Abstract

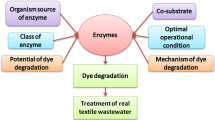

In this article an effort has been made to review literature based on the role of peroxidases in the treatment and decolorization of a wide spectrum aromatic dyes from polluted water. Peroxidases can catalyze degradation/transformation of aromatic dyes either by precipitation or by opening the aromatic ring structure. Peroxidases from plant sources; horseradish, turnip, tomato, soybean, bitter gourd, white radish and Saccharum uvarum and microbial sources; lignin peroxidases, manganese peroxidases, vanadium haloperoxidases, versatile peroxidases, dye decolorizing peroxidases have been employed for the remediation of commercial dyes. Soluble and immobilized peroxidases have been successfully exploited in batch as well as in continuous processes for the treatment of synthetic dyes with complex aromatic molecular structures present in industrial effluents at large scale. However, recalcitrant dyes were also decolorized by the action of peroxidases in the presence of redox mediators.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Since 1856, when the first synthetic dye was reported, the use of dyes in industries and household has increased remarkably. There are more than 10,000 dyes available commercially and about 7 × 105 metric tons of dyestuffs are produced annually (Zollinger 1991; Aksu and Tezer 2005). The main consumers of dyes are the textile, plastic, tannery, paper and pulp and electroplating industries (Rai et al. 2005). Dyes are also used as additives in petroleum products. In addition to above mentioned applications of dyes, a number of dyes and dyestuffs are also used in the food, pharmaceutical and cosmetic industries (Harazono and Nakamura 2005). The huge growth in the textile dyeing and dyestuff manufacturing industries has resulted in an immense increase in the volume and complexity of the wastewater discharged to the environment. During textile processing, inefficiencies in dyeing resulted in a large amount of dyestuff being directly lost in wastewater, which ultimately finds its way into the environment. Most of the used dyes lost about 15–20% in the effluent during dyeing processes while in the case of reactive dyes, as much as 50% of the initial dye load moved to the dye bath effluent (Azmi and Banerjee 2001). The presence of even very low concentrations of dyes in effluent is highly visible and undesirable (Hao et al. 2000).

Intensive industrial and agricultural activities during twentieth century have led to a considerable contamination of soil and water by toxic organic pollutants, which may have catastrophic impact on human health and environment (Torres et al. 2003; Bhole et al. 2004). Like the climate change issues, biodiversity and increasing municipal waste generation, these ‘‘red lights’’ signal pressures on the environment for which urgent measures are needed. Among the industrial effluents, wastewater from textile and dyestuff industries is one of the most difficult to treat. This is because dyes usually have synthetic and complex aromatic molecular structures, which make them more stable and difficult to degrade (Padmesh et al. 2005). Dye effluent usually contains chemicals, including dye itself that may be toxic, mutagenic or carcinogenic to various microbiological and aquatic animals. Concern arises, as several dyes are made of known carcinogens such as benzidine and other aromatic compounds (Robinson et al. 2001). It has been reported that azo and nitro compounds have reduced in sediments of aquatic bodies, consequently yielded potentially carcinogenic amines that spread in the ecosystem (Verma et al. 2003). The presence of dyes or their degraded products in water can also cause human health disorders such as nausea, hemorrhage, ulceration of skin and mucous membranes and the presence of such compounds also resulted into severe damage to the kidney, reproductive system, liver, brain and central nervous system. These concerns have led to new and stricter regulations related to colored wastewater discharges, compelling the dye manufacturers and users to adopt “cleaner technology” approaches, for instance, development of new lines of ecologically safe dyeing auxiliaries and improvement of exhaustion of dyes onto fiber (Hao et al. 2000; Rott 2003; Hai et al. 2007).

2 Chemical and physical methods for dye decolorization

Water pollution control is presently one of the major thrust areas of scientific research. However, the colored organic compounds generally impart only a minor fraction of the organic load to wastewaters but their color renders them aesthetically unacceptable (Anjaneyulu et al. 2005). Stringent regulations have been imposed on industries to treat their waste effluents prior to their final discharge in the environment. Several decolorization techniques have been reported during past two decades, but very few of them have been accepted by some industries.

3 Biological methods for dye decolorization and their limitations

Biological processes have attracted as an viable aleternative to the known chemico-physical methods due to their cost, effectiveness and environmental benignity (McMullan et al. 2001; Chen et al. 2003). These processes have potential to mineralize dyes to harmless inorganic compounds like CO2, H2O and the formation of a lesser quantity of relatively insignificant amount of sludge (Mohan et al. 2002). Many researchers have demonstrated partial or complete biodegradation of dyes by pure or mixed cultures of bacteria, fungi and algae. Numerous types of microorganisms have been isolated in recent years that are able to degrade dyes previously considered non-degradable (Stolz 2001; Nyanhongo et al. 2002). Biological treatment for degradation of textile effluents may be aerobic, anaerobic or combination of both depending on the type of microorganism being employed (Keharia and Madamvar 2003).

Chung et al. (1978) have reported that the bacterial (Bacillus subtilis) cultures were capable of degrading azo dyes. Later on the use of different other bacteria in the decolorization of dyes have also been demonstrated. Several investigators have shown that mixtures of dyes were decolorized by anaerobic bacteria in 24–30 h, using free growing cells or in the form of biofilms on various support materials (Robinson et al. 2001). Pearce et al. (2003) described the use of whole bacterial cells for the reduction of water-soluble dyes present in textile effluents. Moreover, bacteria including Citrobacter sp., Kurthia sp., Corneybacterium and Mycobacterium sp. and a mixed culture consisting of Pseudomonas mendocina and Pseudomonas alcaligenes could also successfully degrade triphenylmethane dyes from solution (Rai et al. 2005). Parshetti et al. (2006) evaluated that Malachite Green (C.I. Basic Green 4; 50 mg l−1) was completely decolorized under static anoxic conditions within 5 h by bacteria Kocuria rosea MTCC 153. It has been reported that Kocuria rosea cells have potential to decolorize azo, triphenylmethane and other industrial dyes; Cotton Blue, Methyl Orange (Acid Orange 52), Reactive Blue 25, Direct Blue 6, Reactive Yellow 81 and Red HE4B. Sulfonated azo dyes were decolorized by two wild type photosynthetic bacterial strains (Rhodobacter sphaeroides AS1.1737 and Rhodopseudomonas palustris AS1.2352) and a recombinant strain (Escherichia coli YB). All the strains could decolorize azo dyes up to 900 mg l−1 (Liu et al. 2007).

The majority of studies on biological decolorization have been focused on fungal strains. Decolorization of the azo dyes; Orange II, Tropeolin O (Acid Orange 6), Congo Red (Direct Red 28), Acid Red 114, Acid Red 88, Biebrich Scarlet, Direct Blue 15, Chrysopheninetetrazine and Yellow 9 and the triphenylmethane dyes; Basic Green 4, Crystal Violet (Basic Violet 3), Brilliant Green, Cresol Red, Bromophenol Blue (BPB) and Para Rosanilines by various fungi have been reported (Selvam et al. 2003). Pointing (2001) studied the degradation of azo, anthraquinone, heterocyclic, triphenylmethane and polymeric dyes by Phanerochaete chrysosporium. Trametes versicolor, Bjerkandera adusta and Phanerochaete chrysosporium were able to decolorize commercially used reactive textile dyes; Reactive Orange 96, Reactive Violet 5 and Reactive Black 5 and two phthalocyanine dyes; Reactive Blue 15 and Reactive Blue 38 (Heinfling et al. 1997). Matthew and Bumpus (1998) reported degradation of Congo Red by Phanerochaete chrysosporium in agitated liquid cultures. Aspergillus foetidus (Sumathi and Manju 2000), Phanerochaete chrysosporium (Mielgo et al. 2001), Trametes versicolor (Borchert and Libra 2001), Trametes hirsute (Abadulla et al. 2000) Coriolus versicolor (Kapdan and Kargi 2002)), Cunninghamella polymorpha (Sugimori et al. 1999), Geotrichum candidum (Yang et al. 2003) and Rhizopus arrhizus (Aksu and Tezer 2005) are the major fungal strains used for the purpose of dye decolorization. Some workers have reported decolorization of sulfur containing dyes by using WRF, Dichomitus squalens and Coriolus versicolor (Eichlerova et al. 2006a; Sanghi et al. 2006).

The degradation of few of azo dyes by algae was also evaluated by some workers (Semple et al. 1999). It was observed that more than 30 azo compounds were decolorized and biodegraded into simpler aromatic amines by Chlorella pyrenoidosa, Chlorella vulgaris and Oscillateria tenuis (Yan and Pan 2004). The potential of Cosmarium species, belonging to green algae, was investigated as a viable biomaterial for biological treatment of triphenylmethane dye; Malachite Green (Daneshvar et al. 2007).

Dye effluents were poorly decolorized by conventional biological treatments and might be toxic for the microorganisms present in the treated effluent plants due to their complex aromatic structures. Furthermore, following anaerobic digestion, nitrogen-containing dyes were transformed into aromatic amines which were found more toxic and mutagenic than the parent molecules (Gottlieb et al. 2003; Zouari-Mechichi et al. 2006). Biological degradation of dyes included properties such as water solubility, large molecular weight (M r) and fused aromatic ring structures, which inhibited permeation through biological cell membranes. Other limitations of using microbes for treating pollutants were high costs of production of microbial culture, slow process of decolorization/degradation of dyes and metabolic inhibition (Duran 2000; Husain and Jan 2000; Nazari et al. 2007). Various organisms have been used for the complete degradation of aromatic compounds but much success has not been achieved yet.

