Abstract

Disposal of effluent from conventional shrimp farms containing high concentration of organic matter and nutrients into different environmental systems can have detrimental impacts on their adjacent ecosystems (e.g. coastal ecosystem ). To minimize the environmental impacts of shrimp farming effluents, recirculating raceway system has recently been introduced, producing high density shrimp yields . Although it is a zero water exchange system, a certain portion of water from the recirculating system needs to be treated or disposed of on regular basis due to an increase in the concentration of nitrate and nitrites owing to the protein enriched diet of shrimps. Hence, an effective approach for the treatment of nitrogen enriched wastewater produced by the recirculating raceway system is needed. Biological wastewater treatment capable of nitrification and denitrification is simple and environmentally friendly approach. In this regard, removal of ammonia and nitrates was assessed in aerobic sequencing batch reactor (SBR), providing almost complete removal of organic impurities (above 99%) as well as of ammonia. On the other hand, anaerobic SBR achieved efficient denitrification and also provided above 99% total nitrogen removal. Notably, the addition of Bacillus consortium in SBR can be helpful to control the growth of shrimp pathogen , Vibrio harveyi in the wastewater. This chapter discusses global shrimp production, biosecurity , recirculating raceway system, and the use of SBR in treating shrimp wastewater.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Denitrification

- Nitrification

- Sequencing batch reactor

- Recirculating raceway system

- Zero water exchange

- Probiotic

10.1 Introduction

Over the last two decades there has been an increase in consumer demand for shrimp (Weirich et al. 2002). In 1998, 80% of shrimp consumed in the United States was imported to meet consumer demand (Browdy 1998), which has led to a 3.2 billion dollar trade deficit (Aquaculture Outlook 1999). This deficit increased, due mostly to a strong United States domestic economy, resulting in an increase in both restaurant sales and home consumption of shrimp (Jory 2000). In order to reduce this trade deficit, the United States Department of Agriculture developed the United States Marine Shrimp Farming Program (USMSFP) to increase shrimp production in the United States.

In order for the United States to compete within the global shrimp market and decrease the trade deficit, new research and development must create technology to increase domestic shrimp farm production. Traditional pond systems, which are used to produce the bulk of farm raised shrimp in the United States, have three main limiting factors: length of growing season, land limitations, and high rates of water exchange (Browdy and Moss 2005). Shrimp have a growing season based on temperature. Therefore, ponds can only produce shrimp during the time of year when the temperature is conducive for growth. Land limitations refer to the fact that pond aquaculture is typically located close to the coast for easy water exchange with estuaries and other bodies of water. Coastal land is often expensive and limited in availability due to coastal development, making farming activities difficult (Landesman 1994). Finally, effluents from conventional shrimp farming ponds having a wide range of organic and inorganic impurities generally contains high level of organic carbon and nutrients. The potential environmental problems caused by aquaculture effluents include, but are not limited to, oxygen depletion, degradation of benthic communities, and exacerbation of toxic algae bloom (Goldburg and Triplett 1997). Because of the potential detrimental effects of aquaculture effluents on adjacent water bodies and ecosystems criteria and standards for the disposal of aquaculture effluent have been developed and enforced by different government agencies (Kinne et al. 2001). For instance, the United Stated Environmental Protection Agency enforced the code of a federal regulation (part 451) under the Clean Water Act in 2004, establishing a narrative of technology based limitations as well as establishing environmental quality standards for the disposal of effluent from aquatic animal production facilities.

The USMSFP developed recirculating raceway system for high intensive shrimp farming in the U.S. In a recirculating aquaculture system , 95–99% of water is reused. This means that the system is required to have some type of water treatment process, such as a biological bead filter or sedimentation cones, to control the accumulation of suspended solids (Summerfelt et al. 2001). Because recirculating systems do not require water exchange with the environment, these systems can operate with minimal water exchange. Raceways are culture units in which the water flow is sufficient to induce a current to which aquatic organisms respond and in which detrital material can be transported. The advantages of this system include increased production of shrimp per unit space and the ease of harvesting and feeding (Mazik and Parker 2001). When recirculating and raceway systems are combined the system is called a recirculating raceway system. The recirculating raceway system combines advantages from both the recirculating and raceway systems. The recirculating raceway system can grow shrimp in high densities, increase the ease of feeding and harvesting, and operate with minimal water exchange.

Recirculating raceway systems can be very intensive system that produce large yields of shrimp per unit volume. However, the waste produced due to the high shrimp density, can cause substantial environmental impacts if discharged into the environment (Kinne et al. 2001). This waste consists of uneaten fish feed, fecal matter, and urine. The feed and fecal wastes produced in the raceway system is made almost entirely of organic matter (Goldburg and Triplett 1997), and is characterized by high amounts of COD, BOD, total suspended solids (TSS), dissolved particulate matter, volatile suspended solids (VSS) and nutrients (Kinne et al. 2001; Cohen et al. 2005).

