Abstract

This chapter provides an overview of the state of knowledge of starch production as an ultimate energy reserve in algae. It includes a survey of recent discoveries on controls that direct the metabolism of algal cells towards starch hyper-accumulation with the aim of providing starch-enriched biomass for the production of bioethanol as a biofuel of the future. We also outline basic research from the 1960s, from which the recent starch research stems, although the use of algal starch for biofuel production was not considered at that time. The principles of, and basic approaches to a directed synthesis of starch are described in both laboratory experiments and large scale-up outdoor photobioreactors.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Algae

- Bioethanol

- Cell cycle

- Carbon dioxide

- Inhibitors

- Light intensity

- Nutrient limitation

- Starch

- Temperature

1 Introduction

Algae represent a vast variety of photosynthetic species growing photoautotrophically using light as a source of energy for photosynthesis and fixing inorganic carbon, from which a reserve material such as starch and/or lipid is synthesized and then serve as an energy and carbon source for future cellular growth and reproduction.

Despite the pioneering papers from the 1960–1980s, not much attention was paid to starch research for more than twenty years. The main motivation for the recent boom in starch research is that algae can be a high-yielding source of energy-rich reserve components, which can be used for the production of biofuels (third generation biofuels) without compromising food supply chains and be a renewable alternative to fossil fuels (Nigam and Singh 2010) . In general, the algae from different taxons can produce either lipids (Nannochloropsis, Trachydiscus and other members of Eustigmaceae) or starch (most chlorococcal and volvocean algae) as their energy and carbon reserves. In general, starch-producing algae can also accumulate small amounts of lipid under standard conditions, but only some of them, under specific growth conditions, can be induced to overproduce lipids instead of starch (Zhukova et al. 1969) .

In this review, we will focus exclusively on those algal species that accumulate polysaccharides (starch, cellulose), which can be used as a feedstock for the production of bioethanol.

In these species, starch is the final energy storage molecule formed in the photosynthetic fixation of carbon dioxide . Located in chloroplasts, it is utilized to provide energy for the cell’s vital metabolic processes, and is independent of varying external energy and carbon supplies.

Many microalgae grow rapidly and are considerably more productive than land plants and macroalgae (seaweed) (Chisti 2007) . There are several main groups of microalgae, which differ primarily in pigment composition, biochemical constituents, ultrastructure, and life cycle. In this chapter, we will pay attention to those representatives of the green algae (Chlorophyta) that may be a potential source of starch for future biotechnological applications in the production of bioethanol .

The green algae are a large group from which the Embryophytes (higher plants) emerged. The group, including both green algae and embryophytes, is monophyletic (and often just known as the Kingdom Plantae). There are about 6,000 species of green algae; many live most of their lives as single cells, while others form colonies or long filaments.

Almost all forms have chloroplasts. These contain chlorophylls a and b, giving them a bright green color (as well as the accessory pigments β-carotene and xanthophylls), and have stacked thylakoids (van den Hoek et al. 1995) . All green algae have mitochondria with flat cristae. The storage product for members of this group is true starch , found inside the chloroplasts and consisting of amylose and amylopectin. The starch (seen as whitish granules under the electron microcopy) can often be observed surrounding the pyrenoid, a distinct spherical structure embedded in the chloroplast. There may be more than one pyrenoid, the pyrenoid may not always be present (e.g., Ankistrodesmus and Tetraedron), or the pyrenoid may be lacking completely. In most representative taxa, the cells are surrounded by a cellulosic wall. Some taxa may also have sporopollenin deposited on the wall. This gives added strength and is thought to help prevent desiccation.

Some microalgae (Chlorella, Scenedesmus, Chlamydomonas, Tetraselmis etc.) are known to contain a large amount of starch and cellulose, providing the raw materials for bioethanol production (Matsumoto et al. 2003) . Many of the properties of starches, which determine their suitability for particular end-uses, depend on their amylose/amylopectin ratios. These properties include gelatinisation characteristics, solubility, and the formation of resistant starch . The structure of algal starch (Chlorella) resembles that of cereals (ca. 34 % of amylose content) and its gelatinisation temperature (ca. 65 °C), as determined by viscosity measurements, also suggests a structural similarity (Maršálková et al. 2010) .

2 Starch Synthesis During the Cell Cycle

As early as 1967, Duynstee and Schmidt (1967) monitored the net content of starch within the cell cycle in synchronous cultures of a high-temperature strain of Chlorella pyrenoidosa . They found that in light, starch accumulates continuously nearly to the end of the cell cycle, followed by cessation immediately prior to and during the period of nuclear division and cytokinesis (Fig. 1).

Total cellular starch per ml of culture and per cell during two cycles of synchronized culture of Chlorella pyrenoidosa. Full circles: starch/ml; empty circles: starch/cell; crosses, dashed line: cell number/ml of culture. (modified according to Duynstee and Schmidt 1967)

These results were confirmed in synchronized cultures of the chlorococcal alga Scenedesmus quadricauda (Šetlík et al. 1972) where the starch content, promoted mainly by light energy input, was also dependent on the stage of cell development. Starch content rose in the early growing phase and decreased thereafter, even under continuous light (Hirokawa et al. 1982) . Net starch accumulation can be an indicator of the balance between material and energy supply (provided by photosynthesis) and their use in synthetic processes. During nuclear and cellular divisions, starch is dramatically degraded, as indicated by cytological (Murakami et al. 1963) and biochemical (Baker and Schmidt 1964a; Baker and Schmidt 1964b; Curnutt and Schmidt 1964; Herrmann and Schmidt 1965; Johnson and Schmidt 1966; Cole et al. 1998; Schmidt 1966) changes and increased activity of starch degrading enzymes (Levi and Gibbs 1984; Wanka et al. 1970) . Starch degradation products fulfill demands for both carbon building blocks for organic synthesis and increased energy demands during nuclear and cellular division. Because the photosynthetic rate was approaching its lowest level of the cell cycle during this stage of cellular development (Sorokin 1957) , accumulated carbon and energy reserve starch was mobilized and utilized during this stage of cellular development. The net content of starch is comprised of starch that was synthesized minus that which was utilized. It is apparent therefore that net accumulation data underestimates the value of actual starch synthesis during the cell cycle . Accumulation of starch during the cell cycle and its phases was also studied in synchronized batch cultures of Chlorella vulgaris (Fig. 2). Culture proliferation and changes in starch content were monitored under continuous illumination. The relative starch content reached a maximum of 46 % of DW just prior to cell division, which commenced at about the 10th hour of growth in light (Brányiková et al. 2011) .

