Abstract

Synthetic biodegradable polyesters are commonly used in biomedical applications, especially as three-dimensional porous scaffolds for soft and hard tissue engineering. In addition to straightforward fabrication procedures, good mechanical strength and adjustable degradation properties all contribute to the appeal of these polymers. Still, scaffolds synthesized from polyesters are hydrophobic in nature and lack cell recognition signals. Coating or modifying their surface with molecules that enhance cellular adhesion and activity is therefore necessary to make them suitable as biomaterials, while preserving their bulk properties. This chapter reviews current strategies used to modify the surface of polyester-based scaffolds, with a specific focus on the modifications necessary to stimulate soft and hard tissue regeneration. The methods reviewed mostly involve two steps. During the first step, the polymer hydrophilicity is increased by generating carboxylic, amino or hydroxyl groups on the surface by either chemically or photochemically breaking the polymeric ester bonds, or by plasma treatment. This step also allows introducing functional groups on the polymeric surface, which can be used as anchors to bind biomolecules in the next step. In the second step, biomolecules of different types are bound to the previously modified polymer surface, to stimulate a specific tissue response. After providing an overview and many recent examples of the strategies used to achieve both steps, the chapter concludes by summarizing the main achievements to date and the challenges that still remain open.

Hesameddin Mahjoubi and Sara Abdollahi contributed equally to this chapter.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

7.1 Introduction

7.1.1 The Importance of Surfaces in Tissue Engineering

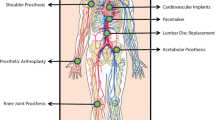

Tissue engineering is an emerging discipline at the junction of engineering, biology and medicine, which is changing the traditional ways of improving people’s health by restoring, maintaining, or enhancing tissue and organ functions [1]. The main goal of tissue engineering is to recreate living tissue in the lab, for applications that can be either therapeutic (for example, replace a damaged organ in a patient), or diagnostic (for example, check the metabolism and toxicity of drugs). To achieve this goal, cells related to the tissue to be recreated are harvested from the target organ and cultured in a petri dish. Once enough cells are generated, they are seeded onto porous structures called scaffolds and kept in an incubator to grow. Then they are implanted in the patient’s body in order to enhance regeneration of the damaged tissue or organ (Fig. 7.1).

Most of the current research in tissue engineering focuses on improving the scaffolds used for tissue culture. Optimal scaffolds should not only provide a physical support for the cells, but also an environment for their proliferation, growth and differentiation, which can finally lead to successful tissue regeneration. Said in a different way, scaffolds should mimic the extra cellular matrix (ECM), which is the natural support over which cells bind and grow in the body. To achieve this, the scaffolds should meet four basic requirements: (1) they should be biocompatible, so no infection occurs when they are implanted in the patient body; (2) they need to be porous, to support two dimensional (2D) expansion and three dimensional (3D) growth of the cells, and the pores must be interconnected, to allow for easy delivery of nutrients to the cells and waste removal; (3) they should be mechanically stable, so they do not deform and collapse before complete regeneration of tissue; and (4) they should be biodegradable, i.e. gradually decompose as the tissue is regenerated, meanwhile producing residues that can be removed by normal metabolic activity of the body. In addition to these basic requirements, it is crucial that the scaffold’s surface elicit the desired response from the cells in contact with it. Indeed, it is the scaffold’s surface that determines the initial cellular response to the implant, and therefore its acceptance and durability in the body [2].

Many biological reactions happen at interfaces [3]. As chemists have known for more than a century, surfaces can provide catalytic sites that can lower reaction energy barriers, and enhance turnover rate. In a similar way, biological surfaces can expose enzymatic sites, facilitate interactions between biomolecules, and encourage specific aspects of cellular activity. The ECM represents one of the most important examples of a biological surface: cells anchor on it through actin filaments, and their proliferation and differentiation is affected by the presence of several signaling complexes on the ECM, such as growth and differentiation factors [4]. Cells respond to biomaterial surfaces somewhat similarly to ECM, and spread and anchor on them if they recognize them as a suitable environment (Fig. 7.2).

Scanning electron microscopy picture of a myoblast cell (length is approximately 10 μm) interacting with a synthetic biomaterial surface [3]

Serum proteins adsorb on a biomaterial’s surface within minutes from its implantation, and these in turn influence the type and quantity of cells that adhere and spread on it [5]. A successful scaffold for tissue engineering will thus be able to attract the desired type of proteins and cells at its interface, to regenerate the originally damaged tissue. To achieve this, scaffold’s surface properties such as wettability, surface charge, and morphology need to be carefully controlled [6]. In addition, the scaffold’s surface can be modified to generate functional groups for the immobilization of drugs, receptors, enzymes, signaling molecules, antibodies or other biologically active molecules for different biomedical applications.

7.1.2 Scaffold Materials for Soft and Hard Tissue Regeneration

The material chosen to fabricate the scaffolds influences both surface and mechanical properties of the implants, and therefore material selection is dictated by the final scaffold application. For example, a scaffold to be used in bone tissue engineering must be able to bear loads, and therefore should have sufficient mechanical strength [7]. For soft tissue regeneration, such as skin, the material should be able to act as a barrier, allow for water flow above it, and be adherent to the tissues underneath [8]. Materials currently used to prepare scaffolds for hard or soft tissue regeneration can be divided into three main categories: bioceramics, natural and synthetic polymers.

Bioceramics are produced by sintering or melting inorganic raw materials to create an amorphous or crystalline solid piece, which can be used as an implant. Products used for scaffold applications are usually porous. Bioceramics can be further classified in three groups. (1) Nonresorbable ceramics: these are relatively inert, and include alumina, zirconia and silicon nitride. Implants made with this type of bioceramics are mainly used as fixtures in medical applications and they need to be removed from the body during a second surgery. (2) Bioactive or surface active ceramics: examples include Bioglass® or porous hydroxyapatite Ca10(PO4)6(OH)2—these materials are mostly used for surface modification and fabrication of scaffolds with enhanced surface properties; (3) Biodegradable or resorbable ceramics, like coralline hydroxyapatite [9] and ferrite calcium phosphates [10]. These materials degrade after some time of implantation in the body, and can be completely resorbed.

Among the natural polymers, both polypeptides such as collagen, gelatin and silk, and polysaccharides such as agarose, alginate and chitosan have been used. These polymers are biocompatible and enzymatically biodegradable. The main advantage for using natural polymers is that they contain bio-functional molecules that aid the attachment, proliferation, and differentiation of cells. Their main disadvantage lies in the difficulty of controlling their degradation rate; this is mainly dependent on enzymes, whose level may vary from patient to patient. Additionally, natural polymers are often mechanically weak, although cross-linking has shown to enhance their structural stability [11].

Synthetic polymers are chemically synthesized, which implies that properties such as mechanical strength and degradation rate can be tuned by changing composition and synthesis parameters. Also, since most of them degrade hydrolytically, the degradation rate of scaffolds made with these polymers does not vary significantly between different patients. The most common synthetic polymers are polyesters such as poly(glycolic) acid (PGA), poly(d,l-lactic) acid (PDLLA), poly(l-lactic) acid (PLLA), and poly(d,l-lactic acid-co-glycolic acid) (PLGA) [12]. Other types include polyanhydrides, polycarbonates, and polyphosphazenes [11–13]. Most of these polymers degrade forming acidic compounds that are naturally occurring in the body. Although these products are not toxic, high concentrations of them may increase local acidity, resulting in inflammation or fibrous encapsulation [12, 14, 15]. Despite this potential disadvantage, synthetic polymers are among the most promising materials for biomedical applications due to their low production costs and the ease of controlling their properties.

Among biodegradable synthetic polymers, polyesters such as PDLLA and PLGA have been explored extensively because of their excellent biodegradability and non-toxicity, which allowed them to be FDA approved [16]. However, their inherent hydrophobicity hinders the interactions between scaffolds made with these polymers and biomolecules, proteins and cells—especially if compared with hydrophilic biomaterials such as polyvinyl alcohol [17]. Surface treatments are thus necessary to optimize the properties of these polymers for biomedical applications.

This chapter will focus on surface modifications of scaffolds made with polyesters for orthopedic and soft tissue regeneration. Surface treatments of these scaffolds aim first at increasing their hydrophilicity, while maintaining their biocompatibility and bulk properties. Both physical methods such as plasma treatment and chemical methods such as hydrolysis can be used to achieve this goal. The functional groups introduced with either method can then be used as anchors to bind specific biomolecules, such as cell signaling molecules and proteins, to improve cell adhesion, proliferation and growth. Compared with relatively recent reviews on surface modification of biomaterials [5, 18–21], the present book chapter aims at giving a more in-depth perspective on the modifications adopted so far on polyesters, and providing examples from recent literature relative to applications in soft (mainly skin and cartilage) and hard (mainly bone) tissue engineering. After reviewing plasma treatments (Sect. 7.2) and chemical methods (Sect. 7.3) used to increase scaffold hydrophilicity and generating anchoring groups, we will provide examples of modifications that have increased the scaffolds’ biological activity (Sect. 7.4). In the last section of this review (Sect. 7.5), we will summarize the most important trends of research so far and describe what is left to be done to achieve a complete control of scaffold’s surface properties. The large number of examples proposed from the most recent literature together with the final summary and perspective should provide the reader with a comprehensive, up-to-date understanding of the importance and potential of surface modifications for biomaterial development.