Waste-treatment methods for aquaculture are largely adapted from municipal wastewater (sewage) treatment (Goldburg and Triplett 1997). In many shrimp farms, an industrial bead filter constantly filters the water. The bead filter works by passing the water through a filter bed without the addition of chemicals. The granular material inside the filter will remove suspended solids, through a series of complex processes involving one or more removal mechanisms. These mechanisms include straining, interception, impaction, sedimentation, and adsorption. Once the filtration process is complete, the filter must be backwashed to remove the suspended solids that have accumulated in the filter. This is achieved by reversing the flow of water through the filter. The granular material is fluidized and the suspended solids are washed out of the filter (Cerra and Maisel 1979). Bacterial processes, such as nitrification, also occur within the bead filter. In some shrimp farms sedimentation cones are used to remove suspended solids. Water from the raceway systems are pumped into the sedimentation cones, where the suspended solids are allowed to settle out into the bottom of the cones, and then the water on top of the cone is pumped back into the recirculating raceway system. Valves and gravity are used to empty the solids from the bottom of the cones. Both sedimentation and filtration methods produce large amounts of wastewater. This wastewater gets pumped out of the recirculating raceway systems via emptying the sedimentation cones or backwashing the bead filter, and has to be disposed. Disposal of this wastewater is complicated by the wastewater’s saline properties, and reuse of this water will cause problems due to the toxic concentrations of ammonia and nitrite. Most of the studies focusing on the treatment of wastewater from aquaculture have been carried out in small scale systems under controlled environmental conditions. For instance, Boopathy et al. (2005) achieved significant removal of organic impurities as well as nutrients following the treatment of shrimp farming wastewater in a sequencing batch reactor (SBR). A SBR consisting of a single reactor utilizes activated sludge for the treatment of wastewater and can be operated in aerobic as well as anaerobic mode (Boopathy et al. 2005; Fontenot et al. 2007; Morgenroth and Wilder 1998). Despite the excellent performance of SBR, it is imperative to assess its operational feasibility as well as treatment efficiency at large scale for its practical applications (Brune et al. 2003). This chapter discusses global shrimp production, biosecurity , recirculating raceway system, and the use of SBR in treating shrimp wastewater.

10.1.1 Global Shrimp Production

Total global shrimp production consists of (i) planned shrimp farming activities; and (ii) wild harvesting . According to an estimate by Keithly et al. (2005), total global production of shrimps increased significantly with an approximate growth rate of 220 million pounds per annum from 1980 to 2001 (Fig. 10.1) 220 million pounds is a significant number in the fact that the southeast (North Carolina to Texas) United States shrimp harvest usually falls within the 220–280 million pounds per year (Keithly et al. 2005). As the population increases in the United States, the southeast shrimp harvest cannot meet the United States consumer demand for marine shrimp. In 1980, 258 million pounds of headless shell-on shrimp were imported into the United States and accounted for 55% of the total United States shrimp supply. By 2001, imports into the United States advanced to 1.18 billion pounds at which point they represented 85% of total United States shrimp supply (Keithly et al. 2005). In 1998, approximately 80% of shrimp consumed in the United States were imported and of this amount over 50% of the shrimp came from shrimp farms located in Asia (Browdy 1998). To reduce the trade deficit, shrimp farming must increase, because the wild-caught harvest can be variable due to weather variation, increasing oil prices, and fishing pressure on shrimp populations. In 1980, global production of farmed shrimp equaled about 160 million pounds, and by 2001, global production of farmed shrimp increased to 2.8 billion pounds, or more than 35% of total shrimp output. Overall farmed shrimp production increased by approximately 130 million pounds per year during 1980–2001 (Keithly et al. 2005). The increased farmed shrimp production allowed more shrimp product to enter the global trade market. This made shrimp more affordable for consumers dropping the price of shrimp per pound from $5.82 in 1980 to $2.87 in 2001 (Keithly et al. 2005). Csavas (1994) stated that farm-raised shrimp are of greater importance to global trade than wild-caught product because farm-raised product has greater freshness, can be grown year round, sizes can be controlled better in a farm-based system, and the farming system will help meet consumer demands. Although the United States demand for marine shrimp is high, the United States’ contribution to world farm-raised shrimp production is insignificant. In the United States there are only a few facilities that focus on the production of the pacific white shrimp, Litopenaeus vannamei. These facilities are primarily located in Florida, Hawaii, South Carolina, and Texas, and of these facilities some produce only larval shrimp, which are sold and distributed to foreign buyers (Weirich et al. 2002).

Global Peneaid shrimp supply for the period of 1981–2001 (Ostrowski et al. 2005)

10.1.1.1 Litopenaeus Vannamei

Litopenaeus vannamei, or the pacific white shrimp, is the most widely produced shrimp in recirculating raceway systems (Williams et al. 1996). In 1996, this shrimp constituted 30% of the farmed penaeid shrimp worldwide (Williams et al. 1996). L. vannamei grows naturally in salinities ranging from 1 to 40 g/L (Menz and Blake 1980), by using different osmotic regulation mechanisms such as hyper-osmotic regulation in low salinity and hypo-osmotic regulation in high salinity (Castille and Lawrence 1998). However, most marine shrimps are grown in water with salinities higher than 15 g/L.

