Abstract

Different nanotechnological strategies have been designed to implement the production of innovative diagnostic and optical sensing devices for genomic and proteomic applications. In this chapter, we will give an overview on the novel nanobiotechnological approaches recently developed, combining top-down nanostructuring and bottom-up molecular self-assembly to soft lithography, with molecular biology tools, aimed at the production of high-performance plastic chips for diagnostics and nanostructured materials to be applied in advanced sensing and imaging. Highly sensitive fluorescence imaging/sensing schemes, enabling the enhancement of sensors sensitivity and detection limits, such as Metal Enhanced Fluorescence- and Photonic Crystals-based approaches, will be discussed as novel tools for the detection of biological targets (e.g., DNA, proteins, and fibrils).

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

In the last 2 decades, various modes of optical detection and measurement, including absorption, reflection, fluorescence, chemiluminescence, and phosphorescence [1–5], have been exploited in the biosensoristic field. Despite considerable advances, extensive work has still to be done in order to develop and optimize a general optical detection sensing platform in terms of signal high sensitivity, linear dynamic range, and robustness to relevant biomatrices such as serum, urine, saliva, or cell lysates. In recent times, various organic molecules possessing unique assets kept the attention of investigators to achieve the recognition of different targets [6, 7]. Molecular probe design represents a key element in biosensing systems; moreover, the conjugation of functional molecules (nucleic acid based as aptamer, DNAzyme, or modified peptides and proteins) with nanomaterials has resulted in great improvement in the field of molecular recognition. With their unique physical and chemical properties, nanomaterials facilitate the sensing process and amplify the signal of recognition events. As functional surfaces, they provide an ideal platform for biomolecules immobilization achievable by physical adsorption, including electrostatic and hydrophobic binding, covalent bonding, and specific interactions such as biotin–avidin, antibody–antigen interaction, and DNA hybridization [8]. Generally bio-interaction methods lead to high functionality within the biosensor fabrication process [9] and combination of self-assembly and nanolithography can be considered as an effective nanofabrication methodology for device realization.

This chapter mainly intends to provide an overview of the different molecular and nanotechnological interaction-mediated biosensor fabrication route that leads to sensing systems with controlled structures on both nanofunctionalized surfaces and functional nanomaterials. Herein soft and advanced technical approaches suitable for biosensor architecture are discussed, in particular referring to a combination of top-down and molecular self-assembly to soft lithography, as well as novel, highly sensitive fluorescence imaging/sensing schemes, such as those exploited in Metal Enhanced Fluorescence (MEF)- and Photonic Crystals (PCs)-based analytical system.

2 Nanoscale Fabrication of Biomolecular Layer: Soft and Advanced Approach

Micro- and nanofabrication have provided several possibilities for chemical, biological, and physical processes at molecular scale, as well as for the design of synthetic devices capable of interacting with biological systems at this level. Since 1990s, micro- and nanofabrication have represented the main contribution for the development of sensors [10], microreactors [11], combinatorial arrays [12], microanalytical systems [13, 14], and micro-optical systems [15, 16].

Particularly, analysis of complex biological samples and the requisite to test multiple analytes simultaneously has led to the development of multiplex analytical strategies which are essentially based on array technologies. The main technique exploited in this field is photolithography, and as an emerging procedure, Xia et al. more than 10 years ago developed an alternative, non-photolithographic process of microfabrication referred to as soft lithography [17–19].

Soft lithography, similar to photolithography, is a method also used to transfer a pattern onto a surface. Xia et al. [20], describing different softlitography approaches, focused on microcontact printing (μCP) [21], replica molding (REM) [22], microtransfer molding (μTM) [23], micromolding in capillaries (MIMIC) [24], solvent-assisted micromolding (SAMIM) [25], and phase-shift photolithography [26], as also cast molding [27], embossing [28], and injection molding [29, 30].

Aiming to depict a map of different routes for biosensor architectures, it is useful to basically divide them into top-down or bottom-up approaches. Many of such applications have been described in a recent review [31] and shown in Table 1; essentially, the top-down approach for nanoscale patterning besides traditional soft lithography methods includes electron-beam lithography, nanoshaving, nanografting, dip-pen nanolithography, colloid lithography, block copolymer micelle lithography, and extreme UV-interference lithography too [32, 33]. On the other hand, the bottom-up approach for nanofabrication of biosensors involves self-assembly of biomolecules onto nanomaterials by interaction and recognition of the complementary molecule as well as physicochemical synthesis of nanomaterials such as nanoparticles, nanorods, nanotubes, and nanowires [34, 35].

