Abstract

Wastewater from the textile industry contains significant amounts of synthetic dyes that require treatment to prevent groundwater contamination. These synthetic dyes are stable and are highly persistent in nature. The search for innovative, cost-effective, and environment-friendly technologies has become the real challenge in recent years. In view of the need for a technical and economically satisfying treatment technology, a flurry of emerging technologies has been proposed and examined at different stages of commercialization. Appliance of biotechnological techniques in recent period emerged as a very promising area for decolorization of textile wastewater, i.e., targeted at breaking down the dye molecule to basic elements (mineralizing them), and has much less environmental impact than conventional methods. A lot of research in this field revealed the existence of a variety of microbial communities capable of decolorizing a wide group of dyes. This chapter reviews the usage of various microorganisms such as bacteria, fungi, algae, and microbial consortium as free cells or in immobilized form for the decolorization of different types of textile dyes. The performance and results of latest research studies with pure and mixed cultures in various reactors have been also compiled pertaining to the bioremediation of dyes and colorants from wastewater with the possible alternative emerging technologies.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

6.1 Introduction

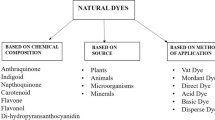

Due to rapid industrialization and urbanization, manufacturing and usage of synthetic dyes have been increased in various sectors. Dyes are the substances that impart color to the substrate. They adhere on compatible surfaces by mechanical retention, physical adsorption, and formation of covalent bond/complexes with metals. Dyes are used in the textile industry, leather tanning industry, paper production, food industry, photography, wood staining, biological and chemical research, pharmaceutical and medicine, light-harvesting arrays, photo-electrochemical cells, hair colorings, and cosmetics. The color of dye is combined effects of chromophores, delocalized electron system with conjugated double bonds, and auxochrome–electron-withdrawing or electron-donating substituent that enhance the color of chromophore by changing the overall energy of electron system. In addition to enhance the chromophore in production of color, auxochromes are also responsible for the solubility of dye and increase its reactivity toward fibers (Dos Santos et al. 2005).

Textile industry is one of the greatest consumers of water uses about 100 L of raw water per kg of textile materials in dying process. So during dyeing and finishing operations, approx. 200,000 tons of these textile dyes are lost to effluent every year (Jin et al. 2007). The discharge of highly colored synthetic dye effluent can be very damaging to the receiving water bodies since these dyes in the water strongly absorb sunlight that decrease the light intensity absorbed by the plants and phytoplankton-reducing photosynthesis and the oxygenation of water reservoir. Moreover, the presence of unnatural color is aesthetically unpleasant and tends to be associated with contamination. In addition, dyes used in the textile industries are toxic to aquatic organism and can be resistant to natural biological degradation.

During the last few years, stringent regulations coupled with increased enforcement concerning colored wastewater discharges have been established in many countries. Government legislation is becoming more and more stringent, especially in the more developed/developing countries, regarding the removal of dyes from industrial effluent (Robinson et al. 2001). Enforcement of this law will continue to ensure that textile and other dye-utilizing industries treat their dye-containing effluent to the required standards. So, traditional wastewater treatment technologies have proven to be markedly ineffective for handling wastewater of synthetic textile dyes because of the chemical stability of these pollutants. A wide range of methods has been developed for removal of synthetic dyes from aqueous solution to decrease their impact on the environment.

They are divided in following major categories:

-

Physical method: Adsorption, (activated carbon, peat, bagasse, wood chips, fly ash and coal, silica gel), irradiation, ion exchange, electrokinetic coagulation

-

Chemical method: Oxidative process, Fenton’s reagent, ozonation, sodium hypochlorite photochemical

-

Biological method: Activated sludge process, enzymatic treatment, anaerobic process

-

Emerging technologies: Advanced oxidation process, membrane filtration, photocatalysis, sonication, redox mediators and engineered wetland systems, etc.

Biological and chemical methods involve the destruction of the dye molecule, while physical methods usually transfer the pollutant to another phase. Many of the conventional methods used for treating dye wastewater have not been widely applied on large scale as a result of the high operational cost and sludge disposal problems associated with them. Due to the complex nature of dye effluent, there is hardly any single method to treat the dye wastewater efficiently. So, combinations of different process are preferred to achieve the economical and desired level water quality (Saratale et al. 2010; Loncˇar et al. 2013; Karthik et al. 2014). Different combinations of treatment methods have been proposed in order to effectively manage the textile wastewater. Thus, chemical coagulation-flocculation, chemical oxidation, activated carbon adsorption, and anaerobic biological treatment usually combined with a activated sludge secondary treatment step are among the most well-known techniques (Hao et al. 2000; Robinson et al. 2001; Forgacs et al. 2004; Joshi et al. 2004).

6.2 Biological Methods

Bioremediation, or the use of microbial techniques to deal with pollution, is a key research area in the environmental sciences. Microbes acclimatize themselves to the toxic wastes, and new resistant strains develop naturally, which then transform various toxic chemicals into less harmful forms.

The ability of biological treatment for decolorizing of industrial effluent is ambiguous, different, and divergent. A number of biotechnological approaches have been suggested by recent research as of potential interest toward combating this pollution source in an eco-efficient manner, including the use of bacteria or fungi often in combination with physicochemical processes (Beydilli et al. 1998; Willmott et al. 1998; Borchert and Libra 2001; McMullan et al. 2001; Robinson et al. 2001; Zissi and Lyberatos 2001). Bioremediation of textile effluent using pure bacterial and fungal decolorization are represented in Table 6.1. Bioremediation systems were commonly applied in the treatment of industrial effluent using many microorganisms such as bacteria, yeasts, algae, and fungi that have capability to accumulate and degrade different pollutants. There were three principle advantages of biological technologies for the removal of pollutants; first, biological processes can be carried out in situ at the contaminated site; second, bioprocess technologies are usually environmentally benign (no secondary pollution); and third, ex situ method is cost-effective.

Recent fundamental work has revealed the existence of wide variety of microorganisms capable of decolorizing wide range of dyes. The use of microorganisms for the removal of synthetic dyes from industrial effluent offers considerable advantages, and the process was relatively inexpensive, running costs were low, and the end products were completely mineralized with no toxicity. Biodegradation is defined as biologically mediated breakdown of chemical compounds. When biodegradation is complete, the process is called mineralization, i.e., the total breakdown of organic molecules into water, carbon dioxide, and/or any other inorganic end products (Banat and Faison 1999). Degradation by mixed culture enhances the degradation process since individual strains attack the dye molecule at different positions or uses decomposed products produced by one strain will be further decomposed by another strain (Mohana et al. 2008). However, it was stressed that the composition of mixed cultures may change during the decomposition process, which interferes with the control of technologies using mixed cultures. Moreover, the efficacy of decomposition considerably depends on the chemical character of the synthetic dye and biodegradation capacity of the microorganism consortium (Schliephake et al. 2000). Decolorization of dyes with pure culture was found to be impractical, as the isolated culture would be dye specific, and their application in large-scale wastewater treatment plants with a variety of contaminant dyes was not feasible (Murugesan and Kalaichelvan 2003). Efficient biodegradation of dyes can be accomplished when catabolic activity of individual strain was complement with each other in a mixed culture community. The other biological treatment method that includes bioaccumulation was defined as the accumulation of pollutants by actively growing cells by metabolism and temperature-independent and metabolism-dependent mechanism steps (Nigam et al. 2000; Robinson et al. 2001; Ola et al. 2010; Tan et al. 2013; Saratale et al. 2013). These processes have potential to mineralize dyes to harmless inorganic compounds like carbon dioxide, water, and the formation of relatively insignificant amount of sludge.

6.3 Microbial Decolorization

The application of microorganisms for the biodegradation of synthetic dyes is an attractive and simple method by operation. However, the biological mechanisms can be complex. The large number of species has been tested for decolorization and mineralization of various dyes. Besides the traditional wastewater cleaning technologies, other methods have been employed in the microbial decolorization of dyes. The effectiveness of microbial decolorization depends on the adaptability and the activity of selected microorganisms including bacteria, actinomycetes, fungi, yeasts, and algae capable of degrading azo dyes (Chen et al. 2003; Daneshvar et al. 2007; Kalyani et al. 2009).

