Abstract

Neutron sources are commonly used in research, industry, and clinical applications. Many of these are in sealed radiological sources used in petroleum engineering (e.g., well logging for oil exploration), in medicine (cancer treatment, pacemakers, and diagnostics), in homes (smoke detectors), and to make electricity (in radiothermal generators that generate power in remote areas ranging from lighthouses to outer space). For example, Cf-252 and Am-Be are used to provide multi-MeV neutrons for activation analysis and well logging. Radioactive sources can be portable or fixed, and most are quite small, ranging from tiny brachytherapy needles or seeds (implanted for localized cancer treatment) to thimble-sized plugs sealed within secure capsules for industrial gauges.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Neutron Yield

- Boron Neutron Capture Therapy

- Neutron Generator

- Lawrence Berkeley National Laboratory

- Neutron Production

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Neutron sources are commonly used in research, industry, and clinical applications. Many of these are in sealed radiological sources used in petroleum engineering (e.g., well logging for oil exploration), in medicine (cancer treatment, pacemakers, and diagnostics), in homes (smoke detectors), and to make electricity (in radiothermal generators that generate power in remote areas ranging from lighthouses to outer space). For example, Cf-252 and Am-Be are used to provide multi-MeV neutrons for activation analysis and well logging. Radioactive sources can be portable or fixed, and most are quite small, ranging from tiny brachytherapy needles or seeds (implanted for localized cancer treatment) to thimble-sized plugs sealed within secure capsules for industrial gauges.

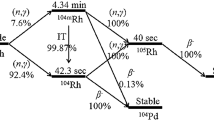

In recent years, substantial effort has been spent in the development of radio frequency (RF) plasma-based neutron generators that can provide high yields of neutrons for clinical applications such as boron neutron capture therapy (BNCT). By using the D-D fusion reaction, 2.4 MeV neutrons can be produced with a compact generator operating with ∼100 keV of deuterium beam energy. Similarly, 14 MeV neutrons can be produced by the D-T fusion reaction. These RF plasma-based neutron sources are safe to operate and they can be turned on and off conveniently. A number of these D-D neutron generators have already been operating in universities, research institutions, and private industries around the world to replace the radioisotope neutron sources. In particular, a compact D-D neutron generator has been installed in Turin, Italy, for BNCT development.

BNCT brings together two components. The first component is the delivery of 10B – a stable isotope of boron with a large cross section for thermal neutron absorption – preferentially to the tumor cells with the help of tumor-seeking compounds. The second component is a beam of low-energy neutrons. When a thermal neutron is captured by 10B, the reaction 10B(n,α)7Li occurs, releasing two high-energy ions. Because of the high linear energy transfer and relative biological effectiveness (RBE) of these ions, only cells in close proximity to the reaction are damaged, leaving adjacent cells unaffected. The enhanced uptake of the boron-labeled agent in tumor cells versus normal cells results in selective killing of tumor cells, due to the higher dose that can be delivered to them. So far, the neutrons used for BNCT are produced mostly in a fission reactor. In recent years, attempts have been made to generate the neutrons by using a compact neutron generator so that one can house the complete BNCT system inside a medical facility.

2 RF-Driven Plasma Source for Neutron Production

A compact neutron generator consists of three components: an ion source, an electrostatic accelerator, and a target electrode (Fig. 4.1). RF-driven plasma source is now commonly used for ion beam generation. A schematic of an RF-driven plasma source is shown in Fig. 4.2. This type of ion source is being used in all compact neutron generators developed by the Plasma and Ion Source Technology Group at Lawrence Berkeley National Laboratory (LBNL). Three deuterium ion species (D+, D +2 , and D +3 ) are present in a deuterium gas discharge plasma. The atomic D+ ions are preferred for neutron production because they can provide full energy for the fusion reaction when they impinge on the target surface. The molecular deuterium D +2 and D +3 ions will disintegrate into two or three atoms at the target. Each of these atoms will carry only one-half or one-third of the beam energy. With lower interaction energy, the fusion neutron production rate will be reduced.

