Abstract

Automatic section control was analyzed in a whole farm decision-making framework when implemented on an agricultural sprayer and/or planter. In addition, various field types and navigational scenarios were examined to determine their impact on profitability. It was determined that automatic section control increased net returns under all scenarios; up to $36/ha. This investigation highlighted the importance of considering field size in addition to field shape as well as initial navigational scenarios when determining the profitability of automatic section control.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A precision agriculture technology that is gaining popularity for applying various agricultural inputs is automatic section control. Automatic section control selectively manages input application by controlling sections, nozzles and rows on agricultural sprayers and implements. This technology utilizes a global positioning system to locate the position of the machine within the field, and then records the areas covered. If the machine traverses an area previously covered, it can automatically turn the appropriate section/nozzle/row off, thereby eliminating over-application. In addition, automatic section control can manage the application of inputs in undesirable areas such as point rows, waterways and during headland turns. Currently, automatic section control is available from many manufacturers and is often complemented with a navigational aid such as auto-steer. With this capability, numerous benefits are possible.

The largest benefit associated with automatic section control is the reduction in overlapped areas especially prevalent on irregular shaped fields. As a result, this technology has the potential to increase profits due to reduced input costs. By reducing inputs such as herbicides and insecticides, environmental benefits are possible and land stewardship can improve. This is also evident with the ability to manage buffer zones and protect sensitive areas in and around the field. Other benefits that could occur include reduced operator fatigue and improved machinery efficiency. To evaluate automatic section control as an economically viable replacement for standard application of inputs, economic analyses must be conducted.

Batte and Ehsani (2006) investigated the possible economic benefits of this technology and concluded that input savings alone could be substantial. Once a prototype was developed and farm trials conducted, Dillon et al. (2007) examined the economic implications of utilizing automatic section control and determined that input expense savings from the application of herbicide alone would justify adoption. In addition, results indicated a break-even area of 318 ha and a payback period of 3.19 years based on herbicide alone. Shockley et al. (2008) expanded the above study to include additional inputs and benefits associated with light-bar guidance. Results from the study indicated a break-even area as low as 163 ha and payback period of less than one year for herbicide rates at the high end of the range recommended by specialists. Mooney et al. (2009) conducted the most recent economic analysis and determined that automatic section control became profitable at input saving levels of 11% or above.

Even though previous economic studies have provided valuable insight into automatic section control, numerous shortcomings exist. The previous analyses only focused on cost savings via section control and did not consider the economic impact when coupled with auto-steer navigation. In addition, the previous studies only focused on section control for agricultural sprayers and ignored other possibilities such as automatic section control on the planters. Moreover, the results are understated since they did not consider the impacts that automatic section control has on the entire farming system yet only analyzed the technology for individual enterprises. In addition, field shape and size could have a substantial impact on the economic viability of automatic section control, which has not been investigated.

The objectives of this study were to: (1) determine the economic impact of automatic section control on an agricultural sprayer (2) determine the economic impact of automatic section control on a planter (3) demonstrate the impact that field shape and size has on the profitability of automatic section control, and (4) determine the payback period and simple rate of return for automatic section control. Four different fields were analyzed to accomplish the above objectives.

Materials and methods

Given the need for analyzing the impacts for the entire farming system, a whole farm decision-making framework was required. Shockley et al. (2011) developed a whole farm planning model to analyze auto-steer on both the sprayer and planter. The expansion of this model as a base was appropriate because auto-steer is often coupled with automatic section control. Auto-steer reduces overlap while conducting parallel paths and automatic section control reduces the off-target applications in non-desired areas. The economic model was a resource allocation model embedded within a mean variance quadratic programming formulation which represented a Kentucky corn and soybean producer operating under a 2 year crop rotation and no-till farming conditions. However, the risk element incorporated into Shockley et al.’s model was omitted for this analysis. The model utilized simulated yield data for 30 years of crop production given historical weather conditions. The objective of the model was to maximize net returns above selected costs (input variable costs, operating costs and ownership costs of precision technologies). Variables decided within the economic model included the production of corn and soybeans which were identified by the area produced by various production strategies (planting date, plant population, maturity group and nitrogen rate on corn). The model was constrained by the land available, field days available for production based on suitable field days, crop rotation and ratio of soil types. The model retained the assumed benefits of auto-steer as with the previous study (reduction in skips and overlaps, increased field speed and the ability to work longer hours) and was modified and updated to include the benefits and costs of automatic section control. For more detailed information regarding the economic model, see Shockley et al. (2011).

