Abstract

Regardless of the crop production system used, weeds must be controlled at or below an economic threshold in order to achieve an acceptable level of profitability. The best method of weed control will depend on a number of factors, including labor, fuel and machinery cost, crop prices, and farmer’s willingness to accept production risks. In this chapter, we discuss economic factors that drive innovation in precision weed control technologies for agriculture and influence producer adoption of those technologies. We present a theoretical framework to help explain the economic incentives or disincentives to adoption of these emerging technologies. We also introduce the concept of externalities – costs or benefits realized by groups other than producers – which, if internalized to farm firms through taxes, subsidies, or restrictions, may influence producer adoption of a specific technology. We conclude with highlighting a number of important farm-level economic impacts of precision weed technology adoption.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Precision weed control is a set of technologies that uses spatial and temporal information to locate, identify, and manage weeds. Precision weed control takes advantage of various innovations in automation, site-specific sensing, and application technologies to manage weeds in crop fields but essentially utilizes strategies similar to traditional weed management approaches, including chemical, mechanical, cultural, and biological methods (Swinton 2005). With only a limited number of commercialized hardware and software tools available to date, precision weed control is still a nascent concept compared to other precision farming technologies that have been in the marketplace for some time. A precision weed control system is comprised of three basic requirements, including a weed sensing system to detect and identify weeds, a weed management model to turn knowledge and gathered information into management decisions, and a precision weed control implement, such as a sprayer with automatic section (or individual nozzle) control for variable applications of herbicides (Christensen et al. 2009). Variable rate technology for herbicide application has received much of the attention to date, largely because of the perception that it provides the most economical and environmental benefits of all emerging precision weed control technologies (Wiles 2009).

Weed control practices have evolved considerably over the last decades with development of new herbicides, herbicide-tolerant crops, and improved application technologies. Still, weed management remains a constant challenge to agricultural productivity because of the dynamic nature of weed populations resulting from the complex interactions between production practices, soil resource characteristics, and environmental conditions (Buhler 2002). Weed populations are unevenly distributed within crop fields and tend to grow in aggregated patches varying in size, shape, and density (Dille et al. 2003; Cardina et al. 1997). Therefore, uniform herbicide applications lead to unnecessary input application on areas with weed densities below economic or weed density threshold values and have been identified as a major source of inefficiency in managing weeds (Cardina et al. 1997). Many studies have documented the potential for input and cost savings when weed control is adapted to the actual spatial and temporal distribution of weeds, and a variety of technologies have been successfully developed for precision treatment of weeds (Ritter et al. 2008; Sökefeld 2010; Schroers et al. 2010; Christensen et al. 2009; Takács-György et al. 2013). For example, precision spraying systems with automatic section control have evolved to allow selective management of input applications across the spray boom in response to detected weed populations. This technology holds substantial promise for reducing input application overlap, thus saving chemicals, fuel, and time during the application of herbicides. The potential for input savings is particularly high in situations where sprayer patterns become more complex, for example, in the case of irregular shaped fields, waterways, drainage ditches, or similar obstructions. The efficiency of this technology increases even more when combined with a precision guidance system, such as lightbar or auto-steer (Sökefeld 2010; Batte and Ehsani 2006; Shockley et al. 2012). Additional input savings are possible for applications with multiple tank sprayers, direct injection systems, and intermittent spraying of full and reduced herbicide rates that allow to more selectively control weed species in the field with different herbicides and herbicide mixtures (Gutjahr et al. 2008; Schroers et al. 2010; Wiles 2009). The full potential of precision spraying of herbicides would involve micro-targeted spraying of individual weed plants with a spray material best suited to control this weed species. To be successful, this will require advances in computer vision and plant recognition software as well as continued development of sprayer technologies.

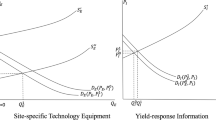

Whether precision management of inputs is economically more viable than conventional management will vary between fields depending on the crop, the inputs, prices, the cost of new technology compared to existing technology, and the yield response variability within each field. For example, expected cost savings of variable rate technologies relative to uniform treatment will increase with greater spatial and temporal variability because optimal input application rate will vary more (English et al. 2001; Roberts et al. 2006). The economic benefits of precision weed control in particular are related to the proportion of the field that is weed infested, the degree of weed patchiness, and the spatiotemporal resolution of available sampling and spraying technologies (Barroso et al. 2004). The management of spatial and temporal variability of weed populations in general will be economically viable only when then degree of in-field variability is large enough to offset the additional costs of obtaining the information and managing the differences accordingly (Forcella 1993). In particular, development of cost-effective map-based or sensor-based technologies for detecting, mapping, and controlling weeds at the required spatial and temporal resolution remains a major challenge before the technology will become an economically viable option for farmers (Andujar et al. 2011; Wilkerson et al. 2002; Christensen et al. 2009). Developing valid decision rules that guide translation of gathered information about spatial and temporal heterogeneity of weed populations, weed-crop interactions, and cost functions into site-specific management decisions is equally critical (Gutjahr and Gerhards 2010; Gutjahr et al. 2008).

