Abstract

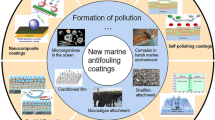

Antifouling based on biocides is the most important method preventing biofoulings in modern maritime industries and boating communities. Most antifouling paints, such as the famous but already banned organotin containing self-polishing coatings, belong to this category. Decades of development of the technology has resulted in a variety of biocides, organic matrixes, and paint systems. However, with increasing environmental concerns, the most challenging for these coatings is preventing fouling settlement effectively and meanwhile fulfilling regulations imposed by the International Marine Organization (IMO) to stop environmental damages. More and more efforts, including developing nontoxic or green biocides, new organic matrixes and advanced embedding and encapsulating technologies, and learning from nature, have been addressing the challenge. This chapter seeks to combine all these topics: the biocides from toxic to green, the organic matrix and paint system, the antifouling effects and the environmental impacts, and to draw a developing trend map for biofouling based on biocides.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

5.1 Introduction

Antifouling, preventing the growth of marine organisms including plants and animals on submerged surfaces, is essential for the maritime industries and boating communities worldwide. It is not a new concept. Application of coatings to hulls of boats to prevent settling of fouling organisms can be dated back to Ancient Greece [1] and even earlier probably when man started to conquer the oceans. The earliest antifoulants were used as physical barriers more than chemical toxicants because protecting the hull was initially the principal concern. Lead sheathing was used to coat vessels in ancient Romans and Greeks. Asphalt and tallow were thought to be coated on Columbus’ ships. Tar, grease, sulfur pitch and brimstone containing paints were also developed. The majority of them were protecting the hardwood planking against the infamous Teredo worm and the isopod crustacean gribble. However, it was found that hull damage was not the only concern, especially when iron vessels were sailed in oceans. The application of copper sheathing on iron hulls clarified that it was the toxic metal ions dissolved in seawater that prevented marine biofouling. From then on, antifouling paints really started to develop, where toxicants, usually termed biocides, such as arsenic, copper oxide, and mercury oxide, were added to resin binders. These paints containing biocides proved to be effective and created a new road, biofouling based on biocides, in the history of navigation to combat biofouling on ship’s hulls.

A wide range of chemicals have been used as antifouling biocides. Organic tin compound, tributyltin (TBT), developed in the late 1950s and early 1960s, was the most famous and successful one in the prevention of biofouling. Due to its remarkable efficiency, application of TBT-based paints, especially the “self-polishing” formulations, expanded rapidly. These paints were estimated to cover 70 % of the fleet in the world. With no doubt, the benefits obtained from the widespread use of TBT-based antifouling paints were remarkable. Unfortunately, we had to pay a serious price because of the adverse environmental consequences caused by TBT. It has been proved that extremely low concentration of TBT is harmful to marine life. For example, it showed that 20 ng/l of TBT caused shell malformations in the oyster (Crassostrea gigas) and 1 ng/l resulted in imposex in the dog whelks (Nucella sp.) [2]. TBT accumulation in mammals and negative effects on immunological defense in fishes and other species were also reported by the International Maritime Organization (IMO). Accordingly, responding to environmental protection, TBT-based antifouling paints have been forbidden since January 1, 2008. Obviously, alternative and effective biocides and relevant antifouling paints/coatings with little environmental impact are under urgent need.

Considerable efforts have been made to develop efficient and environmentally friendly biocides for antifouling. A variety of organictin-free biocides, including metal and metal-based compounds and booster biocides have been investigated. Some new substances such as ionic liquids, natural compounds extracted from marine organisms, and enzymes have also been employed to find “green” biocides. These green biocides may act through nontoxic mechanisms.

Despite the advanced fouling release and non-biocidal strategies, coating with paints containing biocides is still the most common practice for antifouling of the current maritime industries. Therefore, this chapter seeks to combine all main topics related to antifouling based on biocides: the biocides from toxic to green, the antifouling effects, and the environmental impacts. Hence, it includes an introduction to the antifouling technology based on biocides, a description of various biocides, and antifouling paints containing biocides. The active mechanism, effects, and environmental risks of these biocides are analyzed, and the antifouling paints containing biocides are described by an analysis of the binder systems, incorporation technologies, and leaching process, which constitutes the backbone of the chapter.

5.2 Antifouling Based on Biocides

Antifouling based on biocides is a most important method that is used to prevent biofoulings in modern maritime industries and boating communities. Most antifouling paints belong to this category. Figure 5.1 schematically illustrates a typical antifouling paint containing biocides. As shown in the figure, it includes two main parts: the biocides and the binder. The biocides are usually embedded in or linked to the binder, the film-forming organic matrix.

In the paint, biocides are the active ingredients that prevent the adhesion, growth, and settlement of marine organisms. The effectiveness of a biocide differs with its concentration and duration of the exposure. Therefore, the release of the biocides in the paint is of top importance. Basically, release of biocides involves the dissolution and diffusion, where seawater must get into the paint to dissolve the biocides and the dissolved active components must get back to the paint surface again. A highly efficient getting in and getting out path is thus critical for biocide-based antifouling. This is why self-polishing technology is employed, which can keep the thickness of the biocide-depleted layer as thin as possible.

Since the two main parts of biocide-based antifouling are important, detailed descriptions of biocides from the already forbidden TBTs to the most recent green and nontoxic natural products, and the film-forming matrix are followed.

5.3 Antifouling Biocides

Biocides are chemicals that can kill all sizes and life stages of organisms. They are widely used in medicine, agriculture, forestry, and industry for water treatment, disinfectants, and antifouling agents. For example, quaternary ammonium compounds are used as algicide in pool and industrial water and chlorine is used as a short-life disinfectant in swimming pool. According to the application categories, biocides can be broken down into more than 20 types. What we are concerned here is biocides as antifouling agents, especially as marine antifoulants. Among all chemicals that have been employed to be marine antifouling biocides throughout the history of navigation, TBT has been the most successful one in preventing biofoulings on hulls. The widespread use of TBT-based paints had resulted in remarkable economic benefits. However, the very serious environmental issues and extensive damages to shellfish caused by the accumulation of TBT have attracted extensive attention from all over the world. Although the organic tin concentration has been found to decrease in many marinas and bays after 20 years of regulation and prohibition, the adverse effects may still last tens of years. The good lesson from TBT tells people that it is quite necessary for the use of biocides in antifouling paints. As a result of prohibitions of organotin, copper and organic booster biocides have been used as alternative biocides for more than 20 years. Moreover, considerable effort has been made recently to develop low toxic and even nontoxic biocides, such as various organic booster biocides, inorganic nanoparticles, natural products, and ionic liquids. They have different properties and thus distinguishing antifouling mechanisms, behavior, and environmental effects.

5.3.1 Metal and Metal-Based Compounds

Various metals and metal-based compounds as antifouling biocides have been used for decades. They play important roles in combating biofouling in the whole history of navigation. Two representatives of them are tin and copper.

5.3.1.1 Organotin

In 1950s, Professor Ven der Kerk’s team made important contributions to the study of organotin chemistry [3]. Particularly, trialkyltin and its derivatives such as tributyltin (TBT) and triphenyltin (TPT) were found to have powerful biocidal properties [4–7]. In the late 1950s, triorganotin compounds were started to be used as agricultural fungicides. Their use in antifouling paints in the early 1960s, while its blossom started from the invention of organotin self-polishing coatings SPC. Since then, organic tin-based paints have been used widely on mariculture structures and ocean-going ships throughout the world. It is estimated that organic tin-based paints covered 70 % of the world fleet.