7.2 Plasma Treatment

Treating polymeric materials with plasma is perhaps the only method that allows modifying their surface without resorting to wet chemistry. In this section we will quickly describe the principles of plasma surface modification, and we will then provide examples of plasma surface modification of biodegradable polyesters used as thin films or scaffolds for soft and hard tissue engineering.

7.2.1 The Principles of Plasma Surface Modification

Plasma is a state of matter composed of highly excited atomic, molecular, ionic, and radical species, achieved by gas excitation with radio frequency [22], or electrons from a hot filament discharge [23]. Since plasma processing has been widely used in microelectronics, coating and painting, the underlying physics and chemistry of plasma is relatively well-known [24]. Plasma is generated by ionizing atoms or molecules in a medium. The ionization takes place when the components of the plasma absorb enough energy from an external excitation source or by collisions with one another. There are many different plasma sources, but the most common ones are gas discharge [23], pulsed vacuum arcs initiated on the surface of a consumable cathode [25–27], and laser [28].

Plasma surface modification techniques can be categorized into plasma sputtering, etching, cleaning, implantation and deposition. In plasma sputtering and cleaning, the surface is bombarded with inert gases such as neon or argon; some of the material surface is etched away, and a clean layer is eventually exposed [29]. Plasma implantation can introduce elements on the surface of the materials by bombarding them with ions coming from a target material [30, 31]. In plasma deposition different groups such as amine and carboxyl groups are deposited on the surface of polymer to change its surface charge and prepare it for attachment of other functional groups and bio molecules [32].

Plasma’s highly reactive chemical environment can modify the surface of materials exposed to it. Indeed plasma engineering has been used to modify almost any type of materials, and change their surface chemical, physical, tribological, electrical, or mechanical properties. Plasma treatments are reproducible and relatively inexpensive, and they can be monitored precisely, and work extremely well on 2D polymer films [86–90]. In biomedical engineering, plasma treatments have been used for many diverse applications, ranging from surface treatment of devices in contact with human blood such as blood bags and vascular grafts to prevent thrombosis [33, 34], sterilization of surgical tools [35], and enhancing anti-bacterial properties [36].

7.2.2 Plasma Treatment of Polyesters for Soft and Hard Tissue Engineering

The advantages of plasma treatment such as easy preparation, achievement of a homogenous surface layer, and sterilization during the treatment, make this method a strong candidate for surface modifications of polyester-based implants and devices. Most commonly, plasma modification of biodegradable polyesters involves their exposure to gases like air, NH3, SO2 and CO2. These treatments aim at introducing polar functionalities on the polymer surfaces, such as hydroxyl, carboxyl, amino and sulfate groups, to increase their hydrophilicity. For example, Yang et al. [32] showed that plasma treatment using N2, NH3 and/or O2 gas could decrease the water contact angle on PDLLA films from a starting value of 78° all the way to 17° in just 2 min of exposure, thus indicating a very large increase in hydrophilicity of the polymer surface. The NH3 plasma-treated PDLLA samples were then exposed to a collagen-containing solution. 3T3 fibroblast adhesion and spreading was compared on these materials and on PDLLA samples coated with collagen without the plasma pretreatment, as well as on PDLLA treated with NH3 plasma only. Cell spreading and growth was maximized by the combination of plasma treatment and collagen exposure (Fig. 7.3). This was attributed to the fact that collagen was present in larger amounts and was more stably anchored to the plasma-treated PDLLA. Positively charged groups present on collagen were suspected to be responsible for the greater interactions with negatively charged cells [32].

Photomicrograph (x150) of 3T3 fibroblasts cultured on different PDLLA films for 9 h. a control; b sample modified by NH3 plasma (50 W, 20 Pa, 300 s); c sample modified by collagen coating, and d sample modified by ammonia plasma pre-treatment collagen anchorage [32]

Shen et al. [37] investigated immobilization of basic fibroblast growth factor (bFGF) on PLGA after plasma treatment. They introduced acid carboxylic functional groups on the surface of PLGA scaffolds via a CO2 plasma, and incubated the samples in a solution containing bFGF. They characterized the composition of PLGA films before and after CO2 plasma treatment with X-ray photoelectron spectroscopy (XPS) and water contact angle, and observed an increase in the fraction of carboxylated species and in hydrophylicity of the PLGA films with longer plasma treatments. To characterize cell adhesion on these surfaces, they cultivated 3T3 fibroblasts on them, and then applied a constant shear stress. They found that plasma treatment followed by bFGF coating drastically increased the amount of cells remaining on the surface, compared with uncoated PLGA or PLGA coated with bFGF without the plasma pretreatment (Fig. 7.4).

The fraction of adherent 3T3 fibroblasts on different PLGA films as a function of time under 36.5 N/m2 of shear stress. While on untreated PLGA films (UT-PLGA) about 76 % of cells detached within 10 min and on PLGA samples just coated with bGFG (UT-PLGA/bFGF) about 80 % detached after 60 min, only ~23 % of cells detached from plasma treated PLGA (PT-PLGA) and less than 5 % on bFGF coated, plasma treated PLGA (PT-PLGA/bFGF) after 60 min [37]

In another work, Shen et al. [38] studied immobilization of human bone morphogenetic protein-2 (rhBMP-2) on PLGA scaffolds. BMP-2 is a powerful osteogenic factor that promotes proliferation, migration and osteogenic differentiation of stem cells. In this paper, the authors modified PLGA scaffolds with different plasma treatments, such as O2, NH3 and CO2, and then incubated them in rhBMP-2 solution to bind the protein onto the surface of the scaffolds. In order to measure the amount of the attached protein on the surface of non-treated and plasma treated PLGA scaffolds, they used a modified enzyme-linked immunosorbent (ELISA) assay method used by other researchers [39, 40]. The results revealed that O2 plasma allowed for the largest binding of rhBMP-2 (Fig. 7.5). The adsorption of rhBMP-2 allowed mouse OCT-1 osteoblast-like cells to better attach and spread on the scaffolds.

Untreated (UT-PLGA), ammonia treated (AT-PLGA), CO2 treated (CT-PLGA) and O2 treated (OT-PLGA) PLGA films with a diameter of 7 mm were loaded with 100 ml rhBMP-2 solution (15 mg/ml) for 1 h. rhBMP-2 binding ability is shown here based on ELISA assay results. * p < 0.05 against UT-PLGA films; # p < 0.05 against AT-PLGA films; $ p < 0.05 against CT-PLGA films [38]

Khorasani et al. [41] studied the radio frequency (RF) oxygen plasma surface treatment of PLLA and PLGA used in nerve tissue engineering. Their water drop contact angle results showed a large increase in polymer hydrophilicity: 1 h of plasma treatment caused a decrease in contact angle from 85° to 10° for PLLA, and from 74.5° to 36.6° for PLGA. B65 nervous tissue cells showed much larger adhesion and growth both on PLLA and PLGA treated samples compare to the untreated ones (Fig. 7.6).

B65 cell attachment on: (a) untreated PLGA; (b) O2 plasma treated PLGA (magnification 400x) [41]

Demina et al. [42] investigated the effect of direct current (DC) discharge plasma modification on composite films made of chitosan, gelatin and PLLA (CGP). This composite has a homogenous bulk structure due to the strong molecular interactions between its components, and thus keeps its chemical and mechanical properties during in vivo degradation. To see the effect of DC discharge plasma treatment on CGP films, a set of samples was treated while connected to the anode side of the DC plasma, and another other set to the cathode. The same treatments were performed on PLLA and chitosan films. The water contact angle measurements showed more than 55° decrease from untreated to plasma-treated CGP samples. Mouse fibroblasts (L929) viability was tested on all the films. Cell viability decreased on CGP after plasma treatment, while it increased on treated PLLA samples (Fig. 7.7). This result indicated that while cell viability on PLLA was mainly affected by changes in wettability, which increased upon plasma treatment, other physicochemical properties such as surface morphology and charge affected cell viability on CGP samples. Differences in cell viability observed upon changes in surface morphology and charge was observed by other researchers as well [43, 44].

Relative viability of L929 mouse fibroblasts cultured on the PLLA, CGP, and chitosan films for 1 week. Results of MTT-test expressed as mean ± standard deviation for three replicates. Viability of the cells cultivated on polystyrene plates was used as a control (100 %) [42]

All these examples show why plasma treatments are becoming more and more common ways to modify the surface of polyesters and biomaterials in general: they allow changing surface properties without altering the bulk properties of the material, thereby offering a high degree of quality control, reliability and reproducibility that is difficult to achieve with other methods. The main drawback of plasma treatment is its difficulty in penetrating pores, which is a major obstacle when trying to modify the surface of 3D scaffolds [45–48].