As a whole, precision weed control is a fairly recent technology, and adoption is still not widespread (Christensen et al. 2009; Takács-György et al. 2013; Jensen et al. 2012). Lowenberg-DeBoer (2003) noted that adoption rates of precision farming technologies, including precision weed control, have been much slower compared to other agricultural innovations, such as Roundup Ready© technologies in corn and soybeans that were introduced during the same time period. An extensive body of literature investigates adoption of precision farming technologies since the first components became commercially available about two decades ago and identifies key factors that influence adoption decisions (see, e.g., Khanna et al. 1999; Batte and Arnholt 2003; Adrian et al. 2005; Reichardt and Jürgens 2009; Reichardt et al. 2009). Findings suggest that adoption of precision farming technologies is influenced by a broad range of factors involving farmers’ socioeconomic characteristics (Khanna 2001; Daberkow and McBride 1998; Fernandez-Cornejo et al. 2001), farmers’ professional experience and education (Reichardt et al. 2009; Reichardt and Jürgens 2009; Kitchen et al. 2002; Batte and Arnholt 2003), access to information and familiarity with related information technologies (Daberkow and McBride 2003; Fountas et al. 2005), attitudes and perceptions toward precision farming technology (Adrian et al. 2005), and physical characteristics of the farm (Swinton and Lowenberg-DeBoer 1998). Other important factors influencing adoption decisions include the need for a new set of managerial abilities and additional management time required to effectively use precision farming technologies for decision making (Lowenberg-DeBoer 2003; Griffin et al. 2004). Because precision farming is intrinsically information and data intensive, the complexity of farmers’ information management processes and the need for specific information management skills increase substantially, and lack thereof may restrict the effective use of these technologies (Nash et al. 2009; Reichardt and Jürgens 2009; Kitchen et al. 2002).

In the remainder of this chapter, we focus on the economic factors that drive innovation in precision weed control technologies for agriculture and influence producer adoption of those technologies. We will present a theoretical framework to help explain the economic incentives or disincentives to adoption of these emerging technologies. We will also introduce the concept of externalities – costs or benefits realized by groups other than producers – which, if internalized to farm firms through taxes, subsidies, or restrictions, may influence producer adoption of a specific technology. We will conclude with highlighting a number of important farm-level economic impacts of precision weed technology adoption.

2 Innovation and Technological Change

Technological change is a process that occurs over time. An early conceptual model identifies three phases of technology development and implementation: invention, innovation, and diffusion (Schumpeter 1942). Invention refers to the discovery or development of new knowledge. Examples relevant to precision agricultural technologies would be the discovery of methods to identify an exact position on the earth’s surface through triangulation using known locations (global positioning systems or GPS) and the development of computer vision technology to allow identification of crop and weed species. Innovation refers to application of these inventions to produce new methods of accomplishing work related to a particular production process. There have been many areas of innovation related to the discovery of satellite-based global positioning, ranging from military applications to civilian transportation management to precision farming applications. Some of these innovations are successful and lead to new technologies that are broadly adopted, and others are dismissed as not useful. In this chapter, technology is referred to as methods and materials of production. Technology often is embodied in durable capital assets (machines or buildings), other inputs (hybrid seeds or agrichemicals), or even combinations of inputs (e.g., Roundup© herbicide and Roundup Ready© seed). Technology, once developed, is spread among potential users through a process of diffusion. Diffusion of a successful technology typically is observed to follow an S-shaped curve (Fig. 12.1) where adoption first occurs for small groups of innovators and early adopters who are innovative, embrace change, and are willing to accept risk (Rogers 2003). Research generally has shown that innovators and early adopters tend to be younger, more highly educated people, and tend to have larger farm businesses (Diederen et al. 2003). As the benefits of the technology become more broadly known, adoption accelerates with adoption by the early majority (Rogers 2003). The late majority adopt more slowly, only after advantages of the new technology are clearly demonstrated. Finally, the laggards are the last to adopt and typically are very averse to change. To the extent that a technology increases outputs for a given level of inputs, profits tend to exist for those who adopt a technology early. These profits tend to diminish as larger proportions of producers adopt the technology and market prices adjust to the increased supply (Silverberg et al. 1988).

S-shaped cumulative adoption curve (Modified from Rogers 2003)

To give some perspective on how the process of invention, technology formulation, and adoption/diffusion proceed over time, let’s consider the historical case of US agriculture throughout the twentieth century and explore those issues that shaped this technological change. As the century began, agriculture was characterized by draft animal power and the intense use of human labor on small farms. Inventions of internal combustion engines, mass production techniques, and related methods created opportunities that agricultural innovators soon recognized. The concept of a mechanical draft machine (tractor) followed, with many innovators, both farmers and industrialists, combining these new inventions into early tractors. Indeed, some of the earliest innovators were farmers who converted Model T automobiles into tractors.

The drive to innovate usually follows from a motive to increase the profitability of a given enterprise. Hicks (1932) first introduced the concept of induced innovation to help explain this drive to innovate. Following this concept within our example, farmers use a number of inputs in farming. Categorizing these into broad categories, one can think about these inputs as human labor and capital (draft animals, machinery, purchased inputs, etc.). Both input categories were required to produce a crop product using the technology of the day. However, during this time labor was increasing in cost relative to capital due to increased off-farm employment opportunities and declining machinery costs due to improvements in manufacturing. Under the prevailing farming technology, the rising cost of labor reduced the profitability of farming, and the limited availability of labor restricted farm size. Thus, farmers had an incentive to develop and adopt technology that would reduce labor needs by substituting labor-saving capital. Although the newly emerging tractor technology required substantial new capital investment, it allowed greater efficiency in the use of limited and increasingly expensive human labor. It also allowed for increased farm size. With the adoption of tractors, and expansion of the farm to fully utilize this technology, average total cost of production actually decreased (Fig. 12.2) with the adoption of mechanization relative to that of draft animal agriculture.