4 Enzymatic approach

The implementation of increasingly stringent standards for the discharge of wastes into environment has necessitated the need for the development of alternative processes for waste treatment. A large number of enzymes from different plants and microorganisms have been reported to play an important role in an array of waste treatment applications (Mielgo et al. 2001; Husain 2006). This was mainly because, unlike the chemical catalysts, the enzymatic catalysis showed its merits to convert complex chemical structures under mild environmental conditions with high efficiency (Husain 2006; Husain and Husain 2008; Michniewicz et al. 2008). The variety of chemical transformations catalyzed by enzymes has made these catalysts a prime target of exploitation by the emerging biotechnological industries. Enzymes can act on specific recalcitrant pollutants to remove them by precipitation or transformation to other products (Akhtar and Husain 2006; Rojas-Melgarejo et al. 2006). They can also alter properties of a given waste to render it more acceptable for the treatment or help in transforming waste material to value-added products (O’Neill et al. 1999).

Enzymatic systems fall between the two traditional categories of chemical and biological processes, since they involved chemical reactions based on the action of biological catalysts (Anjaneyulu et al. 2005). Enzymes that have been isolated from their parent organisms were often preferred over intact organisms containing the enzymes because the isolated enzymes offered several advantages such as greater specificity, better standardization, easy handle and store and no dependence on bacterial growth rates (Husain and Husain 2008; Husain et al. 2009). Due to their high specificity to individual species or classes of compounds, enzymatic processes can be developed to target specific compound which is dangerous to the environment (Ryan et al. 2003). The compounds those can be treated by enzymatic system usually cannot be targeted effectively or reliably using traditional techniques (Kadhim et al. 1999; Couto and Sanroman 2007). Alternatively, enzymatic treatment can be used as a pretreatment step to remove one or more compounds that can interfere with subsequent downstream treatment processes. For example, if inhibitory or toxic compounds can be removed selectively, the bulk of the organic material could be treated biologically, thereby minimizing the cost of treatment (Gianfreda and Rao 2004). Due to susceptibility of enzymes to inactivation by the presence of other chemicals, it is likely that enzymatic treatment would be most effective in those conditions where the highest concentration of target contaminants and the lowest level of other contaminants that may tend to interfere with enzymatic treatment are present (Ghioureliotis 1997). It is suggested that the following situations are those where the use of enzymes might be most useful. Removal of specific chemicals from a complex industrial waste prior to on-site or off-site biological treatment is necessary. Treatment of low-volume, highly-concentrated wastewater at the point of its generation permitted reuse of decontaminated water which facilitated the recovery of soluble products or the removal of pollutants known to cause problems downstream when mixed with other wastes from the plant (Karam and Nicell 1997).

Some potential applications of enzymes that have been identified for the improvement of waste quality included the transformation of aromatic compounds, cyanide, color-causing compounds, pesticides, surfactants and heavy metals (Duran 2000; Karam and Nicell 1997; Basheer et al. 2004). Before the full potential of enzymes may be realized, a number of significant issues should be addressed. These include: development of low-cost sources of enzymes in quantities that are required at the industrial scale, demonstration of the feasibility of utilizing the enzymes efficiently under the conditions encountered during wastewater treatment, characterization of reaction products and assessment of their impact on downstream processes or on the environment into which they are released and identification of methods for the disposal of solid residues (Lopez et al. 2002; Akhtar et al. 2005a; Alcalde et al. 2006; Mao et al. 2006). Current research work has focussed on these issues, particularly for the development of enzymatic treatment systems that carried the removal of aromatic compounds from wastewaters. The enzymatic decolorization of industrial dyes has a challenge due to large diversity of chemical structures among the synthetic dyes, which included anthraquinones, azo, nitro, nitroso and polyenes compounds (Wesenberg et al. 2003; Akhtar et al. 2005b).

5 Oxidative enzymes in dye removal

In the early 1980’s, researchers have developed an idea of using oxidoreductases for the remediation of water contaminated by aromatic pollutants (Duran 2000; Husain and Jan 2000; Duran et al. 2002). This procedure has an advantage because these enzymes can act on a broad range of substrates, like phenols, chlorophenols, methylated phenols, bisphenols, anilines, benzidines and other heterocyclic aromatic compounds under dilute conditions and are less sensitive to operational upsets than the microbial populations (Husain and Husain 2008; Held et al. 2005; Gonzalez et al. 2006). The major oxidoreducatases; laccases and peroxidases have great potential in treating a wide spectrum colored compounds (Yang et al. 2003; Akhtar et al. 2005a, b; Bhunia et al. 2001). These enzymes convert a broad range of substrates into less toxic insoluble compounds, which can be easily removed out of waste by a mechanism involving the formation of free radical followed by insoluble product (Torres et al. 2003; Husain 2006).

5.1 Peroxidases

Peroxidase (E.C. 1.11.1.7) is a heme-containing enzyme that is widely distributed in plants, microorganisms and animals (Duarte-Vazquez et al. 2003). Heme is a complex between an iron ion (Fe+3) and the molecule protoporphyrin IX. Peroxidases are classified into two superfamilies, animal and plant enzymes having a M r ranging from 30 to 150 kDa (Regalado et al. 2004). The plant peroxidase superfamily is further categorized into three classes according to its origin. Class I the intracellular peroxidases, include yeast cytochrome c peroxidase, ascorbate peroxidase and bacterial catalase peroxidases (Passardi et al. 2007). Class II consists of secretory fungal peroxidases: ligninases, or lignin peroxidase (LiP), and manganese peroxidases (MnP). These are monomeric glycoproteins involved in the degradation of lignin. The peroxidases most commonly studied for dye decolorization are fungal LiP and MnP. Class III consists of secretory plant peroxidases, which have multiple tissue specific functions; e.g. removal of H2O2 from chloroplasts and cytosol, oxidation of toxic compounds, biosynthesis of the cell wall, defence responses towards wounding, indole-3-acetic acid catabolism, ethylene biosynthesis, etc. Some of the well known peroxidases of this class are horseradish peroxidase (HRP), turnip peroxidase (TP), bitter gourd peroxidase (BGP) and soybean peroxidase (SBP). Class III peroxidases are also monomeric glycoproteins; containing four conserved disulphide bridges and required calcium ions for their activity (Schuller et al. 1996). In recent years a lot of research has been done to develop processes based on peroxidases from plants and fungi for the treatment of wastewater containing colored pollutants (Husain 2006; Husain and Husain 2008; Akhtar et al. 2005a, b; Wesenberg et al. 2003; Bhunia et al. 2001; Mohan et al. 2005).

6 Microbial peroxidases

6.1 Manganese peroxidase

Table 1 summarizes different MnPs and their applications in dye decolorization.

The catalytic cycle of MnP proceeds through an initial oxidation by H2O2 to an intermediary compound that in turn promoted the oxidation of Mn2+ to Mn3+ (Gold et al. 2000; Hofrichter 2002). Mn3+ is stabilized by organic acids such as oxalic acid and the Mn3+-organic acid complex formed, which acts as an active oxidant (Schlosser and Hofer 2002). Thus, MnP was able to oxidize their natural substrate, i.e. lignin as well as textile dyes (Heinfling et al. 1998a). MnP isoenzymes could efficiently decolorize azo dyes and phthalocyanine complexes in a Mn2+ independent manner. Moreira et al. (2001) have studied an enzymatic action of ligninolytic enzyme, MnP as a feasible system for in vitro degradation of highly recalcitrant polymeric dye, Poly R-478. The enzymatic treatment catalyzed not only the destruction of the chromophoric groups but also a noticeable breakdown of chemical structure of the dye. MnP was reported as the main enzyme involved in dye decolorization by Phanerochaete chrysosporium (Chagas and Durrant 2001). A novel dye-decolorizing strain of the bacterium Serratia marcescens efficiently decolorized two chemically different dyes; Ranocid Fast Blue and Procion Brilliant Blue-H-GR belonging to the azo and anthraquinone groups, respectively. However, an involvement of MnP was found in the decolorization of both dyes (Verma and Madamwar 2002a).

MnP was detected during dye decolorization by culture of Phlebia tremellosa when the culture medium was supplemented with MnCl2 (Kirby et al. 2000). MnP from Clitocybula dusenii was involved in the breakdown of dyes in the real dye-containing effluent (Wesenberg et al. 2002). Some investigators have developed MnP containing membrane reactors for the oxidation of azo dyes (Basheer et al. 2004; Lopez et al. 2004, 2007). Under the best conditions, continuous operation with a dye decolorization higher than 85% and minimal enzymatic deactivation was feasible for 18 d, attaining an efficiency of 42.5 mg Orange II (C.I. Acid Orange 7) oxidized/MnP unit consumed (Lopez et al. 2004). Yang et al. (2003) have shown that the two yeasts; Debaryomyces polymorphus, Candida tropicalis and a filamentous fungi; Umbelopsis isabellina could completely decolorize 100 mg Reactive Black 5 within 16–48 h. MnP was the main ezyme in culture supernatants of these organisms. Selvam et al. (2003) reported that an azo dye, Orange G (C.I. Acid Orange 10) was decolorized 10.8% by 15 U ml−1 of MnP present in WRF, Thelephora sp. Mielgo et al. (2003) described a MnP based azo dyes degradation. The WRF, Irpex lacteus decolorized the textile effluent efficiently without adding any chemicals. The degree of decolorization of the dye effluent by shaking or stationary cultures was 59 and 93% on 8th day, respectively. Higher decolorization was reported in stationary cultures as compared to shaken cultures and this decolorization was related to MnP (Shin 2004).

Partial decolorization was observed in cultures containing 200 ppm of Brilliant Cresyl Blue (C.I. Basic Dye) and Methylene Blue (C.I. Basic Blue 9). High MnP activity but very low LiP and laccase activities were reported in the culture of WRF, Lentinula edodes. The findings have shown the role of MnP from Lentinula edodes which involved in the decolorization of synthetic dyes (Boer et al. 2004). Verma and Madamwar (2005) described that basidiomycete PV002, a white-rot strain efficiently decolorized Ranocid Fast Blue (96%) and Acid Black 210 (70%) on 5th and 9th day under static conditions, respectively. The degradation of azo dyes under different conditions was strongly correlated with high MnP activity. Remazol Brilliant Blue R (C.I. Reactive Blue 19, RBBR) dye was used as a substrate to examine ligninolytic activity in 125 basidiomycetous fungi isolated from tropical ecosystems. Extracellular extracts of 30 selected fungi grown on solid medium with sugar can bagasse showed RBBR decolorization and peroxidase activity. Eight fungi produced MnP, which exhibited significant RBBR decolorization activity (Machado et al. 2005).

