Abstract

There has been a global concern about the use of tributyltin-based coatings in combating biofouling in the marine industry. Although there have been alternatives to tributyltin in preventing biofouling, the emphasis is now on the use of nontoxic and/or ecofriendly natural materials which do not negatively affect the environment upon application. Natural materials are ecofriendly, biodegradable, cost-effective, and can be employed as precursors in the synthesis and formulation of biodegradable antifouling coatings. Consequently, many researchers are investing time into the synthesis and formulation of natural, ecofriendly antifouling coatings, comprised of higher biofiber, which would perform analogous antifouling like other conventional coatings, thus minimizing the more toxic base polymer proportion. A safe environment is surely the signal of a bright future; hence, cost-effective, biodegradable raw materials result in a long-term attainment of sustainability of these products to replace the expensive conventional ones. This review presents an overview of ecologically friendly, cost-effective, and legally acceptable ways of preventing and mitigating the growth of algae and other marine organisms from settling on the hull of a ship and other static constructions in oilfields.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The link between society, technology, and environment is the key determinant of a safe and comfortable society. Technology has indeed contributed to the growth of our society in diverse fields but with untold harmful consequences to the environment. Science and industrialization are now focusing on sustainable future technologies, which incorporate the environmental impact from such technologies. The interaction between humans and their environment has become more of our culture and should not only focus on raw materials but also green, ecofriendly, and biodegradable raw materials. Meeting this development need has focused research into materials that have little or no toxicity, are economical, and are socially accepted. So far, antifouling paints have been extensively formulated and used in the marine industry in many parts of the world. Their application has been critiqued over the years due to the harm they cause to the natural environment.1,2 The challenge is that most of these products are not degradable after disposal or may take millions of years to be broken down. A bright future calls for the production of green materials and products. Renewable materials and products, usually synthesized from natural products, are environmentally friendly.

Antifouling in this context is basically any strategic application that prevents the attachment of micro- and macroorganisms to manmade surfaces.3,4 In anticorrosive systems, a physical barrier such as paint is created that keeps out and decelerates the perforation of water and oxygen.5,6 Over the years, antifouling paints have played diverse and significant roles ranging from prevention of marine growth to acting as a barrier against corrosion on metal hulls. Several antifouling and anticorrosion paints have been synthesized over the past few years. Application of these coatings in the 1970s continued for about 20 years until some environmental concerns were raised. Several studies into antifouling paints have proven that biocides are the active ingredients that prevent the settlement, adhesion, and growth of organisms to a painted surface and are arguably the second most hazardous ingredient to tributyltin which is a major component. Antifouling paints leach into the marine environment after application, thereby destroying aquatic life. This resulted in a total ban in early 2008 following a resolution from governments in many countries.4,7,8,9,–10 This created a need for the development of ecofriendly conventional coatings which have lower toxicities. Coatings made from environmentally friendly, ecologically acceptable, and readily available precursors have received much attention, as evidenced in several studies.6,11,12,13,14,15,–16

Green antifouling and anticorrosion paints are basically made of natural precursors from plants and marine organisms and are mostly of lower toxicity and/or are nontoxic as compared to other booster biocides on the market.11,17,18 Over the past few years, natural product antifouling and anticorrosion paints have been synthesized by many researchers. According to earlier research,13 coatings synthesized from plant extracts are responsible for bacterial and fouling inhibition. After 25 days of immersing acrylic plates coated with natural (tannin-based) antifouling paints, the leaching rate of tannin from insoluble matrix paint decreased considerably, reaching a constant value. A green synthesis of polyethylene glycol-based silver nanocomposites and their application in marine environment resulted in a better antifouling protection due to the self-cleaning property.19 Ethanolic extracts of African bush pepper (Piper guinensis) exhibited corrosion inhibition on mild steel.17,20 Copper-based antifouling paints, which are less toxic than tributyltin in an aquatic environment, have been synthesized and applied in many countries. It was found out that the coatings are only effective against marine fauna. Combating weed growth may require incorporation of herbicides which are is environmental friendly.7,9,21,22,–23 Although tin-free antifouling paints have proved adequate on passenger ferries in Korea, their contamination in the marine world is high.7,24,25

The challenge in replacing conventional coatings with biodegradable types is to synthesize materials that possess structural and functional stability during application and yet effectively prevent growth of microorganisms with rapid biodegradability devoid of any major environmental impacts.26 Environmentally benign antifouling coatings would not only save the marine industry huge sums of money invested in fuel, maintenance, and labor but would also have significant benefits for our citizens and society.12,27,28 Local sourcing of raw materials for antifouling paint formulation is currently being explored. Of late, scientists have been investigating the use of agro-wastes as a source of raw materials (precursors) in synthesizing a number of benign functional products. This development has led to a cost-effective way of introducing diverse products in combating some of the production challenges in oil fields.

This work aims at providing a holistic overview of the research achievements that are driving the emerging commercially available antifouling paint technologies for both large and small vessels. It also seeks to introduce ecologically friendly, cost-effective, and legally acceptable ways of preventing and mitigating the growth of algae and other marine organisms from settling on the hull of a ship and other static constructions in oilfields.

Biofouling and corrosion—brief details and problems

In the marine industry, surfaces normally become encrusted with unwanted materials: a phenomenon known as fouling. Marine biofouling therefore is the amassing of unwanted micro- and macroorganisms as well as their metabolites, plants, and animals on structures submerged in seawater.29,30,–31 These organisms settle not only on submerged structures but on buoys, piers, undercover cables, offshore platforms, heat exchange equipment, and other static constructions.30,32,33 This problem increases drag resistance which causes an increase in fuel consumption to as much as 30–40%,11,29,30 thereby increasing the emission of greenhouse gases into the atmosphere, i.e., an environmental concern.34 Consequently, additional cost is incurred in production and maintenance of ship hulls. Other issues of biofouling include metal corrosion and microbial-induced corrosion due to hydrogen sulfide formed by the bacteria.33,35 Biofouling results in a corrosive environment (corrosion fouling) which involves a chemical reaction between the metal surface and a reactant. Equipment performance and other installations in seawater are some of the problems related to corrosion.36 Microbiologically induced corrosion, also known as biocorrosion, is influenced by sulfate-reducing bacteria on the metal surface causing extensive damage to aquatic, maritime, and process industries.37,38

The biofouling process

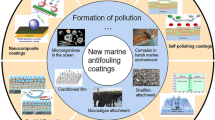

Normally, when a solid is immersed in the seawater, there is the colonization of a substratum. The attachment of marine biofouling occurs in four main stages, namely formation of primary film, formation of microbial biofilm, development of a more complex community, and attachment of larger invertebrate larvae (Fig. 1).

Formation of primary film

During this stage, there is adsorption of organic and inorganic macromolecules onto the surface/substrate immersed in the seawater (usually proteins, polysaccharides, and nucleic acids). This is a physical interaction which leads to the formation of a nonliving chemical/biochemical film, a process known as conditioning which occurs within seconds to minutes10 and sets the solid for further attachments.

Formation of microbial biofilm

The second stage involves bacteria transport/absorption, reversible adhesion, irreversible adhesion, and maturation and dispersion of biofilm. Microbiological cells are adhered onto the surface and immobilized onto the surface via reversible adhesion. The microorganisms are permanently attached during this chemical (irreversible) reaction to the substratum through extracellular polymeric substances.22,39 Afterward, nutrients in the conditioned film enhance the growth and settlements of larger marine invertebrates and microalgae on the substratum. The entire process takes between minutes to hours.10,27

Development of a more complex community

Within days to weeks after immersion of a new substratum, a colony of multicellular species, microalgae, debris, and sediments develop on the surface leading to a sophisticated community.27,40

Attachment of larger invertebrate larvae

The final stage encompasses the settlement and/or growth of larger invertebrate including marine fungi, protozoa, algal spores, barnacles, and mussels. This stage normally occurs after several days to weeks of immersing a solid in seawater. During this period, the roughness of irregular microbial colonies and the existence of extracellular polymeric substances enhance trapping of more microorganisms.10

Persistent growth of these biofouling layers depends on a number of environmental conditions such as salinity, temperature, conductivity, pH, dissolved oxygen content, organic material content, hydrodynamic conditions, current, light, depth, and distance from the shore.41 Additional factors are the organism and the substrate. Also, the strength of bio-adhesion depends on the organism type, the surface on which the organism is growing, and the separating fluid which are all regulated by electrostatic forces and surface wettability.29

Characteristics of biofouling organisms

Biofouling organisms are diverse, and most of them live along the coasts. Generally, there are two types of processes that drive biofouling as far as microorganisms are concerned, namely micro- and macrofouling. Over 400 biofouling species have been reported worldwide; but generally they have been categorized into two classes: (a) microfouling/biofilm organisms—bacteria and diatoms and (b) macrofouling organisms—algae, barnacles mussels, polychaete worms, bryozoans, and seaweeds.14 According to the literature,29 “micro-fouling consists of microbes like bacteria, unicellular algae, and diatoms; macrofouling contains fouling organisms such as mussels, algae, and barnacles.” Several authors have confirmed the categorization of biofouling organisms. According to Chapman’s group,42 antifouling classification of biofouling organisms was comprised of three categories: (1) microfoulers comprising bacteria, diatoms, fungi, and microalgae biofilms, (2) soft macrofoulers (macroalgae) and (3) hard macrofoulers—barnacles, mussels, tubeworms, and bryozoans. Others include microorganisms with a hard outer layer, such as encrusting bivalves (oysters, scallops, chamas), encrusting bryozoans, and hard corals, and those with soft exteriors, i.e., sponges, anemones, foliose bryozoans, soft corals, and hydroides.43,44 These macroorganisms ranging from bacteria to seaweeds and molluscs colonize on submerged surfaces that already have a microbial film present which in turn attracts larger microfoulers. Favorable conditions would result in a permanent attachment, thereby facilitating initial growth, final growth, and dispersion.29 Table 1 shows characteristics of some macrofouling organisms.