Induced innovation, to increasingly save relatively expensive human labor, continued over the remainder of the twentieth century, with farmers rapidly replacing existing machinery with ever larger farm machines. Figure 12.3 illustrates average cost curves for various sizes of farm equipment. Larger farm equipment allowed for increased economic efficiency (and profits) relative to smaller equipment, thereby lowering average variable costs, and, by expanding farm size to take full advantage of the larger equipment, were able to keep average fixed costs low. Thus, larger farm operators were able to produce at a lower total cost per unit of output.

Tweeten (1988) has suggested that much of the expansion of farm size that occurred during the past century was done to take advantage of larger and larger farm equipment. The introduction of other technologies such as no tillage and conservation tillage systems that reduce the number of machine passes over the field and chemical weed control technologies that eliminate tillage passes and save labor and machine operating costs have exacerbated these trends. Recently, genetic engineering has allowed crops to be modified to be tolerant of selected herbicides, further allowing substitution of chemical weed control for mechanical tillage in field crops.

3 Adoption of Emerging Weed Control Technologies in Conventional Agriculture

There is no reason to believe that motives for technology selection will be vastly different in the future than they were in the past. Induced innovation, and the desire to substitute relatively inexpensive inputs for more expensive ones, will remain as a key element driving technological change. That said, there are a number of key elements in the economic, social, and political environments that may encourage new technologies for weed control discussed in this book.

3.1 Increasing Recognition of Externalities of Production

The discussion of economics in the preceding section was based on private costs and returns to farm firms. That is, when a farmer makes a choice among competing products, or decides which technology to use, they attempt to maximize the difference in returns and costs. However, in recent decades, we have increasingly recognized that there are external costs associated with production activities. For instance, soil erosion not only costs the farmer in terms of diminished future productivity, but it costs downstream residents in terms of sediments filling streams and reservoirs, carrying fertilizer nutrients and agrichemical compounds to urban water supplies, diminishing recreational values, lowering housing values along streams and lakes, and many other impacts. These impacts are referred to as external costs. They do not impact farmers’ choice of production methods unless these costs somehow are internalized. One way this can happen is if governmental agencies place a tax on farmers to offset a portion of the external costs or impose restrictions (resulting in added costs or reduced production) on producers to reduce the level of external costs. An alternative approach is to provide subsidies (external returns) tied to adoption of desired production practices. For instance, societal concerns about greenhouse gas emissions and climate change have and likely will continue to result in increased governmental regulation of agriculture. This may well translate into changes in the relative profitability of various production technologies. Should policy makers decide to encourage a particular technology, the application of an investment tax credit or other form of subsidy can dramatically alter the economics of adoption of that technology.

High technology approaches to weed control will likely fit well with an increased societal awareness (and hence policy maker concern) about adverse environmental impacts of agriculture. Spot targeted spraying techniques that apply herbicide materials only to weed plants rather than broadcast applications have significant potential to reduce off-site movement of herbicides (Wiles 2009; Burgos-Artizzu et al. 2011). Farmers may be very willing to adopt these improved weed control technologies if rewarded for this by imposing lower “externality taxes” for pollution or providing investment tax credits or other subsidies for adoption of these technologies.

3.2 Increasing Energy Costs

Since 2000, we have witnessed a significant increase in the real cost of energy. If this trend continues due to rapidly expanding demand in the developing world with slower increases in worldwide supply, then high energy prices may become an important driver of adoption of new agricultural technologies. Agrichemical inputs (fertilizers and herbicides) are highly reliant on energy. Machine vision weed control technologies allow substitution of machinery services for energy-intensive herbicide applications and may provide a profit advantage for the adopting farmer. A number of recent studies, for example, have shown the potential of micro-targeted herbicide applications to substantially reduce herbicide material application (e.g., Gutjahr and Gerhards 2010; Luck et al. 2010; Sökefeld 2010; Wiles 2009). This would be a significant cost savings for this technology, one that will increase with the rate of energy cost inflation.

3.3 International Elements of Agricultural Demand

Agricultural commodity markets typically are international in scope. Much of the US production of food and feed grains is sold in the work market. Yet, many of our potential trading partners have restrictions on commodity specifications that may limit our ability to sell to that market. For instance, the European Union, China, Japan, Thailand, and many other countries have placed restrictions on the use of genetically modified organisms (GMOs) in food and feed commodities. The Economic Research Service, US Department of Agriculture, estimates that 88 (93) percent of US corn (soybean) production used GMO varieties in 2012 (USDA 2013). The resistance in many foreign markets to GMOs raises concern about the long-term viability of GMO varieties in US agricultural production. Unless there is a lessening of these trade restrictions over time, farmers who produce GMO-free varieties may receive a price premium. Movement away from herbicide-resistant GMO varieties may be more feasible if micro-targeted spraying technologies and computer vision weeding technologies are available.

