Abstract

Reliability sensitivity analysis (SA) is a method to identify the relationship between the change in reliability and the change in the characteristics of uncertain variables. Very few methods can be applied for the reliability SA for long-term degeneracy mechanism, especially when the time-dependent limit state function regarding the interested performance is implicit. This paper proposes a new method to compute the reliability sensitivity measures. First, a surrogate model called time-dependent polynomial chaos expansion (PCE) is employed to approximate the uncertain output of the model and the extensive probabilistic collocation method (PCM) and moving least squares (MLS) method-based algorithm is proposed to compute the coefficients of the time-dependent PCE. Then, the explicit time-dependent limit state function can be obtained and the reliability sensitivity measures can be calculated straightforwardly. Finally, this approach is applied to an engineering case and the time-dependent reliability sensitivity measures are obtained for the long-term degeneracy mechanism model.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

5.1 Introduction

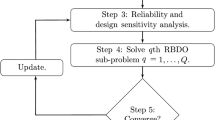

Reliability of the mechanism is defined as the probability that a kinematic mechanism will perform its intended movement function during a specified period of time under stated conditions. From a design engineering viewpoint, in order to maximize the mechanism performance under constrains of target mechanism reliability, the reliability-based design optimization (RBDO) should be employed [1]. However, the computation time for RBDO greatly depends on the number of random design variables [2]. Reliability sensitivity analysis (SA) aims at quantifying the respective effects of uncertain parameters onto the reliability of a model, and helps the designer to answer the following question: (1) Which uncertain parameters have the highest contribution to reliability, (2) which uncertain parameters are not so important to reliability that can be ignored when selecting the design variables, and (3) how will reliability be affected if the mean or the standard deviation of a particular variable is changed [3]? Thus, the RBDO for kinematic mechanism can benefit from the answers of the above questions.

In recent decades, many studies have been devoted to time-dependent RBDO [1, 4, 5]. The inputs (such as design parameters, loads) of mechanism vary with time, so the interested output and reliability is time-dependent consequently. In this case, calculating the time-dependent mechanism reliability sensitivity measures is much more time-consuming than static mechanism reliability SA.

However, the time-dependent reliability SA for performance degradation mechanism is rarely investigated so far, some literatures propose [6, 7] the dynamic reliability SA concentrating on the structural reliability of mechanical components. This is based on the assumption that the distribution of the load or the maximum load is known, thus the time-dependent limit state function is explicit. But it is hardly applicable for performance degradation mechanism, because the distribution of the performance is unknown since it is affected by a lot of uncertain factors.

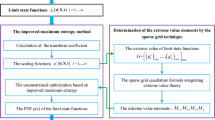

In order to meet the needs of time-dependent RBDO for performance degradation mechanism, this paper proposes a polynomial chaos expansion (PCE)-based method to compute the time-dependent mechanism reliability sensitivity measures. First, the complicated and computational model can be replaced by the surrogate model of time-dependent PCE, the performance of the mechanism can be computed analytically. Then, the limit state function can be constructed. After that, time-dependent mechanism reliability sensitivity measures can be obtained straightforwardly.

5.2 Time-Dependent Reliability Sensitivity Analysis

5.2.1 Performance Degradation Model for the Mechanism

For the performance degradation model, the interested output of mechanism G may be influenced and changed with time. This can be defined in Eq. (5.1.1), where G is a vector of performance variables, \({\mathbf{X}} = [X_{1} ,X_{2} , \ldots ,X_{n} ]\) is a vector of random variables, \({\mathbf{Y}}(t) = [Y_{1} (t),Y_{2} (t), \ldots ,Y_{m} (t)]\) is a vector of stochastic process of the degradation parameters, and \({\mathbf{t}} = (1,2, \ldots ,n)\) is the vector of the number of tasks.

