Abstract

The idea of sustainability through spreading Awareness in reduce, reuse, and recycle are important techniques for waste management and become a vital factor for improving the economic and environmental condition of textile industries. Because of a remarkable expansion in population, generally improvement of expectation for everyday comforts and the worldwide manufacturing of various textile Textiles items are being expanded in the previous few decades, which prompts a significant degree of utilization and waste generation. The major wastes such as wastewater and fiber waste disposed by in an unplanned manner, which causes many environmental problems, since the textile and clothing industry is one of the most polluting industry. Consequently, the proper management practices of waste generation is becoming important worldwide. This study focuses on identifying the current production, waste generation, source of waste and its characteristics, utilization and environmental concerns. This paper also addresses the possible framework for the textile waste management practices to value added products in textile and apparel industry and future needs for further development are also discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Attributable to the contemporary quick development and smart manufacturing climate, the apparel enterprises have been confronting different difficulties such as sustainability, item quality, effectiveness and administrative consistence while discovering its reality. Besides, the textile and attire mechanical biological system, worldwide sustainable waste administration and economy, puts focus on enterprises to turn out to be more feasible, imaginative particularly zeroing in on more eco-mindful and eco-accommodating items. Thus, much research on textile and apparel industry wastes has focused on value added products in the textile and apparel industry for the long term benefits [1]. Thereby, representing the advanced waste management techniques for the current problems of textile wastes, the textile and apparel consumption can become more sustainable by disposing of the garbage from the households instead of being reused or recycled. Furthermore, this review article will develop a clear understanding of the methodologies adopted by various textile and apparel industries, where wastes are being managed, initiatives should be taken for recycling, reusing and sustainable waste management especially in developing countries. Therefore, this article emphasizes the importance of the different sources on the problem of textile and apparel industries waste by which it can be utilized in a more sustainable way and various application and management solutions to solve the problem of increasing textile and apparel industry wastes.

The global textile market scenario

Textiles and attire industry is perhaps the oldest, biggest and a set up area of the world. Industrialization and financial development assumes a significant part in the advancement of any country. Along these lines, it is difficult to envision a world without Textiles, which is a key piece of everyday life and a significant area in the worldwide economy [2,3,4,5]. The Textiles business is blasting all through the entire world and India involves 2nd and US 3rd in terms of production after China. Textiles industry improvement impacts the worldwide economy. The Textiles business has gotten one of the principle mainstays of the economy. China and India are the best two Textiles makers around the world. India is the second-biggest exporter of Textiles and apparel with a portion of 5% of worldwide trade [2, 6]. The global textile industry was estimated at around $920 billion in 2018 and it is projected to reach approximately $1,230 billion by 2024, representing a steady compound annual growth rate (CAGR) of nearly 5% during the forecast period. China is the world’s largest clothing exporter, produced around 79 billion meters of cloth in 2017 and 5.99 million metric tons of cotton in 2018. The Indian textiles and apparel industry, currently estimated at around $150 billion, is expected to reach $250 billion by 2019. The current estimated exports stood at around $38.70 billion in 2019 and is expected to $82.00 billion by 2021 from $ 22.95 billion in 2020.The total value of U.S. textile and apparel shipments total an estimated $76.8 billion in 2018, this is an increase from $73 billion in output in 2017. Indian textile and apparel industry is one of the largest segments of Indian economy, occupies a distinctive position in terms of production, employments, and exports [7]. Some of the major textile manufacturing industries in India include: Arvind Ltd, Vardhman Textiles Ltd, Welspun India Ltd, Raymond Ltd and Trident Ltd. These industries contributed 7% of the industry output (in value terms), 2% to the gross domestic product (GDP), employs more than 45 million people and 15% to the export earnings of India in 2018–19 [8,9,10]. Moreover, recently initiatives taken by Government of India under Union Budget 2020–21, a National Technical Textiles Mission is proposed for a period from 2020 to 21 to 2023–24 at an estimated outlay of Rs 1,480 crore. This can achieve the position of India as a global leader in technical textiles, such as development of rainwear, sportswear, retarded apparel and fire resistance garments [11]. The textile business market for the most part incorporates yarns and fabrics. The market cost is assessed by the estimation of home-grown creation with imports and without trades, surveyed at producer costs. The worldwide material plants market esteem added up to $748.1 billion in the year 2016 (up 3.5% from the year 2015 and compound yearly development of the market was 2.7% somewhere during 2012 and 2015. The Asia–Pacific region contributed to 59.6% of the global textile mills market value, Europe and the United States accounted for a further 19.1% and 10.8%, respectively. The global textile mills market is projected to reach $961.0 billion in value in 2021, an increase of 28.5% since 2016. The global textile market value scenario are depicted in Table 1. The compound annual growth rate of the market between 2016 and 2021 is estimate to be 5.1%.This specifies the extensive growth of worldwide textile industry and the consumption products which lead to the increase in production of textile products [12, 13].

Waste from textile and apparel industry in pre product development

The waste product is an undesirable substance that is disposed of after essential use or/is damaged, no utilization item, and of moderately minor monetary worth. Waste reusing is assumed as an imperative part of the minimization of environmental change and save natural resources [14]. It has been stated that the textiles and apparel are almost 100% recyclable and everything in these industries should be utilized. Due to the increasing environmental awareness, there is a need to optimize solid waste management is becoming significant. Consequently, the textile and apparel industries are making efforts to decrease post-consumer textile waste disposal [15,16,17]. In modern way of living we cannot limit the material and waste production but explore the alternative recycling techniques to reduce the burden on nature. Thus, the environmental friendly techniques are very important to save our nature sustainably [18].

