Abstract

Recently, biodegradable polymers have come to light as an influential platform for biomedical field to be used in various areas such as biosensor, therapeutics, targeted drug delivery, tissue engineering, biomedical implants, etc., due to their biodegradability, biocompatibility, controlled crystallinity, and adequate stability in biological environment. However, tailoring the properties of the polymeric surface widens the functionality, durability, and applicability of the biodegradable polymers to be used for various applications. For example, the performance and functionality of the biodegradable polymer-based devices utilized for biomedical applications are significantly marked by the method of modification and its process parameters, emphasizing the need for understanding the methods used for modification. The methods selected for modification of polymer surface invariably impacts the surface properties of the polymer without altering the bulk property. In this chapter, several methods used for the modification of biodegradable polymer surfaces are described. In addition, advantages of the different techniques adopted for surface modifications and their application area in various fields including biomedical are also illustrated.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Surface modification

- Grafting-to

- Grafting-from

- Targeted drug delivery

- Biomedical implant

- Cell adhesion

- Interfacial catalysis

1 Introduction

Biodegradable polymers are polymers that maintain good mechanical strength during their service life and degrade to form low molecular weight and non-toxic compounds such as water and carbon dioxide, when desired [1]. In the recent era, biodegradable polymers have shown promising role in biomedical science including the potential replacement of metallic implants [2]. For example, devices made out of biodegradable polymers could be implanted in the human body without the need of a second surgical procedure necessary to remove the implant (e.g., made of stainless steel) [3, 4]. Also, to fix a fractured bone, an implant made out of stainless steel has a tendency to cause refracture once the implant is removed. However, an implant based on biodegradable polymer degrades gradually to transfer the load slowly to the fractured bone, thus reducing the chance of refracturing the bone. Another impressive application shown by biodegradable polymers is their use in controlled delivery of drug [5]. A wide range of biodegradable polymers has been employed as carriers of drug useful for the treatment of diseases such that it kills only the infectious cells without harming the healthy ones [6, 7]. Biodegradable polymers also show significant applications in the domain of tissue engineering. They can be produced in the form of three-dimensional scaffolds to offer optimal support and environment for the growth of tissues [8].

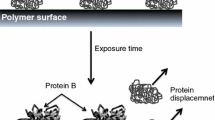

Although biodegradable polymers have been shown as the promising candidates in the biomedical arena, their surface properties greatly influence their wide range of applications suggesting the need for its modification [9]. Surface modification of biodegradable polymers hase been widely utilized to achieve attractive long-term and short-term effects for their desirable functionality. Tunable bulk material properties of biodegradable polymers like tensile strength, elasticity, and density also aid in widening the scope of their application with further increase in their effectiveness after the surface treatment. For example, extensive studies of biodegradable aliphatic polyesters as scaffold materials for applications in tissue engineering have been carried out, due to their non-toxicity, good mechanical properties, adjustable degradation rates, and low immunogenicity [10, 11]. However, there is ineffective cell attachment, spreading of cells and their proliferation caused by backbone hydrophobicity of the polymers which reduces the surface energy of these polymers [11]. Consequently, surface modification of these polyesters is required to enhance their affinity towards healthy cells [12]. Exploration in controlling the behavior of cells while interacting with artificial surfaces is the way for many applications in the field of biotechnology [13].

Further, microbial infections and their contamination have been viewed as hazardous complications faced by the medical, healthcare, and sanitation industries [14, 15]. Biomaterial-based biomedical implants exhibit infections caused by bacteria while using them inside the human body and have been considered as a major threat to human health. Generally, the interactions of bacteria with any surface, including the biomedical device comprising of biodegradable polymers lead to the growth of planktonic cells on the substrates which flourish to form biofilm. Removal of the proliferated biofilm on the surface becomes a very difficult task. Without intervention, the biofilm rapidly spreads to cause deadly infections. Thus, surface modifications with anti-infective coatings, i.e., resisting the microbes, promise a great potential in mitigating the infections associated with biomaterials used inside the body. Understanding these aspects for designing the biomaterials, it is crucial to control and manipulate the surface properties of the biomaterial without compromising their bulk properties [16, 17]. Ultimately, surface treatment of polymers did exhibit excellent properties related to antibacterial and cytotoxicity permitting their use in biomedical applications [18].

Biodegradable polymers have also been extensively explored as drug delivery systems for carrying low-molecular-weight drugs [19]. Research additionally shows that there are failures in achieving favorable clinical outcomes in delivering the drug at the targeted site of action [20]. It has been found that a sufficient amount of drug is spread among the normal tissues or organs which are not included in the pathological process, frequently leading to harsh side effects. This envisions the need for the development of systems for targeted drug delivery involving the delivery of bioactive agents or drugs at the desired site of action [21, 22]. Thus, the biodegradable polymeric surface is modified chemically or with different substances to remain in systematic circulation for longer duration of time and reach the specific organ in order to release the drug [6, 23]. The improvement in biodistribution of drugs and pharmacokinetics could increase the compliance of patients and efficacy in therapy, thus enhancing the outcome of the treatment [6]. Moreover, biodegradable polymers have also been employed in the field of catalysis where they can be used as Pickering emulsion stabilizers and participate in interfacial catalysis to remediate the pollutants from water. In replacement of surfactants, surface-modified biodegradable polymers are used as emulsion stabilizers as they are converted into particles to modify their surface in such a way that they can be adsorbed at the interface of oil and water to produce a stable emulsion consisting of these two phases [24, 25].