Some investigators have demonstrated the decolorization of sulfonaphthalein (SP) at pH 4.0 by MnP from Pleurotus ostreatus. The order of preference for SP dyes as substrate for MnP was Phenol Red > o-Cresol Red > m-Cresol Purple > Bromophenol Red > Bromocresol Purple > BPB > Bromocresol Green (Christian et al. 2003; Shrivastava et al. 2005). Harazono and Nakamura (2005) investigated the decolorization of mixtures of four reactive textile dyes, including azo and anthraquinone dyes, by a white-rot basidiomycete Phanerochaete sordida. This organism decolorized dye mixtures (200 mg l−1) by 90% within 48 h in nitrogen-limited glucose-ammonium media. MnP was the major enzyme participated in dye decolorization by Phanerochaete sordida. Svobodová et al. (Svobodová et al. 2006) have compared the dye decolorization capacity of two WRF, Irpex lacteus and Phanerochaete chrysosporium in N-limited liquid cultures. The agitated cultures showed lower ability to decolorize azo dyes; Reactive Orange 16 and Naphthol Blue Black than static cultures. Similar results were also obtained with other structurally different synthetic dyes. A significant increase in the decolorization of Reactive Orange 16 by the agitated Irpex lacteus cultures was reported after adding 0.1% Tween 80. These workers evaluated the production of a higher Mn-dependent peroxidase. In vitro this purified enzyme has shown its decolorization potential. Eichlerova et al. (2006b) tested eight different Pleurotus species for their Orange G and RBBR decolorization capacity and their ligninolytic properties. Strain CCBAS 461 of species Pleurotus calyptratus produced a relatively high amount of MnP, laccase and aryl-alcohol oxidase activity. This strain decolorized up to 91% Orange G and 85% RBBR in liquid culture and more than 50% of these dyes on agar plates within 14 d. Litter-decomposing basidiomycete fungi including environmental isolates from oak forest soil were compared with WRF for ligninolytic enzymes production and decolorization of synthetic dyes; Poly B-411, Reactive Black 5, Reactive Orange 16 and RBBR. The highest activity of MnP was reported in the culture of Collybia dryophila with the activity over 30 U l−1. The fastest degradation of Poly B-411 was shown by the strains with high levels of MnP and laccase while the decolorization of other dyes did not depend so strictly on enzyme activities (Baldrian and Snajdr 2006). The production of MnP by Phanerochaete chrysosporium and the level of decolorization of 13 dyes were carried using static, agitated batch and continuous cultures. For concentrations of 100 mg l−1 of Acid Black 1, Reactive Black 5, Reactive Orange 16 and Acid Red 27, the decolorization efficiency was over 90%. In batch cultures with Acid Black 1 and Reactive Black 5 a significant increment in primary post-metabolism biomass was observed. For Acid Black 1 and Reactive Black 5, it was possible to explore the response of the continuous system during 32–47 d, with concentrations between 25 and 400 mg l−1, obtaining decolorization greater than 70% for 400 mg l−1 (Urra et al. 2006). A partially purified MnP from Bjerkandera adusta was tested for the decolorization of several artificial dye baths. The most efficient decolorization was observed in dye bath of anthraquinone dyes; Reactive Blue 19, diazo dyes; Reactive Black 5 and Acid Orange 7 (Mohorcic et al. 2006).

The decolorization of 12 different azo, diazo and anthraquinone dyes was demonstrated by using a new isolate of WRF strain L-25. A decolorization efficiency of 84.9–99.6% was obtained by cultivation in 14 d using an initial dye concentration of 40 mg l−1. MnP from strain L-25 has shown its potential in the decolorization of dyes (Kariminiaae-Hamedaani et al. 2007). The azo dyes; Congo Red (C.I. Direct Red 28), Orange G (C.I. Acid Orange 10) and Orange IV were effectively decolorized by MnP isolated and purified from Schizophyllum sp. (Cheng et al. 2007). Purified MnP from Ischnoderma resinosum could decolorize textile dyes; Reactive Black 5, Reactive Blue 19, Reactive Red 22 and Reactive Yellow 15. The highest decolorization was found at acidic pH (Kokol et al. 2007). Park et al. (2007) described the decolorization of six commercial dyes by 10 fungal strains. Extracellular laccase and MnP activities were reported under experimental conditions. The decolorization mechanisms by Funalia trogii ATCC 200800 involved a complex interaction of enzyme activity and biosorption. This study suggested that it was possible to decolorize a high concentration of commercial dyes, which could be a great opportunity in the remediation of dye containing wastewater. Pricelius et al. (2007) investigated the conversion of azo dyes; Flame Orange and Ruby Red, into their N-demethylated form and accompanying polymerization by different oxidoreductases. Laccase from Pycnoporus cinnabarinus, MnP from Nematoloma frowardii and the novel Agrocybe aegerita peroxidase used a similar mechanism to decolorize/degrade azo dyes. Thus the mechanism for cleavage of the azo bonds by azo-reductases of Bacillus cereus and Bacillus subtilis was based on reduction of azo bond at the expense of NAD(P)H. MnP oxidized a wide range of substrates, rendering it an interesting enzyme for potential applications. The significant decolorization of azo dyes in static and shaky situation by gelatin-immobilized MnP was studied, and there was no loss of immobilized enzyme activity after two repeated uses in batch process (Xiao-Bin et al. 2007). Three new chromatographic forms of Dichomitus squalens manganese-dependent peroxidase were isolated from wheat-straw cultures using Mono Q and connective interaction media (CIM) fast protein liquid chromatography. The purified CIM1 MnP could decolorize specific azo and anthraquinone dyes more rapidly than laccase 1. In vitro dye decolorization was as a result of synergistic action of MnP and laccase (Susla et al. 2008).

6.2 Lignin peroxidase

Table 2 shows different lignin peroxidases and their applications in dye decolorization.

LiP also known as ligninase or diaryl propane oxygenase and this enzyme was first reported in 1983. LiP catalyzed the oxidation of non-phenolic aromatic lignin moieties and similar compounds, and it also catalyzed several oxidations in the side chains of lignin and related compounds (Tien and Kirk 1983). LiP has been used to mineralize a variety of recalcitrant aromatic compounds (Gottlieb et al. 2003), polychlorinated biphenyls (Krcmar and Ulrich 1998) and dyes (Abadulla et al. 2000; Husain 2006). Heinfling et al. (1998b) have described the transformation of six industrial azo and phthalocyanine dyes by ligninolytic peroxidases from Bjerkandera adusta and other WRF. Phanerochaete chrysosporium cultures, extracellular fluid and purified LiP were able to degrade Crystal Violet (C.I. Basic Violet 10) and six other triphenylmethane dyes by sequential N-demethylations (Bumpus and Brock 1988). Pointing and Vrijmoed (2000) have shown that LiP had a major role in the decolorization of azo, triphenylmethane, heterocyclic and polymeric dyes by Phanerochaete chrysosporium. LiP was reported as the main enzyme involved in dye decolorization by Bjerkandera adusta (Robinson et al. 2001). Verma and Madamwar (2002b) demonstrated that more than 50% decolorization of Procion Brilliant Blue HGR, Ranocid Fast Blue, Acid Red 119 and Navidol Fast Black was catalyzed by partially purified LiP from Phanerochaete chrysosporium grown on neem hull waste.

Ferreira-Leitao et al. (2007) reported oxidation of Methylene Blue (C.I. Basic Blue 9) and Azure B dyes by plant HRP and LiP from Phanerochaete chrysosporium. Results showed HRP was able to N-demethylate both dyes, but exhibited much slower reaction kinetics than LiP and required higher H2O2 concentrations. Product yield was also different for HRP as compared to LiP. HRP was unable to cleave the aromatic ring structure of the dyes. These workers further compared the usefulness of fungal LiP with HRP for the degradation of Methylene Blue and its demethylated derivatives. It has been shown that although both enzymes were able to oxidize Methylene Blue and its derivatives but HRP reactions required higher H2O2 and exhibited lower reaction rate than the LiP. However, HRP could not achieve aromatic ring cleavage. The oxidation potential of LiP was roughly double than that of less effective HRP. Thus, LiP could be more suitable for decolorization/degradation of phenothiazine dyes from wastewaters (Ferreira-Leitao et al. 2003). Lan et al. (2006) has made an effort to couple a H2O2 producing enzymatic reaction to the LiP catalyzed oxidation of dyes. H2O2 was produced by glucose oxidase and its substrate glucose. Due to controlled release of H2O2, a sustainable constant activity of LiP was observed. Degradation of three dyes; Xylene Cyanol, Fuchsine and Rhodamine B (C.I. Basic Violet 3) by LiP coupled with glucose oxidase indicated that H2O2 was very effective for improvement of efficiency of the decolorization of dyes. In vitro decolorization of an industrial azo dye, Reactive Brilliant Red K-2BP by crude LiP and MnP from Phanerochaete chrysosporium have been demonstrated. Decolorization by LiP was enhanced to the greatest extent (89%) with higher addition of H2O2 and VA. It was suggested that the optimization of H2O2 and VA was responsible for a high efficiency in continuous dye degradation by LiP (Yu et al. 2006).