7.3 Chemical Modifications

Similar to plasma treatment, chemical modifications have the goal of increasing the hydrophilicity of polyesters while generating surface reactive groups that can be used as anchors to immobilize biomacromolecules. In this section we will describe the two main avenues available for chemical modification of polyester scaffolds, i.e. wet chemistry or photochemistry.

7.3.1 Wet Chemistry Modifications

The two most commonly used and simplest wet chemical techniques to modify polyesters are aminolysis and alkali hydrolysis. In both cases, the abundant ester bonds are hydrolyzed, and either amide or carboxylate groups are formed, along with hydroxyl and primary or secondary amine functional groups [49, 50].

Alkali hydrolysis is performed by simply immersing the scaffolds in solutions of concentrated NaOH, for periods ranging from minutes [51] to hours [52]. This treatment leads to cleavage of the ester –COO– bonds and formation of carboxyl and hydroxyl groups. Aminolysis is most commonly achieved by exposing the scaffolds to diamine solutions, which can react with the ester bonds and form amide bonds and amino groups. Both treatments are schematically shown in Fig. 7.8.

Schematic representation of alkali hydrolysis and amynolysis to achieve functionalization of PLGA films adapted from [49]

Aminolysis can be performed with reactants other than diamines. For example, PDLLA can be exposed to poly(ethyleneimine) [53], which leads to the formation of a surface containing a high density of positively charged secondary and tertiary amino groups that can be used as a starting point for further modification with negatively and positively charged biopolymers using the layer-by-layer assembly technique described in Sect. 7.4.4.

The introduction of carboxyl/hydroxyl and amino/amide groups on the scaffolds changes both their chemical properties and topography. Croll et al. [49] performed a thorough physico-chemical study of the changes in chemical properties of thin PLGA films upon both hydrolysis and aminolysis, and found that both treatments caused a decrease in advancing contact angle of approximately five degrees after few minutes of treatment; the decrease was faster for alkali hydrolysis. Major changes in surface topography and a large increase in surface roughness accompanied this modification, as shown in Fig. 7.9 [51]. Indeed, if aminolysis is performed for several hours on PLLA fibers, complete breakdown can occur, leading to the formation of irregularly shaped particles in the nano to micron size range [54]. Thapa et al. prepared a silastic mold to reproduce the nanofeatures obtained on PLGA films treated with NaOH, in an attempt to decouple to changes in chemical surface features and topography induced by the treatment. They found that the increase in nanometer roughness achieved with NaOH treatment was alone responsible for an increase in density of bladder smooth muscle cell attachment to PLGA films [55]. This result shows the complexity of the changes occurring upon chemical treatments of polyester materials, and how hard it is to pinpoint the variables responsible for a specific biological response to the modified surfaces.

SEM images showing increase in surface roughness upon NaOH treatment: PLGA porous films before (a), and after (b) 10 min exposure to 1 N NaOH. Scale bars are 10 mm. Adapted from [51]

Although in most cases chemical modifications were performed on polymeric films, a few reports show examples of extension of this technique to 3D scaffolds [51, 52]. For example, Zhang et al. [56] extended the 2D immobilization of the Arg-Gly-Asp (RGD) peptide on film surfaces to 3D scaffold constructs on which amino functional groups were prior introduced with 1,6-hexanediamine. In a later study [57], they conjugated bone morphogenetic protein-2 (BMP-2) to 3D poly(ε-caprolactone) (PCL) scaffolds following aminolysis and demonstrated the effectiveness of this technique for surface modification versus simple adsorption. The group of Zhu et al. [58] took a similar appraoch to create functional groups in a first aminolysis step followed by grafting of fibronectin on poly(L-lactide-co-caprolactone) (PLLC) scaffolds for epithelium regeneration. 3D PLLA surfaces have also been chemically modified by hydrolysis. Hydrolyzed PLLA scaffolds rich in COOH and OH has been shown to promote hydroxyapatite formation after incubation in SBF [59]. When carrying out chemical surface modifications, reaction conditions must be properly controlled in order to maintain the inherent properties of the polymer and avoid accelerated degradation. Furthermore, thorough rinsing is necessary to remove excess reactants from the porous structure [18, 19].

7.3.2 Photochemical Modification

The photochemical strategy uses high-energy photons (ultraviolet (UV) rays, x-rays, γ-rays) to break chemical bonds and introduce initiators (free radicals) on the chemically inert surface of polyesters [18, 60]. Upon exposure of the free radicals to air or oxygen and in the presence of a monomer and heat or UV light, a polymeric layer is grafted (Fig. 7.10). This technique has been often used to modify the surface of polyesters with polymers rich in reactive groups (for example, carboxylic groups in polyacrylic acids), which serve as anchors to subsequently bind biomolecules [61].

Photochemical modification for graft copolymerization on polymer surface (Adapted from [19])

To create a biomimetic film for meniscus regeneration, poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), a polyester extracted from microorganisms, was photo-grafted with polyacrylamide, a spacer subsequently used for collagen immobilization [62]. In the first step, the amide-modified PHBV was generated by dipping the polymeric films into benzophenone and aqueous acrylamide solutions followed by UV lamp irradiation under nitrogen purge. In a second step, the films were functionalized with collagen, a main constituent of meniscal ECM, via the hydrophilic polyacrylamide spacers.

PHBV was similarly studied by Grondahl et al. [63] for grafting acrylic acid (AAc), this time using gamma irradiation. The extent of modification and introduction of carboxylic acid groups was controlled through adjustment of AAc concentration, thus avoiding a radiation dose that could have resulted in polymer degradation. The polymeric coating obtained was apt for subsequent covalent attachment of glucosamine.

The photochemical technique can also be applied for bulk modification. Shibata et al. [64], for instance, synthesized linear polyesters having pendant azido groups. They used UV irradiation to generate unstable nitrene radicals. These radicals then reacted with the surrounding polymer backbone and yielded cross-links. The reactive nitrene radicals could attack other chemical bonds as well (C–H, N–H and O–H), and be reduced to corresponding amines. Thus, the photo-crosslinking of azidopolyesters occurred without the use of any photo- or radical-initiator. This technique established an important design strategy for advanced materials, since the azidopolyester can be used as a photolithography material.

Gamma irradiation was applied by Bat et al. [65] to cross-link trimethylene carbonate and d,l-lactide (co)polymers using pentaerythritol triacrylate as cross-linking agent. This is an effective and simple method to prepare form stable and creep resistant materials with low glass transition temperatures and tunable degradation properties.

Overall, photochemical modification is advantageous because of its low operation cost and mild reaction conditions compared to other chemical modification techniques [5]. In addition, the target species can be selectively immobilized at specific regions of the substrate [18]. The need for specialized equipment that provides an irradiation source is the inconvenience of this approach [66]. Furthermore, similar to wet chemical methods, high energy treatments can weaken the polymer’s mechanical properties and accelerate degradation. These factors have so far limited the application of photochemical modification mostly to 2D substrates rather than 3D scaffolds [18].

7.4 Functionalization with Biomolecules

Functional groups such as carboxylates, hydroxyls, and amino groups are introduced on the surface of polyesters with plasma or chemical techniques not only to increase their hydrophilicity, but also to provide anchors to bind specific biomolecules that can improve the performance of the materials when implanted in the body. A few examples of biomolecules bound to polyesters were provided in Sects. 7.2 and 7.3. Here we describe more specifically the main techniques used to perform this step, and we give more examples showing the changes in biological properties upon functionalization.

7.4.1 Physical Adsorption

One of the most common methods for protein immobilization on a polymeric scaffold consists in immersing it in a solution containing the molecule of interest and simply allowing the molecule to physisorb on the material’s surface [18]. ECM proteins like fibronectin, collagen, laminin, or molecules such as gelatin have often been coated on polymeric scaffolds with this technique, to make them more biomimetic [5, 67]. Since a protein layer may not form at all or be uneven and unstable if the protein solution is simply cast on a hydrophobic surface [66], polyesters are often treated with plasma or chemicals before contacting them with the protein-containing solutions.

7.4.1.1 ECM Protein Coating

Collagen, fibronectin and laminins are among the most commonly used proteins to modify the surface of scaffolds intended to be used for soft and hard tissue regeneration. Gamboa-Martínez et al. [68] prepared macroporous PLLA scaffolds and coated their walls with a thin network of fibrin, without any chemical or physical pretreatment. The scaffolds were simply evacuated and then exposed to a fibrinogen solution and later to a thrombin solution. The result was scaffolds coated with a network of fibrin fibrils (Fig. 7.11). This coating doubled the elastic modulus of the scaffolds (from 0.29 MPa for pure PLLA to 0.65 MPa for the coated scaffolds), and improved the uniformity of mouse pre-osteoblastic cells seeded on the scaffolds.