L. vannamei is a rapidly growing species, which is disease tolerant, and has a good survival rate in a high density system (Williams et al. 1996). Even though L. vannamei is the most widely produced species in aquaculture , there are still problems associated with mass production of the species. L. vannamei can be an invasive species if released into areas that are non-native.

10.1.2 Biosecurity

Biosecurity has been defined as the sum of all procedures in place to protect living organisms from contracting, carrying, and spreading diseases and other non-desirable health conditions (Pruder 2004). Biosecurity is comprised of a series of activities that include preventive medicine, adequate diagnosis, containing outbreaks that occur, and the eradication or disinfection of the pathogen (Pruder 2004). A biosecure facility should also be designed around the concept of biosecurity. Materials used in ponds and raceways should be easy to disinfect, the facility should not have unauthorized vehicles or visitors, and also the facility should prevent the escape of the organisms while preventing the entry of others (Pruder 2004).

The main objective of biosecurity for shrimp farms is to control pathogens such as Taura Syndrome Virus (TSV), White Spot Virus (WSV), the Hepatopancreatic Parvovirus (HPV), and other major shrimp pathogens. The main vector for these pathogens appears to be shrimp larvae, both wild-caught shrimp larvae and shrimp larvae that have been raised in a hatchery (Pruder 2004; Otoshi et al. 2003). In order to reduce pathogens related to shrimp larvae, researchers have developed high health shrimp or specific pathogen-free (SPF) shrimp. These shrimp go through rigorous quarantine and screening efforts. Once the SPF shrimp leave the hatchery the SPF shrimp are considered high health shrimp (Pruder 2004; Browdy and Moss 2005; Otoshi et al. 2003).

The second vector that is responsible for introducing disease and pathogens into aquaculture systems is water exchange (Pruder 2004; Cohen et al. 2005; Browdy and Moss 2005). The use of untreated water can put the entire aquaculture facility at risk of disease . With some shrimp farming methods, water is discharged daily into a receiving body of water, and then replaced with untreated water (Cohen et al. 2005; Otoshi et al. 2003). This technique helped to ensure water quality in the aquaculture system, but is no longer practiced due to conflicts with other potential users, pathogen induction, and government regulations on effluent . The discharge issue has generated interest in the shrimp aquaculture industry to achieve zero-water exchange using recirculating systems (Cohen et al. 2005). The zero-water exchange method simply continues to use the same water, helping to guarantee biosecurity. For the recirculating raceway system to be successful when using the zero-water exchange method, proper feed management, adequate aeration and circulation, and nitrogen cycling processes must be managed carefully (Cohen et al. 2005).

Finally, the third major vector for pathogen induction is through excess feed. Elevated concentrations of nitrogen and phosphorous from the excess feed can stimulate growth or blooms of phytoplankton (algae), a process termed eutrophication (Goldburg and Triplett 1997). Due to the lack of water-exchange in aquaculture systems, nutrients can easily build up and cause eutrophication . When algae die in large numbers, there is a large influx of organic matter into the water column. BOD is used to measure the concentration of organic matter available for degradation by microorganisms. When BOD is high, microorganisms are using oxygen in the water to decompose organic matter (Goldburg and Triplett 1997). So, eutrophication due to excess feed can cause a population increase in microbial, algal, and other microscopic communities. The increase of microscopic communities can impact the carrying capacity of the culture system by disrupting water quality parameters such as dissolved oxygen (Cohen et al. 2005).

10.1.3 Recirculating Raceway Systems

Recirculating raceway systems have many advantages over traditional pond aquaculture. First, this system allows for biosecurity measures to be implemented very easily and prevents losses due to infectious diseases (Bratvold and Browdy 1999; Browdy and Moss 2005). Also, recirculating raceway systems can achieve year round production if kept indoors (Browdy and Moss 2005). This is because recirculating raceway systems can be enclosed in greenhouses that can be heated using heat-exchange units located on the bottom of the raceway or cooled by fans built into the greenhouses in order to maintain the optimal growth temperature for the shrimp (Weirich et al. 2002). With the ability to grow shrimp year round farmers can time production to market conditions rather than the seasons of the year (Goldburg and Triplett 1997). An additional benefit to the recirculating raceway being indoors is the ability to reduce losses of shrimp to predators, which also helps to reduce pathogen induction from wild organisms. Finally, environmental impacts due to effluent discharges are reduced or eliminated because of the minimal water exchange between the recirculating raceway system and the environment. Additionally, the recirculating raceway systems also use less land than traditional pond systems (Browdy and Moss 2005). Greater environmental control means that recirculating raceway systems offer better control of contaminants, product quality, predators, and introduction of pathogens. There are disadvantages to the recirculating raceway system, most notably the fact that the raceway has to treat and circulate large volumes of water and typically require larger capital investments. Additionally, recirculating raceway systems have higher operating costs due to energy, labor, and supplies such as supplemental oxygen.