Pseudomonas desmolyticum NCIM 2112 was able to degrade a diazo dye, Direct Blue 6 (100 mg l−1) completely within 72 h of incubation with 88.95% reduction in chemical oxygen demand (COD) in static anoxic condition. Decolorization of Direct Blue 6 in batch culture exhibited the involvement of oxidative enzymes; LiP, laccase and tyrosinase. Dye also induced the activity of aminopyrine N-demethylase, one of the mixed function oxidase system. The final biodegradation products, 4-amino naphthalene and amino naphthalene sulfonic acid were monitored and characterized by UV–Vis, IR spectroscopy and HPLC and GC-mass spectroscopy (Kalme et al. 2007). Ghodake et al. (2009) have purified a LiP from Acinetobacter calcoaceticus NCIM 2890 and they investigated the decolorization of textile dyes by this enzyme. Purified LiP could oxidize a number of substrates including L-dopa, hydroquinone, Mn2+, mimosine, n-propanol, tryptophan, VA, xylidine and ten textile dyes of different chemical groups, which suggested it as a versatile peroxidase. Most of the dyes decolorized up to 90%. It was found that tryptophan had played a stabilizing role for LiP activity during decolorization of dyes. Alam et al. (2009) have evaluated optimization of the decolorization of Methylene Blue by LiP produced by Phanerochaete chrysosporium using sewage treatment plant sludge as a major substrate. The one-factor-at-a-time method indicated that the optimum conditions for decolorization of 20 mg l−1 Methylene Blue dye removal (14–40%) was at 55°C, pH 5.0 in the presence of 4.0 mM H2O2 and 0.487 Um l−1 LiP. The addition of VA to the reaction mixtures had no effect on the rate of dye decolorization. Sedighi et al. (2009) have demonstrated the effect of Tween 80, Mn(II) and VA on the production of ligninolytic enzymes by Phanerochaete chrysosporium in a packed-bed bioreactor using small pieces of Kissiris as carrier. The activities of enzymes were described in terms of decolorization and COD removal of the textile effluent containing an azo dye, Astrazon Red FBL. The maximum decolorization of the dye and COD removal in the presence of 0.05% (w/v) Tween 80 was 87 and 42%, respectively. The maximum activities of LiP and MnP were 17 and 52 U l−1, respectively. The MnP was an important enzyme in the decolorization of dye whereas COD removal was more in case of LiP action.

6.3 Other microbial peroxidases

Table 3 depicts other microbial peroxidases and their role in dye decolorization.

6.3.1 Dye decolorizing peroxidase

The potential of a newly isolated fungus, Geotrichum candidum Dec 1 peroxidase, a glycoprotein was investigated for the degradation and decolorization of many xenobiotic compounds such as synthetic dyes, food coloring agents, molasses, organic halogens, lignin and kraft pulp effluents (Kim and Shoda 1999). Sugano et al. (2000) isolated a new DyP from Trametes cucumeris Dec 1, which decolorized more than 30 types of synthetic dyes. DyP was a main enzyme that degraded azo and anthraquinone dyes (Sato et al. 2004). Further, these workers have reported that DyP from Trametes cucumeris Dec 1 was able to decolorize an anthraquinone dye, Reactive Blue 5 to light red-brown compounds (Sugano et al. 2006). Decolorization of anthraquinone dye, RBBR was performed by crude recombinant DyP (rDyP) obtained from Aspergillus oryzae. In batch culture, equimolar batch addition of H2O2 and RBBR produced complete decolorization of RBBR by rDyP, with a turnover capacity of 4.75. In stepwise fed-batch addition of H2O2 and enzyme, the turnover capacity increased to 5.76 and 14.3, respectively. When H2O2 was added in continuous fed-batch and 1.6 mM dye was added in stepwise fed-batch mode, 102 g of RBBR was decolorized by 5,000 U of crude rDyP in 650 min increasing the turnover capacity to 20.4 (Shakeri and Shoda 2007). Shakeri and Shoda (2008) immobilized rDyP produced by Aspergillus oryzae on silica-based mesoporous materials, FSM-16 and AlSBA-15. FSM-16 immobilized rDyP decolorized eight sequential batches of an anthraquinone dye, RBBR in a repeated-batch process at pH 4.0. Further these workers have shown that the recombinant Aspergillus oryzae expressing a DyP gene was cultivated in the presence of maltose as a carbon source or repeated-batch production of rDyP. One liter filtrate showed 4600U rDyP activity and it decolorized 5.07 g RBBR at the apparent decolorization rate of 17.7 mg l−1 min−1 (Shakeri et al. 2008).

6.3.2 Versatile peroxidase

VP has been recently described as a new family of ligninolytic peroxidases, together with LiP and MnP obtained from Phanerochaete chrysosporium (Martinez 2002). Interestingly, these enzymes exhibited both LiP and MnP-like activity and they could oxidize Mn2+ to Mn3+ at around pH 5.0 while aromatic compounds at around pH 3.0, regardless of the presence of Mn2+ (Heinfling et al. 1998b; Ruiz-Duenas et al. 2001). Therefore these enzymes were called as hybrid MnP-LiP peroxidases or VP. VPs from various sources Pleurotus pulmonarius (Camarero et al. 2005), Pleurotus ostreatus (Cohen et al. 2002), Bjerkandera adusta (Heinfling et al. 1997, 1998a, c; Krcmar and Ulrich 1998) Pleurotus eryngii (Gomez-Toribio et al. 2001) and Bjerkandera sp. (Mester and Field 1998; Moreira et al. 2005) have proved their potential to degrade azo dyes. A new VP was identified and purified from an extracellular fluid of a novel strain of Bjerkandera sp and this enzyme had catalyzed decolorization of RBBR (Moreira et al. 2006). Sugano et al. (2006) purified and characterized another VP from dye decolorizing microbe, Thanatephorus cucumeris Dec 1(TcVP1). TcVP1 exhibited particularly high decolorizing activity towards azo dyes. Furthermore, co-application of TcVP1 and DyP from Thanatephorus cucumeris Dec 1 was able to completely decolorize a model dye, Reactive Blue 5. DyP decolorized Reactive Blue 5 to light red-brown compounds sequentially and then TcVP1 decolorized such colored intermediates to colorless products. These findings showed important new insights into microbial decolorizing mechanisms and had facilitated the future development of treatment strategies for dye wastewater. Purified VP from Bjerkandera adusta was used for the industrial dye decolorization. The presence of redox mediator VA, acetosyringone or TEMPO as oxidizing mediators in the reaction mixture generally enhanced the rate of dye decolorization (Tinoco et al. 2007).

6.3.3 Vanadium haloperoxidase

VHP have been reported to mediate the oxidation of halides to hypohalous acid and the sulfoxidation of organic sulfides to the corresponding sulfoxides in the presence of H2O2. However, traditional heme peroxidase substrates were reported not to be oxidized by VHP. It was found that the recombinant vanadium chloroperoxidase from the fungus Curvularia inaequalis catalyzed bleaching of an industrial sulfonated azo dye, Chicago Sky Blue 6B (Direct Blue 1, C.I. No. 24410) in the presence of H2O2 (ten Brink et al. 2000).

7 Plant peroxidases

Table 4 demonstrates various types of plant peroxidases and their dye decolorization potential.

7.1 Horseradish peroxidase

Bhunia et al. (2001) have described that HRP can catalyze an effective degradation and precipitation of industrially important azo dyes. They demonstrated specificity of HRP toward different dyes, such as Remazol Blue and Cibacron Red. For Remazol Blue, the enzyme activity was found to be far better at pH 2.5 than at neutral pH. In addition, Remazol Blue worked as a strong competitive inhibitor of HRP at neutral pH. HRP showed broad substrate specificity towards a variety of azo dyes. Acrylamide gel immobilized HRP showed effective performance compared to alginate entrapped and free HRP in the removal of Acid Black 10 BX. Alginate entrapped HRP had inferior performance over the free enzyme due to the consequence of non-availability of the enzyme to the dye molecule (Mohan et al. 2005). Maddhinni et al. (2006) studied decolorization of Direct Yellow 12 by soluble and immobilized HRP under various experimental conditions such as pH, H2O2, dye and enzyme concentrations. The efficiency of polyacrylamide entrapped HRP for the oxidation of Direct Yellow 12 was higher followed by alginate entrapped HRP and then by free HRP. The alginate and polyacrylamide immobilized HRP preparations were further used to 2–3 times for removal of same dye with lower efficiency, respectively. Ulson de Souza et al. (2007) investigated the potential of HRP in the decolorization of textile dyes and their effluents. The results indicated that the decolorization of treated dyes; Remazol Turquoise Blue G 133% (C.I. Reactive Blue 21) and Lanaset Blue 2R was ~59 and 94%, respectively while the decolorization of textile effluent was 52%. The tests for toxicity towards Daphnia magna exhibited that there was a reduction in toxicity after enzymatic treatment. However, the toxicity of the textile effluent showed no change towards Artemia salina after the enzymatic treatment. This study had shown the viability of the use of HRP in the biodegradation of textile dyes.

An electroenzymatic process is an interesting approach that combines enzyme catalysis and electrode reactions. Kim et al. (2005) studied an electroenzymatic method that uses an immobilized HRP to degrade Orange II, an azo dye within a two-compartment packed-bed flow reactor. Electroenzymatic degradation of Orange II was performed by HRP (0.42 U ml−1) at 0.5 V. The overall application of the electroenzymatic approach led to a greater degradation rate than the use of electrolysis alone. The by-products formed were found to consist of primarily of an aromatic amine, sulfanilic acid and unknown compounds. Degradation of Orange II by an electroenzymatic method using HRP immobilized on an inexpensive and stable inorganic support, Celite®R-646 beads was studied in a continuous electrochemical reactor with in situ generation of H2O2. Based on the parametric studies, over 90% degradation of Orange II occurred during continuous operation for 36 h. The degradation products were identified by GC/MS analysis and a possible breakdown pathway for Orange II was also proposed (Shim et al. 2007).