Like other industry, the textile business likewise delivers a few sorts of solid wastes, which leads onto different ecological difficulties. India as an emerging nation, the fast industrialization and monetary development is fundamental. In any case, the explanation which drives comparing with modern development is the generation of industrial wastes [19]. Different sorts of waste can be named as solids, fluids, or gases, in light of their actual state. These solid waste can be ordered dependent on their unique use (bundling waste, material waste, food waste, and so forth), actual properties (flammable, compostable, recyclable, and so on), materials (glass, paper, and so on), source (homegrown, business, agrarian, modern, and so on) and security level (perilous or non-unsafe). Domestic waste and business squander together can be delegated civil strong waste [17].Due to late trend setting innovation, material and clothing ventures create enormous measures of waste dependent on crude material utilized during material creation and piece of clothing producing, which possess a huge spot. Owing to an exponential increase in global population (8 billion, India—1.38 billion in 2020), the demand for new products have led to enormous textile production and consumption and most important reasons for waste generation. However, with development of technologies and scope of being recycled and re-use, these waste are recognized as resource. It is predicted that global fiber consumption will reach 110 million tonnes in the year 2020 [20, 21].Textile and apparel industrial waste refers to that generated in the manufacturing process of fibrous products. This industrial waste is composed of natural and synthetic polymeric materials. Natural and synthetic fibers are like cotton, jute, wool and silk polyester, nylon, polypropylene, etc. There are different processes of stages of industrial waste generation in textile and apparel sectors. In view of this, the material and clothing business waste can predominantly be separated into three general classes: (i) production, (ii) pre-consumer or post-industrial, and (iii) post-consumer waste. The production waste contains waste from various textile manufacturing steps, pre-consumer waste from harmed items in stores and post-buyer squander from arranged waste from the shoppers. Consequently, the first type of waste as production waste comprises of waste from numerous textile-manufacturing processes or at production stage, second type of waste as pre-consumer waste from damaged products in stores and in production stage and the third waste as post-consumer waste from disposed waste from the consumers in consumption stage [22].

Production waste

This is fundamentally made out of strands, yarns, fabric scraps, and clothing cuttings created by fiber makers, material plants, and texture and attire make. The manufacturing sector, fabric cutoffs, and fabric rolls are establishing a lot of wastage. During the assembling and creation produce a gigantic measure of squanders, which impacts in huge expenses to the associations. Besides, the carpet area likewise produces a ton of single stringy type waste. The disposal techniques has been reported by several researchers and are divided in to three categories like: (i) solid waste stream and end up in landfills or waste incinerators, (ii) energy to power the manufacturing process, and (iii) sold to a textile waste recycler. Some researchers already have been reported in their study that, overall apparel industry contributes to both pre-consumer and post-consumer textile waste [22,23,24].

Pre-consumer or post-industrial waste

This kind of waste refers to the left-over materials generated during the stage of production and manufacturing process in fiber, textile and cotton industries, such as design mistakes, wrong colour and fabric faults. The waste related to crude materials, which are utilized in textile creation can be ordered into three primary gatherings, which are cellulose fiber, protein fiber, and engineered fiber [25]. Cellulose fiber is produced using plant materials, such as cotton, flex, hemp, and ramie. Protein fiber is created from creatures including fleece, angora, cashmere, and silk and engineered fiber is produced using oil-based synthetic substances, such as polyester, nylon, spandex, acrylic, and polypropylene [3]. Previously, the four methods of disposal process of these waste has been given by several researcher, such as: (i) waste sent directly to the companies (ii) sold to other outlets, jobbers, or consolidators, who in turn resell the merchandise to other outlet stores; (iii) sent directly to non-profit organizations; and (iv) sent directly to landfill by retailers [17, 22, 26]. Some of the pre-consumer textile material wastes in the textile manufacture route are given in Table 2 [27].

Post-consumer waste

This waste refers to any types of the unwanted apparel or other household products from fabricated textiles that the owner decides to discard. Previous study stated that the waste is usually generated after the textiles have been consumed and discarded by the consumers. It has been reported the volume of post-consumer waste is generated a huge amount in comparison with other and also comparable with the fiber consumption rate [23].The post-consumer textile waste has been projected to landfills are 10.5 million tonnes per year in the USA, 350,000 tonnes per year in the UK and 287,000 tonnes per year in Turkey. It has also been reported that in USA around 75% of the pre-consumer textile wastes can be diverted from the landfills and recycled, while only 15% of post-consumer textile wastes are recycled. However, in India due to the manufacturers and less aware of consumers of the hazards related to environmental degradation the situation appears miserable. According to a fashion magazine, 73% of discarded clothes end up in landfills which are packed with so much urban waste that by 2050, India will require one bigger size to fit the wastes it produces [20, 22, 28].

