomass concentration. It should be noted that sometimes detoxification process are costly due to the consumption of some chemicals or activated charcoal, loss of sugars and discharge of wastewater. Nevertheless, it is impossible for the oleaginous yeast to directly grow on the non-detoxified dilute acid hydrolyzate. However, simple detoxification such as concentration and over-liming can be effective for oleaginous yeasts to utilize biomass hydrolyzate to produce lipid [34, 35], but in some cases detoxification with activated charcoal has to be employed to reduce the concentrations of lignin degradation products (phenolic compounds) [33].

Biodiesel preparation by enzymatic transesterification of the obtained lipids

To further investigate the convertibility of the yeast lipid to biodiesel, we used the lipids as feedstock for biodiesel preparation by enzymatic transesterification. The time courses of biodiesel yield are shown in Fig. 7. For comparison, refined soybean oil was also used as feedstock for biodiesel preparation. The biodiesel yield for yeast lipid was lower than that of refined soybean oil, especially for the lipid obtained from bagasse hydrolyzate. After reaction for 24 h, the biodiesel yield for yeast lipid from pure sugars and hydrolyzate were 79.3 and 67.2%, respectively, but corresponding biodiesel yield for refined soybean oil reached 85.1%. However, it should be noted that biodiesel yield was defined as the weight of biodiesel produced from 100 g of lipid or oil. Since the yeast lipid was extracted by acid-heating methods, the crude lipid contained not only triglyceride but also some cell membrane components such as phospholipid and fermentation byproducts such as β-carotene. The presence of these impurities naturally decreased the biodiesel yield of yeast lipid. It was found that the maximum biodiesel yield from refined soybean oil could reach about 1 g of biodiesel per gram of oil. However, for lipids obtained from pure sugar and hydrolyzate, the maximum biodiesel yield were only about 0.86 and 0.76 g of biodiesel per gram of crude lipid. Therefore, according to the above biodiesel yield data, it can be calculated that the lipid-to-biodiesel conversions were 92.2 and 88.4% for the lipids obtained from pure sugar and bagasse hydrolyzate, respectively, which were similar to that of refined soybean oil. Purification of the lipid might be helpful to increase conversion ratio and obtaining some other high added-value products such as β-carotene. For further comparing the convertibility of the yeast lipid-to-biodiesel, we defined the lipid-to-biodiesel conversion shown in the aforementioned expression (2). It was found that the rates (speed) of lipid-to-biodiesel conversion for yeast lipids were slightly lower than that of refined soybean oil when the reaction time was <12 h, especially for the lipid obtained from bagasse hydrolyzate. However, similar lipid-to-biodiesel conversions were obtained for all of the three lipids/oils after reaction for 24 h. It illustrated that the crude yeast lipid could be well converted to biodiesel by enzymatic transesterification, which demonstrated that the lipid could be a potential biodiesel feedstock.

Conclusions

To investigate their inhibitions to the growth and lipid accumulation of oleaginous yeast R. toruloides, several compounds present in the acid hydrolyzate of lignocellulosic biomass were added to the nitrogen-limited medium as inhibitors. The experimental results indicated that the toxicity of these compounds strongly depended on their concentrations, while furfural and vanillin showed much higher toxicity to cell growth and sugar consumption. Sodium lignosulphonate had no negative effect on biomass accumulation when its concentration was in the range of 0.5–2.0 g/L; instead it was found to facilitate cell growth and sugar-to-lipid conversion. When the compounds were present in isolation in the medium, to obtain a high cell biomass accumulation, the concentration of formic acid, acetic acid, furfural and vanillin should be lower than 2, 5, 0.5 and 1.5 g/L, respectively. However, the synergistic effects of these compounds could dramatically decrease the inhibitor critical concentrations, resulting in significant inhibitions. Addition of formic acid, acetic acid, vanillin or sodium lignosulphonate to the culture medium did not cause significant difference in fatty acid composition of the yeast lipid. Nevertheless, furfural appeared capable of inducing more synthesis of unsaturated fatty acid, especially for oleic acid. Dilute acid hydrolyzate of sugarcane bagasse could well be used as a carbon source by R. toruloides for growth and lipid accumulation after detoxification. The extracted lipid could be well converted to biodiesel by enzymatic transesterification under the catalysis of immobilized lipase in tert-butanol system.