The ion source is operated with a 13.5 MHz power supply and an impedance matching network. The plasma is produced by RF induction discharge via a copper coil antenna covered with quartz tubing. By operating the source with pure deuterium gas (or a mixture of deuterium and tritium gas), D+ ions (or D+ and T+ ions) will be extracted from the exit aperture of the source. A simple single gap extraction system is used to accelerate the ions to 100 keV or higher energy. An actively cooled Ti target electrode is used to catch the accelerated D+ (or D+ and T+) ion beam. As a result, the target surface will continue to be loaded with deuterium (or deuterium and tritium). The incoming D+ ions will react with the D atoms on the target surface forming the 2.45 MeV D-D neutrons (or the 14 MeV D-T neutrons). This type of beam-loaded target has been employed in all the neutron generators developed at LBNL. It provides a very long-life operation and can be designed in various configurations. With a 100 keV, 1 A D+ ion beam, one should be able to achieve a D-D neutron yield >1011 n/s (or D-T neutron yield > 1013 n/s).

Compared with other types of ion sources (such as the Penning discharge source used in most commercial neutron generators), the RF-driven ion source has two advantages. It can provide high atomic D+ or T+ ion percentage (>90 %), and it can easily generate deuterium (or tritium) ion current density higher than 100 mA/cm2 with modest RF input power. Figure 4.3 shows the ion species distribution when a beam is extracted from a 10-cm-diam RF-driven hydrogen plasma source. It can be seen that the atomic ion concentration is higher than 90 % with 1.5 kW of RF input power. Similar results are obtained with a deuterium, tritium, or a mixed deuterium-tritium RF discharge.

Figure 4.3 shows the extractable ion current density from the RF-driven plasma source increases linearly with the RF input power. In principle, there is no limitation on the extractable ion current density as long as the RF power supply is capable of providing the required input power. However, for optimal neutron production, the beam power density on the target electrode of the neutron generator should not exceed 700 W/cm2. If the beam energy is 100 keV, the current density should not exceed 7 mA/cm2 on the target surface. In order to increase the neutron yield, one has to increase the fusion reaction rate by increasing the total beam current and at the same time maintaining the optimum beam power density on the target electrode. One can meet these two requirements by using multiple beamlet extraction, and at the same time, spreading the ion beamlets to a large target surface.

The external surface of the ion source chamber is normally surrounded with columns of permanent-magnets forming a series of magnetic line-cusp field for plasma confinement. This type of multicusp plasma source can provide large areas of very uniform plasma density (Fig. 4.4) that will enable multi-beamlet extraction and therefore high neutron output.

3 Compact Neutron Generator for High Neutron Yield

Two neutron generator configurations have been used to provide high neutron yield. The first is the axial-type configuration shown schematically in Fig. 4.1. In this type of generator, the external surface of the ion source chamber is surrounded with columns of permanent-magnets for plasma confinement (a multicusp ion source). As a result, a large area of very uniform plasma density can be formed. Multiple ion beams can be extracted from the uniform plasma density region. Figure 4.4 shows the cross-sectional view of a 30-cm-diam multicusp ion source chamber and the radial plasma density profile for three different discharge power. The multicusp source configuration enables multi-beamlet extraction and therefore high total beam current.

Figure 4.5 shows a schematic diagram of a sealed axial-type D-T neutron generator [1]. In this system, the RF-driven ion source, the accelerator column, and the target electrode are all housed in a sealed metal container without external pumping. During operation, deuterium and tritium will be released from the reservoir element and the target. After operation, both gases will return to the reservoir element and target due to their lower temperatures. The ion beamlets are extracted from one side of the ion source. In order to reduce the beam power density, the beamlets are focused at the high-voltage electrode. They then spread out to a much larger area on the target electrode as illustrated in Fig. 4.5. With a 150 keV and 2 A mixed D+ and T+ beam hitting a well-cooled target, a neutron yield of 1014 n/s can be achieved over long periods of operation.

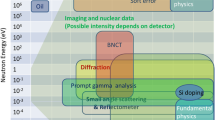

In order to treat deep brain tumor with BNCT, one has to deliver thermal neutrons to it. A previous study showed that one ideally needs to supply epithermal neutrons with an energy distribution peaking at ∼10 keV [2]. The high hydrogen content of the brain slows down the incoming epithermal neutrons in such a way that they become thermalized when they reached the desired depth. Verbeke et al. [3] and Cerullo et al. [4] demonstrated that the 14 MeV D-T neutrons can be moderated to the desired energy range without reducing the neutron flux to a negligible level. With the optimal moderator and lead reflector configuration, a 1-A mixed D+/T+ beam with energy of 150 keV accelerated onto a titanium target leads to a treatment time of 1 h [3]. The dose near the center of the brain obtained with this neutron generator and moderator system is more than 65 % higher than the dose from a typical spectrum produced by the Brookhaven Medical Research Reactor and is comparable to the dose obtained by the other accelerator-produced neutron beams. Figures 4.6 and 4.7 show the beam-shaping assembly (BSA) design and the resulting neutron energy distribution as reported in Ref. [3].

