Abstract

Brazil is one of the largest world producers of textiles and clothing. It is an important producer of cotton fiber , yarn, plain and knitted fabrics. This stimulates the country’s GDP generating millions of direct and indirect jobs in this sector. However, such activity generates various environmental problems, such as the generation of solid wastes from textile and clothing industrial processes, as well as the post-consumer clothing, which are discarded commonly in landfills. Thus, the present study presents considerations about mechanical processes for textile recycling , recycled cotton yarn and jeans characteristics, the generation of solid wastes in textile and clothing Brazilian industry and the actions directed toward sustainability. The textile reuse and recycling may contribute to the reduction of environmental problems, in addition to being economically viable source of income and social benefits for all involved in this chain, from street collectors to the industrial sector.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Besides being a major producer of goods and services in sectors such as agriculture, mining and petroleum (Mattos 2006), Brazil is also one of the major world manufacturer of textiles: the fifth largest producer, with a production of about 1.8 million tons of made-up articles (IEMI 2014) and also the 5th largest producer of cotton (ABIT 2011), one of the most employed natural fiber in the world, with which are made 60 % of the garments in the country (Mello et al. 2007; ABIT 2011). The country ranks 7th in the production of yarns and woven fabrics and the 3rd in the production of knitted fabrics (Finkler et al. 2005), as well as generating 8 million of direct and indirect jobs (Neuls 2012).

According to IEMI—Institute of Studies on Industrial Marketing (2014), specialized in research and analysis of textile and clothing sectors, in 2013 the textile and clothing chain produced about R$ 58.2 billion (near 20 billion €), equivalent to 5.7 % of total Brazilian industrial production, disregarding the activities of mining and construction, which complement the secondary sector of Brazilian economy. In 2013, the textile and clothing sector had 1.6 million of jobs or the equivalent of 16.4 % of the workers at the industrial production in that year, proving to be a strong social impact segment—by employing a huge number of women and workers with lower qualification—and economic, since their production centers are extended nationwide.

São Paulo State is the main industrial producer and employer in Brazil, presenting all the segments of textile chain. The companies located in this State represent 29 % of the national total and employ about 30 % of people (more than 500 thousand) in comparison to whole Brazilian textile chain in 2010 (out of 1.6 million people) (IEMI 2014).

Even bringing economic benefits to the country, on the other hand the textile and clothing sectors creates many environmental problems. Along the textile and clothing chain there are several operations generating solid, liquid and gaseous wastes. For instance, since the cotton ginning up to generation of sludge in biological treatment of liquid effluents (Sinditêxtil-SP 2009). However, the main focus of this paper is about solid wastes generated by mainly the Brazilian clothing industrial sector.

Mechanical Processes for Textile Recycling

The textile recycling can be classified depending on raw materials to be reprocessed, resulting in the use of different production lines and specific processes to obtain the final products. They can be divided into: mechanical recycling, chemical recycling; thermal recycling and mix of technologies (Groupe CTT and ITS 2014).

Mechanical recycling is the most found, because it can process textile wastes of various compositions. Both virgin and recycled fibers can further employed in known yarning or nonwoven processes. However, textiles wastes, consolidated in the form of articles or fabrics, should be previously separated by composition and color (or not, depending on the final product to be obtained) and then be shredded in a specific machinery (Zonatti 2013; Zonatti et al. 2015).

The activity of the textile recycling emerged in the Prato city (Italy) in the mid-nineteenth century with the recovery of wastes of wool (Camera di Commercio Prato 2014). It is characterized as the practice or technique in which wastes and leftovers from industrial processes, clothing manufacturers or from disposal of post consumption items can be reprocessed with a treatment to change their physical and/or chemical characteristics. They can be classified into (Sinditêxtil-SP 2009):

-

(i)

recycling within the process: it allows the reuse of the wastes as raw material in the process that caused their generation (for instance, in the industry of homewear articles);

-

(ii)

recycling out of the process: it allows the reuse of the wastes as raw material in a different process from which that caused their generation (for instance, the employment of textile fibers for composite production in automotive industry).

Wang (2006) stated that the recycled fibers are produced in a secondary cycle processing. To obtain them, there are mechanical processes on the textile wastes. Conventionally, the waste is pre-treated by means of cutting or separation and then transported to undergoing the proper recycling, transforming the consolidated material into individual fibers.