The methods of surface modification such as plasma treatment, corona treatment, chemical modification, ultraviolet (UV) treatment, and their process parameters such as wavelength of UV, gas flow in plasma treatment, source in corona treatment, etc., greatly affect the performance and functionality of these biodegradable polymer-based systems or devices suggesting the need for focusing on these methods. The selection of the modification method perpetually destines the properties in the enhanced polymer. Hence, this particular chapter pursues to focus and stipulate a broad outlook on several methods for the treatment of surface of biodegradable polymers in addition to their use (Fig. 1). Emphasis has also been given on their durability, lifetime, and advantages/disadvantages of the particular method used for modifying the surface.

2 Methods to Modify Surfaces

There is a wide range of methods to achieve the surface treatment of biodegradable polymers. It is most commonly accomplished by modulating the surface energy of the material in order to manipulate its adhesiveness and other properties such as wetting, releasing, or absorbing by subjecting the polymer to various treatment processes such as chemical, ionic, or light-induced techniques to introduce different functional groups on the surface of the material [29,30,31]. The surface roughness of the biodegradable polymer can also be altered by chemical or mechanical processes in order to modify the polymer top layer [32]. However, the various methods to modify the surface of biodegradable polymers are discussed below.

2.1 Physical Routes

The use of techniques like extrusion, injection molding, and lamination modifies the surface of polymer during the fabrication [33,34,35]. Physical method for polymer surface modification induces micro and nanoscale roughness changing its wettability while maintaining the existing polymer’s chemical nature. The change in roughness of the surface helps in attaining properties such as superhydrophobicity to attain several applications. The surface changes from hydrophilic to hydrophobic as the roughness of the surface is altered [36]. Surface modification of the polymer performed by physical methods is comparatively cost-effective, scalable, and simple. These methods do not require any use of chemicals to make the method eco-friendlier. This also increases the robustness of the modified polymer surface for use in industrial applications [37]. In this method, the modification is different from other methods for surface treatment where the treatment is accomplished as part of surface treatment rather than the modification on the surface of the already formed polymer surface. For example, Wang et al. prepared blend films of PLA/epoxidized soy oil/zeolite in a melt blow mold by extrusion (Fig. 2). Zeolite was used as a nucleating agent and oil as the plastizer to produce a film with a higher tensile strength [38]. The main advantage of the modification performed by physical methods over other methods is that they do not involve the use of any fluorine-based chemicals which are unsafe for environment. These methods are always preferred unless otherwise required. Nonetheless, the approach of physical modification is constrained to thermoplastic polymers to process in their solid or molten states, and not manipulating bulk properties of them involving elasticity and mechanical strength.

Schematic representation of the preparation of blown film of PLA reinforced with zeolite and epoxy soybean oil as a plasticizer. Reprinted from Ref. [38] under a CC BY license

2.2 Chemical Modification of Biodegradable Polymeric Surface

Specific chemical reactions are involved in the chemical modification of polymeric surface. Polymer brushes grafted on the surface of biodegradable polymers are an attractive class of surface modification of biodegradable polymers as they have controlled architectural features. These are the polymeric chains attached to a solid substrate via one end. The functional groups present on the surface are exposed to react with the particular functional group present in the polymeric chains to graft the polymer brushes bound to the material surface. As compared to the physical method, chemical reactions are involved in the chemical method to chemically bind the polymer brush to the surface of the substrate. It is a well-known fact that chemical bonds are stronger than physical bonds and thus, a graft layer attached chemically binds more firmly to the surface. Polymer brushes can be attached via a “grafting-to” approach (chains of polymer are covalently bound to the surface) or via a “grafting-from” approach (initiator molecules present on the surface allows the growth of polymer chain from surface) [11] (Fig. 3).

Reproduced with permission from Ref. [39]; Copyright 2020 Elsevier

Schematic representation of “grafting-from” and “grafting-onto” methods for surface modification.

2.2.1 Grafting-To

This approach involves the chemical reaction between the reactive groups present on the surface of the substrate and the functionalized polymers. The characterization of the grafted polymers and their structure in the grafting-to approach is more convenient as compared to the other technique. However, the effect of steric hindrance includes the difficulty for grafting the polymer chains which generally reduces the grafting density of the attached polymer.

2.2.2 Grafting-From

An active site present on the surface of the substrate is used to initiate the polymerization in situ for the reaction of the monomer in this “grafting-from” approach. This approach involves the growth of polymeric chains from the surface of the substrate utilizing initiator moieties attached to the surface or self-assembled monolayers known as surface-initiated polymerization. As compared with the “grafting-to” approach, this approach can effectively control the grafting density and thickness of polymer brushes grafted on the surface with accurate precision. Moreover, densely grafted polymeric chains onto the polymeric surface can be achieved, since small initiator moieties and monomer molecules are interacting, thus devoid of crowding problem caused by steric congestion.