Electron microscopic photographs of daughter (a) and mother (b) cells of Chlorella vulgaris grown in complete mineral medium, N, nucleus; S, starch granules. Bars: 2 μm. (modified according to Branyiková et al. 2011)

During cell division, the relative starch content decreased, even in cells grown in light, to 13 % of DW. If the cells were transferred to the dark, they exhausted the stored starch nearly completely (4 % of DW). Hence, significant cellular energy and material reserves are maintained to ensure that at any point in development, vital processes can run to completion even if the cells are placed in the dark.

2.1 Starch Production as Affected by Light Intensity

As the ultimate storage form of photosynthetically fixed carbon, starch plays a central role in algal metabolism. Chloroplasts convert carbon dioxide into glucose, which, with the action of starch synthases and branching enzymes , is converted to a mixture of linear and branched glucans (amylose and amylopectin) that determine the properties of the starch . The extent of starch synthesis and degradation in the chloroplast is tightly regulated by the available light (Sundberg and Nilshammar-Holmvall 1975; Brányiková et al. 2011) and by a number of environmental factors.

Synchronized cultures of Scenedesmus quadricauda were grown at two different light intensities and thus differing in specific growth rate . Populations characterized by low growth rates accumulated starch to somewhat more than one third of the value (per cell) obtained in cells with a high specific growth rate. Hence even in light-limited growth, significant cellular energy and material reserves are maintained. As described above for Chlorella , this is, perhaps, to ensure that at any point in development, vital processes can run to completion even if the cells are placed in the dark. Starch reserves were consumed nearly completely if cultures were transferred to the dark (Šetlík et al. 1972) .

In synchronized cultures of Chlorella vulgaris grown under continuous illumination, the relative content of starch was substantially reduced (maximum 26 % of DW) in response to an increase in biomass concentration and corresponding decreased mean light intensity (Sundberg and Nilshammar-Holmvall 1975; Brányiková et al. 2011) . The important role of light intensity on starch content was confirmed in experiments with asynchronous cultures grown at different starting biomass concentrations and consequently, at different mean light intensities, which were continuously decreasing with increasing biomass (Fig. 3).

The effect of mean light intensity (c) on changes in biomass concentration (DW in g/L) (a), starch content in g/L (b) in asynchronous cultures of Chlorella vulgaris. The cultures were grown in a laboratory photobioreactor continuously illuminated by a constant incident light intensity of 780 μmol/(m2 s1) and at various biomass concentrations (numerals on curves indicate initial dry weight in g/L). Dashed horizontal lines indicate the biomass concentration (panel a) and the mean light irradiance (panel c) under which the net starch content begins to decrease. (modified according to Brányiková et al. 2011)

The higher the mean light intensity, the higher was the starch content. A decrease in mean light intensity below a certain level (275 μmol/(m2 s1))caused a gradual decline in the rate of starch synthesis, leading finally, to no net increase in starch content or even to its decrease in the case of very low mean light intensities (Fig. 3) (Zhang et al. 2002; Eriksen et al. 2007; Thu et al. 2009) .

Beside light quantity, its quality can also play a role in starch synthesis and its degradation. Kamiya and Kowallik (1986) studied starch synthesis and degradation in Chlorella vulgaris under autotrophic conditions in blue and red light and found that in blue light, increased starch degradation occurred, causing a decrease in total starch content when compared with cells grown in red light (Miyachi et al. 1978; Kamiya and Kowallik 1986) .

2.2 Starch Production as Affected by Temperature

Semenenko and his collaborators published a series of papers in which they described and analyzed restrictive effects of high temperatures on the reproductive and synthetic processes in different strains and species of Chlorella (Semenenko et al. 1967, 1969; Semenenko and Zvereva 1972a, b) . Unfortunately, their work was published in Russian more than 40 years ago and was neglected by researchers both then and now. They had, however, discovered the basic principles and rules, which control the production of energy reserves in algae, information, which only recently has been rediscovered.

The authors found that for the high-temperature strain of Chlorella sp. K (growth optimum at 36–38 °C) the effective restrictive temperature was 43–44 °C. With a mesophilic strain of C. pyrenoidosa (growth optimum 26–28 °C) the restrictive temperature for cellular division is 35–36 °C. At the time when cells ceased dividing, giant cells with a diameter up to 5–6 times that of the daughter cells formed a significant part of the population. The higher the average irradiation received by the cells, the greater were the number of giant cells ultimately obtained, and also the faster was attainment of the final stage. Very large quantities of starch were found in the giant cells of Chlorella sp. K, while extensive lipid inclusions appeared in C. pyrenoidosa. To explain the behavior of cell populations at the restrictive temperature, Semenenko et al. assumed that the extreme temperatures effectively blocked reproductive events while other synthetic processes were mainly unaffected or were even stimulated by the high temperature, as was the case with photosynthesis . However, with reproduction processes inhibited, the demand for cell construction material gradually decreased, photosynthates accumulated in the later phases and by a feedback type of inhibition, they finally stopped photosynthesis.

The effect of temperature on CO2 fixation in photosynthesis and on starch conversion into sucrose was studied in a series of papers by Nakamura and Miyachi (Nakamura and Miyachi 1982a, b, 1980; Nakamura 1983; Nakamura and Imamura 1983) . They found that in Chlorella vulgaris , a temperature higher than 30 °C caused acceleration of the conversion of starch to sucrose. This temperature-induced degradation of starch also occurred in the dark, proving that photosynthetic electron transport is not involved (Nakamura and Miyachi 1982a; Nakamura and Miyachi b) .

3 Treatments for Overproduction of Starch

Algal cells grown in light synthesize starch in chloroplasts, in the form of starch bodies (see, chapter Starch synthesis during the cell cycle ). However, these starch reserves only represent the net production of starch, comprising the difference between gross synthesis of starch and that used to drive many cellular processes and events, particularly for the highest consumers of energy and carbon such as DNA replication, nuclear division and cytokinesis.

The final cellular content of starch is determined by two main factors: (1) the mean light intensity , which determines the rate of starch synthesis and its final content, and (2) processes (mainly cell division) consuming starch for their energy demands. Therefore to attain a maximum yield of starch, processes that utilize starch as energy and carbon source must be stopped or minimized, while conditions enabling production of starch should be optimized (Brányiková et al. 2011) .