BPB and Methyl Orange (C.I. Acid orange 52) removal capability of citraconic anhydride-modified HRP was compared with those of native HRP. Upon chemical modification, the decolorization efficiency was increased by 1.8 and 12.4% for BPB and Methyl Orange, respectively. Citraconic anhydride-modified HRP was required in low amount as compared to native enzyme for the decolorization of both dyes to obtain the same decolorization efficiency. Modified HRP showed a good decolorization of dye over a wide range of dye concentrations from 8 to 24 or 32 μmol l−1 at 300 μmol l−1 H2O2, which would meet industrial expectations (Liu et al. 2006).

7.2 Turnip peroxidase

Turnip roots, which are readily grown in several countries, are a good source of peroxidase and because of their kinetic and biochemical properties they have a high potential as an economic alternative to HRP (Duarte-Vazquez et al. 2002). The decolorization of acid dyes by TP was significantly enhanced in the presence of 2.0 mM HOBT. The maximum decolorization of dyes was obtained in 1 h. The decolorization of dyes was maximum at pH 5.0 and 40°C. Phytotoxicity test based on Allium cepa root growth inhibition has shown that majority of the TP-treated dye product were less toxic than their parent dye. The polluted wastewater contaminated with single dye or mixtures of dyes were treated with enzyme and it had resulted in a remarkable loss of TOC (Kulshrestha and Husain 2007). Matto and Husain (2007) have demonstrated the effect of salt fractionated turnip proteins on the decolorization of direct dyes, used in textile industry, in the presence of H2O2 and various redox mediators. The decolorization of the dyes and their mixtures was maximum in the presence of 0.6 mM redox mediator (HOBT/VLA) at pH 5.5 and 30°C. TOC analysis of treated dyes or their mixtures exhibited that these results were quite comparable to the loss of color from solutions.

A comparative study for the decolorization and removal of two textile carpet industrial effluents by soluble and immobilized turnip and tomato peroxidases was studied. However, the decolorization of effluents was enhanced in the presence of 2.0 mM HOBT. Industrial effluents; textile carpet effluent red and textile carpet effluent blue were decolorized 75 and 80% by soluble TP (0.423 U ml−1), respectively. Both effluents were maximally decolorized at pH 5.0 by soluble and immobilized TP. Effluent treated by immobilized TP exhibited significant loss of TOC (Husain and Kulshrestha 2009). An inexpensive Con A-wood shaving immobilized TP was employed for the decolorization of some direct dyes in batch as well as in continuous reactors. Con A-wood shaving bound TP exhibited 67% of its initial dye decolorization activity. Both soluble and immobilized TP could effectively remove more than 50% color from dyes in the presence of metal ions/salts and 0.6 mM HOBT after 1 h of incubation. The columns containing immobilized TP could decolorize 64% Direct Red, 23 and 50% mixture of direct dyes at 4 and 3 months of operation, respectively. TOC analysis of treated dye and their mixtures revealed that these results were quite comparable with those of loss of color from solutions (Matto and Husain 2009a).

7.3 Bitter gourd peroxidase

Akhtar et al. (2005b) have studied the decolorization of 21 different reactive textile and other industrially important dyes by using BGP in sodium acetate buffer, pH 5.6 in the presence of 0.75 mM H2O2 and 1.0 mM HOBT. Decolorization was drastically increased when dyes were treated by BGP in the presence of 1.0 mM HOBT. Complex mixtures of dyes were also significantly decolorized by BGP in the presence of 1.0 mM HOBT. Con A-Sephadex bound BGP was used for the decolorization of industrially important dyes from polluted water. Decolorization of dyes by BGP was maximum in the buffer of pH 3.0 and at 40°C. Immobilized BGP was repeatedly employed for the decolorization of eight reactive textile dyes and even after its 10th repeated use the immobilized enzyme retained nearly 50% of its initial activity. The mixtures of dyes were also successfully decolorized by immobilized BGP (Akhtar et al. 2005a). Calcium alginate-starch gel entrapped Con A-BGP and BGP immobilized on the surface of Con A layered calcium alginate–starch beads were studied for the removal of a textile industrial effluent in batch as well as in continuous reactor. The textile effluent was recalcitrant to the action of BGP; thus, its decolorization was examined in the presence of 1.0 mM HOBT. Entrapped and surface immobilized BGP preprations could remove more than 70 and 90% effluent color in a stirred batch process after 3 h of incubation, respectively. Entrapped BGP retained 59% effluent decolorization reusability even after its tenth repeated use (Matto et al. 2009; Matto and Husain 2009b).

Water insoluble-disperse dyes; Disperse Red 17 and Disperse Brown 1 were decolorized by partially purified BGP in the presence of nine different redox mediators; bromophenol, 2,4-dichlorophenol, guaiacol, HOBT, m-cresol, quinol, syringaldehyde, VLA, and vanillin. HOBT among the tested compounds was the most effective redox mediator for the decolorization of both dyes. BGP (0.36 U ml−1) could decolorize Disperse Red 17 maximally 90% in the presence of 0.1 mM HOBT while the Disperse Brown 1 was decolorized 65% in the presence of 0.2 mM HOBT. Maximum decolorization of the dyes was at pH 3.0 and 40°C after 1 h of incubation (Satar and Husain 2009a). These disperse dyes were also decolorized by BGP in the presence of phenol, a redox mediator. BGP (0.215 U ml−1) could decolorize about 60% Disperse Red 17 in the presence of 0.2 mM phenol while Disperse Brown 1 was decolorized nearly 40% in the presence of 0.4 mM phenol. Maximum decolorization could be obtained in the presence of 0.75 mM H2O2 at pH 3.0 and 40°C within 30 min of incubation (Satar and Husain 2009b).

7.4 Tomato peroxidase

Several efforts have been made towards developing processes in which peroxidase from cheap plant sources were used to remove dyes from polluted water (Husain 2006). Decolorization and decontamination of two textile carpet industrial effluents was catalyzed by TMP. Textile carpet effluent red and blue were decolorized 69 and 59% by 0.705 U ml−1 TMP at pH 6.0 and 40°C, respectively. The TMP treated effluents exhibited significant loss of total organic carbon (TOC) from the effluent (Matto and Husain 2007). TMP immobilized on a bioaffinity support, Con A-cellulose was highly effective in decolorizing direct dyes as compared to free TMP. However, Direct Red 23 and Direct Blue 80 were recalcitrant to the action of TMP. The role of six different compounds as redox-mediator was investigated. However, HOBT emerged as a potential redox mediator for TMP catalyzed decolorization of direct dyes. Direct Red 23 and Direct Blue 80 were decolorized more than 70% by soluble and immobilized TMP at pH 6.0 and 40°C. However, immobilized TMP exhibited lower Michaelis constant, K m for the direct dyes as compared to free enzyme (Matto and Husain 2008).

7.5 White radish peroxidase

A comparative decolorization of Reactive Red 120 and Reactive Blue 171 by soluble and Celite immobilized WRP was carried in the presence of some redox mediators; HOBT, syringaldehyde, VA and VLA. HOBT was found to be the most effective mediator for the decolorization of these dyes by WRP. The dyes were maximally decolorized at pH 5.0 and 40°C. Operational stability of soluble and immobilized WRP was evaluated in the presence of different inactivating and inhibiting agents such as sodium azide, organic solvents and mercuric chloride. Immobilized WRP decolorized dyes more effectively in batch process as compared to soluble enzyme. Celite bound WRP was employed in a reactor for the continuous decolorization of dyes (Satar and Husain 2009).

8 Microperoxidase 11

MP 11, a heme containing undecapeptide derived from horse heart cytochrome C, was utilized as a peroxidative catalyst. The decolorization of water insoluble synthetic dyes by MP 11 in 90% methanol was catalyzed by MP 11. MP 11 exhibited effective decolorization activity against azo or anthraquinone dyes. The pathway for degradation of Solvent Orange 7 was studied, it showed that MP 11 catalyzed the oxidative cleavage of azo linkage to generate 1,2-naphthoquinone and 2,4-dimethylphenol as key intermediates (Wariishi et al. 2002). MP 11 entrapped in the system of bis (2-ethylhexyl) sulphosuccinate sodium salt (AOT)-reversed micelles exhibited peroxidase activity in the presence of H2O2. It effectively catalyzed decolorization of an azo dye; Solvent Yellow 7 and an anthraquinone dye, Solvent Blue 11 in the hydrophobic organic solvent. To optimize the reversed micellar system, the effect of pH and molar ratio of H2O/AOT hydration degree (W o) was examined and it indicated that MP 11 exhibited a maximal decolorization activity at pH 8.0–10 with the W o value of 20 (Okazaki et al. 2002). MP 11 was immobilized in hybrid periodic mesoporous organosilica materials and in a nano-crystalline metal organic [Cu(OOC–C6H4–C6H4–COO)ƽ C6H12N2] n framework. The conversion of Amplex-Ultra Red and Methylene Blue to their respective oxidation products catalyzed successfully in the presence of immobilized MP 11 (Pisklak et al. 2006).

9 Other peroxidases

Fruhwirth et al. (2002) have employed a catalase-peroxidase from the newly isolated Bacillus SF to treat textile-bleaching effluents. This enzyme was immobilized on various alumina-based carriers of different shapes. Bleaching effluent was treated in a horizontal packed-bed reactor containing 10 kg of the immobilized catalase-peroxidase at a textile-finishing company. The treated liquid was reused within the company for dyeing fabrics with various dyes, resulting in acceptable color differences of below Delta E = 1.0 for all dyes. Hydrophobic matrix bound Saccharum peroxidase was used for the degradation of four textile dyes; Procion Navy Blue HER, Procion Brilliant Blue H-7G, Procion Green HE-4 BD and Supranol Green. These dyes at an initial concentration of 50 mg l−1 were completely degraded within 8 h by the peroxidase immobilized on modified polyethylene matrix. The immobilized peroxidase was used in a batch reactor for the degradation of Procion Green HE-4BD and its reusability was studied for 15 cycles and the half-life was 60 h (Shaffiqu et al. 2002). Knutson et al. (2005) demonstrated an effective decolorization of two recalcitrant dyes; stilbene dye, Direct Yellow and Methine dye, Basazol 46L by HRP, SBP and laccase in the presence of ABTS as a redox mediator. The stilbene dye, Direct Yellow 11 responded to both SBP and laccase/ABTS. SBP was more effective in the oxidative removal of methine dye, Basazol 46L as compared to the other peroxidases.