Figure 5.2 shows the organotin compounds that are used as industrial antifouling paint biocides. They are stable, solid at room temperature, and easy to handle. Toxicity of organotin compounds has been widely investigated to probe the biocidal mechanisms. Among all the organotin compounds which can be expressed by the formula RnSnX4-n, where R is organic group, n = 1–4, and X is inorganic substituent, R3SnX has the maximum toxicity to all living species, such as TBT chloride and TPT chloride. Evidence also showed that the toxicity of organotin to mammals reaches the top when R is ethyl group, and falls with the length of alkyl chain. Table 5.1 summarizes the toxic effects of TBT on different organisms and the relevant inhibitory concentration. It is found that TBT inhibits microbial processes for all major groups including the growth, primary productivity, respiration, energy-linked reaction, metabolism, photophosphorylation, and ATP synthesis, etc., and that the interactions happened at cellular membranes, chloroplasts, and/or mitochondria, etc. These researches explain why organotin compounds like TBT and TPT have powerful antifouling activities.

Structures of a tributyltin (TBT) (Reprinted with permission from Ref. [1]. Copyright 2004, Elsevier), b triphenyltin (TPT) (Reprinted with permission from Ref. [8]. Copyright 2001, John Wiley and Sons), c TBO and d a repeating unit of a copolymer of tributyltin methacrylate (TBTM) and methyl methacrylate (Reprinted with permission from Ref. [9]. Copyright 1969, Springer)

Trialkyltin had been considered as an ideal antifouling agent till early 1980s. Figure 5.3 illustrates the typical degradation scheme of TBT in the environment by UV, bacteria, or hydrolysis. It can be seen that the degradation of TBT results in less toxic di- and mono-organotin derivatives, and finally harmless inorganic tin residue. Therefore, organotin compounds were never thought to cause environmental problems. Actually, all these trialkyltin-based biocides have low aqueous solubility, only a few ppm mostly. Such trialkyltin biocides getting into seawater can be degraded very fast. The persistence in seawater is not a concern at all. However, the high affinity for particulate matter of TBT resulted in the tendency of TBT accumulating in sediment and marine organisms, leading to serious environmental issues.

The degradation scheme of TBT and TPT compounds. TBT tributyltin, TPT triphenyltin. (Reprinted with permission from Ref. [9]. Copyright 1969, Springer)

TBT was then described as the most toxic substance ever deliberately introduced into the aquatic environment; the concentrations of TBT as low as 2 ng L−1 can affect shell calcification in C. gigas and cause the development of imposex in N. lapillus [6]. Accumulation of TBT in marine organisms is also thought to be a threat to human health. Therefore, in 1982, legislation to ban the use of TBT-based antifouling paints on vessels < 25 m in length was first issued by the French government [6,11], followed by the UK in 1987, then the USA, Australia, Japan, and New Zealand. It was reported that the cytotoxic and genotoxic effects of TBT, including the induction of stress response proteins and DNA damage, have also been observed in sea urchins, bivalve mollusks, and polychaetes [12,13]. The International Maritime Organization (IMO) agreed to ban the application of organotin antifouling paints on ships by 2003 and completely prohibit the use of TBT by 2008. Fortunately, the concentration of TBT has been found to decrease in seawater environment, sediments, and tissues of molluscs due to the execution of legislation prohibiting the use of TBT-based paints on small vessels [2,14,15]. The environmental effects caused by TBT are getting better and better.

5.3.1.2 Copper and Copper Compounds

Copper has become the most important alternative biocides since organotin compounds were banned. Various copper agents including copper metal, copper alloys, cuprous oxide, and copper compounds have been used as principal biocides for decades. They are copper plate and flake, copper alloys such as cupronickel (90–10), arsenical copper (As = 0.34 %), Cu-Ni-M (M = Cr, Fe, Co, Ti, Zr, Nb, Ta, V, P, Ga, In, Ag), inorganic compounds including Cu2O, CuO, Cu2S, and CuS, and the mixtures, and some organocopper compounds for example copper pyrithione, copper picolinic acid amide, and copper acrylates. Most of them are commercially available now [16,17].

For the copper and inorganic copper compounds based hull surface, biocides are released from the hull surface and then enter in the water in the form of free copper ions Cu2+ or. The Cu2+ ion is the main biocidal form, which is more stable than Cu+ ion. The Cu+ ion is immediately oxidized to Cu2+ ion or reduced to Cu, while the Cu2+ ion forms copper complexes with organic and inorganic ligands. The process is thought to be very short. For example, Elisabete Almeida addressed the process using the following reactions [18]:

Actually, copper acrylates (CA) are more widely used in available coatings. It is reported that the reaction in contact with seawater can probably be written as [1]

The Cu-acrylate coatings have been reported to maintain performance being active for up to 3 years in several early papers.

Along with the growing use of copper-based paints, the problem of the accumulation of copper has gained much more focus in the vicinity of some marinas and mooring area. Copper can effectively prevent marine organisms such as tube worms, barnacles, and the majority of algal fouling species [16]. However, different organisms exhibit different sensitivity to copper and a general decreasing order of sensitivity would be: microorganisms > invertebrates > fish > bivalves > macrophytes [1,16]. N. Voulvoulis et al. reported that most of the total copper is strongly bound or chelated with organic ligands in coastal waters, considerably reducing the concentration of free Cu2+ so that it is nontoxic to most organisms [1]. The most toxic form is the free hydrated ion, Cu(H2O)2+ [16]. The current Environmental Quality Standard (EQS) for copper in seawater is 5 μg L−1 (expressed as an annual average) in the UK [16]. In 1999, P. Matthiessen et al. reported that 21.7 % (30/138) of sampling locations/year exceeded EOS (5 μg L−1) for copper and in six cases (4.3 % (6/138)) the concentrations lay between 10 and 15 μg L−1 [17].

Although copper is the essential element for marine organisms, it will be deleterious to marine organisms when the concentrations are high. Therefore, extensive efforts have been conducted and several recent papers have reviewed the copper biocides on their occurrence, environmental effects and fates [19]. While honestly, uncertain environmental impacts are still there in a long run. It is thus important to monitor the concentrations of copper and research these marine organisms which can decrease the concentration of copper.

5.3.1.3 Zinc

At present, the approved antifouling agents containing zinc include zincomadine, zineb, and ziram. These biocides kill the spores or larvae of marine organisms which settle on the substrate surface. Diego Meseguer Yebra reported Kansai paint which is derived from the reaction mechanism assumed for an acrylic backbone: ion exchange [1]. But it is not realistic, in the process of exchanging of Zn2+ for Na+, the pendant group will release as a result of the different ionic charges. A new antifouling paint based on a zinc acrylate copolymer can satisfy the market demands. The copper release rate and erosion rate of this new antifouling paint is established on the basis of sailing conditions [20]. Iwao Omae reported that zinc pyrithione which has the highest biocidal property and a short half-life (2–17 min when exposed to direct sunlight) is mainly used as the organic booster biocide component in Japanese tin-free antifouling paints [17]. But at the concentration of zinc pyrithione 0.9 nM (0.3 μg L−1), zinc pyrithione is toxic in the early stages of development of the ascidian Ciona intestinalis [21] and 0.5 nM for the larval growth of the sea urchin [22]. Zinc pyrithione may be a threat to marine organisms from exposure in the aquatic environment. It is necessary to develop new eco-friendly antifouling pigments. Combined with natural products, the paint is not only eco-friendly but also antifouling. Tannins can resist the attack of pathogens and the paint which is less toxic than cuprous oxide is synthesized by plants and zinc oxide. Natalia Bellotti et al. studied the effective antifouling paints containing zinc “tannate” which can last longer time (6 months) without fouling [23].