6.3.1 Bacterial

Numerous bacterial strains isolated from the contaminated sites of textile dyes, having the ability to decolorize dyes, have been reported by various researchers (Table 6.2). Bacterial cultures capable of degrading azo dyes are Bacillus subtilis (Mabrouk and Yusef 2008), Aeromonas hydrophila (Ogugbue and Sawidis 2011), and Bacillus cereus (Ola et al. 2010). Klebsiella pneumoniae RS-13 and Acetobacter liquefaciens S-1 having the ability to decolorizing textile industrial effluent containing methyl red have been reported for bioremediation of azo dye (Wong and Yuen 1996). An efficient isolated species of Pseudomonas from soil degraded and decolorized dyes belonging to triphenylmethane and azo group. Malachite green, fast green, brilliant green, Congo red, and methylene blue were decolorized in the range of 30–70% under aerobic condition (pH 6–8 and temp. 30–40 °C) (Mali et al. 2000). Decolorization of Congo red and direct black 38 were carried out using E. coli and Pseudomonas sp. under anaerobic, aerobic, and microaerophilic conditions (Isik and Sponza 2003). Color of the Congo red and direct black 38 was removed up to 98 and 72%, respectively, by E. coli at the end of anaerobic incubation, while no color was observed under aerobic incubation, whereas under microaerophilic condition, the azo dyes such as Congo red and direct black 38 were decolorized by E. coli up to 39 and 75%, respectively, 5-day incubation with anaerobic Pseudomonas sp., and showed 100% color removal. Further, out of the six bacterial strains which were isolated from sludge samples and mud lakes having ability of degrading textile dyes, Aeromonas hydrophila exhibited the higher color removal efficiency with various dyes (Chen et al. 2003) under optimal conditions (pH 5.5–10, temp. 20–35.8 °C). More than 90% of decolorization of red RBN was examined within 8 days at a dye concentration of 3000 mg/L. Pearce et al. (2003) presented an excellent review on the color removal from textile wastewater using whole bacterial cells. Mixed cultures of bacteria from a wide variety of habitats have also been shown to decolorize the diazo-linked chromophore of dye molecule in 15 days (Nagarathnamma et al. 1999). Ramya et al. (2010) reported 100% and 92% effective decolorization of indigo carmine by Paenibacillus larvae under shaking condition. Moosvi et al. (2007) also reported decolorization of Reactive Violet 5R (100 mg/L) by a microbial consortium consisted Paenibacillus polymyxa and Micrococcus sp. within 36 h, whereas individual isolates could not show decolorization even on extended incubation. Similarly, Palamthodi et al. (2011) also revealed effective decolorization of green and blue dye by Paenibacillus azoreducers and further investigated 70% decolorization of textile wastewater by microbial flocs consisted Bacillus sp., Paenibacillus sp., Achromobacter sp., etc. and their ability to accumulate heavy metals present in the textile wastewater. Cetin and Donmez (2006) revealed that E. coli and Pseudomonas luteola had the ability to decolorize reactive black B, remazol Blue, and reactive red RB at pH 7.0 with constant decolorization rates up to pH 9.5. In contrast Klebsiella pneumoniae RS-13 completely degrades methyl red in pH range from 6.0 to 8.0 (Wong and Yuen 1996; Mali et al. 2000). A pH from 7 to 8.5 has been reported as the optimum pH for the decolorization of reactive red 5 (Moosvi et al. 2005) and reactive violet 5R (Moosvi et al. 2007).

6.3.2 Fungi

Fungi have proved to be a suitable organism for treatment of textile effluent and dye removal. Fungal mycelia have an additive advantage over single cell organisms by solubilizing the insoluble substrates by producing extracellular enzymes. Due to an increased cell-to-surface ratio, fungi have a greater physical and enzymatic contact with the environment. The extracellular nature of the fungal enzymes is also advantageous in tolerating high concentrations of the toxicants. Many genera of fungi have been reported for the various types of textile dye decolorization (Table 6.3). White rot fungi are most efficient in breaking down synthetic dyes as these constitute a diverse ecophysiological group comprising mostly basidiomycetous fungi capable of extensive aerobic lignin depolymerization and mineralization. This property is based on the WRF’s capacity to produce one or more extracellular lignin-modifying enzymes (LME), which is due to their lack of substrate specificity are also capable of degrading a wide range of xenobiotics.

Extracellular production of ligninolytic enzymes by mycelium growing on solid malt extract/glucose medium supplemented with different dyes (malachite green, azure B, poly R-478, anthraquinone blue, Congo red, and xylidine), dye decolorization, and the relationship between these two processes were studied with 26 white rot fungi from Argentina (Levin et al. 2004). Only ten strains decolorized all the dyes and produced laccase, lignin peroxidase, and manganese peroxidase on solid medium. Comparing the isolates with the well-known dye degrader Phanerochaete chrysosporium, a new fungus, Coriolus versicolor, is potentially a candidate for use in biodecolorization processes. Eighteen-day-old cultures of P. chrysosporium were able to decolorize within hour up to 28, 30, 43, 88, and 98% of xylidine (24 mg/L), poly R-478 (75 mg/L), remazol brilliant blue R (9 mg/L), malachite green (6 mg/L), and indigo carmine (23 mg/L), respectively. Moreover, five species of white rot fungi were further evaluated for their ability to decolorize amaranth, remazol black B, remazol orange, remazol brilliant blue, reactive blue, and tropaeolin O in agar plates, Bjerkandera sp. BOS55, Phanerochaete chrysosporium, and Trametes versicolor. In static aqueous culture, the three cultures form fungal mats, which did not decolorize any dye beyond some mycelial sorption. When agitated at 200 rpm, the biomass grew as mycelial pellets. Bjerkandera sp. BOS55 pellets decolorized only amaranth, remazol black B, and remazol orange dye. Batch cultures of Bjerkandera sp. BOS55 and P. chrysosporium had a limited ability to decolorize repeated dye additions; however, T. versicolor rapidly decolorized repeated additions of the different dyes and dye mixtures without any visual sorption of any dye to the pellets (Swamy and Ramsay 1999). Similarly, decolorization and biodegradation of orange II, tropaeolin O, Congo red, and azure B with white rot fungus, Phanerochaete chrysosporium, were demonstrated by Cripps et al. (1990). Nyanhongo et al. (2002) examined the four ligninolytic fungi, namely, Trametes modesta, Trametes hirsuta, Trametes versicolor, and Sclerotium rolfsii, having the ability to produce fungal laccases which were screened for their ability to decolorize dyes such as anthraquinone, azo, indigo, and triarylmethane. The decolorization rate of this laccase increased with the rise in temperature to 50–60 °C. The decolorization efficiency of T. modesta laccase was improved remarkably in the presence of mediators like 1-hydroxybenzotriazole and 2-methoxyphenothiazine.

The strain Aspergillus fumigatus XC6 isolated from mildewing rice straw was found to be capable of decolorizing dyes effluent over a pH range 3.0–8.0 with the dyes as sole carbon and nitrogen sources (Jin et al. 2007). The optimum pH was 3.0; however, supplemented with either appropriate nitrogen sources (0.2% NH4Cl or (NH4)2SO4) or carbon sources (1.0% sucrose or potato starch), the strain decolorized the effluent completely at the original pH of the dyes effluent. A new azo dye-decolorizing fungi strain identified as Penicillium sp. based on 26S rRNA gene sequence analysis was isolated from activated sludge (Gou et al. 2009). Penicillium sp. could aerobically decolorize 70% of reactive brilliant red X-3B at optimum pH 4–5, up to salinity 6% by the way of bioadsorption, and nutrient-poor medium was more beneficial for adsorption. Furthermore, the decolorization of azo dyes by fungal-bacterial co-cultures demonstrated that Penicillium sp. and Sphingomonas xenophaga QYY co-cultures performed better than any single strain.