3.4 Demand for Differentiated Food Products or Production Practices

Prices of farm products are a key determinant of profitability of farm production. Prices are determined in the market as an interaction of supply and demand. However, demand is not static over time. For instance, in the case of food products, it is strongly influenced by perceptions, real or imagined, of food characteristics. Most US farmers produce commodity products: These products are not differentiated among farmers or by method of production. Their outputs are intermingled with the products of similar farmers, and the price is determined in the world market for such commodities. A recent trend has been the production of differentiated (non-commodity) food products, where the farm’s product is somehow set apart as different from commodity crops.Footnote 1 Examples are certified organic foods, locally grown foods, GMO-free crops, beef produced without antibiotics or hormone supplements, pasture-finished beef or lamb, humanely produced animal products, or any other characteristic that consumers view as important. The decision to produce for one of these specialty markets will impact technology choice. For instance, foods that are certified to be organic cannot use chemical weed control or genetically modified organisms; GMO-free product producers cannot use Roundup Ready© or similar technologies. For these producers, improvements in mechanical weed control will be of increased interest. Consumers also have indicated a willingness to pay extra for products that are certified to be environmentally friendly – e.g., to have a smaller carbon footprint or to use lower levels of agrichemical inputs (Gifford and Bernard 2008; Dannenberg 2009; Lusk et al. 2005). Computer vision mechanical weed control or micro-targeted herbicide application technologies will be of increased interest to farmers who may produce for these specialty markets.

3.5 Crop-Specific Impacts

Each crop has a unique production function and each responds differently to weed pressures. Thus, the economics of weed control differ for each crop. With all else equal, the greater the relative impact of weed competition on crop yield, and the greater the value of the crop, the higher will be the value of effective weed control. Characteristics of the crop production method also will impose restraints on the feasible weed control methods. For instance, crops grown in rows (e.g., corn, cotton) versus solid-seeded (e.g., alfalfa) or narrow row (e.g., soybeans, wheat) cropping methods create very different opportunities/constraints for tillage-based control methods. On the other hand, these characteristics may create opportunities for innovation and application of new methods. For example, machine vision combined with plant species identification may allow for mechanical weed control or micro-targeted spraying even in solid-seeded crops where tillage previously was not feasible.

3.6 Farm Size Issues

US farms range widely in size, from very small, part-time businesses to large businesses that may be international in scope. Farm size has frequently been shown to be an important determinant of technology adoption, with larger farm business operators typically being much more willing to innovate and adopt new technologies (Diederen et al. 2003; Fernandez-Cornejo et al. 2001; Sunding and Zilberman 2001). From a purely economic standpoint, larger farms have greater ability to spread the fixed costs of a new technology over greater amounts of output, resulting in lower costs per unit of production. These fixed costs arise from investment in capital assets (especially true for technologies that are embodied in machinery) or the development of special knowledge or the hiring of specially trained workers to operate the technology. Research has also shown that the operators of larger farms also tend to be more willing to innovate and to take on risks associated with technological change than operators of smaller businesses (Sunding and Zilberman 2001). Combined, this suggests that diffusion of a new agricultural technology will proceed much more rapidly among larger farms than for smaller ones.

3.7 Risk Preferences of Producers

Each individual differs in their willingness to accept (or to bear) risk. This affects willingness to take on business or financial risks. Business risks that might be important are those that differ among technologies. For instance, chemical control of weeds may be viewed as lower risk than mechanical weed control due to possible constraints on the timing of tillage due to weather events. Also, an extended period of wet weather may prevent mechanical tillage at key times, thus creating exposure to risks of yield reduction due to high weed pressure. One reason that Roundup Ready© technologies have been so rapidly adopted is that farmers have great latitude in timing weed control activities, thus greatly reducing yield risks associated with failed weed control. Financial risks are those that arise from the financial structure of the firm. Financial risks increase with the level of debt and other non-equity funding of the firm. For this reason, the size of the financial investment costs associated with a technology may be an important determinant of a farmer’s willingness to adopt a technology. Lower investment systems, or those that can be performed by custom service providers, will have lower financial risks and thus be adopted more rapidly.

4 Adoption by Organic Farmers

In order to be certified to market agricultural products as organic, farmers must comply with a rigorous set of guidelines. Certification rules require that a highly structured production system be followed – one that does not allow use of most pesticide and herbicide materials, genetically modified organisms, and many other practices currently used in conventional agriculture.

Organic farmers currently use a variety of techniques to help control weed populations. A common practice in the US corn belt region is to use multiple cultivations prior to planting to allow sprouting of weed seeds which are then killed through cultivation, combined with a later than conventional planting date. Expanded crop rotations, to incorporate crops with different planting dates, can vary the habitat for weeds and allow better control. Cover crops with rapid growth can help starve weeds of light and nutrients and reduce weed pressures in subsequent crop cycles. For densely planted crops, hand weeding may be necessary to control weeds. While each of these practices is beneficial as part of an organic production system, they may come with substantial costs. Delayed planting dates may result in yield penalties due to a shorter growing season. More tillage passes require additional fuel and labor and may increase soil compaction. Specialized tillage tools will increase fixed machine investment costs. Expanded rotations mean that lower-profit crops may replace higher-profit crops in the rotation. Because weed control is such a challenge for organic producers, we believe that computer vision tillage-based weed control systems will be a huge advance for organic producers. Such technology will both reduce costs of weed control, will perhaps allow greater specialization in more profitable crops, and will reduce risks that organic farmers face due to weather-related poor weed control.