SEM images of PLLA and fibrin coated PLLA scaffolds [68]

Zhang et al. [69] used a salt leaching method to construct PDLLA/biphasic calcium phosphate bone scaffolds. The applicability of this construct for drug delivery was then analyzed by coating the scaffold with the hydrophilic polymer poly(ethylene glycol) (PEG) and the antibiotic vancomycin. The surface modification of the scaffold with the mixed coating took place by simple adsorption, by immersing the scaffolds in a solution of PEG/antibiotic after evacuation. The drug on the scaffold surface was active as demonstrated by a standardized bacterial assay. In vitro drug release showed that the antibiotic release profile could be controlled by the concentration of the PEG solution used during the co-adsorption.

Another composite scaffold, in this case made from PCL and mesoporous bioactive glass (MBG) was developed by Yun et al. [70]. MBG is an attractive addition in scaffolds for hard tissue regeneration because it encourages hydroxyapatite (HA) growth, which is the mineral component of bone, when immersed in body fluid. However, the bioactive glass component induces local pH variations during its dissolution, which can result in inflammation in vivo. In this study, the MBG-PCL constructs were immersed in a solution of collagen and simulated body fluid (SBF) in an attempt to create a mixed coating of hydroxyapatite and collagen, and eliminate the potential negative side effects of MBG. Both osteoblast attachment and mineralization were significantly improved after this adsorptive surface modification method (Fig. 7.12).

Field emission SEM images of PCL, MBG-PCL, and ECM-coated PCL scaffolds (left), and same scaffolds after 21 days of MC3T2-E1 culture [70]

Finally, another study [71] employed a 100 μl poly(dopamine) solution as coating agent in an attempt to increase the cell affinity for synthetic polyester films such as PCL, PLLA, and PLGA. Although not an ECM protein, this coating was inspired by the repeated 3,4-dihydroxy-L-phenylalanine-lysine (DOPA-K) motif found in mussel adhesive proteins. The presence of the physisorbed poly(dopamine) coating increased chondrocyte adhesion 1.35–2.69-fold compared with the untreated substrates. The coating was then further extended to 3D polyurethane scaffolds with success.

7.4.1.2 Osteogenic Proteins

Several researchers have coated scaffolds for bone repair with BMP-2. A recent example was provided by Dupont et al. [72], who coated synthetic PCL cylindrical scaffolds with adeno-associated virus encoding BMP-2 to promote endogenous bone repair. The researchers did not pretreat the scaffold surface before exposure to biomolecules; however they physically adsorbed both the biomimetic peptide GFOGER and collagen type I before adding particles of adenoassociated viral vectors encoding for BMP-2 (scAAV2.5-BMP2). Two sets of experiments were performed, with and without preseeding of human mesenchymal stem cells (hMSCs) on the scaffolds prior to implantation in rat femoral defects. The results showed more mineral formation on the scaffolds containing BMP after 12 weeks of implantation (Fig. 7.13). BMP2 scaffolds preseeded with hMSCs did not display significant differences of bone ingrowth in comparison with those containing no hMSCs. Overall, scaffolds coated with BMP2, whether preseeded with hMSCs or not, showed a significant increase of mineral formation and mechanical properties at all time points.

Mineral formation post-mortem (12 weeks) on rat femoral defects, with scaffolds containing scAAV2.5-BMP2 particles, without (a, e, i) or with (b, f, j) the pre-seeding with hMSCs, compared with control samples coated with AAV-luciferase (AAV-Luc) without (c, g, k) or with (d, h, l) pre-seeding with hMSCs. Bony bridge formation was observed on 5/10 defects for scAAV2.5-BMP2 scaffolds, 3/10 for scAAV2.5-BMP2 scaffolds + hMSCs scaffolds, 1/6 defects for AAV-Luc scaffolds and 0/8 for AAV-Luc + hMSCs scaffolds [72]

Another recent study [73] involved the direct physisorption of BMP2 on PLGA scaffolds either as-prepared or pre-coated with an hydroxyapatite layer by immersion in SBF. The osteogenic differentiation of hMSCs was then assessed on both the uncoated and hydroxyapatite-coated scaffolds. Mineralized scaffolds were more hydrophilic and adsorbed more BMP2. It was found that the hydroxyapatite/BMP2 combination enhanced the osteogenic response of hMSCs. Another example of the coating of polyester scaffolds with BMP2 is provided by Yanoso-Scholl et al. [74]. These authors coated PLLA scaffolds with beta-tricalcium phosphate (TCP), and then physisorbed on the PLLA/beta-TCP composites a mix of BMP2 and vascular endothelial growth factor (VEGF). Although the retention efficiency of the growth factors was suboptimal, a 1.8-fold increase in neo vessel formation was nevertheless observed in scaffolds containing the growth factors.

7.4.1.3 Limitations

Although these recent examples show successful enhancement of mechanical and biological properties of scaffolds coated with biomacromolecules (alone or in conjunction with pre-mineralization treatments), physical adsorption has its limitations. For example, the orientation of the adsorbed proteins is random and influenced by factors such as surface topography, charge, and wettability [75, 76]. In addition, the protein may lose its structural conformation upon adsorption [18]. Oriented immobilization of ECM proteins on the material’s surface can overcome this challenge, and is thus the topic of the next section [77].

7.4.2 Covalent Immobilization

Covalent immobilization of biological molecules is an effective method to modify the surface properties of polymers controllably and permanently. Proteins can be covalently bonded by reacting their amino, carboxyl, hydroxyl and thiol functionalities with complementary reactive groups [18, 78]. Unlike physical adsorption, this approach allows oriented protein immobilization [78]. Though similar to coating, the chemically inert polymeric surface needs modification prior to biomolecule immobilization.

One of the most common methods to covalently immobilize biomolecules on polymer surfaces is to crosslink them using carbodiimides such as N,N-(3-Dimethylaminopropyl)-N,N-ethylcarbodiimide (EDC) [52, 79, 80]. These are referred to as zero length cross-linking agents because they form bonds without addition of other atoms or spacers [81]. In a recent example, Ghasemi-Mobarakeh et al. [52] covalently crosslinked a mix of ECM proteins found in basement membranes (collagen IV, fibronectin, heparin sulphate proteoglycans, AKA “matrigel”) to PCL nanofibrous scaffolds. Before crosslinking, carboxylate groups were formed on PCL surfaces by alkaline hydrolysis. The importance of crosslinking was proved by characterizing nerve precursor cells (NPC) adhesion and proliferation on scaffolds that were built with PCL fibers, fibers treated with alkaline hydrolysis (PCL-H), fibers made by simple blending PCL with matrigel (PCL-B), and PCL fibers covalently modified with matrigel (PCL-F). The results of the study showed that cells adhered and proliferated to a greater extent on fibers modified by covalent crosslinking, while simple blending was ineffective (Fig. 7.14).

SEM of NPC cultured for 4 days on PCL (A), PCL-H(B), PCL-B(C), and PCL-F(D) [52]

EDC was used to covalently bind cationized gelatin (CG) gelatin to electrospun PLLA nanofibers (NF) also by Chen et al. [82]. In this case, surface carboxylation was achieved using a DC-pulsed plasma system [83]. The goal of this work was to prove the potential of this modified scaffold for cartilage tissue engineering. XPS characterization successfully confirmed CG binding to PLLA NF membranes (CG-PLLA NFMs). Rabbit articular chondrocytes showed enhanced viability, proliferation and differentiation on CG-PLLA NFMs. In-vivo tests in New Zealand white rabbits carried out with chondorocyte-seeded CG-PLLA NFMs showed only a small inflammatory reaction (Fig. 7.15). Also, the seeded chondrocytes maintained their ability to generate and secrete cartilage ECM markers after 4 weeks of in vivo culture, which confirmed the ability of CG-PLLA NFM to induce ectopic cartilage formation after long-term in vivo implantation.

Histological images of (a–d) control CG-PLLA NFM and (e–h) chondrocyte-seeded CG-PLLA NFM 4 weeks post-implantation. Sections were stained with H&E (a, e), Alcian blue (b, f) Saffranin O (c, g), and immunohistochemically for collagen type II (d, h). N nanofiber; IC inflammatory cells; ST surrounding tissue. Bar 100 μm [82]

In a very recent example, Grafahrend et al. [84] covalently functionalized electrospun PLGA fibers with the cell-adhesion-mediating peptide sequence Gly-Arg-Gly-Asp-Ser (GRGDS). Covalent crosslinking was not performed directly on PLGA, but on the additive star-shaped poly(ethylene oxide-stat-propylene oxide) containing isocyanate end groups (NCO-sP(EO-stat-PO)), which was mixed with PLGA during electrospinning. Isocyanate end groups allowed for covalent binding with amino groups from GRGDS, and the resulting fibers had several advantages over plain PLGA because they were hydrophilic and resisted non-specific protein adsorption thanks to the presence of sP(EO-stat-PO), and able to support cell adhesion and proliferation because of the presence of the RGD domain in the GRDGS peptide. Indeed, human fibroblast cells did not adhere on scaffolds composed by just PLGA and sP(EO-stat-PO), while thrived on those covalently modified with GRGDS (Fig. 7.16).

