Abstract

To compensate the drawback of most kinematic hardening rules that exhibit hardening saturation, a solution is proposed by replacing the accumulated plastic strain rate in the springback term by a rate related to the kinematic hardening variable itself. The proposed approach defines a power-law counterpart to the linear (Prager) and exponential (Armstrong-Frederick) laws.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Kinematic Hardening

- Accumulated Plastic Strain

- Deviatoric Plastic Strain Rate

- Armstrong-Frederick Rule

- Monotonic Stress-strain Response

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Most modern nonlinear kinematic hardening rules in metals plasticity have the generic form

with \(\mathbf{X}\) the kinematic hardening, \(p\) the accumulated plastic strain, \({ {\varvec{\sigma }}}\) the stress, \(\dot{{ {\varvec{\varepsilon }}}}^p\) the plastic strain rate, \(C\) a material parameter, and where the springback term \({\varvec {\fancyscript{B}}} \dot{\fancyscript{P}}\) is sometimes replaced by a sum \(\sum {\varvec {\fancyscript{B}}}_k \dot{\fancyscript{P}}_k\). The scalar function \(\dot{\fancyscript{P}}\) (as \(\dot{\fancyscript{P}}_k\)) is a homogeneous function of degree 1 in \(\dot{{ {\varvec{\varepsilon }}}}^p\), such as \(\dot{\fancyscript{P}}(\mathbf{X}, { {\varvec{\sigma }}}, \lambda \dot{{ {\varvec{\varepsilon }}}}^p)= \lambda \dot{\fancyscript{P}}(\mathbf{X}, { {\varvec{\sigma }}}, \dot{{ {\varvec{\varepsilon }}}}^p)\) \(\forall \lambda \ge 0\). The tensorial function \({\varvec {\fancyscript{B}}}\) has usually the sign of \(\mathbf{X}\) and \(\Vert {\varvec {\fancyscript{B}}}\Vert \) increases when the loading increases (in norm). This last feature gives back the concave shape of stress-strain curves for metals.

For instance, this is the form of Armstrong-Frederick rule [1],

with \(\gamma \) a material parameter, but also of Burlet-Cailletaud rule [2], of Chaboche rule [3] and of Ohno-Wang rule [9]. The normal \(\mathbf{n}=\frac{\partial f}{\partial { {\varvec{\sigma }}}}\) of the yield surface \(f=0\) is used in some models,Footnote 1 it is a function of the stress \({ {\varvec{\sigma }}}\) and of the kinematic hardening \(\mathbf{X}\), the plastic strain rate reading then \(\dot{{ {\varvec{\varepsilon }}}}^p=\dot{p}\,\mathbf{n}({ {\varvec{\sigma }}}, \mathbf{X})\).

In uniaxial monotonic tension the generic law (1) simplifies in \(\dot{X}=(C-B) \dot{\varepsilon }_p\), with \(B\) a positive increasing nonlinear function, rate independent. One observes then that a saturation \(\dot{X}=0\), \(X=X_{\infty }=\textit{Const}\), is reached for all rules ensuring \(B\rightarrow C\) at high loading.

Different possibilities to avoid such a saturation of the kinematic hardening exist: make \(\gamma =\gamma (p)\) a decreasing (to zero) function of the accumulated plastic strain as in [8], make \(C\) dependent of the plastic strain amplitude, through an index function written in the strain space, as in [6]. None recover the power law shape at high plastic strains. Simple ways to naturally gain the non saturation of the kinematic hardening have been proposed in [5]. They allows to define for kinematic hardening a power law counterpart to the usual exponential law.

2 A First Family of Non Saturating Kinematic Hardening Rules

Kinematic hardening \(\mathbf{X}\) is a thermodynamics force associated with a tensorial internal state variable denoted \({ {\varvec{\alpha }}}\), homogeneous to a strain. It is often derived from a quadratic thermodynamics potential as [7]

where \(C\) is the hardening parameter previously introduced, temperature dependent. Initially isotropic and plastically incompressible materials are considered next, with then the expression \(p=\int {(\frac{2}{3}\dot{{ {\varvec{\varepsilon }}}}^p:\dot{{ {\varvec{\varepsilon }}}}^p)^{1/2}\mathrm{d } t}\) for the accumulated plastic strain and with \({ {\varvec{\varepsilon }}}^p={{ {\varvec{\varepsilon }}}^p}^{\prime }\) the deviatoric plastic strain rate. In Prager law of linear hardening the internal variable \({ {\varvec{\alpha }}}\) is equal to \({ {\varvec{\varepsilon }}}^p\). In case of (anisothermal) Armstrong-Frederick rule it is given by the evolution law \(\dot{{ {\varvec{\alpha }}}}=\dot{{ {\varvec{\varepsilon }}}}^p-\gamma { {\varvec{\alpha }}} \dot{p}\). It is almost equal to the plastic strain either when \(\gamma \) is small or when the plastic strain remains limited.