What are antifouling paints?

Combating biofouling in the twentieth century informed the development of antifouling paints. An interesting feature about antifouling paints is that they combine material properties in ways not found in nature. Antifouling paints, therefore, are coatings, paints, and surface treatments employed on a solid substrate (e.g., ship hull) to control or prevent the attachment of unwanted organisms.29 The problem researchers found with antifouling paint is the leaching out of biocides into seawater after its application. It has been discovered that biocides leach out into seawater, killing barnacles and other marine organisms, and thus harm the environment.7,45,46

Currently, the most widely used commercial antifouling coatings are biocide-based. Table 2 lists categories of commercial antifouling paints currently used in the marine industry.

Contact leaching paints contain biocides or toxicants that are released slowly after application, thereby weakening the protection effect of substrates. Controlled depletions adapt a similar mechanism but release the biocides for a short period of time but at a sustained pace. Ablative systems erode and release the biocide over a sustained period of time.37,47 Biocides in antifouling paints prevent the attachments of organisms on the ship hulls by killing them. This is a threat to the ecosystem, and researchers should focus on substituting antifouling systems containing copper and organotin compounds with additives containing nontoxic biocides that are equally effective as tin and copper-containing biocides.29

Antifouling paints have two main components, namely the polymer/binder/resin and the pigment. There is also a vehicle (solvent) in which the main components are dissolved plus other additives (e.g., catalysts, plasticizers) which may be included at low levels.5,9,49 Ecofriendly antifouling paints are synthesized incorporating local raw materials as pigments and binder. The composition of antifouling paints may vary but not without the two main components.

Biocides employed in antifouling systems

It is believed that antifouling paints, in their bid to kill or deter attached microorganisms, release biocides or toxins into the aquatic environment. Throughout history, diverse biocides have been employed for this purpose. Until today, biocides such as cuprous oxide (Cu2O), tributyltin, tributyltin oxide (TBT/TBTO), and organic additives/booster biocides (e.g., Irgarol 1050®, Sea Nine 211®, dichlofluanid, chlorothalonil, zinc pyrithione, and Zineb) released from antifouling systems can have toxic effects on organisms50,51 at all points in the food chain, including mammals.29 Several reviews have described and compared the extent of toxicity of biocides.10,51,52,–53 According to the findings,54 some booster biocides are more toxic than biocides; in that some applications result in high-level accumulation, resulting in a higher toxic effect on nontarget marine species (Table 3).

The fact that the alternatives to tributyltin are also toxic has generated a keen interest among researchers to study their contamination in the aquatic environment. To secure a congenial atmosphere in the aquatic environment, there is a need to develop nontoxic technologies.56 Formulation of antifouling paints comprising environmentally safe natural products would not only give us a safe environment but also secure the future of the marine industry.

Mechanism of ecofriendly antifouling coatings

Antifouling is a chemical reaction between the fluid that reacts and the surface of the component.4 The mechanism of operation of traditional biobased coatings is based on a dual mode of action, namely nonstick properties and release behavior (inlay) on a biological scale.58 Pei and Ye59 hypothesized that antifouling coatings prevent the organisms from adhering in the first place or reduce the adhesion force of those that adhere, so that they can be easily removed by the shear forces generated by the movement of the ship or by the soft mechanical cleaning devices. In general, an antifouling agent or compound should avoid biofilm formation, which is considered a signal for further settlement of invertebrate larvae in the marine environment. The mode of action of antibiofilm activity of microbial strains related with marine macroorganisms includes antibiotic activity and antiadhesion property and impacts the production of extracellular polymers (EPS), which is necessary for biofilm formation.60

The antifouling mechanisms of ecofriendly biobased coatings have been extensively studied. Feng et al.61 reported that compounds synthesized from indole derivatives exhibited a good antifouling activity with low toxicity against algal cells by a molecular inhibition mechanism. Del Grosso et al. dissolved antioxidants into host coatings and evaluated their antifouling characteristics on mussels in the laboratory. It was found that all the coatings with antioxidants minimized adhesion via a reduction process, thereby discontinuing the crosslinking reactions required to form glues.62 The above results not only reveal that natural antifouling compounds are ecofriendly, but they also help us to understand the mechanisms of bio-adhesion for marine applications.

Under normal circumstances, the ecofriendly biobased coatings act through diverse ways and subsequently prevent the formation of biofilms and/or the attachment of microorganisms on a substratum. The strategies given as follows summarize the mode of action of ecofriendly antifouling coatings/paints:

Inhibition of adhesive production: These compounds inhibit the production or release of adhesives during settlement on a surface.

Biofilm inhibition: Antifouling compounds inhibit the fixing of microbes on surfaces.

Quorum blockers: The communication between cells between microbial cells is inhibited.

Protein expression regulation: Regulators inhibit the sedimentation of contaminating organisms by altering their protein expression.

Neurotransmission blocking: Blockers interrupt signal transduction during settlement.

Surface modification: Surface modifiers block the bacterial binding site and prevent biofilm formation.60

Development of antifouling coating mechanisms based on the principles of biofouling has become an effective way of combating the menace. Thus, the biobased coatings upon application oppose the formation of a conditioning film and/or release sitting biofoulants before the secretion and differentiation of natural adhesives occur, thus keeping the adhesion strength to a minimum.60,63 Table 4 shows a summary of the mode of action of antifouling coatings.

The mechanisms in Table 4 give an insight into how biobased compounds react with the target organism and/or prevent the attachment of biofilms to surfaces in the marine environment.

Natural products as precursors in antifouling paints

Following the ban on tributyltin and other booster biocides in antifouling paints, there has been an interest in the synthesis of effective and novel ecofriendly compounds from natural resources. Diverse natural products have been successfully employed as starting materials in the development of antifouling paints.56,71 Notably, ecofriendly natural antifouling agents are found in seaweed,31,72 bacteria,16,27 algae,15,73 corals,27,74 sponges,60,75 and terrestrial plants.10,26,64

It is believed that tannins found in aquatic and terrestrial plants contain special pigments that exhibit antifouling properties. Thus, they are complex polyphenolic compounds, which have antimicrobial and anticorrosive properties. Application of tannins in antifouling coatings has successfully prevented the attachment of barnacles.11,27,72,76 The antifouling activity of an active compound from Andrographis paniculata plant extracts has been reported. It showed an outstanding antifouling activity against marine bacteria.27 Normally, fouling inhibition of these pigments is enhanced by complexation with metal ions, which results in less leaching of polyphenol. Several studies have affirmed this with the incorporation of metal ions with tannins.11,22,71 Hemaida et al.8 synthesized copper(II) and cobalt complexes of 3-(2-furrylidene) hydrazine-5,6-diphenyl-1,2,4-triazine and discovered in vitro antifouling activity against barnacle larvae. After a 12-month immersion test, copper dodecanoate antifouling paint showed similar antifouling inhibition when compared with those with commercial coating.77

The use of agricultural by-products or waste in solving environmental problems has become an emerging area in the world of research. This approach could be a strategy of reducing waste through improved design, recycling, and reuse, i.e., turning waste to wealth. In the formulation of natural ecofriendly antifouling paints, extracts from peanut skin, onion skin, grapes, nuts, vegetables cereals, etc. could be used as sources of phenolic compounds78 for the synthesis of pigments. Naturally occurring polymers, including plant exudates and extracts such as gum Arabic,79,80 shellac81 rosin,32 gum tragacanth,82,83 and galactomannans,84 are good sources of polymer/binder. Cashew nut shell, also an agro-waste, could be deployed by extracting the liquid from the shell and subsequently using it as a precursor for the synthesis of polymer/resin.85