Optical microscope image of human dermal fibroblasts after 24 h in cell culture on GRGDS-functionalized PLGA/sP(EO-stat-PO) fibers [84]

Covalent immobilization has been tested also to bind inorganic particles to polyester scaffolds. Koo et al. [85] first introduced carboxylate groups on a PLLA scaffolds by chemical modification (treatment in NaOH); then they aminated the surface using ethylenediamine (EDA), covalently bound to the carboxylate groups through EDC coupling. Nanohydroxyapatite (N-HAp) was modified with ethylene glycol methacrylate phosphate (EGMP), and the phosphonate groups on N-HAp could be crosslinked with the amino groups on the PLLA surface again with the use of EDC (Fig. 7.17). Using XPS, the authors showed a higher surface Ca atomic ratio (4.6 %) when N-HAp was surface immobilized on the scaffolds rather than bulk-mixed (0.4 %). The covalently immobilized N-HAp provides a favorable environment for enhanced in vivo bone tissue growth in comparison to the unmodified and N-HAp bulk-modified surfaces. The phosphonic acid groups on the immobilized N-HAp surface could also provide opportunities for fuctionalization with other biomolecules.

Surface immobilization of N-HAp on PLLA scaffolds [85]

Wu et al. [86] even used covalent immobilization as a means to create a stable gelatin gradient on the surface of PLLA scaffolds in order to obtain a continuous increment of signaling for chondrocytes adhesion and viability. To aminolyze the PLLA surface, 1,6-hexanediamine/propanol solution was continuously injected by a micropump into a glass vial where the scaffold stood vertically fixed (Fig. 7.18). The reaction time difference along the longitude of the PLLA scaffold resulted in an increase of –NH2 groups from the bottom upward, thus enabling a graded coupling with gelatin.

Creation of an amino gradient along the surface of PLLA scaffold [86]

One of the challenges of covalent biomolecule immobilization on polymeric surfaces is that chemicals and crosslinkers can result in the loss of the protein’s natural conformation [66]. Furthermore, the complex architecture of the scaffold surface and buried ligand sites may lead to below optimal cell-receptor interactions [18]. This technique is nevertheless effective and surface immobilized proteins can be quantified [87].

7.4.3 Entrapment

Entrapment was first introduced by Desai and Hubbell as a non-covalent but stable technique to modify polyester surfaces with biomacromolecules [88]. The two-step method first involves swelling the polymer in a mixture of solvent and non-solvent of the polymer, containing the molecules. A gel-like layer then forms on the surface of the polymer, within which proteins diffuse. These proteins are then “entrapped” in the gel through immersion of the polymer in a pure non-solvent (Fig. 7.19) [89].

Surface modification by entrapment (adapted from [5])

Different molecules have been confined in polyester films or scaffolds through entrapment. In one of the earliest examples, Quirk et al. modified PLLA films with both PEG and a cell adhesive peptide conjugate poly(L-lysine)-RGD (PLL-RGD). Their results showed that bovine aortal endothelial cell adhesion was drastically decreased in the presence of PEG alone, due to the suppression of non-specific protein adsorption on the PLLA surface, while the entrapment of both PEG and PLL-RGD allowed cells to adhere on the PLLA [89].

Another early work using entrapment is that by Liu et al. [90], who modified PDLLA films with baicalin, a flavonoid compound purified from the herbal medicinal plant Scutellaria baicalensis Georgi, known for its antioxidant and anti-inflammatory properties. The entrapment procedure consists of (1) firstly immersing the polymer film in an acetone/water mixture (solvent/nonsolvent), (2) exposing the film to the baicalin solution, and finally (3) rinsing with distilled water and phosphate buffered saline (PBS). The behavior of osteoblasts on the modified films was then compared with controls. The results of MTT assay and alkaline phosphatase activity reveal higher cell attachment, greater cell proliferation and viability, and an overall improvement in biocompatibility for the surface-modified PDLLA.

Recently, a similar entrapment of PEG on PDLLA nanofibrous mats prepared by electrospinning was reported by Xie et al. [54]. Water contact angles before and after entrapment indicated an increase in the hydrophilicity of the surface of the mats. In this case, although PEG was the sole entrapped species, an improvement in biocompatibility after surface modification was visible following canine fibroblast cell seeding and cell viability tests by MTT assay.

In another recent study, Duan et al. [91] designed 3D composite scaffolds for bone tissue engineering from calcium phosphate (Ca–P) nanoparticles and PHBV. Selective laser sintering (SLS), which is a form of rapid prototyping technique, was used to create the structures. The high crystallinity of PHBV makes it such that the overall surface is hydrophobic, impairing cell affinity and weakening cell-scaffold interactions. Gelatin was therefore physically entrapped in the scaffold to increase its hydrophilicity. A decrease in contact angle proved the efficacy of the modification. At the same time, the entrapment did not affect surface morphology and mechanical properties, as demonstrated by SEM analysis (Fig. 7.20) and compression tests, respectively.

SEM images of Ca–P/PHBV scaffold surface before (a) and after (b) gelatin entrapment [91]

Entrapment is thus a commonly used method for protein immobilization, where the amount of entrapped biomolecules can be controlled through adjustment of solvent composition and reaction time [18, 91]. Limitations of the technique include random orientation and over-crowding of the proteins [76].

7.4.4 Self-Assembly

The most common technique that exploits molecular self-assembly for surface modification is layer-by-layer self-assembly. This consists of alternate depositions of oppositely charged polyanions and polycations on the polymer surface (Fig. 7.21) [92, 93]. Prior to the multilayer build-up, initial charges are usually introduced on the substrate. The thickness and charge of the assembly can be precisely controlled. Additionally, the nature of polyelectrolytes, pH, and ionic strength of the deposition solutions are adjustable and affect both the physical and chemical properties of the coating [92].

Constructing layer by layer film by adsorption of positively and negatively charged species [93]

Layer-by-layer assembly has been used by several authors to coat polyester films or scaffolds with ECM proteins or other naturally occurring polypeptides. Most commonly, positively charged polypeptides are deposited in alternating layers with negatively charged polyelectrolytes such as poly(styrene sulfonate) (PSS) [94, 95].

Li et al. [94] used layer-by-layer deposition to coat electrospun PCL scaffolds with gelatin. The deposition started with the immersion of the PCL scaffolds for 20 min in a 2 mg/mL gelatin solution in 20 mM acetic buffer. This was followed by rinsing the matrix with water and dipping for another 20 min in a 3 mg/mL PSS sodium salt solution in 20 mM acetic buffer. The aforementioned process was repeated to reach the desired number of layers. When the gelatin-surface modified scaffolds were mineralized in SBF, a drastically higher amount of bonelike calcium phosphate was deposited on their surface. The incorporation of gelatin thus promoted nucleation and growth of calcium phosphate. The authors also showed that MC3T3-E1 preosteoblastic cells adhered and spread to a greater extent on the mineralized scaffolds compared to the pure PCL scaffolds (Fig. 7.22).

Fluorescence micrographs of MC3T3-E1 cells cultured for 7 days on (a, b) membranes of electrospun PCL fibers and (c, d) membranes of electrospun PCL fibers coated with gelatin and then calcium phosphate. The F-actin was stained with fluorescein isothiocyanate-phallodin (green color), while the cell nucleus was stained with 4′-6-diamidino-2-phenylindole (DAPI) (purple color) [94]

A different kind of self-assembly strategy was adopted by Stendahl et al. [96] for PLLA fiber surface modification. The authors synthesized a triblock molecule containing cholesterol, an oligomer of L-lactic acid, and lysine moieties (Fig. 7.23). The cholesterol and oligo-lactic acid segments are hydrophobic, and thus have an affinity for PLLA, while the hydrophilic dendron is displayed on the outer surface upon self-assembly. Cholesterol has the added advantages of generating ordered layers on PLLA, and having a strong affinity to plasma membranes. The study showed that the ordered self-assembled layer formed on PLLA resulted in biomaterials that were more biocompatible. Indeed, both the adhesion and proliferation of 3T3 mouse calvaria cells was enhanced on the surface modified structures.

The amphiphilic triblock molecule made from a rigid cholesterol segment, a flexible oligomer of L-lactic acid, and an L-lysine dendron used to modify PLLA scaffold fibers [96]

Self-assembly is a simple and conceptually intriguing technique, since it exploits the chemical properties of biomolecules to generate truly “bottom-up” structures. The structures are stable without the need for extra cross-linkers, and therefore this method can be applied not only to modify material surfaces, but also to create bulk structures that include biological functionalities [97].