2.3 Plasma Treatment

Inert gases like hydrogen, oxygen, and nitrogen during the plasma treatment dissociate to react with surface of the substrate for changing the surface properties like adhesion, wettability, and printability [40, 41] (Fig. 4). The gaseous mixture composed of particles like free-ions, electrons, and radicals having no net electrical charge is used to create plasma while interacting with electric field or radiation. Photon emission takes place as the electron returns to the ground energy level causing the plasma luminosity. There are two subcategories in which plasma can be divided based on the temperature of the gas, i.e., thermal and cold (non-thermal) plasma [42,43,44]. Thermal plasma consists of electrons at a very high temperature and charged/neutral heavy particles which cannot be utilized in the modification of polymeric surface as they are heat sensitive. However, in non-thermal plasma, charged and neutral particles at low temperature are involved along with the electrons emitted at high temperature. He, Ar, N2, and O2 are inert gases that do not induce a polymerized coating on the surface, rather they can induce or replace the functional groups present on the surface or generate free radicals contributing to the modification of the surface to create desired properties like improved hydrophilicity or adhesive properties [12]. Modification on the surface is achieved indirectly or directly. However, the methods involved directly induce the free radicals when treated with inert surface to manipulate them for applications which are targeted in nature, e.g. making them hydrophilic to repel bacteria and improve the anti-adhesion property of the surface. On the contrary, the methods involving the indirect methods comprised of grafting of polymer [45]. The methods used for plasma treatment of the surface of the sample decide its efficiency through the parameters such as type of gas used, frequency, pressure, time, and power [46, 47]. However, the polymers face the recovery of their hydrophobicity due to their inherent nature in order to attain equilibrium by decreasing the surface energy. The reduction in surface energy takes place due to the several processes involved such as chemical rearranging on the surface treated with plasma, degradation and oxidation of the surface treated by plasma.

Reproduced with permission from Ref. [48]; Copyright 2009 ACS

A scheme representing different gases involved in the treatment of plasma on a substrate.

2.4 Corona Treatment

This treatment is associated with the non-local thermodynamic equilibrium of plasma being created in air or active or inert gas atmosphere [49]. The corona discharge helps in introducing the polar groups to improve the energy of the surface significantly to affect the surface properties such as roughness, adhesion, and wettability. The treatment of polymeric surface by the corona discharge has significantly undergone advancements in the last decade. In this treatment process, power devices with logic control have taken over the power supply being driven by the generator or manually providing the more consistent parameters for the process such as time of exposure, distance between the electrode and substrate, and the power (Fig. 5). Among these parameters, the most important is the density of the power facilitating the increase in surface energy by discharging ions in the presence of oxygen to create oxygenyl functional groups depending on the application such as printing, extrusion or coating, extrusion or printing of the material and variables involved in the process [50].

Reproduced with permission from Ref. [51] under CC BY license

The schematic representation of the mechanism for corona treatment on solid substrate.

2.5 Self-assembled Monolayers

In 1946, Zisman was the first scientist to report about Self-assembled monolayers also known as SAM [52, 53]. They are assemblies of molecules formed spontaneously on a solid substrate by the gas or solution phase adsorption. However, the molecules present in the gas or solution phase spontaneously adsorb to organize themselves in a singular layer on the surface to call them the self-assembled monolayer. The common examples of polymer samples mounted on the surface are protein, polyethylene glycol, and deoxyribonucleic acid (DNA) [54]. Gong et al. synthesized carboxymethyl chitosan grafted Cis-3-(9H-purin-6-ylthio)-acrylic acid polymeric prodrug which self assembles in presence of aqueous media into the spherical micelles. These micelles were successful in the storage and release of 6-Mercaptopurin (6-MP) in the presence of glutathione (GSH) [55] (Fig. 6).

Reproduced with permission from Ref. [55] under CC BY license

Self-assembly of conjugates of chitosan–6-MP for self-assembly and the conjugates releasing 6-MP.

2.6 Layer-by-Layer (LbL) Self-assembly

Twenty years ago, Moehwald, Decher, and Lvov first propped the method of deposition using LbL self-assembly [56]. In this method, self-organized polyelectrolytes are adsorbed alternately on the surface of the material and form the films in the form of polyelectrolyte multilayer (PEM) [47]. These PEM films are well known for providing a huge surface area to adsorb a large number of biomolecules and maintaining their biological activity. The process parameters are adjusted and controlled to manipulate the growth of their internal structure. Aqueous conditions are utilized to prepare the PEM films under mild conditions leading to a great advantage for the use of bioactive agents and biopolymers. Therefore, wide use of the components involved in the LbL process regulates their parameters and controls the cell adhesion behaviour [45]. For example, Khademhosseini utilized micropatterns of hyaluronic acid (HA) for immobilizing proteins and cells on a glass substrate. The authors also utilized the HA surface for understanding the subsequent adsorption of poly-L-Lysine (PLL) [57] (Fig. 7).

Reproduced with permission from Ref. [57]; Copyright 2004 Elsevier

Deposition of HA-PLL on solid substrate.

2.7 Ultraviolet (UV) Treatment

The treatment of the surface by the UV has proved to be efficient, effective, and economical for non-contact purposes consisting of less number of processing steps. The treatment of surface by UV alters and modifies the adhesion and wettability of the polymeric surface. The surface modification is extended through the penetration into the surface of polymer by a magnitude of tens of microns and is analyzed utilizing the treatment conditions of UV involving intensity duration of treatment and wavelength. The poor adhesion of polymers is due to their decreased surface energy and thus, limits their applications. The adhesion or hydrophilicity of polymers can be enhanced by the oxidation process using UV–Ozone or UV [58, 59]. The oxidation of polymer with the breakage of polymeric chains into free radicals is caused by the irradiation by UV to react with the atmospheric ozone or oxygen and forms hydrophilic groups such as carbonyl or carboxyl. Time of irradiation, concentration of monomer, solvent, and photo initiator controlled the extent of the modification of the surface. Oxidation by UV also creates roughness at nanoscale on the surface having RMS (root mean square) value of 3–5 nm in addition to the formation of polar functional groups containing oxygen which also contributes to the increase in surface polarity and adhesion. For example, Gudko et al. explained the incorporation of nanoparticles prepared from cadmium sulfide (CdS) in the polymer polyvinyl alcohol (PVA) for enhancing the persistence to UV light. The defect formation was diminished due to the nanoparticle incorporation in the polymer [60] (Fig. 8).