6.3.3 Algae

Algae have become significant organisms for biological purification of wastewater since they are able to accumulate plant nutrients, heavy metals, pesticides, organic, inorganic toxic substances, and radioactive matters in their cells. Biological wastewater treatment systems with microalgae have particularly gained importance in the last 50 years, and it is now widely accepted that algal wastewater treatment systems are as effective as conventional treatment systems. These specific features have made algal wastewater treatment systems significant low-cost alternatives to complex expensive treatment systems particularly for purification of municipal wastewater (Table 6.4). The microalgae biomass production from textile waste effluent is a possible solution for the environmental impact generated by the effluent discharge into water sources. Pure and mixed algal cultures removed 50–70% of color within 3 months of incubation, and color reduction pattern showed a rapid removal rate phase followed by declining removal rate phase. Color removal by algae was due to three intrinsically different mechanisms of assimilative utilization of chromophores for production of algal biomass, CO2 and H2O transformation of colored molecules to noncolored molecules, and adsorption of chromophore on algal biomass. A report of algae capable of degrading azo dyes, through an induced form of an azo reductase, showed good color removal (Jinqui and Houtian 1992). Several species of Chlorella and Oscillatoria were capable of degrading azo dyes to their aromatic amines and to further metabolize the aromatic amines to simpler organic compounds. Some were even capable of utilizing azo dyes as their sole carbon and nitrogen source. Use of such algae in stabilization ponds was proposed by Banat et al. (1996) as they play an important role in aromatic amine removal. The biodegradation of azo dyes by the algae (Chlorella pyrenoidosa, C. vulgaris, and Oscillatoria tenuis) has also been assessed (Liu and Liu 1992). In addition, the algae can play a direct role in degradation of azo dyes. Chlorella vulgaris which have biosorption capacity for several reactive dyes were reported by Aksu (2005). Dried Spirogyra rhizopus have the ability to decolorize acid red 274 dye by both biosorption and biocoagulation process, and the removal amounts decreased, while the removed concentration of AR 274 dye increased with increasing S. rhizopus concentration (Ozer et al. 2006). The potential of Cosmarium sp. belonging to green algae was investigated as a viable biomaterial for biological treatment of triphenylmethane dye and malachite green (Daneshvar et al. 2007). Immobilized thermophilic cyanobacterial strain Phormidium sp. has good decolorization activity under thermophilic condition (Ertugrul et al. 2008). Agitated batch sorption performed on algae Spirogyra 102 revealed the ability of test biosorbent to remove azo dye from the aqueous phase at acidic pH 2 at optimized temperature 30 °C and dye concentration 5 mg/L (Verkata Mohan et al. 2008). C. vulgaris culture in the textile waste effluent demonstrated the possibility of using this microalga for the color and COD removal and for biomass production. The cultivation of C. vulgaris presented maximum cellular concentrations C max and maximum specific growth rate μ max in the wastewater concentration of 5.0% and 17.5%, respectively (El-Kassas and Mohamed 2014).

6.4 Enzymatic Treatment

Enzymes are able to break apart large sludge particles, creating more surface area for microbes to attack. This allows for a more complete and more efficient degradation of the sludge particles. Such particles are held together by extracellular polymeric substances that come from cell autolysis, bacterial metabolic reactions, and wastewater itself. Researcher has recognized the potential for enzymatic treatment systems. Hence, enzymes are the ultimate molecules which deal with the dye compounds and bring about cleavage and successive degradation. The initial step in degrading the azo dye is to cleave the electrophilic azo linkage, which immediately causes decolorization. Azoreductase brings about the cleavage of azo linkages in compounds containing azo bond to produce aromatic amines. A large number of enzymes from different plants and microorganisms have been reported to play an important role in array of waste treatment applications. The enzymatic decolorization of industrial dyes was a big challenge due to large diversity of chemical structures (Wesenberg et al. 2003; Akhtar et al. 2005). Enzymes can act on specific recalcitrant pollutants to remove them by precipitation or transformation to other products (Akhtar and Husain 2006). Enzymatic approach has attracted much interest in the removal of phenolic pollutants from aqueous solutions (Duran and Esposito 2000). Oxidoreductive enzymes, polyphenol oxidases, and peroxidases are participating in the degradation/removal of aromatic pollutants from various contaminated sites (Husain and Jan 2000; Bhunia et al. 2001). Polyphenol oxidases can act on a broad range of substrates such as substituted polyphenols, aromatic amines, benzene thiols, and a series of other easily oxidizable compounds. Thus, they can catalyze the decolorization and decontamination of organic pollutants. White rot fungi were able to degrade dyes using lignin peroxidase (LiP) and manganese-dependent peroxidase (MnP) (Murugesan et al. 2007). Other enzymes used for this purpose include H2O2-producing enzymes, such as glucose-2-oxidase along with laccase and phenol oxidase enzyme (Husain 2010).

Decolorization of eight synthetic dyes including azo, anthraquinone metal complex, and indigo was examined in white rot fungi by peroxidase-catalyzed oxidation (Young and Yu 1997). The dyes were not decolorized by manganese-dependent peroxidase (MnP), and while above 80% color was removed by ligninase-catalyzed oxidation, further dye decolorization rate increased linearly with ligninase dosage (Lip). Some azo and heterocyclic dyes were almost completely degraded by P. chrysosporium in ligninolytic solution but decolorized to different extent (0–80%) by crude ligninase (Cripps et al. 1990). Peralta-Zamora et al. (1999) reported that enzymatic process promotes quick decolorization of the dye; nevertheless, maximum decolorization degree of about 30% is insignificant in relation to the decolorization degree achieved by the other processes. The enzymatic activity of four white rot fungi, viz., P. tremellosa, P. ostreatus, B. adusta, and C. versicolor, has the ability to produce ligninolytic enzymes, which decolorize dyes in artificial effluent (Robinson et al. 2001). Recently enzyme membrane reactors are emerging for wastewater treatment more specifically for dye decolorization (Lopez et al. 2002). In view of the potential of the enzymes in treating the phenolic compounds, several microbial and plant oxidoreductases have been employed for the treatment of dyes, but none of them has been exploited at large scale due to low enzymatic activity in biological materials and high cost of enzyme purification. In order to improve polyphenol oxidases activity and stability, enzyme immobilization technology has been applied. This technology is an effective means to make enzymes reusable and to improve its stability, which is considered as a promising method for the effective decolorization of dye effluents.

Further, immobilization of microbial biomass for dye removal in growth-restricted conditions is advantageous when the effluent has toxicity and does not promote cellular growth. Also, inactivated biomass does not require a continuous supply of nutrients and can be regenerated and reused in many cycles (Prigione et al. 2008). Immobilization can be of two types: entrapment and attachment. Entrapment means entrapment of microorganisms in the interstices of fibrous or porous material, whereas attachment means adherence of microorganisms on surfaces due to chemical bonding or self-adhesion (Couto and Toca Herrera 2007). Prigione et al. (2008) immobilized the conidial suspension of Cunninghamella elegans in calcium alginate beads. This immobilized biomass (300 g beads corresponding to 50 g biomass on wet weight basis) was then inactivated through autoclaving and packed in a glass column for treatment of synthetic dye-containing effluent. After 30 min, 70% decolorization and nearly complete decolorization were obtained after 6 h.

6.5 Reactors Studied in Dye Decolorization

The widely used systems were stirred tank reactor (Linko 1988), airlift and bubble column, fixed-bed bioreactor, rotating disk reactor (Kirk et al. 1986), packed-bed reactors (Feijoo et al. 1995), and silicone membrane reactor. Researcher also investigated continuous decolorization of an azo dye, orange II, in a packed-bed reactor (Zhang et al. 2009) and pulsed flow bioreactor packed (Mielgo et al. 2001), achieving high 97% and 90% decolorization efficiency, respectively, and up to 80% decolorization of a disperse dye (red-553) in a continuous (10–20 days) fixed-film bioreactor (Yang and Yu 2003).