Natural antifoulants work through various physical and chemical control mechanisms, including low drag, low adhesion, wettability, microtexture, grooming, sloughing, and chemical secretion.29 Natural products as antifoulants coated on substrates could exhibit a low drag flow, thus removing microorganisms from the surface.58,64 When the adhesion strength of the surface is reduced, attached microorganisms are released easily; this is low adhesion.29,37 Adhesive interactions (strong or weak) between marine organisms and the substratum are dependent on the wettability of the surface. As noted in reference (14), fouling diatoms cling more securely to a hydrophobic polydimethylsiloxane substratum than to glass. Some marine organisms crave for suitable surfaces of attachment, known as microtextured surfaces. Once they settle on such surfaces, attachment of fouling organisms is prevented or early release of already attached ones is enhanced.86,87 Examples of such are barnacle, mussels, and shark-skins. Cypris larvae, a type of barnacle, are turned away by microtextured surfaces if the features are the same in size.29 Furthermore, other marine organisms possess brush-like structures for removal of fouling from substrates. This method, known as grooming, is normally employed by decapods, crustaceans, and echinoderms. Pedicellaria, a special structure in echinoderms and bryozoans, is used in grooming macroepibionics.29 One other physical means of defense against biofouling is sloughing. This involves the periodic shedding of surface tissue or outermost layer of an organism. It has been88 reported that sloughing is an effective mechanism for getting rid of foulants, although it occurs rarely. Another interesting mechanism is chemical secretion, which involves the secretion of a lubricant which enhances the repulsion of extraneous foulants and also self-cleaning attributes. Retention of the lubricant onto the substrate occurs either by wetting into the configuration of the surface or by grafting to substrates through chemical bonds.89,90

Natural product antifouling mechanisms have motivated researchers to develop effective antifouling systems, otherwise known as bioinspired antifouling methods or biomimicry. In confirming the efficiency of this method, they have invented many microtextured surfaces. Some of these techniques include: Sharklet antifouling™ microtopographical structures,29 laser ablation,42 silver nanoparticles,91 casting,92 and molds.93 Several green antifouling natural products have been used around the world. Table 5 gives a summary of these products. For this matter, ecofriendly natural products could be deployed as reliable and motivating precursors in arresting biofouling in oilfields.

Biodegradable polymers as matrices for antifouling coatings

As a result of the ban of tributyltin-based or toxic coatings, researchers and the marine industry have developed a keen interest in coatings formulated from less toxic, biodegradable raw materials (pigments and polymers). The global concern for a safe environment due to complete degradation of these materials has increased the demand for biodegradable products. Waste generation and management have become a costly global menace, and researchers have resorted to converting waste to biodegradable polymers. Moreover, biodegradable polymers when incorporated with pigments with antifouling properties increase the antifouling period.95 A biodegradable polymer, according to reference 96, is the polymer type that disintegrates by the action of microorganisms (fungi, bacteria, algae) through photodegradation, oxidation, and hydrolysis to yield carbon dioxide, methane, inorganic compounds (biomass), and other natural substances in a specified period of time (Fig. 2). For example, a polymer synthesized from a renewable or biodegradable precursor is a “green polymeric material,” and interestingly, the biodegrading process has become a carbon source in the environment.96 Figure 2 is a summary of the life cycle of degradable polymer.

Life cycle of biodegradable polymers96

Biodegradable polymers are of two sources—natural/renewable and synthetic. Although natural polymers exist in a perfect combination, a detailed comprehension of how they are formed, inconsistencies in biological and chemical composition with respect to geographical and weather conditions, etc. remain to be understood. Synthetic polymers, however, have varied applications in medicine and the chemical industries.97,98,–99 Our focus in this review is on polymers synthesized from naturally occurring biodegradable phenolic compounds such as cashew nut shell liquid (CNSL), lignin, tannins, vegetable oil, or palm oil, which can be used as monomers. One interesting property of these naturally occurring phenols is that they can be used for the synthesis of sustainable polymers with or without modification.98

Many natural and synthetic biodegradable polymers have been employed as matrices in antifouling systems. Properties influencing the decomposition of these polymers are chemical composition, physico-mechanical characteristics (density, melting point, tensile strength), and morphology.100,101 Some researchers102 synthesized a biodegradable polymer from a blend of poly(ɛ-caprolactone) and poly(butylene succinate). It was then employed as a marine antibiofouling polymer which exhibited good antifouling ability over a long period of time. In a recent study, a copolymer of 2-methylene-1,3-dioxepene (MDO), tertiary carboxybetaine ester (TCE), and 7-methacryloyloxy-4-methylcoumarin (MAMC) was prepared and found not only with strong adhesion to the substrate, but also with a good inhibition of bacteria adhesion.95 As we appreciate the fact that biodegradable polymers are promising antibiofouling matrices, the demanding situation regarding their stability and time span for the degradation should not be relegated to the background.96,103

Biodegradable polymers from cashew nut shell liquid

The cashew nut shell liquid (CNSL), an alkyl phenolic oil, is a reddish-brown viscous liquid from the cashew nut shell, a by-product obtained from the cashew nut industry.104,105,–106 The cashew nut shell, an agro-waste, has now become a raw material for polymer synthesis105 and a source of petrochemical phenolic compounds,107,108 among others. The CNSL has the following components based on the method of extraction: anacardic acid (71.7%), cardanol (4.7%), cardol (18.7%), methylcardol (2.7%), and unnamed polymeric materials (2.2%) as shown in Fig. 3.109 The side chain, R, comprises 15 carbon atoms in the meta-position from the hydroxyl groups.106

Components in CNSL: (1) anacardic acid, (2) cardanol, (3) cardol, and (4) methylcardol106

Chemistry of CNSL

The chemistry is dependent on the presence of its reactive operational aromaticity, phenolic hydroxyl, and unsaturated alkyl phenol (side chain), R,108 making it suitable for polymerization into resins. Consequently, modified CNSL has diverse industrial applications,110 some of which are: plasticizers,98 adhesives,105 fuel additives,111 surfactants,112 resin additives,98,105,113,114 friction materials as well as flame retardants,108 and as intermediates or precursors for other chemical synthesis.105 Recent reviews have captured the varied applications of CNSL.109,110,115,116 CNSL is highly stable at room temperature due to the presence of strongly polar aromatic group.98 Storage at high temperature will lead to polymerization.105

Extraction of the liquid from the cashew nut shell could be done by techniques such as hot oil processes,112,117 solvent extraction,109 mechanical processes,98 vacuum distillation,112,118 or supercritical fluids.105 These techniques have been employed successfully in many research studies.104,105,119,120 Cardanol (52–60%) is a major component of a heat-extracted CNSL with cardol (10%) and polymeric materials (30%). Technical-grade CNSL (without polymeric material) has about 78% cardanol, 8% cardol, and 0–2% polymeric material.98,106,110

Structural and functional group properties of cardanol make it highly reactive and, hence, undergo reactions such as sulfonation,115,121,122 nitration,105 esterification,112 halogenation,105,121 etherification,123 and epoxidation.107,124 Figure 4 shows a summary of possible reactions of CNSL and their derivatives.

Possible reactions of CNSL and their derivatives105

CNSL resins and polymers

A number of resins and polymeric derivatives can be synthesized from CNSL for diverse applications.106 This is due to CNSL’s phenolic construction and lengthy hydrocarbon chain with carbon–carbon double bonds which affords additional reaction sites. Reactions such as polycondensation with electron deficient species (e.g., formaldehyde) or polymerization of the reactive side chain with acid and/or base catalysts, followed by a linkage of a number of monomers, could yield CNSL polymers/resin.112 The condensation reaction with formaldehyde is commonly employed. CNSL resins such as epoxy, alkyd, polyurethane, phenolic resin, vinyl, and acrylic can be put together for diverse modified coatings.105 Various resins obtained from CNSL can be used in the following: coating of surfaces,105 rubber or plastic modifiers,115,122 brake lining or friction materials,112,125 waterproof materials,112,121 flame retardants,112 ion-exchange resins,126,127 and anticorrosive paints.118 These novel biobased resins exhibit similar and periodically better chemical, mechanical, and thermal properties than other commercially available petro-based products.110 Synthesis and application of resin from CNSL have been reported in many research papers and reviews. One of the earliest was the preparation of varnishes from cardanol–formaldehyde resins, with equally good chemical and mechanical properties as other commercial precursors.115,128 Researchers129 successfully synthesized CNSL-resin via a base-catalyzed formaldehyde reaction. The resin was coated on the surface of wooden samples, and it was found that the sample with the thickest CNSL-resin had the lowest wetness and water absorption capacity. Table 6 is a summary of some CNSL resins and their applications.

Biodegradable polymers from other sources

Renewable naturally occurring phenolic compound precursors such as vegetable oil, lignin, and tannin matrix systems can also be employed for bio-composite applications. Over the years, several classes of phenolic resins have been developed from these matrices.98 The reasons are not far-fetched: availability, affordability, and biodegradability.