3.1 Applying Specific Inhibitors

3.1.1 Inhibition of Nuclear DNA Replication

In the chlorococcal alga Scenedesmus quadricauda , specific inhibition of nuclear DNA synthesis by 5-fluorodeoxyuridine (FdUrd) was used to study cell cycle regulatory processes (Zachleder 1994; Zachleder 1995) . FdUrd interrupts the deoxyribonucleotide metabolic pathway just before the last step by inhibiting the enzyme thymidylate synthase (EC 2.1.1.45), which catalyzes the reductive methylation of 2′-deoxyuridylate to form deoxythymidylate (Cisneros et al. 1993; Follmann 1983; Bachmann et al. 1983) . As a consequence, subsequent events such as nuclear division and cytokinesis were also blocked (Zachleder et al. 1996) . If FdUrd was added to a synchronized culture of Scenedesmus quadricauda at the beginning of the cell cycle , the cells remained uninuclear with no nuclear DNA replication, and no nuclear or cellular division occurred during experiments (Zachleder 1995) . The growth of cells and processes involved in their growth, like RNA and protein accumulation, were not affected for an interval corresponding to at least the duration of two or three cell cycles, attaining six doublings in cell volume by the end of this period. While FdUrd effectively blocked DNA replication in Scenedesmus quadricauda, growth processes were not affected by the presence of the inhibitor. Because activity of the chloroplast was not affected, cells grew to a giant size, producing large numbers of starch grains in their chloroplasts (Fig. 4).

Microphotographs of the mixture of daughter coenobia (A), dividing mother cells (M) in a control culture of Scenedesmus quadricauda (after 14 h of light), and “giant” cells (F) from an FdUrd-treated culture (36 h of growth in the presence of FdUrd 25 mg/L). Scale bar = 10 μm. (modified according to Zachleder 1995)

3.1.2 Inhibition of Cytoplasmic Proteosynthesis

Cycloheximide, an antibiotic inhibiting eukaryotic cytoplasmic protein synthesis, prevented cultures of Scenedesmus quadricauda (Zachleder et al. 2002) or Chlorella vulgaris (Brányiková et al. 2011) from undergoing nuclear division and consequently no cell division occurred. Starch , however, was intensively synthesized and in the case of Chlorella vulgaris, attained (within 4–5 h) a level of at least 60 % of DW (Figs. 5 and 6).

Effect of cycloheximide (1 mg/L) treatment on changes in biomass concentration (DW in g/L), starch content in g/L, and relative starch content (% of DW) in asynchronous cultures of Chlorella vulgaris. The cultures were grown in a laboratory photobioreactor at a constant incident light intensity of 780 μmol/(m2 s1). (modified according to Brányiková et al. 2011)

Electron microscopic photographs of cells of Chlorella vulgaris grown in the presence of cycloheximide (1 mg/L). S, starch granules. Bar: 5 μm. (modified according to Brányiková et al. 2011)

After 5 h of growth in the presence of cycloheximide, the rate of starch synthesis equilibrated with biomass growth, and a high relative content of starch remained constant (Fig. 5). This shows that starch synthesis in the chloroplast is independent of cytoplasmic protein synthesis as well as DNA replication and other cell reproductive processes.

3.2 Nutrient Limitation

While treatments with inhibitors are useful and important from the viewpoint of basic research, their industrial utilization is problematic for reasons of economics and possible environmental contamination. Suppression of cell cycle events requiring energy and carbon from starch reserves can however, be attained by limitation of macroelements in mineral media used for culturing autotrophically grown algae . An increase of starch content in algal cells upon limitation of some elements (nitrogen, sulfur, or phosphorus) was described a long time before the utilization of algal starch for production of biofuels was considered (Klein 1987; Ball et al. 1990; Zachleder et al. 1988; Šetlík et al. 1988; Ballin et al. 1988) . Although in contrast to the use of specific inhibitors, the exact mechanism of element limitation-induced starch synthesis is neither well known nor specific, their application for scale up culturing is advantageous both from economic (saving fertilizers) and environmental points of view. Nevertheless, the principles of this approach are similar to that of inhibitors ; the absence of different elements caused a cessation of processes consuming starch while starch production was unaffected.

3.2.1 Effect of Nitrogen Starvation

When microalgae are starved for nitrogen , the main element of protein and nucleic acids, cell division ceases and photosynthetic carbon partitioning is switched towards starch synthesis. In Chlamydomonas reinhardtii cultivated in 1.0 mM KNO3, protein and chlorophyll a content decreased when nitrate was exhausted, while carbohydrate content increased nearly six-fold (Klein 1987) . Similarly in Scenedesmus quadricauda , macromolecular syntheses of RNA, protein and DNA were arrested when a nitrogen source was lacking (Fig. 7). This diverted the photosynthetic carbon flow into starch without it being consumed as a carbon and energy source (Ballin et al. 1988) .

Variation in RNA (a), protein (b), DNA (c), starch (d) content during the cell cycle in control (open symbols) and nitrogen-starved (closed symbols) synchronous populations of Scenedesmus quadricauda. Arrows indicate the beginning of the dark period in control cultures. The nitrogen-starved culture was kept in continuous light. (modified according to Ballin et al. 1988)

More than 20 years later, the effect of nitrogen starvation was verified in a production strain of Chlorella vulgaris p12 that accumulated starch from 35 to 58 % of dry weight (DW) in nitrogen-limited medium (Brányiková et al. 2011; Behrens et al. 1989; Dragone et al. 2011) .

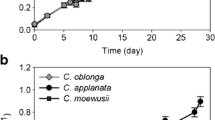

Starch accumulation has been studied mostly in freshwater microalgal strains including Chlamydomonas reinhardtii (Zhang et al. 2002; Eriksen et al. 2007; Thu et al. 2009) , Chlorella vulgaris (Brányiková et al. 2011; Behrens et al. 1989; Dragone et al. 2011) and Scenedesmus obliquus (Rodjaroen et al. 2007). Less attention, however, has been paid to marine microalgae other than Dunaliella tertiolecta (Ike et al. 1997) , and Chlamydomonas perigranulata (Hon-Nami 2006) .

The marine green microalga, Tetraselmis subcordiformis , accumulates starch autotrophically (Zheng et al. 2011) or mixotrophically (Ji et al. 2011) . The maximum starch content was 35 % DW and starch productivity was 0.26 g L−1 d−1. Using sulfur starvation to direct starch overproduction, T. subcordiformis could achieve a starch productivity of 0.62 g L−1 d−1 and a starch content of 62.1 % DW, thus endowing it with great potential for starch production (Yao et al. 2012) .

3.2.2 Effect of Phosphorus Starvation

Phosphorus is indispensable for the basic processes of energy flow in cells and is one of the essential macromolecules. In Scenedesmus quadricauda , the first process affected by the absence of phosphorus was RNA synthesis, which leveled off relatively early in the cell cycle , i.e. around the 5th hour. Protein synthesis showed the first signs of restriction much later and ceased at the time when protoplast fissions were taking place and the release of daughter cells started (Zachleder et al. 1988) . Accumulation of starch , however, indicated that the rate of photosynthesis was nearly normal during the entire cycle in which RNA synthesis stopped as well as in the next cycle, in which no macromolecular syntheses took place (Fig. 8). There were sufficient cellular phosphate reserves in diverse forms at the stage when RNA synthesis leveled off (Voříšek and Zachleder 1984) .