Generally the mechanical textile recycling process is as follows: pecking of textile wastes (to decrease the size and maximize the uniformity of the scraps) and subsequent shredding this material by pricked cylinders (generally 3–6, wherein the number of needles increases in each next cylinder in the process). Subsequently, at the industrial level, connected to these first steps it can be, for example, nonwoven continuous production lines, production of composites by airlay process or others.

The mechanical recycled fibers have lower lengths in comparison to virgin ones, but it is difficult to clearly define their other characteristics compared to materials produced from primary fibers. According to Gulich (2006a, b), processes and equipment conventionally used for measuring the characteristics of textiles are not very helpful when applied to recycled fibers. This is due to the mixture of recycled fibers, which are not homogeneous and/or they can be of the same composition (for example, 100 % cotton wastes), but with different origins and also different qualities.

Recycled Cotton Yarn and Jeans

Regarding yarn characteristics, it is known that the elongation, tenacity and irregularities are the most important parameters indicating its quality (Araújo and Mello e Castro 1986). Halimi et al. (2008) studied comparatively recycled cotton and virgin cotton yarns. This study demonstrated that the tenacity of recycled yarn decreased 26.3 % when 100 % of waste as raw material was employed (Fig. 1). The tenacity decreased only 11.6 % when only 25 % of waste mixed with 75 % virgin fiber was employed. In addition the yarn regularity was not affected until the proportion of 25 % of waste material. However, when the cotton waste content was above 25 %, the effect on the yarn irregularity was considerable. According to the literature (Klein 1993; Jackowsk et al. 2002), the yarn elongation is mainly related to the properties of the raw material. According to Halimi et al. (2008), when the waste material in the yarn is 25 %, its elongation decreased 1.6 % in relation to the yarn composed exclusively of virgin raw material. In this way, it can be concluded that the introduction of 15–25 % of cotton waste material in yarn does not affect significantly the tenacity, regularity and stretching, fundamental properties regarding quality, reliability, comfort, dyeing, among others.

Duarte (2013) evaluated the characteristics of fiber jeans mixed cotton and recycled polyester compared to CO/PET conventional jeans, as the environmental impact in textile production, as well as the durability of its materials. To evaluate the durability of jeans physical tests of resistance to elongation and tensile strength; tear resistance; and pilling, according to NBR 11912, ASTM D 2261-11 and ISO 12945-1, respectively were conducted. It was also evaluated two prototypes of pants, with each type of jeans, subjected to intensive wear and washes every 30 days. Regarding the results obtained, the environmental impact assessment showed that the production of jeans with recycled fiber consumes fewer resources, such as water, energy and chemical inputs than the production of conventional jeans. On the other hand, mechanical strength tests and wear test showed that the CO/PET recycled jeans is less durable than the jeans made by conventional manufacturing. The materials and prototypes evaluated were contextualized in scenarios of sustainability and fashion. This author concludes that the jeans with recycled fibers is suitable for hyper technological scenario and fast fashion, while the conventional jeans is appropriate for the scenario of slow fashion and hyper culture.

The Generation of Textile Wastes in Brazil

Countries as China, Bangladesh and India, among others, are major exporters of apparel, mainly to developed countries of the European Union and United States, which in their turn do not need to hardly deal with the environmental problems arising from industrial textile and clothing production, but with the problems related to the disposal of garments by individuals after their use. This justifies the fact that there are more scientific reports and international bibliographic references focusing on the reuse of clothing items than the textile physical recycling, since the textile waste generation is a more important issue for developing or underdeveloped countries, which has the largest textile industries worldwide.

Thus, one of the main environmental problems of the textile chain in Brazil is the generation of solids wastes from industrials processes, clothing manufacturers and also the post-consumption, being the waste generation of clothing industries the most significant of all (Zonatti 2013; Zonatti et al. 2015).

Only one reference was found (Sinditêxtil-SP 2013), which states that Brazil produces 175,000 tons per year of solid wastes from its textile and clothing industries, being mostly scraps from clothing industries. More than 90 % of these scraps was discarded incorrectly in landfills. This reference also report the situation in neighborhood of Bom Retiro, located in São Paulo city. In this neighborhood are installed 1200 clothing enterprises (60 % large generators), which dispose 16 tons per day of waste textiles and this amount represents 2 % of scraps generated annually in Brazil.