Vegetable oil, which consists of monosaturated and polysaturated long-chain fatty acids, can be converted into vegetable oil-based polymer via polymerization reaction.110 Over the past few years, polymerization has been a common method for synthesizing vegetable oil-based polymers.137,138 Copolymerization of these resins with other materials yields products with comparable or better chemical and mechanical properties. Glass fibers (45%) were augmented with cationic copolymers of corn oil (COR), styrene (ST), and divinylbenzene (DVB). In this application, it was discovered that there was an increase in Young’s modulus, tensile strength, crosslinking density, and other mechanical properties of the composites.139 Earlier work140 fortified free radical resins consisting of: 50 wt% conjugated linseed oil, aliquots of DVB, and n-butyl methacrylate (BMA) with 20–80 wt% of corn stover. In this work, varying proportions of increasing corn stover and decreasing length of fiber boosted the overall mechanical properties with a corresponding decrease in thermal sturdiness. The reaction of Nahar seed oil monoglyceride with phthalic and/or maleic anhydride yielded polyesters with acceptable qualities for application as surface coatings and resin for composites.141,142

The most abundant natural phenolic polymer, lignin, is a complex class of organic molecules which are linked together with ether and limited carbon–carbon molecules in a spiral construction.143 They are primarily found in terrestrial plants, although some aquatic plants may be made up of lignin. Consequently, hardwood, softwood, fiber, grasses, and many plant materials contain varied compositions of lignin. They are alternatives to nonrenewable petroleum feedstocks in that they basically possess an alkyl–aryl–ether system of links, straight chain and aromatic hydroxyl groups, and low polydispersity. Major properties that determine the reactivity of lignin are attributed to the presence of hydroxyl, methoxy, carbonyl, and carboxyl functional groups. Reactions of lignin do occur under vigorous conditions, a property arising from the chemical stability of the polyphenolic group.144 Lignin extracts from composite materials have proven to be excellent coating materials as per earlier reports.145

The literature73 defined tannins as “inexpensive and ubiquitous natural polymers, polyphenolic secondary metabolites of higher plants mainly present in soft tissues (sheets, needles or bark).” They are unrefined, benign, biodegradable compounds containing more than one phenolic hydroxyl group. Sources of tannin include: diverse plant species,146 mangrove bark,22 wine wastes and chestnut peels,73 and forest exploitation wastes.98 They are divided into two main categories, namely hydrolyzable tannins (gallic acids easily hydrolyzed in acidic media) and condensable tannins, which are polymeric flavonoids.73 Tannins have various applications including their use as: corrosion inhibitors in aqueous media,147 constituents of rust convertors,146 pigments in paint coatings,13 natural antioxidants,148 tanning agents in the leather industry,98 and adhesives and polymers.147,149

Biodegradable antifouling paints as alternatives to TBT coatings

The use of TBT-based antifouling paints in the twentieth century was globally patronized until its ban in 2003 due to its effect on aquatic organisms. This consensus was reached globally after reports on higher concentrations of TBT in the coastal areas of many countries reached the International Maritime Organization in the early 1990s.65 The formulation, use, and degradation of TBT antifouling paints have been scrutinized from an environmental point of view, after their global approval as the most efficacious antifouling paints ever produced.60,150 This concern was attributed to the lifespan of TBT in the aquatic environment after its disposal, and the fact that it was exerting a negative influence on nontarget creatures. Studies and reviews have confirmed that even low levels of TBT kill or weaken other species in the aquatic system.3,51,53,150,151,–152

Antifouling paints are primarily made up of pigments and matrix polymer systems. A biodegradable antifouling paint should be composed of a biodegradable pigment and a biodegradable polymer or binder, among others. Such a system would be categorized as “completely biodegradable” since they are open to microbial and environmental mortification upon disposal without any negative environmental consequences.96,153 Marine industry players would appreciate the potential in biodegradable antifouling paints if they can deliver the same or better performance as conventional antifouling systems.150,154 Moreover, the biocides used in antifouling systems should have broad spectrum activity, low or no mammalian toxicity, and no bioaccumulation in the food chain.155

The formulation of antifouling paints with natural or biodegradable pigments and polymer composites has been reported. Researchers56 have formulated ecofriendly antifouling paints using biodegradable polymer and lower toxicity substances. When these precursors or substances were deployed in the biodegradable polymer, they provided antifouling protection against biofouling for several months. Also, reference (156) reported the preparation of novel antifouling paints made up of biodegradable polymer, which, when incorporated with butenolide, exhibited antifouling properties for over 3 months. Biodegradability of the polymer in seawater was enhanced in the presence of marine organisms. Natural resin (rosin) was incorporated into the system, and the resultant effect was an increased release of the butenolide. The general concern has to do with novel, low-cost, and biodegradable natural raw materials with effective or excellent antifouling properties in the formulation of antifouling coatings for combating marine biofouling without impacting nontargeted organisms.

Sustainable biobased products: new materials for a new economy

Sustainable chemistry (green chemistry) encompasses the use of less toxic precursors to formulate new products and processes without compromising the environment.157 With sustainable development, our focus covers not only current generations, but also puts measures in place to ensure the concerns of posterity are not compromised.158 Development today that does not jeopardize future development is the goal of all processes, ecosystems, communities, companies, and countries. The globe is now conscious of what is emitted into the environment and hence the inception of environmental legislation. Therefore, combating environmental problems should not only consider the ecofriendly starting materials but also the consequences of application of the product. Furthermore, there is the need to formulate “green antifouling coatings” using sustainable and environmentally friendly raw materials, with no or less dangerous influence on the environment. Going forward, in assessing the sustainability of a novel antifouling coating as compared to TBT-based coatings, the technology development time gap between TBT-based coatings and biobased antifouling paints should be considered.

Cost-effective biodegradable precursors or raw materials which would inform a long-term attainment of sustainability were recommended to replace the expensive conventional ones. Indeed, green antifouling paints with over 50% cheap natural raw materials would not only be cost-effective, but also possess other environmental advantages, thus economic and environmental sustainability. A firm foundation for developing novel and/or benign and emerging biobased antifouling coatings will depend on a good comprehension of natural pigments, polymers, and their basic formulation concepts.

Natural biobased antifouling coatings are likely to be environmentally superior to conventional TBT-based coatings. The reasons are not far-fetched: (a) Natural biobased antifouling coatings result in lower or no environmental impact; (b) natural, ecofriendly antifouling coatings, comprising higher biofiber, perform analogous antifouling like other conventional coatings, thus minimizing more toxic base polymer proportion; (c) synthesis, formulation, and application of natural, ecofriendly antifouling coatings is a new, cost-saving solution to an old problem.

Conclusions and future perspectives

To date, the marine industry is plagued with an old problem of biofouling. Several attempts have been made to solve this problem with new perspectives and concepts since it became a global concern in the nineteenth century. It has become necessary to develop environmentally benign antifouling coatings are developed as a means of finding a sustainable solution to this problem. Many researchers have recommended that green chemistry concepts are developed to highlight the use of biodegradable, natural precursors and other constituents in the development of new chemical compounds.

Contemporary environmental considerations have also justified the need to develop novel materials, policies, and procedures that will improve the quality of life, health, safety, and the environment. The inclusion of bio resources into these materials, policies, and procedures of today will meet these considerations and lessen extra reliance on TBT-based antifouling paints. Going forward, biodegradable and ecofriendly materials would become the best resort, with varied applications in the marine industry, because the production, use, and removal of these materials are not harmful to the environment. Natural materials are ecofriendly, biodegradable, cost-effective, and can be employed as precursors in the synthesis and formulation of biodegradable antifouling coatings. These products then can become an unrivaled portfolio of effective products to replace nonbiodegradable materials on the market—thus providing a means of introducing sustainable and safe biobased products into the market.

References

Ciriminna, R, Bright, FV, Pagliaro, M, “Ecofriendly Antifouling Marine Coatings.” ACS Sustain. Chem. Eng., 3 (4) 559–565 (2015)

McVay, IR, Maher, WA, Krikowa, F, Ubrhien, R, “Metal Concentrations in Waters, Sediments and Biota of the Far South-East Coast of New South Wales, Australia, with an Emphasis on Sn, Cu and Zn Used as Marine Antifoulant Agents.” Environ. Geochem. Health, 41 (3) 1351–1367 (2019)

Magin, CM, Cooper, SP, Brennan, AB, “Non-toxic Antifouling Strategies.” Materials Today, 13 (4) 36–44 (2010)

Ulaeto, SB, Rajan, R, Pancrecious, JK, Rajan, TPD, Pai, BC, “Developments in Smart Anticorrosive Coatings with Multifunctional Characteristics.” Prog. Org. Coat., 111 (1) 294–314 (2017)

Yebra, DM, Weinell, CE, “Key Issues in the Formulation of Marine Antifouling Paints.” In: Hellio, C, Yebra, D (eds.) Advances in Marine Antifouling Coatings and Technologies, pp. 308–333. Woodhead Publishing Limited, Sawston (2009)

Shevchenko, VY, Shilova, OA, Kochina, TA, “Environmentally Friendly Protective Coatings for Transport.” Her. Russ. Acad. Sci., 89 (3) 279–286 (2019)

IMO, “Focus on IMO: Anti-fouling Systems.” Int. Marit. Organ., 44 1–31 (2002)

Hemaida, HAE, Ali, AED, Sadek, SMM, “Potential Anti-Fouling Agents: Metal Complexes of 3-(2-Furylidene)hydrazino-5,6-diphenyl-1,2,4-triazine.” Pigment Resin Technol., 37 (4) 243–249 (2008)