Variation in RNA (circles), protein (squares), DNA (triangles) and starch (solid circles) content during the light period of the second cell cycle in a phosphate-starved synchronous population of Scenedesmus quadricauda. (modified according to Zachleder et al. 1988)

Daughter cells generated under phosphate deficiency and exposed to light in a phosphate-free medium were unable to develop further. The synthesis of nucleic acids was completely suppressed. Protein synthesis was also severely restricted, and only a slight increase in the amount of protein was observed (Fig. 8). The photosynthetic apparatus continued to work at a moderate but sustained rate and starch accumulated, characteristic of a phosphorus-fed cell.

In complete medium, the phosphorus-starved daughter cells resumed macromolecular syntheses with a lag of about 5 h. Due to the large amount of starch accumulated in these cells, they were able to progress through an entire cell cycle in the dark after being supplied with phosphorus (Zachleder et al. 1988) .

Phosphorus limitation in Chlorella vulgaris caused cell division to be blocked and was severe enough to reduce biomass synthesis from the very beginning of the experiment and to stop it completely after 12 h in the absence of phosphorus in the medium, or after 20 h of growth in medium with a five fold decreased concentration of phosphate . Thereafter, starch began to degrade, and its concentration (in g/L) and relative content (% of DW) decreased (Fig. 9, Brányiková et al. 2011) .

Effect of nitrogen, phosphorus, or sulfur limitation on changes to relative starch content (% of DW) in asynchronous cultures of Chlorella vulgaris. The cultures were grown in a laboratory photobioreactor with continuous illumination at an incident light intensity of 780 μmol/(m2 s1) in a complete mineral medium (diamonds, dotted line) or in nitrogen (diamonds, solid line), phosphorus (triangles), or sulfur (squares) limited media. (modified according to Brányiková et al. 2011)

3.2.3 Effect of Sulfur Starvation

Sulfur, which is necessary for the metabolism of proteins, lipids , and molecules associated with electron transport chains, is another essential element that regulates starch accumulation in microalgae.

If synchronized cultures of Scenedesmus quadricauda were incubated under photosynthesizing conditions in a sulfur-free medium, inhibition of RNA synthesis occurred close to the end of the first cell cycle and protein synthesis ceased two hours later (practically at the time of protoplast fission). If the daughter cells derived from the starved populations were kept in sulfur-free medium, macromolecular syntheses were dramatically restricted (Fig. 10).

Variation in RNA (circles), protein (squares), DNA (triangles) and starch (solid circles) content during the light period of the second cell cycle in a sulfur-starved synchronous population of Scenedesmus quadricauda. (modified according to Šetlík et al. 1988)

Only photosynthesis continued to produce starch at a similar rate to that of normally grown cells. Thus, a very large amount of starch accumulated (Figs. 10 and 11).

Electron microscopic photographs of cells of Chlorella vulgaris grown in sulfur-limited medium. S, starch granules. Bar: 5 μm. (modified according to Brányiková et al. 2011)

Supported by these reserves, when starved cells were refed with sulfur, they progressed through an entire cell cycle in the dark and divided into eight daughter cells. In sulfur-supplied cells, both in the dark and in light, RNA protein and DNA synthesis started without any delay in a similar way to the control culture. If competition for sulfur reserves occurred between growth and division processes, the former were preferred in the light and the latter in the dark (Šetlík et al. 1988) .

In Chlamydomonas reinhardtii, deprivation of sulfur caused changes in cellular metabolism resulting in cell expansion, regulated protein degradation and a significant increase (nearly ten times) in the starch/protein ratio (Ball et al. 1990; Zhang et al. 2002) . Similarly, the alga Dunaliella salina altered the partitioning of photosynthate between starch and protein and, under sulfur-deprived conditions, induced a ten-fold increase in the starch/protein ratio (Cao et al. 2001) .

Similarly, it was recently demonstrated that a sulfur-limited culture of Chlorella vulgaris maintained a high starch content (60 %) and a starch productivity of 0.8 g l−1 d−1 (Brányiková et al. 2011) , levels significantly higher than those calculated under nitrogen limiting conditions (0.119–0.55 g l−1 d−1) (Dragone et al. 2011; Fernandes et al. 2010; Behrens et al. 1989) . This suggests that compared to nitrogen and phosphorus , sulfur limitation is more effective in enhancing starch productivity. For practical and industrial applications, it was also important that, in the case of sulfur limitation, the high level of starch was maintained for more than 24 h, whereas limitation of either nitrogen or phosphorus caused a decay in starch content and cell death within a few hours (Fig. 9, Brányiková et al. 2011) .

Comparing cultures grown in complete medium and sulfur-starved cultures under conditions simulating alternating days and nights, degradation of starch was substantially lower in sulfur-starved cultures than in cultures grown in complete medium, while net synthesis during the light period was substantially higher (Fig. 12).

Effect of alternating light and dark periods on changes in biomass concentration (DW in g/L) (a), starch content (g/L) (b) and relative starch content (% of DW) (c) in untreated (empty symbols) and in sulfur limited (full symbols) cultures of Chlorella. (modified according to Brányiková et al. 2011)

The effect of sulfur limitation was apparently due to inhibition of processes using energy and carbon derived from starch reserves (Brányiková et al. 2011) as is the case for other treatments.

3.3 Utilization of Waste CO2

To attain high productivity , microalgae require CO2 as a photosynthetic carbon source at the same time the cost of CO2 represents one of the major cost factors for algal biomass. Microalgae can tolerate and utilize substantial levels of CO2; thus, photosynthetic carbon dioxide can be derived from cheap sources such as combustion of organic waste, fermentation processes or other sources (Mann et al. 2009; Douskova et al. 2009; Doucha et al. 2005) . Some cheap sources of CO2, such as flue gas from incineration of domestic waste (Douskova et al. 2009) , biogas produced from distillery stillage (Doušková et al. 2010; Douskova et al. 2009; Kaštánek et al. 2010) or flue gas from cogeneration unit combusting biogas from anaerobic digestion of swine manure (Doušková et al. 2010; Douskova et al. 2009; Kaštánek et al. 2010) have been used successfully.

This provides an additional benefit of algal biomass production because carbon dioxide from different sources including waste incinerators, power stations, limekilns, cogeneration units, etc. in situ could be bioremeditated (Doušková et al. 2010; Douskova et al. 2009; Kaštánek et al. 2010; Nigam and Singh 2010) .

3.4 Scale Up Culturing

To verify laboratory findings, experimentation using large-scale production units is the only way to prove real outcomes of any proposed approach. Unfortunately, to date, with the exception of the paper by Brányiková et al. (2011) , large-scale production studies giving relevant data on the production of lipid-enriched algal biomass have not been carried out.