5.2.2 Time-Dependent Reliability

As for performance degradation models, the reliability of the model is time dependent. In Eq. (5.1.1), since the G is a random variable, if we define the threshold of a failure is z, then the time-dependent limit state function can be defined as:

The failure state and safe state can also be defined as follows:

The time-dependent probability of failure over time interval \([t_{0} ,t_{s} ]\) can be written as

Thus, the time-dependent reliability can defined as follows correspondingly:

5.2.3 Time-Dependent Reliability Sensitivity Measures

The reliability sensitivity measures are defined as the derivative of the failure probability with respect to distribution parameters. When the time factor t is involved, the time-dependent reliability sensitivity measures can be defined as

where \(S\mu_{{x_{i} }} (t) /S\sigma_{{x_{i} }} (t)\) means the reliability sensitivity of the mean/the standard deviation of variable \(x_{i}\) at the time instant t. \(\mu_{{x_{i} }}\) and \(\sigma_{{x_{i} }}\) represent the mean and the standard deviation of the variable, respectively.

There are a number of ways to compute the reliability sensitivity measures, e.g., the first order and second moment method (FOSM), Monte Carlo simulation (MCS) based on linear regression method, MC integration method, and finite difference method. Among these methods, FOSM is a widely used method. At each time instant, Eqs. (5.1.6) and (5.1.7) can be seen as the point reliability sensitivity. If the random variables are mutually independent, it is easily shown that [8]:

where \(\varvec{\mu}_{{\mathbf{x}}} = (\mu_{{x_{1} }} ,\mu_{{x_{2} }} , \ldots ,\mu_{{x_{n} }} )\) stands for the mean of the variables, \(\mu_{F} /\sigma_{F}\) means the mean/the standard deviation of the limit state function.

And the reliability indicator can be defined as

Thus, the time-dependent reliability sensitivity can be calculated as follows:

5.3 Time-Dependent PCE for the Model Output

In Eqs. (5.1.13) and (5.1.14), the performance function G must be evaluated to obtain the time-dependent reliability sensitivity measures. As a performance degradation mechanism, the performance function is implicit or is too complex for explicit evaluation. Thus, a surrogate model called PCE is employed here.

5.3.1 Time-Dependent PCE

PCE is a promising surrogate model that uses a set of orthogonal polynomial basis to approximate the random space of the system response. It is more accurate and effective to deal with the uncertainty compared to the conventional surrogate models, e.g., response surface method (RSM), Kriging method, and artificial neural networks method (ANN) [9]. The polynomial chaos of a performance degradation model response can be described as follows:

where \(G = g(t,\varvec{\xi})\) is the random system response, \(a_{i} (t)\) is the coefficient of PCE, \(\Gamma _{p} (\xi_{{i_{1} }} , \ldots ,\xi_{{i_{p} }} )\) is the polynomial of the selected basis, and p is the polynomial degree. In practical engineering, Eq. (5.1.15) can be simplified as follows:

where \(\psi_{j} (\varvec{\xi}) = \prod\nolimits_{i = 1}^{p} {\psi_{{m_{i} }}^{j} (\xi_{i} ) =\Gamma _{p} (\xi_{{i_{1} }} , \ldots ,\xi_{{i_{p} }} )}\) and \(N_{c}\) is the total number of PCE coefficients, which can be calculated as:

where n is the number of random variables in the model.

5.3.2 Computation of the Time-Dependent PCE Coefficients

The probabilistic collocation method (PCM) is a widely used method to compute the PCE coefficient, however, collocation methods are inherently unstable, especially with PCE of high order [10]. This paper proposes an extensive PCM based on regression, which needs to select a number of points equaling twice the number of coefficients, and it is more stable than the conventional method.

Suppose the mechanism will perform Nc tasks. The proposed method requires choosing m time points among the Nc tasks, i.e., \(T = \left\{ {T = t_{1} ,t_{2} , \ldots ,t_{m} } \right\},\) and constructing PCEs at each point. At \(t{\kern 1pt} (t \in T)\) time point, we can use the extensive PCM to compute the coefficients of PCE and the matrix form is Eq. (5.1.18), where \(\varvec{\xi}_{{_{j} }}\) represents the jth set of collocation points. Equation (5.1.18) can be written in a compact form of Eq. (5.1.19). The vector of coefficients can be derived as Eq. (5.1.20). At each time point, the coefficients of PCE can be calculated according to Eq. (5.1.20) (see Eq. 5.1.21), where \(\text{r}^{{t_{i} }}{(}{\boldsymbol{\Xi}})\) is the vector of responses at \(t_{i}\), and \({\mathbf{a}}^{{t_{i} }}\) is the vector of the coefficients of PCE at \(t_{i}\). Equation (5.1.21) can be simplified as Eq (5.1.22).