The second configuration is the coaxial type of source (Fig. 4.8). In this arrangement, the ion source is cylindrical in shape and is located at the center of the generator. The target is a larger diameter aluminum cylinder with the inner surface coated with a layer of titanium. In normal operation, the ion source chamber is at ground potential while the target is biased at −120 kV. The plasma is produced by 13.5 MHz RF induction discharge. Positive deuterium ions are extracted from the apertures on the source chamber wall and they will be accelerated toward the target. When the deuterium ions impinge on the titanium target surface, neutrons will be generated by the D-D fusion reaction. If the ion source is operated with a mixture of deuterium and tritium discharge, both D+ and T+ ions will be extracted and accelerated to the target cylinder. In this case, both D-T, D-D, and T-T neutrons will be produced. Since the D-T reaction has a much larger cross section, most of the neutrons produced will have energies of 14 MeV.

Columns of permanent-magnets are installed in the target chamber so as to suppress the secondary emission electrons generated by the ion beams. These electrons will constitute a large power supply drain current. They will also generate unwanted X-rays when they impinge on the ion source chamber. Since the diameter of the target chamber is larger than that of the ion source, the applied electric field will spread the ion beam to a larger surface area. As a result, the beam power density on the target electrode is reduced (at least by a factor of R t/R s where R t and R s are the radius of the target chamber and the ion source chamber, respectively). Thus, one can produce high neutron flux without overheating the target surface.

A photograph of a coaxial type D-D neutron generator is displayed in Fig. 4.9. This generator was developed by LBNL for the EUROSEA Committee in Turin, Italy, for BNCT application. Both the ion source and the target electrode are designed to operate with a total beam power of 120 kV, 1 A so that a D-D neutron yield higher than 1011 n/s can be achieved. This coaxial neutron generator was delivered to Turin, Italy, at the end of 2004. The commissioning of this D-D neutron generator was performed in the University of Turin in March, 2005. In order to reduce the treatment time for liver tumor, MCNP computation shows that the neutron yield has to increase to about 2 × 1012 n/s. Different schemes for upgrading the EUROSEA generator yield to higher than 1012 D-D n/s have been investigated, and the results were reported in the 13th International Congress on Neutron Capture Therapy, November 2–7, 2008, Florence, Italy.

4 Moderator Design for the Coaxial Neutron Generator

D-D fusion neutrons have energies of 2.45 MeV, and D-T fusion neutrons have energies of 14 MeV. These neutrons need to be moderated to the optimal neutron energy spectrum for BNCT. MCNP computation code has been employed for the moderator design study. Preliminary results have been reported by H. Koivunoro et al. [5]. Figure 4.10 shows one of the moderator designs developed by the Plasma and Ion Source Technology Group at LBNL. With the use of a different material such as Fluental and iron, one can optimize the neutron energy spectrum for liver cancer treatment as illustrated in Fig. 4.11. In order to optimize the therapeutic ratio, various beam shaping assemblies (BSA) have been investigated by E. Durisi et al. [6] using different materials and geometrical shapes.

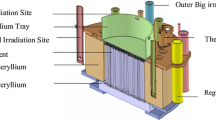

5 Use of a Subcritical Multiplier for BNCT

Even though the upgraded coaxial neutron generator can provide a D-D neutron source intensity of 2 × 1012 n/s, it is still an order of magnitude short of the intensity needed for BNCT of deep-seated brain tumors. The feasibility of using a small, safe, and inexpensive subcritical fission assembly (SCM) to multiply the D-D fusion neutrons from a compact neutron generator (CNS) has recently been investigated [7]. This will enable one to treat deep-seated brain tumors in approximately one hour. It was identified that the optimal design of a passively cooled SCM should be made of 20 %-enriched, aluminum clad metallic uranium fuel. The SCM geometry was designed so as to increase the solid angle by which the SCM “views” the CNS (Fig. 4.12); it was arranged as a “cup” shape that surrounds the CNG on three sides: k eff is 0.98. The required 20 %-enriched uranium amount is 8.5 kg. The required SCM power level is estimated at 400 W when driven by a 1 × 1012 D-D n/s neutron source. This translates into consumption of only about 0.5 % of the initially loaded 235U atoms during 50 years of continuous operation. It thus appears that the SCM could operate continuously for the entire lifetime of the machine without refueling. Also as desired, cooling the SCM does not pose a challenge; it may be accomplished passively; i.e., without resorting to forced circulation.