An increase in starch production in sulfur-limited culture, up to a maximum of 50 % of algal biomass (DW) was demonstrated under field conditions using the outdoor scale up, thin-layer solar photobioreactor (Fig. 13).

Changes in biomass concentration (DW in g/L), starch content (g/L) (a), and relative starch content (% of DW) (b) in cultures of Chlorella vulgaris. The cultures were grown in an outdoor scale-up thin-layer photobioreactor in complete mineral medium for 96 h and then in sulfur-limited medium (-S). Dark periods (nights) are marked by black stripes and separated by vertical solid lines. Linear regression curves of the 1st order (solid lines) were fitted to the experimental data separately for the periods of culture grown in complete medium and sulfur-limited cultivation. (after Brányiková et al. 2011)

Despite the relatively unfavorable climatic conditions of Trebon (Czech Republic), a total yield of starch, calculated per ha over a season of 150 days, was 7 t (Brányiková et al. 2011) . In optimum locations for photoautotrophic production, such as Greece, with a season lasting approximately 250 days, the overall harvest might be increased by a factor of 5.

Based on the findings described above cheap starch-enriched biomass could be produced from highly productive Chlorella cultures if grown in suitable outdoor photobioreactors in which photosynthetic carbon dioxide is derived from combustion of organic waste, fermentation processes or other sources (Mann et al. 2009; Douskova et al. 2009; Doucha et al. 2005) . Furthermore, after starch extraction, the remaining cell residue, comprising mostly protein, can be used as an animal feed supplement to further decrease the cost of starch production. This characteristic enhances the ecological and economic impact of the proposed technology because of its potential to bioremediate carbon dioxide emissions from different CO2 sources including waste incinerators, power stations, limekilns, cogeneration units, etc. in situ.

4 Bioethanol

4.1 Principles of Bioethanol Production from Algae

Even though some algae can act as mini factories for the production of ethanol during dark fermentation , and attempts have been made to create genetic engineered microalgae for the direct production of ethanol (Ueda et al. 1996; Hirano et al. 1997) , these approaches are still not applicable in large-scale biotechnology. The general principle of bioethanol production from microalgal biomass is similar to its production from higher plants. Algal polysaccharides (starch, eventually cellulose and hemicellulosis) are enzymatically hydrolyzed to fermentable sugars, which are subsequently fermented to ethanol by a suitable ethanol producer (yeast, bacteria) (Kelsall and Lyons 1999) . Ethanol is then concentrated by distillation or membrane filtration and dehydrated. Despite the fact that the overall procedure is quite simple, and for different raw materials, well managed even in large scale, each step poses specific difficulties in the case of microalgal biomass. The microalgae store starch inside the cell, which is why the cells must be disintegrated prior to hydrolysis in order to liberate starch for the action of enzymes. Disintegration can be by mechanical means (e.g., ultrasonic, explosive disintegration, mechanical shear, etc.) or by dissolution of cell walls using enzymes (Percival Zhang et al. 2006) . The starch-rich biomass is then processed using technologies similar to other starch-based feedstocks, involving processes of (1) gelatinization (heating in water) which improves the availability of starch for amylase hydrolysis (2) liquefaction i.e. breaking of starch via α-amylases into soluble, short-chain dextrins and oligosaccharides resulting in significant reduction of viscosity, (3) saccharification of the starch‐hydrolysate to glucose syrup catalyzed by glucoamylase and (4) fermentation of simple sugars to ethanol by a suitable strain of yeast, (e.g. Saccharomyces cerevisiae, for review, see Singh et al. 2010) or bacteria, e.g. Zymomonas mobilis (Matsumoto et al. 2003; Rubin 2008) . Using special enzymes and yeast strains, the whole process can be designed so that no gelatinisation is necessary and liquefaction, saccharification and fermentation are carried out simultaneously (Doran-Peterson et al. 2009) .

Finally, the ethanol is separated from the fermentation broth by distillation or membrane filtration and the concentrated ethanol (95 %) can be directly used in special types of engines as so called E100, or dehydrated and blended with gasoline (Demirbas 2001; Nigam and Singh 2010; Brennan and Owende 2010) . The solid residue from the process can be used as animal feed (McKendry 2002) , agricultural fertilizer or as a feedstock for biogas production (for more details, see review John et al. 2011) .

The recent extensive research effort to develop algal biomass with a high starch/cellulose content is aimed at providing a product that could serve as a substrate for ethanol production. As mentioned in the preceding chapters there are algal species that can be directed to produce large amounts (> 50 % of the dry weight) of starch, suitable for ethanol production after hydrolysis (Brányiková et al. 2011; Yao et al. 2012) .

4.2 Approaches to Cheapen Bioethanol Production

4.2.1 Carbon Dioxide Supply from Flue Gases

Since biomass accumulation by feedstock crops can utilize carbon dioxide from flue gases , their growth for bioethanol production can reduce green house gas levels as well as the price of bioethanol production (Borowitzka 2008; Douskova et al. 2009) .

4.2.2 Hydrolysis of Algal Biomass for Yeast Nutrition

In order to achieve the highest possible fermentation yield (theoretically 0.5L g of ethanol/L g of glucose) appropriate nutrition for yeast has to be ensured (source of N, P, S etc.). The cost of nutrients can be cut by adding proteases during polysaccharide hydrolysis, which liberates free amino acids (a source of nitrogen for yeast) from the protein fraction of the algal biomass. The processes of enzymatic hydrolysis and fermentation can also be carried out simultaneously (Doran-Peterson et al. 2009) .

4.2.3 Production of Ethanol from Residual Algal Biomass

The residual biomass obtained e.g. after oil extraction can also be used as a substrate for ethanol production, as was shown when Chlorococcum sp. was used as a substrate for bioethanol production through fermentation by Saccharomyces bayanus (Harun et al. 2010; Harun et al. 2011) . The lipid-extracted microalgal debris was used for fermentation and the yield of bioethanol was about 3.8 g/L from 10 g/L of the substrate. Enzymatic hydrolysis of Chlorococcum sp. by cellulase obtained from Trichoderma reesei was examined. Hydrolysis was conducted under varying conditions of temperature, pH and substrate concentration, with constant enzyme dosage. The highest glucose yield of 64.2 % (w/w) was obtained at a temperature of 40 °C, pH 4.8, and a substrate concentration of 10 g/L of microalgal biomass (Ueno et al. 1998) . Overall, the enzymatic hydrolysis process proved to be an effective mechanism to enhance the saccharification process of microalgal biomass.