Reproduced with permission from Ref. [60] under a CC BY license

a, c The schematic representation of control polymer sample and b, d nanocomposite of CdS/PVA in the process induced by UV.

3 Applications

3.1 Targeted Drug Delivery

A variety of different materials are employed as carriers of drugs such as synthetic or natural polymers, surfactants, lipids, and dendrimers [61,62,63,64]. Among these, a natural polymer known as chitosan has gained enormous consideration due to their outstanding biological and physical properties. Due to the presence of various reactive functional groups, it has offered a pronounced opportunity for modification chemically to afford a varied range of derivatives like carboxyalkyl chitosan, N,N,N-trimethyl chitosan (quaternized in nature), sugar-bearing chitosan, thiolated chitosan, cyclodextrin-linked chitosan, bile acid-modified chitosan, etc. [65,66,67,68]. The derivatives of chitosan are fabricated to improve the properties specific to the chitosan native. The amphiphilicity is imparted in chitosan by the chemical modification of their surface to synthesize chitosan-based self-assembled nanoparticles for their potential applications in drug delivery. The nanoparticles contain a hydrophobic core acting as microcontatiner or reservoir for the different bioactive agents. Nanoparticles can be intravenously injected due to their small size for the application of drug delivery. The targeting moieties are conjugated to the surface of the nanoparticles loaded with the drug which improves the therapeutic efficiency of the drug. It has been extensively used as delivery system for the drugs such as low molecular weight drugs, peptides, and genes. For example, the idea of polymer–drug conjugates for releasing small molecular hydrophobic drugs to the targeted site where the action is required [68]. The drug–polymer conjugates consist of a polymer which is soluble in water and is conjugated chemically through a biodegradable spacer to the drug. This biodegradable spacer can be present in the stream of blood stably and cleaved by degradation of enzyme or by hydrolysis at the site of target. In general, the drug-conjugated polymer particles whose surface was decorated with targeting moiety, can be selectively accumulated at the site of tumor to be followed by the delivery of drug due to the spacer cleavage (Fig. 9). Due to this concept, various conjugates of drug-polymer have recently been utilized in clinical trials at phase I/II level. One important example is N-(2-hydroxypropyl)methacrylamide (HPMA) drug conjugates based on copolymer like HPMA copolymer–doxorubicin conjugate (PK1) and a targeting moiety of HPMA copolymer–doxorubicin conjugate having galactosamine (PK2), employed for the primary or secondary liver cancer treatment.

Reproduced with permission from Ref. [60]; Copyright 2010 Elsevier

Schematic representation of the conjugates of chitosan and drug having a cleavable linker. Chemical structure of a glycol chitosan–doxorubicin conjugate with the cis-aconityl linkage and b chitosan–paclitaxel conjugate with the succinate linkage.

3.2 Biomedical Implant

For different biomedical applications such as biosensing, antibacterial coatings and delivery of drugs, and modification of surface by polymeric brushes regardless of their geometry have been widely studied [69]. Most importantly, anti-infective polymer brushes tethered on biomedical implants are known to provide bacteria-free implant surface which generally serves as platform to proliferate bacteria causing infections when used inside the body. Therefore, polymer brushes are considered as the essential modifications in the applications of antibacterial coatings due to their good mechanical stability, thickness, roughness, and morphology. During their adhesion on the surface, these polymer brushes are utilized for the barrier in adhesion of bacteria or these coatings can kill the bacteria through the mechanism known as contact killing. For instance, biodegradable surfaces of polylactide (PLA) were covalently modified to immobilize polymers of three different types showing effective antibacterial property. Three different polymers, namely, poly(2-[(methacryloyloxy)ethyl]trimethylammonium chloride) (PMETA), poly(poly(ethylene glycol) methacrylate) (PPEGMA), and poly(2-hydroxyethyl methacrylate) (PHEMA) were grafted on the PLA surface via the technique known as surface-initiated atom transfer radical polymerization (ATRP). These brushes were tested against both Gram-negative (Escherichia coli) and Gram-positive (Staphylococcus aureus) bacteria. Verma et al. found that the PLA surface modified with PMETA exhibited the highest killing of bacteria. This work exhibited the creation of polymer brushes on the biodegradable PLA surface having excellent antibacterial property [70]. Dhingra et al. modified the biomaterials based on aliphatic polyester derived from tartaric acid through the growth of antibacterial (PMETA) polymer brushes and antifouling/antiadhesive (PPEGMA and PHEMA) polymer brushes using surface-initiated polymerization (specifically ATRP). The authors explained the process of synthesis for preparing the polyester based on tartaric acid in which the protected hydroxyl groups can be unmasked and conjugated to the initiating moiety of ATRP to grow the polymer brushes as mentioned above. The conditions used are mild to prevent the degradation of backbone of the biodegradable polymer. PMETA brushes contain cationic ammonium groups that exhibited the highest antibacterial property. The authors have further expanded the work by blending the polyester based on tartaric acid with PLA to form the 3D scaffold fabricated from 3D printing. These scaffolds were used to grow PMETA polymer brushes for evaluating the antibacterial study against Gram-negative and Gram-positive bacteria and the test of cytocompatibility against the mammalian osteoblast cells (Fig. 10). The authors reported a balanced antibacterial and cytocompatibility by the growth of PMETA brushes onto the surface. Therefore, a cytocompatible coating which is anti-infective, stable, and non-leaching can be used to address the infections originated from biomedical implants [71].