Environmental concerns on textile and apparel waste

Textile and apparel waste is a significant environmental concern that is growing rapidly due to the increase in exponential population growth and consumer demand for fast fashion and low-cost clothing. There are several significant environmental problems associated with waste, including (a) landfill waste, which contributes to greenhouse gas emissions (GHGs) and energy consumption throughout the production, transportation, and disposal of textiles and apparel, contributing to climate change, (b) chemical pollution, as textiles and apparel items made using synthetic materials can take hundreds of years to decompose and release harmful chemicals into the environment, and (c) water consumption, as textile production requires significant amounts of water, and the disposal of textile waste can also lead to water pollution [29, 30]. In 1975, world textile production was reported to be about 8.4 kg per person. However, this figure is expected to reach 14 kg per person in 2021 and increase to about 17.5 kg per person by 2030 [31]. Therefore, the global consumption of textile products will increase to 62 million tons per year, and by 2030, it is projected to reach 102 million tons [32]. Top 10-textile exporter by value in 2021 is depicted in Table 3 [33]. Population growth that is accelerating and the globalisation of the textile and fashion industries have led to an unequal distribution of the environmental effects, with developing nations suffering the brunt of the costs for developed nations. The environmental impacts of the textile and apparel industry are extensive and significant. Water resources use intensity, use of chemical, including toxic chemicals, wastewater discharges and lack of treatment processes, as well as energy use and electricity’s carbon intensity are some of these significant impacts [34]. The textile and apparel industry is generally, regarded as the second most dangerous industry to the climate after oil, because the textile industries and the generated wastes are dumped in to the landfills, which has become a major concern globally. This deed can create a serious environmental problem owing to its high greenhouse gas emissions and contamination of air and water supplies [35]. Furthermore, the fashion industry contributes up to 10% to global pollution and accounts for 6–8% of CO2 emissions, or more than 1.7 billion tonnes annually, ranking second only to aviation [32]. The textile ventures utilize tremendous measures of resources such as water, oil, and land during the whole life cycle, creation, assembling, dissemination, and customer use to garments end of life at disposal. The environmental impacts in terms of emissions during the textile production route and the final product is depicted in Fig. 1 [36]. It has been reported that textile industry is one of the largest generators of GHGs (CO2 emission is highest during initial fiber extraction), not smallest because of its huge size. The global textile industry uses large quantity of non-renewable energy sources, consumed in the form of electricity, uses 378 billion liters of water and approximately 4% of global freshwater, resembles to 93 billion cubic meters of water is being utilized annually in the year of 2014 and 2020, respectively. The carbon footprint is estimated to be of approximately 15 kg or approximately 20 times its own weight for a textile product like one T-shirt [35, 37, 38]. Researchers also reported the current global trends in the textile sector are projected to represent a quarter of the 26% global carbon budget and if current trends continue, the consumption of non-renewable raw materials from the textile and apparel sector will reach 300 million tonnes by 2050. Thus, the GHG emissions from textile production were responsible for 1.2 billion tons of CO2 equivalent of GHG [37]. The improvement of these units influences the climate, as around 10–20% of all material items are viewed as waste products. Annual waste from the textile and apparel industries in several countries are estimated at 26.0 million tons in China, 12.4 million tons in the United States, 1.0 million tons in the United Kingdom in 2017 and 1.0 million tons in India in 2011, respectively [3, 40]. There are many factors leading to environment pollution. Earlier researchers reported that, the textiles and aluminium produce the most greenhouse gases per unit of material. Correspondingly, the Intergovernmental Panel on Climate Change claims that the textile industry causes 10% of global greenhouse gas emissions [32, 39]. However, limited data exist on the geographical distribution of emissions from the textile and apparel industries. The worldwide energy sources of textiles and garment production have a large impact on the emission intensity. Table 4 shows the primary energy consumption of the textile and garment industry by fuel type in certain nations in 2019 [34].

Environmental impacts in terms of emissions during the textile production process and the final product, Modified from [37]

The quick development of enterprises is fundamental for financial improvement in an emerging nation like India. However, the principal factor, which goes corresponding with modern development, is the misuse of both mechanical assembling and operations. Cotton is developed worldwide and is the main fiber to make material and clothing products. The yearly world production of cotton changed from 26.7 million tons in 2017/2018 to 25.6 million tons in 2018/2019 and is right now assessed with 25.9 million tons for the year 2019/2020. The top 10 cotton producers are India, China, United States, Brazil, Pakistan, Turkey, Uzbekistan, Mexico, Australia and Mali for the year 2019/2020 [41]. During cotton production, huge amount of water, several deadly toxic chemicals such as pesticides and insecticides have been used, which has a negative effect on the surroundings. The textile industries are using extensive amounts of water, energy, chemicals and raw materials throughout the supply chain, which places heavy demands on Earth’s natural resources. During cloth production disquieting amounts of chemical pollutants, CO2 gas and other toxic substances are released into surrounding waterbodies, soil and air [37].Earlier study stated the roughly 65% of insecticides, 20% herbicides and 14% were defoliants and growth regulators, while fungicides and others comprise only 1% of the total toxic chemical. The water required for irrigation during cotton cultivation exceeds profusely for same amount of synthetic fiber production. It has been observed that, the major environmental concern in the textile industry is the amount of chemical content water discharged. Moreover, some important issues such as energy consumption, air emissions, solid wastes and odors can be of significant problem in certain treatments [12, 42, 43]. The ecological effects on which the textile area is a significant benefactor incorporate the consumption of material resources and water, land use, environmental change and synthetics toxicity [44]. Owing to these exercises the cotton creation in textile and attire businesses are obliterating with time the common assets, contaminating the water bodies and to the all-out environment. Earlier said that Textile effluent is a reason for huge measure of natural debasement and human diseases. About 40% of internationally utilized colorants contain naturally bound chlorine, a known cancer-causing agent. Textile industrial wastewater is extremely alkaline and contains high concentration or biological oxygen demand (BOD), chemical oxygen demand (COD), total dissolved solids (TDS). This discharged effluent leads to environmental hitches if it is not properly treated prior to its safe disposal. Researchers also stated that, chemicals are dissolving in to wastewater and having a negative effect to human health. Moreover, these waste are not easily decomposed, accumulates and occupies more space which, may lead to infectious diseases, attract pests, and spread odors in the environment [3]. For environmental and economic benefits the reuse and recycling of textile and apparel waste is a sound technology in recent time which, protects from many polluting and energy intensive textile make processes. However, the landfill of textile waste lead to many problems in landfill methods, such as slow decomposition of fiber and CH4 gas production from decomposed woolen, which contributes to global warming. Hence, this can create environmental problems without appropriate waste management practices [45, 46].