References

Boyer LJ, Vega JL, Klasson KT, Clausen EC, Gaddy JL (1992) The effects of furfural on ethanol production by Saccharomyces cerevisiae in batch culture. Biomass Bioenergy 3:41–48

Delgenes J, Moletta R, Navarro JM (1996) Effects of lignocellulose degradation products on ethanol fermentations of glucose and xylose by Saccharomyces cerevisiae, Zymomonas mobilis, Pichia stipitis and Candida shehatae. Enzyme Microb Technol 19:220–225

Fjerbaek L, Christensen KV, Norddahl B (2009) A review of the current state of biodiesel production using enzymatic transesterification. Biotechnol Bioeng 102:1298–1315

Guo GL, Chen WH, Chen WH, Men LC, Hwang WS (2008) Characterization of dilute acid pretreatment of silvergrass for ethanol production. Bioresour Technol 99:6046–6053

Hu C, Zhao X, Zhao J, Wu S, Zhao ZK (2009) Effects of biomass hydrolysis by-products on oleaginous yeast Rhodosporidium toruloides. Bioresour Technol 100:4843–4847

Hu C, Wu S, Wang Q, Zhao Z (2011) Simultaneous utilization of glucose and xylose for lipid production by Trichosporon cutaneum. Biotechnol Biofuels 4:25

Huang C, Zong MH, Wu H, Liu QP (2009) Microbial oil production from rice straw hydrolysate by Trichosporon fermentans. Bioresour Technol 19:4535–4538

Karmakar A, Karmakar S, Mukherjee S (2010) Properties of various plants and animals feedstocks for biodiesel production. Bioresour Technol 101:7201–7210

Lee WG, Lee JS, Shin CS, Park SC, Chang HN, Chang YK (1999) Ethanol production using concentrated oak wood hydrolysates and methods to detoxify. Appl Biochem Biotechnol 78:547–559

Li ZF, Zhang L, Shen XJ, Lai BS, Sun SQ (2001) A comparative study on four method of fungi lipid extraction. Microbiol 28:72–75

Li YH, Liu B, Sun Y, Zhao ZB, Bai FW (2005) Screening of oleaginous yeasts for broad-spectrum carbohydrates assimilation capacity. Chin Biotechnol 25:39–43

Li YH, Liu B, Zhao ZB (2006) Optimization of culture conditions for lipid production by Rhodosporidium toruloides. Chin J Biotechnol 22:650–656

Li L, Du W, Liu D, Li Z (2006) Lipase-catalyzed transesterification of rapeseed oils for biodiesel production with a novel organic solvent as the reaction medium. J Mol Catal B Enzym 43:58–62

Li YH, Zhao ZB, Bai FW (2007) High-density cultivation of oleaginous yeast Rhodosporidium toruloides Y4 in fed-batch culture. Enzyme Microb Technol 41:312–317

Li Q, Du W, Liu D (2008) Perspectives of microbial oils for biodiesel production. Appl Microbiol Biotechnol 80:749–756

Ma F, Hanna MA (1999) Biodiesel production: a review. Bioresour Technol 70:1–15

Modig T, Lidén G, Taherzadeh MJ (2002) Inhibition effects of furfural on alcohol dehydrogenase, aldehyde dehydrogenase and pyruvate dehydrogenase. Biochem J 363:769–776

Mussatto SI, Roberto JC (2004) Alternatives for detoxification of diluted-acid lignocellulosic hydrolyzates for use in fermentative processes: a review. Bioresour Technol 93:1–10

Nigam JN (2001) Ethanol production from wheat straw hemicellulose hydrolysate by Pichia stipitis. J Biotechnol 87:17–27