5.3.2 Booster Biocides

Booster biocides are one of the most important components in tin-free antifouling paints. It is well known that too many marine organisms, ~ 1800 species estimated, have been found to attach to mariculture constructions in seawater, which include algae, barnacles, ascidians, shellfishes, and hydrozoa. Following the legislation to ban the use of TBT-based antifouling paints on vessels < 25 m in length, copper biocides were found ineffective for all these species. Some of the marine organisms are tolerant to copper biocides. Therefore, additional biocides, termed as booster biocides, were developed to be used in combination with copper. A variety of booster biocide compounds have been developed. Table 5.2 shows some of the booster biocides. Among them, some have been commercialized, and some are not.

It can be observed from Table 5.2 that these booster biocides are organic compounds that contain elements of nitrogen, halogen, sulfur, and boron, which include heterocylic amines, aromatic halides, carbamates, phenols, arylboron amines, and phosphorus compounds. Since they are all organic compounds, they are also named as organic booster biocides.

These organic compounds are mainly used as pesticides, herbicides, and fungicides depending on their toxicities. Assays carried out by Kobayashi et al. exhibited that zinc pyrithione had the maximum toxicity on sea urchin eggs and embryos, then Sea-Nine 211, pyridine triphenyl borate, and copper pyrithione, whose toxicity is lower than that of tributyltin oxide. The Irgarol 1051 had the lowest toxicity. Compared with organotin biocides, these organic booster biocides are generally easier to be degraded. However, high concentrations of organic booster biocides have already been found in harbors and marinas [17,19].

A representative organic booster biocide is Irgarol (Irgarol 1051, N-tert-butyl-N′-cyclopropyl-6-methylthio-1,3,5-triazine-2,4-diamine), whose structure is shown in Fig. 5.4. Irgarol 1051 is a highly toxic and effective biocide used in antifouling coatings to prevent the growth of autotrophic organisms on ship hulls [24], which has been widely used over a number of decades.

Degradation pathway of Irgarol 1051. (Reprinted with permission from Ref. [17]. Copyright 2003, American Chemical Society)

Compared with other triazines like simazine and atrazine, Irgarol is a more potent photosystem II inhibitor of algal photosynthesis. It is highly toxic to macrophytes, periphyton, and phytoplankton. The mechanism can be described as follows: The biocide Irgarol inhibits the electron transfer in the photosystem II (PS II); Irgarol binds with high affinity to the plastoquinone (Qb) site of PS II, displacing the Qb quinone and preventing electron transfer; this results in oxidative stress, including photo-oxidation of chlorophyll and cell necrosis [1, 24].

Comparison with other booster biocides, Irgarol 1051 has low water solubility and partition coefficient (logKoc) [1]. Compounds with low partition coefficients will predominantly exist in the dissolved phase. Irgarol is easily dispersed and diluted in the aquatic environment (water solubility 7 mg L−1 [25]) and it tends to accumulate in marine organisms. The half-life (DT50) of Irgarol in water is between 24 and 200 days [24]. Under anaerobic conditions, the degradation in sediments is considerably slower. Under sunlight conditions, the Irgarol 1051 can quickly degrade to produce M1 by dealkylation of cyclopropane ring in seawater (Fig. 5.4), which remained even after the Irgarol 1051 disappeared from the system [17].

Studies have shown that time-weighted average calculations yielded high BCF values of up to 10,560 L kg−1 dry weight for M. verticillatum indicating a high potential for accumulation [24]. Both Irgarol 1051 and its degradation product M1 were highly toxic to marine organisms, but in the root elongation inhibition bioassay, M1 showed a phytotoxicity at least 10 times greater than that of the Irgarol 1051 [17]. It has been reported that the Irgarol 1051 is highly toxic to nontarget marine algae, at a concentration as low as 50 ng/L [17].

5.3.3 Inorganic Nanoparticles

Nanotechnology is a new way to figure and prevent disease using atomic scale tailoring of materials. Among the most promising nanomaterials with antibacterial properties are metallic nanoparticles, which exhibit increased chemical activity due to their large surface to volume ratios and crystallographic surface structure [26].

5.3.3.1 Nano-Silver

Nano-silver has attracted considerable attention in the field of antibacterial materials due to its high efficiency, wide spectrum, and low drug resistance to bacteria. Nano-silver is widely used in baby bottles, toys, toothbrushes, toothpaste, air purifiers, and other products as an antifouling agent. Nano-silver bactericidal mechanism is as follows: (i) damages the DNA of bacteria and then results in the increase of the total DNA degradation degree in the bacteria; (ii) Ag+ activates oxygen in air or water to produce hydroxyl radicals and reactive oxygen ions to inhibit or kill bacteria; (iii) damages cell membranes to change the permeability of the cell membrane and cause leakage of a large number of necessary substances for metabolism, leading to cell death [26, 27].

Jose Ruben Morones and coworkers studied the effect of silver nanoparticles in the range of 1–100 nm on gram-negative bacteria using high angle annular dark field (HAADF) scanning transmission electron microscopy (STEM) [26]. The result shows that the bactericidal properties of the nanoparticles are affected by the particle size, since the only nanoparticles that present a direct interaction with the bacteria preferentially have a diameter of ~ 1–10 nm. The study of the antifouling properties of silver nanoparticles immobilized on thin film composite polyamide membrane indicated that hybrid membranes exhibited dramatic antifouling property for Pseudomonas [28]. Jinhua Dai and Merlin L. Bruening prepared catalytic nanoparticles by reduction of Ag+ in multilayered polyelectrolyte films which were formed by alternating adsorption of polyethyleneimine–metal ion complexes and polyanions [29]. The result showed that the silver nanoparticle-containing films have excellent antibacterial effect. Simon Silver reported that Ag is generally without adverse effects for humans, and argyria (irreversible discoloration of the skin resulting from subepithelial silver deposits) is rare and mostly of cosmetic concern [30]. But it is necessary to control the use of silver products, or it may result in more bacteria developing resistance.

5.3.3.2 TiO2

It has been proved that TiO2 has excellent bactericidal property against Pseudomonas aeruginosa, Escherichia coli, Staphylococcus aureus, Salmonella, Aspergillus, and so on. The antibacterial action of TiO2 is performed through photocatalysis and its antibacterial property will not decrease with the gradual depletion of the antimicrobial agents. Moreover, ultrafine TiO2 is inorganic constituent, nontoxic, tasteless, nonirritating, thermally stable and heat resistant, non-flammable. Therefore, TiO2 has been considered as a promising nontoxic biocide.

Rong-Min Wang and coworkers prepared composite nano-TiO2 with doping Fe3+ and Ag, and further modified with 3-methacryloxypropyltrimethoxysilane [31]. It was shown that antibacterial activity of multifunctional fluorocarbon coatings containing modified composite nano-TiO2 was improved. Fu and coworkers fabricated nanoparticles of TiO2 and prepared the gold-capped TiO2 nanocomposites and vanadium-doped TiO2 nanoparticles which have a size of about 12–18 nm and an anatase phase by taking a sol–gel chemistry approach [32]. It was observed that these nanoparticles have good antibacterial effect (60–100 % killing efficiency as observed) and this may be due to those particles’ small size, large band gap energy, large surface area, and more active sites for carrying out catalytic reactions (Fig. 5.5).