10 Conclusion

The advantages and disadvantages of various chemical, physical, biological and enzymatic methods used for the treatment of dyes have been compared in Table 5. This study finally emphasized that an enzymatic approach based on peroxidase activity has attracted much interest in the remediation/decolorization of various dyes present in wastewater/industrial effluent. The treatment of such pollutants by peroxidases sometimes caused problems due to inactivation of enzyme by its own product/products and recalcitrant nature of the dye compounds. The inactivation effect of the enzyme can be prevented by adding some adsorbents during reaction. Recalcitrant dyes could be successfully decolorized by peroxidases in the presence of some suitable redox mediators. Immobilized peroxidases have shown their superiority over the free enzymes in the remediation of synthetic dyes. Immobilized enzymes could be successfully used in the reactors for continuous decolorization of dyes from wastewater. Treatment of recalcitrant pollutants by using enzyme-redox mediator system will be significantly useful procedure for targeting a number of dyes of diversified structures. The viability of developing commercial scale treatment processes by using peroxidases and their potential deactivation and slow process kinetics can be improved by adding an adsorbent in the reaction mixture or by developing a two reactor systems for decolorization/degradation of dyes where one reactor containing immobilized enzyme and second reactor filled with the adsorbent. The activated product created by peroxidase would bind to the adsorbent in the second reactor and pollutant free water will move out of second reactor. Indeed, the described system has to be developed with a cheaper biocatalyst and adsorbent that would be cost effective. Thus, peroxidase based dyes treatment will provide a reasonable basis for the development of biotechnological processes for continuous color and aromatic compounds removal from various industrial effluents at large scale.

Abbreviations

- HRP:

-

Horseradish peroxidase

- BGP:

-

Bitter gourd peroxidase

- BPB:

-

Bromophenol blue

- Con A:

-

Concanavalin A

- COD:

-

Chemical oxygen demand

- DyP:

-

Dye decolorizing peroxidase

- HOBT:

-

1-Hydroxybenzotriazole

- LiP:

-

Lignin peroxidase

- MnP:

-

Manganese peroxidase

- MP 11:

-

Microperoxidase 11

- M r :

-

Molecular weight

- rDyP:

-

Recombinant dye decolorizing peroxidase

- RBBR:

-

Remazol brilliant blue R

- SBP:

-

Soybean peroxidase

- SP:

-

Sulfonaphthalein

- TMP:

-

Tomato peroxidase

- TOC:

-

Total organic carbon

- TP:

-

Turnip peroxidase

- VHP:

-

Vanadium haloperoxidase

- VA:

-

Veratryl alcohol

- VP:

-

Versatile peroxidase

- VLA:

-

Violuric acid

- WRP:

-

White radish peroxidase

- WRF:

-

White rot fungi

References

Abadulla E, Tzanov T, Costa S, Robra KH, Cavaco-Paulo A, Gubitz GM (2000) Decolorization and detoxification of textile dyes with a laccase from Trametes hirsuta. Appl Environ Microbiol 66:3357–3362

Acemioglu B (2004) Adsorption of Congo red from aqueous solution onto calcium-rich fly ash. J Colloid Interf Sci 274:371–379

Adams CD, Grog S (2002) Effect of pH and gas-phase ozone concentration on the decolorization of common textile dyes. J Environ Eng 128:293–298

Akhtar S, Husain Q (2006) Potential applications of immobilized bitter gourd (Momordica charantia) peroxidase in the removal of phenols from polluted water. Chemosphere 65:1228–1235

Akhtar S, Khan AA, Husain Q (2005a) Potential of immobilized bitter gourd (Momordica charantia) peroxidases in the decolorization and removal of textile dyes from polluted wastewater and dyeing effluent. Chemosphere 60:291–301

Akhtar S, Khan AA, Husain Q (2005b) Partially purified bitter gourd (Momordica charantia) peroxidase catalyzed decolorization of textile and other industrially important dyes. Bioresour Technol 96:1804–1811

Aksu Z, Tezer S (2005) Biosorption of reactive dyes on the green alga Chlorella Vulgaris. Process Biochem 40:1347–1361

Alam MZ, Mansor MF, Jalal KC (2009) Optimization of decolorization of methylene blue by lignin peroxidase enzyme produced from sewage sludge with Phanerocheate chrysosporium. J Hazard Mater 162(2–3):708–715

Alcalde M, Ferrer M, Plou FJ, Ballesteros A (2006) Environmental biocatalysis: from remediation with enzymes to novel green processes. Trends Biotechnol 24:281–287

Aleboyeh A, Moussa Y, Aleboveh H (2005) The effect of operational parameters on UV/H2O2 decolorization of Acid Blue 74. Dyes Pigm 66:129–134

Anjaneyulu Y, Chary NS, Raj DSS (2005) Decolorization of industrial effluents-available methods and emerging technologies: a review. Rev Environ Sci Biotechnol 4:245–273

Azmi W, Banerjee U (2001) Biological decolorization of Crystal Violet by a newly isolated Bacillus sp. and microbial assessment of toxicity of untreated and treated dye. Scientia Iranica 8:171–178

Balchioglu IA, Arslan I, Sacan MT (2001) Homogeneous and heterogeneous advanced oxidation of two commercial reactive dyes. Environ Technol 22:813–822

Baldrian P, Snajdr J (2006) Production of ligninolytic enzymes by litter-decomposing fungi and their ability to decolorize synthetic dyes. Enzyme Microb Technol 39:1023–1029

Banat IM, Nigam P, Singh D, Marchant R (1996) Microbial decolorization of textile-dye-containing effluents: a review. Bioresour Technol 58:217–227

Basheer S, Kut ÖM, Prenosil JE, Bourne JR (2004) Development of an enzyme membrane reactor for treatment of cyanide-containing wastewaters from the food industry. Biotechnol Bioeng 41(4):465–473

Bhole BD, Ganguly B, Madhuram A, Deshpande D, Joshi J (2004) Biosorption of Methyl Violet, basic fuchsin and their mixture using dead fungal biomass. Current Science 86:1641–1645

Bhunia A, Durani S, Wangikar PP (2001) Horseradish peroxidase catalyzed degradation of industrially important dyes. Biotechnol Bioeng 72:562–567

Boer CG, Obici L, de Souza CGM, Peralta RM (2004) Decolorization of synthetic dyes by solid state cultures of Lentinula (Lentinus) edodes producing manganese peroxidase as the main ligninolytic enzyme. Bioresour Technol 94:107–112

Borchert M, Libra JA (2001) Decolorization of reactive dyes by the white rot fungus Trametes versicolor in sequencing batch reactors. Biotechnol Bioeng 75:313–321

Bousher A, Shen X, Edyvean RGJ (1997) Removal of colored organic matter by adsorption onto low cost waste materials. Water Res 31:2084–2092

Bras R, Gomes A, Ferra MIA, Pinheiro HM, Goncalves IC (2005) Monoazo and diazo dye decolorization studies in a methanogenic UASB reactor. J Biotechnol 115:57–66

Bulc TG, Ojstrsek A (2008) The use of constructed wetland for dye-rich textile wastewater treatment. J Hazard Mater 155:76–82

Bumpus JA, Brock BJ (1988) Biodegradation of Crystal Violet by the white rot fungus Phanerochaete chrysosporium. Appl Environ Microbiol 54:1143–1150

Camarero S, Ibarra D, Martίnez MJ, Martίnez AT (2005) Lignin derived-compounds as efficient laccase mediators for decolorization of different types of recalcitrant dyes. Appl Environ Microbiol 71:1775–1784

Chagas EP, Durrant LR (2001) Decolorization of azo dyes by Phanerochaete chrysosporium and Pleurotus sajorcaju. Enzyme Microb Technol 29:473–477

Chen KC, Wu JY, Liou DJ, Hwang SCJ (2003) Decolorization of the textile dyes by newly isolated bacterial strains. J Biotechnol 101:57–68

Cheng X, Jia R, Li P, Tu S, Zhu Q, Tang W, Li X (2007) Purification of a new manganese peroxidase of the white-rot fungus Schizophyllum sp. F17, and decolorization of azo dyes by the enzyme. Enzyme Microb Technol 41:258–264

Christian V, Shrivastava R, Novotny C, Vyas BR (2003) Decolorization of sulfonaphthalein dyes by manganese peroxidases activity of the white-rot fungus Phanerochaete chrysosporium. Folia Microbiol (Praha) 48:771–774

Chung KT, Fulk GE, Egan M (1978) Reduction of azo dyes by intestinal anaerobes. Appl Environ Microbiol 35:558–562

Cohen R, Persky L, Hazan-Eitan Z, Yarden O, Hadar Y (2002) Mn2+ alters peroxidases profiles and lignin degradation by the white-rot fungus Pleurotus ostreatus under different nutritional and growth conditions. Appl Biochem Biotechnol 102–103:415–429

Couto SR, Sanroman MA (2007) The effect of violuric acid on the decolourization of recalcitrant dyes by laccase from Trametes hirsute. Dyes Pigm 74:123–126

Daneshvar N, Ayazloo M, Khataee AR, Pourhassan M (2007) Biological decolorization of dye solution containing Malachite Green by microalgae Cosmarium sp. Bioresour Technol 98:1176–1182

Dascalu T, Acosta-Ortiz ES, Morales OM, Compean I (2000) Removal of the indigo colour by laser beam-denian interaction. Opt Lasers Eng 34:179–189