5 Farm-Level Economics of Adopting Precision Weed Control Technologies

From the previous discussion in this chapter, it becomes clear that adoption of precision weed control practices may have significant economic impacts at the farm level. Our focus in this chapter is on private costs and benefits associated with adoption of emerging weed control technologies, but it should be noted that this technology is likely to have economic implications beyond the farm level. For example, it seems feasible that spatial and temporary information and knowledge gathered at the farm level could be utilized to manage agricultural systems at local or regional scales for reduced weed interference with field crops (Swinton 2005; Maxwell and Luschei 2005). A major focus of the economic studies conducted so far in the context of precision weed control has been to investigate whether production costs per unit input can be decreased to make it more cost-effective than uniform application (Swinton 2005). Unit costs can be reduced by lowering operating input with the same output level (yield) or by increasing the output level while maintaining the same operating inputs. For example, weed control costs can be lowered by decreasing the amount of herbicides applied or by improving the placement of herbicides, thereby maximizing the net return of herbicide applications. Adoption of precision weed control technology has the potential to both increase revenues and/or lower costs at the farm level.

In the absence of subsidies or other extra-market payments to the farmer, the only source of returns to the farmer for adoption of precision weed control technologies is in the value of the crop. Total gross receipts to the cropping enterprise are the product of crop yield, price, and the number of acres harvested. The specific farm situation to which the technology is applied and how the individual farmer chooses to manage the technology will determine the impact on each of these parameters. The efficacy of weed control in most conventional cropping systems is already high, generally providing good protection against yield losses through weed interferences (Gianessi and Reigner 2007; Oerke 2006). The prospects of precision weed control to increase average yields in a significant way, therefore, are likely limited (Swinton 2005). Precision application of herbicides may mitigate negative yield effects often associated with herbicides misapplied to low weed densities areas (Weis et al. 2008; Ritter et al. 2008; Donald 1998). Oebel and Gerhards (2006) reported that site-specific herbicide applications may increase average yields in low weed density areas in cereal crops. Cedergreen (2008) found that herbicides applied at low doses can stimulate crop growth. Depending on dose-response relationships at different levels of competition between crops and weeds, precision weed control supports application of herbicides below label rates with the goal of reducing weed competitiveness sufficiently for crops to subsequently suppress weeds completely (Swinton 2005). Precision weed control can also impact crop yields indirectly, as shown by Deike et al. (2005) who reported an increase of nitrogen efficiency under reduced herbicide applications in fields with low weed infestations. Precision management practices that enhance crop vigor (e.g., by improving nutrient and water availability for crops) may also strengthen crop competitiveness and, in turn, mitigate yield losses to weed interferences (Buhler 2002; Swinton 2005). Weed distribution patterns are often associated with soil properties, agronomic practices, and environmental variation (Buhler 2002). Because weed distributions and densities tend to vary between years and crops, input applications will need to be adjusted to the particular situation. It appears reasonable, therefore, to assume that with adoption of a technology that allows precision regulation of multiple inputs (e.g., variable rate applications for fertilizers and herbicides), average yields in some fields will increase while in others it will decrease.

Price received clearly impacts gross receipts. Crop quality for most crops is not expected to change sufficiently to impact price. However, as we discussed earlier, commodity prices may increase if crops are grown that have special characteristics, such as non-GMO, herbicide-free, or organic certification that command premium prices in the marketplace. Precision weed control technologies can help to at least partially offset higher weed management costs for these crops and will also provide the ability to preserve the identity of these crops during and after harvest. Note, however, that this is not an automatic consequence of the technology, but rather is an opportunity afforded to the adopter.

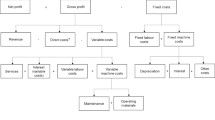

Much of the economic focus of precision weed control and other precision farming technologies to date has been on the potential for cost reductions. There are two broad categories of costs that must be borne by the farmer. Variable costs are a function of the level of output of the farm. Fixed costs represent those inputs that are invariant with the level of production. The adoption of a precision weed control system is expected to result in changes in both variable and fixed cost categories. Typical expenditures associated with precision weed control technology include output-related variable costs, such as expenditures for spatial information, data acquisition and processing, and chemical and cultural weed control, and fixed costs associated with purchase and ownership of precision weed control equipment. Examples of common fixed costs are depreciation, interest on investment, as well as taxes, insurance, and storage costs associated with yield monitors, computers and software, GPS equipment, variable rate technology application equipment, and other necessary equipment (Mooney et al. 2009). Farmers may choose to use financial leasing or custom hire in lieu of ownership for some durable assets. In the case of a financial lease, for example, the farmer will face a fixed financial lease payment instead of a charge for depreciation and interest on invested capital. A farmer may also elect to custom hire weed control services instead of owning equipment. Generally, such operating leases are offered on a variable cost basis, priced per acre or per day of operation. Depending on the implemented technology, expenditures for map-based or sensor-based (online) information and data acquisition technologies for boundary mapping, soil and site surveys, and the establishment of base and prescription maps need to be considered (Roberts et al. 2006; Rider et al. 2006). These items can incur substantial expenditures and should be considered durable investments with their costs being amortized as a fixed cost over a number of years. There are also costs associated with management time and the development of human capital that are often not considered in economic assessments for precision farming technologies (Lowenberg-DeBoer 2003). Labor and management are inputs that will not be regulated by the adopted technology, but rather are required inputs. Given the current state of the technology, we expect that human intervention in the data acquisition and decision processes will remain an important component in the foreseen future implying a substantial time commitment on part of the farm manager. Accordingly, these input costs which have been cited as an important impediment to adoption of precision farming technologies will, at least in the short term, increase with adoption of emerging weed control technologies (Lowenberg-DeBoer 2003; Fountas et al. 2005; Reichardt and Jürgens 2009). Herbicides represent a major share of crop production costs in conventional cropping system, and the monetary gains resulting from precision application based on spatial and temporal distribution of weeds, soil types, and other parameters have been well documented (see, e.g., Berge et al. 2008; Sökefeld 2010; Oebel and Gerhards 2006; Gutjahr and Gerhards 2010; Wilkerson et al. 2004; Wiles 2009; Luck et al. 2010; Dammer and Wartenberg 2007; Ritter et al. 2008; Takács-György et al. 2013). The actual amount of inputs applied under practical field conditions, however, will always be a site-specific decision. As discussed earlier, optimal input application rates depend on other crop management practices, weed infestation levels, soil properties, and the spatial and temporal variability of these factors and may increase from a conventional application level. Expenditures for gathering site-specific information and data will inevitable rise relative to the uniform application strategy regardless whether map-based or sensor-based approaches are adopted (Mooney et al. 2009). Better integration of existing technologies and advances in the development of autonomous machinery for weed detection and control are promising to help reducing the information costs of precision weed control technology in the future (Pedersen et al. 2006; Shockley et al. 2012).