When managing recirculating raceway systems, heterotrophic and autotrophic bacteria are important, and an adequate understanding of the role bacteria play is essential in maintaining recirculating raceway water quality. Heterotrophic bacteria obtain carbon and energy for growth from organic compounds, survive during periods of stress (such as limited food sources and low oxygen) by forming spores, and are important dietary components of detritivores such as shrimp (McGraw 2002). Autotrophic bacteria obtain energy from light (photoautotroph) or the oxidation of inorganic compounds such as ammonia (chemoautotrophs), survive during periods of stress through inactivity, and are a poor source of nutrition for detritivores (McGraw 2002). However, autotrophic bacteria are more efficient at nitrification than heterotrophic bacteria. Most recirculating raceway systems are heterotrophic systems. Heterotrophic systems are managed by a large input of feed, which maintains the C:N ratio in the system. With the excessive carbon, bacteria populations increase, and become a feed source for the shrimp. Significant nitrification occurs within the raceway system, although the overall rate of nitrification is limited by the faster growing heterotrophic microbial population (Brune et al. 2003). Nitrification limitation in the recirculating raceway system is due to the availability of biodegradable organic matter, which supports the growth of heterotrophic bacteria. These heterotrophs compete with the autotrophic nitrifiers for oxygen, nutrients , and space (Sharma and Ahlert 1977; Zhu and Chen 2001). Heterotrophic recirculating raceway systems are also designed to maximize aeration to mix suspended solids to improve nitrification (Avinmelech et al. 1986, 1999). Excessive carbon matter, typically in the form of molasses, can be added to the recirculating raceway system in order to stimulate heterotrophic bacteria growth and increase nitrogen uptake.

10.1.4 Sequencing Batch Reactor

An activated sludge based wastewater treatment process was studied for the first time in 1914 and was operated in batch mode. This batch-fed wastewater treatment system was comprised of following steps: (i) addition of wastewater; (ii) aeration for biological degradation of pollutants; and (iii) sedimentation to allow the settlement of activated sludge. After the settlement of activated sludge, the supernatant containing low levels of organic and nutrients was collected for discharge and above steps were repeated for the treatment of next wastewater batch (Fang et al. 1993). However, this batch operation was discontinued in favor of continuous operation, because at the time batch operation did not seem as effective at treating wastewater, compared to other wastewater treatments. Eventually, interest in batch-fed reactors were resuscitated again during 1950–1960 mainly to test newly developed treatment process as well analytical equipment (Fang et al. 1993). The fill-and-draw type of batch operation was re-examined and renamed Sequencing Batch Reactor (SBR). Owing to the development of improved control devices as well as aeration equipment, SBR can compete with continuous flow conventional activated sludge treatment system such as the plug flow reactor, continuous stir tank reactor, and an arbitrary flow reactor, providing comparable reduction in pollutant concentrations (Fang et al. 1993).

The SBR is used in shrimp industry (Boopathy et al. 2005, 2007; Fontenot et al. 2007) because of its ability to accomplish equalization, aeration, and clarification in a timed sequence in a single reactor basin (Fig. 10.2). Other activated sludge systems use multiple structures to achieve equalization, aeration, and clarification, which require extensive plant space and pumping and piping systems. The SBR promises to reduce operating costs and plant space (Jang et al. 2004). The sequencing series for wastewater treatment using the SBR consists of the following process stages: fill, react, settle, decant and idle (Boopathy et al. 2005; Kargi and Uygur 2005; Morgenroth and Wilder 1998). The SBR has been well studied in terms of the potential for simultaneous removal of carbon and nitrogen (Murat et al. 2002), and has been successfully used to treat both municipal and industrial wastewater (Peters et al. 2004). Murat et al. (2002) used a SBR to successfully remove high levels of COD and nitrogen from tannery wastewater. The SBR is also extensively used in the treatment of swine wastewater (Juteau et al. 2005; Deng et al. 2006). Peters et al. (2004) showed that SBR can be used to effectively remove high levels of COD and nitrogen from sewage effluent .