Antibacterial effect on B. megaterium. Left: a Control solution without TiO2 nanoparticles; b 5 mM TiO2 nanoparticle suspension. Right: 4 mM TiO2 nanoparticle suspension, a dark control covered with an aluminum foil and b under room light. (Reprinted with permission from Ref. [32]. Copyright 2005, American Chemical Society)

5.3.4 PEG

From the 1970s, PEG has been widely used to modify particles and surfaces by physical adsorption, chemical adsorption, direct covalent attachment, or block or graft copolymerization [33]. PEGylation has become a standard modification method for biological applications [34]. PEG has steric exclusion, amphilic property, and excellent hydrophilic nature which plays a vital role in its non-fouling property [34]. Angus Hucknall et al. reported that surface modification with long-chain PEGs (nominally defined as PEGs with a molecular weight of 2000 Da) can significantly reduce protein adsorption (Fig. 5.6) [35].

Model picture for the theoretical study by Jeon et al. showing a protein of infinite size in water with a solid substrate having terminally attached PEG chains. PEG polyethylene glycol. (Reprinted with permission from Ref. [33]. Copyright 2010, John Wiley and Sons)

In addition, the surface density of the PEG can also affect the antifouling property [33]. High surface density and long chain length of polyethylene oxide are desirable for protein resistance and the surface density has a greater effect than chain length on the steric repulsion [36]. Commercial oligo (ethylene glycol) grafted to surfaces is exceptionally resistant to protein and cell adhesion by ATRP [35]. Electrospun nanofibrous meshes composed of PLGA-SH and 8cPEGa had superior antifouling effect on protein and mammalian cell binding in proportion to the amount of 8cPEGa in the mesh compared to non-crosslinked meshes [37]. Messersmith and coworkers used 3,4-dihydroxyphenylalanine (DOPA) to tether PEG to titania (TiO2) substrates and found these m-PEG-DOPA-modified surfaces to resist protein adsorption [33]. Maria M. Santore et al. arbitrarily placed isolated poly(L-lysine) coils on the silica prior to adsorption of the PLL-PEG [38] and the modified surface exhibits excellent antifouling properties. PLL has positively charged amine groups, which bind to the negatively charged metal oxide substrate, while the hydrophilic, uncharged PEG chains remain free and exposed to the seawater and form comb-like structures [33].

Although PEG is the most commonly used substance and has excellent antifouling properties, it is prone to auto-oxidize and form aldehydes and ethers in the presence of oxygen, which leads to the surfaces to lose their antifouling ability [33]. Compared with PEG, ionic liquid has thermal stability and chemical stability and has a wide field of applications as a candidate of nontoxic biocide with good prospects.

5.3.5 Ionic Liquid

Imidazolium, pyridinium, and quaternary ammonium-based ionic liquids have standard biocidal activity against gram-positive and gram-negative bacteria, fungi, and algae. For example, quaternary ammonium salts possess biocidal activity due to lipophilic interactions with the cell wall of microorganisms. They can diffuse through the cell wall, disrupt the cytoplasmic membrane leaking potassium and other constituents, and finally cause cell death. We have shown that ionic liquids (ILs; Fig. 5.7) consisting of ammonium, imidazolium, etc, are low-melting organic salts with low melting point that have been attracting considerable attention in the past decade [39–41] and have reported that poly(NM-MIm-PF6) polymer brush coatings effectively resist chlorella spores bacterial adhesion at room temperature(Fig. 5.8) [42].

Cations and anions that constitute ionic liquids. (Reprinted with permission from Ref. [39]. Copyright 2009, Royal Society of Chemistry)

The structure of poly(NM-MIm-PF6). (Reprinted with permission from Ref. [42]. Copyright 2012, Royal Society of Chemistry)

Adam Latała and coworkers reported that the toxicity of 1-alkyl-3-methylimidazolium ionic liquids (ILs) which consisted of five 1-alkyl-3-methylimidazolium chlorides (from -ethyl to -decyl) for evaluating the expected alkyl chain length effect, together with 1-butyl-3-methylimidazolium tetrafluoroborate, dicyanamide, trifluoromethanesulfonate, methyl sulfate ana-methyl[poly(oxy −1,2-ethanediyl)]sulfate [43] for investigating the influence of the anion on IL toxicity towards various algal species [44]. The study showed that no significant differences were observed between alkylimidazolium salts and an alkylpyridinium compound of similar lipophilicity but the use of tetrafluoroborate and trifluoromethanesulfonate as counteranions in the IL structure gave rise to the most pronounced toxic effects in comparison with the other anions tested.

5.3.6 Zwitterionic

Zwitterionic polymers have strong hydration that is electrostatically induced and the surfaces modified with zwitterionic polymers have excellent antifouling properties against proteins, cells, and bacteria [34, 45, 46]. Zwitterionic polymers have anionic and cationic terminal groups, such as poly(carboxybetaine), poly(sulfobetaine methacrylate), and poly(2-methacryloyloxyethyl phosphorylcholine) [47, 48]. These materials have good chemical stability and low cost [49] and zwitterionic materials possess anti-adsorption of nonspecific protein via a bound hydration layer from solvation of the charged terminal groups, in addition to hydrogen bonding [50].

Poly(carboxybetaine) polymer brush coatings effectively resist nonspecific protein adsorption from undiluted blood plasma and serum to an extremely low level (< 0.3 ng/cm2) using a surface plasmon resonance (SPR) sensor, and keep the antifouling performance and delay biofilm formation for 10 days at room temperature [45, 51]. Alicia L. Gui et al. found that zwitterionic coatings (phenyl phosphorylcholine, 4-(trimethylammonio)-phenyl, 1:1 mixed layers of 4-sulfophenyl and 4-(trimethylammonio)-phenyl (mix), 4-sulfophenyl) are as effective as the OEG SAMs at resisting the nonspecific adsorption of bovine serum albumin and cytochrome c and created low impedance anti-biofouling layers on electrodes [52]. Yuwei Liu designed the surface of PDMS by incorporating PDMS with quaternary ammonium salts and found that lower degree of quaternization offers more freedom for the alkyl groups to extend and penetrate the microbial membranes [53]. Yung Chang and coworkers studied the performance and stability of a highly stable antifouling surface with well-packed grafted zwitterionic polysulfobetaine, zwitterionic sulfobetaine methacrylate (SBMA) [54]. The well-packed polySBMA grafted surface performs stable and excellent blood compatibility at human body temperature (Fig. 5.9, 5.10).

SEM photographs of platelets adhered onto the surface of a CH3-SAMs, b OEG-SAMs, and c polySBMA surface. (Reprinted with permission from Ref. [54]. Copyright 2008, American Chemical Society)

Adsorption of plasma proteins on CH3-SAMs, OEG-SAMs, and polySBMA grafted surfaces at 37 °C from human blood plasma. A wavelength shift of approximately 1 nm in the SPR response is equivalent to 15 ng/cm2 of adsorbed proteins. (Reprinted with permission from Ref. [54]. Copyright 2008, American Chemical Society)

5.3.7 Natural Products as Antifoulants

Marine organisms, such as corals, sponges, sharks, marine plants, and dolphins, etc., can prevent the surface of their bodies from antifouling substances without causing serious environmental problems [17]. At present, it mainly includes five kinds of terpenoids, nitrogen compounds, phenols, steroidal, and other compounds. Nobuhiro Fusetani summed up some marine natural products including terpenoids, steroids and saponins, fatty acid-related compounds, bromotyrosine derivatives, and heterocyclic compounds which prevent larvae to settle and metamorphose [55, 56]. Antifouling biocides can also be extracted from the land vegetation such as a green tea, mango, and euphorbia (Table 5.3 and Fig. 5.11).