Reproduced with permission from Ref. [63]; Copyright 2021 Elsevier

3D scaffold of aliphatic polyester based on tartaric acid and their antibacterial and cell compatibility study.

3.3 Cell Adhesion

Extracellular matrix (ECM) is a natural 3D structure that surrounds the cell when present in vivo. To maximize the environmental simulation in vivo around the cells, vast development in 3D scaffolds for meeting biological needs has been made. Behavior of cells is affected by these developed 3D biological scaffolds offering the most suitable tool for providing the real environment for growing cells. In this regard, Dhingra et al. developed a brush system consisting of a copolymer of poly(3-dimethyl-(methacryloyloxyethyl) ammonium propane sulfonate) (PDMAPS) and poly((oligo ethylene glycol) methyl ether methacrylate) (PPEGMA) grown on the aliphatic polyester as mentioned above. In a similar manner, a blend of PLA and polyester was used to prepare 3D scaffold to attach the mixed copolymer brush on its surface through SIATRP. Authors found 100% suppression of bacteria on the mixed brush system as mentioned above. In addition, 100% cytocompatibility was also found for mixed brush system comprising of PDMAPS and PPEGMA. These results show a promising and innovative mixed brush coating revealing the high potential in a durable implant used inside the body being anti-infective with preservation of healthy cells [72]. Further, treatment by hydrolysis technique is simple that it can be utilized for increasing the roughness of the surface in addition to the hydrophilicity through the NaOH treatment. This method was used by Yuan et al. for functionalizing the porous microspheres of PLGA using PLL (poly-L-lysine) shown in Fig. 11. Briefly, the PLGA microspheres were hydrolyzed to form PLGA-OH to soak in PLL solution kept overnight. Treatment by hydrolysis results in the creation of a homogeneous and interconnected porous structure due to the dissolution of a thin polymer around the pores. Finally, the authors found that the surface modification via the PLL treatment promoted the initial attachment of cell and also found the improvement in the interactions of cell matrix [73].

Reproduced with permission from Ref. [65]; Copyright 2018 Elsevier

a An illustration for the process involved in the formation of microspheres of PLL modified porous PLGA. b Fluorescence images of microspheres stained with FDA after culturing by MG63 at different time. The scale bar is 200 μm.

3.4 Interfacial Catalysis

Biodegradable polymers can be converted into solid particles whose surfaces are modified to use them as an emulsion stabilizer. The anisotropically modified solid particles having polymer brushes in hemisphere which are hydrophilic in nature can employ a balance between hydrophilic and hydrophobic parts to use them as an ideal surfactant, commonly known as pickering emulsion stabilizer [25]. Zoppe et al. proposed an interesting work based on stabilization by pickering emulsion stabilizers using polymer brush-modified anisotropic particles (PBMAP) [74]. The authors have shown a system based on oil-in-water with heptane and water, respectively. They utilized the thermosensitive polymer poly (NIPAM) to modify the surface of anisotropic nanocrystals of cellulose for emulsion stabilization to form poly(NIPAM)-g-CNCs. This system having brush-modified anisotropic particles was able to stabilize the emulsion in oil–water for up to 4 months as compared to unmodified naked anisotropic solid particles of cellulose nanocrystals (CNC). Poly(NIPAM) plays the role of reducing the interfacial tension among oil and water due to its hydrophilic nature after the emulsification at the oil–water interface. Apart from this, Ifra et al. experimented to form PLA based microparticles which are spherical and anisotropic Janus type. These particles were fabricated through a technique known as electrohydrodynamic co-jetting where two compartments consisting of macroinitiator containing polymers blended with PLA were co-jetted in side by side manner so that macroinitiator (used to grow polymer brushes later) is present on one side of the particle. The surface of these microparticles was utilized to graft pH-responsive poly(DMAEMA) polymer brushes on one compartment selectively through SIATRP. This modification of the surface of these microparticles imparted the amphiphilicity in them. Further, this system was used and applied in stabilizing emulsion comprised of octanol/water to form a pickering emulsion (Fig. 12). The authors found that the amphiphilic Janus particles as a pickering emulsion stabilizer by tuning the pH of the brush-modified particles was stable for more than 4 months [75]. They are considered to contribute towards the green chemistry and sustainability with the promise to work as an interfacial catalyst in various chemical reactions and cleaning of contaminated water by degrading the waste via iron nanoparticles embedded in Janus particles. Due to the amphiphilic nature, the particles were located at oil/water interface to facilitate interfacial catalysis for remediating water.

Reproduced with permission from Ref. [67]; Copyright 2021 ACS

A Scheme showing the pickering emulsion being stabilized by brush-modified Janus particles. B Digital images of pickering emulsion stabilized by Janus microparticles modified with brush. C (a) Brightfield micrograph of pickering emulsion stabilized by Janus particles modified with brush. (b) Fluorescence micrograph of droplet of pickering emulsion stabilized by dye-loaded Janus particles and modified by brushes.