Two optimal beam shaping assembly (BSA) designs were identified: one for maximizing the dose rate (illustrated in Fig. 4.13) and the other for maximizing the total dose that can be delivered to a deep-seated tumor. The maximum dose rate that can be delivered by the former is 10.1 Gy/h, and the maximum dose that can be delivered by the latter is 51.8 Gy. The former features a harder neutron spectrum and relatively high neutron dose component to the skin, while in the latter the neutron, gamma-ray, and boron-dose components in the skin are comparable. The corresponding maximum dose rates that can be delivered to the tumor are 10.1 Gy/h and 51.8 Gy.

The study concludes that the addition of a SCM makes it possible to increase the treatment beam intensity by a factor of 18 – from 0.56 to 10.1 Gy/h, with the CNS intensity of 1 × 1012 n/s. Therefore, a practical BNCT facility based on the optimal system identified in this study could deliver the desired tumor dose in less than an hour, if either one of the following approaches is adopted: (1) irradiating the patient in 3 to 4 one-hour sessions; (2) irradiating the patient using 3 or 4 beams simultaneously; or (3) increasing the permissible SCM maximum k eff to 0.995. However, if the CNS intensity of 2.3 × 1012 n/s could be achieved, the above mentioned remedies would not be needed.

6 Summary

In summary, compact neutron generators based on the D-D and D-T fusion reactions can provide the required neutron yield for boron neutron capture therapy. Two neutron generator configurations have been developed to meet the BNCT requirement. These compact neutron generators coupled with the proper moderator design and efficient boron-10 compound can provide a low cost and easy to operate BNCT facility well-suited for installation in the hospital environment.

References

Verbeke JM, Leung KN, Vujic J (2000) Development of a sealed-accelerator-tube neutron generator. Appl Radiat Isot 53:801–809

Yanch JC, Zhou XL, Brownell GL (1991) A Monte Carlo investigation of the dosimetric properties of monoenergetic neutron beams for neutron capture therapy. Radiation Res 126:1–20

Verbeke JM, Vujic J, Leung KN (2000) Neutron beam optimization for boron neutron capture therapy using the D-D and D-T high-energy neutron sources. Nucl Technol 129:257–278

Cerullo N, Esposito J, Leung K-N, Custodero S (2002) An irradiation facility for Boron Neutron Capture Therapy application based on a radio frequency driven D–T neutron source and a new beam shaping assembly. Rev Sci Instrum 73(10):3614

Koivunoro H, Bleuel DL, Nastasi U, Lou TP, Reijonen J, Leung KN (2004) BNCT dose distribution in liver with epithermal D-D and D-T fusion-based neutron beams. Appl Radiat Isot 61:853–859

Durisi E, Zanini A, Manfredotti C, Palamara F, Sarotto M, Visca L, Nastasi U (2007) Design of an epithermal column for BNCT based on D-D fusion neutron facility. Nucl Instrum Methods Phys Res A 574:363–369

Ganda F. Vujic J, Greenspan E, Leung K (2010) Compact D-D neutron source-driven subcritical multiplier and beam-shaping assembly for boron neutron capture therapy. Nucl Technol 172(3):302–324

Acknowledgment

The author would like to thank members of the Plasma and Ion Source Technology Group at Lawrence Berkeley National Laboratory, the Nuclear Engineering Department at the University of California, Berkeley, and the EUROSEA Committee in Turin, Italy, for the material presented in this article.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Leung, KN. (2012). Compact Neutron Generator for BNCT. In: Sauerwein, W., Wittig, A., Moss, R., Nakagawa, Y. (eds) Neutron Capture Therapy. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-31334-9_4

Download citation

DOI: https://doi.org/10.1007/978-3-642-31334-9_4

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-31333-2

Online ISBN: 978-3-642-31334-9

eBook Packages: MedicineMedicine (R0)