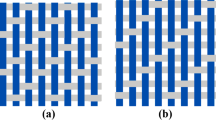

In the case of clothing industry, the generation of solids wastes comes from the spreading and cutting processes. According to Ribeiro and Andrade Filho (1987), the spreading is characterized by the provision of the fabric in superposed layers, according to a predetermined schedule. For spreading the fabric, the operator lays it successively on the cutting table and over all place the risk marker paper. Then the cutting machine work follows the lines present in this risk marker paper. Between the pieces destined to be sewn, scraps left over and can overcome the proportion of 10 % in relation to the surface of all fabric layers (Fig. 2a and b).

Representing this Brazilian problematic the neighborhoods of Bom Retiro and Brás (São Paulo city) are important textile centers in São Paulo and large generators of solid waste, which is incorrectly discarded (Zonatti 2013; Zonatti et al. 2015). Only in Bom Retiro 25 % of all Brazilian garment production is generated (Yázigi 2006). There are so few cooperatives working with this industry (IPT and SEBRAE 2003) and the wastes are minimally availed by issues of logistics, transportation and due to the poor infrastructure of these cooperatives, which do not have physical space to store large amounts of scraps. Within this perimeter are estimated per day, originated by the clothing manufacturer sector, 16 tons of textile waste from Bom Retiro area and 10 tons near Republic of Korea Plaza in Brás according to the enterprise LOGA—Environmental Logistics (2014), which collects solid wastes from São Paulo city. From a total of 100 % of trash solid residues, 50 % are estimated to be scraps of fabric, and from this, about 10 % are not synthetic and 90 % of synthetic fabrics such as polyester and minority polyamide (Sinditêxtil-SP 2013). Still, according to LOGA (2011), all collected fabric scraps end up in landfills. Informally in the metropolitan region of São Paulo city 50 tons per day of textile scraps and discarded garments were estimated.

Despite the large amount of textile wastes not employed and discarded in landfills, on the other hand, in 2012 in Brazil 9,829,928 Liq. kg of textile scraps and residues composed by silk, wool, cotton, man-made fibers, were imported. This is equivalent to US $ 11,421,644 (FOB—Free on Board). This fact shows that there is a great demand for textile waste aiming recycling and for various purposes, such as: production of blankets (for industrial and geotextile applications), coatings, composites for industrial and civil construction, fillers, production of yarns and strings among others (Sinditêxtil-SP 2013).

It is observed that the Brazilian market involved with textile reuse and recycling prefers to import instead to use the national textile waste available in abundance, due to a number of problems related to mismanagement of this material, such as: mixture of different raw materials and its difficult separation (Fig. 3a–c), various types of dirt mixed to the waste (Fig. 3d), lack of tax incentives related to the textile recycling, little qualified and specialized workers in this segment, few references and research that propagate the knowledge in this area, among others. Despite of the existence of an incipient little national market for textile wastes (mainly focused in scraps made of cotton—for mechanical recycling aiming automotive applications; and polyamide—for thermal recycling aiming automotive and technical applications), it is emphasized that besides to still disregard the domestic textile waste from textile and clothing industries, the Brazilian market for textile reuse and recycling also disregards the potential integration of discarded garments by individuals after consumption, due to the lack of studies and data aiming technical possibilities, for example, either the absence of a strongly reverse logistics established for this specific case.

Incipient Brazilian Actions Toward the Sustainability

In 2010 the National Policy on Solid Wastes (NPSW)—Law 12,305—August 2, 2010—was approved. From there Brazil can regulate issues related to solid wastes. According this regulation the trash is classified as: (i) wastes with potential of being availed through reuse or recycling; and (ii) rejects, which cannot be reused or recycled. The Law content ranges from conceptualizations about solid wastes, the instruments of legal interference, their management, company responsibilities and other issues that allow intervention in the matter of solid wastes (Brazil 2010; Brazilian Environment Ministry 2015).

An example of application of NPSW in the industrial clothing sector was in the case of Londrina city (Paraná State, Brazil), notorious polo of clothing manufacturers in the south part of the country. In this city textile scraps were disposed indiscriminately in public spaces, “passing” the responsibility for these wastes (and the consequences of environmental degradation) to the population. Since 2011 the clothing manufactures were heavily audited, held accountable and penalized, in reason of the prosecution proposed by “Protection of Environment of Londrina” and “Environmental Institute of Paraná” resulted in a joint recommendation to regulate the management of solid wastes in that city (Public Prosecution of Brazilian State of Paraná 2011).