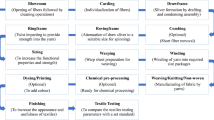

Textile and apparel waste management and possibility of recycling

The vast majority of the nations are attempting to diminish the measure of disposal in landfills and increment the measure of reusing. Because of the absence of reasonable treatment and removal strategy, the executives of huge measure of city and mechanical waste has reached in a basic stage in metropolitan urban areas [17]. The waste chain of importance of the textile and clothing industry waste the executives' alternatives and reusing plausibility are portrayed in Figs. 2 and 3 [51]. These features underscore prevention, reuse, and recycling as key to feasible administration of waste material. Waste the board choices are as indicated by best natural works on taking into consideration of a material life cycle. This is an ecological appraisal of an item's life. Hence, three R's have gotten a focal fundamental in maintainable waste administration endeavors. In recent years, some of the developing and developed countries implemented the six level concepts for waste management, such as prevention, minimize or reduce, reuse, recycling, energy recovery and disposal or landfill [22, 46].

Waste from textile and apparel industry and recycling possibility, Modified from [48]

In recent times, to counter the negative impacts textile industry has taken many measures for reducing its negative contribution towards environment. For reducing environmental impacts and resource usage the circular economy has recently gained a lot of attention worldwide from scientists, entrepreneurs and authorities to promote recycling to maximize material service and materials life. Circular economy is the sustainable future and a recent economic model occurred as a response to the new needs of society and our planet. It has a direct connection with sustainable development, which requires a balanced coordination among the economic, technological, social and environmental aspects of manufacturing process [17, 47,48,49,50].

There are four principles that explain the concept of circular economy in textile and apparel waste as follows: zero waste—nothing is thrown away, because waste is designed out by making things for repair, disassembly and reuse. Two types of industrial ingredients as (i) disposable and biodegradable and (ii) durable and reusable. Entirely renewable energy in the industrial cycle—this also reduces businesses exposure to depletion of sources of energy resources. Customers are no longer consumers, but users seek to provide access to a service instead of ownership of a good. Companies are responsible for the product and its waste [43]. A few waste administration methodology are talked about before for textile and clothing waste materials, such as reuse and recycle, energy from waste, and last removal or land filling. The measure of textile and attire waste being transferred to landfills and incinerators is expanding and gigantic as of late. The waste discard is the most un-supported administration cycle and landfill is the last objective of garbage removal. In this strategy, the engineered textile wastes are not decayed as expected and fleece articles of clothing are deteriorated and produce CH4 and CO2. It is expressed that CH4 is more hurtful than CO2 and they are adding to a worldwide temperature alteration [51,52,53,54]. By way of development of technologies and scope of being recycled and re-use, the waste are recognized as resource. Energy recovered from waste can be recovered by different methods, such as incineration, gasification and anaerobic digestion. Incineration is the practical burning process in which the residual or textile wastes are burned at a high temperature and energy is recovered as electricity or heat and can be used as sources of energy. In this process amount of waste decreased by about 90% depending on composition of the materials and degree of recovery. Here, the main sources of fuel energy as flue gases such as CO2, H2O, O2 and N2 are generated. In the meantime, gasification is partial oxidation of organic substances at high temperatures (500–1800 °C) to produce a synthetic gas. Gasification is preferably used for electricity production and the advantage of gasification compared with incineration is higher electrical generation efficiency. In anaerobic digestion, conversion of organic textile waste by microorganisms into CH4 rich biogas to generate electricity. This renewable fuel is used for the production of green electricity or as a vehicle fuel [17, 55].Earlier study stated, the quality of recycled final product is equal to the original product in recycling. Based on this the recycling technologies are categorized in to four ways, primary, secondary, tertiary and quaternary. They are summed up as follows: in the initial stages of recycling the material are in a unique structure for recuperation of equivalent worth. Auxiliary preparing is of the post-purchased item by mechanical methods into an item with various physical and additionally compound properties as mechanical reusing. Tertiary cycles such as pyrolysis and hydrolysis, in which waste is changed over to fundamental substance constituents, monomers. Quaternary handling or recuperation is the waste-to-energy change cycles, for example, burning of strong waste or usage of warmth generated [56]. Moreover, the recycling process earlier states as physical and chemical recycling. In physical process, manufacturing waste and post-consumer products are recovered into different products using reclamations process. In chemical process the conversion of high molecular weight polymers into low molecular weight substances. It has been stated that, the physical recycling is more favourable than chemical recycling due to its simpler, cheaper and more environmental friendly process [57].Textile and apparel recycling can be classified into thermal, mechanical, chemical and material recycling technologies. Thermal recycling is to recover heat energy generated from incineration of wastes as thermal or electrical energy. Thermal methods include different types of pyrolysis processes, which performs at high temperature range of 450–900 °C depending upon the type of resin. Pyrolysis is referred to the decomposition process with high temperature in absence oxygen condition. From this process depending upon the conditions various products are generated, such as activated carbon fiber, char, bio-oil and syn-gas [58, 59].