Structures of some natural biocides. (Reprinted with permission from Ref. [17]. Copyright 2003, American Chemical Society)

5.3.7.1 Chitosan

Chitosan consists of β-(1→4)-2-acetamido-D-glucose and β-(1→4)-2-amino-D-glucose units and is derived from chitin by deacetylation in the presence of alkali (Fig. 5.12). Chitosan is an abundant natural biopolymer which is biodegradable, biocompatible, biological, and nontoxic. It inhibits microbes and also considered as a kind of good material for developing eco-friendly biocides. Chitosan has excellent antibacterial function and effectively inhibits the growth and reproduction of bacteria and fungi. Bactericidal mechanisms are as follows [57]:

-

(1)

The bactericidal mechanism is different between low molecular weight chitosan and high molecular weight chitosan. Small molecular weight chitosan can enter cells and combine negatively charged protein and nucleic acid to affect the normal function of cells and then it triggers cell death. But macromolecule chitosan exhibits antifouling property by attaching to the surface of microorganism to form a layer of polymer film to block the transport of nutrients.

-

(2)

The reaction of the effective group −NH3+ and lipid–protein complex reaction on the membrane leads to protein denaturation and then cell death.

-

(3)

When the concentration of chitosan is high enough, it will lead to activate the chitinase activity of some microorganisms or express the chitinase too much, as a result of cell wall degradation.

JAE-YOUNG JE and coworkers prepared water-soluble chitosan derivatives with different degrees of deacetylation by grafting amino functionality onto chitosan at the C−6 position. It has been shown that all derivatives showed a higher antimicrobial activity than native chitosan and killed bacteria by disrupting the outer membranes and inner membranes of bacteria [58]. Rajesha Kumar reported that two different compositions of polysulfone in N-methylpyrrolidone (NMP) and chitosan in 1 % acetic acid were blended to prepare PSf-CS ultrafiltration membranes by the diffusion-induced phase separation (DIPS) method and the permeation and antifouling properties of PSf-CS membranes increased with an increase in chitosan composition [59].

5.3.7.2 Capsaicin

Capsaicin is a spicy vanilla amide alkaloid extracted from peppers. Figure 5.13 shows the structures of capsaicin and capsaicin analogues. In 1993, Kenneth J. Fischer reported that the coating contains capsicum derivatives such as cayenne pepper or oleoresin capsicum to repel the organisms that might otherwise attach themselves to submerged objects (US5226380). And then, James L. Wattsmixed finely divided capsaicin, an oleoresin capsaicin liquid solution, or crystallized capsaicin with a suitable corrosion resistant epoxy resin and then mixed with a hardening catalyst to apply to the surface to be treated (US5397385).

Structures of capsaicin and capsaicin analogues. (Reprinted with permission from Ref. [61]. Copyright 2011, Springer)

Maj-Britt Angarano and coworkers reported that capsaicin (8-methyl-Nvanillyl-trans-6-nonenamide) exhibited excellent antifouling property against byssal with potency values (EC50) in the micromolar range and they were lethal to adult specimens of the water flea, Daphnia magna, at concentrations that inhibited mussel byssal attachment [60]. Capsaicin and dihydrocapsaicin exhibited excellent antifouling performance at lower concentration [61]. Capsaicin effectively inhibited the reattachment of zebra mussels and the reattachment of zebra mussels can also be prevented by selected antioxidants (butylated hydroxyanisole, tert-butylhydroquinone, and tannic acid) [62]. Although marine organisms provide an excellent, alternative source of potential antifouling compounds, they generally contain only low quantities of the compounds and it is difficult to be widely used.

5.3.7.3 Enzymes

Enzymes such as protease, amylase, ligninase and cellulose are widely used in biofuel production, paper industry, baby food, cleaning preparations, and molecular biology. Enzymes are rapidly biodegraded and are therefore expected to be eco-friendly. Some enzymes have better inhibitory activity of chitinase. Efficient enzymes are combined with coatings as the primary antifouling mechanism, the environment would benefit from nontoxic biocides (Fig. 5.14) [63].

Classification and proposed mechanism of enzymatic antifouling. Coating A is based on biocidal direct antifouling. Coating B is based on adhesive degrading direct antifouling. Coating C is based on indirect antifouling with substrate in the environment. Coating D is based on indirect antifouling with the substrates provided from the paint. (Reprinted with permission from Ref. [64]. Copyright 2012, American Chemical Society)

Any enzyme utilized must have at least the following qualities: (1) be robust towards the composition of coatings; (2) be nondestructive towards coating mechanisms; (3) have a broad spectrum AF effect, and (4) have stable activity in the coating and upon exposure of the coating to seawater. Under these conditions, an enzyme-based AF coating can be commercially successful [63]. In order to achieve a microbicidal effect, two types of enzymes can be used: reagent-requiring and reagentless. The former utilizes reagents from the surrounding solution to produce an antimicrobial agent; the latter can directly produce a bactericidal effect, often as a result of cell wall degradation [33].

Enzyme is mainly extracted from creature. Xiaojian Zhou and coworkers extracted 17 flavone and isoflavone derivatives from terrestrial plant and reported that these flavone and isoflavone derivatives possess antifouling properties against flavone and isoflavone derivatives and genistein which is easy to decompose can effectively inhibit barnacle fouling [65]. Styloguanidines isolated from the marine sponge Stylotella aurantium inhibit the activity of chitinase (hydrolyze integumental chitin), thus inhibit the moulting of cyprid larvae of barnacles which control the molting cycle of crustaceans at a concentration of 10 ppm [66]. The first study of butenolide’s molecular targets in three representative fouling organisms were reported by zhang’s group. The results showed that butenolide inhibited fouling by influencing the primary metabolism of target organisms [67]. Butenolide can also inhibit the settlement of barnacle cypris larvae by sustaining the expression level of stress-associated and metabolism-related proteins (vitellogenin), thus arresting the development until a fully competent stage has been reached [12]. Scott J. Novick et al. combined enzymes with other proteins into hydrophobic polymeric coatings and films to generate biologically active materials for biocatalysis, antifouling surfaces, and biorecognition by using standard solution coating techniques with poly(methyl methacrylate), polystyrene, and poly(vinyl acetate) as polymers and α-chymotrypsin and trypsin as biocatalysts [68]. 12-Methyltetradecanoid acid (12-MTA) inhibited the larval settlement of the biofouling polychaete H. elegans and its effects on the expression of Ran GTPase activating protein and ATP synthase for larval settlement [69].

10β-Formamidokalihinol-A and kalihinol A which were isolated and purified from the marine sponge Acanthella cavernosa (Dendy) inhibited the growth of bacteria isolated from the natural environment whereas kalihinol A suppressed larval settlement of a major fouling polychaete, Hydroides elegans with an EC50 of 0.5 μg mL−1 [70]. Figure 5.15 refers to the steps and the estimated time needed to develop a novel A/F system based on natural compounds. Although a large number of natural products which have excellent antifouling activities have been isolated and characterized, only few of these compounds can be commercialized and introduced into the market due to the limited information available on their mode of action, possible environmental effects, and environmental fate [12]. It is difficult to realize the commercialization of natural antifouling products, but it is possible to synthesize products with structures similar as natural products.

A possible research management schedule for the development of a novel antifouling system based on natural antifouling compounds (with permission of Surfex Limited). (Reprinted with permission from Ref. [1]. Copyright 2004, Elsevier)

5.4 Antifouling Paints Containing Biocides

For most biocides such as CuO and booster biocides, it is difficult to apply them on the hull surface directly. Incorporating biocides into organic matrix to form paints is the most efficient manner for hull antifouling based on biocides. Nowadays, antifouling paints are widely used in ships, yachts, oil platforms, and so on. Antifouling paints should meet these requirements as follow: prevent the settlement of marine organisms in the required time; release biocides into seawater continuously and steadily; make full use of biocides; effectively resist the impact of seawater; eco-friendly and no threat to human; good storage stability.