4.2.4 Hydrolysis of Cellulose from Cell Walls

Besides starch , green algae can accumulate cellulose as the cell wall carbohydrate, which can also be used for ethanol production. The cellulosic biomass from other plant sources that from algae can be enzymatically or chemically hydrolyzed to simple sugars, which can then be fermented to ethanol (Kelsall and Lyons 1999; Doran-Peterson et al. 2009) .

The advantage of microalgal cellulose is that it is not linked to lignin (unlike cellulose in wood, straw, etc.), which makes hydrolysis easier comparing to the lignocellulosic materials.

4.2.5 Dark Fermentation—Direct Production of Ethanol

Some algae can even serve as a self-biorefinery for ethanol production during anaerobic dark conditions by utilizing their photosynthates. Microalgae fix CO2 during photosynthesis and accumulate starch in their cells. Some microalgae can also grow under dark conditions in the presence of organic nutrients such as sugars and thereby accumulate starch (heterotrophic nutrition) (Chen et al. 2009) . If dark and anaerobic conditions are established, the oxidative degradation of starch becomes incomplete and, depending on the type of the microalga, hydrogen gas, carbon dioxide , ethanol, lactic acid, formic acid, acetic acid and other products can be produced in varying proportions (John et al. 2011) . Algal cells contain large amounts of polysaccharides composed of glucose, which can be catabolized rapidly under dark and anaerobic conditions to ethanol. Conversion from intracellular starch to ethanol under dark and anaerobic conditions was observed in several algal strains (Hirano et al. 1997) . However, the levels of conversion to ethanol were significantly different from each other. Relatively high conversion rates of 30–40 % (vs. a theoretical yield of 0.56 g of ethanol/L g of starch) were observed in two strains, Chlamydomonas reinhardtii (UTEX2247) and Sak-1. Importantly, there was no need for nitrogen flushing due to the complete utilization of oxygen and there was no need for agitation for ethanol production. The optimal pH for ethanol production from Chlamydomonas was 7–8 and a temperature of 25–30 °C. Ethanol was also produced via dark fermentation of cellular starch from Chlorococum littorale, where an increase in the incubation temperature affected the mode of cellular starch decomposition and brought about an increase in ethanol productivity. If methyl viologen was added to the reaction, hydrogen formation drastically decreased while ethanol productivity increased (Ueno et al. 1998) . Exploiting microalgal strains to accumulate starch/cellulose and directly utilize their enzymatic or anaerobic digestion systems to produce ethanol can provide a cost-effective bioethanol production process. (For detail review of these alternative ways of ethanol production, see John et al. 2011) .

Abbreviations

- FdUrd:

-

5-fluorodeoxyuridine

- CHX:

-

Cycloheximide

- DW:

-

dry weight

- PBR:

-

photobioreactor

References

Bachmann B, Hofmann R, Follmann H (1983) Tight coordination of ribonucleotide reduction and thymidilate synthesis in synchronous algae. FEBS Lett 152:247–250

Baker AL, Schmidt RR (1964a) Further studies on the intracellular distribution of phosphorus during synchronous growth of Chlorella pyrenoidosa. Biochim Biophys Acta 82:336–342

Baker AL, Schmidt RR (1964b) Induced utilization of polyphosphate during nuclear division in synchronously growing Chlorella. Biochim Biophys Acta 93:180–182

Ball SG, Dirick L, Decq A, Martiat JC, Matagne RF (1990) Physiology of starch storage in the monocellular alga Chlamydomonas reinhardtii. Science 66:1–9

Ballin G, Doucha J, Zachleder V, Šetlík I (1988) Macromolecular syntheses and the course of cell cycle events in the chlorococcal alga Scenedesmus quadricauda under nutrient starvation: effect of nitrogen starvation. Biol Plant 30:81–91

Behrens PW, Bingham SE, Hoeksema SD, Cohoon DL, Cox JC (1989) Studies on the incorporation of CO2 into starch by Chlorella vulgaris. J Appl Phycol 1:123–130

Borowitzka MA (2008) Marine and halophilic algae for the production of biofuels. J Biotechnol 136:7–12

Brányiková I, Maršálková B, Doucha J, Brányik T, Bišová K, Zachleder V, Vítová V (2011) Microalgae—novel highly-efficient starch producers. Biotechnol Bioeng 108:766–776

Brennan L, Owende P (2010) Biofuels from microalgae—a review of technologies for production, processing, and extractions of biofuels and co-products. Renew Sustain Energy Rev 14:557–577

Cao HM, Zhang LP, Melis A (2001) Bioenergetic and metabolic processes for the survival of sulfur-deprived Dunaliella salina(Chlorophyta). J Appl Phycol 13:25–34

Chen P, Min M, Chen Y, Wang L, Li Y, Chen Q, Wang C, Wan Y, Wang X, Cheng Y, Deng S, Hennessy K, Lin X, Liu Y, Wang Y, Martinez B, Ruan R (2009) Review of the biological and engineering aspects of algae to fuels approach. Int J Agric Biol Eng 2:1–30

Chisti Y (2007) Biodiesel from microalgae. Biotechnol Adv 25:294–306

Cisneros RJ, Zapf JW, Dunlap RB (1993) Studies of 5-fluorodeoxyuridine 5’-monophosphate binding to carboxypeptidase A-inactivated thymidylate synthase from Lactobacillus casei. J Biol Chem 268:10102–10108

Cole DG, Diener DR, Himelblau AL, Beech PL, Fuster JC, Rosenbaum JL (1998) Chlamydomonas kinesin-II-dependent intraflagellar transport (IFT): IFT particles contain proteins required for ciliary assembly in Caenorhabditis elegans sensory neurons. J Cell Biol 141:993–1008

Curnutt SG, Schmidt RR (1964) Possible mechanisms controlling the intracellular level of inorganic polyphosphate during synchronous growth of Chlorella pyrenoidosa. II. ATP/ADP ratio. Biochim Biophys Acta 86:201–203

Demirbas A (2001) Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers Mgmt 42:1357–1378

Doran-Peterson J, Jangid A, Brandon SK, DeCrescenzo-Henriksen E, Dien B, Ingram LO (2009) Simultaneous saccharification and fermentation and partial saccharification and co-fermentation of lignocellulosic biomass for ethanol production. Meth Mol Biol 581:263–280

Doucha J, Straka F, Livansky K (2005) Utilization of flue gas for cultivation of microalgae (Chlorella sp.) in an outdoor open thin-layer photobioreactor. J Appl Phycol 17:403–412

Douskova I, Doucha J, Livansky K, Machat J, Novak P, Umysova D, Zachleder V, Vitova M (2009) Simultaneous flue gas bioremediation and reduction of microalgal biomass production costs. Appl Microbiol Biotechnol 82:179–185