A schematic of a sequencing batch reactor showing different processes/stages of wastewater treatment. All stages of treatment are carried out in a single reactor at different time intervals (Boopathy et al. 2005)

10.1.5 Bacteriology of Nitrification and Denitrification

Nitrogen is an essential nutrient for all organisms, as part of important molecules such as proteins, nucleic acids, adenosine phosphates, pyridine nucleotides, and pigments (Hagopian and Riley 1998). Shrimp expel nitrogen through urination and excretion. Uneaten feed and decomposing deceased shrimp also contributes to nitrogenous waste in aquaculture systems (Hagopian and Riley 1998; Cripps and Bergheim 2000). Both un-ionized ammonia and nitrite are toxic to shrimp at low concentrations. L. vannamei, exhibited a 96-h LC50 (median lethal concentration) of 24.39 mg/L ammonia with a salinity at 15 ppt, 8.05 pH, and a temperature of 23 °C (Lin and Chen 2001). The 96-h LC50 for nitrite in L. vannamei is 76.5 mg/L at 15 ppt salinity , with a water temperature at 18 °C, and the pH at 8.02 (Lin and Chen 2003). Therefore, nitrification and denitrification are very important processes in the treatment of shrimp aquaculture wastewater, so that ammonia and nitrite do not accumulate in recirculating raceway systems. Ammonia and nitrite become mineralized through nitrification into nitrate compound and then nitrate becomes volatilized through denitrification and into nitrogen gas.

10.1.5.1 Nitrification

Autotrophic as well as heterotrophic bacteria, under aerobic conditions, can be involved in a biological nitrification process (Zhu and Chen 2001). Notably, two groups of bacteria with different phylogenetic evolution, namely ammonia-oxidizing bacteria and nitrite-oxidizing bacteria, are known to perform nitrification. Ammonia-oxidizing bacteria such as Nitrosomonas, Nitrosovibrio and Nitrosospira perform nitrification via catabolic conversion of ammonia to nitrite (Reaction 1), while nitrite-oxidizing bacteria such as Nitrobacter and Nitrospira (Reaction 2) are responsible for the conversion of nitrite to nitrate (Hagopian and Riley 1998; Zhu and Chen 2001). Compared to the conversion of nitrite to nitrate, ammonia conversion to nitrite generates more energy (Hagopian and Riley 1998; Remde and Conrad 1990; Rijn 1995) as shown:

As mentioned above, Nitrosomonas, Nitrosovibrio and Nitrosospira are involved in Reaction 1 i.e. conversion of ammonia to nitrate, while Reaction 2 i.e. conversion of nitrite to nitrate is carried out by Nitrobacter and Nitrospira, indicating that nitrifying bacteria belongs to Nitrobacteraceae family that is a group of chemoautotrophic gram negative bacteria (Tanaka et al. 1983). Chemoautotrophic bacteria utilize inorganic chemical substrates (NH3, NO2) as an electron source to immobilize inorganic carbon (CO2), thereby allowing carbon fixation to occur (Hagopian and Riley 1998; Ritchie and Nicholas 1972; Sundermeyer-Klinger et al. 1984).

10.1.5.2 Denitrification

Nitrification oxidizes toxic ammonia and nitrite, to the relatively non-toxic form of nitrate; however, over a long period of time nitrate concentrations could become toxic to aquatic organisms (Sauthier et al. 1998; Ng et al. 1993). This is even more prevalent in recirculating raceway systems where the water is continuously reused. Denitrification is the process, where heterotrophic bacteria, such as Pseudomonas denitrificans and Escherichia coli, under anaerobic conditions convert nitrate to nitrogen gas, and completely volatize nitrogen from the system (Sauthier et al. 1998). The bacteria oxidize organic matter using the following electron acceptors in the following order: dissolved oxygen , nitrate, and sulfates. If there are poor reducing conditions then partial denitrification can occur, and if there are drastic reducing conditions sulfates can be reduced to toxic sulfides (Sauthier et al. 1998). Figure 10.3 shows how ammonia is converted into nitrate under aerobic conditions (nitrification), and then how nitrate is converted into nitrogen gas under anaerobic conditions (denitrification).

10.2 Case Study of Shrimp Wastewater Treatment

Performance of a sequencing batch reactor (SBR) for the treatment of shrimp farming effluent/sludge was studied to improve the quality of water in recirculating raceway system. Timing to remove wastewater and sludge is same in recirculating raceway shrimp farming system. This study was conducted with the aim to assess: (i) the performance of SBR for the removal of carbon and nitrogen from shrimp farming effluent ; and (ii) the suitability of treated effluent for reuse in shrimp ponds.

10.2.1 Shrimp Waste Sludge

Bead filter backwash was collected in 3 L sealed containers from a recirculating raceway shrimp farming system located at Waddell Mariculture Center, South Carolina. Effluent/waste sludge samples were stored at 4 °C until use.

10.2.2 Sequencing Batch Reactor (SBR)

For the treatment of shrimp farming effluent, four laboratory scale SBRs each having a working volume of 19 L were erected. Initially, each SBR was fed with 4 L shrimp farming effluent and was operated under aerobic mode by providing aeration using air stones. A stirring motor (Model RW 20/RW 20DZM; Tekmar Company, Cincinnati, OH) was installed in each reactor and operated at 100 rpm to keep the contents of reactors well mixed. After a certain period of time, SBRs were operated in anaerobic mode by turning off aeration as well as mixing. Different time sequences for aerobic and anaerobic modes were tested until the end of the experiment to optimize aerobic and anaerobic time sequences for the removal of carbon and nitrogen from shrimp farming effluent. Aerobic and anaerobic mode of operation in SBR are vital because organic carbon oxidation and nitrification occur in aerobic mode, while denitrification occurs in anaerobic/anoxic mode. Without anaerobic mode of operation, total nitrogen removal can deteriorate due to poor denitrification. Since all four SBRs were operated simultaneously under identical operating condition, carbon and nitrogen removal represents the average of results obtained from four SBRs.