As pointed before, the neighborhoods of Bom Retiro and Brás, located in São Paulo city, represent important textile centers. Only in Bom Retiro, the revenues of the district reaches, approximately, R$ 6 billion (near 2 billion €) a year. The wholesaler clients are originated from all over Brazil, Latin America and Africa—approximately 70,000 shoppers a day (Yázigi 2006). However, these clothing manufacturers are also major generators of solid wastes (Zonatti 2013). Routinely, employees of thousands of clothing manufactures discards bags mixing ordinary trash with fabric scraps on the streets (LOGA 2011; Sinditêxtil-SP 2013). Almost the totality ends up in landfills, but before the trash collection performed by enterprise LOGA, it is common street collectors to open these bags, select the textile wastes with higher market value (cotton fabric and jeans scraps followed by scraps of other compositions and larger dimensions) and leave spread the rest of the garbage/waste on public streets, generating pollution, clogged drains, floods and other environmental and social impacts (Sinditêxtil-SP 2013).

Directed to the clothing industrial sector there is no governmental institutionalized policies regarding Reverse Logistics , cooperatives, social inclusion of street collectors or other relevant actions regarding the industrial clothing segment neither in São Paulo city or in any other part of the country. In addition, there is no concern or Brazilian public policy about the issues related to harmful chemical elements or biological agents in fabrics that can be hazardous to human or animal health due the contact of textile with the body skin or about the contamination of the soil after their discard.

As pointed before, there is an incipient and increasing private and increasing recycling sector in Brazil, mainly focused in scraps made of cotton—for mechanical recycling aiming automotive and other applications; and polyamide—for thermal recycling aiming automotive and technical applications. Regarding post consumption garments, exception some private thrift shops or few non-governmental organizations dedicated to reuse and donation of garments, there is no institutionalized actions and the most part of apparels ends up in landfills as ordinary solid trash.

In the neighborhood of Bom Retiro (São Paulo city) a pioneer project called “Retalho Fashion” is still in implementation. The “Retalho Fashion” is headed by “Sinditêxtil-SP—Union of Industries of Spinning and Weaving of São Paulo State” together with “ABIT—Brazilian Association of Textile and Apparel Industries”, “Francisco Matarazzo school—SENAI—National Industrial Learning Service”, the “Chamber of Shopkeepers of Bom Retiro” and the “Municipality of the São Paulo city”. This project aims to develop a waste management plan, organizing and facilitating the collection of textiles wastes in the neighborhood, seeking to preserve the environmental and to generate skilled occupation, creating socially fair working conditions for workers who depend on this means of livelihood and restoring the environmental and cleaning conditions of the area involved (ABIT 2012; Sinditêxtil-SP 2013; São Paulo City Hall 2014).

Thus, the “Retalho Fashion” was divided into three stages (Sinditêxtil-SP 2013):

- 1st Stage:

-

Diagnosis of the region; mobilizing the business community; planning of project execution;

- 2nd Stage:

-

Determination of the necessary infrastructure for implementation of the project and the demand for textile waste;

- 3rd Stage:

-

Project Implementation.

Currently the project is in the 2nd Stage, in which is scheduled to determine the minimum needed infrastructure for its consolidation, including the price and rental of physical space, quotation and purchase of machinery such as forklifts, presses and industrial scales, among others. At this stage, the project is primarily focused on manual separation of textile wastes (by color, size, composition, for example) generated in the Bom Retiro neighborhood. Thus, it is intended to skill street collectors already in the region, improving the process and, hence, to allocate in a way more sustainable way the textile wastes to private recycling companies, in order to preserve the cleaning and environmental conditions (Sinditêxtil-SP 2013).

Thus, despite current actions are important, it is necessary for the feasibility of proposals related to NPSW, Reverse Logistics , clear plans and objectives for managing solid wastes, as well as specific legislation about toxicity and correct disposal of textiles, to account and declare how much is generated, the shared liability for goods, to encourage the creation and operation of cooperatives, public policies for social inclusion of street collectors, environmental monitoring and development of technical and scientific knowledge that will benefit all sectors of society.

Conclusion

Despite of the absence of Brazilian governmental policies related to textile recycling and reuse, excepted NPSW, there is an incipient and increasing private recycling industry in Brazil employing textile scraps from clothing manufacturers. Regarding post consumption garments the most part of apparels ends up in landfills. The implantation of beneficial actions, such as “Retalho Fashion”, are also noticed. Thus, it is concluded the textile reuse and recycling can contribute to the reduction of environmental problems, in addition to being economically viable source of income and social benefits for all involved in this chain, from street collectors to the industrial sector.