Doušková I, Kaštánek F, Maléterová Y, Kaštánek P, Doucha J, Zachleder V (2010) Utilization of distillery stillage for energy generation and concurrent production of valuable microalgal biomass in the sequence: biogas-cogeneration-microalgae-products. Energy Convers Mgmt 51:606–611

Dragone G, Fernandes BD, Abreu AP, Vicente AA, Teixeira JA (2011) Nutrient limitation as a strategy for increasing starch accumulation in microalgae. Appl Energy 88:3331–3335

Duynstee EE, Schmidt RR (1967) Total starch and amylose levels during synchronous growth of Chlorella pyrenoidosa. Arch Biochem Biophys 119:382–386

Eriksen NT, Riisgard FK, Gunther WS, Lonsmann Iversen JJ (2007) On-line estimation of O(2) production, CO(2) uptake, and growth kinetics of microalgal cultures in a gas-tight photobioreactor. J Appl Phycol 19:161–174

Fernandes BD, Dragone GM, Teixeira JA, Vicente AA (2010) Light regime characterization in an airlift photobioreactor for production of microalgae with high starch content. Appl Biochem Biotechnol 161:218–26

Follmann H (1983) Deoxyribonucleotide biosynthesis: a critical process for life. In: Pullman B, Jortner J (eds) Nucleic acids: the vectors of life. D. Reidel Publishing Company, Jerusalem, pp 547–557

Harun R, Danquah MK, Forde GM (2010) Microalgal biomass as a fermentation feedstock for bioethanol production. J Chem Technol Biotechnol 85:199–203

Harun R, Jason WSY, Cherrington T, Danquah MK (2011) Exploring alkaline pre-treatment of microalgal biomass for bioethanol production. Appl Energy 88:3464–3467

Herrmann EC, Schmidt RR (1965) Synthesis of phosphorus-containing macromolecules during synchronous growth of Chlorella pyrenoidosa. Biochim Biophys Acta 95:63–75

Hirano A, Ueda R, Hirayama S, Ogushi Y (1997) CO2 fixation and ethanol production with microalgal photosynthesis and intracellular anaerobic fermentation. Energy 22:137–142

Hirokawa T, Hata M, Takeda H (1982) Correlation between the starch level and the rate of starch synthesis during the development cycle of Chlorella ellipsoidea. Plant Cell Physiol 23:813–820

Hon-Nami K (2006) A unique feature of hydrogen recovery in endogenous starch-to-alcohol fermentation of the marine microalga, Chlamydomonas perigranulata. Appl Biochem Biotechnol 131:808–828

Ike A, Toda N, Tsuji N, Hirata K, Miyamoto K (1997) Hygrogen photoproduction from CO2-fixing microalgal biomass: application of halotolerant photosynthetic bacteria. J Ferment Bioeng 84:606–609

Ji CF, Yu XJ, Chen ZA, Xue S, Legrand J, Zhang W (2011) Effects of nutrient deprivation on biochemical compositions and photo-hydrogen production of Tetraselmis subcordiformis. Intern J Hydrogen Energy (ol) 36:5817–5821

John RP, Anisha GS, Nampoothiri KM, Pandey A (2011) Micro and macroalgal biomass: a renewable source for bioethanol. Bioresour Technol 102:186–193

Johnson RA, Schmidt RR (1966) Enzymic control of nucleic acid synthesis during synchronous growth of Chlorella pyrenoidosa. I. Deoxythymidine monophosphate kinase. Biochim Biophys Acta 129:140–144

Kamiya A, Kowallik W (1986) Blue light-induced starch breakdown in Chlorella cells. Plant Biol 2:671–676

Kaštánek F, Šabata S, Šolcová O, Maléterová Y, Kaštánek P, Brányiková I, Kuthan K, Zachleder V (2010) In-field experimental verification of cultivation of microalgae Chlorella sp. using the flue gas from a cogeneration unit as a source of carbon dioxide. Waste Mgmt Res 28:961–966

Kelsall DR, Lyons TP (1999) Grain dry milling and cooking for alcohol production: designing for 23 % ethanol and maximum yield. In: Jacques K, Lyons TP, Kelsall DR (eds) The alcohol textbook. Nottingham University Press, Nottingham, pp 7–24

Klein U (1987) Intracellular carbon partitioning in Chlamydomonas reinhardtii. Plant Physiol 85:892–897

Levi C, Gibbs M (1984) Starch degradation in synchronously grown Chlamydomonas reinhardtii and characterization of the amylase. Plant Physiol 74:459–463

Mann G, Schlegel M, Schumann R, Sakalauskas A (2009) Biogas-conditioning with microalgae. Agronomy Res 7:33–38

Maršálková B, Širmerová M, Brányik T, Brányiková I, Melzoch K, Zachleder V (2010) Microalgae Chlorella sp. as an alternative source of fermentable sugars. Chem Eng Trans 21:1279–1284

Matsumoto M, Yokouchi H, Suzuki N, Ohata H, Matsunaga T (2003) Saccharification of marine microalgae using marine bacteria for ethanol production. Appl Biochem Biotechnol 105–108:247–254

McKendry P (2002) Energy production from biomass (part 2): conversion technologies. Bioresour Technol 83:47–54

Miyachi S, Miyachi S, Kamiya A (1978) Wavelenght effects on photosynthesis carbon metabolism in Chlorella. Plant Cell Physiol 19:277–288

Murakami S, Morimura Y, Takamiya A (1963) Electron microscope studies along cellular cycle in Chlorella ellipsoidea. In studies on microalgae and photosynthetic bacteria. The University of Tokyo Press, Tokyo, pp 65–84

Nakamura Y (1983) Change in molecular weight distribution in starch when degraded at different temperatures in Chlorella vulgaris. Plant Sci Lett 30:259–265

Nakamura Y, Miyachi S (1980) Effects of temperature on glycolate metabolism in Chlorella. Plant Cell Physiol 21:1541–1549

Nakamura Y, Miyachi S (1982a) Effect of temperature on starch degradation in Chlorella vulgaris 11h cells. Plant Cell Physiol 23:333–341

Nakamura Y, Miyachi S (1982b) Change in starch photosynthesized at different temperatures in Chlorella. Plant Sci Lett 27:1–6

Nakamura Y, Imamura M (1983) Change in properties of starch when photosynthesized at different temperatures in Chlorella vulgaris. Plant Sci Lett 31:123–131

Nigam PS, Singh A (2010) Production of liquid biofuels from renewable resources. Prog Energy Combust Sci 37(1):52–68. doi:10.1016/j.pecs.2010.01.003

Percival Zhang Y-H, Himmel ME, Mielenz JR (2006) Outlook for cellulase improvement: screening and selection strategies. Biotechnol Adv 24:452–481

Rodjaroen S, Juntawong N, Mahakhant A, Miyamoto K (2007) High biomass production and starch accumulation in native green algal strains and cyanobacterial strains of Thailand Kasetsart. J Nat Sci 41:570–575

Rubin EM (2008) Genomics of cellulosic biofuels. Nature 454:841–845

Schmidt RR (1966) Intracellular control of enzyme synthesis and activity during synchronous growth of Chlorella. In: Cameron IL, Padilla GM (eds) Cell Synchrony. Academic Press, New York, pp 189–235

Semenenko VE, Zvereva MG (1972a) Comparative study on the modification of photobiosynthesis direction in two Chlorella strains during decoupling of cellular functions by extreme temperature. Physiol Plant (Fiziol. Rast.) 19:229–238 (In Russ.)