5.4.1 Insoluble Matrix Paints (Contact Leaching Coatings)

In insoluble matrix paints, the polymer matrix which possesses high mechanical performance is insoluble and does not polish or erode after immersion in water [1, 18]. The matrix resin used in the traditional insoluble antifouling coating mainly includes chlorinated rubber, acrylic resin, vinyl chloride and vinyl acetate copolymer, and vinyl chloride and vinyl isobutyl ether copolymers [71]. Since the binder is not soluble in seawater, as a toxicant agent its contents are released, the seawater spreads through the pores and capillaries that are left empty by the latter and goes on to dissolve the next toxicant particles [64, 72]. However, the spongy structure left in the coating blocks the release of the residual biocides due to the longer and longer leaching route. So it is necessary to regularly clean the non-active coating. For these reasons, the duration of the coatings obtained with these paints is between 12 and 24 months, depending on the severity of the exposure conditions [64].

5.4.2 Soluble Matrix Paints

The characteristic of the soluble matrix paints is that the matrix and the biocide are dissolved and released simultaneously. These paints are mainly based on rosins and their derivatives which consist generally of about 85–90 % of acidic materials (rosin acid) [71]. The biocides are incorporated, such as cuprous oxide, iron or zinc oxides, copper acetoarsenite, and previously arsenic and mercury [18]. In contact with seawater, the carboxyl groups reacted with sodium and potassium ions, and thus gave resonates of high solubility. These paints do not maintain an antifouling protection for more than 12–15 months due to the high erosion and release rates [64]. The main advantage of soluble matrix paints is that they can be applied on smooth bituminous-based primers. But the erosion rate of the paint increases exponentially with increasing vessel speed when the rosin content was above a certain value [1].

5.4.3 Self-Polishing Coatings

The most successful antifouling paint in the entire history of navigation is organotin self-polishing coatings, which were invented based on acrylic or methacrylic copolymers at late 1960s [18]. Such paints undergo the following mechanism when immersed in seawater: They release organic tin and copper oxcide by organotin ester side chain of the polymer hydrolyzing, and the remaining hydrophilic polymer dissolves through the action of the seawater, then the fresh surface will be exposed; by this way, organotin polymer continues to hydrolyse and dissolve so that organic tin toxic constantly release to achieve the purpose of long-term antifouling (Fig. 5.16) [73]. The advantage of this paint is that it possesses remarkable drag reduction effect and antifouling property and the biocides continuously and steadily release. For the first time, paints of this type could reach 5 years of excellent AF performance [74].

Tin-free controlled depletion paints have been greatly developed after the prohibitions that the International Maritime Organization (IMO) agreed to ban the application of organotin antifouling paints on ships by 2003. Their working mechanisms are similar to those of conventional rosin-based paints and these self-polishing paints mainly contain cuprous oxide instead of toxic organic tin [18]. Most of these paints are based on acrylic polymers which can undergo hydrolysis or ion exchange, such as copper acrylic polymer, zinc acrylate polymers, and acrylic silicone polymer. Yonehara et al. prepared a new antifouling paint based on a zinc acrylate copolymer and found that the polymers became soluble and leached out by flow of seawater with the ion exchange reaction proceeds [20]. The advantages of these paints are controllable polishing rate and antifouling agent leaking rate, and the maximum service life of this type of paints is normally around 3 years [18, 71].

5.4.4 Antifouling Paints with Microencapsuled Biocides

In antifouling paints containing biocides, biocides can be linked to the matrix or more often buried in the film-forming organic matrix which is widely used. The former, such as the self-polishing paints, the biocides are linked to the matrix such as acrylic or methacrylic copolymers. The release rate is different for different embedding ways. The release rate of biocides is dependent on many factors including the binder, the nature of biocides, and the type of matrix, etc [76, 77]. In order to achieve the controllable release, many methods have been developed besides the self-polishing and direct embedding. Microcapsulary has been thought of as a useful one. Microcapsulary has been widely used in self/healing composites [78], diagnostics and control release [79–81], and drug delivery [82], due to the biocompatibility and controllable release of encapsulated molecules. For example, the polydopamine capsules, the release of the trapped molecules can be regulated by controlling pH value [83]. Alginate/chitosan/alginate (ACA) hydrogel microcapsules modified with methoxy poly(ethylene glycol; MPEG) was prepared to improve protein repellency and biocompatibility [84]. Liu et al. synthesized Ag nanoparticles on nano SiO2 modified with PDA (SiO2/PDA/Ag NPs) which were able to damage the membrane and penetrate into the cell effortlessly [85]. Microcapsulary promises to provide a facile and robust strategy to form capsules containing a pH-triggered release mechanism which enhance antifouling effectiveness.

5.5 Conclusion

Antifouling based on biocides is the most important method used in the modern boating and marine industry to prevent the adhesion, growth, and settlement of marine organisms. Decades of development of the technology has resulted in a variety of biocides, organic matrixes, and paint systems. Among them, the most important one is the development of biocides, which will be significantly affected by the economy and environmental impacts. Modern antifouling coatings must prevent fouling settlement effectively, and fulfill regulations imposed by the International Marine Organization (IMO) to stop environmental damage meanwhile [23]. Although many toxic biocides such as Cu, Zinc, and Irgarol 1051 are being used nowadays and the impacts of some of them on the environments are still uncertain, the unfortunate thing is that they may be still used in a very long time before green alternatives are invented. However, these regulations have created, during the past decade, the necessity of developing new antifouling pigments that are safe for the environment and humans. More and more efforts on the development of green biocides such as ionic liquids and natural products are devoted on new organic matrixes and advanced embedding and encapsulating technologies. Green and high-tech has become the developing trend for biofouling based on biocides. Learning from the nature to develop the most sustainable and environmental friendly antibacterial agents to control biofouling is believed to be the promising way.

References

Yebra DM, Kiil S, Dam-Johansen K (2004) Antifouling technology-past, present and future steps towards efficient and environmentally friendly antifouling coatings. Prog Org Coat 50:75–104

Evans SM, Leksono T, Mckinnell PD (1995) Tributyltin pollution: a diminishing problem following legislation limiting the use of TBT-based anti-fouling paints. Mar Pollut Bull 30:14–21

Ruiz JM, Bachelet G, Caumette P, Donard OFX (1996) Three decades of tributyltin in the coastal environment with emphasis on arcachon bay. Environ Pollut 93:195–203

Champ MA (2000) A review of organotin regulatory strategies, pending actions, related costs and benefit. Sci Total Environ 258:21–71

Xu Y, He HP, Schulz S, Liu X, Fusetani N, Xiong HR, Xiao X, Qian PY (2010) Potent antifouling compounds produced by marine Streptomyces. Bioresour Technol 101:1331–1336

Evans SM (1999) TBT or not TBT? That is the question. Biofouling 14:117–129

Sousa A, G´enio L, Mendo S, Barrosoi C (2005) Comparison of the acute toxicity of tributyltin and copper to veliger larvae of Nassarius reticulatus (L.). Appl Organometal Chem 19:324–328

Mailhot G, Brand N, Astruc M, Bolte M (2002) Photoinduced degradation by iron (III): removal of triphenyltin chloride from water. Appl Organometal Chem 16:27–33

Konstantinou IK (2006) Antifouling paint biocides. In: Omae I (ed) Chemistry and fate of organotin antifouling biocides in the environment, 2nd edn. Springer, Berlin, p 17–50

Gadd GM (2000) Microbial interactions with tributyltin compounds: detoxification, accumulation, and environmental fate. Sci Total Environ 258:119–127

Huggett RJ, Unger MA, Seligman PF, Valkirs AO (1992) Assessing and managing the environmental risks. Environ Sci Technol 26:232–237