7.5 Conclusions and Perspective

In this chapter we have shown that many different techniques can be used to modify the surface of polyesters for biomedical applications. Such modifications are necessary in order to make the materials suitable for interactions with cells and implantation. Indeed, polyesters are hydrophobic materials, which might attract unwanted proteins on their surface if implanted as they are. Also, since they do not have any biological activity, they cannot provoke a specific reaction in the surrounding tissue. Therefore, although biodegradable and bioresorbable in most cases, in a certain sense these materials should be compared to bioinert materials. Altering their surface properties and binding biological molecules on their surface allows them to overcome this limitation.

Table 7.1 summarizes the biomolecules bound to 2D or 3D polyester scaffolds discussed in this chapter. As we can see, many examples relate to proteins found in the ECM. Synthetic polyesters are used as scaffolds to simulate the organic matrix on which osteoblasts lay down hydroxyapatite (for bone tissue engineering), or chondrocites, fibroblasts or endothelial cells start building soft tissue (for cartilage and skin engineering). ECM proteins therefore can be used to make the scaffolds biomimetic, and imitate the physiological matrix that cells meet in the body, thus promoting their attachment and spreading. Other examples related to proteins belonging to the extended family of growth factors. Incorporating these molecules on the surface of a polymeric scaffold makes it bioactive: the molecules are able to elicit specific functions in the cells that adhere on the substrates, and improve the success of the implant. Finally, the last few examples listed in the table relate to the binding of drugs. In this case, the overall goal is to achieve controlled release of these substances. Binding the drugs to a biodegradable scaffold surface allows for a controlled local delivery, since the scaffold is to be implanted at the site where the drug needs to be delivered. In this case, we could say that the scaffolds are transformed into local delivery vectors.

Table 7.1 also shows the techniques used to bind the biomolecules to the polymeric surfaces. Pros and cons of these methods as well as all those presented in this chapter are summarized in Table 7.2.

By looking at Table 7.1, we can observe that the most prevalent methods used for biomolecule attachment are physisorption and covalent binding, which are also the simplest methods to (a) achieve a continuous coverage (in the case of physisorption) and (b) control the orientation of the molecules bound to the polymer surface (in the case of covalent binding) (see Table 7.2). Both methods require a preliminary surface modification step, i.e. introducing anchoring groups that the biomolecules will interact with or will be crosslinked to. As shown in Table 7.2, there is no ideal preliminary surface modification technique. Methods explored so far are either limited mostly to 2D film modification (plasma and photochemical treatment) or, if they allow for 3D modification, they tend to degrade the polymeric bulk structure (chemical treatment based on hydrolysis or aminolysis). Since 3D and not 2D structures are mainly implanted in vivo, there is clearly a strong need to find a new way to improve the preliminary surface modification step. We recently showed a different type of chemical modification based on diazonium salts. This method allowed us to generate anchoring groups on a PDLLA 3D scaffold without modifying its bulk structure. The amino groups introduced with this technique were used to covalently bind phosphonate-containing molecules without the use of crosslinkers, which improved scaffold mineralization when immersed in SBF [98].

The second step of the functionalization, i.e. the biomolecule attachment, could be improved as well. Even covalent binding, despite offering a better control of protein orientation compared to simple physisorption, cannot always ensure that the protein will maintain its natural configuration. In fact, covalent bonding works with crosslinkers that can bind to any amino, carboxylates, or thiol groups present in the protein. Since there are many of them, the protein can end up being bound in different ways depending on which of the groups react more easily, or in a more open configuration than in its natural state. Although not ideal, in some cases this could be an advantage, especially for bone tissue engineering—in fact, the same phenomenon happens when proteins interact with the ECM. It is well known that the same proteins (e.g. osteopontin) are able to inhibit mineralization when in solution, while promote it when bound to the ECM [99]. In view of this, one could consider modifying scaffold surfaces not necessarily with the physiological biomolecules, but with synthetic analogues that are designed to mimic the density and spacing of important functional sites present on the natural proteins when they are bound to the ECM. Several researchers have worked on understanding the amount and density of negatively charged amino acids in the structure of proteins involved in bone mineralization [99]. A recent study showed that by controlling the density of hydroxyl and carboxylate groups on a hydrogel, a hydroxyapatite-like layer could be easily produced when the hydrogels were immersed in Ca and P-containing solutions [100]. If a similar strategy was applied to modify the surface of a scaffold with the correct density of functional groups, one could obtain a biomaterial able to improve mineralization without using natural proteins. Such controlled density could be obtained using photoligraphy, or by covalent binding of small molecules containing the groups of interest, e.g. amino acids.

Possibly a similar method could be used to mimic more complex functions of natural proteins, and not only their ability to induce mineralization. Binding small peptides mimicking the active sites of natural proteins goes in this direction. Most of the work done so far in this respect involves binding peptides containing the cell adhesive RGD sequence. Still, active peptides other than RGD have been recently discovered. For example, D’Andrea et al. [101] found a short peptide part of VEGF responsible for its activity. Leslie-Barbick et al. [102] then bound this peptide to PEG hydrogels, and found that it was able to promote vascularization better than the whole VEGF, most likely because it suffered less from steric hindrance from the hydrogel. Peptides are much easier to bind to scaffold surfaces with the correct orientation than the whole growth factor, they are stable in harsher solvents, which implies that they could be incorporated in synthetic scaffolds even during their preparation, and are definitely less expensive. For all these reasons, we predict that in the near future many more researchers will work on binding small peptides rather than the complete biomolecules to polyester-based scaffolds.

As a final remark, we would like to point out that all the work described in this chapter on surface functionalization of polyester scaffolds aims at making materials that are able to better communicate with the body, by exposing signaling molecules able to elicit a specific response. However, true communication can be achieved only if the scaffolds were able to not only talk the same language of the body, but also listen to its response. The next generation of scaffolds and biomaterials will have both functional groups bound to their surfaces able to provide correct signals, and sensors able to track changes in physiological variables. Ideally, scaffolds should be able to dynamically respond to these changes, for example by releasing drugs on demand. A scaffold that was at the same time biomimetic, bioactive, local delivery vector, and able to sense physiological changes could cause a real paradigm shift in tissue engineering.

References

Sipe, J.D., Tissue engineering and reparative medicine. Reparative Medicine: Growing Tissues and Organs, 961 (2002)

Hench, L.L.: Biomaterials. Science 208, 4446 (1980)

Castner, D.G., Ratner, B.D.: Biomedical surface science: Foundations to frontiers. Surf. Sci. 500(1–3), 28–60 (2002)

Kim, S.-H., Turnbull, J., Guimond, S.: Extracellular matrix and cell signalling: the dynamic cooperation of integrin, proteoglycan and growth factor receptor. J. Endocrinol. 209, 2 (2011)

Jiao, Y.P., Cui, F.Z.: Surface modification of polyester biomaterials for tissue engineering. Biomed. Mater. 2(4), R24–R37 (2007)

Zeb, G., et al.: Decoration of graphitic surfaces with Sn nanoparticles through surface functionalization using diazonium chemistry. Langmuir 1, 13042–13050 (2012)

Sabir, M., Xu, X., Li, L.: A review on biodegradable polymeric materials for bone tissue engineering applications. J. Mater. Sci. 44(21), 5713–5724 (2009)

Metcalfe, A.D., Ferguson, M.W.J.: Tissue engineering of replacement skin: the crossroads of biomaterials, wound healing, embryonic development, stem cells and regeneration. J. Roy. Soc. Interf. 4, 14 (2007)

Aragon, J., et al.: Development and characterization of a novel bioresorbable and bioactive biomaterial based on polyvinyl acetate, calcium carbonate and coralline hydroxyapatite. Mater. Res. -Ibero-Am. J. Mater. 14, 1 (2011)

Le Guehennec, L., Layrolle, P., Daculsi, G.: A review of bioceramics and fibrin sealant. Eur. Cells Mater. 8, 1–11 (2004)

Dhandayuthapani, B., et al.: Polymeric scaffolds in tissue engineering application: A review. Int. J. Polymer Sci. 2011, 1–19 (2011)

Thomson, R.C., et al.: Biodegradable polymer scaffolds to regenerate organs. Biopolymers Ii 122, 245–274 (1995)

Cheung, H.-Y., et al.: A critical review on polymer-based bio-engineered materials for scaffold development. Compos. B-Eng. 38, 3 (2007)

Seal, B.L., Otero, T.C., Panitch, A.: Polymeric biomaterials for tissue and organ regeneration. Mater. Sci. Eng. R-Reports 34, 4–5 (2001)

Gunatillake, P.A., Adhikari, R.: Biodegradable synthetic polymers for tissue engineering. Eur. Cells Mater. 5, 1–16 (2003)