Basically, self-assembly is referred to the property of self-organizing of organic molecules occurring spontaneously at solid–fluid interfaces, with reference to a paper by Netzer and Sagiv [36]. The physicochemical phenomenon of molecular auto-assembly is based on thermodynamically favored interactions of molecules such as peptides, proteins, and DNA, and other organic or inorganic molecules [37]; several advantages are provided, including the ability to fabricate three-dimensional structures and the potential for molecular control of the material [33]. Engineered surfaces for protein immobilization include two different types of immobilization: (1) physical adsorption onto surfaces through weak contact of proteins and (2) formation of covalent bonds between protein and surface; the last is typically preferred due to the molecular orientation, density, and activity control [38]. Considerably, by using the nanopatterning techniques, biomolecules can be positioned within desired nanoregions with well-defined feature size and shape retaining their native 3D structures and, hence, biological functionalities [33]. Biomolecules’ high-resolution nanopatterning has been achieved by applying various kinds of lithographic techniques to self-assembled monolayers (SAM) containing Layer by Layer (LBL) assembly [37]. Essentially, it consists on the consecutive deposition of multiple thin polyion films from solution, with intermediate washes, exploiting the electrostatic attraction between oppositely charged molecules as well as covalent bonding and specific interaction as a driving force for assembly [39, 40]. Allowing a variety of materials to be incorporated within the film structures, LBL is widely accepted as a versatile and powerful bottom-up nanofabrication technique [40] that provides great control over the film structure, thickness, and function and permits the use of numerous materials, including macro-biomolecule such as both proteins [41] and DNA [42]. A key role in soft nanofabrication approach for bioanalytical devices is represented by scaffold material too; actually, this kind of top-down approach can be easily performed on several nanomaterials such as nanotubes, nanorods, nanowires, and nanoparticles [43] as well as polymeric ones, providing fascinating integration between bio/organic and inorganic structures. Mainly, certain plastic organic polymers such as poly(methylmethacrylate) (PMMA) and poly(dimethylsiloxane) (PDMS) have been exploited for the fabrication of various devices, including microchannels and valves [44], and as substrates for DNA/protein arrays [45, 46]. Specifically, PDMS has been used widely in the biomedical and pharmaceutical application fields because of its biocompatibility and good thermal, mechanical, and optical properties. In this respect, what is valuable to note is that such materials can be processed by various techniques, such as soft lithography, hot embossing, laser ablation, micromilling, and in situ polymerization, while maintaining, in some cases, the typical properties of resist materials (i.e., photoresist or electronic resist for micro- and nanofabrication).

These features provide the additional possibility to create tailored integrated bioanalytical platforms, and in this respect, some examples of advanced strategies will be reported, herein, as demonstration of applications in device fabrication.

A few years ago, Tan and colleagues [47], exploiting Parylene-C, a biocompatible inert polymer, showed a high-throughput plain method to generate multicomponent biomolecular arrays with sub-100 nm nanoscale feature width, namely “Print-and-Peel.” Briefly, they first aligned an inkjet printer to a parylene template containing nanoscale openings. After printing, they peeled off parylene to reveal uniformly patterned nanoscale features, despite the imperfect morphologies of the original inkjet spots. Moreover, they attempted to expand the multiplexing capability of the applied technique to combinatorial nanoarrays by performing a second print-run superimposed over the first pattern. In Fig. 1, the schematic process of PNP is represented. Antibody arrays created using this method could be used effectively for immunoassays, molecular diagnostics, and screening.

Fabrication process of the parylene template and the PNP process to generate the protein nanoarrays. (b) Peeling off the parylene template from a wafer substrate. For simplicity of illustration, the parylene peeling is shown in dry conditions, but the protein nanopatterning and parylene peeling were performed in aqueous environments that did not require drying. Reproduced with permission from [47]

Optimization of suitable and reproducible surface (bio)chemistry approaches for the high-density immobilization of biomolecules probe onto various substrates is a key point to improve the detection sensitivity and selectivity of the biochip toward specific bioanalytes. A reliable strategy that combines self-assembly and lithographic techniques has been recently applied by Sabella et al. [48], leading to very precise micro- or nanopositioning of biomolecules for the realization of micro- and nanoarrays of functional DNA and antibodies. In Fig. 2, a schematic process of this advanced approach is showed. In addition, combining polymer flexibility and photophysical properties of nanostructures such as colloidal nanocrystals (NCs), novel outcomes in the form of solid-state optical detection platforms have been achieved. Sabella et al. [49], in a recent paper, presented an integrated plastic biochip that exploits a “smart” polymeric layer with both optical and biorecognition properties that allows optical monitoring of biomolecular interactions, DNA hybridization, and quantitative offline analyses of real-time polymerase chain reaction (RT-PCR). The microdevice, represented in Fig. 3, consists of a layer with both optical and sensing properties, and is made of NCs uniformly dispersed in a polymeric a poly(methylmethacrylate) (PMMA) matrix.