Profits are the difference in total receipts and total costs. As discussed in this chapter, the change in profitability with the adoption of precision weed control technologies depends largely on the circumstances for the specific farm. On the one hand, total receipts will depend on the relative increase or decrease in average yields, change in commodity prices, and possible change in enterprise size, while increases and decreases in the variable and fixed costs categories will determine the overall costs associated with precision weed control. As pointed out, all these factors will be influenced by site-specific factors. Only as we gain more experience with precision weed control technology at the farm level will the relative contribution of each of these parameters become clearer.

6 Conclusion

Agricultural technologies are changing rapidly. New innovations arise in response to changing prices and other market and non-market signals. Market prices for labor and management continue to be high relative to the cost of machinery or agrichemical capital inputs. Farmers will continue to embrace those technologies which create the greatest relative advantage in terms of financial reward to their businesses. Even though the past decades have witnessed movement away from tillage and mechanical weed control toward chemical and biological control technologies, there may be a shift over the coming decades. Weed resistance to herbicides will reduce the effectiveness of chemical control agents. Consumers are becoming increasingly health and safety conscious, and many view the increased reliance on agrichemical control agents as risky both to the consumer and to the environment. Whether or not this perception is real, it may well translate into a demand for differentiated products that are certified to be herbicide- or pesticide-free, and which may command premium prices. If this demand materializes, it will produce an additional incentive for farmers to shift toward precision weed control. Finally, technology advancement continues. Previously, many of the precision farming technologies were high cost both in terms of investment and operation. Improvements have and will continue to decrease these costs, making these technologies much more competitive relative to traditional chemical weed control. As these changes occur, we can expect to see a continual shift toward this lower cost or higher profit allocation of resources.

Notes

- 1.

Differentiated products each face an individualized demand curve. Hence, the prices of commodity corn and organic corn may vary substantially because a subset of consumers views these as different products with greatly differing attributes.

References

Adrian AM, Norwood SH, Mask PL (2005) Producers’ perceptions and attitudes toward precision agriculture technologies. Comput Electron Agric 48:256–271. doi:10.1016/j.compag.2005.04.004

Andujar D, Ribeiro A, Fernandez-Quintanilla C, Dorado J (2011) Accuracy and feasibility of optoelectronic sensors for weed mapping in wide row crops. Sensors 11(3):2304–2318. doi:10.3390/s110302304

Barroso J, Fernandez-Quintanilla C, Maxwell BD, Rew LJ (2004) Simulating the effects of weed spatial pattern and resolution of mapping and spraying on economics of site-specific management. Weed Res 44(6):460–468. doi:10.1111/j.1365-3180.2004.00423.x

Batte MT, Arnholt MW (2003) Precision farming adoption and use in Ohio: case studies of six leading-edge adopters. Comput Electron Agric 38(2):125–139. doi:10.1016/S0168-1699(02)00143-6

Batte MT, Ehsani MR (2006) The economics of precision guidance with auto-boom control for farmer-owned agricultural sprayers. Comput Electron Agric 53(1):28–44. doi:10.1016/j.compag.2006.03.004

Berge TW, Cederkvist HR, Aastveit AH, Fykse H (2008) Simulating the effects of mapping and spraying resolution and threshold level on accuracy of patch spraying decisions and herbicide use based on mapped weed data. Acta Agric Scand B 58(3):216–229. doi:10.1080/09064710701593087

Buhler DD (2002) Challenges and opportunities for integrated weed management. Weed Sci 50(3):273–280. doi:10.1614/0043-1745(2002)050[0273:AIAAOF]2.0.CO;2

Burgos-Artizzu XP, Ribeiro A, Guijarro M, Pajares G (2011) Real-time image processing for crop/weed discrimination in maize fields. Comput Electron Agric 75(2):337–346. doi:10.1016/j.compag.2010.12.011

Cardina J, Johnson GA, Sparrow DH (1997) The nature and consequence of weed spatial distribution. Weed Sci 45(3):364–373

Cedergreen N (2008) Herbicides can stimulate plant growth. Weed Res 48(5):429–438. doi:10.1111/j.1365-3180.2008.00646.x

Christensen S, Sogaard HT, Kudsk P, Norremark M, Lund I, Nadimi ES, Jorgensen R (2009) Site-specific weed control technologies. Weed Res 49(3):233–241. doi:10.1111/j.1365-3180.2009.00696.x

Daberkow SG, McBride WD (1998) Socioeconomic profiles of early adopters of precision agriculture technologies. J Agribus 16(2):151–168