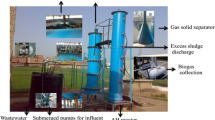

10.2.3 Pilot Scale SBR

After optimizing the operating conditions in laboratory scale SBRs for the treatment of shrimp farming sludge, two identical pilot scale SBRs (500 L) were installed at the recirculating raceway farming system, Waddell Mariculture Center, South Carolina. Arrangement of a SBR as well as water flow directions with respect to culture system and bead filter is shown in Fig. 10.4. SBRs were operated in aerobic and anaerobic mode for 3 and 6 days, respectively. Carbon and nitrogen removal was reported as the average of duplicate SBRs.

10.2.4 Chemical Analysis

30 mL samples from SBRs were collected at regular intervals to quantify COD, ammonia, nitrate and nitrite concentrations. Supernatant of each sample centrifuged at 5000 rpm for 10 min was used for chemical analyses. COD was analyzed as per the method described in standard methods for the examination of water and wastewater (APHA 1998). Ammonia, nitrate and nitrite were quantified via colorimetric method using HACH water analysis kit (Hach 1999). The dissolved oxygen (DO) and salinity were measured using an YSI DO and salinity probe (Model No. 85-10FT, Yellow Spring, OH), respectively. The pH was measured using a pH probe (Model UB 10, Denver Instruments, Boulder, CO).

10.2.5 Data Analysis

Data of removal efficiencies was subjected to a number of statistical analyses. Paired t-test (p ≤ 0.05; SAS Institute 2003) was used to analyze total concentration of COD. Analysis of variance (ANOVA) followed by tukey “post hoc” analysis (SAS Institute 2003) were used for all results.

10.3 Results of Case Study

10.3.1 Characterization of Shrimp Farming Effluent

Wastewater characterization is vital to: (i) understand the physical and chemical composition of wastewater; and (ii) select or design an effective wastewater treatment system. Based on the characteristics of shrimp farming effluent (Table 10.1), an activated sludge based treatment system may be efficient because of high levels of COD and nitrogen (nitrate, nitrite and ammonia). However, adequate nitrification and denitrification may be required for efficient removal of total nitrogen.

10.3.2 Performance of Laboratory SBR

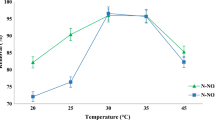

Four laboratory scale SBRs (19 L each) were operated simultaneously under identical operating conditions in aerobic (0–3 days) and anaerobic (4–9 days) modes. SBRs achieved above 99% ammonia removal under aerobic conditions (Fig. 10.5). On the other hand, concentration of nitrates increased from 47 and 93 mg/L (Fig. 10.5) in SBRs at the end of aerobic operating mode, indicating that an effective nitrification occurred. When SBRs were operated in anaerobic operating conditions from 4–9 day, nitrate concentration decreased gradually. Concentration of nitrates reduced from 93 mg/L (day 3) to 2 mg/L (day 8). Similarly, concentration of nitrite increased from 235 to 401 mg/L under aerobic conditions (0–3 days) and gradually reduced to 5 mg/L at the end of anaerobic operating mode (Fig. 10.5). Reduction in nitrite and nitrate concentration under anaerobic operating mode suggests that an effective denitrification process occurred in SBRs.

Variations in the concentration of ammonia, nitrate and nitrite in laboratory scale SBRs during the treatment of shrimp farming effluent. SBRs were operated in aerobic and anaerobic modes from 0 to 3 and 4 to 9 days, respectively. Results are presented as average ± standard-deviation achieved in four SBRs

Influent concentration of organic matter quantified in terms of COD was on the higher side (1596 mg/L) probably because shrimp effluent mainly contains shrimp food contents. COD concentration reduced from 1596 to 400 mg/L in SBR operated in aerobic mode for 3 days (Fig. 10.6). Similarly, SBR operated in anaerobic operating mode further reduced the concentration of COD from 4 to 6 days (Fig. 10.6) but COD removal did not improve significantly during the last three days of anaerobic operating condition i.e. 7–9 days. Operation of laboratory scale SBRs for 9 days achieved significant COD, ammonia, nitrate and nitrite removal. Nitrogen removal (Fig. 10.5) from shrimp effluent also indicate that level of nitrifying and denitrifying bacteria was adequate in sludge. Moreover, there was no need to add specific microbes to carry out nitrification and/or denitrification.