It has been expressed, out of these advancements the mechanical recycling is the most favoured procedure and can be utilized for recycling of a wide scope of textile waste composition. In this technique, the textures are earlier destroyed into little pieces and isolated by their synthesis and shading to set up the recycled filaments for yarns or non-woven utilizes, such as protection materials, napkins, floor covering, and expendable diapers [17]. On the other hand, the compound recycling recovers monomers from disposed strands by polymer deterioration. It is applied to synthetic fibers and their blends, which are separated chemically, degraded and re-polymerized into new fibers, such as sports material, furniture, insulators, automobile carpeting and toys [60]. Reuse and reduction or prevention means any operation by which products are not waste, which are used again. The importance of textile waste reduction and reuse of products are to bring awareness among the people on adverse effects on the environment. There are many governmental roles for the management of textile wastes are like technology advancements for waste recycling, create logistic chains and market for recyclable products, promote the use of or environmental friendly material and reduce the packaging material and encourage compliance. Furthermore, there are certain obstacles appeared in textile and apparel waste recycling process, such as deficit of appropriate equipment, lack of awareness among consumers, end products cost and lack of marketing [57].

Usage of textile and apparel waste in various fields

The designing answers for the recycled textile and apparel waste materials might be changed over into comparative items from virgin and normal filaments. At present, the sustainable administration of any items is fundamental as opposed to being a choice. Writing an overview giving a portion of the powerful endeavors of utilizing material waste appears to have expanded its use for different applications. A portion of the recycled textile items and their application field from material and clothing waste are given in Table 5. Several researches have summarized the main applications for textile and apparel waste as reinforced composites. These are such as inforce polyethylene matrix, for soil reinforcement to improve the strength and stability of soil, for bricks making, as an adsorbent fiber for heavy metal adsorption, for making chipboards, for lightweight polymer concrete as aggregate, as activated carbon, for thermal insulation material and for heat and energy generation [47, 61,62,63,64,65,66,67,68]. A study has been carried out on recycling of Indian textile and apparel waste and results stated, the production of various designer products using recycled textile waste in India. An alternative network has been also developed for merchandising of pre-owned clothing by online app. Nowadays, some of the small-scale industries are now converting the textile waste to fibers and they used as fillers for mattress, pillows and cushion to recycle yarns [69].

It has been seen that the textile and apparel enterprises wastes are generally utilized for warm protection building materials from reused polyester (RPET) filaments, squander fleece, and a combination for building [75]. The cotton and carpet wastes are corrupted gradually in landfill process and causing different climate issues. Thus, recently the recovered fibers recovered from them. The recovered products can be used as building material and thermal insulation and concrete reinforcing material to improve the shrinkage and toughness [3, 70]. Textile fiber wastes has also been used as reinforcement and ability to expand the strength and rigidity in composites for various applications [77,78,79]. Researches have also been studied and compared the mechanical properties, such as tensile, bending and impact, which revealed the tensile and bending strength of waste yarn reinforced were lower than glass fiber reinforced samples. Their findings stated the impact energy of the waste yarn reinforced samples was greater [14, 64]. Earlier study focused on dissolution of purified cotton waste garments in N-methyl morpholine-N-oxide solution and spun them into new fibers. Then, the molecular and mechanical properties were analyzed and compared with those of standard lyocell fibers [17, 80, 81]. Besides, for textile and apparel waste management there is some govt. obligation and certain roles are there to empower innovation head ways for waste reuse, to make calculated chains and market for recyclable items, to promote the utilization of natural cordial material, to diminish the bundling material, and encourage consistency [57]. From this study, it can be confirmed that textile and apparel waste may be used in different fields due to its various important properties.

Conclusions

The textile and apparel industries have been a major contributor to environmental pollution and waste generation for decades. The manufacturing processes involve various chemicals, dyes, and finishing agents that can be harmful to the environment and human health. From the above study, it tends to be reasoned that the material business is currently centered on expanding the waste reusing systematically to preserve energy and normal assets and eventually improve production. Creative advances and additionally the improvement of existing innovations have been explored and created to accomplish the aggressive objective of "zero-waste" in the approaching years. The powerful use of textile and apparel waste transforms into a high-valued item and permits improving the material enterprise's seriousness. In addition, the practical utilization of textile and apparel waste adds to common asset saving. Thus, the usage of textile and apparel waste in different fields produces not only economic but also ecological advantages, since their use has led to resource conservation and thus solves the disposal problems. Therefore, reduce; reuse and recycling textile and apparel waste seems to be a better approach. This will not only solve the contemporary problem of textile waste but will also lead to the achievement of zero waste status and sustainable application of waste from textile and apparel industries. Various techniques of pollution prevention in textile processing need to implement to reduce wastewater volume by the techniques, such as good housekeeping, counter-flow processing, reuse of process water, automation of the machinery. In addition to reduce the amount of dyes and chemicals consumption by good housekeeping, process optimization by careful selection of dyestuffs, auxiliaries and process conditions, recovery and reuse of process chemicals, automation of the machinery and computerized recipe optimization is also needed. Besides these, the life cycle assessment (LCA) is a technique used to evaluate the environmental impacts and burden associated with all the stages in the life cycle of a textiles product (from raw material extraction, processing, manufacture, application, repair and maintenance and final disposal or recycling), waste minimization and used for estimating CO2 and GHG emissions [82]. It is needed to lower the current uncertainties in LCA of textile and apparel industries production. In addition the textile and apparel industries production with its waste management of textile waste reveals that it can be cost effective if manage properly in terms of their properties and applications. Consequently, to solve these environmental issues, it is crucial to promote sustainable fashion practises such as create public awareness, lowering consumption using eco-friendly materials, financial and administrative help, superior collection techniques, partnerships, and an engineered way of closed-loop recycling systems can be applied for landfilling after checking the long-term environmental properties. By opting to purchase clothing and textiles made responsibly, as well as by choosing to donate or recycle their used clothing rather than toss it away, consumers can also make a difference. Government rules and industry standards can also support sustainability and lessen the textile and clothing sector's environmental effect. Subsequently, the achievement of the new textile economy thus requires innovative levels of research coordination with NGOs, government agencies, and industry associations, to develop and implement sustainable management approaches. It also requires the cooperation and system-level changes are required to transform the textile industry into new circular economy principles, involves designing products that are durable, repairable, and recyclable, as well as implementing recycling and upcycling programs. In addition, the ambition for a new textile economy relies on four ambitions is depicted in Fig. 4, which would lead to better outcomes in terms of economic, environmental and societal textiles system [83]. These measures and steps would encourage more sustainable management approaches in the textile and apparel industries. However, there is still a long way to go, and it is important for all stakeholders to work together to achieve a more sustainable and circular future.