Biomolecular patterning based on E-beam lithography and multistep self-assembly. Left: (a) A resist layer (PMMA) was deposited onto silicon dioxide by spin coating; (b) EBL patterning and development; (c) selective SAM deposition by self-assembly in the exposed regions of the substrate; (d) lift-off; (e, f) spatially confined self-assembling of cross-linking molecules and probe biomolecules. Right: real images of the steps (b), (c), and (f), respectively. (I) Holographic microscopy 3D image of 1 μm wide PMMA stripes after EBL patterning and development; (II) confocal microscopy image of Fluorescein isothiocyanate (FITC)-labeled 3-aminopropyltriethoxysilane (APTES) stripes (features: 20 μm); and (III) confocal microscopy image of Cy3-labeled ssDNA stripes (features: 20 μm). Reproduced with permission from [48]

(a) Optical scheme for the real-time monitoring of biomolecular interactions. The detection principle is based on resonance energy transfer processes (FRET) from a thin film of CdSe/ZnS core/shell NCs, dispersed in a PMMA matrix, to the fluorophores conjugated to the target biomolecules (for instance, a specific DNA sequence). Adapted with permission from [49]. (b) High-resolution patterning of NCs/PMMA blend for multiplexing applications: simultaneous imaging of E-beam patterned 500 nm emitting CdSe/ZnS core/shell NCs (left) and of solid-state DNA hybridization events by FRET (right), according to the optical detection scheme reported in (a)

The thin NCs/PMMA layer acts as the bottom of a PDMS microchamber. The upper surface of the hybrid polymeric blend is chemically modified to covalently immobilize, by a multistep solid-state chemistry, biomolecules, such as specific sequences of amino-modified single-strand DNA probes (ssDNA) or antibodies, receptors, and aptamers selective toward the analytes, such as target DNA sequences (or antigens, ligands, etc.) present in the biological sample.

The obtained hybrid material is suitable for multiplexing analysis by controlling the probe species immobilization outline and the consequent spatial confinement of the resulting FRET signals in the patterned areas; in this respect, two methods can be performed: (1) directly patterning in a controlled manner the active polymeric blend, thus localizing the detection process (since PMMA is an electronic resist and the hybrid NCs/PPMA film can be patterned by electron beam lithography (EBL) [49] without significant perturbation of the NCs spectral features [50]), or (2) as above reported, by biomolecular patterning based on EBL [48]. Similar advanced fluorescence schemes will be discussed in more detail in the next section.

3 Nanostructured Materials for Advanced Sensing/Imaging

Optical sensing has become one of the dominant sensing technologies in medical diagnostics. In various detection platforms such as ELISAs or protein microarrays [51, 52], the readout is based on a fluorescent or colorimetric signal. Intrinsic matrix autofluorescence or optical absorption of relevant biological samples or reagents represents for such sensing approach a crucial limiting factor as well as the quantum yield and photostability of the fluorophores. Within the last decade, functional nanomaterials have been exploited to highly enhance the assay sensitivity, specifically improving the detection ability of biosensing devices; nanostructured materials offer wide combinations of various compositions and shapes with unique and controllable size- and structure-dependent properties [53].

3.1 Metal-Enhanced Fluorescence

Recently, the great developments in the MEF technology have been exploited to favorably modify the spectral properties and to play down photophysical limitations of the dye molecules [54]. In fact, the ability to control the surface structure, in particular of noble metals, gives rise to the possibility to engineer the spectral properties of the molecules/fluorophores positioned in its vicinity, thanks to plasmonic coupling. In the early 1990s, Johnson and Aroca [55] reported a model on the distance dependence of the transfer of electronic energy from a donor plane of molecules to an acceptor plane. Changing experimental parameters (such as material, shape, and dimensions of the metallic nanostructures, as well as the average fluorophore—nanostructure distance) [54, 56], the efficiency of the coupling, and therefore the spectral properties of the dye, can be properly modified. Really, metal surfaces can amplify or decrease the radiative decay rates of fluorophores and increase the extent of resonance energy transfer [56–60].

In the last few years, several interesting MEF approaches have been demonstrated [56, 60–64]. The interactions between the dipole moments of the dye molecule and the surface plasmon field of the metal can increase the incident light field and may result in a local MEF [56, 65–68] as an important increase of fluorophore emission intensity, significantly enhancing the signal detectability [69]. A comprehensible example of the theoretical model was presented in the first report on “the release of self-quenching of fluorophores near-to metallic surfaces” [70]. The authors, underlining the need of brightness of labeled antibodies for maximal sensitivity and observability over sample autofluorescence in bioassays, and since the obvious approach to increasing the molecule brightness by increasing the extent of labeling is not useful due to self-quenching (homo RET), examined fluorescein-labeled human serum albumine (HSA) when bound to quartz and to silver island films (SIFs). As imaged in Fig. 4, Lakowicz and colleagues showed that binding of fluorescein-labeled HSA to SIFs eliminated much of the self-quenching.

Fluorescence enhancement from silver islands. Image of fluorescein-labeled human serum albumin (molar ratio of fluorescein/human serum albumin = 7) on quartz and on SiFs as observed with 430-nm excitation and a 480-nm long-pass filter. The excitation was progressively moved from the quartz side to the silver side. Adapted with permission from [70]

This outcome has a variety of applications in biodiagnostics imaging and sensing [54]. Specially, MEF has been employed to increase the sensitivity in the detection of DNA, RNA, and proteins in microarray systems [58, 71, 72].