Dominguez JR, Beltran J, Rodriguez O (2005) Vis and UV photocatalytic detoxification methods (using TiO2, TiO2/H2O2, TiO2/O3, TiO2/S2O8 2−), O3, H2O2, S2O8 2−), Fe3+/H2O2 and Fe3+/H2O2/C2O4 2−) for dyes treatment. Catal Today 101:389–395

Duarte-Vazquez MA, Ortega-Tovar MA, García-Almendárez BE, Regalado C (2002) Removal of aqueous phenolic compounds from a model system by oxidative polymerization with turnip (Brassica napus L. var. purple top white globe) peroxidase. J Chem Technol Biotechnol 78:42–47

Duarte-Vazquez MA, Whitaker JR, Rojo-Dominguez A, Garcia-Almendárez BE, Regalado C (2003) Isolation and thermal characterization of an acidic isoperoxidase from turnip roots. J Agric Food Chem 51:5096–5102

Duran N, Esposito E (2000) Potential applications of oxidative enzymes and phenoloxidase-like compounds in wastewater and soil treatment. Rev Appl Catal B Environ 28:83–99

Duran N, Rosa MA, D’Annibale A, Gianfreda L (2002) Applications of laccase and tyrosinases (phenoloxidases) immobilized on different supports: a review. Enzyme Microb Technol 31:907–931

Eichlerova I, Homolka L, Nerud F (2006a) Synthetic dye decolorization capacity of white rot fungus Dichomitus squalens. Bioresour Technol 97:2153–2159

Eichlerova I, Homolka L, Nerud F (2006b) Ability of industrial dyes decolorization and ligninolytic enzymes production by different Pleurotus species with special attention on Pleurotus calyptratus, strain CCBAS 461. Process Biochem 41:941–946

Ferreira-Leitao VS, Godinho da Silva J, Bon EPS (2003) Methylene Blue and Azure B oxidation by horseradish peroxidase: a comparative evaluation of class II and class III peroxidases. Applied Catalysis B: Environmental 42:213–221

Ferreira-Leitao VS, de Carvalho MEA, Bon EPS (2007) Lignin peroxidase efficiency for Methylene Blue decolouration: comparison to reported methods. Dyes Pigm 74:230–236

Frank MJW, Westerink JB, Schokker A (2002) Recycling of industrial wastewater by using a two step nanofiltration process for the removal of colour. Desalination 145:69–74

Fruhwirth G, Paar A, Gudelj M, Cavaco-Paulo A, Robra KH, Gubitz G (2002) An immobilised catalase peroxidase from the alkalothermophilic Bacillus SF for the treatment of textile-bleaching effluent. Appl Microbiol Biotechnol 60:313–319

Ghioureliotis M (1997) Assessment of residual by-product from the enzyme-catalyzed polymerization of aqueous phenolic compound. M.Sc. Thesis, Department of Civil Engineering and Applied Mechanics, McGill University

Ghodake GS, Kalme SD, Jadhav JP, Govindwar SP (2009) Purification and partial characterization of lignin peroxidase from Acinetobacter calcoaceticus NCIM 2890 and its application in decolorization of textile dyes. Appl Biochem Biotechnol 152(1):6–14

Gianfreda L, Rao MA (2004) Potential of extracellular enzymes in remediation: a review. Enzyme Microb Technol 35:339–354

Gold MH, Youngs HL, Gelpke MDS (2000) Manganese peroxidase. In: Sigel A, Sigel H (eds) Metal ions in biological systems. Marcel Dekker Inc, New York, pp 559–586

Gomez-Toribio V, Martínez AT, Martínez MJ (2001) Oxidation of hydroquinones by the versatile ligninolytic peroxidase from Pleurotus eryngii. Eur J Biochem 268:4787–4793

Gonzalez PS, Capozucca CE, Tigier HA, Milrad SR, Agostini E (2006) Phytoremediation of phenol from wastewater, by peroxidases of tomato hairy root cultures. Enzyme Microb Technol 39:647–653

Gottlieb A, Shaw C, Smith A, Wheatley A, Forsythe S (2003) The toxicity of textile reactive azo dyes after hydrolysis and decolourisation. J Biotechnol 101:49–56

Grzechulska J, Morowski WA (2002) Photocatalytic decomposition of azo dye Acid Black 1 in water over modified titanium dioxide. Appl Catal B Environ 36:45–51

Hai FI, Yamamoto K, Fukushi K (2007) Hybrid treatment systems for dye wastewaters. Crit Rev Environ Sci Technol 37:315–377

Hao OJ, Kim H, Chiang P-C (2000) Decolorization of wastewater. Crit Rev Environ Sci Technol 30:449–505

Harazono K, Nakamura K (2005) Decolorization of mixtures of different reactive textile dyes by the white-rot basidiomycete Phanerochaete sordida and inhibitory effect of polyvinyl alcohol. Chemosphere 59:63–68

Heinfling A, Bergbauer M, Szewzyk U (1997) Biodegradation of azo and phthalocynanide dyes by Trametes versicolor and Bjerkandera adusta. Appl Microbiol Biotechnol 48:261–266

Heinfling A, Martínez MJ, Martínez AT, Bergbauer M, Szewzyk U (1998a) Purification and characterization of peroxidases from the dye-decolorizing fungus Bjerkandera adusta. FEMS Microbiol Lett 165:43–50

Heinfling A, Martínez MJ, Martínez AT, Bergbauer M, Szewzyk U (1998b) Transformation of industrial dyes by manganese peroxidase from Bjerkandera adusta and Pleurotus eryngii in a manganese-independent reaction. Appl Environ Microbiol 64:2788–2789

Heinfling A, Ruiz-Duenas FJ, Martínez MJ, Bergbauer M, Szewzyk U, Martínez AT (1998c) A study on reducing substrates of manganese-oxidizing peroxidases from Pleurotus eryngii and Bjerkandera adusta. FEBS Lett 428:141–146

Held C, Kandelbauer A, Schroeder M, Cavaco-Paulo A, Guebitz GM (2005) Biotransformation of phenolics with laccase containing bacterial spores. Environ Chem Lett 3:74–77

Hofrichter M (2002) Review: lignin conversion by manganese peroxidase (MnP). Enzyme Microb Technol 30:454–466

Husain Q (2006) Potential applications of the oxidoreductive enzymes in the decolorization and detoxification of textile and other synthetic dyes from polluted water: a review. Crit Rev Biotechnol 60:201–221

Husain M, Husain Q (2008) Applications of redox mediators in the treatment of organic pollutants by using oxidoreductive enzymes: a review. Crit Rev Environ Sci Technol 38:1–41

Husain Q, Jan U (2000) Detoxification of phenols and aromatic amines from polluted wastewater by using phenol oxidases. A review. J Sci Ind Res 59:286–293

Husain Q, Kulshrestha Y (2009) Removal of colored compounds from textile carpet industrial effluents by using immobilized turnip (Brassica rapa) and tomato (Lycopersicon esculentum) peroxidases. Water Sci Technol (in press)

Husain Q, Husain M, Kulshrestha Y (2009) Remediation and treatment of organo-pollutants mediated by peroxidases: a review. Crit Rev Biotechnol 29(2):94–119

Ince HN, Tezcanli G (2001) Reaction dyestuff degradation by combined sonolysis and ozonation. Dyes Pigm 49:145–153

Jung J, Hyo-Yoon J, Ching HH, Lee JM (2002) Radiation treatment of secondary effluent forms a sewage treatment plant. Radiat Phys chem 65:533–537

Kadhim H, Graham C, Barrat P, Evans CS, Rastall RA (1999) Removal of phenolic compounds in water using Coriolus versicolor grown on wheat bran. Enzyme Microb Technol 24:303–307

Kalme SD, Parshettia GK, Jadhav SU, Govindwar SP (2007) Biodegradation of benzidine based dye, Direct Blue-6 by Pseudomonas desmolyticum NCIM 2112. Bioresour Technol 98:1405–1410

Kapdan IK, Kargi F (2002) Biological decolorization of textile dyestuff containing wastewater by Coriolus versicolor in a rotation biological contactor. Enzyme Microb Technol 30:195–199

Karam J, Nicell JA (1997) Potential application of enzymes in wastewater treatment. J Chem Technol Biotechnol 69:141–153

Kariminiaae-Hamedaani H-R, Sakurai A, Sakakibara M (2007) Decolorization of synthetic dyes by a new manganese peroxidase-producing white rot fungus. Dyes Pigm 72:157–162

Keharia H, Madamvar D (2003) Bioremediation concept for treatment of dye containing wastewater: a review. Indian J Exp Biol 41:1068–1075

Kim SJ, Shoda M (1999) Purification and characterization of a novel peroxidase from Geotrichum candidum Dec 1 involved in decolorization of dyes. Appl Environ Microbiol 65:1029–1035

Kim GY, Lee KB, Cho SH, Shim J, Moon SH (2005) Electroenzymatic degradation of azo dye using an immobilized peroxidase enzyme. J Hazard Mater 126:183–188

Kirby N, Merchant R, McMullan G (2000) Decolorization of synthetic textile dyes by Phlebia tremellosa. FEMS Microbiol Lett 188:93–96

Knutson K, Kirzan S, Ragauskas A (2005) Enzymatic biobleaching of two recalcitrant paper dyes with horseradish and soybean peroxidase. Biotechnology Letters 27:753–758

Kokol V, Doliska A, Eichlerova I, Baldrian P, Nerud F (2007) Decolorization of textile dyes by whole cultures of Ischnoderma resinosum and by purified laccase and Mn-peroxidase. Enzyme Microb Technol 40:1673–1677

Krcmar P, Ulrich R (1998) Degradation of polychlorinated biphenyl mixtures by the lignin-degrading fungus Phanerochaete chrysosporium. Folia Microbiol (Praha) 43:79–84