Among others, a rule avoiding kinematic hardening saturation is the following, valid for anisothermal cases (see Sect. 4 for thermodynamics considerations),

in which the back stress is now governed by von Mises norm \(\dot{a}\) of the rate \(\dot{{ {\varvec{\alpha }}}}\) and with \(\varGamma \) as material parameter.

In case of isothermal loading, \(C\) is constant, and Eq. (4) can be rewritten as

and leads to a non vanishing rate \(\dot{\mathbf{X}}\) solution of the separate variables differential equation \(\dot{ \mathbf{X}}+\varGamma \mathbf{X}\, \dot{x}=\frac{2}{3} C\dot{{ {\varvec{\varepsilon }}}}^p\).

In order to recover a power-law like reponse in monotonic loading, Eq. (4) can be generalized as

or (isothermal case):

with \(M\ge 2\) an additional parameter (already introduced in [3] in another context).

In uniaxial tension-compression (along 1), \({ {\varvec{\varepsilon }}}^p=diag[\varepsilon _p, -\frac{1}{2}\varepsilon _p, -\frac{1}{2}\varepsilon _p]\), \(\mathbf{X}=diag[\frac{2}{3}X, -\frac{1}{3} X, -\frac{1}{3} X]\) so that \(X_{eq}=| X |\), \(\dot{x}=| \dot{X} |\). Such a first proposal reduces to the scalar expression

-

In case of monotonic tension,\(X\) and \(\dot{X}\) are positive and Eq. (8) reduces to \(\left(1+\varGamma X^{M-1}\right) \dot{X}= C\dot{\varepsilon }_p\) therefore to the kinematic hardening solution of

$$\begin{aligned} X+\frac{1}{M}\varGamma X^M= C \varepsilon _p \end{aligned}$$(9)At large plastic strains \(X\) is unbounded and behaves in \(\varepsilon _p^{1/M}\)

$$\begin{aligned} X \approx K \varepsilon _p^{1/M} \qquad K=\left(\frac{MC}{\varGamma }\right)^{\! 1/M} \end{aligned}$$(10) -

In case of symmetric cyclic loading,\(X\) ranges between \(X_{Max}\) and \(X_{min}=-X_{Max}\), the same calculation with now \(\dot{X}>0\) in tension and \(\dot{X}<0\) in compression ends up to cycle stabilization and to the maximum kinematic hardening solution of

$$\begin{aligned} X_{Max}+\frac{1}{M}\varGamma X_{Max}^M= C\frac{\varDelta \varepsilon _p}{2} \end{aligned}$$(11)and then to a cyclic hardening lawFootnote 2\(\frac{\varDelta \sigma }{2}=k+X_{Max}\) linear in plastic strain amplitude at small \(\varDelta \varepsilon _p\) and asymptotically a power function at large \({\varDelta \varepsilon _p}\) with then

$$\begin{aligned} X_{Max} \approx K \left(\frac{\varDelta \varepsilon _p}{2}\right)^{1/M} \end{aligned}$$(12)Again it is unbounded and no saturation is reached.

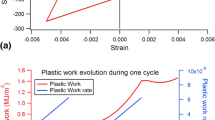

The tensile responses obtained for different sets of parameters are given in Fig. 1. Young’s modulus is taken as \(E=200000\) MPa and \(k=400\) MPa is set. For the comparison with Prager and Armstrong-Frederick rules (Fig. 1a), the same constant \(C=20000\) MPa is used for all models and the chosen value for \(\varGamma {(M=2)}\) is \(2.5\times 10^{-3}\) MPa\(^{-1}\) and corresponds to the same first \(\frac{\mathrm{d }\sigma }{\mathrm{d }\varepsilon }\) and second \(\frac{\mathrm{d }^2\sigma }{\mathrm{d }\varepsilon ^2}\) derivatives at yielding onset than with Armstrong-Frederick rule (for which \(C=20000\) MPa still and \(\gamma =50\)). Parameters \(\varGamma \) for other \(M\) are chosen such as all the curves meet at point (\(\varepsilon =0.02\), \(\sigma =655\) MPa).