4 Conclusion

In recent years, a novelty in research related to biomedical field has aimed at developing new methods for modifying the surface of biodegradable polymers to achieve stable, infection-free, biomaterials. These modified biomaterials are widely applied in the area of targeted drug delivery, tissue engineering, wound healing, and infection-resistant coating. Therefore, the novel surface modification methods for biodegradable polymers have emerged with developed traditional technologies, thus facilitating the manufacturing of durable functional surfaces of polymers. In this chapter, the most common methods for polymer surface modification (physical, chemical, SAMs, plasma, corona, UV) have been described with a focus on the methods to alter the surface morphology and their properties in addition to their use in specific areas for biomedical field. An attempt has been made to compare the surface modification methods with the prospective area of applications. However, alternative surface treatment routes for the modification of biomaterials are also emerging to achieve similar surface properties to meet the needs of future for biomedical field. A wide range of biodegradable polymers with their unexplored functionalities and properties are being investigated to improve their surface-property relationship for broadening their use in different applications in the real world.

References

Morent R, De Geyter N, Desmet T, Dubruel P, Leys C (2011) Plasma surface modification of biodegradable polymers: a review. Plasma Process Polym 8(3):171–190

Liston E, Martinu L, Wertheimer M (1993) Plasma surface modification of polymers for improved adhesion: a critical review 7(10):1091–1127

Athanasiou KA, Agrawal CM, Barber FA, Burkhart SS (1998) Orthopaedic applications for PLA-PGA biodegradable polymers. Arthroscopy 14(7):726–737

Middleton JC, Tipton AJ (2000) Synthetic biodegradable polymers as orthopedic devices. Biomaterials 21(23):2335–2346

Amass W, Amass A, Tighe B (1998) A review of biodegradable polymers: uses, current developments in the synthesis and characterization of biodegradable polyesters, blends of biodegradable polymers and recent advances in biodegradation studies. Polym Int 47(2):89–144

Park JH, Saravanakumar G, Kim K, Kwon IC (2010) Targeted delivery of low molecular drugs using chitosan and its derivatives. Adv Drug Deliv Rev 62(1):28–41. https://doi.org/10.1016/j.addr.2009.10.003

Strebhardt K, Ullrich A (2008) Paul Ehrlich’s magic bullet concept: 100 years of progress. Nat Rev Cancer 8(6):473–480

Djordjevic I, Britcher LG, Kumar S (2008) Morphological and surface compositional changes in poly (lactide-co-glycolide) tissue engineering scaffolds upon radio frequency glow discharge plasma treatment. Appl Surf Sci 254(7):1929–1935

Michael FM, Khalid M, Walvekar R, Siddiqui H, Balaji ABJB (2018) Biodegradable and biocompatible polymer composites: processing, properties and applications. Surface modification techniques of biodegradable and biocompatible polymers, pp 33–54

Shen H, Hu X, Yang F, Bei J, Wang S (2007) Combining oxygen plasma treatment with anchorage of cationized gelatin for enhancing cell affinity of poly (lactide-co-glycolide). Biomaterials 28(29):4219–4230

Morent R, De Geyter N, Trentesaux M, Gengembre L, Dubruel P, Leys C et al (2010) Influence of discharge atmosphere on the ageing behaviour of plasma-treated polylactic acid. 30:525–536

Desmet T, Morent R, De Geyter N, Leys C, Schacht E, Dubruel P (2009) Nonthermal plasma technology as a versatile strategy for polymeric biomaterials surface modification: a review. Biomacromolecules 10(9):2351–2378

Cai S, Wu C, Yang W, Liang W, Yu H, Liu L (2020) Recent advance in surface modification for regulating cell adhesion and behaviors. Nanotechnol Rev 9(1):971–989

Lee SB, Koepsel RR, Morley SW, Matyjaszewski K, Sun Y, Russell AJ (2004) Permanent, nonleaching antibacterial surfaces. 1. Synthesis by atom transfer radical polymerization. Biomacromolecules 5(3):877–882

Patel MB, Patel SA, Ray A, Patel RM (2003) Synthesis, characterization, and antimicrobial activity of acrylic copolymers. J Appl Polym Sci 89(4):895–900

Knetsch ML, Koole LH (2011) New strategies in the development of antimicrobial coatings: the example of increasing usage of silver and silver nanoparticles. Polymers 3(1):340–366

Darouiche RO (2004) Treatment of infections associated with surgical implants. N Engl J Med 350(14):1422–1429

Dhingra S, Gaur V, Saini V, Rana K, Bhattacharya J, Loho T et al (2022) Cytocompatible, soft and thick brush-modified scaffolds with prolonged antibacterial effect to mitigate wound infections. Biomater Sci 10(14):3856–3877

Overington JP, Al-Lazikani B, Hopkins AL (2006) How many drug targets are there? Nat Rev Drug Discov 5(12):993–996

Langer R (1998) Drug delivery and targeting. Nature 392(6679 Suppl):5–10

Poste G, Kirsh R (1983) Site–specific (targeted) drug delivery in cancer therapy. Bio/Technology 1(10):869–878

Gregoriadis G (1977) Targeting of drugs. Nature 265(5593):407–411

George A, Shah PA, Shrivastav PS (2019) Natural biodegradable polymers based nano-formulations for drug delivery: a review. Int J Pharm 561:244–264