Kulshrestha Y, Husain Q (2007) Decolorization and degradation of acid dyes mediated by partially purified turnip (Brassica rapa) peroxidase. Toxicol Environ Chem 89:255–267

Lan J, Huang X, Hu M, Li Y, Qu Y, Gao P, Wu D (2006) High efficient degradation of dyes with lignin peroxidase coupled with glucose oxidase. J Biotechnol 123:483–490

Liu JZ, Wang TL, Ji LN (2006) Enhanced dye decolorization efficiency by citraconic anhydride-modified horseradish peroxidase. J Mol Catal B Enzym 41:81–86

Liu G, Zhou J, Qu Y, Ma X (2007) Decolorization of sulfonated azo dyes with two photosynthetic bacterial strains and a genetically engineered Escherichia coli strain. World J Microbiol Biotechnol 23:931–937

Lopez C, Mielgo I, Moreira MT, Feijoo G, Lema JM (2002) Enzymatic membrane reactors for biodegradation of recalcitrant compounds: application to dye decolourisation. J Biotechnol 99:249–257

Lopez C, Moreira MT, Feijoo G, Lema JM (2004) Dye decolorization by manganese peroxidase in an enzymatic membrane bioreactor. Biotechnol Prog 20:74–81

Lopez C, Moreira MT, Feijoo G, Lema JM (2007) Dynamic modelling of an enzymatic membrane reactor for the treatment of xenobiotic compounds. Biotechnol Bioeng 97:1128–1137

Machado KMG, Matheus DR, Bononi VLR (2005) Ligninolytic enzymes production and Remazol Brilliant Blue R decolorization by tropical Brazilian basidiomycetes fungi. Braz J Microbiol 36:246–252

Maddhinni VL, Vurimindi HB, Yerramilli A (2006) Degradation of azo dye with horseradish peroxidase (HRP). J Indian Inst Sci 86:507–514

Mao X, Buchanan DI, Stanley JS (2006) Phenol removal from aqueous solution by fungal peroxidases. J Environ Eng Sci 5:103–109

Martinez AT (2002) Molecular biology and structure function of lignin-degrading lignin-degrading heme peroxidases. Enzyme Microb Technol 30:425–444

Matthew T, Bumpus JA (1998) Biodegradation of Congo Red by Phanerochaete chrysosporium. Water Res 32:1713–1717

Matto M, Husain Q (2007) Decolorization of direct dyes by salt fractionated turnip proteins enhanced in the presence of hydrogen peroxide and redox mediators. Chemosphere 69(2):338–345

Matto M, Husain Q (2008) Redox mediated decolorization of Direct Red 23 and Direct Blue 80 catalyzed by bioaffinity based immobilized tomato (Lycopersicon esculentum) peroxidases. Biotechnol J 3(8):1224–1231

Matto M, Husain Q (2009a) Decolorization of direct dyes by immobilized turnip peroxidase in batch and continuous processes. Ecotoxicol Environ Saf 72:963–971

Matto M, Husain Q (2009b) Decolorization of textile effluent by bitter gourd peroxidase immobilized on concanavalin A layered calcium alginate-starch beads. J Hazard Mater 164:1540–1546

Matto M, Satar R, Husain Q (2009) Application of calcium alginate–starch entrapped bitter gourd (momordica charantia) peroxidase for the removal of colored compounds from a textile effluent in batch as well as in continuous reactor. Appl Biochem Biotech. doi:10.1007/s12010-008-8396-8

Mbuligwe SE (2005) Comparative treatment of dye-rich wastewater in engineered wetland systems (EWSs) vegetated with different plants. Water Res 39:271–280

McMullan G, Meehan C, Conneely A, Kirby N, Robinson T, Nigam P, Banat IM, Marchant R, Smyth WF (2001) Microbial decolourisation and degradation of textile dyes. Appl Microbiol Biotechnol 56:81–87

Mester T, Field JA (1998) Characterization of a novel manganese peroxidase-lignin peroxidase hybrid isozyme produced by Bjerkandera species strain BOS55 in the absence of manganese. J Biol Chem 273:15412–15417

Michniewicz A, Ledakowicz S, Ullrich R, Hofrichter M (2008) Kinetics of the enzymatic decolorization of textile dyes by laccases from Cerrena unicolor. Dyes Pigm 77:295–302

Mielgo I, Moreira MT, Feijoo G, Lema JM (2001) A packed-bed fungal bioreactor for the continuous decolorization of azo dyes (Orange II). J Biotechnol 89:99–106

Mielgo I, Lopez C, Moreira MT, Feijoo G, Lema JM (2003) Oxidative degradation of azo dyes by manganese peroxidase under optimized conditions. Biotechnol Prog 19:325–331

Mohan SV, Roa CN, Prasad KK, Karthikeyan J (2002) Treatment of simulated Reactive Yellow 22 (Azo) dye effluents using Spirogyra species. Waste Manage 22:575–582

Mohan SV, Prasad KK, Rao NC, Sarma PN (2005) Acid azo dye degradation by free and immobilized horseradish peroxidase catalyzed process. Chemosphere 58:1097–1105

Mohorcic M, Teodorovic S, Golob V, Friedrich J (2006) Fungal and enzymatic decolorisation of artificial textile dye baths. Chemosphere 63:1709–1717

Moreira MT, Palma C, Mielgo I, Feijoo G, Lema JM (2001) In vitro degradation of a polymeric dye (Poly R-478) by manganese peroxidase. Biotechnol Bioeng 75:362–368

Moreira PR, Duez C, Dehareng D, Antunes A, Almeida-Vala E, Frere JM, Malcata FX, Duarte JC (2005) Molecular characterization of a versatile peroxidase from a Bjerkandera strain. J Biotechnol 118:339–352

Moreira PR, Bouillenne F, Almeida-Vara E, Malcata FX, Frère JM, Duarte JC (2006) Purification, kinetics and spectral characterisation of a new versatile peroxidase from a Bjerkandera sp. isolate. Enzyme Microb Technol 38:28–33

Muthukumar M, Sargunamani D, Selvakumar N (2005) Statistical analysis of the effect of aromatic, azo and sulphonic acid groups on decolouration of acid dye effluents using advanced oxidation processes. Dyes Pigm 65:151–158

Mutlu SH, Yetis V, Gurkan T, Yilmaz L (2002) Decolorization of wastewater of a baker’s yeast plant by membrane processes. Water Res 36:609–616

Nazari K, Esmaeili N, Mahmoudi A, Rahimi H, Moosavi-Movahedi AA (2007) Peroxidative phenol removal from aqueous solutions using activated peroxidase biocatalyst. Enzyme Microb Technol 41:226–233

Nigam AG, Banat IM, Singh D, Marchant R (2000) Physical removal of textile dyes from effluents and solid state fermentation by dye-adsorbed agricultural residues. Bioresour Technol 72:219–226

Nyanhongo GS, Gomesa J, Gubitz GM, Zvauya R, Read J, Steiner W (2002) Decolorization of textile dyes by laccases from a newly isolated strain of Trametes modesta. Water Res 36:1449–1456

O’Neill C, Hawkes FR, Hawkes DL, Lourenco ND, Pinheiro HM, Delee W (1999) Colour on textile effluents-source, measurement, discharge contents and simulation: a review. J Chem Technol Biotechnol 74:1009–1018

Okazaki S-Y, Nagasawa S-I, Goto M, Furusaki S, Wariishi H, Tanaka H (2002) Decolorization of azo and anthraquinone dyes in hydrophobic organic media using microperoxidase-11 entrapped in reversed micelles. Biochem Eng J 12:237–241

Padmesh TVN, Vijayaraghavan K, Sekaran G, Velan M (2005) Batch and column studies on biosorption of acid dyes on fresh water macro alga Azolla filiculoides. J Hazard Mater 125:121–129

Park C, Lee M, Lee B, Kim SW, Chase HA, Lee J, Kim S (2007) Biodegradation and biosorption for decolorization of synthetic dyes by Funalia trogii. Biochem Eng J 36:59–65

Parshetti G, Kalme S, Saratale G, Govindwar S (2006) Biodegradation of Malachite Green by Kocuria rosea MTCC 1532. Acta Chim Slov 53:492–498

Passardi F, Bakalovic N, Teixeira FK, Margis-Pinheiro M, Penel C, Dunand C (2007) Prokaryotic origins of the non-animal peroxidase superfamily and organelle-mediated transmission to eukaryotes. Genomics 89:567–579

Pearce CI, Lloyd JR, Guthrie JT (2003) The removal of colour from textile wastewater using whole bacterial cells: a review. Dyes Pigm 58:179–196

Pisklak TJ, Macías M, Coutinho DH, Huang RS, Balkus KJ (2006) Hybrid materials for immobilization of MP-11 catalyst. Top Catal 38:269–278

Pointing SB (2001) Feasibility of bioremediation by white-rot fungi. Appl Microbiol Biotechnol 57:20–33

Pointing SB, Vrijmoed LLP (2000) Decolorization of azo and triphenylmethane dyes by Pycnoporus sanguineus producing laccase as the sole phenoloxidase. World J Microbiol Biotechnol 16:317–318

Pricelius S, Held C, Sollner S, Deller S, Murkovic M, Ullrich R, Hofrichter M, Cavaco-Paulo A, Macheroux P, Guebitz GM (2007) Enzymatic reduction and oxidation of fibre-bound azo-dyes. Enzyme Microb Technol 40:1732–1738

Rai HS, Bhattacharyya MS, Singh J, Bansal TK, Vats P, Banerjee UC (2005) Removal of dyes from the effluent of textile and dyestuff manufacturing industry: a review of emerging techniques with reference to biological treatment. Crit Rev Environ Sci Technol 35:219–238

Regalado C, Garcia-Almendarcz BE, Duarte-Vazquez MA (2004) Biotechnological applications of peroxidases. Phytochem Rev 3:243–256