Figure 1b shows a feature specific to the present law: the possibility with large modulus \(C\) (\(10^6\) MPa in the example) to model very steep stress increase at low plastic strain. In the figure all stress-strain curves are plotted with the same value for modulus \(K\), i.e. for the same power law limit at large plastic strains.

Tensile stress-strain response from proposed non saturating kinematic hardening rule: (a) compared to linear Prager law and Armstrong-Frederick saturating law (\(C=20000\) MPa, \(\gamma =50\)) at given \(C\) for different exponents \(M\), (b) at given \(K=({MC}/{\varGamma })^{\! 1/M}\) and \(M\) for different values of parameter \(C\) (\(K=347\) MPa, \(M=5\))

In cyclic loading a (classical) modelling flaw is encountered if the value of the kinematic hardening obtained in tension reaches the critical value \(X_{Max}=\varGamma ^{\frac{1}{1-M}}\). For \(X_{Max}=\varGamma ^{\frac{1}{1-M}}\), the slope \(\frac{\mathrm{d }X}{\mathrm{d } \varepsilon _p}\) becomes negative (!) right after load reversal. Such a flaw has been pointed out and solved in [9] simply by making linear the kinematic hardening after load reversal. The law proposed next uses this remedy.

3 Proposal of a Non Saturating Kinematic Hardening Rule

In order to avoid kinematic hardening saturation, one proposes instead of Eq. (6) the following law, this time with no flaw at large plastic strain amplitudes,

where \(\langle . \rangle \) stands for positive part, i.e. \(\langle \dot{X}_{eq}\rangle = \dot{X}_{eq}=\frac{\mathrm{d }}{\mathrm{d } t}(\frac{3}{2}{\mathbf{X}}:{\mathbf{X}})^{1/2}\) when positive, \(\langle \dot{X}_{eq}\rangle = 0\) else. The tensile response is unchanged compared to previous law. But a linear kinematic hardening is now obtained in the cycle parts at decreasing (in norm) kinematic hardening, i.e. at re-yielding just after load reversal (note that this feature is encountered in Ohno-Wang model). Both the monotonic and cyclic features of the new kinematic hardening rule (13) are illustrated in Fig. 1 (again with constant isotropic hardening), still with \(E=200000\) MPa and \(k=400\) MPa.

Cycle stabilization is obtained in case of symmetric (immediate, Fig. 2) and of non symmetric periodic applied strains (cyclic softening up to stabilization, see [5]).

Figure 2 illustrates the main model feature for large values of \(C\): the possibility to represent very steep stress increase at the onset of plasticity (with no visible elasticity/plasticity slope discontinuity), also then in case of cyclic loading. The stress-amplitude is increased after each two cycles (starting from \(\varDelta \varepsilon = 5\times 10^{-2}\)). Such a smooth shape of cyclic strain-stress curves, very steep just out from elasticity domain and decreasing rapidly when yielding (but with no saturation), cannot be represented by means of a single Armstrong-Frederick law. As the value for \(C\) is large, the linear part after load reversal is barely noticeable. The monotonic tensile model response is reported in the figures.

The monotonic stress strain response is still given by Eq. (11) so that

or at constant isotropic hardening and setting still \(k=\sigma _y+R_\infty \), \(K=(MC/\varGamma )^{1/M}\),

The cyclic plasticity response (at saturated hardening) is given by

or

An illustration of the ability the proposed kinematic rule to model cyclic plasticity is given for a material usually quite complex to model (the 316L stainless steel) in Figs. 3 (hysteresis loops) and 4 (cyclic plasticity law, Eq. 17). Note that no modelling at all of the isotropic hardening is introduced (\(k=const\)) (Fig. 5).

Other examples of identifications are given in Fig. 6 for different materials. The corresponding material parameters are (setting \(K_c=\left(\frac{2MC}{\varGamma }\right)^{n}=2^n K\) with \(n={1}/{M}\):

Cyclic plasticity curves (experiments from Lemaitre and Chaboche, 1985, model from Eq. (17))

The ratcheting behavior with the new rule is found at given \(C\) intermediate between linear Prager modelling (no ratcheting at all) and Armstrong-Frederick modelling (which usually overestimates ratcheting). The ratchet step—i.e. the plastic strain increment over an hysteresis loop—for a stress varying cyclically between \(\sigma _{min}>-k\) and \(\sigma _{Max}>k\) (with \(\sigma _{Max}-\sigma _{min}>2k\)) is gained in a closed form as

It is found constant—at saturated isotropic hardening—and related to the value of exponent \(M\) and modulus \(K\) governing the non saturation of the kinematic hardening (and to the size of elasticity domain through \(k\)). Note that ratcheting is often modeled by the introduction of several kinematic hardening variables \(\mathbf{X}_i\), setting \(\mathbf{X}=\sum \mathbf{X}_i\) and taking for \(k\) a relatively small value. According to the corresponding different plasticity mechanisms at the microscopic scale, it seems judicious to consider different laws, i.e. laws of different nature, of different mathematical expression for each \(\mathbf{X}_i\), including rules of Armstrong-Frederick type, including rule (13) (Table 1).