Daberkow SG, McBride WD (2003) Farm and operator characteristics affecting the awareness and adoption of precision agriculture technologies in the US. Precis Agric 4:163–177

Dammer KH, Wartenberg G (2007) Sensor-based weed detection and application of variable herbicide rates in real time. Crop Prot 26(3):270–277. doi:10.1016/j.cropro.2005.08.018

Dannenberg A (2009) The dispersion and development of consumer preferences for genetically modified food – a meta-analysis. Ecol Econ 68(8–9):2182–2192. doi:10.1016/j.ecolecon.2009.03.008

Deike S, Pallutt B, Christen O (2005) Langzeitwirkungen von Pflanzenschutzmaßnahmen in Bezug auf die N-Effizienz. Mitt Ges Pflanzenbau 17(17):361–362

Diederen P, Van Meijl H, Wolters A, Bijak K (2003) Innovation adoption in agriculture: innovators, early adopters and laggards. Cahiers d’économie et sociologie rurales 67:30–50

Dille JA, Milner M, Groeteke JJ, Mortensen DA, Williams MM (2003) How good is your weed map? A comparison of spatial interpolators. Weed Sci 51(1):44–55. doi:10.1614/0043-1745(2002)051[0044:hgiywm]2.0.co;2

Donald DD (1998) Estimating relative crop yield loss resulting from herbicide damage using crop ground cover or rated stunting, with maize and sethoxydim as a case study. Weed Res 38(6):425–431. doi:10.1046/j.1365-3180.1998.00110.x

English BC, Mahajanashetti SB, Roberts RK (2001) Assessing spatial break-even variability in fields with two or more management zones. J Agric Appl Econ 33(3):551–565

Fernandez-Cornejo J, Daberkow S, McBride WD (2001) Decomposing the size effect on the adoption of innovations: agrobiotechnology and precision agriculture. AgBioForum 4(2):124–136

Forcella F (1993) Value of managing within-field variability. In: Robert PC, Rust RH, Larson WE (eds) Soil specific crop management: a workshop on research and development issues. American Society of Agronomy, Crop Science Society of America, and Soil Science Society of America, Minneapolis, pp 125–131

Fountas S, Blackmore S, Ess D, Hawkins S, Blumhoff G, Lowenberg-Deboer J, Sorensen CG (2005) Farmer experience with precision agriculture in Denmark and the US Eastern Corn Belt. Precis Agric 6(2):121–141. doi:10.1007/s11119-004-1030-z

Gianessi LP, Reigner NP (2007) The value of herbicides in U.S. crop production. Weed Technol 21(2):559–566. doi:10.1614/wt-06-130.1

Gifford K, Bernard JC (2008) Factor and cluster analysis of willingness to pay for organic and non-GM food. J Food Distrib Res 39(2):26–39

Griffin TW, Lowenberg-DeBoer J, Lambert DM, Peone J, Payne T, Daberkow SG (2004) Adoption, profitability, and making better use of precision farming data. Staff paper 04–06. Department of Agricultural Economics, Purdue University, West Lafayette

Gutjahr C, Gerhards R (2010) Decision rules for site-specific weed management. In: Oerke E-C, Gerhards R, Menz G, Sikora RA (eds) Precision crop protection – the challenge and use of heterogeneity. Springer, Dordrecht, pp 223–239. doi:10.1007/978-90-481-9277-9_14

Gutjahr C, Weis M, Sokefeld M, Ritter C, Mohring J, Buchse A, Piepho HR, Gerhards R (2008) Creating decision rules for site-specific weed management. J Plant Dis Prot (21):143–148

Hicks J (1932) The theory of wages. Macmillan, London

Jensen H, Jacobsen L-B, Pedersen S, Tavella E (2012) Socioeconomic impact of widespread adoption of precision farming and controlled traffic systems in Denmark. Precis Agric 13(6):661–677. doi:10.1007/s11119-012-9276-3

Khanna M (2001) Sequential adoption of site-specific technologies and its implications for nitrogen productivity: a double selectivity model. Am J Agric Econ 83(1):35–51

Khanna M, Epouhe OF, Hornbaker R (1999) Site-specific crop management: adoption patterns and incentives. Rev Agric Econ 21(2):455–472. doi:10.2307/1349891

Kitchen NR, Snyder CJ, Franzen DW, Wiebold WJ (2002) Educational needs of precision agriculture. Precis Agric 3(4):341–351

Lowenberg-DeBoer J (2003) Precision farming or convenience agriculture. In: 11th Australian agronomy conference “Solutions for a better environment”. Australian Society of Agronomy, Geelong

Luck JD, Pitla SK, Shearer SA, Mueller TG, Dillon CR, Fulton JP, Higgins SF (2010) Potential for pesticide and nutrient savings via map-based automatic boom section control of spray nozzles. Comput Electron Agric 70(1):19–26. doi:10.1016/j.compag.2009.08.003

Lusk JL, Jamal M, Kurlander L, Roucan M, Taulman L (2005) A meta-analysis of genetically modified food valuation studies. J Agric Resour Econ 30(1):28–44

Maxwell BD, Luschei EC (2005) Justification for site-specific weed management based on ecology and economics. Weed Sci 53(2):221–227. doi:10.1614/WS-04-071R2

Mooney DF, Larson JA, Roberts RK, English BC (2009) Economics of the variable rate technology investment decision for agricultural sprayers. In: 2009 annual meeting southern agricultural economics association, Atlanta