Qian PY, Chen LG, Xu Y (2013) Mini-review: molecular mechanisms of antifouling compounds. Biofouling 29:381–400

Dowson PH, Bubb JM, Lester JN (1993) Temporal distribution of organotins in the aquatic environment: five years after the 1987 UK retail ban on TBT based antifouling paints. Mar Pollut Bull 26:487–494

Minchin D, Oehlmann J, Duggan CB, Stroben E, Keatinge M (1995) Marine TBT antifouling contamination in Ireland, following legislation in 1987. Mar Pollut Bull 30:633–639

Sapozhnikova Y, Wirth E, Schiff K, Fuiton M (2013) Antifouling biocides in water and sediments from California marinas. Mar Pollut Bull 69:189–194

Voulvoulis N, Scrimshaw MD, Lester JN (1999) Alternative antifouling biocides. Appl Organometal Chem 13:135–143

Omae I (2003) General aspects of tin-free antifouling paints. Chem Rev 103:3431–3448

Almeidaa E, Diamantino TC, Sousa O (2007) Marine paints: the particular case of antifouling paints. Prog Org Coat 59:2–20

Thomas KV, Brooks S (2010) The environmental fate and effects of antifouling paint biocides. Biofouling 26:73–88

Yonehara Y, Yamashita H, Kawamura C, Itoh K (2001) A new antifouling paint based on a zinc acrylate copolymer. Prog Org Coat 42:150–158

Bellas J (2005) Toxicity assessment of the antifouling compound zinc pyrithione using early developmental stages of the ascidian Ciona intestinalis. Biofouling 21:289–296

Bellas J, Granmo A, Beiras R (2005) Embryotoxicity of the antifouling biocide zinc pyrithione to sea urchin (Paracentrotus lividus) and mussel (Mytilus edulis). Mar Pollut Bull 50:1382–1385

Bellotti N, Deya C, Amo B, Romagnoli R (2010) Antifouling paints with zinc “Tannate”. Ind Eng Chem Res 49:3386–3390

Mohr S, Berghahn R, Mailahn W, Schmeiediche R, Feibicke M, Schmidt R (2009) Toxic and accumulative potential of the antifouling biocide and TBT successor Irgarol on freshwater macrophytes: a pond mesocosm study. Environ Sci Technol 43:6838–6843

Schoknecht U, Gruycheva J, Mathies H, Bergmann H, Burkhardt M (2009) Leaching of biocides used in facade coatings under laboratory test conditions. Environ Sci Technol 43:9321–9328

Morones JR, Elechiguerra JL, Camacho A, Holt K, Kouri JB, Ram´ırez JT, Yacaman MJ (2005) The bactericidal effect of silver nanoparticles. Nanotechnology 16:2346–2353

Qu F, Xu HY, Xiong YH, Lai WH, Wei H (2010) Research progress in bactericidal mechanisms of nano-silver. Food Sci 31:420–424

Lee SY, Kim HJ, Patel R, Im SJ, Kim JH, Min BR (2007) Silver nanoparticles immobilized on thin film composite polyamide membrane: characterization, nanofiltration, antifouling properties. Polym Advan Technol 18:562–568

Dai JH, Bruening ML (2002) Catalytic nanoparticles formed by reduction of metal ions in multilayered polyelectrolyte films. Nano Lett 2:497–501

Silver S (2003) Bacterial silver resistance: molecular biology and uses and misuses of silver compounds. FEMS Microbiol Rev 27:341–353

Wang RM, Wang BY, He YF, Lv WH, Wang JF (2009) Preparation of composited nano-TiO2 and its application on antimicrobial and self-cleaning coatings. Polym Advan Technol 21:331–336

Fu GF, Vary PS, Lin CT (2005) Anatase TiO2 nanocomposites for antimicrobial coatings. J Phys Chem B 109:8889–8898

Banerjee I, Pangule RC, Kane RS (2010) Antifouling coatings: recent developments in the design of surfaces that prevent fouling by proteins, bacteria, and marine organisms. Adv Mater 23:690–718

Cao ZQ, Jiang SY (2012) Super-hydrophilic zwitterionic poly(carboxybetaine) and amphiphilic non-ionic poly(ethylene glycol) for stealth nanoparticles. Nano Today 7:404–413

Hucknall A, Rangarajan S, Chilkoti A (2009) In pursuit of zero: polymer brushes that resist the adsorption of proteins. Adv Mater 21:2441–2446

Jeon SI, Lee JH, Andrade JD, Gennes PG (1990) Protein-surface interactions in the presence of polyethylene oxide. J Colloid Interf Sci 142:149–158

Kim HS, Ham HO, Son YJ, Messersmith PB, Yoo HS (2013) Electrospun catechol-modified poly(ethyleneglycol) nanofibrous mesh for anti-fouling properties. J Phys Chem B 1:3940–3949

Gon S, Kumar KN, NuÌsslein K, Santore MM (2012) How bacteria adhere to brushy PEG surfaces: clinging to flaws and compressing the brush. Macromolecules 45:8373–8381

Zhou F, Liang YM, Liu WM (2009) Ionic liquid lubricants: designed chemistry for engineering applications. Chem Soc Rev 38:2590–2599

Hallett JP, Welton T (2011) Room-temperature ionic liquids: solvents for synthesis and catalysis. 2. Chem Rev 111:3508–3576

Dobbs W, Heinrich B, Bourgogne C, Donnio B, Terazzi E, Bonnet ME, Stock F, Erbacher P, Bolcato-Bellemin AL, Douce L (2009) Mesomorphic imidazolium salts: new vectors for efficient siRNA transfection. J Am Chem Soc 131:13338–13346

Ye Q, Gao TT, Wan F, Yu B, Pei XW, Zhou F, Xue QJ (2012) Grafting poly(ionic liquid) brushes for anti-bacterial and anti-biofouling applications. J Mater Chem 22:13123–13128

Manna U, Carter MCD, Lynn DM (2013) “Shrink-to-fit” superhydrophobicity: thermally-induced microscale wrinkling of thin hydrophobic multilayers fabricated on flexible shrink-wrap substrates. Adv Mater 25:3085–3089

Latała A, Nedzi M, Stepnowski P (2009) Toxicity of imidazolium and pyridinium based ionic liquids towards algae. Chlorella vulgaris, Oocystis submarina (green algae) and Cyclotella meneghiniana, Skeletonema marinoi (diatoms). Green Chem 11:580–588

Zhang Z, Chen SF, Jiang SY (2006) Dual-functional biomimetic materials: nonfouling poly(carboxybetaine) with active functional groups for protein immobilization. Biomacromolecules 7:3311–3315

Zhang Z, Chen SF, Chang Y, Jiang SY (2006) Surface grafted sulfobetaine polymers via atom transfer radical polymerization as superlow fouling coatings. J Phys Chem B 110:10799–10804

Callow JA, Callow ME (2011) Trends in the development of environmentally friendly fouling-resistant marine coatings. Nat Commun 2:244–253

West SL, Salvage JP, Lobb EJ, Armes SP, Billingham NC, Lewis AL, Hanlon GW, Lloyd AW (2004) The biocompatibility of crosslinkable copolymer coatings containing sulfobetaines and phosphobetaines. Biomaterials 25:1195–1204

Jiang SY, Cao ZQ (2010) Ultralow-fouling, functionalizable, and hydrolyzable zwitterionic materials and their derivatives for biological applications. Adv Mater 22:920–932

Yin HY, Akasaki T, Sun TL, Nakajima T, Kurokawa T, Nonoyama T, Taira T, Saruwatarie Y, Gong JP (2013) Double network hydrogels from polyzwitterions: high mechanical strength and excellent anti-biofouling properties. J Mater Chem B 1:3685–3693