Several routes have been followed; among these, an interesting approach was showed by Zhang and Geddes in 2010 that emphasized the high thermal stability (before and after autoclaving) of different density rhodium (Rh) nanoparticulate glass substrates fabricated by electron-beam physical vapor deposition in order to study the fluorescence scheme of fluorophores in close proximity. The authors did not observe a shorter fluorescence lifetime, suggesting only an enhanced electric field component as the mechanism for fluorescence enhancement; moreover, they concluded that Rh substrates may be of particular value for higher temperature MEF experiments or indeed may be used as an autoclavable substrate [73].

To address the two major shortcomings of fluorescence-based bioassays: sensitivity and rapidity, a new platform technology called microwave-accelerated metal-enhanced fluorescence (MAMEF) was recently introduced [74, 75]. In effect, the MAMEF method combines low power microwave heating, kinetically accelerating assays to completion within a few seconds with metal-enhanced fluorescence (MEF) [54]. As a specific application, Kadir Aslan [76] in 2010 has given the proof-of-principle demonstration of rapid whole blood bioassays based on microwave-accelerated metal-enhanced fluorescence (MAMEF) method by silver nanoparticle-deposited surfaces.

On the other hand, concerning topographical control of signal enhancement, highly reproducible EBL fabrication of ordered arrays of gold nanostructures coupled to NCs dispersed in a polymer blend was used by Pompa et al. [77] to demonstrate that this approach can be exploited to obtain a spatially controlled amplification of the fluorescence signal in two different nanomaterials, namely colloidal Quantum Dots (QDs) and Quantum Rods (QRs). The authors highlighted the ability to modulate the spectral properties of semiconductor nanocrystals as useful strategies in various optical-based technologies, such as highly sensitive optical sensors and photonic devices operating at nanoscale and/or requiring very low densities of fluorescent emitters. Actually, microfabrication developments have enabled high-density chip-scale integration of optical elements, such as light sources and photodetectors [78, 79].

3.2 Photonic Crystals

Photonic crystal structures have their origin in an observed phenomenon called “Wood’s anomaly.” The so-called anomalies were effects detected in the spectrum of light reflected by optical diffraction gratings as rapid variations in the intensity of particular diffracted orders in certain narrow frequency bands [80].

It is now known that analogous bandgaps offered between the valence and the conduction energy bands of a semiconductor can subsist when electromagnetic (EM) waves propagate in a macroscopic periodic dielectric structure. EM waves with frequencies inside such a gap cannot propagate in any direction inside this lattice-like crystal that, since late 1980s, has been referred to as photonic crystals (PCs) or photonic band-gap (PBG) materials [81, 82]. Recently, PCs have been under intensive investigation as a novel label-free optical biosensing platform [83, 84]. By introducing “defects” into the PCs structure, the electric field can be strongly confined and enhanced in the vicinity of the sensing surface where target analytes are adsorbed. Thus the corresponding optical spectrum shows narrow transmission peaks or reflection dips in the photonic bandgap, which enables highly sensitive biomolecular detection. On the high-energy side, Luo et al. [85] concluded that for particles traveling through an all-air path inside a photonic crystal, a Cerenkov radiation (CR), with a spiky radiation wavefront, is possible, allowing complete absence of the impurity scattering and random ionization losses intrinsic in a dense medium. Indeed this possibility improves the performance of detectors, as they put forward in 2003; furthermore, the CR frequency that is set by the photonic crystal is selectively scalable beyond optical wavelengths, opening up the possibility of flexible radiation sources for frequencies that are otherwise difficult to access. Investigations on one-dimensional patterned dielectric slab PC have showed good sensitivity values, simplified light coupling schemes, and compatibility with plastic substrates [86, 87]. Moreover, many recent efforts have focused on the study of two-dimensional planar PC structures, where light is associated with in-plane guided modes from the narrow face of a slab, as reviewed by Mortensen and colleagues [88].

PCs, incorporated into standard 96-, 384-, or 1,536-well microplates, as sensor elements, have been used to detect antibody–antigen, small molecule, protein, and whole cell–protein interactions on the biosensor surface, cheaply fabricated on sheets of plastic film, without the use of fluorescent labels [89].

Practically, PCs’ surface may be coated with a thin layer of biorecognition molecules that bind specifically to an analyte (e.g., antibodies with affinity to a specific antigen, or streptavidin with an affinity to biotin). When excited at a guided resonance frequency, the PCs will have significant electric field energy surrounding the biorecognition layer [90]. In other words, when illuminated with white light, appropriately structured PCs are able to reflect a single wavelength, whose value is dependent on the local concentration of adsorbed biomolecules or cells [91].

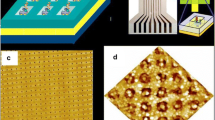

Proper selection of photonic crystal slab design structure permits biosensing of a wide variety of analytes, including proteins, antigens, and cells. In this regard, ultracompact monitoring of reaction kinetics and protein concentration has been reported by Zlatanovic and colleagues [92]. In a PC microcavity, the field enhancement depends on confinement of light within a very small volume, enabling an ultra-small attoliter detection volume, many orders of magnitude smaller than in Surface Plasmon Resonance (SPR) and microtoroid sensors, thus allowing the reduction of sample required for sensing. Moreover, Martiradonna et al., in 2010 [93], proposed a strategy based on an efficient spectral modeling and enhancement of marker fluorescence through the insertion of PC nanocavities (PC–NCs) (Fig. 5) in the readout area of biochips to univocally associate a characteristic emission wavelength with a specific bioprobe immobilized on a nanocavity (as represented in Fig. 6), thereby guaranteeing multiplexed detection and faster analysis time in addition to higher sensitivity.