Let us end this section by a remark indirectly related to the implementation in a finite element code: the form given by Eq. (13) is implicit since the rate of \({ {\varvec{\alpha }}}\) (therefore of \(\mathbf{X}\)) depends on the rate of \(X_{eq}\). Recalling the definition of von Mises norm gives \(\langle \dot{X}_{eq}\rangle =\frac{3}{2}\langle \mathbf{X}:\dot{\mathbf{X}}\rangle /X_{eq}\). Altogether with Eq. (13), this allows to show that \(\mathbf{X}:\dot{\mathbf{X}}\) is of same sign than \(\mathbf{X}:\dot{{ {\varvec{\varepsilon }}}}^p\), at least in the isothermal case. After some algebraic work, the following alternative (nevertheless fully equivalent) expression for \(\dot{\mathbf{X}}\) to isothermal law (13) is derived,

more classical to implement.

4 Positivity of the Intrinsic Dissipation

A full plasticity model using the proposed kinematic hardening laws is a non standard model, the new springback terms not deriving from an evolution potential. One must then prove the positivity of the intrinsic dissipation \({\fancyscript{D}}=\left.{ {\varvec{\sigma }}}:\dot{{ {\varvec{\varepsilon }}}}^p-R\dot{p}-\mathbf{X}:\dot{{ {\varvec{\alpha }}}}\right.\) [7]. Isotropic hardening is introduced as the couple of variables \((R, p)\). The criterion function is the classical \(f=({ {\varvec{\sigma }}}-\mathbf{X})_{eq}-R-\sigma _y\) such as \(f <0 \; \rightarrow \;\mathrm{elasticity }\). Also classically, the plastic strain rate is derived by normality: \(\dot{{ {\varvec{\varepsilon }}}}^p=\dot{p} \frac{3}{2} \frac{{ {\varvec{\sigma }}}^{\prime }-\mathbf{X}}{({ {\varvec{\sigma }}}-\mathbf{X})_{eq}}\). Plasticity is incompressible (\(\mathop {\mathrm{{tr}}}\dot{{ {\varvec{\varepsilon }}}}^p=0\)) and kinematic hardening is deviatoric (\(\mathbf{X}=\mathbf{X}^{\prime }\)), as announced.

After some algebraic work, the dissipation takes the form

and is therefore positive for any loading, proportional or not, isothermal or not (\(\dot{p}\), \(\dot{a}\) and \(\langle \dot{X}_{eq}\rangle \) are positive by definition).

5 Conclusion

Families of non saturating kinematic hardening laws have been proposed. In order to gain non saturation of the kinematic hardening, the springback term \({\varvec {{\fancyscript{B}}}}\dot{{\fancyscript{P}}}\) in Eq. (1) is not assumed linear in \(\dot{p}\) anymore but in \(\dot{a}=(\frac{2}{3}\dot{{ {\varvec{\alpha }}}}:\dot{{ {\varvec{\alpha }}}})^{1/2}\) or, better, in the positive part \(\langle \dot{X}_{eq}\rangle \), with \(X_{eq}\) the von Mises norm of kinematic hardening \(\mathbf{X}\). By use of this replacement, any existing rule \(\dot{\mathbf{X}}=\frac{2}{3} C\dot{{ {\varvec{\varepsilon }}}}^p-{\varvec {{\fancyscript{B}}}} \dot{p}\) can then easily gain the non saturation property by changing it into \(\dot{\mathbf{X}}=\frac{2}{3} C\dot{{ {\varvec{\varepsilon }}}}^p-{\varvec {{\fancyscript{B}}}} \,\langle \dot{X}_{eq}\rangle \). As examples:

-

Burlet-Cailletaud rule [2] made non saturating,

$$\begin{aligned} \dot{ \mathbf{X}}=\frac{2}{3}C \dot{\varepsilon }^p-\varGamma \, X_{eq}^{M-2} (\mathbf{X}:\mathbf{n})\;\mathbf{n}\,\langle \dot{X}_{eq}\rangle \qquad \mathrm{normal }\; \mathbf{n}=\frac{\partial f}{\partial \varvec{{\sigma }}}\; \mathrm{such\ as }\; \dot{\varepsilon }^p=\mathbf{n}\,\dot{p} \end{aligned}$$(21) -