Number of ambitions for a new textiles economy, Modified form [83]

References

Ahmad S, Miskon S, Alabdan R, Tlili I (2020) Towards sustainable textile and apparel industry: exploring the role of business intelligence systems in the era of industry 40. Sustainability 12(7):2632

Morlet A, Opsomer R, Herrmann S, Balmond L, Gillet C, Fuchs L (2017) A new textiles economy: redesigning fashion’s future. Ellen MacArthur Foundation, pp 1–150

Pensupa N, Leu SY, Hu Y, Du C, Liu H, Jing H, Lin CSK (2017) Recent trends in sustainable textile waste recycling methods: Current situation and future prospects. Chemistry and chemical technologies in waste valorization. Springer, Cham, pp 189–228

Holkar CR, Jadhav AJ, Pinjari DV, Mahamuni NM, Pandit AB (2016) A critical review on textile wastewater treatments: possible approaches. J Environ Manage 182:351–366

Shishoo R (2012) Introduction: trends in the global textile industry. The Global Textile and Clothing Industry. Woodhead Publishing

Weaving The Way For Indian Textile Industry, Available online: https://niti.gov.in/weaving-way-indian-textile-industry

Chavan RB (2001) Indian textile industry-environmental issues

Sharma M, Dhiman R (2016) Determinants affecting Indian textile exports: a review. Biz Bytes 6:193–200

Global Textile Industry Factsheet (2020): Top 10 Largest Textile Producing Countries and Top 10 Textile Exporters in the World, Available online: https://www.bizvibe.com/blog/top-10-largest-textile-producing-countries/

Textile Industry & Market Growth in India, Available online: https://www.ibef.org/industry/textiles.aspx

India budget 2020 for textile & clothing: what industry leaders have to say, Available online:https://www.fashionatingworld.com/new1-2/india-budget-2020-for-textile-clothing-what-industry-leaders-have-to-say

Sivaram NM, Gopal PM, Barik D (2019) Toxic waste from textile industries. Energy from toxic organic waste for heat and power generation. Woodhead Publishing, pp 43–54

Market Size of the Global Textile and Apparel Industry: 2016 to 2021/2022, https://shenglufashion.com/2018/12/18/market-size-of-the-global-textile-and-apparel-industry-2016-to-2021-2022/

Umar M, Shaker K, Ahmad S, Nawab Y, Umair M, Maqsood M (2017) Investigating the mechanical behavior of composites made from textile industry waste. J Textile Inst 108:835–839

Hawley JM (2006) Textile recycling: a systems perspective. Recycling in textiles. Woodhead Publishing Limited, UK, Cambridge, pp 7–24

Domina T, Koch K (1997) The textile waste lifecycle. Cloth Text Res J 15:96–102

Yalcin-Enis I, Kucukali-Ozturk M, Sezgin H (2019) Risks and management of textile waste. Nanoscience and biotechnology for environmental applications. Springer, Cham, pp 29–53

Prena J, Charu G (2016) Textile recycling practices in Índia: a review. Int J Textile Fashion Technol 6:21–36

Agrawal R, Sharan M (2015) Municipal textile waste and its management. Res J Family 4:40–60

Karaosman H, Brun A, Morales-Alonso G (2017) Vogue or vague: sustainability performance appraisal in luxury fashion supply chains. Sustainable management of luxury. Springer, Singapore, pp 301–330

Voncina B (2016) Recycling of textile materials. 2B Funtex-MDT. http://www.2bfuntex.eu/sites/default/files/materials/Recycling%20of%20textile%20materials_Bojana%20Voncina.pdf

Shakya A (2017) Integrated waste minimization techniques in apparel design

Wang Y (2010) Fiber and textile waste utilization. Waste Biomass Valorization 1:135–143

Gardetti MA, Torres AL (eds) (2017) Sustainability in fashion and textiles: values, design, production and consumption. Routledge

Ghaly AE, Ananthashankar R, Alhattab MVVR, Ramakrishnan VV (2014) Production, characterization and treatment of textile effluents: a critical review. J Chem Eng Process Technol 5:1–19