Semenenko VE, Zvereva MG (1972b) Endogenous regulation of photosynthesis and coupled processes. I. On thermolability of repressors of light dependent protein synthetic system in cells of Chlorella. Plant Physiol (Fiziol. Rast.) 19:116–120 (In Russ.)

Semenenko VE, Vladimirova MG, Orleanskaja OB (1967) Physiological characteristics of Chlorella under conditions of high extreme temperatures. I. Uncoupling effect of extreme temperatures on the cellular functions of Chlorella. Plant Physiol (Fiziol. Rast.) 14:612–625 (In Russ.)

Semenenko VE, Vladimirova MG, Orleanskaja OB, Raikov NI, Kovanova ES (1969) Physiological characteristics of Chlorella sp. K under conditions of high extreme temperatures. II. Changes in biosyntheses, ultrastructure and activity photosynthetical apparatus during uncoupling of cellular functions by extreme temperature. Physiol Plants (Fiziol. Rast.) 16:210–220 (in Russ.)

Šetlík I, Berková E, Doucha J, Kubín Š, Vendlová J, Zachleder V (1972) The coupling of synthetic and reproduction processes in Scenedesmus quadricauda. Arch Hydrobiol. Algolog Stud 7:172–217

Šetlík I, Ballin G, Doucha J, Zachleder V (1988) Macromolecular syntheses and the course of cell cycle events in the chlorococcal alga Scenedesmus quadricauda under nutrient starvation: effect of sulphur starvation. Biol Plant 30:161–169

Singh V, Johnston DB, Rausch KD, Tumbleson ME (2010) Improvements in corn to ethanol production technology using Saccharomyces cerevisiae. In Vertes AA, Qureshi N, Blaschek, HP, Yukawa H (eds) Biomass to biofuels: strategy for global industries. Part III: Ethanol and butanol. Wiley, Chippenham, Wiltshire, Great Britain, pp 187–198

Sorokin C (1957) Changes in photosynthetic activity in the course of cell development in Chlorella. Physiol Plant 10:659–666

Sundberg I, Nilshammar-Holmvall M (1975) The diurnal variation in phosphate uptake and ATP level in relation to deposition of starch, lipid and polyphosphate in synchronized cells of Scenedesmus. Z Pflanzenphysiol 76:270–279

Thu NM, Choi SP, Lee J, Sim SJ (2009) Hydrothermal acid pretreatment of Chlamydomonas reinhardtii biomass for ethanol production. J Microbiol Biotechnol 19:161–166

Ueda R, Hirayama S, Sugata K, Nakayama H (1996) Process for the production of ethanol from microalgae. US Patent 5(578):472

Ueno Y, Kurano N, Miyachi S (1998) Ethanol production by dark fermentation in the marine green Chlorococcum littorale. J Ferment Bioeng 86:38–43

van den Hoek C, Mann DG, Jahns HM (1995) Algae, an introduction to phycology. Cambridge University Press, Cambridge

Voříšek J, Zachleder V (1984) Redistribution of phosphate deposits in the alga Scenedesmus quadricauda deprived of exogenous phosphate—an ultra-cytochemical study. Protoplasma 119:168–177

Wanka F, Joppen MMJ, Kuyper CMA (1970) Starch degrading enzymes in synchronous cultures of Chlorella. Z Pflanzenphysiol 62:146–157

Yao C, Ai J, Cao X, Xue S, Zhang W (2012) Enhancing starch production of a marine green microalga Tetraselmis subcordiformis through nutrient limitation. Bioresour Technol, 118:438–444

Zachleder V (1994) The effect of hydroxyurea and fluorodeoxyuridine on cell cycle events in the chlorococcal alga Scenedesmus quadricauda (Chlorophyta). J Phycol 30:274–279

Zachleder V (1995) Regulation of growth processes during the cell cycle of the chlorococcal alga Scenedesmus quadricauda under a DNA replication block. J Phycol 30:941–947

Zachleder V, Kawano S, Kuroiwa T (1996) Uncoupling of chloroplast reproductive events from cell cycle division processes by 5-fluorodeoxyuridine in the alga Scenedesmus quadricauda. Protoplasma 192:228–234

Zachleder V, Ballin G, Doucha J, Šetlík I (1988) Macromolecular syntheses and the course of cell cycle events in the chlorococcal alga Scenedesmus quadricauda under nutrient starvation: effect of phosphorus starvation. Biol Plant 30:92–99

Zachleder V, Bišová K, Vítová M, Kubín Š, Hendrychová J (2002) Variety of cell cycle patterns in the alga Scenedesmus quadricauda (Chlorophyta) as revealed by application of illumination regimes and inhibitors. Eur J Phycol 37:361–371

Zhang L, Happe T, Melis A (2002) Biochemical and morphological characterization of sulfur-deprived and H2-producing Chlamydomonas reinhardtii (green alga). Planta 214:552–561

Zheng Y, Chen ZA, Lu HB, Zhang W (2011) Optimization of carbon dioxide fixation and starch accumulation by Tetraselmis subcordiformis in a rectangular airlift photobioreactor. Afr J Biotechnol 10:1888–1901

Zhukova TS, Klyachko-Gurvich GS, Vladimirova MG, Kurnosova AT (1969) Comparative characterisation of the growth and direction of biosynthesis of various strains of Chlorella under conditions of nitrogen starvation. II. Formation of carbohydrates and lipids. Physiol Plant (Fiziol. Rast.) 16:79–83 (In Russ.)

Acknowledgements

The work was supported by the projects EUREKA of the Ministry of Education Youth and Sports of the Czech Republic (no. OE 221; no. OE 09025), by project CREST of Japan Science and Technology Agency.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Zachleder, V., Brányiková, I. (2014). Starch Overproduction by Means of Algae. In: Bajpai, R., Prokop, A., Zappi, M. (eds) Algal Biorefineries. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-7494-0_9

Download citation

DOI: https://doi.org/10.1007/978-94-007-7494-0_9

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-7493-3

Online ISBN: 978-94-007-7494-0

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)