Textile wastewater was treated by means of a fluidized-bed loop reactor and immobilized anaerobic bacteria at low hydraulic residence time of 6 h for a period of 3 months and achieved complete decolorization of the wastewater in addition to the production of methane-rich biogas. Furthermore, the effluent proved to be highly biodegradable by aerobic microbes (activated sludge), whereas Shah et al. (2012) reported the overall color, COD, and BOD removal in the stirred tank bioreactor system were 49.67%, 37.45%, and 33.89%, respectively, with 50 mg/L dye concentration, pH 6.6 ± 1, and HRT of 24 h in a reactor with 2 L capacity. The color removal efficiency in activated sludge process was 75 ± 10%, and around 50–70% of removed color was adsorbed on biomass or precipitated within the reactor. The color rejection of nano-filtration after biological treatment was almost complete and permeates color was always lower than 10 Pt–Co (Ayed et al. 2011). The performance of a bench-scale submerged microfiltration bioreactor using the white rot fungus Coriolus versicolor NBRC 9791 for treatment of textile dye wastewater was investigated with an average flux of 0.05 m/d (HRT = 15 h) for a month at controlled temperature and pH of 29 ± 1 °C and 4.5 ± 2.0, respectively (Hai et al. 2006)

Upflow Anaerobic Sludge Blanket (UASB) reactor, considered as high rate reactor, are generally more resistant to toxic compounds as a result of structure of formed granular sludge with good settling velocities and mechanical strength, and suitable for the treatment of wastewater containing xenobiotic and recalcitrant compounds, and it promotes adaptation of bacteria to the presence of toxic compounds, and as well as it can be used for treatment of wastewater previously considered unsuitable for anaerobic treatment (Jantsch et al. 2002; Harada et al. 1996; VanLier et al. 2001; Donlon et al. 1997). Synthetic textile wastewater containing three acid dyes was treated in UASB reactor system and achieved decolorization up to 89 ± 1.86% at 300 mg/L dye concentration.

Immobilized Phanerochaete chrysosporium decolorized 94% of the maxilon red dye in the trickle-bed reactor over a period of 4–5 days (Afzal et al. 2009), using the basal nitrogen-limited growth medium. Moreover, it continuously decolorized three different mixed azo dye effluents by greater than 90% in rotating tube bioreactor system over the 38-day operating period (Alleman et al. 1995; Kirby 1999) to investigate the remediation of actual textile effluent by P. chrysosporium. However, Phanerochaete sordida decolorized 80% of the phthalocyanine dye basic blue 22 in a rotating disk reactor operating with a retention time of 48 h (Yang et al. 2004) and 90.3% in 72 h for an initial reactive black 5 concentration of 100 mg/L on nylon sponge and sunflower seed shells (SS) in laboratory-scale bioreactors (Enayatizamir et al. 2011). Similarly, Blánquez et al. (2004) reported the biodegradation of Grey Lanaset G, a mixture of metal complex dyes, was studied in a reactor with the fungus Trametes versicolor. The ability to achieve 80% decolorization with Irpex lacteus to decolorize the remazol brilliant blue R and reactive orange 16 was reported by Pocedic et al. (2009).

Moreover, a fixed-bed bioreactor packed with Trametes pubescens was able to decolorize, for four successive cycles, 200 ml of a solution of the dye reactive black 5 at a concentration of 60 mg/L (Enayatzamir et al. 2009), and Casieri et al. (2008) have shown the efficiency of degradation of Bacillus adusta and Pseudomonas ostreatus against successive cycles of solutions containing 200, 1000, and 2000 mg/L of one model and two industrial dyes. Sponza and Isik (2005) reported the 96% color removal efficiencies of direct red 28 azo dye in a sequential upflow anaerobic sludge blanket reactor systems. The decolorization efficiency for malachite green was found to be 85.2% at pH in the range of 7–10, with increasing initial MG concentration up to 100 mg/L with immobilized P. pulmonicola YC32 continuous column system (Chen et al. 2009).

6.6 Microbial Consortia for Treatment of Textile Wastewater

In nature there is a diverse range of microorganisms and energy sources that makes it possible to break down a large number of different organic chemicals. Basically, microorganisms cannot mineralize most hazardous substances individually. So, the target pollutant being a complex molecule/mixture of compounds can only be broken down by a very specific combination of microorganisms (a “consortium”) and pathways. Therefore, the use of microbial consortia offers considerable advantages over the use of pure cultures in the degradation and decolorization of synthetic dyes. The individual strains may attack the dye molecule at different positions or may use the decomposition products produced by another strain for further decomposition. However, the composition of mixed cultures may change during the decomposition process interfering with the control of the system. The most commonly used consortium in activated sludge system is mainly constituted by bacteria in addition to the presence of fungi and protozoa.

Various researchers have examined the microbial consortium JW-2 (Moosvi et al. 2005) consisting of Paenibacillus polymyxa, Micrococcus luteus, and Micrococcus sp. completely decolorizes reactive violet 5R (100 mg L−1) within 36 h, and aerobic bacterial consortium SKB-II [Tony et al. 2009] comprised of Bacillus sp. decolorizes the azo dyes such as Congo red, Bordeaux, Ranocid fast blue, and blue BCC of 10 mg/L concentration each. Joshi et al. (2008) have investigated bacterial consortium that decolorizes acid orange 7 and consists of A. caviae P. mirabilis and R. globerulus. Further, a microbial consortium (comprising of two spp. of Bacillus and six spp. of fungi, viz., Aspergillus flavus, A. niger, A. fumigates, Cladosporium cladosporioides, Trichoderma harzianum, Fusarium oxysporum) isolated from the textile wastewater polluted habitats of Sanganer showed the 95% decolorization of 100 mg/L methyl red (Kumar et al. 2006). Similarly, significantly a higher reduction in color (90.14%) and COD removal (77.47%) from textile wastewater in less time (96 h) were achieved with the consortium comprises of Sphingomonas paucimobilis, Bacillus sp., and Staphylococcus epidermidis (Ayed et al. 2011). The variance in the microbial communities in these consortia might involve different mechanisms for dye decolorization.

Waghmode et al. (2012) reported the enhanced decolorization and degradation of azo dye rubine GFL (50 mg/l within 30 h) using defined consortium GG-BL of Galactomyces geotrichum MTCC 1360 yeast and Brevibacillus laterosporus MTCC 2298 bacterium, whereas individual cultures fail to completely decolorize the dye. The rate of decolorization of consortium AP was significantly higher than that of individual cultures. The increased decolorization rate might be due to the synergistic enzymes actions of both the organisms in the consortium. As researcher reported, the degradation of intermediates metabolites by bacteria could decline the fungal inhibition and thus enhances the decolorization efficiency of consortium (Gou et al. 2009). It is also known that the degradation products of one culture in the consortium may act as inducer for another co-culture, which results in the further mineralization of dye and metabolites (Chang et al. 2001; Forgacs et al. 2004). Similar findings were reported by Kurade et al. (2011), who observed higher decolorization rate of azo dye navy blue HE2R in solid state fermentation by developed consortium PA of Aspergillus ochraceus NCIM-1146 and Pseudomonas sp. SUK1.

6.7 Conclusions

This chapter concluded the effective decolorization of a wide variety of commercial textile dyes from simulated and real textile wastewater by the utilization of various types of microorganisms (bacteria, fungi, algae, and yeast) isolated from textile wastewater, sludge, and soil contaminated with textile effluent. Such microbes acclimatized themselves against the highly toxic dyes and make use of them for their growth with or without supplementing additional nutrients. This was also observed that a combination of different microorganisms (viz., bacterial-fungal, bacterial-algal and bacterial yeast, etc.) were more potent decolorizer than single pure cultures. Decolorization performance in reactor studies also confirmed the complete decolorization and degradation of toxic synthetic dyes with a small hydraulic residence time (HRT) and enhancing the efficiency of continuous reactor system. No doubt, bioremediation is considered to be one of the green approaches to clean the planet. Although advances in bioremediation techniques seem to be highly attractive, these technologies need scale-up trials in order to increase its market potential. Broader validation of these techniques and integration of different methods in the current treatment schemes will most likely, in the near future, render both efficient and economical viability.

In most cases, single technology fails to work in field due to various environmental factors associated and the toxicity of targeted compounds. Hence there is a need to develop hybrid technologies which can fit to ever-changing environmental conditions and toxicity of the compound. Researchers and scientists have been trying to develop a single and economical method for the treatment of dyes in the textile wastewater, but economical removal of color from effluent remains a big challenge. Thus, there is a necessity to develop better integrated technique to decolorize and completely mineralize the textile industrial effluent in spite of various successful systems of physicochemical techniques.