The benefits of automatic section control modeled herein consisted of input cost savings by the reduction in overlap due to the technology. The reductions in overlap were determined from the Field Coverage Analysis Tool (FieldCAT) (Zandonadi and Stombaugh 2010; Stombaugh et al. 2009). FieldCAT estimated the overlapped area in a particular field by utilizing field boundary shape files, implement width and number of sections controlled. The program generated field coverage using straight parallel paths in which overlaps occurred due to encroachment in headland and point row areas and when avoiding obstacles within the field boundary. The profitability of automatic section control is dependent on the difference between the percentage of the field overlapped before (zero sections controlled) and after utilizing the technology (a positive number of sections controlled). The percent of the field overlapped without automatic section control is dependent on field shape, field size, possible obstacles and the size of the implement traversing the field. The percent of the field overlapped when utilizing automatic section control is also dependent on the number of sections controlled. Therefore, four fields and two implement widths (sprayer and planter) with varying sections controlled were chosen to reflect the influential attributes critical in determining the profitability of automatic section control.

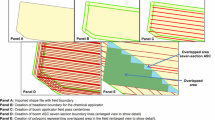

The four fields reflected a broad spectrum of shape, size and obstacles within the field boundary typical in Kentucky agricultural production (Fig. 1). Fields 1 and 2 are relatively square in shape and ranged from 4 to 40 ha. On the other hand, Fields 3 and 4 are “irregular” in shape and ranged from 3 to 100 ha in size. “Irregular” shaped fields like Fields 3 and 4 are common for Kentucky farms, therefore automatic section control could be more profitable for Kentucky producers than square fields like those found in the Midwest of the U.S. In addition, fields can contain obstacles that must be avoided which often lead to the double application of inputs. Field 4 contained three obstacles and was chosen to demonstrate the capabilities of FieldCAT and analyze how overlap was reduced by utilizing automatic section control when obstacles within the field boundary were present.

Two implement widths were modeled, 24 m for the self-propelled sprayer and 12 m for the 16-row planter. For this study, 10 sections were controlled on the self-propelled sprayer and 16 sections (individual row) were controlled on the planter. The resulting overlaps with and without section control for both machines and fields were determined (Table 1). The difference between the percent overlaps with and without section control represented the input cost savings under each scenario. For example, there was a 2.16% reduction in seed cost for Field 1 due to automatic section control on the planter. The average reduction in overlap across the chosen fields due to automatic section control was approximately 9% when utilized on the sprayer and 6% when utilized on the planter. This demonstrates that as the width of an implement decreases, the potential for automatic section control to reduce overlaps within the field also decreases as would be expected. However, this relationship does not necessarily exist when analyzing profitability across various implements since the cost of the inputs applied must be taken into consideration. In addition, the fields chosen demonstrated that field size had a profound impact on overlap reduction. The two smaller fields (Fields 2 and 3) had the largest percent reduction in overlap, regardless of shape. Therefore, the relevant input cost savings for each implement and field were modeled to determine the economic impact of automatic section control.

The inclusion of ownership costs for automatic section control and auto-steer on the sprayer and planter were also required (Shockley et al. 2011). Automatic section control was coupled with sub-meter auto-steer on the sprayer and RTK auto-steer on the planter which was consistent with Shockley et al. (2011). These costs were annualized and incorporated both depreciation and the opportunity cost of capital invested (Table 2). Depreciation for both auto-steer and section control were calculated using the straight-line method with an assumed 8 year useful life, an 8% interest rate on capital investment and 0% salvage value for the technologies. Both depreciation and opportunity cost of capital invested followed Kay et al. (2004).

The model was also updated with a new farm size of 850 ha which reflected the farms in the upper one-third for 2009 management returns as represented by net farm income of the Ohio Valley region of Kentucky that enrolled in the Kentucky Farm Business Management Program (Pierce 2010). Furthermore, the number of probable suitable field days per week was determined from historical Crop Progress and Condition Reports for Kentucky (U.S. Department of Agriculture-National Agricultural Statistics Service 2010). In addition, commodity prices for corn of $0.17 and $0.36/kg for soybeans were updated to reflect 2011 median estimates less Kentucky’s basis (World Agricultural Outlook Board 2010). The above modifications and updates were implemented to address the objectives within this study.