Almeida, E, Diamantino, TC, de Sousa, O, “Marine Paints: The Particular Case of Antifouling Paints.” Prog. Org. Coat., 59 (1) 2–20 (2007)

Amara, I, Miled, W, Ben, Slama R, Ladhari, N, “Antifouling Processes and Toxicity Effects of Antifouling Paints on Marine Environment: A Review.” Environ. Toxicol. Pharmacol., 57 115–130 (2018)

Idora, MSN, Ferry, M, Wan Nik, WB, Jasnizat, S, “Evaluation of Tannin from Rhizophora apiculata as Natural Antifouling Agents in Epoxy Paint for Marine Application.” Prog. Org. Coat., 81 125–131 (2015)

Pérez, M, García, M, Blustein, G, “Evaluation of Low Copper Content Antifouling Paints Containing Natural Phenolic Compounds as Bioactive Additives.” Mar. Environ. Res., 109 177–184 (2015)

Bellotti, N, Deyá, C, Del Amo, B, Romagnoli, R, “Antifouling Paints with Zinc ‘Tannate’.” Ind. Eng. Chem. Res., 49 (7) 3386–3390 (2010)

Cao, S, Wang, JD, Chen, HS, Chen, DR, “Progress of Marine Biofouling and Antifouling Technologies.” Chinese Sci. Bull., 56 (7) 598–612 (2011)

Qian, P, Li, Z, Xu, Y, Li, Y, Fusetani, N, “Mini-review: Marine Natural Products and Their Synthetic Analogs as Antifouling Compounds: 2009–2014.” Biofouling, 31 (1) 101–122 (2015)

Ma, C, Zhang, W, Zhang, G, Qian, P, “Environmentally Friendly Antifouling Coatings Based on Biodegradable Polymer and Natural Antifoulant.” ACS Sustain. Chem. Eng., 5 (7) 6304–6309 (2017)

Rani, BEA, Basu, BBJ, “Green Inhibitors for Corrosion Protection of Metals and Alloys: An Overview.” Int. J. Corros. (2012). https://doi.org/10.1155/2012/380217

Escobar, A, et al., “Alkyl 2-Furoates Obtained by Green Chemistry Procedures as Suitable New Antifoulants for Marine Protective Coatings.” J. Coat. Technol. Res., 16 (1) 159–166 (2019)

Punitha, N, Saravanan, P, Mohan, R, Ramesh, PS, “Antifouling Activities of β-Cyclodextrin Stabilized Peg Based Silver Nanocomposites.” Appl. Surf. Sci., 392 126–134 (2017)

Verma, S, Mohanty, S, Nayak, SK, “A Review on Protective Polymeric Coatings for Marine Applications.” J. Coat. Technol. Res., 16 (2) 307–338 (2019)

Ytreberg, E, Karlsson, J, Eklund, B, “Comparison of Toxicity and Release Rates of Cu and Zn from Anti-fouling Paints Leached in Natural and Artificial Brackish Seawater.” Sci. Total Environ., 408 (12) 2459–2466 (2010)

Achmad, AB, Synthesis of Metal-Tannate Complexes and Their Application as Antifoulant for Fish Cage Neys. University of Malaysia, Kuala Lumpur (2016)

Zhang, X, et al., “An Eco- and User-Friendly Herbicide.” J. Agric. Food Chem., 67 (28) 7783–7792 (2019)

Lee, MRN, Kim, UJ, Lee, IS, Choi, M, Oh, JE, “Assessment of Organotin and Tin-Free Antifouling Paints Contamination in the Korean Coastal Area.” Mar. Pollut. Bull., 99 (1–2) 157–165 (2015)

Lagerström, M, Yngsell, D, Eklund, B, Ytreberg, E, “Identification of Commercial and Recreational Vessels Coated with Banned Organotin Paint Through Screening of Tin by Portable XRF.” J. Hazard. Mater., 362 (September 2018) 107–114 (2019)

Nurioglu, AG, Esteves, ACC, de With, G, “Non-toxic, Non-biocide-Release Antifouling Coatings Based on Molecular Structure Design for Marine Applications.” J. Mater. Chem. B, 3 (32) 6547–6570 (2015)

Gopikrishnan, V, Radhakrishnan, M, Pazhanimurugan, R, Shanmugasundaram, T, Balagurunathan, R, “Natural Products: Potential and Less Explored Source for Antifouling Compounds.” J. Chem. Pharm. Res., 7 (7) 1144–1153 (2015)

Selim, MS, El-safty, SA, Shenashen, MA, Superhydrophobic Foul Resistant and Self-cleaning Polymer Coating. Elsevier, Amsterdam (2019)

Telegdi, J, Trif, L, Roma, L, “Smart Anti-biofouling Composite Coatings for Naval Applications.” In: Telegdi, J, Trif, L, Románszki, L (eds.) Composites Science and Engineering, pp. 123–155. Woodhead Publishing Limited, Sawston (2015)

Yan, T, Yan, WX, “Fouling of Offshore Structures in China—A Review.” Biofouling, 19 (supp 1) 133–138 (2003)

Palanichamy, S, Subramanian, G, “Antifouling Properties of Marine Bacteriocin Incorporated Epoxy Based Paint.” Prog. Org. Coat., 103 33–39 (2017)

Garcia, M, Stupak, M, Perez, M, Blustein, G, “Transitioning to Nontoxic Antifouling Paints.” Pigment Resin Technol., 44 (2) 116–121 (2015)

Li, Y, Ning, C, “Latest Research Progress of Marine Microbiological Corrosion and Bio-fouling, and New Approaches of Marine Anti-corrosion and Anti-fouling.” Bioact. Mater., 4 (December) 189–195 (2019)

Selim, MS, et al., “Modeling of Spherical Silver Nanoparticles in Silicone-Based Nanocomposites for Marine Antifouling.” RSC Adv., 5 (78) 63175–63185 (2015)

Detty, MR, Ciriminna, R, Bright, FV, Pagliaro, M, “Environmentally Benign Sol–Gel Antifouling and Foul-Releasing Coatings.” Acc. Chem. Res., 47 678–687 (2014)

Al-Fori, M, Dobretsov, S, Myint, MTZ, Dutta, J, “Antifouling Properties of Zinc Oxide Nanorod Coatings.” Biofouling, 30 (7) 871–882 (2014)

Yang, WJ, Neoh, KG, Kang, ET, Teo, SLM, Rittschof, D, “Polymer Brush Coatings for Combating Marine Biofouling.” Prog. Polym. Sci., 39 (5) 1017–1042 (2014)

Pugazhendhi, A, Prabakar, D, Jacob, JM, Karuppusamy, I, Saratale, RG, “Synthesis and Characterization of Silver Nanoparticles Using Gelidium amansii and Its Antimicrobial Property Against Various Pathogenic Bacteria.” Microb. Pathog., 114 41–45 (2018)

Burlibaşa, L, et al, “Synthesis, Physico-Chemical Characterization, Antimicrobial Activity and Toxicological Features of Ag ZnO Nanoparticles.” Arab. J. Chem. (2019). https://doi.org/10.1016/j.arabjc.2019.06.015

Abed, RMM, Al Fahdi, D, Muthukrishnan, T, “Short-term Succession of Marine Microbial Fouling Communities and the Identification of Primary and Secondary Colonizers.” Biofouling, 35 526–540 (2019)

Legg, M, Yücel, MK, Garcia De Carellan, I, Kappatos, V, Selcuk, C, Gan, TH, “Acoustic Methods for Biofouling Control: A Review.” Ocean Engineering, 103 237–247 (2015)

Chapman, J, et al., “Bioinspired Synthetic Macroalgae: Examples from Nature for Antifouling Applications.” Int. Biodeterior. Biodegrad., 86 6–13 (2014)

Page, HM, Dugan, JE, Piltz, F, Fouling and Antifouling in Oil and Other Offshore Industries, pp. 252–266. Blackwell Publishing Ltd, Hoboken, NJ (2010)

Moodie, LWK, et al., “Prevention of Marine Biofouling Using the Natural Allelopathic Compound Batatasin-III and Synthetic Analogues.” J. Nat. Prod., 80 (7) 2001–2011 (2017)

Azemar, F, Faÿ, F, Réhel, K, Linossier, I, “Development of Hybrid Antifouling Paints.” Prog. Org. Coat., 87 10–19 (2015)

Agostini, VO, Macedo, AJ, Muxagata, E, da Silva, MV, Pinho, GLL, “Natural and Non-toxic Products from Fabaceae Brazilian Plants as a Replacement for Traditional Antifouling Biocides: An Inhibition Potential Against Initial Biofouling.” Environ. Sci. Pollut. Res., 26 (26) 27112–27127 (2019)

Pradhan, S, Kumar, S, Mohanty, S, Nayak, SK, “Environmentally Benign Fouling-Resistant Marine Coatings: A Review.” Polym. Technol. Mater., 58 (5) 498–518 (2019)