Nash E, Korduan P, Bill R (2009) Applications of open geospatial web services in precision agriculture: a review. Precis Agric 10(6):546–560. doi:10.1007/s11119-009-9134-0

Oebel H, Gerhards R (2006) Camera-guided weed control – a technology for practice. J Plant Dis Prot 20:181–187

Oerke EC (2006) Crop losses to pests. J Agric Sci 144(1):31–43. doi:10.1017/S0021859605005708

Pedersen S, Fountas S, Have H, Blackmore B (2006) Agricultural robots – system analysis and economic feasibility. Precis Agric 7(4):295–308. doi:10.1007/s11119-006-9014-9

Reichardt M, Jürgens C (2009) Adoption and future perspective of precision farming in Germany: results of several surveys among different agricultural target groups. Precis Agric 10(1):73–94. doi:10.1007/s11119-008-9101-1

Reichardt M, Jürgens C, Klöble U, Hüter J, Moser K (2009) Dissemination of precision farming in Germany: acceptance, adoption, obstacles, knowledge transfer and training activities. Precis Agric 10(6):525–545. doi:10.1007/s11119-009-9112-6

Rider TW, Vogel JW, Dille JA, Dhuyvetter KC, Kastens TL (2006) An economic evaluation of site-specific herbicide application. Precis Agric 7(6):379–392. doi:10.1007/s11119-006-9012-y

Ritter C, Dicke D, Weis M, Oebel H, Piepho HP, Büchse A, Gerhards R (2008) An on-farm approach to quantify yield variation and to derive decision rules for site-specific weed management. Precis Agric 9(3):133–146. doi:10.1007/s11119-008-9061-5

Roberts RK, English BC, Larson JA (2006) The variable-rate input application decision for multiple inputs with interactions. J Agric Resour Econ 31(2):391–413

Rogers EM (2003) Diffusion of innovations, 5th edn. Free Press, New York

Schroers JO, Gerhards R, Kunisch M (2010) Economic evaluation of precision crop protection measures. In: Oerke E-C, Gerhards R, Menz G, Sikora RA (eds) Precision crop protection – the challenge and use of heterogeneity. Springer, Dordrecht, pp 417–426. doi:10.1007/978-90-481-9277-9_26

Schumpeter JA (1942) Capitalism, socialism, and democracy. Harper, New York

Shockley J, Dillon CR, Stombaugh T, Shearer S (2012) Whole farm analysis of automatic section control for agricultural machinery. Precis Agric 13(4):411–420

Silverberg G, Dosi G, Orsenigo L (1988) Innovation, diversity and diffusion: a self-organisation model. Econ J 98(393):1032–1054

Sökefeld M (2010) Variable rate technology for herbicide application. In: Oerke E-C, Gerhards R, Menz G, Sikora RA (eds) Precision crop protection – the challenge and use of heterogeneity. Springer, Dordrecht, pp 335–347. doi:10.1007/978-90-481-9277-9_21

Sunding D, Zilberman D (2001) The agricultural innovation process: research and technology adoption in a changing agricultural sector, Chapter 4. In: Bruce LG, Gordon CR (eds) Handbook of agricultural economics, vol 1, Part A. Elsevier, Amsterdam, pp 207–261. doi:10.1016/s1574-0072(01)10007-1

Swinton SM (2005) Economics of site-specific weed management. Weed Sci 53(2):259–263. doi:10.1614/WS-04-035R2

Swinton SM, Lowenberg-DeBoer J (1998) Evaluating the profitability of site-specific farming. J Prod Agric 11(4):439–446

Takács-György K, Lencsés E, Takács I (2013) Economic benefits of precision weed control and why its uptake is so slow. Stud Agric Econ 115(1):40–46. doi:10.7896/j.1222

Tweeten L (1988) Agricultural technology – the potential socio-economic impact. In: Goldberg RA (ed) Research in domestic and international agribusiness management, vol 8. JAI Press, London, pp 183–212

USDA (2013) Adoption of genetically engineered crops in the U.S. Economic Research Service, U.S. Department of Agriculture. http://www.ers.usda.gov/data-products/adoption-of-genetically-engineered-crops-in-the-us. Accessed 15 Apr 2013

Weis M, Gutjahr C, Rueda Ayala V, Gerhards R, Ritter C, Scholderle F (2008) Precision farming for weed management: techniques. Gesunde Pflanz 60(4):171–181. doi:10.1007/s10343-008-0195-1

Wiles L (2009) Beyond patch spraying: site-specific weed management with several herbicides. Precis Agric 10(3):277–290. doi:10.1007/s11119-008-9097-6

Wilkerson GG, Wiles LJ, Bennett AC (2002) Weed management decision models: pitfalls, perceptions, and possibilities of the economic threshold approach. Weed Sci 50(4):411–424. doi:10.1614/0043-1745(2002)050[0411:WMDMPP]2.0.CO;2

Wilkerson GG, Price AJ, Bennett AC, Krueger DW, Roberson GT, Robinson BL (2004) Evaluating the potential for site-specific herbicide application in soybean. Weed Technol 18(4):1101–1110. doi:10.1614/WT-03-258R

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Diekmann, F., Batte, M.T. (2014). Economics of Technology for Precision Weed Control in Conventional and Organic Systems. In: Young, S., Pierce, F. (eds) Automation: The Future of Weed Control in Cropping Systems. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-7512-1_12

Download citation

DOI: https://doi.org/10.1007/978-94-007-7512-1_12

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-7511-4

Online ISBN: 978-94-007-7512-1

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)