Chavan RB (2014) Environmental sustainability through textile recycling. J Text Sci Eng 2:1–5

Babu BR, Parande AK, Raghu S, Kumar TP (2007) Cotton textile processing waste generation and effluent treatment. J Cotton Sci 11:141–153

Waste to Sales: 4 Ways to Get a Sizzlingly Sustainable Wardrobe in 2020, https://www.thebetterindia.com/208427/fashion-industry-upcycle-recycle-swap-green-resolutions-shopping-landfills-diy-hacks-lifestyle-ser106/. Accessed 1 Apr 2021

Bick R, Halsey E, Ekenga CC (2018) The global environmental injustice of fast fashion. Environ Health 17:1–4

Abbate S, Centobelli P, Cerchione R, Nadeem SP, Riccio E (2023) Sustainability trends and gaps in the textile, apparel and fashion industries. Environment, Development and Sustainability, p.1–28

Per capita production of textile fibers worldwide from 1975 to 2020, with a forecast for 2025 and 2030: https://www.statista.com/statistics/1260339/global-textile-fiber-production-per-capita/

Niinimäki K, Peters G, Dahlbo H, Perry P, Rissanen T, Gwilt A (2020) The environmental price of fast fashion. Nat Rev Earth Environ 1:189–200

WTO Reports World Textiles and Clothing Trade in 2021: https://shenglufashion.com/2022/12/02/. Accessed 13 Feb 2023

Sharpe S, Dominish E, Martinez-Fernandez MC (2022) Taking climate action: measuring carbon emissions in the garment sector in Asia. ILO Working Paper, UK

Moorhouse D, Moorhouse D (2017) Sustainable design: circular economy in fashion and textiles. Des J 20(sup1):S1948–S1959

Choudhury AK (2014). Environmental impacts of the textile industry and its assessment through life cycle assessment. Roadmap to sustainable textiles and clothing: environmental and social aspects of textiles and clothing supply chain. 1–39.

The economic design award fashion and the environment, (2014). https://static1.squarespace.com/static/582d0d16440243165eb756db/t/585b485d2994ca583275e5f0/1482377319742/LEARN2014_LEARN2014_FashionEnvironment_ENG_FINAL.pdf

Ütebay B, Çelik P, Çay A (2020) Waste in textile and leather sectors. Textile wastes: status and perspective. IntechOpen, pp 39–58

United Nations Climate Change (2018). UN helps fashion industry shift to low carbon. unfccc.int https://unfccc.int/news/un-helps-fashion-industry-shift-to-low-carbon. Accessed 5 Dec 2022

Circular economy need of the hour to minimize textile waste: Study https://timesofindia.indiatimes.com/business/circular-economy-need-of-the-hour-to-minimize-textile-waste-study/articleshow/63583328.cms. Accessed 8 Jan 2021

Top 10 Cotton Producing Countries in the World, https://dnfi.org/cotton/top-10-cotton-producing-countries-in-theworld_4785/#:~:text=For%20the%20season%202019%2F2020%20the%20Top%2010%20cotton%20producers,of%20cotton%20to%20its%20customers

Bhar C (2016) Indian textile industry and its impact on the environment and health: a review. Int J Informat Syst Serv Sector (IJISSS) 8:33–46

Kumar RS (2015) Process management in spinning. CRC Press Tailor & Francis Group

Srinivasan NSK, Shah Hasmukh (2020) Textile Circular Economy, https://textilevaluechain.in/2020/03/16/textile-circular-economy/

Dubey B, Jain K (2015) Recycling of textile waste is the best way to protect environment. IOSR J Environ Sci Toxicol Food Technol 1:37–43

Raj CS, Arul S, Sendilvelan S, Saravanan CG (2009) Bio gas from textile cotton waste-an alternate fuel for diesel engines. Open Waste Manag J 2(1):1–5

Pandit P, Singha K, Shrivastava S, Ahmed S (2020) Overview on recycling from waste in fashion and textiles: a sustainable and circular economic approach. Recycling from waste in fashion and textiles: a sustainable and circular economic approach, 1

Maity S, Singha K, Pandit P, Ray A (2020) Circular economy in fashion and textile from waste. Recycling from waste in fashion and textiles: a sustainable and circular economic approach, 235

Koszewska M (2018) Circular economy—challenges for the textile and clothing industry. Autex Research Journal 18:337–347

Tisserant A, Pauliuk S, Merciai S, Schmidt J, Fry J, Wood R, Tukker A (2017) Solid waste and the circular economy: a global analysis of waste treatment and waste footprints. J Ind Ecol 21:628–640

Gadkari R, Burji MC (2014) Textiles waste recycling. https://textilevaluechain.in/2014/06/06/textiles-waste-recycling/

Bukhari MA, Carrasco-Gallego R, Ponce-Cueto E (2018) Developing a national programme for textiles and clothing recovery. Waste Manage Res 36:321–331

Bhuiya MH (2017) Upcycling the garment solid waste in Bangladesh (Doctoral dissertation, Thesis, Tallinn University of Technology)

Strähle J, Hauk K (2017) Impact on sustainability: production versus consumption. Green fashion retail. Springer, Singapor, pp 49–75e

Bosmans A, Vanderreydt I, Geysen D, Helsen L (2013) The crucial role of Waste-to-Energy technologies in enhanced landfill mining: a technology review. J Clean Prod 55:10–23

Le K (2018) Textile Recycling Technologies, Colouring and Finishing Methods. Prepared for Karen Storry, Senior Project Engineer, Solid Waste Services, Metro Vancouver