Most of the microbes are unculturable in laboratory condition, but their role in the particular niche cannot be neglected particularly in the process like bioremediation. In order to trace the microbial population and their role in the environment, molecular techniques prove to be a boon in this field. The genes involved in the bioremediation of the targeted compound and their respective enzymes can be traced, and hence in turn the microbial floras involved in the bioremediation process are traceable. It also helps to record the metabolic pathway followed by the organism to degrade the particular compounds.

References

Abraham CI, Kurup GM (2014) Decolorization of acid Orange 7 by selected bacterial strains isolated from dye contaminated industrial area. Scrutiny Inter Res J Biol Environ Sci 1(4):1–7

Afzal K, Farzaneh V, Majid M, Mehrnaz M (2009) Decolorization of maxilon-red by Kissiris immobilized Phanerochaete chrysosporium in a trickle bed bioreactor involvement of ligninolytic enzymes. Iran J Chem Chem Eng 28(2):1–13

Akdogan HA, Topuz MC, Urhan AA (2014) Studies on decolorization of reactive blue 19 textile dye by Coprinus plicatilis. J Environ Health Sci Eng 12:49–56

Akhtar S, Husain Q (2006) Potential applications of immobilized bitter gourd (Momordica charantia) peroxidase in the removal of phenols from polluted water. Chemosphere 65:1228–1235

Akhtar S, Khan AA, Husain Q (2005) Partially purified bitter gourd (Momordica charantia) peroxidase catalyzed decolorization of textile and other industrially important dyes. Bioresour Technol 96:1804–1811

Aksu Z (2005) Application of biosorption for the removal of organic pollutants: a review. Process Biochem 40:997–1026

Alalewi A, Jiang C (2012) Bacterial influence on textile wastewater decolorization. J Environ Prot 3:889–901

Ali N, Hameed A, Ahmed S (2009) Physicochemical characterization and bioremediation perspective of textile effluent, dyes and metals by indigenous bacteria. J Hazard Mater 164:322–328

Alleman BC, Logan BE, Gilbertson RL (1995) Degradation of pentachlorophenol by fixed films of white rot fungi in rotating tube bioreactors. Water Res 29:61–67

Anwar F, Hussain S, Ramzan S, Hafeez F, Arshad M, Imran M, Maqbool Z, Abbas N (2014) Characterization of reactive red-120 decolorizing bacterial strain Acinetobacter junii FA10 capable of simultaneous removal of azo dyes and hexavalent chromium. Water Air Soil Pollut 225:2017–2023

Asgher M, Yasmeen Q, Nasir Iqbal HM (2013) Enhanced decolorization of solar brilliant red 80 textile dye by an indigenous white rot fungus Schizophyllum commune IBL-06. Saudi J Biol Sci 20(4):347–352

Ayed L, Achour S, Bakhrouf A (2011) Application of the mixture design to decolourise effluent textile wastewater using continuous stirred bed reactor. Water SA 37(1):21–26

Balamurugan B, Thirumarimurugan M, Kannadasan T (2011) Anaerobic degradation of textile dye bath effluent using Halomonas sp. Bioresour Technol 102:6365–6369

Banat JW, Faison BD (1999) Use of fungi in biodegradation. In: Hurst CJ (ed) Manual of environmental microbiology. ASM Press, Washington, DC, pp 758–765

Banat IM, Nigam P, Singh D, Marchant R (1996) Microbial decolorization of textile-dye-containing effluents: a review. Bioresour Technol 58:217–227

Bergsten-Torralba LR, Nishikava MM, Baptista DF, Megalhaes DP, daSilva M (2009) Decolorization of different textile dyes by Penicillium simplicissimum and toxicity evaluation after fungal treatment. Braz J Microbiol 40:808–817

Beydilli MI, Pavlostathis SG, Tincher WC (1998) Decolorization and toxicity screening of selected reactive azo dyes under methanogenic conditions. Water Sci Technol 38(4–5):225–232

Bhunia A, Durani S, Wangikar PP (2001) Horseradish peroxidase catalyzed degradation of industrially important dyes. Biotechnol Bioeng 72(5):562–567

Blánquez P, Casas N, Font X, Gabarrell M, Sarrá M, Caminal G (2004) Mechanism of textile metal dye biotransformation by Trametes versicolor. Water Res 38:2166–2172

Borchert M, Libra JA (2001) Decolorization of reactive dyes by the white rot fungus Trametes versicolor in sequencing batch reactors. Biotechnol Bioeng 75(3):313–321

Casieri L, Varese GC, Anastasi A, Prigione V, Svobodova K, Filippelo Marchisio V, Novotny NS (2008) Decolorization and detoxication of reactive industrial dyes by immobilized fungi Trametes pubescens and Pleurotus ostreatus. Folia Microbiol 53(1):44–52

Cetin D, Donmez G (2006) Decolorization of reactive dyes by mixed cultures isolated from textile effluent under anaerobic conditions. Enzym Microb Technol 38:926–930

Chakraborty S, Basak B, Dutta S, Bhunia B, Dey A (2013) Decolorization and biodegradation of Congo red dye by a novel white rot fungus Alternaria alternata CMERI F6. Bioresour Technol 147:662–666

Chang JS, Chou C, Chen SY (2001) Decolorization of azo dyes with immobilized Pseudomonas luteola. Process Biochem 36:757–763

Chen KC, Wua JY, Liou-Sz DJ, Hwang J (2003) Decolorization of the textile dyes by newly isolated bacterial strains. J Biotechnol 101:57–68

Chen CY, Kuo JT, Cheng CY, Huang YT, Ho IH, Chung YC (2009) Biological decolorization of dye solution containing malachite green by Pandoraea pulmonicola YC32 using a batch and continuous system. J Hazard Mater 172:1439–1445

Chen G, Huang MH, Chen L, Chen D (2011) A batch decolorization and kinetic study of reactive black 5 by a bacterial strain Enterobacter sp. GY-1. Int J Biodeterior Biodegrad 65:790–796

Couto SR, Toca Herrera JL (2007) Laccase production at reactor scale by filamentous fungi. Biotechnol Adv 25:558–569

Cripps C, Bumpus JA, Aust SD (1990) Biodegradation of azo and heterocyclic dyes by Phanerochaete chrysosporium. Appl Environ Microbiol 56(4):1114–1118

Daneshvar N, Ayazloo M, Khataee AR, Pourhassan M (2007) Biological decolorization of dye solution containing malachite green by microalgae Cosmarium sp. Bioresour Technol 98:1176–1182

Dayaram P, Dasgupta D (2008) Decolorisation of synthetic dyes and textile wastewater using Polyporus rubidus. J Environ Biol 29(6):831–836

Donlon B, Razo-Flores E, Luijten M, Swarts H, Lettinga J, Field J (1997) Detoxification and partial mineralization of the azo dye mordant orange 1 in a continuous upflow anaerobic sludge-blanket reactor. Appl Microbiol Biotechnol 47:83–90

Dos Santos AB, deMadrid MP, Stams AJ, VanLier JB, Cervantes FJ (2005) Azo dye reduction by mesophilic and thermophilic anaerobic consortia. Biotechnol Prog 21(4):1140–1145

Duran N, Esposito E (2000) Potential applications of oxidative enzymes and phenol oxidase-like compounds in wastewater and soil treatment: a review. Appl Catal B 8(2):83–99

Elisangela F, Andrea Z, Fabio DG, deMenezes CR, Regina DL, Artur CP (2009) Biodegradation of textile azo dyes by a facultative Staphylococcus arlettae strain VN-11 using a sequential microaerophilic/aerobic process. Int Biodeterior Biodegrad 63:280–288

El-Kassas HY, Mohamed LA (2014) Bioremediation of the textile waste effluent by Chlorella vulgaris. Egypt J Aqua Res 40(3):301–308

El-Sersy NA (2007) Bioremediation of methylene blue by Bacillus thuringiensis 4G1: application of statistical design and surface plots for optimization. Biotechnology 6(1):34–39