Scheme of the proposed strategy for photonic crystal nanocavities (PhC–NCs) biochip. (a) Array of nanocavities patterned on the readout area. Inset: detail showing examples of NCs. The cavities are functionalized with different probes molecules, which specifically interact with complementary target analytes labeled with fluorescent markers. The signal is collected from this area and spectrally resolved in order to identify the different spectral tags univocally associated to each NC and thus to each bioprobe. (b) Example of a possible luminescence detected from the whole readout area (black line) as compared to the unmodified broad marker luminescence (red dotted line). The occurrence of each peak in the spectrum identifies the corresponding analyte in the performed assay. Reproduced with permission from [93]

Toccafondo and colleagues [94] presented an experimental demonstration of single-strand DNA (ssDNA) sensing exploiting a photonic-crystal-waveguide-based optical sensor, and, in particular, they showed the possibility to observe DNA hybridization events using planar PCs structures, with a detection limit as low as 19.8 nM for the detection of the complementary DNA strand. In a similar way, Pisanello et al. [95] exploited nanofabricated arrays of 2D-PC cavities onto a thin oxide (silicon nitride (Si3N4)) membrane for highly selective enhancement of fluorescent molecules emission. Cyanine (Cy3)-labeled target DNA molecules were immobilized on the 2D-PC, allowing the intensification of the emission of the organic dye due to resonating modes of the cavities, with high spectral resolution. By means of fine-tuning of the fabricated planar resonators, it was possible to assign a spectral fingerprint to targets bound to different resonators in the arrays, so that the presence of different DNA molecules in an investigated assay was assessed through spectral analysis of the emission coming from the whole array in a single shot. A clear sketch of the detection scheme in showed in Fig. 7.

Scheme of a DNA-chip integrated with array of PhC nanocavities. The cavities are functionalized with different DNA probes, which specifically interact with complementary target analytes labeled with fluorescent markers. Inset: detail showing an example of nanocavities. Adapted with permission from [95]

4 Conclusion and Perspective

In this chapter, we have tried to illustrate the progress of nanotechnological strategies, which have been recently developed to implement the production of innovative diagnostic and optical sensing devices for genomic and proteomic applications. As many research works have shown, the recent trends in these nanobiotechnological platforms exploit the combination of top-down nanostructuring and bottom-up molecular self-assembly to soft lithography and molecular biology tools. The new generation of produced systems for diagnostics and nanostructured materials demonstrates that high information content, high sensitivity, and selectivity can be joined with ultra-high-throughput in advanced sensing and imaging. The current status of mature technologies for the fabrication of MEF and PCs-based platforms for sensing, combined with FRET and BRET methods, is expected to evolve in a rapid fashion on many different aspects to produce systems more and more miniaturized, sensitive, and with high performances, to be applied in the fields of molecular recognition and drug discovery, and be involved in several strategies for the molecule-based identification and diagnostics in cellular systems which comprise genotyping, phenotyping, DNA sequencing, and proteomics. The need is to perform different methodologies to apply for rapid sensitive detection system in multiplexed channels and for sensitive detection of single nucleotide polymorphism (SNP), genetic variation, and protein markers for cancer and other diseases, with the aim to contribute quickly and positively to the improvement of current early-diagnostic methods.

References

Cooper MA (2002) Optical biosensors in drug discovery. Nat Rev Drug Discov 1(7):515–528

Fan XD, White IM, Shopoua SI et al (2008) Sensitive optical biosensors for unlabeled targets: a review. Anal Chim Acta 620(1–2):8–26

Ligler FS (2009) Perspective on optical biosensors and integrated sensor systems. Anal Chem 81(2):519–526

Martin-Palma RJ, Manso M, Torres-Costa V (2009) Optical biosensors based on semiconductor nanostructures. Sensors 9(7):5149–5172

Collings AF, Caruso F (1997) Biosensors: recent advances. Rep Prog Phys 60(11):1397–1445

Gellman SH (1997) Introduction: molecular recognition. Chem Rev 97(5):1231–1232

deSilva AP, Gunaratne HQN, Gunnlaugsson T, Huxley AJM, McCoy CP, Rademacher JT, Rice TE (1997) Signaling recognition events with fluorescent sensors and switches. Chem Rev 97(5):1515–1566

Jung Y, Jeong JY, Chung BH (2008) Recent advances in immobilization methods of antibodies on solid supports. Analyst 133(6):697–701

Rauf S, Zhou D, Abell C et al (2006) Building three-dimensional nanostructures with active enzymes by surface templated layer-by-layer assembly. Chem Commun (Camb) 16:1721–1723

Barrett CR (1993) Silicon valley, what next. Mrs Bull 18(7):3–10

Clark RA, Hietpas PB, Ewing AG (1997) Electrochemical analysis in picoliter microvials. Anal Chem 69(2):259–263