References

ABIT – ASSOCIAÇÃO BRASILEIRA DA INDÚSTRIA TÊXTIL E DE CONFECÇÃO. Guia Têxtil 2011. Available in <http://www.guiatextil.com/site/noticias/industria/abit_esclarece_principais_duvidas_das_normas_de_vestibilidade>Accessed Set. 8, 2011.

ABIT – ASSOCIAÇÃO BRASILEIRA DA INDÚSTRIA TÊXTIL E DE CONFECÇÃO. ABIT participa de projeto de Formação e Inclusão Social. Available in<http://www.abtt.org.br/boletim/boletim12/abit3.htm>. Accessed Jan. 9, 2012.

ARAÚJO, M. de; MELLO E CASTRO, M. Manual de Engenharia Têxtil – Vol. I. Portugal: Ed. Calouste Gulbenkian, 1986. 694p.

BRAZIL. Política Nacional de Resíduos Sólidos (“National Policy on Solid Wastes”) (2010). Brazilian Law nº 12.305, Aug. 2, 2010. Establishes the National Policy on Solid Wastes; modifies the Brazilian Law no 9.605, Feb. 12, 1998; and other matters.

BRAZILIAN ENVIRONMENTAL MINISTRY. Relatório técnico de caracterização de resíduos sólidos. Available in<http://www.mma.gov.br/port/conama/processos/18018FE8/Relat_LixiviacaoAmiantoFibrocimento_Rel031E09.pdf>Accessed Feb. 10, 2015.

CAMARA DI COMMERCIO PRATO. Cardato Regenerated CO 2 Neutral. Available in < file:///C:/Users/W/Downloads/Prato_Chamber_of_Commerce_project_description.pdf > . Accessed Dec. 23, 2014.

DUARTE, L. S. Estudo comparativo do impacto ambiental do jeans CO/PET convencional e de jeans reciclado. 2013. 89 p. Dissertation (Master in Production Engineering). Engineering School. Federal University of Minas Gerais. Belo Horizonte/MG, 2013.

FINKLER, M.; SCAPINI, P.; FREIRE, E.; ZATTERA, A. J.; ZENI, M. Compósitos de HDPE com Resíduos de Fibras Têxteis. Parte I: Caracterização Mecânica. Polímeros: Ciência e Tecnologia, vol. 15, n. 3, p. 171-175, 2005.

GROUPE CTT – CENTRE MULTISERVICES POUR L’INDUSTRIE TEXTILE; ITS – INSTITUTE OF TEXTILE SCIENCE. Textile recycling: an overview on technologies and tendencies applications. Available in <http://www.textilescience.ca/downloads/april12_2013/Recycling_Claire_Guignier_apr12_2013.pdf>. Accessed Dec. 10, 2014.

GULICH, B. Designing textile products that are easy to recycle. In: Recycling in textiles (Edited by Youjiang Wang). Cambridge (England): Woodhead Publishing Limited in association with The Textile Institute, 2006a. 230 p.

GULICH, B. Development of products made of reclaimed fibres. In: Recycling in textiles (Edited by Youjiang Wang). Cambridge (England): Woodhead Publishing Limited in association with The Textile Institute, 2006b. 230 p.

HALIMI, M. T.; HASSEN, M. B.; SAKLI, F. Cotton waste recycling: Quantitative and qualitative assessment. Resources, Conservation and Recycling, vol. 52, p. 785–791, 2008.

IEMI - INSTITUTO DE ESTUDOS E MARKETING INDUSTRIAL. Relatório Setorial da Indústria Têxtil Brasileira - Brasil Têxtil 2014. 14ª edição. São Paulo, 2014.

IPT - INSTITUTO DE PESQUISAS TECNOLÓGICAS; SEBRAE – SERVIÇO BRASILEIRO DE APOIO ÀS MICRO E PEQUENAS EMPRESAS. Cooperativa de Catadores de Materiais Recicláveis – Guia para Implantação. São Paulo: Publicação IPT, 2003.

JACKOWSKI, T.; CHYLEWSKA, B.; CYNIAK, D. Influenceofspinningprocessparametersonstrengthcharacteristicsofcottonyarns. Fibres& Textiles in Eastern Europe, v.10, n. 3, p. 27–31, 2002.