Wang, S.G., Cui, W.J., Bei, J.Z.: Bulk and surface modifications of polylactide. Anal. Bioanal. Chem. 381(3), 547–556 (2005)

Lin Y et al (2006) Surface modification of poly (L-lactic acid) to improve its cytocompatibility via assembly of polyelectrolytes and gelatin. Acta Biomater 2(2):155–164

Vasita, R., Shanmugam, I.K., Katt, D.S.: Improved biomaterials for tissue engineering applications: Surface modification of polymers. Curr. Top. Med. Chem. 8(4), 341–353 (2008)

Ma, Z.W., Mao, Z.W., Gao, C.Y.: Surface modification and property analysis of biomedical polymers used for tissue engineering. Colloids Surf. B-Biointerf. 60(2), 137–157 (2007)

Jacobs, T., et al.: Plasma surface modification of biomedical polymers: Influence on cell-material interaction. Plasma Chem. Plasma Process. 32(5), 1039–1073 (2012)

Ratner, B.D.: Plasma deposition for biomedical applications—a brief review. J. Biomater. Sci. Polymer Edn. 4(1), 3–11 (1992)

Urano, Y., et al.: Production of 1-m size uniform plasma by modified magnetron-typed RF discharge with a subsidiary electrode for resonance. Thin Solid Films 316, 1–2 (1998)

Raizer, Y.P.: J. Atmos. Terr. Phys. 55(10), 1487 (1993). (Gas discharge physics: 1991, p. 449. Springer. Heidelberg, DM 148.00 hb, ISBN 3-540-19462-2)

Ohl, A., Schroder, K.: Plasma-induced chemical micropatterning for cell culturing applications: a brief review. Surf. Coat. Technol. 116, 820–830 (1999)

Boxman, R.L., Goldsmith, S., Greenwood, A.: Twenty-five years of progress in vacuum arc research and utilization. IEEE Trans. Plasma Sci. 25(6), 1174–1186 (1997)

Yushkov, G.Y., et al.: Effect of multiple current spikes on the enhancement of ion charge states of vacuum arc plasmas. J. Appl. Phys. 87(12), 8345–8350 (2000)

Oks, E.M., Yushkov, G.Y., Anders, A.: A summary of recent experimental research on ion energy and charge states of pulsed vacuum arcs. 23rd international symposium on discharges and electrical insulation in vacuum, 2008. ISDEIV 2008

Amoruso, S., et al.: Characterization of laser-ablation plasmas. J. Phys. B-Atomic Molecular Opt. Phys. 32(14), R131–R172 (1999)

Chan, C.M., Ko, T.M., Hiraoka, H.: Polymer surface modification by plasmas and photons. Surf. Sci. Rep. 24(1–2), 3–54 (1996)

Inagaki, N., Plasma Surface Modification and Plasma Polymerization. Pennsylvania, Technomic Publishing Company, Inc (1996)

Chu, P.K., et al.: Plasma immersion ion implantation, Äîa fledgling technique for semiconductor processing. Mater. Sci. Eng. R: Reports 17(6–7), 207–280 (1996)

Yang, J., Bei, J.Z., Wang, S.G.: Enhanced cell affinity of poly (D, L-lactide) by combining plasma treatment with collagen anchorage. Biomaterials 23, 12 (2002)

Kiaei, D., Hoffman, A.S., Horbett, T.A.: Tight-binding of albumin to glow-discharge treated polymers. J. Biomater. Sci. Polymer Edn 4, 1 (1992)

Garfinkle, A.M., et al.: Effects of a tetrafluoro ethylene glow-discharge on patency of small diameter dacron vascular grafts. Trans. Am. Soc. Artif. Inter. Organs 30, 169 (1984)

Gombotz, W.R., Hoffman, A.S.: Gas-discharge techniques for biomaterial modification. CRC Crit. Rev. Biocompat. 4, 1 (1987)

Bazaka, K., et al.: Plasma-assisted surface modification of organic biopolymers to prevent bacterial attachment. Acta Biomater. 7(5), 2015–2028 (2011)

Shen, H., et al.: The immobilization of basic fibroblast growth factor on plasma-treated poly(lactide-co-glycolide). Biomaterials 29, 15 (2008)

Shen, H., et al.: The bioactivity of rhBMP-2 immobilized poly(lactide-co-glycolide) scaffolds. Biomaterials 30, 18 (2009)

Chen, B., et al.: Homogeneous osteogenesis and bone regeneration by demineralized bone matrix loading with collagen-targeting bone morphogenetic protein-2. Biomaterials 28, 6 (2007)

Han, B., et al.: Collagen-targeted BMP3 fusion proteins arrayed on collagen matrices or porous ceramics impregnated with Type I collagen enhance osteogenesis in a rat cranial defect model. J. Orthopaedic Res. 20, 4 (2002)

Khorasani, M.T., Mirzadeh, H., Irani, S.: Plasma surface modification of poly (L-lactic acid) and poly (lactic-co-glycolic acid) films for improvement of nerve cells adhesion. Radiat. Phys. Chem. 77, 3 (2008)

Demina, T., et al.: DC discharge plasma modification of chitosan/gelatin/PLLA films: Surface properties, chemical structure and cell affinity. Surf. Coat. Technol. 207, 508–516 (2012)

van Wachem, P.B., et al.: Adhesion of cultured human endothelial cells onto methacrylate polymers with varying surface wettability and charge. Biomaterials 8(5), 323–328 (1987)

Chen, H., et al.: Electrospun chitosan-graft-poly (ɛ-caprolactone)/poly (ɛ-caprolactone) cationic nanofibrous mats as potential scaffolds for skin tissue engineering. Int. J. Biol. Macromol. 48(1), 13–19 (2011)

Demirbilek, M.E., et al.: Oxidative stress parameters of L929 cells cultured on plasma-modified PDLLA scaffolds. Appl. Biochem. Biotechnol. 164, 6 (2011)

Tian, H., et al.: Biodegradable synthetic polymers: Preparation, functionalization and biomedical application. Progress in Polymer Science 37, 2 (2012)

De Bartolo, L., et al.: Evaluation of cell behaviour related to physico-chemical properties of polymeric membranes to be used in bioartificial organs. Biomaterials 23, 12 (2002)

Groth, T., et al.: Interaction of human skin fibroblasts with moderate wettable polyacrylonitrile-copolymer membranes. J. Biomed. Mater. Res. 61, 2 (2002)

Croll, T.I., et al.: Controllable surface modification of poly(lactic-co-glycolic acid) (PLGA) by hydrolysis or aminolysis I: Physical, chemical, and theoretical aspects. Biomacromolecules 5(2), 463–473 (2004)

Zhu, Y.B., et al.: Immobilization of biomacromolecules onto aminolyzed poly(L-lactic acid) toward acceleration of endothelium regeneration. Tissue Eng. 10, 1–2 (2004)

Park, G.E., et al.: Accelerated chondrocyte functions on NaOH-treated PLGA scaffolds. Biomaterials 26(16), 3075–3082 (2005)

Ghasemi-Mobarakeh, L., et al.: Bio-functionalized PCL nanofibrous scaffolds for nerve tissue engineering. Mater. Sci. Eng. C 30(8), 1129–1136 (2010)

Zhu, H.G., Ji, J., Shen, J.C.: Construction of multilayer coating onto poly-(DL-lactide) to promote cytocompatibility. Biomaterials 25, 1 (2004)

Xie, Z., et al.: Electrospun poly(D, L)-lactide nonwoven mats for biomedical application: Surface area shrinkage and surface entrapment. J. Appl. Polym. Sci. 122(2), 1219–1225 (2011)

Thapa, A., et al.: Nano-structured polymers enhance bladder smooth muscle cell function. Biomaterials 24(17), 2915–2926 (2003)

Zhang, H.N., Lin, C.Y., Hollister, S.J.: The interaction between bone marrow stromal cells and RGD-modified three-dimensional porous polycaprolactone scaffolds. Biomaterials 30(25), 4063–4069 (2009)

Zhang, H.N., et al.: Chemically-conjugated bone morphogenetic protein-2 on three-dimensional polycaprolactone scaffolds stimulates osteogenic activity in bone marrow stromal cells. Tissue Eng. Part A 16(11), 3441–3448 (2010)

Zhu, Y.B., et al.: Esophageal epithelium regeneration on fibronectin grafted poly(L-lactide-co-caprolactone) (PLLC) nanofiber scaffold. Biomaterials 28(5), 861–868 (2007)

Jao, Y.P., et al.: Effect of hydrolysis pretreatment on the formation of bone-like apatite on poly(L-lactide) by mineralization in simulated body fluids. J. Bioactive Compat. Polymers 22(5), 492–507 (2007)

Poncinepaillard, F., Chevet, B., Brosse, J.C.: Modification of isotactic polypropylene by a cold-plasma or an electron-beam and grafting of the acrylic-acid onto these activated polymers. J. Appl. Polym. Sci. 53(10), 1291–1306 (1994)