After the calculation of Λ, a new matrix Η of PCEs coefficients is created. Each row represents coefficients of the PCE, and each column represents a specific coefficient varying with steps. Η can be then expressed in a column form

where \({\mathbf{a}}_{0}\) is the vector of the first coefficients of PCEs along with the steps. According to [11], the approximation functions of coefficients are derived as

where \({\hat{\mathbf{f}}}({\mathbf{t}}) = [\hat{f}_{0} ({\mathbf{t}}),\hat{f}_{1} ({\mathbf{t}}), \ldots ,\hat{f}_{{N_{c} - 1}} ({\mathbf{t}})],\hat{f}_{i} ({\mathbf{t}})\) is defined as the approximation function of the ith coefficient. Then the conventional PCE can be translated into time-dependent PCE, which is written as follows:

5.4 Case Study

The engineering case is an airborne retractable mechanism (see Fig. 5.1). The process where the mechanism moves from I position to II position and moves back is defined as a task. At the initial design stage, the positions of and orientation of the front arm, rear arm, the link in pin-and-lug hinge and hydraulic actuator at IIposition are determined by requirements from higher level system. Therefore, the link length of pin-and-lug hinge depends on the \(X_{\text{A}}\), the length of the hydraulic actuator depends on the \(X_{\text{B}}\), the length of rear arm and front arm depends on the \(Y_{\text{C}}\) and \(Y_{\text{D}}\), respectively. Thus, \(X_{\text{A}} ,X_{\text{B}} ,Y_{\text{C}} /Y_{\text{D}}\) are all significant design variables. When the system is performing, it is under the weight of the functional device. The top hinge (pin-and-lug hinge) is working in a nonlubricated environment. As a result, the radius of the lug \(R_{\text{lug}}\) is bigger for the wear of the hinge.

The maximum driving force (MDF) is generated by the hydraulic actuator, while the output resistance force is resulted from loads and imposed on the hydraulic actuator. During the whole running process, the resistance force (RF) varies with the change of input displacement, i.e., the elongation of hydraulic actuator. If the maximum RF (MRF) is larger than the MDF, the seizure failure will happen. Thus, the time-dependent limit state function concerning seizure failure can be given as

where \(Q({\mathbf{X}},{\mathbf{Y}}(t),{\mathbf{t}})\) is the stochastic process of the MRF, \(\upgamma \sim N(78{,}500,10)\) is the distribution of MDF.

In order to compute the wear depth \(\Delta h\) of the top hinge, the multidiscipline simulation model including kinematics model built by ADAMS, FE model built by ANSYS, and Archard wear model is constructed (see Fig. 5.2).

In this case, the interested output of the mechanism, MRF, is approximated by the PCE regardingthe uncertain variables \(X_{\text{A}} ,X_{\text{B}} ,Y_{\text{C}} /Y_{\text{D}}\) and \(R_{\text{lug}}\) (listed in Table 5.1), and the reliability sensitivity of the four parameters is studied.

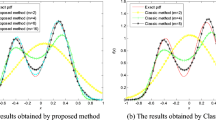

5.4.1 Time-Dependent PCE for the MRF

It can be seen that the degree of the PCE is p = 3 which is sufficient from Tables 5.2 and 5.3. The responses at every 100 steps are selected to build the PCEs, which means that the PCE are constructed at Step 1, 100, 200, and so on till 1000. Figure 5.3 is the first coefficients of time-dependent PCE. The blue points are computed by the extensive PCM and the red curve is approximated by the moving least squares (MLS). The other 34 coefficients of time-dependent PCE are also obtained by the same method.

Then the time-dependent PCEs are constructed completely. The comparative results of MRF are obtained at selected time steps which are 1, 250, 450, 650, and 850 steps. The MCS with 10,000 samples is employed as a benchmark for the comparison. The statistics including the mean and the variance of the MRF, are shown in Tables 5.2 and 5.3, respectively. It can be seen that the results approximated by the MLS is very close to the results from MCS, which indicates the proposed method is feasible and efficient.