10.3.3 Performance of Pilot Scale SBR

Performance of pilot SBR plants (500 L) was assessed for the treatment of shrimp farming effluent after confirming the efficient COD and nitrogen removal in laboratory scale SBRs (Figs. 10.5 and 10.6). Two identical pilot scale SBRs were installed at Waddell Mariculture Center, SC as shown in Fig. 10.4 and the backwash of bead filter was used as an influent to pilot SBR plants. The objective of the treatment of shrimp farming effluent was to recycle the treated effluent back to shrimp culture. Pilot scale SBRs achieved 100% removal of COD, ammonia, nitrite and nitrate within a week of their operation (Table 10.2).

SBRs (laboratory and pilot scale) successfully achieved almost complete removal of organic matter as well as ammonia, nitrate and nitrites from shrimp farming effluent or sludge. SBR have a number of advantages over continues flow activated sludge treatment system including simple reactor design as well as simplicity of operation. SBR have been studied for the treatment of different type of wastewater such as slaughterhouse effluents, dairy effluent, swine manure and sewage (Irwine and Ketchum 1989; Masse and Masse 2000; Fernandes et al. 1991; Lo et al. 1991). Although performance of SBRs was excellent for shrimp farming effluents, a number of treatment systems such as conventional activated sludge process as well as the use of filtration systems have also been studied for the treatment of shrimp farming effluents. Moreover, apparatus for the removal of sludge and foam fractions from shrimp farming effluents has also been designed and investigated (Arbiv and Rijn 1995; Browdy et al. 1995; Hopkins 1994; Holloway 2002). However, these systems can be expensive and may have higher operating expenditures. Design of SBR is simple and all processes occur in a single tank compared to the requirement of multiple tanks in continuous flow activated sludge process. This case study showed that shrimp farming effluents or sludge can be efficiently treated in SBRs. Simple operation of SBR in aerobic (0–3 days) and anaerobic mode (4–9 days) led to almost complete removal (above 99%) of COD and total nitrogen. Although nitrifying bacteria bacteria are slow growing microbes, efficient ammonia removal was achieved, meaning that shrimp farming effluent already contained these microbes. On the other hand, denitrification i.e. nitrate and nitrite removal was achieved only during the anaerobic operating mode (Fig. 10.5). At the end of the operation the sludge can be dewatered and the water can be recycled back into shrimp production. The application of SBR technology for intensive shrimp production is an attractive alternative to various methods currently used in shrimp aquaculture .

The practice of introducing microbes has become a common practice in commercial aquaculture activities, particularly in shrimp farming, around the globe. Purpose of bacterial amendments is to improve: (i) the digestion of food in aquaculture; (ii) the immune system of cultures against pathogens ; and (iii) the quality of water as well as ponds bottom conditions. These products containing certain strains of bacteria used to improve the environmental quality of the aquaculture ponds are marketed as “probiotics ”. Use of probiotics in aquaculture industry has grown rapidly, suggesting a positive perception towards these products. On the other hand, there are many products in the market which range in price and quality. Some have followed meticulous quality control systems and are based on years of scientific research. Unfortunately, the market also has many low quality products, which offer the grower little to no value. These types of low quality products cast doubt on the use of microbial amendments in aquaculture.

10.3.4 Use of Probiotics in Shrimp Aquaculture

Effects of probiotics in aquaculture is not completely understood because available studies are not enough to develop a definitive opinion. Probiotics have mostly been studied with the view point of their impacts on the environmental quality of aquaculture ponds as well as on the diversity of pathogens. Bacterial amendments are not only used in aquaculture but are also used in wastewater treatment and/or bioremediation. Bacterial amendments in bioremediation are known to provide favorable conditions for the growth of certain bacterial communities to: (i) competitively exclude other microbial communities ; and (ii) provide direct bioremediation or biodegradation . On the other hand, impacts of bacterial amendments in aquaculture have not been demonstrated clearly mainly because environmental conditions are highly variable in aquaculture ponds, thereby making it difficult to either maintain effective controls or to replicate environmental conditions. A better understanding of comparative efficacy and mode of action of various probiotic products will depend upon the development of more controlled laboratory testing models.

In order to study the efficacy of any probiotic, focus should be on the in vitro microbiological assessment of probiotics . FDA Bam and AOAC procedures were used to verify bacterial populations in the product in the order of a billion per gram. Disc diffusion methods and broth inhibition assays were used to confirm inhibition rates against pathogens of interest including Vibrio harveii.

A commercially available probiotic, namely MeraBac W (Novus corporation, MO, USA) was tested in a small scale assay system under controlled environmental conditions with the objective to: (i) develop as small scale assay for testing the effects of probiotic in shrimp ponds; and (ii) elucidate the effects of selected probiotic on the water quality of shrimp ponds as well as on the abundance of a shrimp pathogen (Vibrio harveyii). In this study, 250 mL of shrimp farming effluent containing frozen aquaculture sludge collected from a shrimp ponds was incubated separately in two benchtop reactor (500 mL each) and was aerated. Moreover, autoclaved shrimp farming effluent was also incubated separately in two benchtop reactors mainly to assess the impact of the probiotic on shrimp pathogen. COD removal in bench top reactors from non-autoclaved shrimp effluent was measured with and without the addition of the probiotic. Initial COD concentration of shrimp effluent was ranged from 2800 to 3300 mg/L.