Yin D, Zhang Q, Yin C, Zhao X, Zhang H (2012) Hollow microspheres with covalent‐bonded colloidal and polymeric shell by Pickering emulsion polymerization. Polym Adv Technol 23(3):273–277

Pradhan SS, Saha S (2022) Advances in design and applications of polymer brush modified anisotropic particles. Adv Colloid Interface Sci 300:102580

Lih E, Oh SH, Joung YK, Lee JH, Han DK (2015) Polymers for cell/tissue anti-adhesion. Prog polym sci 44:28–61. https://doi.org/10.1016/j.progpolymsci.2014.10.004

Puppi D, Chiellini FJ (2020) Biodegradable polymers for biomedical additive manufacturing 20:100700

De R, Mahata MK, Kim K-T (2022) Structure-based varieties of polymeric nanocarriers and influences of their physicochemical properties on drug delivery profiles 9(10):2105373. https://doi.org/10.1002/advs.202105373

Aliofkhazraei M (2015) Wetting and wettability. BoD–Books on Demand

Sojoudi H, Arabnejad H, Raiyan A, Shirazi SA, McKinley GH, Gleason KK (2018) Scalable and durable polymeric icephobic and hydrate-phobic coatings. Soft Matter 14(18):3443–3454

Sojoudi H, Walsh MR, Gleason KK, McKinley GH (2015) Investigation into the formation and adhesion of cyclopentane hydrates on mechanically robust vapor-deposited polymeric coatings. Langmuir 31(22):6186–6196

Encinas N, Pantoja M, Abenojar J, Martínez M (200) Control of wettability of polymers by surface roughness modification. J Adhesion Sci Technol 24(11–12):1869–1883

Weng C, Wang F, Zhou M, Yang D, Jiang B (2018) Fabrication of hierarchical polymer surfaces with superhydrophobicity by injection molding from nature and function-oriented design. Appl Surface Sci 436:224–233

Okulova N, Johansen P, Christensen L, Taboryski R (2017) Replication of micro-sized pillars in polypropylene using the extrusion coating process. Microelectron Eng 176:54–57

Xu QF, Mondal B, Lyons AM (2011) Fabricating superhydrophobic polymer surfaces with excellent abrasion resistance by a simple lamination templating method. ACS Appl Mater Interfaces 3(9):3508–3514

Liu TL, Kim C-JC (2014) Turning a surface superrepellent even to completely wetting liquids. Science 346(6213):1096–1100

Yohe ST, Grinstaff MW (2013) A facile approach to robust superhydrophobic 3D coatings via connective-particle formation using the electrospraying process. Chem Commun (Camb) 49(8):804–806

Wang S, Liu B, Qin Y, Guo H (2021) Effects of processing conditions and plasticizing-reinforcing modification on the crystallization and physical properties of PLA films. 11(8):640

Yan J, Bockstaller MR, Matyjaszewski K (2020) Brush-modified materials: Control of molecular architecture, assembly behavior, properties and applications. Prog Polym Sci 100:101180. https://doi.org/10.1016/j.progpolymsci.2019.101180

Yasuda H, Gazicki M (1982) Biomedical applications of plasma polymerization and plasma treatment of polymer surfaces. Biomaterials 3(2):68–77

Zhou J, Ellis AV, Voelcker NH (2010) Recent developments in PDMS surface modification for microfluidic devices. Electrophoresis 31(1):2–16

Denes FS, Manolache S (2004) Macromolecular plasma-chemistry: an emerging field of polymer science. Progr Polym Sci 29(8):815–885

Fridman A (2008) Plasma chemistry. Cambridge University Press

Bogaerts A, Neyts E, Gijbels RJSAPB. van der Mullen J (2002) 57:609

Kim S, Sojoudi H, Zhao H, Mariappan D, McKinley GH, Gleason KK et al (2016) Ultrathin high-resolution flexographic printing using nanoporous stamps. Sci Adv 2(12):e1601660

Jelil RA (2015) A review of low-temperature plasma treatment of textile materials. J Mater Sci 50(18):5913–5943

Laroussi M (2009) Low-temperature plasmas for medicine? IEEE Trans Plasma Sci 37(6):714–725

Desmet T, Morent R, De Geyter N, Leys C, Schacht E, Dubruel P (2009) Nonthermal plasma technology as a versatile strategy for polymeric biomaterials surface modification: a review. Biomacromolecules 10(9):2351–2378. https://doi.org/10.1021/bm900186s

Tendero C, Tixier C, Tristant P, Desmaison J, Leprince P (2006) Atmospheric pressure plasmas: a review. Spectrochim Acta Part B: Atom Spectrosc 61(1):2–30

Guzel-Seydim ZB, Greene AK, Seydim A (2004) Use of ozone in the food industry. LWT Food Sci Technol 37(4):453–460

Ovaska S-S, Rinkunas R, Lozovksi T, Maldzius R, Sidaravicius J, Johansson L-S et al (2016) Occurrence of reverse side effects in corona treatment of dispersion-coated paperboard and its influence on grease barrier properties. J Appl Packag Res 8(3):2

Schaubroeck D, De Baets J, Desmet T, Van Vlierberghe S, Schacht E, Van Calster A (2009) Introduction of amino groups on the surface of thin photo definable epoxy resin layers via chemical modification. Appl Surface Sci 255(21):8780–8787