Xiang XD, Sun XD, Briceno G et al (1995) A combinatorial approach to materials discovery. Science 268(5218):1738–1740

Manz A (1996) What can chips technology offer for next century’s chemistry and life sciences? Chimia 50(4):140–143

Kovacs GTA, Petersen K, Albin M (1996) Silicon micromachining – sensors to systems. Anal Chem 68(13):A407–A412

Wu MC, Lin LY, Lee SS et al (1996) Integrated devices make an optical bench on a chip. Laser Focus World 32(2):64–68

Nussbaum P, Volke R, Herzig HP et al (1997) Design, fabrication and testing of microlens arrays for sensors and microsystems. Pure Appl Opt 6(6):617–636

Xia YN, Tien J, Qin D et al (1996) Non-photolithographic methods for fabrication of elastomeric stamps for use in microcontact printing. Langmuir 12(16):4033–4038

Xia YN, Rogers JA, Paul KE et al (1999) Unconventional methods for fabricating and patterning nanostructures. Chem Rev 99(7):1823–1848

Xia YN, Whitesides GM (1998) Soft lithography. Angew Chem Int Ed Engl 37(5):551–575

Xia YN, Whitesides GM (1998) Soft lithography. Annu Rev Mater Sci 28:153–184

Kumar A, Whitesides GM (1993) Features of gold having micrometer to centimeter dimensions can be formed through a combination of stamping with an elastomeric stamp and an alkanethiol ink followed by chemical etching. Appl Phys Lett 63(14):2002–2004

Xia YN, Kim E, Zhao XM et al (1996) Complex optical surfaces formed by replica molding against elastomeric masters. Science 273(5273):347–349

Zhao XM, Xia YN, Whitesides GM (1996) Fabrication of three-dimensional micro-structures: microtransfer molding. Adv Mater 8(10):837–840

Kim E, Xia YN, Whitesides GM (1995) Polymer microstructures formed by molding in capillaries. Nature 376(6541):581–584

Kim E, Xia YN, Zhao XM et al (1997) Solvent-assisted microcontact molding: a convenient method for fabricating three-dimensional structures on surfaces of polymers. Adv Mater 9(8):651–654

Rogers SS, van der Walle C, Waigh TA (2008) Microrheology of bacterial biofilms in vitro: Staphylococcus aureus and Pseudomonas aeruginosa. Langmuir 24(23):13549–13555

Terris BD, Mamin HJ, Best ME et al (1996) Nanoscale replication for scanning probe data storage. Appl Phys Lett 69(27):4262–4264

Chou SY, Krauss PR, Renstrom PJ (1995) Imprint of sub-25 Nm vias and trenches in polymers. Appl Phys Lett 67(21):3114–3116

Masuda H, Fukuda K (1995) Ordered metal nanohole arrays made by a 2-step replication of honeycomb structures of anodic alumina. Science 268(5216):1466–1468

Hoyer P (1996) Semiconductor nanotube formation by a two-step template process. Adv Mater 8(10):857–859

Kim DC, Kang DJ (2008) Molecular recognition and specific interactions for biosensing applications. Sensors 8(10):6605–6641

Blattler T, Huwiler C, Ochsner M et al (2006) Nanopatterns with biological functions. J Nanosci Nanotechnol 6(8):2237–2264

Mendes PM, Yeung CL, Preece JA (2007) Bio-nanopatterning of surfaces. Nanoscale Res Lett 2(8):373–384

Whitesides GM (2001) The once and future nanomachine – biology outmatches futurists’ most elaborate fantasies for molecular robots. Sci Am 285(3):78–83

Yu B, Meyyappan M (2006) Nanotechnology: role in emerging nanoelectronics. Solid State Electron 50(4):536–544

Netzer L, Sagiv J (1983) A new approach to construction of artificial monolayer assemblies. J Am Chem Soc 105(3):674–676

Miyake T, Tanii T, Kato K et al (2007) Selectivity improvement in protein nanopatterning with a hydroxy-terminated self-assembled monolayer template. Nanotechnology 18(30):e6

Ferretti S, Paynter S, Russell DA et al (2000) Self-assembled monolayers: a versatile tool for the formulation of bio-surfaces. TrAC-Trends Anal Chem 19(9):530–540

Decher G (1997) Fuzzy nanoassemblies: toward layered polymeric multicomposites. Science 277(5330):1232–1237

Ariga K, Hill JP, Ji Q (2007) Layer-by-layer assembly as a versatile bottom-up nanofabrication technique for exploratory research and realistic application. Phys Chem Chem Phys 9(19):2319–2340

Lvov YM, Lu ZQ, Schenkman JB et al (1998) Direct electrochemistry of myoglobin and cytochrome p450(cam) in alternate layer-by-layer films with DNA and other polyions. J Am Chem Soc 120(17):4073–4080

Taton TA, Mucic RC, Mirkin CA et al (2000) The DNA-mediated formation of supramolecular mono- and multilayered nanoparticle structures. J Am Chem Soc 122(26):6305–6306