Enayatizamir N, Tabandeh F, Rodríguez-Couto S, Yakhchali B, Alikhani HA, Mohammadi L (2011) Biodegradation pathway and detoxification of the diazo dye reactive black 5 by Phanerochaete chrysosporium. Bioresour Technol 102:10359–10362

Enayatzamir K, Alikhani HA, Couto SR (2009) Simultaneous production of laccase and decolouration of the diazo dye reactive black 5 in a fixed-bed bioreactor. J Hazard Mater 164:296–300

Ertugrul S, Bakir M, Donmez G (2008) Treatment of dye rich wastewater by an immobilized theromophilic cyanobacterial strain: Phormidium sp. Ecol Eng 32(3):244–224

Feijoo G, Soto M, Mendez R, Lema JM (1995) Sodium inhibition in the anaerobic digestion process. Antagonism and adaptation phenomena. Enzym Microb Technol 17:180–188

Forgacs E, Cserháti T, Oros G (2004) Removal of synthetic dyes from wastewaters: a review. Environ Int 30(7):953–971

Franciscon E, Zille A, Fantinatti-Garboggini F, Silva IS, Cavaco-Paulo A, Durrant LR (2009) Microaerophillic-aerobic sequential decolorization/biodegradation of textile azo dyes by a facultative Klebsiella sp. strain VN-31. Process Biochem 44:446–452

Franciscon E, Grossman MJ, Paschoal JAR, Reyes FGR, Durrant LR (2012) Decolorization and biodegradation of reactive sulfonated azo dyes by a newly isolated Brevibacterium sp. strain VN-15. Springerplus 1:37–46

Gajare SM, Menghani S (2012) Biosorption of malachite green by naturally grown algal biomass from Girna river, Jalgaon District, Maharashtra. J Algal Biomass Util 3(4):60–65

Garg SK, Tripathi M, Singh SS, Tiwari JK (2012) Biodecolorization of textile dye effluent by Pseudomonas putida SKG-1 (MTCC 10510) under the conditions optimized for monoazo dye orange II color removal in simulated minimal salt medium. Int Biodeterior Biodegrad 74:24–35

Ghodake G, Jadhav S, Dawkar V, Govindwar S (2009) Biodegradation of diazo dye direct brown MR by Acinetobacter calcoaceticus NCIM 2890. Int Biodeterior Biodegrad 63:433–439

Gou M, Qu Y, Zhou J, Ma F, Tan L (2009) Azo dye decolourization by a new fungal isolate, Penicillium sp QQ and fungal-bacterial cocultures. J Hazard Mater 170:314–319

Hai FI, Yamamoto K, Fukushi K (2006) Development of a submerged membrane fungi reactor for textile wastewater treatment. Desalination 192(1–3):315–322

Hao JO, Kim H, Chiang PC (2000) Decolorization of wastewater. Crit Rev Environ Sci Technol 30(4):449–505

Harada H, Uemura S, Chen AC, Jayadevan J (1996) Anaerobic treatment of a recalcitrant distillery wastewater by a thermophilic UASB reactor. Bioresour Technol 55(3):215–221

Hema N, Suresha S (2014) Bioremediation of textile dye effluent by Shewanella putrefaciens. Int J Pharm Bio Sci 4(2):109–116

Henciya S, Murali S, Malliga P (2013) Decolorization of textile dye effluent by marine cyanobacterium Lyngbya sp. BDU 9001 with coir pith. Int J Environ Sci 3(6):1909–1918

Husain Q (2010) Peroxidase mediated decolorization and remediation of wastewater containing industrial dyes: a review. Rev Environ Sci Biotechnol 9(2):117–140

Husain Q, Jan U (2000) Detoxification of phenols and aromatic amines from polluted wastewater by using phenol oxidases. J Sci Ind Res 59(4):286–293

Hussain S, Maqbool Z, Ali S, Yasmeen T, Imran M, Mahmood F, Abbas F (2013) Biodecolorization of reactive black-5 by a metal and salt tolerant bacterial strain Pseudomonas sp. RA20 isolated from Paharang drain effluents in Pakistan. Ecotoxicol Environ Saf 98:331–338

Isik M, Sponza DT (2003) Effect of oxygen on decolorization of azo dyes by E. coli and Psedomonas sp. and fate of aromatic amines. Process Biochem 38(8):1183–1192

Jadhav UU, Dawkar VV, Ghodake GS, Govindwar SP (2008) Biodegradation of direct red 5B, a textile dye by newly isolated Comamonas sp. UVS J Hazard Mater 158:507–516

Jantsch TG, Angelidaki I, Schmidt JE, BE B dH, Ahring BK (2002) Anaerobic biodegradation of spent sulphite liquor in a UASB reactor. Bioresour Technol 84:15–20

Jin XC, Liu GQ, Xu ZH, Tao WY (2007) Decolorization of a dye industry effluent by Aspergillus fumigatus XC6. Appl Microbiol Biotechnol 74:239–243

Jinqui L, Houtian L (1992) Degradation of azo dyes by algae. Environ Pollut 75:273–278

Joe J, Kothari RK, Raval CM, Kothari CR, Akbari VG, Singh SP (2011) Decolorization of textile dye remazol black B by Pseudomonas aeruginosa CR-25 isolated from the common effluent treatment plant. J Bioenerg Biomembr 2:118–123

Joshi M, Bansal R, Purwar R (2004) Color removal from textile effluent. Indian J Fiber Text Res 29:239–359

Joshi T, Iyengar L, Singh K, Garg S (2008) Isolation, identification and application of novel bacterial consortium TJ-1 for the decolourization of structurally different azo dyes. Bioresour Technol 99:7115–7121

Joshi B, Kabariya K, Nakrani S, Khan A, Parabia FM, Doshi HV, Thakur MC (2013) Biodegradation of turquoise blue dye by Bacillus megaterium isolated from industrial effluent. Am J Environ Prot 1(2):41–46

Kalme SD, Parshetti GK, Jadhav SU, Govindwar SP (2007) Biodegradation of benzidine based dye direct blue-6 by Pseudomonas desmolyticum NCIM 2112. Bioresour Technol 98(7):1405–1410

Kalpana D, Velmurugan N, Shim JH, Oh BT, Senthil K, Lee YS (2012) Biodecolorization and biodegradation of reactive levafix blue E-RA granulate dye by the white rot fungus Irpex lacteus. J Environ Manag 111:142–149

Kalyani DC, Telke AA, Dhanve R, Jadhav JP (2009) Ecofriendly biodegradation and detoxification of reactive red 2 textile dye by newly isolated Pseudomonas sp. SUK1. J Hazard Mater 163:735–742

Karthik V, Saravanan K, Thomas T, Devi M (2014) Review on microbial decolourisation of textile dyes. J Chem Pharm Sci 7(3):393–300

Kaushik P, Malik A (2009) Microbial decolorization of textile dyes through isolates obtained from contaminated sites. J Sci Ind Res 68:325–331

Khataee AR, Pourhassan M, Ayazloo M (2009) Biological decolorization of CI basic green 4 solution by Chlorella sp. effect of operation parameters. Chin J Appl Environ Biol 15(1):110–114

Khataee AR, Zarei M, Dehghan G, Ebadi E, Pourhassan M (2011) Biotreatment of a triphenylmethane dye solution using a Xanthophyta alga: modeling of key factors by neural network. J Taiwan Inst Chem Eng 42:380–386

Kirby N (1999) Bioremediation of textile industry wastewater by white-rot fungi. Ph.D. thesis, University of Ulster, UK

Kirk TK, Croans TM, Murtagah KE, Farrell RL (1986) Production of multiple ligninases by Phanerochaete chrysosporium: effect of selected growth conditions and use of a mutant strain. Enzym Microb Technol 8:27–32

Krishnaveni M (2011) Characterization and decolorization of dye and textile effluent by laccase from Pluerotusflorida – a white rot fungi. Int J Pharm Bio Sci 2(1):913–918

Kumar S, Sharma KP, Sharma S, Grover R, Kumar P, Soni P, Sharma S (2006) Optimization of microbial degradation of an azo dye (methyl red) in fixed film bioreactors. Indian J Biotechnol 5:68–75