Palmqvist E, Hahn-Hagerdal B (2000) Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresour Technol 74:25–33

Palmqvist E, Grage H, Meinander NQ, Hahn-Hägerdal B (1999) Main and interaction effects of acetic acid, furfural and p-hydroxybenzoic acid on growth and ethanol productivity of yeasts. Biotechnol Bioeng 63:46–55

Papanikolaou S, Dimou A, Fakas S, Diamantopoulou P, Philippoussis A, Galiotou-Panayotou M, Aggelis G (2011) Biotechnological conversion of waste cooking olive oil into lipid-rich biomass using Aspergillus and Penicillium strains. J Appl Microbiol 110:1138–1150

Parajó JC, Domnguez H, Domnguez JM (1998) Biotechnological production of xylitol. Part 3: operation in culture media made from lignocellulose hydrolysates. Bioresour Technol 66:25–40

Pienkos PT, Zhang M (2009) Role of pretreatment and conditioning processes on toxicity of lignocellulosic biomass hydrolysates. Cellulose 16:743–762

Saha BC, Bothast RJ (1999) Pretreatment and enzymatic saccharification of corn fiber. Appl Biochem Biotechnol 76:65–77

Sárvári Horváth I, Taherzadeh MJ, Niklasson C, Lidén G (2001) Effects of furfural on anaerobic continuous cultivation of Saccharomyces cerevisiae. Biotechnol Bioeng 75:540–549

Sivers MV, Zacchi G (1996) Ethanol from lignocellulosics: a review of the economy. Bioresour Technol 56:131–140

Taherzadeh MJ, Niklasson C, Liden G (1997) Acetic acid—friend or foe in anaerobic batch conversion of glucose to ethanol by Saccharomyces cerevisiae. Chem Eng Sci 52:2653–2659

Taoka Y, Nagano N, Okita Y, Izumida H, Sugimoto S, Hayashi M (2011) Effect of Tween 80 on the growth, lipid accumulation and fatty acid composition of Thraustochytrium aureum ATCC 34304. J Biosci Bioeng 111:420–424

Van Zyl C, Prior B, du Preez JC (1991) Acetic acid inhibition of d-xylose fermentation by Pichia stipitis. Enzyme Microb Technol 13:82–86

Wu S, Hu C, Jin G, Zhao X, Zhao ZK (2010) Phosphate-limitation mediated lipid production by Rhodosporidium toruloides. Bioresour Technol 101:6124–6129

Wu S, Zhao X, Shen H, Wang Q, Zhao ZK (2011) Microbial lipid production by Rhodosporidium toruloides under sulfate-limited conditions. Bioresour Technol 102:1803–1807

Xing D, Pan A, Xue D, Fang M, Gu R (2010) Biomass carbohydrates assimilation and lipid accumulation by Mortierella isabellina. Chin J Biotechnol 26:189–193

Yu X, Zheng Y, Dorgan KM, Chen S (2011) Oil production by oleaginous yeasts using the hydrolysate from pretreatment of wheat straw with dilute sulfuric acid. Bioresour Technol 102:6134–6140

Zaldivar J, Martinez A, Ingram LO (2000) Effect of alcohol compounds found in hemicellulose hydrolysate on growth and fermentation of ethanologenic Escherichia coli. Biotechnol Bioeng 68:524–530

Acknowledgments

This work was supported by Tsinghua Research Funding (No. 2009THZ0223). The authors sincerely appreciate Mr. Ilan E. Cuperstein, Dr. Quin Garcia and Dr. Erik Chavez for their help in polishing English language.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhao, X., Peng, F., Du, W. et al. Effects of some inhibitors on the growth and lipid accumulation of oleaginous yeast Rhodosporidium toruloides and preparation of biodiesel by enzymatic transesterification of the lipid. Bioprocess Biosyst Eng 35, 993–1004 (2012). https://doi.org/10.1007/s00449-012-0684-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-012-0684-6