Wohlstadter JN, Wilbur JL, Sigal GB et al (2003) Carbon nanotube-based biosensor. Adv Mater 15(14):1184–1187

Shaikh KA, Ryu KS, Goluch ED et al (2005) A modular microfluidic architecture for integrated biochemical analysis. Proc Natl Acad Sci USA 102(28):9745–9750

Fixe F, Dufva M, Telleman P et al (2004) Functionalization of poly(methyl methacrylate) (PMMA) as a substrate for DNA microarrays. Nucleic Acids Res 32(1):e9

Wingren C, Borrebaeck CAK (2007) Progress in miniaturization of protein arrays – a step closer to high-density nanoarrays. Drug Discov Today 12(19–20):813–819

Tan CP, Cipriany BR, Lin DM et al (2010) Nanoscale resolution, multicomponent biomolecular arrays generated by aligned printing with parylene peel-off. Nano Lett 10(2):719–725

Sabella S, Brunetti V, Vecchio G et al (2009) Micro/nanoscale parallel patterning of functional biomolecules, organic fluorophores and colloidal nanocrystals. Nanoscale Res Lett 4(10):1222–1229

Sabella S, Vecchio G, Cingolani R et al (2008) Real-time PCR in a plastic chip based on solid state FRET. Langmuir 24(23):13266–13269

Martiradonna L, Stomeo T, De Giorgi M, Cingolani R, De Vittorio M (2006) Nanopatterning of colloidal nanocrystals emitters dispersed in a PMMA matrix by e-beam lithography. Microelectron Eng 83(4–9):1478–1481

Mitchell P (2002) A perspective on protein microarrays. Nat Biotechnol 20(3):225–229

Chan SM, Ermann J, Su L, Fathman CG et al (2004) Protein microarrays for multiplex analysis of signal transduction pathways. Nat Med 10(12):1390–1396

Rosi NL, Mirkin CA (2005) Nanostructures in biodiagnostics. Chem Rev 105:1547–1562

Aslan K, Gryczynski I, Malicka J, Matveeva E, Lakowicz JR, Geddes CD (2005) Metal-enhanced fluorescence: an emerging tool in biotechnology. Curr Opin Biotechnol 16(4):55–62

Johnson E, Aroca R (1991) Energy-transfer between langmuir-blodgett monolayers of organic-dyes. Can J Chem Revue Canadienne De Chimie 69(11):1728–1731

Lakowicz JR (2001) Radiative decay engineering: biophysical and biomedical applications. Anal Biochem 298(1):1–24

Lakowicz JR, Shen B, Gryczynski Z et al (2001) Intrinsic fluorescence from DNA can be enhanced by metallic particles. Biochem Biophys Res Commun 286(5):875–879

Lakowicz JR, Shen Y, D'Auria S et al (2002) Radiative decay engineering. 2. Effects of Silver Island films on fluorescence intensity, lifetimes, and resonance energy transfer. Anal Biochem 301(2):261–277

Gryczynski I, Malicka J, Shen YB et al (2002) Multiphoton excitation of fluorescence near metallic particles: enhanced and localized excitation. J Phys Chem B 106(9):2191–2195

Neal TD, Okamoto K, Scherer A (2005) Surface plasmon enhanced emission from dye doped polymer layers. Opt Express 13(14):5522–5527

Tovmachenko OG, Graf C, van den Heuvel DJ et al (2006) Fluorescence enhancement by metal-core/silica-shell nanoparticles. Adv Mater 18(1):91–95

Aslan K, Lakowicz JR, Geddes CD (2005) Rapid deposition of triangular silver nanoplates on planar surfaces: application to metal-enhanced fluorescence. J Phys Chem B 109(13):6247–6251

Nakamura T, Hayashi S (2005) Enhancement of dye fluorescence by gold nanoparticles: analysis of particle size dependence. Jpn J Appl Phys 44(9A):6833–6837, Part 1-Regular Papers Brief Communications & Review Papers

Shimizu KT, Woo WK, Fisher BR et al (2002) Surface-enhanced emission from single semiconductor nanocrystals. Phys Rev Lett 89(11):e4

Fort E, Gresillon S (2008) Surface enhanced fluorescence. J Phys D Appl Phys 41(1):e31

Aslan K, Lakowicz JR, Szmacinski H et al (2004) Metal-enhanced fluorescence solution-based sensing platform. J Fluoresc 14(6):677–679

Aslan K, Badugu R, Lakowicz JR et al (2005) Metal-enhanced fluorescence from plastic substrates. J Fluoresc 15(2):99–104

Aslan K, Holley P, Geddes CD (2006) Metal-enhanced fluorescence from silver nanoparticle-deposited polycarbonate substrates. J Mater Chem 16(27):2846–2852

Geddes CD, Gryczynski I, Malicka J et al (2003) Metal-enhanced fluorescence: potential applications in HTS. Comb Chem High Throughput Screen 6(2):109–117

Lakowicz JR, Malicka J, D’Auria S et al (2003) Release of the self-quenching of fluorescence near silver metallic surfaces. Anal Biochem 320(1):13–20