Pawlak M, Bakker E (2014) Chemical modification of polymer ion‐selective membrane electrode surfaces. Electroanalysis 26(6):1121–1131

Shin S, Kwon Y, Kim Y, Jung J, Lee M, Nah J (2015) ACS Nano 9:4621

Gong X-Y, Yin Y-H, Huang Z-J, Lu B, Xu P-H, Zheng H et al (2012) Preparation, characterization and in vitro release study of a glutathione-dependent polymeric prodrug Cis-3-(9H-purin-6-ylthio)-acrylic acid-graft-carboxymethyl chitosan. 436(1–2):240–247

Luo S, Van Ooij WJ (2002) Surface modification of textile fibers for improvement of adhesion to polymeric matrices: a review. J Adhes Sci Technol 16(13):1715–1735

Khademhosseini A, Suh KY, Yang JM, Eng G, Yeh J, Levenberg S et al (2004) Layer-by-layer deposition of hyaluronic acid and poly-l-lysine for patterned cell co-cultures. Biomaterials 25(17):3583–3592. https://doi.org/10.1016/j.biomaterials.2003.10.033

Mathieson I, Bradley R (1996) Improved adhesion to polymers by UV/ozone surface oxidation. Int J Adhes Adhes 16(1):29–31

Liu J, He L, Wang L, Man Y, Huang L, Xu Z et al (2016) Significant enhancement of the adhesion between metal films and polymer substrates by UV–ozone surface modification in nanoscale. 8(44):30576–30582

Rudko G, Kovalchuk A, Fediv V, Chen WM, Buyanova IA (2015) Enhancement of polymer endurance to UV light by incorporation of semiconductor nanoparticles. Nanoscale Res Lett 10(1):1–6

Duncan R (2003) The dawning era of polymer therapeutics. Nat Rev drug Discov 2(5):347–360

Duncan R (2006) Polymer conjugates for drug targeting. From inspired to inspiration! Preface. J Drug Target 14(6):333–335

Torchilin V (2008) Antibody-modified liposomes for cancer chemotherapy. Expert Opin Drug Deliv 5(9):1003–1025

Sampathkumar S-G, Yarema KJ (2005) Targeting cancer cells with dendrimers. Chem Biol 12(1):5–6

Bernkop-Schnürch A, Guggi D, Pinter Y (2004) Thiolated chitosans: development and in vitro evaluation of a mucoadhesive, permeation enhancing oral drug delivery system. J Control Release 94(1):177–186

Amidi M, Romeijn SG, Borchard G, Junginger HE, Hennink WE, Jiskoot W (2006) Preparation and characterization of protein-loaded N-trimethyl chitosan nanoparticles as nasal delivery system. J Control Release 111(1–2):107–116

Wang Y, Jiang Q, Li R, Liu L, Zhang Q, Wang Y et al (2008) Self-assembled nanoparticles of cholesterol-modified O-carboxymethyl chitosan as a novel carrier for paclitaxel. Nanotechnology 19(14):145101

Kim K, Kwon S, Park JH, Chung H, Jeong SY, Kwon IC et al (2005) Physicochemical characterizations of self-assembled nanoparticles of glycol chitosan−deoxycholic acid conjugates. Biomacromolecules 6(2):1154–1158

Dhingra S, Sharma S, Saha S (2022) Infection resistant surface coatings by polymer brushes: Strategies to construct and applications 5(4):1364–1390

Verma M, Biswal AK, Dhingra S, Gupta A, Saha S (2019) Antibacterial response of polylactide surfaces modified with hydrophilic polymer brushes. Iranian Polym J 28:493–504

Dhingra S, Joshi A, Singh N, Saha S (2021) Infection resistant polymer brush coating on the surface of biodegradable polyester. Mater Sci Eng C 118:111465

Dhingra S, Gaur V, Saini V, Rana K, Bhattacharya J, Loho T et al (2022) Cytocompatible, soft and thick brush-modified scaffolds with prolonged antibacterial effect to mitigate wound infections. Biomater Sci 10(14):3856–3877. https://doi.org/10.1039/D2BM00245K

Yuan Y, Shi X, Gan Z, Wang F (2018) Modification of porous PLGA microspheres by poly-l-lysine for use as tissue engineering scaffolds. Colloids Surf B Biointerfaces 161:162–168

Zoppe JO, Venditti RA, Rojas OJ (2012) Pickering emulsions stabilized by cellulose nanocrystals grafted with thermo-responsive polymer brushes. J Colloid Interface Sci 369(1):202–209

Ifra, Thattaru Thodikayil A, Saha S (2022) Compositionally anisotropic colloidal surfactant decorated with dual metallic nanoparticles as a pickering emulsion stabilizer and their application in catalysis. ACS Appl Mater Interfaces 14(20):23436–23451

Acknowledgements

The Department of Material Science and Engineering (DMSE), Indian Institute of Technology (IIT), Delhi, India, is appreciated for providing research and teaching funds.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Verma, M., Sarkar, C., Saha, S. (2023). Surface Modification of Biodegradable Polymers. In: Saha, S., Sarkar, C. (eds) Biodegradable Polymers and Their Emerging Applications. Materials Horizons: From Nature to Nanomaterials. Springer, Singapore. https://doi.org/10.1007/978-981-99-3307-5_3

Download citation

DOI: https://doi.org/10.1007/978-981-99-3307-5_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-3306-8

Online ISBN: 978-981-99-3307-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)