Le Norcy, T, et al., “Anti-biofilm Effect of Biodegradable Coatings Based on Hemibastadin Derivative in Marine Environment.” Int. J. Mol. Sci., 18 (1520) 1–19 (2017)

Rossini, P, Napolano, L, Matteucci, G, “Biotoxicity and Life Cycle Assessment of Two Commercial Antifouling Coatings in Marine Systems.” Chemosphere, 237 124475 (2019)

Lagerström, M, Lindgren, JF, Holmqvist, A, Dahlström, M, Ytreberg, E, “In Situ Release Rates of Cu and Zn from Commercial Antifouling Paints at Different Salinities.” Mar. Pollut. Bull., 127 (December 2017) 289–296 (2018)

Guardiola, FA, Cuesta, A, Meseguer, J, Esteban, MA, “Risks of Using Antifouling Biocides in Aquaculture.” Int. J. Mol. Sci., 13 (2) 1541–1560 (2012)

Antizar-Ladislao, B, “Environmental Levels, Toxicity and Human Exposure to Tributyltin (TBT)-Contaminated Marine Environment: A Review.” Environ. Int., 34 292–308 (2008)

Bray, S, Langston, W, Tributyltin Pollution on a Global Scale: An Overview of Relevant and Recent Research: Impacts and Issues. WWF, Godalming (2006)

Qian, P, Chen, L, Xu, Y, “Mini-review: Molecular Mechanisms of Antifouling Compounds.” Biofouling J. Bioadhesion Biofilm Res., 29 (4) 381–400 (2013)

Gibbs, PE, Bryan, GW, Pascoe, PL, Burt, GR, “The Use of the Dogwhelk, Nucella lapillus, as an Indicator of Tributyltin (TBT) Contamination.” J. Mar. Biol. Assoc. United Kingdom, 67 (3) 507–523 (1987)

Carteau, D, et al., “Development of Environmentally Friendly Antifouling Paints Using Biodegradable Polymer and Lower Toxic Substances.” Prog. Org. Coat., 77 (2) 485–493 (2014)

Peres, RS, Armelin, E, Moreno-Martínez, JA, Alemán, C, Ferreira, CA, “Transport and Antifouling Properties of Papain-Based Antifouling Coatings.” Appl. Surf. Sci., 341 75–85 (2015)

Lindholdt, A, Dam-Johansen, K, Olsen, SM, Yebra, DM, Kiil, S, “Effects of Biofouling Development on Drag Forces of Hull Coatings for Ocean-Going Ships: A Review.” J. Coat. Technol. Res, 12 415–444 (2015)

Pei, X, Ye, Q, “Development of Marine Antifouling Coatings.” In: Zhou, F (ed.) Antifouling Surfaces and Materials, pp. 135–149. Springer, Berlin, Heidelberg (2015)

Satheesh, S, Ba-Akdah, MA, Al-Sofyani, AA, “Natural Antifouling Compound Production by Microbes Associated with Marine Macroorganisms—A Review.” Electron. J. Biotechn., 21 (2015) 26–35 (2016)

Feng, K, Ni, C, Yu, L, Zhou, W, Li, X, “Synthesis and Antifouling Evaluation of Indole Derivatives.” Ecotoxicol. Environ. Saf., 182 (1) 109423 (2019)

Del Grosso, CA, McCarthy, TW, Clark, CL, Cloud, JL, Wilker, JJ, “Managing Redox Chemistry to Deter Marine Biological Adhesion.” Chem. Mater., 28 (18) 6791–6796 (2016)

Saxena, P, Joshi, Y, Rawat, K, Bisht, R, “Biofilms: Architecture, Resistance, Quorum Sensing and Control Mechanisms.” Indian J. Microbiol., 59 (1) 3–12 (2019)

Nir, S, Reches, M, “Bio-inspired Antifouling Approaches: The Quest Towards Non-toxic and Non-biocidal Materials.” Curr. Opin. Biotechnol., 39 (Figure 2) 48–55 (2016)

Zhou, F, Antifouling Surfaces and Materials. Springer, New York (2015)

Leonardi, AK, Ober, CK, “Polymer-Based Marine Antifouling and Fouling Release Surfaces: Strategies for Synthesis and Modification.” Annu. Rev. Chem. Biomol. Eng., 10 (1) 241–264 (2019)

Bao, Q, Xie, L, Ohashi, H, Hosomi, M, Terada, A, “Inhibition of Agrobacterium Tumefaciens Biofilm Formation by Acylase I-Immobilized Polymer Surface Grafting of a Zwitterionic Group-Containing Polymer Brush.” Biochem. Eng. J., 152 (May) 107372 (2019)

Antunes, J, et al., “A Multi-bioassay Integrated Approach to Assess the Antifouling Potential of the Cyanobacterial Metabolites Portoamides.” Mar. Drugs, 17 (2) 1–19 (2019)

Almeida, JR, Vasconcelos, V, “Natural Antifouling Compounds: Effectiveness in Preventing Invertebrate Settlement and Adhesion.” Biotechnol. Adv., 33 (3–4) 343–357 (2015)

Condren, AR, Kahl, LJ, Kritikos, G, Banzhaf, M, Dietrich, LEP, Sanchez, LM, “Biofilm Inhibitor Taurolithocholic Acid Alters Colony Morphology, Specialized Metabolism, and Virulence of Pseudomonas aeruginosa.” bioRxiv (2019). https://doi.org/10.1101/675405

Prakash, S, Ahila, NK, Sri Ramkumar, V, Ravindran, J, Kannapiran, E, “Antimicrofouling Properties of Chosen Marine Plants: An Eco-friendly Approach to Restrain Marine Microfoulers.” Biocatal. Agric. Biotechnol., 4 (1) 114–121 (2015)

Pérez, M, García, M, Blustein, G, Stupak, M, “Tannin and Tannate from the Quebracho Tree: An Eco-friendly Alternative for Controlling Marine Biofouling.” Biofouling, 23 (3) 151–159 (2007)

Bacelo, HAM, Santos, SCR, Botelho, CMS, “Tannin-Based Biosorbents for Environmental Applications—A Review.” Chem. Eng. J., 303 575–587 (2016)

Pérez, M, García, M, Ruiz, D, Autino, J, Romanelli, G, Blustein, G, “Antifouling Activity of Green-Synthesized 7-Hydroxy-4-Methylcoumarin.” Mar. Environ. Res., 113 134–140 (2016)

Fusetani, N, “Antifouling Marine Natural Products.” Nat. Prod. Rep., 28 (2) 400–410 (2011)

Stupak, ME, Garcã, T, Pã, MC, “Non-toxic Alternative Compounds for Marine Antifouling Paints.” Int. Biodeterior. Biodegradation, 52 49–52 (2003)

Peres, RS, Baldissera, AF, Armelin, E, Alemán, C, Ferreira, CA, “Marine-Friendly Antifouling Coating Based on the Use of a Fatty Acid Derivative as a Pigment.” Mater. Res., 17 (3) 720–727 (2014)

Larrauri, M, Zunino, MP, Zygadlo, JA, Grosso, NR, Nepote, V, “Chemical Characterization and Antioxidant Properties of Fractions Separated from Extract of Peanut Skin Derived from Different Industrial Processes.” Ind. Crops Prod., 94 964–971 (2016)

Yakub, MK, Bello, MSGKAO, Oforghor, AO, “The Performance of 2-Nitroso-1-Naphthol Chelating Pigment in Paint Formulation with Gum Arabic and Polyvinyl Acetate as Binders, Paper I: UV–Visible Spectroscopy, Viscosity and Breaking Stress of the Paints.” African J. Sci. Technol., 8 (1) 28–38 (2007)

Bao, Z, et al, “Process for Preparing High-Purity l-Arabinose by Using Arabic Gum as Raw Material.” Patent no: US010308674B2 (2019). https://patentimages.storage.googleapis.com/88/7d/b6/80d2f275def825/US10308674.pdf

Onyenekenwa, C, A Guide for the Paint Maker, 2nd ed. Welfare & Industrial Promotions (WIPRO) International, Enugu (2016)

Sanyal, B, “Organic Compounds as Corrosion Inhibitors in Different Environments—A Review.” Prog. Org. Coat., 9 (2) 165–236 (1981)

Mohammadian, M, Sahraei, R, Ghaemy, M, “Synthesis and Fabrication of Antibacterial Hydrogel Beads Based on Modified-Gum Tragacanth/Poly(vinyl alcohol)/Ag0 Highly Efficient Sorbent for Hard Water Softening.” Chemosphere, 225 259–269 (2019)

Gadkari, PV, Balaraman, M, “Catechin: Sources, Extraction and Encapsulation: A Review.” Food Bioprod. Process., 93 122–138 (2015)

Srivastava, R, Srivastava, D, “Mechanical, Chemical, and Curing Characteristics of Cardanol—Furfural-Based Novolac Resin for Application in Green Coatings.” J. Coat. Technol. Res., 12 (2) 303–311 (2015)