Ohno-Wang rule [9] made non saturating

$$\begin{aligned} \dot{ \mathbf{X}}=\frac{2}{3}C \dot{\varepsilon }^p-\varGamma \, X_{eq}^{M-2} \langle \mathbf{k}:\mathbf{n}\rangle \;\mathbf{X}\,\langle \dot{X}_{eq}\rangle \qquad \mathbf{k}= \frac{\mathbf{X}}{X_{eq}} \end{aligned}$$(22) -

Chaboche kinematic hardening rule [3], with threshold \(X_{th}\), made non saturating

$$\begin{aligned} \dot{ \mathbf{X}}=\frac{2}{3}C \dot{\varepsilon }^p-\varGamma \, { \langle X_{eq}-X_{th}\rangle ^{M-1}}\mathbf{k}\,\langle \dot{X}_{eq}\rangle \end{aligned}$$(23)

Proposed rule (13) is the power-law counterpart for kinematic hardening, fully complementary to Armstrong-Frederick saturating rule. Its properties have been illustrated on qualitative examples.

General plasticity modelling, including ratcheting, often introduces several kinematic hardening variables \(\mathbf{X}_i\). Considering rules of different nature for each \(\mathbf{X}_i\) can help to extend the validity domain of the plasticity models, setting for example \(\mathbf{X}=\mathbf{X}_{\mathrm{Prager }}+\mathbf{X}_{\mathrm{AF }}+\mathbf{X}_{\mathrm{NSat }}+ \cdots \), with \(\mathbf{X}_{\mathrm{Prager }}=\frac{2}{3}C_\ell \varepsilon ^p\) linear, with \(\mathbf{X}_{\mathrm{AF }}\) following Armstrong-Frederick rule (2), and with \(\mathbf{X}_{\mathrm{NSat }}\) following the non saturating rule (13) or any of the extension (21)–(23).

Notes

- 1.

Often \(f=({ {\varvec{\sigma }}} -\mathbf{X})_{eq}-R-\sigma _y\) in von Mises plasticity, with \(R\) the isotropic hardening and \(\sigma _y\) the yield stress.

- 2.

The constant \(k=\sigma _y+R_\infty \) is the sum of the yield stress and of the (assumed) saturated isotropic hardening \(R_\infty \).

References

Armstrong, P.J., Frederick, C.O.: A mathematical representation of the multiaxial Bauschinger effect, CEGB report RD/B/N731. Berkeley Nuclear Laboratories, Berkeley, UK (1966)

Burlet, H., Cailletaud, G.: Modelling of cyclic plasticity in finite element codes. In: Desai, C.S., Krempl, E., Kiousis, P.D., et al. (eds.) International Conference on Constitutive Laws for Engineering Materials: Theory and Applications, pp. 1157–1164. Tucson, Arizona (1987)

Chaboche, J.L.: On some modifications of kinematic hardening to improve the description of ratcheting effects. Int. J. Plast. 7, 661–678 (1991)

Chaboche, J.L., Dang Van, K., Cordier, G.: Modelization of the strain memory effect on the cyclic hardening of 316 stainless steel. SMIRT-5, Division L Berlin (1979)

Desmorat, R.: Non-saturating nonlinear kinematic hardening laws. C.R. Mec. 338, 146–151 (2010)

Delobelle, P., Robinet, P., Bocher, L.: Experimental study and phenomenological modelization of ratchet under uniaxial and biaxial loading on an austenitic stainless steel. Int. J. Plast. 11, 295–330 (1995)

Lemaitre, J., Chaboche, J.-L., Benallal, A.: Desmorat. R, Mécanique des matériaux solides, Dunod (2009)

Marquis, D.: Phénoménologie et thermodynamique: couplages entre thermoélasticité, plasticité, vieillissement et endommagement. Thèse de Doctorat d’état, Université Paris 6 (1989)

Ohno, N., Wang, J.D.: Kinematic hardening rules with critical state of dynamic recovery. Int. J. Plast. 9, 375–403 (1993)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Desmorat, R. (2013). On the Non Saturation of Cyclic Plasticity Law: A Power Law for Kinematic Hardening. In: Altenbach, H., Kruch, S. (eds) Advanced Materials Modelling for Structures. Advanced Structured Materials, vol 19. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-35167-9_12

Download citation

DOI: https://doi.org/10.1007/978-3-642-35167-9_12

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-35166-2

Online ISBN: 978-3-642-35167-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)