5.4.2 Time-Dependent Reliability Sensitivity Measures

After the time-dependent PCE for MRF is available, time-dependent limit state function can be obtained and the time-dependent reliability sensitivity measures of the four uncertain parameters’ mean values can be calculated according to Eqs. (5.1.13) and (5.1.14). Figures 5.5 and 5.6 list the four uncertain parameters’ time-dependent sensitivity values, respectively.

From Fig. 5.4, we can see that the reliability indicator is decreasing, which means the reliability of the mechanism is becoming worse along the time axis. Figures 5.5 and 5.6 indicate the reliability sensitivity of the four parameters is also time-dependent. As for the mean reliability sensitivity (see Fig. 5.6), Y c and R lug have little effect on the reliability, which means we can ignore these two parameters in the work of time-dependent RBDO and reduce the dimensionality of the problem. Besides, the mean value of Y c have a positive effect on the reliability during 1–600 tasks, and have a negative effect on the reliability during 600–1000 tasks and the designers should pay attention to this phenomenon.

5.5 Conclusion

This paper conducted the time-dependent reliability analysis for long-term degradation mechanism. The research on time-dependent RBDO and time-dependent reliability analysis can benefit from this work. The time-dependent PCE is employed when computing the reliability sensitivity measures. The extension PCM and MLS based time-dependent PCE coefficients computation method is proposed. The greatest advantage of this method is that only little simulation work is needed to construct the time-dependent PCE and we can obtain better approximation of the output of the long-term degradation mechanism. The work of computation of the reliability measures can also benefit from the proposed algorithm. The future work of this paper is to analyze more complex mechanism models to test the effectiveness of the proposed method.

References

Hu Z, Li H, Du X et al (2013) Simulation-based time-dependent reliability analysis for composite hydrokinetic turbine blades. Struct Multi Optim 47(5):765–781

Xiongming L, Zhenghui W (2011) Research on reliability sensitivity for ranking the importance of random influential factors. In: 2011 IEEE 2nd international conference on software engineering and service science (ICSESS), IEEE, pp 235–238

Sues RH, Cesare MA (2005) System reliability and sensitivity factors via the MPPSS method. Probab Eng Mech 20(2):148–157

Hu Z, Du X (2014) Lifetime cost optimization with time-dependent reliability. Eng Optim 46(10):1389–1410

Wang Y, Zeng S, Guo J (2013) Time-dependent reliability-based design optimization utilizing nonintrusive polynomial chaos. J Appl Math 2013(4):561–575

Wang XG, Zhang YM, Yan YF et al (2008) Dynamic reliability sensitivity analysis of torsion bar. Adv Mater Res 44:275–282

Wang XG, Wang BY, Zhu LS et al (2011) Dynamic reliability sensitivity design of mechanical components with arbitrary distribution parameters. Adv Mater Res 199:487–494

Melchers RE, Ahammed M (2004) A fast approximate method for parameter sensitivity estimation in Monte Carlo structural reliability. Comput Struct 82(1):55–61

Wang Y, Zeng S, Guo J (2013) Time-dependent reliability-based design optimization utilizing nonintrusive polynomial chaos. J Appl Math 2013(4):561–575

Isukapalli SS (1999) Uncertainty analysis of transport-transformation models. The State University of New Jersey, Rutgers

Guo J, Du S, Wang Y, et al (2014) Time-dependent global sensitivity analysis for long-term degeneracy model using polynomial chaos. Adv Mech Eng 2014(10):1–16

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Du, S., Yuan, Y., Pan, Y., Wang, X., Chen, X. (2016). Time-Dependent Reliability Sensitivity Analysis for Performance Degradation Mechanism. In: Qin, Y., Jia, L., Feng, J., An, M., Diao, L. (eds) Proceedings of the 2015 International Conference on Electrical and Information Technologies for Rail Transportation. Lecture Notes in Electrical Engineering, vol 378. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-49370-0_5

Download citation

DOI: https://doi.org/10.1007/978-3-662-49370-0_5

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-49368-7

Online ISBN: 978-3-662-49370-0

eBook Packages: EnergyEnergy (R0)