KLEIN, W. New spinning systems, short-staple spinning series. The Textile Institute, v. 5, p. 40-41, 1993.

LOGA – LOGÍSTICA AMBIENTAL DE SÃO PAULO. Coleta domiciliar. Available in<www.loga.com.br> Accessed Feb. 26, 2014.

LOGA – LOGÍSTICA AMBIENTAL DE SÃO PAULO. Interview with Mr. Francisco Vianna on Aug. 18, 2011.

MATTOS, P. T. L. O Novo Estado Regulador no Brasil: Eficiência e Legitimidade. São Paulo: Ed. Singular, 2006. 331 p.

MELLO, M. B. C.; CAVALCANTI, G. A.; GONÇALVES, H. S.; DUARTE, S. T. V. G. Inovações Tecnológicas na Cadeia produtiva Têxtil: Análise e estudo de caso em indústria do Nordeste do Brasil. Revista Produção OnLine, v. 7, n. 2, p. 99-117, 2007.

NEULS, G. Economia movida a CO2. Página 22. Escola de Administração de Empresas de São Paulo da Fundação Getúlio Vargas, n. 68. São Paulo: Ed. Vox, 2012.

PUBLIC PROSECUTION OF BRAZILIAN STATE OF PARANÁ. Oct. 18, 2011. LONDRINA - MP-PR expede recomendação para regularizar gestão de resíduos sólidos. Available in <http://www.mppr.mp.br/modules/noticias/article.php?storyid=1955>Accessed Nov. 5, 2014.

RIBEIRO, L.G.; ANDRADE FILHO, J. Introdução à Engenharia Têxtil. v. 1 (208 p.), v. 2 (214 p.), v.3. (196 p.) Rio de Janeiro: SENAI, 1987.

SÃO PAULO CITY HALL. “Retalho Fashion” dará destinação correta aos resíduos de confecção. Apr. 25, 2014. Available in <http://www.prefeitura.sp.gov.br/cidade/secretarias/servicos/noticias/?p=170087> Accessed Nov. 29, 2014.

SINDITÊXTIL-SP – SINDICATO DAS INDÚSTRIAS DE FIAÇÃO E TECELAGEM DO ESTADO DE SÃO PAULO. Guia técnico ambiental da indústria têxtil – Série P + L. São Paulo: CETESB: SINDITÊXTIL-SP, 2009.

SINDITÊXTIL-SP – SINDICATO DAS INDÚSTRIAS DE FIAÇÃO E TECELAGEM DO ESTADO DE SÃO PAULO. Retalho Fashion: Inclusão social e preservação ambiental por meio da reciclagem de resíduos têxteis. São Paulo /SP, 2013. 15 p.

WANG, Y. (Ed.). Recycling in textiles. Cambridge (UK): WoodheadPublishing, 2006. 248p.

YÁZIGI, E. Esse estranho amor dos paulistanos: requalificação urbana, cultura e turismo. São Paulo: Ed. Global, 2006. 376p.

ZONATTI, W. F. Estudo interdisciplinar entre reciclagem têxtil e o design: avaliação de compósitos produzidos com fibras de algodão. 2013. 177 p. Dissertation (Master in Textile and Fashion). School of Arts, Science and Humanities. University of São Paulo. São Paulo/SP, 2013.

ZONATTI, W.; GUIMARÃES, B.M.G.; DULEBA, W.; BARUQUE-RAMOS, R. Thermoset composites reinforced with recycled cotton textile residues. Textiles and Clothing Sustainability, v. 1, n. 1, p. 1-12, 2015.

Acknowledgments

We gratefully acknowledge CAPES (Coordination for the Improvement of Higher Education Personnel of Brazilian Education Ministry) ands (University of São Paulo).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 RILEM

About this paper

Cite this paper

Zonatti, W.F., Baruque-Ramos, J., Duleba, W. (2016). Brazilian Scope of Management and Recycling of Textile Wastes. In: Fangueiro, R., Rana, S. (eds) Natural Fibres: Advances in Science and Technology Towards Industrial Applications. RILEM Bookseries, vol 12. Springer, Dordrecht. https://doi.org/10.1007/978-94-017-7515-1_34

Download citation

DOI: https://doi.org/10.1007/978-94-017-7515-1_34

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-017-7513-7

Online ISBN: 978-94-017-7515-1

eBook Packages: EngineeringEngineering (R0)