Results and discussion

To determine the economic impact of automatic section control, four base cases were established for comparison (Table 3). The first base case consisted of no previous navigational aid. For this scenario, both auto-steer and automatic section control were added to the equipment analyzed to determine gain in net returns. The three other base cases assumed machinery was already equipped with navigational aids. Therefore, only automatic section control was adopted to determine gains in net returns and automatic section control was always paired with a navigational aid. In addition to the various comparisons, four fields were also examined. Regardless of adoption strategy, navigational scenario or field type, the addition of automatic section control increased average net returns when compared to the respective net returns reported in Table 3. When comparing automatic section control adoption strategies, the greatest economic gains occurred when implementing the technology on both the sprayer and planter. When comparing navigational scenarios, the greatest economic gains occurred when the producer adopted both automatic section control and auto-steer on both the sprayer and planter. This provided evidence to suggest that both auto-steer and section control could be profitable for producers regardless of field type. However, if other costs such as the opportunity cost (e.g. time to learn the new technology) of implementing automatic section control could be quantified and included in the model; the adoption of automatic section control might not be a sound investment on Field 1.

Given all scenarios are profitable, if the producer was faced with deciding between adopting automatic section control on the sprayer or planter, the shape and size of the field as well as the initial navigational scenario must be considered. When comparing the addition of automatic section control on the planter or sprayer only, a smaller input savings associated with larger fields (Fields 1 and 4) favors implementing automatic section control on the sprayer if the producer did not previously own a navigational aid. However, if the machinery was already equipped with auto-steer, automatic section control on the planter was favored. This was attributed to the marginal cost of adding automatic section control only which was U.S.$300 less annually for the planter compared to adopting automatic section control on the sprayer. For larger input savings like those associated with the smaller fields examined (Fields 2 and 3), automatic section control on the sprayer was favored regardless of the navigational scenario. The larger input savings outweigh the differences in addition costs for section control on the sprayer (Tables 4, 5, 6, 7).

The results of this study also indicated that the profitability of automatic section control was influenced the most by the size of the field rather than the shape. Most automatic section control studies emphasize the savings of automatic section control on “irregular” shaped fields. The results of this study however, highlighted the importance of considering field size as well. Smaller field sizes resulted in greater increases in average net returns, greater returns on investments and smaller payback periods. When averaging across section control adoption scenarios for the two small fields examined and comparing that to the two larger fields, utilizing automatic section control on smaller fields resulted in economic gains U.S.$13 ha−1 more than larger fields when no navigation was initially present. In addition, the returns on investment were 51% greater and the payback period was 1.5 years less on smaller fields than larger fields when no navigation was initially present. The results were greater when navigational aids were initially present. Economic gains were U.S.$15 ha−1 higher when operating automatic section control on smaller fields rather than larger fields. Also, the returns on investment were 138% greater and the payback period was 3.4 years less on smaller fields than larger fields.

In addition to the various fields examined herein, a sensitivity analysis was also conducted to determine the influence that the assumed area (850 ha) had on the change in average net returns of automatic section control when compared to the base scenario with no navigational aid. The area was varied ± 10 and ± 20% of the assumed area. The results indicated that the profitability of implementing automatic section control on both sprayer and planter was the most sensitive to changes in the assumed area. When the area was increased by 10 and 20%, the change in average net returns increased by 0.17 and 0.33%, respectively. When area was decreased by 10 and 20%, the change in average net returns decreased by 0.23 and 0.39%, respectively. The sensitivity that occurred was consistent across all fields examined in this study. For example, under Field 1 assumptions, if the assumed area was increased by 10%, the change in average net returns from implementing automatic section control on both the sprayer and planter would increase from 0.97 to 1.14% when compared to no navigational aid. On the other hand, implementing automatic section control on the sprayer only was the least sensitive to changes in assumed area.