Callow, JA, Callow, ME, “Trends in the Development of Environmentally Friendly Fouling-Resistant Marine Coatings.” Nat. Commun., 2 (1) 244 (2011)

Carve, M, Scardino, A, Shimeta, J, “Effects of Surface Texture and Interrelated Properties on Marine Biofouling: A Systematic Review.” Biofouling (2019). https://doi.org/10.1080/08927014.2019.1636036

da Gama, BAP, Plouguerné, E, Pereira, RC, “The Antifouling Defence Mechanisms of Marine Macroalgae.” In: Jacquot, J-P, Gadal, P, Bourgougnon, N (eds.) Advances in Botanical Research, vol. 71, pp. 413–440. Elsevier, Amsterdam (2014)

Higaki, Y, Kobayashi, M, Murakami, D, Takahara, A, “Anti-fouling Behavior of Polymer Brush Immobilized Surfaces.” Polym. J., 48 (4) 325–331 (2016)

Yandi, W, et al., “Charged Hydrophilic Polymer Brushes and Their Relevance for Understanding Marine Biofouling.” Biofouling, 32 (6) 609–625 (2016)

Gao, K, et al., “Creation of Active-Passive Integrated Mechanisms on Membrane Surfaces for Superior Antifouling and Antibacterial Properties.” J. Memb. Sci., 548 621–631 (2018)

Hibbs, MR, Hernandez-Sanchez, BA, Daniels, J, Stafslien, SJ, “Polysulfone and Polyacrylate-Based Zwitterionic Coatings for the Prevention and Easy Removal of Marine Biofouling.” Biofouling, 31 (7) 613–624 (2015)

Brzozowska, AM, et al., “Effect of Variations in Micropatterns and Surface Modulus on Marine Fouling of Engineering Polymers.” ACS Appl. Mater. Interfaces, 9 (20) 17508–17516 (2017)

Acevedo, MS, et al., “Antifouling Paints Based on Marine Natural Products from Colombian Caribbean.” Int. Biodeterior. Biodegrad., 83 97–104 (2013)

Xie, Q, Xie, Q, Pan, J, Ma, C, Zhang, G, “Biodegradable Polymer with Hydrolysis Induced Zwitterions for Antibiofouling.” ACS Appl. Mater. Interfaces, 10 (13) 11213–11220 (2018)

Mohanty, A, Misra, M, Drzal, L, Selke, S, Harte, B, Hinrichsen, G, “Natural Fibers, Biopolymers, and Biocomposites.” In: Mohanty, AK, Misra, M, Drzal, LT (eds.) Natural Fibers, Biopolymers, and Biocomposites. Taylor & Francis, London (2010)

Doppalapudi, S, Jain, A, Khan, W, Domb, AJ, “Biodegradable Polymers—An Overview.” Polym. Adv. Technol., 25 (5) 427–435 (2014)

Lochab, B, Shukla, S, Varma, IK, “Naturally Occurring Phenolic Sources: Monomers and Polymers.” RSC Adv., 4 (42) 21712–21752 (2014)

Sumrith, N, Rangappa, SM, “Biopolymers-Based Nanocomposites: Properties and Applications.” In: Sanyang, ML, Jawaid, M (eds.) Bio-based Polymers and Nanocomposites, pp. 255–272. Springer, Cham (2019)

Katarzyna, L, Grazyna, L, “Polymer Biodegradation and Biodegradable Polymers—A Review.” Polish J. Environ. Stud., 19 (2) 255–266 (2010)

Hu, Q, Luo, Y, “Polyphenol-Chitosan Conjugates: Synthesis, Characterization, and Applications.” Carbohydr. Polym., 151 624–639 (2016)

Chen, S, Ma, C, Zhang, G, “Biodegradable Polymers for Marine Antibiofouling: Poly(ε-Caprolactone)/Poly(Butylene Succinate) Blend as Controlled Release System of Organic Antifoulant.” Polymer (Guildf), 90 215–221 (2016)

Tosin, M, Pischedda, A, Degli-Innocenti, F, “Biodegradation Kinetics in Soil of a Multi-constituent Biodegradable Plastic.” Polym. Degrad. Stab., 166 213–218 (2019)

Mothé, CG, Vieira, CR, Mothé, MG, “Thermal and Surface Study of Phenolic Resin From Cashew Nut Shell Liquid Cured by Plasma Treatment.” J. Therm. Anal. Calorim., 114 (2) 821–826 (2013)

Balgude, D, Sabnis, AS, “CNSL: An Environment Friendly Alternative for the Modern Coating Industry.” J. Coat. Technol. Res., 11 (2) 169–183 (2014)

Lomonaco, D, Giuseppe, M, Mazzetto, S, “Cashew Nut Shell Liquid: A Goldfield for Functional Materials.” In: Anilkumar, P (ed.) Cashew Nut Shell Liquid: A Goldfield for Functional Materials, pp. 1–230. Springer, New York (2017)

Jaillet, F, Darroman, E, Ratsimihety, A, Auvergne, R, Boutevin, B, Caillol, S, “New Biobased Epoxy Materials from Cardanol.” Eur. J. Lipid Sci. Technol., 116 (1) 63–73 (2014)

Andrews, SGJ, Rama, V, Mythili, CV, “Synthesis and Characterization of Polymer Resins from Renewable Resource.” Int. J. Plast. Technol., 21 (2) 427–443 (2017)

Taiwo, EA, “Cashew Nut Shell Oil—A Renewable and Reliable Petrochemical Feedstock.” In: Advances in Petrochemicals, pp. 3–26 (2015). https://doi.org/10.5772/61096

Quirino, RL, Garrison, TF, Kessler, MR, “Matrices from Vegetable Oils, Cashew Nut Shell Liquid, and Other Relevant Systems for Biocomposite Applications.” Green Chemistry, 16 (4) 1700–1715 (2014)

Vedharaj, S, Vallinayagam, R, Yang, WM, Saravanan, CG, Roberts, WL, “Synthesis and Utilization of Catalytically Cracked Cashew Nut Shell Liquid in a Diesel Engine.” Exp. Therm. Fluid Sci., 70 316–324 (2016)

Telascrêa, M, Leão, AL, Ferreira, MZ, Pupo, HFF, Cherian, BM, Narine, S, “Use of a Cashew Nut Shell Liquid Resin as a Potential Replacement for Phenolic Resins in the Preparation of Panels—A Review.” Mol. Cryst. Liq. Cryst., 604 (1) 222–232 (2014)

Mahanwar, PA, Kale, DD, “Effect of Cashew Nut Shell Liquid (CNSL) on Properties of Phenolic Resins.” J. Appl. Polym. Sci., 61 (12) 2107–2111 (1996)

Ikwuagwu, C, “Design and Construction of Cashew Nut Shell Liquid Extractor.” (2008). https://doi.org/10.13140/RG.2.1.1110.0248

Gedam, PH, Sampathkumaran, PS, “Cashew Nut Shell Liquid: Extraction, Chemistry and Applications.” Prog. Org. Coat., 14 (2) 115–157 (1986)

Wazarkar, K, Sabnis, A, “Cardanol Based Anhydride Curing Agent for Epoxy Coatings.” Prog. Org. Coat., 118 (August 2017) 9–21 (2018)

Edoga, MO, Fadipa, L, Edoga, RN, “Extraction of Polyphenols from Cashew Nut Shell.” Leonardo Electron. J. Pract. Technol., 5 (9) 107–112 (2006)

Kathalewar, M, Sabnis, A, D’Melo, D, “Polyurethane Coatings Prepared from CNSL Based Polyols: Synthesis, Characterization, and Properties.” Prog. Org. Coat., 77 (3) 616–626 (2014)

Sheng, C, Wenting, B, Shijian, T, Yuechuan, W, “Preparation of Cardanol-Formaldehyde Resins from Cashew Nut Shell Liquid for the Reinforcement of Natural Rubber.” Appl. Polym. Sci., 104 1997–2002 (2008)

Ugoamadi, CC, “Comparison of Cashew Nut Shell Liquid (CNS) Resin with Polyester Resin in Composite Development.” Niger. J. Technol. Dev., 10 (2) 17–21 (2013)

Lubi, MC, Thachil, ET, “Cashew Nut Shell Liquid (CNSL)—A Versatile Monomer for Polymer Synthesis.” Des. Monomers Polym., 3 (2) 123–153 (2000)

Sharma, SK, et al., “Chemical Characterization and Antioxidant Properties of Fractions Separated from Extract of Peanut Skin Derived from Different Industrial Processes.” J. Appl. Polym. Sci., 73 (2) 1–10 (2015)

Tawade, BV, Salunke, JK, Sane, PS, Wadgaonkar, PP, “Processable Aromatic Polyesters Based on Bisphenol Derived from Cashew Nut Shell Liquid: Synthesis and Characterization.” J. Polym. Res., 21 (12) 1–10 (2014)

Mubofu, EB, “From Cashew Nut Shell Wastes to High Value Chemicals.” Pure Appl. Chem., 88 (1–2) 17–27 (2016)