Steffens, G.C., et al.: High density binding of proteins and peptides to poly(D, L-lactide) grafted with polyacrylic acid. Biomaterials 23(16), 3523–3531 (2002)

Ke, Y., et al.: Bioactive surface modification on amide-photografted poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Biomed. Mater.6, 2 (2011)

Grondahl, L., Chandler-Temple, A., Trau, M.: Polymeric grafting of acrylic acid onto poly(3-hydroxybutyrate-co-3-hydroxyvalerate): Surface functionalization for tissue engineering applications. Biomacromolecules 6(4), 2197–2203 (2005)

Shibata, Y., et al.: Azidation of polyesters having pendent functionalities by using NaN3 or DPPA-DBU and photo-crosslinking of the azidopolyesters. Polym. J. 43(3), 272–278 (2011)

Bat, E., et al.: Crosslinking of trimethylene carbonate and D, L-Lactide (Co-) polymers by gamma irradiation in the presence of pentaerythritol triacrylate. Macromol. Biosci. 11(7), 952–961 (2011)

Ma, Z., Mao, Z., Gao, C.: Surface modification and property analysis of biomedical polymers used for tissue engineering. Colloids Surf. B 60(2), 137–157 (2007)

Shin, H., Jo, S., Mikos, A.G.: Biomimetic materials for tissue engineering. Biomaterials 24(24), 4353–4364 (2003)

Gamboa-Martinez, T.C., Gomez Ribelles J.L., Gallego Ferrer, G.: Fibrin coating on poly (L-lactide) scaffolds for tissue engineering. J. Bioactive Compat. Polymers, 26(5), 464–477 (2011)

Zhang, L.F., et al.: Hydrophilic poly (ethylene glycol) coating on PDLLA/BCP bone scaffold for drug delivery and cell culture. Mater. Sci. Eng., C 28(1), 141–149 (2008)

Yun, H.S., et al.: Biomimetic component coating on 3D scaffolds using high bioactivity of mesoporous bioactive ceramics. Int. J. Nanomed. 6, 2521–2531 (2011)

Tsai, W.B., et al.: Poly(dopamine) coating of scaffolds for articular cartilage tissue engineering. Acta Biomater. 7(12), 4187–4194 (2011)

Dupont, K., et al.: Synthetic scaffold coating with adeno-associated virus encoding BMP2 to promote endogenous bone repair. Cell Tissue Res., pp. 1–14

Davis, H.E., et al.: Osteogenic response to BMP-2 of hMSCs grown on apatite-coated scaffolds. Biotechnol. Bioeng. 108(11), 2727–2735 (2011)

Yanoso-Scholl, L., et al.: Evaluation of dense polylactic acid/beta-tricalcium phosphate scaffolds for bone tissue engineering. J. Biomed. Mater. Res., Part A 95A(3), 717–726 (2010)

Dee, K.C., Puleo, D.A., Bizios, R.: An introduction to tissue-biomaterial interactions, Hoboken, N.J., Wiley-Liss, p. 228

Fu, K., Klibanov, A.M., Langer, R.: Protein stability in controlled-release systems. Nat. Biotechnol. 18(1), 24–25 (2000)

Neff, J.A., Caldwell, K.D., Tresco, P.A.: A novel method for surface modification to promote cell attachment to hydrophobic substrates. J. Biomed. Mater. Res. 40(4), 511–519 (1998)

Goddard, J.M., Hotchkiss, J.H.: Polymer surface modification for the attachment of bioactive compounds. Prog. Polym. Sci. 32(7), 698–725 (2007)

Edlund, U., Sauter, T., Albertsson, A.C.: Covalent VEGF protein immobilization on resorbable polymeric surfaces. Polym. Adv. Technol. 22(1), 166–171 (2011)

Li, L., Wu, J., Gao, C.: Gradient immobilization of a cell adhesion RGD peptide on thermal responsive surface for regulating cell adhesion and detachment. Colloids Surf., B 85(1), 12–18 (2011)

Nakajima, N., Ikada, Y.: Mechanism of amide formation by carbodiimide for bioconjugation in aqueous-media. Bioconjug. Chem. 6(1), 123–130 (1995)

Chen, J.-P., Su C.-H.: Surface modification of electrospun PLLA nanofibers by plasma treatment and cationized gelatin immobilization for cartilage tissue engineering. Acta Biomaterialia, 7, 1 (2011)

Chen, J.P., Chiang, Y.P.: Surface modification of non-woven fabric by DC pulsed plasma treatment and graft polymerization with acrylic acid. J. Membrane Sci. 270, 1–2 (2006)

Grafahrend, D., et al.: Degradable polyester scaffolds with controlled surface chemistry combining minimal protein adsorption with specific bioactivation. Nat. Mater. 10(1), 67–73 (2011)

Koo, A.N., et al.: Enhanced bone regeneration by porous poly(L-lactide) scaffolds with surface-immobilized nano-hydroxyapatite. Macromol. Res. 18(10), 1030–1036 (2010)

Wu, J.D., et al.: Covalently immobilized gelatin gradients within three-dimensional porous scaffolds. Chin. Sci. Bull. 54(18), 3174–3180 (2009)

Brandley, B.K., Schnaar, R.L.: Covalent attachment of an Arg-Gly-Asp sequence peptide to derivatizable polyacrylamide surfaces–support of fibroblast adhesion and long-term growth. Anal. Biochem. 172(1), 270–278 (1988)

Desai, N.P., Hubbell, J.A.: Solution technique to incorporate polyethylene oxide and other water-soluble polymers into surfaces of polymeric biomaterials. Biomaterials 12(2), 144–153 (1991)

Quirk, R.A., et al.: Controlling biological interactions with poly(lactic acid) by surface entrapment modification. Langmuir 17(9), 2817–2820 (2001)

Liu, W.G., et al.: Effects of baicalin-modified poly(D, L-lactic acid) surface on the behavior of osteoblasts. J. Mater. Sci. Mater. Med. 14(11), 961–965 (2003)

Duan, B., et al.: Surface modification of three-dimensional Ca-P/PHBV nanocomposite scaffolds by physical entrapment of gelatin and its in vitro biological evaluation. Front. Mater. Sci. 5(1), 57–68 (2011)

Bertrand, P., et al.: Ultrathin polymer coatings by complexation of polyelectrolytes at interfaces: suitable materials, structure and properties. Macromol. Rapid Commun. 21(7), 319–348 (2000)

Hammond, P.T.: Engineering materials layer-by-layer: Challenges and opportunities in multilayer assembly. AIChE J. 57(11), 2928–2940 (2011)

Li, X., et al.: Coating Electrospun Poly(ε-caprolactone) fibers with gelatin and calcium phosphate and their use as biomimetic scaffolds for bone tissue engineering. Langmuir 24(24), 14145–14150 (2008)

Zhu, Y., Sun, Y.: The influence of polyelectrolyte charges of polyurethane membrane surface on the growth of human endothelial cells. Colloids Surf. B 36(1), 49–55 (2004)

Stendahl, J.C., et al.: Modification of fibrous poly(L-lactic acid) scaffolds with self-assembling triblock molecules. Biomaterials 25(27), 5847–5856 (2004)

Cui, H., Webber, M.J., Stupp, S.I.: Self-assembly of peptide amphiphiles: From molecules to nanostructures to biomaterials. Pept. Sci. 94(1), 1–18 (2010)

Mahjoubi, H., Cerruti, M.: Homogeneous surface modification of poly (D, L-lactic acid) scaffolds for orthopedic applications: a non-destructive method based on diazonium chemistry. Chem. Mater. (2012)

George, A., Veis, A.: Phosphorylated proteins and control over apatite nucleation, crystal growth, and inhibition. Chem. Rev. 108(11), 4670–4693 (2008)

Song, J., Malathong, V., Bertozzi, C.R.: Mineralization of synthetic polymer scaffolds: A bottom-up approach for the development of artificial bone. J. Am. Chem. Soc. 127(10), 3366–3372 (2005)

D’Andrea, L.D., et al.: Targeting angiogenesis: Structural characterization and biological properties of a de novo engineered VEGF mimicking peptide. Proceedings of the national academy of sciences of the United States of America, 102(40), 14215–14220 (2005)

Leslie-Barbick, J.E., et al.: The promotion of microvasculature formation in poly(ethylene glycol) diacrylate hydrogels by an immobilized VEGF-mimetic peptide. Biomaterials 32(25), 5782–5789 (2011)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Mahjoubi, H., Abdollahi, S., Cerruti, M. (2013). Surface Modification of Biodegradable Polyesters for Soft and Hard Tissue Regeneration. In: Nazarpour, S. (eds) Thin Films and Coatings in Biology. Biological and Medical Physics, Biomedical Engineering. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-2592-8_7

Download citation

DOI: https://doi.org/10.1007/978-94-007-2592-8_7

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-2591-1

Online ISBN: 978-94-007-2592-8

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)