Aldred N, Li GZ, Gao Y, Clare AS, Jiang SY (2010) Modulation of barnacle (Balanus amphitrite Darwin) cyprid settlement behavior by sulfobetaine and carboxybetaine methacrylate polymer coatings. Biofouling 26:673–683

Gui AL, Luais E, Peterson JR, Gooding JJ (2013) Zwitterionic phenyl layers: finally, stable, anti-biofouling coatings that do not passivate electrodes. ACS Appl Mater Interfaces 5:4827–4835

Liu YW, Leng C, Chisholm B, Stafslien S, Majumdar P, Chen Z (2013) Surface structures of PDMS incorporated with quaternary ammonium salts designed for antibiofouling and fouling release applications. Langmuir 29:2897–2905

Chang Y, Liao SC, Higuchi A, Ruaan RC, Chu CW, Chen WY (2008) A highly stable nonbiofouling surface with well-packed grafted zwitterionic polysulfobetaine for plasma protein repulsion. Langmuir 24:5453–5458

Fusetani N (2004) Biofouling and antifouling. Nat Prod Rep 21: 94–104

Qian PY, Xu Y, Fusetani N (2010) Natural products as antifouling compounds: recent progress and future perspectives. Biofouling 26:223–234

Feng XQ, Li XF, Yang S, Wang TP (2009) Current research on anti-microbial mechanisms related influencing factors and applications of chitosan. China Brewing 202:19–23

Kim JY, Kim SK (2006) Chitosan derivatives killed bacteria by disrupting the outer. J Agric Food Chem 54:6629–6633

Kumar R, Isloor AM, Ismail AF, Rashid SA, Matsuura T (2013) Polysulfone-chitosan blend ultrafiltration membranes: preparation, characterization, permeation and antifouling properties. Rsc Adv 3:7855–7861

Angarano MB, McMahon RF, Hawkins DL, Schetz JA (2007) Exploration of structure-antifouling relationships of capsaicin-like compounds that inhibit zebra mussel (Dreissena polymorpha) macrofouling. Biofouling 23:295–305

Peng BX, Wang JL, Peng ZH, Zhou SZ, Wang FQ, Ji YL, Ye ZJ, Zhou XF, Lin T, Zhang XB (2011) Studies on the synthesis, pungency and anti-biofouling performance of capsaicin analogues. Sci China Chem 55:435–442

Cope WG, Bartsch MR, Marking LL (1997) Efficacy of candidate chemicals for preventing attachment of zebra mussels (Dreissena polymorpha). Environ Toxicol Chem 16:1930–1934

Olsen SM, Pedersen LT, Laursen MH, Kiil S, Dam-Johansen K (2007) Enzyme-based antifouling coatings: a review. Biofouling 23:369–383

Lejars M, Margaillan A, Bressy C (2012) Fouling release coatings: a nontoxic alternative to biocidal antifouling coatings. Chem Rev 112:4347–4390

Zhou XJ, Zhang Z, Xu Y, Jin CL, He HP, Hao XJ, Qian PY (2009) Flavone and isoflavone derivatives of terrestrial plants as larval settlement inhibitors of the barnacle Balanus amphitrite. Biofouling 25:69–76

Kato T, Shizuri Y, Izumida H, Yokoyama A, Endo M (1995) Styloguanidines, new chitinase inhibitors from the marine sponge stylotella aurantium. Tetrahedron Lett 36:2133–2136

Zhang YF, Zhang HM, He LS, Liu CD, Xu Y, Qian PY (2012) Butenolide inhibits marine fouling by altering the primary metabolism of three target organisms. ACS Chem Biol 7:1049–1058

Novick SJ, Dordick JS (2002) Protein-containing hydrophobic coatings and film. Biomaterials 23:441–448

Xu Y, Li HL, Li XC, Xiao X, Qian PY (2009) Inhibitory effects of a branched-chain fatty acid on larval settlement of the polychaete Hydroides elegans. Mar Biotechnol 11:495–504

Yang LH, Lee OO, Jin T, Li XC, Qian PY (2006) Antifouling properties of 10β-formamidokalihinol-A and kalihinol A isolated from the marine sponge Acanthella cavernosa. Biofouling 22:23–32

Gui TJ, Yu XY (2010) Existing state and development trend of binder resin for marine antifouling coatings. China Coatings 10:7–11

Railkin AT (2004) Marine biofouling: colonization processes and defenses. In: Railkin AT (ed) Protection of man-made structures against biofouling, 9th edn. Chemical Rubber Company (CRC), London, p 179–194

Yan DZ, Jia CG (2002) Technology development and application of antifouling coating. Chem Technol Mark 25(12):21–24

Yebra DM, Kiil S, Weinell CE, Dam-Johansen K (2006) Presence and effects of marine microbial biofilms on biocide-based antifouling paints. Biofouling 22:33–41

Monfared H, Sharif F, Kasiriha SM (2008) Simulation and development of tin-free antifouling self-polishing coatings. Macromol Symp 274:109–115

Thouvenin M, Peron JJ, Charreteur C, Guerin P, Langlois JY, Vallee-Rehel K (2002) A study of the biocide release from antifouling paints. Prog Org Coat 44:75–83

Cima F, Ballarin L (2008) Effects of anitfouling paints alternative to organotin-based ones on macrofouling biocoenosis of hard substrates in the Lagoon of Venice. Fresen Environ Bull 17:1901–1908

Xiao DS, Yuan YC, Rong MZ, Zhang MQ (2009) Self-healing epoxy based on cationic chain polymerization. Polymer 50:2967–2975

Fluri DA, Kemmer C, Daoud-El Baba M, Fussenegger M (2008) A novel system for trigger-controlled drug release from polymer capsules. J Control Release 131:211–219

Kooiman K, Bohmer MR, Emmer M, Vos HJ, Chlon C, Shi WT, Hall CS, de Winter SH, Schroen K, Versluis M, de Jong N, van Wamel A (2009) Oil-filled polymer microcapsules for ultrasound-mediated delivery of lipophilic drugs. J Control Release 133:109–118

Mao Z, Ma L, Gao C, Shen J (2005) Preformed microcapsules for loading and sustained release of ciprofloxacin hydrochloride. J Control Release 104:193–202

Cui J, Yan Y, Such GK, Liang K, Ochs CJ, Postma A, Caruso F (2012) Immobilization and intracellular delivery of an anticancer drug using mussel-inspired polydopamine capsules. Biomacromolecules 13:2225–2228

Liu QZ, Yu B, Ye W, Zhou F (2011) Highly selective uptake and release of charged molecules by pH-responsive polydopamine microcapsules. Macromol Biosci 11:1227–1234

Zheng JN, Xie HG, Yu WT, Tan MQ, Gong FQ, Liu XD, Wang F, Lv GJ, Liu WF, Zheng GH, Yang Y, Xie WY, Ma XJ (2012) Enhancement of surface graft density of MPEG on alginate/chitosan hydrogel microcapsules for protein repellency. Langmuir 28:13261–13273

Liu T, Song X, Guo Z, Dong Y, Guo N, Chang X (2014) Prolonged antibacterial effect of silver nanocomposites with different structures. Colloid Surface B 116:793–796

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Zhao, W., Wang, X. (2015). Antifouling Based on Biocides: From Toxic to Green. In: Zhou, F. (eds) Antifouling Surfaces and Materials. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-45204-2_5

Download citation

DOI: https://doi.org/10.1007/978-3-662-45204-2_5

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-45203-5

Online ISBN: 978-3-662-45204-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)