Sahoo, SK, Swain, SK, Mohapatra, DK, Nayak, PL, Lenka, S, “Polymers from Renewable Resources, V. Synthesis and Characterization of Thermosetting Resins Derived from Cashew Nut Shell Liquid (CNSL)—Furfural-Substituted Aromatic Compounds.” J. Appl. Polym. Sci., 54 1413–1421 (1994)

Gandhi, T, Patel, M, Dholakiya, BK, “Studies on Effect of Various Solvents on Extraction of Cashew Nut Shell Liquid (CNSL) and Isolation of Major Phenolic Constituents From Extracted CNSL.” J. Nat. Prod. Plant Resour., 2 (1) 135–142 (2012)

Gandhi, TS, Dholakiya, BZ, Patel, MR, “Extraction Protocol for Isolation of CNSL by Using Protic and Aprotic Solvents from Cashew Nut and Study of Their Physico-Chemical Parameter.” Polish J. Chem. Technol., 15 (4) 24–27 (2013)

Li, C, Yu, H, Li, F, Zhang, Z, Huang, J, Wang, J, “Physicochemical Properties of Series of Cardanol Polyoxyethylene Ether Carboxylates with Different Ethoxylation Unit at the Interface.” J. Dispers. Sci. Technol., 40 (1) 9–16 (2018)

Keetasombat, K, Soykeabkaew, N, “Coating Based on Cashew Nut Shell Liquid Resin.” 26th Annu. Meet. Thai Soc. Biotechnol. Int. Conf. pp. 145–153, 2014

Jaillet, F, Nouailhas, H, Boutevin, B, Caillol, S, “Synthesis of Novel Bio-based Vinyl Ester from Dicyclopentadiene Prepolymer, Cashew Nut Shell Liquid, and Soybean Oil.” Eur. J. Lipid Sci. Technol., 118 (9) 1336–1349 (2016)

Kanehashi, S, Masuda, R, Yokoyama, K, Kanamoto, T, Nakashima, H, Miyakoshi, T, “Development of a Cashew Nut Shell Liquid (CNSL)-Based Polymer for Antibacterial Activity.” J. Appl. Polym. Sci., 132 (45) 1–9 (2015)

Campaner, P, D’Amico, D, Longo, L, Stifani, C, Tarzia, A, “Cardanol-Based Novolac Resins as Curing Agents of Epoxy Resins.” Polym. Polym. Compos., 114 3585–3591 (2009)

Aggarwal, LK, Thapliyal, PC, Karade, SR, “Anticorrosive Properties of the Epoxy-Cardanol Resin Based Paints.” Prog. Org. Coat., 59 (1) 76–80 (2007)

Pathak, SK, Rao, BS, “Structural Effect of Phenalkamines on Adhesive Viscoelastic and Thermal Properties of Epoxy Networks.” J. Appl. Polym. Sci., 102 4741–4748 (2006)

Kim, Y, An Suk, E, Park Young, S, Song Keun, B, “Enzymatic Epoxidation and Polymerization of Cardanol Obtained from a Renewable Resource and Curing of Epoxide-Containing Polycardanol.” J. Molecular Catal. B Enzym., 45 39–44 (2007)

Tan, MT, Nieu, HN, “Carbon Fiber Cardanol-Epoxy Composites.” J. Appl. Polym. Sci., 61 133–137 (1996)

Bhunia, HP, Nandoa, GB, Chakia, TK, Nando, GB, “Synthesis and Characterization of Polymers from Cashewnut Shell Liquid (CNSL), A Renewable Resource II. Synthesis of Polyurethanes.” Eur. Polym. J., 35 (8) 1381–1391 (1999)

Mukherjee, S, Ghosh, M, “Performance Evaluation and Biodegradation Study of Polyvinyl Chloride Films with Castor Oil-based Plasticizer.” J. Am. Oil Chem. Soc. (2019). https://doi.org/10.1002/aocs.12294

Lu, Y, Larock, RC, “Corn Oil-Based Composites Reinforced with Continuous Glass Fibers: Fabrication and Properties.” J. Appl. Polym. Sci., 102 (4) 3345–3353 (2006)

Larock, RC, Natural Oil-Based Composites Reinforced with Natural Fillers, and Conjugation/Isomerization of Carbon–Carbon Double Bonds. Iowa State University, Iowa (2011)

Dutta, N, Karak, N, Dolui, SK, “Synthesis and Characterization of Polyester Resins Based on Nahar Seed Oil.” Prog. Org. Coat., 49 (2) 146–152 (2004)

Flores, S, Flores, A, Calderón, C, Obregón, D, “Synthesis and Characterization of Sacha Inchi (Plukenetia volubilis L.) Oil-Based Alkyd Resin.” Prog. Org. Coat., 136 (1) 105289 (2019)

Vanholme, R, De Meester, B, Ralph, J, Boerjan, W, “Lignin Biosynthesis and Its Integration into Metabolism.” Curr. Opin. Biotechnol., 56 (Table 1) 230–239 (2019)

Rautiainen, S, Di Francesco, D, Katea, SN, Westin, G, Tungasmita, DN, Samec, JSM, “Lignin Valorization by Cobalt-Catalyzed Fractionation of Lignocellulose to Yield Monophenolic Compounds.” ChemSusChem, 12 (2) 404–408 (2018)

Vaithilingam, S, Jayanthi, J, Muthukaruppan, A, “Synthesis and Characterization of Cardanol Based Fluorescent Composite for Optoelectronic and Antimicrobial Applications.” Polymer (Guildf)., 108 449–461 (2017)

Rahim, AA, Rocca, E, Steinmetz, J, Kassim, MJ, Adnan, R, Sani Ibrahim, M, “Mangrove Tannins and Their Flavanoid Monomers as Alternative Steel Corrosion Inhibitors in Acidic Medium.” Corros. Sci., 49 (2) 402–417 (2007)

Peres, RS, Armelin, E, Alemán, C, Ferreira, CA, “Modified Tannin Extracted from Black Wattle Tree as an Environmentally Friendly Antifouling Pigment.” Ind. Crops Prod., 65 506–514 (2015)

Altemimi, A, Lakhssassi, N, Baharlouei, A, Watson, D, Lightfoot, D, “Phytochemicals: Extraction, Isolation, and Identification of Bioactive Compounds from Plant Extracts.” Plants, 6 (4) 42 (2017)

Vladimir-Knežević, S, Blažeković, B, Štefan, MB, Babac, M, Plant Polyphenols as Antioxidants Influencing the Human Health. In: Rao, V (ed.) Phytochemicals as Nutraceuticals—Global Approaches to Their Role in Nutrition and Health, pp. 155–180, ISBN: 978-953-51-0203-8, China: InTech (2012)

Hutzinger, O, Antifouling Paints Biocides, 5th ed. Springer, Berlin (2006)

Gutner-Hoch, E, et al., “Antimacrofouling Efficacy of Innovative Inorganic Nanomaterials Loaded with Booster Biocides.” J. Mar. Sci. Eng., 6 (1) 6 (2018)

de Oliveira, M, et al., “Disruptive Effect of Organotin on Thyroid Gland Function Might Contribute to Hypothyroidism.” Int. J. Endocrinol., (2019). https://doi.org/10.1155/2019/7396716

Dai, G, Xie, Q, Ma, C, Zhang, G, “Biodegradable Poly(Ester-co-Acrylate) with Antifoulant Pendant Groups for Marine Anti-biofouling.” ACS Appl. Mater. Interfaces, 11 (12) 11947–11953 (2019)

Faÿ, F, Gouessan, M, Linossier, I, Réhel, K, “Additives for Efficient Biodegradable Antifouling Paints.” J. Mol. Sci., Int. (2019). https://doi.org/10.3390/ijms20020361

Vesco, S, Aversa, C, Puopolo, M, Barletta, M, “Advances in Design and Manufacturing of Environmentally Friendly and Biocide-Free Antifouling/Foul-Release Coatings: Replacement of Fluorinate Species.” J. Coat. Technol. Res., 16 (3) 661–680 (2019)

Al-Naamani, L, Dobretsov, S, Dutta, J, Burgess, JG, “Chitosan-Zinc Oxide Nanocomposite Coatings for the Prevention of Marine Biofouling.” Chemosphere, 168 408–417 (2017)

Verma, C, Ebenso, EE, Quraishi, MA, “Ionic Liquids as Green and Sustainable Corrosion Inhibitors for Metals and Alloys: An Overview.” J. Mol. Liq., 233 403–414 (2017)

Haugh, H, Kim, A, Bansal, P, “No Time Like the Present: How a Present Time Perspective Can Foster Sustainable Development.” Acad. Manag. J., 62 (2) 607–634 (2019)

Funding

Funding was provided by World Bank Group.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kyei, S.K., Darko, G. & Akaranta, O. Chemistry and application of emerging ecofriendly antifouling paints: a review. J Coat Technol Res 17, 315–332 (2020). https://doi.org/10.1007/s11998-019-00294-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-019-00294-3