Kurade MB, Waghmode TR, Govindwar SP (2011) Preferential biodegradation of structurally dissimilar dyes from a mixture by Brevibacillus laterosporus. J Hazard Mater 190(1–3):424–431

Levin L, Papinutii L, Forchiassin F (2004) Evaluation of Argentinean white rot fungi for their ability to produce lignin-modifying enzymes and decolorize industrial dyes. Bioresour Technol 94(2):169–175

Li T, Guthrie JT (2010) Colour removal from aqueous solutions of metal-complex azo dyes using bacterial cells of Shewanella strain J18 143. Bioresour Technol 101:4291–4295

Linko S (1988) Production and characterization of extracellular lignin peroxidase from immobilized Phanerochaete chrysosporium in a 10–l bioreactor. Enzym Microb Technol 10:410–417

Liu JQ, Liu HT (1992) Degradation of azo dyes by algae. Environ Pollut 75:273–278

Loncˇar N, Nataša Bozˇic N, Josep Lopez-Santin J, Zoran Vujcˇic Z (2013) Bacillus amyloliquefaciens laccase – from soil bacteria to recombinant enzyme for wastewater decolorization. Bioresour Technol 147:177–183

Lopez C, Mielgo I, Moreira MT, Feijoo G, Lema JM (2002) Enzymatic membrane reactors for biodegradation of recalcitrant compounds. J Biotechnol 99:249–257

Mabrouk MEM, Yusef HH (2008) Decolorization of fast red by Bacillus subtilis HM. J Appl Sci Res 4(3):262–269

Maier J, Kandelbauer A, Erlacher A, Cavaco-Paulo A, Gübitz GM (2004) A new alkali-thermostable azoreductase from Bacillus sp. strain SF. Appl Environ Microbiol 70(2):837–844

Mali PL, Mahajan MM, Patil DP, Kulkarni MV (2000) Biodecolorization of members of triphenyl methane and azo group of dyes. J Sci Ind Res 59:221–224

McMullan G, Meehan C, Conneely A, Kirby N, Robinson T, Nigam P, Banat IM, Marchant R, Smyth WF (2001) Microbial decolourisation and degradation of textile dyes. Appl Microbiol Biotechnol 56(1-2):81–87

Meng X, Liu G, Zhou J, Fu QS, Wang G (2012) Azo dye decolorization by Shewanella aquimarina under saline conditions. Bioresour Technol 114:95–101

Mielgo I, Moreira MT, Feijoo G, Lema JM (2001) A packed bed fungal bioreactor for the continuous decolourisation of azo dyes (Orange II). J Biotechnol 89:99–106

Mohammadian MF, Mesdaghinia AR, Naddafi K, Nasseri S, Yunesian M, Mazaheri AM, Rezaie S, Hamzehei H (2010) Optimization of reactive blue 19 decolorization by Ganoderma sp. using response surface methodology. Iran J Environ Health Sci Eng 7(1):35–42

Mohana S, Shrivastava S, Divecha J, Madamwar D (2008) Response surface methodology for optimization of medium for decolorization of textile dye direct black 22 by a novel bacterial consortium. Bioresour Technol 99:562–569

Moosvi S, Keharia H, Madamwar D (2005) Decolorization of textile dye reactive violet 5 by a newly isolated bacterial consortium RVM 11.1. World J Microbiol Biotechnol 21:667–672

Moosvi S, Kher X, Madamwar D (2007) Isolation characterization and decolorization of textile dyes by a mixed bacterial consortium JW-2. Dyes Pigments 74(723):729

Moutaouakkil A, Zeroual Y, Dzayri FZ, Talbi M, Lee K, Blaghen M (2003) Bacterial decolorization of the azo dye methyl red by Enterobacter agglomerans. Ann Microbiol 53:161–169

Mtui GYS (2007) Characteristics and dyes biodegradation potential of crude lignolytic enzymes from white-rot fungus Crepidotus variabilis isolated in coastal Tanzania. Tanzan J Sci 33:79–81

Murugesan K, Kalaichelvan PT (2003) Synthetic dye decolourization by white rot fungi. Indian J Exp Biol 41(9):1076–1087

Murugesan K, Nam IH, Kim YM, Chang YS (2007) Decolorization of reactive dyes by a thermostable laccase produced by Ganoderma lucidum in solid state culture. Enzym Microb Technol 40:1662–1672

Nagarathnamma R, Bajpai P, Bajpai PK (1999) Studies on decolorization and detoxificate of chlorinated lignin compounds in kraft bleaching effluent by Ceripriopsis Subvermisporre. Process Biochem 334:939–948

Namdhari BS, Rohilla SK, Salar RK, Gahlawat SK, Bansal P, Saran AK (2012) Decolorization of reactive blue MR, using Aspergillus species isolated from textile waste water. ISCA J Biol Sci 1(2):24–29

Nigam P, Armour G, Banat IM, Singh D, Marchant R (2000) Physical removal of textile dyes from effluents and solid-state fermentation of dye-adsorbed agricultural residues. Bioresour Technol 72:219–226

Nyanhongo GS, Gomes J, ubitz GMG, Zvauya R, Read J, Steiner W (2002) Decolorization of textile dyes by laccases froma newly isolated strain of Trametes modesta. Water Res 36:1449–1456

Ogugbue CJ, Sawidis T (2011) Bioremediation and detoxification of synthetic wastewater containing triarylmethane dyes by Aeromonas hydrophila isolated from industrial effluent. Biotechnol Res Int 11:1–11

Ola IO, Akintokun AK, Akpan I, Omomowo IO, Areo VO (2010) Aerobic decolourization of two reactive azo dyes under varying carbon and nitrogen source by Bacillus cereus. Afr J Biotechnol 9(5):672–677

Olukanni OD, Osuntoki AA, Gbenle GO (2009) Decolourization of azo dyes by strain of Micrococcus isolated from a refuse dump soil. Biotechnology 8:442–448

Olukanni OD, Osuntoki A, Kalyani D, Govindwar SP (2010) Decolorization and biodegradation of reactive blue 13 by Proteus mirabilis LAG. J Hazard Mater 184(1–3):290–298

Omar HH (2008) Algal decolorization and degradation of monoazo and diazo dyes. Pak J Biol Sci 11(10):1310–1316

Ozer A, Akkaya G, Turabik M (2006) The removal of acid red 274 from wastewater: combined biosorption and biocoagulation with Spirogyra rhizopus. Dyes Pigments 71(2):83–89

Palamthodi S, Patil D, Patil Y (2011) Microbial degradation of textile industrial effluents. Afr J Biotechnol 10(59):12687–12691

Pandey AK, Dubey V (2012) Biodegradation of azo dye reactive red BL by Alcaligenes sp. AA09. Int J Eng Sci 1(12):51–60

Parshetti GK, Parshetti SG, Telke AA, Kalyani DC, Doong RA, Govindwar SP (2011) Biodegradation of crystal violet by Agrobacterium radiobacter. J Environ Sci 23(8):1384–1393

Pazarlioglu NK, Urek RQ, Ergun F (2005) Biodecolourization of direct blue 15 by immobilized Phanerochaete chrysosporium. Process Biochem 40:1923–1929

Pearce CI, Lloyd JR, Guthrie JT (2003) The removal of colour from textile wastewater using whole bacterial cells: a review. Dyes Pigments 58:179–196

Peralta-Zamora P, Kunz A, Moraes SG, Pelegrini R, Moleiro PD, Reyes J (1999) Degradation of reactive dyes: a comparative study of ozonation, enzymatic and photochemical processes. Chemosphere 38(4):835–852

Pocedic J, Hasal P, Novotný Ý (2009) Decolorization of organic dyes by Irpex lacteus in a laboratory trickle-bed biofilter using various mycelium supports. J Chem Technol Biotechnol 84:1031–1042

Pokharia A, Ahluwalia SS (2012) Decolorization of black WNN dye with Staphylococcus epidermidis MTCC 10623. Curr Trends Biotechnol Chem Res 2(2):65–73

Pourbabaee AA, Malekzadeh F, Sarbolouki MN, Najafi F (2006) Aerobic decolorization and detoxification of a disperse dye in textile effluent by a new isolate of Bacillus sp. Biotechnol Bioeng 93:631–635