The shape of the field should also be considered when analyzing the profitability of automatic section control. The results of this analysis indicated that field shape becomes less important when the field area is larger. When comparing Fields 1 and 4, there is no substantial difference in the economic gains due to the addition of automatic section control, even though the shapes are completely different and Field 4 also had obstacles within the field boundary to avoid. On the other hand, field shape plays a crucial role in determining how profitable section control could be when the field area is small. Comparing Fields 2 and 3, there were substantial differences in economic gains due to the shape of the field. For example, there was an additional U.S.$12 ha−1 economic gain when operating section control on both the sprayer and planter on the more “irregular” shaped field. Therefore, field shape is an important factor in the profitability of automatic section control, especially when the field area is small.

Conclusion

Automatic section control was analyzed in a whole farm decision-making framework when implemented on an agricultural sprayer and/or planter. In addition, various field types and navigational scenarios were examined to determine their impact on profitability. The addition of automatic section control increased average net returns under all scenarios investigated. When considering adopting automatic section control on the sprayer or planter, the shape and size of the field as well as the initial navigational scenario influenced the results. More importantly, the results of this study highlighted the importance of considering field size in addition to field shape. Smaller field sizes resulted in greater potential for profitability when compared to larger fields. In addition, the results of this analysis indicated that field shape becomes less important when the field area is large.

References

Batte, M. T., & Ehsani, M. R. (2006). The economics of precision guidance with auto-boom control for farmer-owned agricultural sprayers. Computers and Electronics in Agriculture, 53, 28–44.

Dillon, C. R., Shearer, S., & Pitla, S. (2007). Improved profitability via enhanced variable rate application management resolution in grain crop production. In J. V. Stafford (Ed.), Proceedings of the 6th European Conference on Precision Agriculture (pp. 819–825). Wageningen: Wageningen Academic Publishers.

Kay, R. D., Edwards, W. M., & Duffy, P. A. (2004). Farm Management. New York: McGraw-Hill.

Mooney, D. F., Roberts, R. K., Larson, J. A., & English, B.C. (2009). Economics of the variable rate technology investment decision for agricultural sprayers. Paper presented at the Southern agricultural economics association annual meeting, Atlanta, Georgia, January 31–Febuary 3. Retrieved December 27, 2011 from http://ageconsearch.umn.edu/handle/46860.

Pierce, J. S. (2010). Kentucky Farm Business Management Program: Annual Summary Data 2009. Lexington, Kentucky: University of Kentucky Cooperative Extension Service.

Shockley, J. M., Dillon, C.R., & Shearer, S.A. (2008). Cost savings for multiple inputs with swath control and auto-guidance technologies. Paper presented at the ninth international conference on precision agriculture, Denver, Colorado. (CD-ROM) (p. 11). Retrieved December 15, 2011 from http:www.ispag.org.

Shockley, J. M., Dillon, C. R., & Stombaugh, T. S. (2011). A whole farm analysis of the influence of auto-steer navigation on net returns, risk, and production practices. Journal of Agricultural and Applied Economics, 43(1), 57–75.

Stombaugh, T. S., Zandonadi, R. S., & Dillon, C. (2009). Assessing the potential of automatic section control. In E. J. van Henten, D. Goense, & C. Lokhorst (Eds.), Proceedings of the 7th European Conference on Precision Agriculture (pp. 759–766). Wageningen: Wageningen Academic Publishers.

U.S. Department of Agriculture-National Agricultural Statistics Service (2010). Crop Progress and Condition Reports. Retrieved on December 27, 2011 from http://www.nass.usda.gov/Statistics_by_State/Kentucky/Publications/Crop_Progress_&_Condition/index.asp.

World Agricultural Outlook Board (2010). World Agricultural Supply and Demand Estimates. Washington, DC: U.S. Department of Agriculture, Technical bulletin no. WASDE-463.

Zandonadi, R. & Stombaugh, T.S. (2010). FieldCAT–Field coverage analysis tool version 1. Retrieved on December 27, 2011 from http://www.bae.uky.edu/tstomb/Extension/FieldCAT_request.asp.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shockley, J., Dillon, C.R., Stombaugh, T. et al. Whole farm analysis of automatic section control for agricultural machinery. Precision Agric 13, 411–420 (2012). https://doi.org/10.1007/s11119-011-9256-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11119-011-9256-z