Rani S, Jamal Z (2018) Recycling of textiles waste for environmental protection. Int J Home Sci 4:164–168

Williams PT, Reed AR (2003) Pre-formed activated carbon matting derived from the pyrolysis of biomass natural fiber textile waste. J Anal Appl Pyrol 70:563–577

Oliveux G, Dandy LO, Leeke GA (2015) Current status of recycling of fiber reinforced polymers: Review of technologies, reuse and resulting properties. Prog Mater Sci 72:61–99

Bhatia D, Sharma A, Malhotra U (2014) Recycled fibers: an overview. Int J Fiber Textile Res 4:77–82

Algin HM, Turgut P (2008) Cotton and limestone powder wastes as brick material. Constr Build Mater 22:1074–1080

Binici H, Temiz H, Aksogˇan O, Ulusoy A (2009) The engineering properties of fired brick incorporating textile waste ash and basaltic pumice. J Faculty Eng Architect Gazi Univers 24:485–498

Binici H, Gemci R, Aksogan O, Kaplan H (2010) Insulation properties of bricks made with cotton and textile ash wastes. Int J Mater Res 101:894–899

Binici H, Gemci R, Kucukonder A, Solak HH (2012) Investigating sound insulation, thermal conductivity and radioactivity of chipboards produced with cotton waste, fly ash and barite. Constr Build Mater 30:826–832

Dong C, Zhang H, Pang Z, Liu Y, Zhang F (2013) Sulfonated modification of cotton linter and its application as adsorbent for high-efficiency removal of lead (II) in effluent. Biores Technol 146:512–518

Meyabadi TF, Dadashian F, Sadeghi GMM, Asl HEZ (2014) Spherical cellulose nanoparticles preparation from waste cotton using a green method. Powder Technol 261:232–240

Rahman A, Urabe T, Kishimoto N, Mizuhara S (2015) Effects of waste glass additions on quality of textile sludge-based bricks. Environ Technol 36:2443–2450

Pakravan HR, Memarian F (2016) Needlefelt carpet waste as lightweight aggregate for polymer concrete composite. J Ind Text 46:833–851

Bairagi N (2017) Recycling of post-consumer apparel waste in India: channels for textile reuse. J Textile Sci Eng 8:2

BiniciH AO (2015) Engineering properties of insulation material made with cotton waste and fly ash. J Mater Cycles Waste Manage 17:157–162

Yalcin I, Sadikoglu TG, Berkalp OB, Bakkal M (2013) Utilization of various non-woven waste forms as reinforcement in polymeric composites. Text Res J 83:1551–1562

Dobircau L, Sreekumar PA, Saiah R, Leblanc N, Terrié C, Gattin R, Saiter JM (2009) Wheat flour thermoplastic matrix reinforced by waste cotton fiber: Agro-green-composites. Compos A Appl Sci Manuf 40:329–334

Liu Y, Zhang Y, Guo Y, Chu PK, Tu S (2017) Porous materials composed of flue gas desulfurization gypsum and textile fiber wastes. Waste Biomass Valorizat 8:203–207

Zheng J, Zhao Q, Ye Z (2014) Preparation and characterization of activated carbon fiber (ACF) from cotton woven waste. Appl Surf Sci 299:86–91

Patnaik A, Mvubu M, Muniyasamy S, Botha A, Anandjiwala RD (2015) Thermal and sound insulation materials from waste wool and recycled polyester fibers and their biodegradation studies. Energy and Buildi 92:161–169

Bodur MS, Bakkal M, Savas M, Berkalp OB (2014) A new approach for the development of textile waste cotton reinforced composites (T-FRP): laminated hybridization vs. coupling agents. J Polym Eng 34:639–648

Briga-Sa A, Nascimento D, Teixeira N, Pinto J, Caldeira F, Varum H, Paiva A (2013) Textile waste as an alternative thermal insulation building material solution. Constr Build Mater 38:155–160

Campbell PE, McMullan JT, Williams BC, Aumann F (2000) Co-combustion of coal and textiles in a small-scale circulating fluidised bed boiler in Germany. Fuel Process Technol 67:115–129

Ramamoorthy SK, Persson A, Skrifvars M (2014) Reusing textile waste as reinforcements in composites. J Appl Polym Sci 131:17

Jordeva S, Tomovska E, Trajković D, Popeski-Dimovski R,Zafirova K (2015) Sound insulation properties of structure designed from apparel cutting waste.In: AUTEX2015_Proceedings

Bediako JK, Wei W, Yun YS (2016) Low-cost renewable adsorbent developed from waste textile fabric and its application to heavy metal adsorption. J Taiwan Inst Chem Eng 63:250–258

Van Der VNM, Patel MK, Vogtländer JG (2014) LCA benchmarking study on textiles made of cotton, polyester, nylon, acryl, or elastane, 2014. Int J Life Cycle Assess 19:331–356

Ellen MacArthur Foundation, A new textiles economy: Redesigning fashion’s future, (2017) http://www.ellenmacarthurfoundation.org/publications)

Acknowledgements

The authors express their sincere thanks to the seniors and colleagues for providing adequate guidance, scientific and technical discussions and necessary support for this review manuscript. The first author and the co-authors acclaim the reviewers and editor for their valuable comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chand, S., Chand, S. & Raula, B. Textile and apparel industries waste and its sustainable management approaches. J Mater Cycles Waste Manag 25, 3132–3143 (2023). https://doi.org/10.1007/s10163-023-01761-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01761-1