Prasad A, Bhaskara Rao KV (2011) Physico-chemical analysis of textile effluent and decolorization of textile azo dye by Bacillus endophyticus strain. VITABR 2(2):55–62

Prigione V, Tigini V, Pezzella C, Anastasi A, Sannia G, Varese GC (2008) Decolourisation and detoxification of textile effluents by fungal biosorption. Water Res 42:2911–2920

Ramsay J, Maria Shin M, Wong S, Goode C (2006) Amaranth decoloration by Trametes versicolor in a rotating biological contacting reactor. J Ind Microbiol Biotechnol 33:791–795

Ramya M, Anusha B, Kalavathy S, Devilaksmi S (2007) Biodecolourization and biodegradation of reactive blue by Aspergillus sp. Afr J Biotechnol 6:1441–1445

Ramya M, Iyappan S, Manju A, Jiffe JS (2010) Biodegradation and decolorization of acid red by Acinetobacter radioresistens. J Bioenerg Biomembr 1(1):1–6

Robinson T, McMullan G, Marchant R, Nigam P (2001) Remediation of dyes in textile effluent: a critical review on current treatment technologies with a proposed alternative. Bioresour Technol 77:247–255

Santos AB, Cervantes FJ, Lier JB (2007) Review paper on current technologies for decolourisation of textile waste waters: perspectives for anaerobic biotechnology. Bioresour Technol 98:2369–2385

Saratale RG, Saratale GD, Chang JS, Govindwar SP (2010) Decolorization and biodegradation of reactive dyes and dye wastewater by a developed bacterial consortium. Biodegradation 21(6):999–1015

Saratale RG, Gandhi SS, Purankar MV, Kurade MB, Govindwar SP, Oh SE, Saratale GD (2013) Decolorization and detoxification of sulfonated azo dye C.I. Remazol red and textile effluent by isolated Lysinibacillus sp. RGS. J Biosci Bioeng 115(6):658–667

Schliephake K, Mainwaring DE, Lonergan GT, Jones IK, Baker WL (2000) Transformation and degradation of the disazo dye Chicago sky blue by a purified laccase from Pyccnoporus cinnabarinus. Enzym Microb Technol 27(1–2):100–107

Selvam K, Swaminathan K, Chae KS (2003a) Decolourization of azo dyes and a dye industry effluent by white rot fungus Thelephora sp. Bioresour Technol 88:115–119

Selvam K, Swaminathan K, Keo-Sang C (2003b) Microbiol decolorization of azo dyes and dye industry effluent by Fomes lividus. World J Microbiol Biotechnol 19:591–593

Shah PD, Dave SR, Rao MS (2012) Enzymatic degradation of textile dye reactive Orange 13 by newly isolated bacterial strain Alcaligenes faecalis PMS-1. Int Biodeterior Biodegrad 69:41–50

Shah MP, Patel KA, Nair SS, Darji AM (2013) Microbial decolorization of methyl Orange dye by Pseudomonas spp. ETL-M Int J Environ Bioremed Biodegrad 1(2):54–59

Shertate RS, Thorat PR (2013) Biotransformation of a textile azo dye acid yellow 25 by Marinobacter gudaonensis AY-13. J Eng Comput Appl Sci 2(4):35–45

Singh RP, Singh PK, Singh RL (2014) Bacterial decolorization of textile azo dye acid Orange by Staphylococcus hominis RMLRT03. Toxicol Int 21(2):160–167

Sponza DT, Isik M (2005) Reactor performances and fate of aromatic amines through decolorization of direct black 38 dye under anaerobic/aerobic sequentials. Process Biochem 40:35–44

Srikanlayanukul M, Kitchwechkun W, Watanabe T, Khanongnuch C (2008) Decolorization of orange II by immobilized thermotolerent white rot fungi Coriolus versicolor RC3 in packed- bed bioreacter. Biotechnology 7(2):280–286

Swamy J, Ramsay JA (1999) The evaluation of white rot fungi in the decoloration of textile dyes. Enzym Microb Technol 24(3–4):130–137

Tan L, Ning S, Zhang X, Shi S (2013) Aerobic decolorization and degradation of azo dyes by growing cells of a newly isolated yeast Candida tropicalis TL-F1. Bioresour Technol 138:307–313

Telke A, Kalyani D, Jadhav J, Govindwar S (2008) Kinetics and mechanism of reactive red 141 degradation by a bacterial isolate Rhizobium radiobacter MTCC 8161. Acta Chim Slov 55:320–329

Tony BD, Goyal D, Khanna S (2009) Decolorization of textile azo dyes by aerobic bacterial consortium. Int Biodeterior Biodegrad 63:462–469

Van Lier JB, Van ZFP d, NCG T, Rebac S, Kleerebezem R (2001) Advances in high-rate anaerobic treatment: staging of reactor systems. Water Sci Technol 44:15–25

Verkata Mohan S, Ramanjah SV, Sarma PN (2008) Biosorption of direct azo dye from aqueous phase onto Spirogyra sp. I02: evaluation of kinetics and mechanistic aspects. Biochem Eng J 38:61–69

Waghmode TR, Kurade MB, Kalagalkar AN, Govindwar SP (2012) Differential fate of metabolism of a disperse dye by microorganisms Galactomyces geotrichum and Brevibacillus laterosporus and their consortium GG-BL. J Environ Sci 24(7):1295–1304

Wang H, Su JQ, Zheng XW, Tian Y, Xiong XJ, Zheng TL (2009) Bacterial decolorization and degradation of the reactive dye reactive red 180 by Citrobacter sp. CK3. Int Biodeterior Biodegrad 63:395–399

Wen-Tung W, Ming-Der J (2012) Evaluation of light irradiation on decolorization of azo dyes by Tsukamurella sp. J8025. Appl Mech Mater 145:304–308

Wesenberg D, Buchon F, Agatho SN (2002) Degradation of dye-containing textile effluent by the agaricus white-rot fungus Clitocybula dusenii. Biotechnol Lett 24:989–993

Willmott N, Guthrie J, Nelson G (1998) The biotechnology approach to color removal from textile effluent. J Soc Dye Colour 114:38–41

Wong PK, Yuen PY (1996) Decolorization and biodegradation of methyl red by Klebsiella phemonial RS-13. Water Res 30:1736–1744

Yang FC, Yu JT (2003) Development of a bioreactor system using an immobilized white rot fungus for decolorization. Bioprocess Eng 15:307–310

Yang G, Liu Y, Kong Q (2004) Effect of environmental factors on dye decolorization by P. sordida ATCC 90872 in an aerated reactor. Process Biochem 39:1401–1405

Younes SB, Bouallagui Z, Sayad S (2012) Catalytic behavior and detoxifying ability of an a typical homotrimeric laccase from the thermophilic strain Scytalidium thermophilum on selected azo and triarylmethane dyes. J Mol Catal B Enzym 79:41–48

Young L, Yu J (1997) Ligninase-catalyzed decolorization of synthetic dyes. Water Res 31:1187–1193

Zeng X, Cai Y, Liao X, Zeng X, Luo S, Zhang D (2012) Anthraquinone dye assisted the decolorization of azo dyes by a novel Trametes trogii laccase. Process Biochem 47:160–163

Zhang FM, Knapp JS, Tapley K (2009) Development of bioreactor system for decolorization of Orange II using white rot fungus. Enzym Microb Technol 24:48–53

Zissi U, Lyberatos G (2001) Partial degradation of p-aminoazobenzene by a defined mixed culture of Bacillus subtilis and Stenotrophomonas maltophilia. Biotechnol Bioeng 72(1):49–54

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Pokharia, A., Ahluwalia, S.S. (2017). Bioremediation Technologies for Decolorization of Effluent. In: Kumar, R., Sharma, A., Ahluwalia, S. (eds) Advances in Environmental Biotechnology. Springer, Singapore. https://doi.org/10.1007/978-981-10-4041-2_6

Download citation

DOI: https://doi.org/10.1007/978-981-10-4041-2_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-4040-5

Online ISBN: 978-981-10-4041-2

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)