Aslan K, Malyn SN, Geddes CD (2006) Multicolor microwave-triggered metal-enhanced chemiluminescence. J Am Chem Soc 128(41):13372–13373

Sabanayagam CR, Lakowicz JR (2007) Increasing the sensitivity of DNA microarrays by metal-enhanced fluorescence using surface-bound silver nanoparticles. Nucleic Acids Res 35(2):e13

Zhang YX, Geddes CD (2010) Metal-enhanced fluorescence from thermally stable rhodium nanodeposits. J Mater Chem 20(39):8600–8606

Aslan K, Geddes CD (2005) Microwave-accelerated metal-enhanced fluorescence: platform technology for ultrafast and ultrabright assays. Anal Chem 77(24):8057–8067

Aslan K, Geddes CD (2006) Microwave-accelerated metal-enhanced fluorescence (MAMEF): application to ultra fast and sensitive clinical assays. J Fluoresc 16(1):3–8

Aslan K (2010) Rapid whole blood bioassays using microwave-accelerated metal-enhanced fluorescence. Nano Biomed Eng 2(1):1–9

Pompa PP, Martiradonna L, Della Torre A, Carbone L, del Mercato LL, Manna L, De Vittorio M, Calabi F, Cingolani R, Rinaldi R (2007) Fluorescence enhancement in colloidal semiconductor nanocrystals by metallic nanopatterns. Sens Actuators B Chem 126(1):187–192

Kang C, Weiss SM (2008) Photonic crystal with multiple-hole defect for sensor applications. Opt Express 16(22):18188–18193

Wojciechowski JR, Shriver-Lake LC, Yamaguchi MY et al (2009) Organic photodiodes for biosensor miniaturization. Anal Chem 81(9):3455–3461

Wood RW (1902) On a remarkable case of uneven distribution of light in a diffraction grating spectrum. Proc Phys Soc London 18:269–275

Yablonovitch E (1987) Inhibited spontaneous emission in solid-state physics and electronics. Phys Rev Lett 58(20):2059–2062

John S (1987) Strong localization of photons in certain disordered dielectric superlattices. Phys Rev Lett 58(23):2486–2489

Cunningham BT, Laing L (2006) Microplate-based, label-free detection of biomolecular interactions: applications in proteomics. Expert Rev Proteomics 3(3):271–281

Mandal S, Erickson D (2008) Nanoscale optofluidic sensor arrays. Opt Express 16(3):1623–1631

Luo C, Ibanescu M, Johnson SG et al (2003) Cerenkov radiation in photonic crystals. Science 299(5605):368–371

Schudel BR, Choi CJ, Cunningham BT et al (2009) Microfluidic chip for combinatorial mixing and screening of assays. Lab Chip 9(12):1676–1680

Block ID, Ganesh N, Lu M et al (2008) Sensitivity model for predicting photonic crystal biosensor performance. IEEE Sens J 8(3–4):274–280

Mortensen NA, Xiao SS, Pedersen J (2008) Liquid-infiltrated photonic crystals: enhanced light-matter interactions for lab-on-a-chip applications. Microfluid Nanofluidics 4(1–2):117–127

Cunningham BT, Li P, Schulz S et al (2004) Label-free assays on the BIND system. J Biomol Screen 9(6):481–490

El Beheiry M, Liu V, Fan SH, Levi O (2010) Sensitivity enhancement in photonic crystal slab biosensors. Opt Express 18(22):22702–22714

Shamah SM, Cunningham BT (2011) Label-free cell-based assays using photonic crystal optical biosensors. Analyst 136(6):1090–1102

Zlatanovic S, Mirkarimi LW, Sigalas MM et al (2009) Photonic crystal microcavity sensor for ultracompact monitoring of reaction kinetics and protein concentration. Sens Actuators B Chem 141(1):13–19

Martiradonna L, Pisanello F, Stomeo T et al (2010) Spectral tagging by integrated photonic crystal resonators for highly sensitive and parallel detection in biochips. Appl Phys Lett 96(11):e6

Toccafondo V, Garcia-Ruperez J, Banuls MJ, Griol A, Castello JG, Peransi-Llopis S, Maquieira A (2010) Single-strand DNA detection using a planar photonic-crystal-waveguide-based sensor. Opt Lett 35(5–8):3673–3675

Pisanello F, Martiradonna L, Pompa PP, Stomeo T, Qualtieri A, Vecchio G, Sabella S, De Vittorio M (2010) Parallel and high sensitive photonic crystal cavity assisted read-out for DNA-chips. Microelectron Eng 87(21):747–749

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Aloisi, A., Rinaldi, R. (2012). Nanotechnology for Diagnostic and Sensing: Soft and Advanced Imaging/Sensing Approaches to Analyze Biomolecules. In: Fritzsche, W., Popp, J. (eds) Optical Nano- and Microsystems for Bioanalytics. Springer Series on Chemical Sensors and Biosensors, vol 10. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-25498-7_3

Download citation

DOI: https://doi.org/10.1007/978-3-642-25498-7_3

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-25497-0

Online ISBN: 978-3-642-25498-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)