Notably, addition of the probiotic significantly improved the removal of COD in compared to that obtained without the addition of the probiotic (Fig. 10.7). Moreover, it was observed that improvement in the rate of COD removal depends on the concentration of probiotics. Addition of the probiotic at a concentration of 1 g/L achieved above 99% removal of COD within 4 days. On the other hand, addition of the probiotic at 0.0001 and 0.1 g/L required 6 and 8 days, respectively, to achieve above 99% COD removal (Fig. 10.7). The complete removal of waste COD within 8 days at recommended concentrations for pond application is a very important finding, particularly in consideration of the fact that most growers treat pond weekly assuring continual enhancement of waste digestion. Of interest was the lack of significant change in digestion rates with the addition of glucose. This suggests that despite the high nitrogen content of the shrimp waste tested here, addition of labile carbon did not change sludge digestion rates. Further research using this model system could help determine if and when use of supplementary molasses can improve probiotic activity in pond systems.

Impact of probiotic addition on the abundance of Vibrio harveyii (a shrimp pathogen) was also assessed in this study by adding a known concentration of V. harveyii i.e. 109 cell/mL in benchtop reactors at the beginning of the experiment and its concentration was monitored until the end of the experiment. A significant reduction in the concentration of V. harveyii was observed in the presence of a probiotic (Fig. 10.8). Initial concentration of V. harveyii i.e. 109 cell/mL was reduced to 102 cell/mL (corresponding to a 5 log removal) within 8 days. On the other hand, concentration of V. harveyii in the absence of the probiotic remained at 109 cell/mL till the end of the experiment (Fig. 10.8). Interestingly, concentration of V. harveyii increased from 109 to 1012 cell/mL in the reactor fed with autoclaved shrimp farming effluent within 8 days. This study clearly showed that the supplemental heterotrophic bacterial amendments have a competitive edge over V. harveyii and thus decreased the population of Vibrio. It is interesting to note that Vibrio proliferated in the absence of other heterotrophic bacteria in autoclaved waste water. Only the selected bacterial strains in the Mera Bac W were effective in significantly reducing the Vibrio concentration in the wastewater.

This study suggests that the application of bacterial amendments contributed significantly to digestion of organic material and suppressed Vibrio populations in shrimp wastewater. These controlled and replicated trials can shed light on mode of action and relative efficiency of probiotic activity. The data from these types of comparisons can provide a more robust statistical analysis than pond -based trials. Nevertheless, these laboratory scale trials have important practical implications for use in shrimp production systems. One of the most significant criticisms of probiotic technologies relate to the application rates relative to pond volumes. This study shows at the recommended application rates, the bacteria had significant effects on water quality.

10.4 Conclusion

Around 85% of shrimp consumed in the United States are imported. This leads to a trade deficit of over 3 billion dollar. In order for the United States to reduce this deficit and compete on a global scale in the shrimp market, new technologies, such as recirculating raceway systems, must be explored. Recirculating raceway systems produce large amounts of shrimp per unit volume. The waste produced due to the high density of these systems can cause substantial environmental problems, and disposing of the waste can be very difficult and expensive. Because the recirculating raceway system is a zero-water exchange system , nutrients such as nitrogen, phosphorous, and organic carbon can build up in these systems. Disposal of this wastewater can be problematic due to the saline properties of the wastewater and reuse of the wastewater within the raceway system is hindered by high concentrations of ammonia and nitrite. Technology such as the sequencing batch reactor (SBR) is being used to help reduce ammonia, nitrite, nitrate, and organic carbon, so that the wastewater can be reused. The application of bacterial amendments contributed significantly to digestion of organic material and suppressed Vibrio populations in shrimp wastewater.

References

APHA (1998) Standard methods for the analysis of water and wastewater, 20th edn. American Public health Association, Alexandria, Virginia, USA

Aquaculture Outlook (1999) Economic Research Service, U.S. Department of Agriculture, Washington, DC. Report number, 20036-5831

Arbiv R, Rijn VJ (1995) Performance of a treatment system for inorganic nitrogen removal in intensive aquaculture systems. Aquac Eng 14:189–203

Avnimelech Y, Weber B, Hepher B, Mitstein A, Zorn M (1986) Studies in circulated fish ponds; organic matter recycling and nitrogen transformation. Aquac Fish Manage 17:231–242

Avnimelech Y, Kochva M, Hargreaves JA (1999) Sedimentation and resuspension in earthen fish ponds. J World Aquaculture Soc 30:401–409

Boopathy R, Fontenot Q, Kilgen MB (2005) Biological treatment of sludge form a recirculating aquaculture system using a sequencing batch reactor. J World Aquaculture Soc 36:542–545

Boopathy R, Bonvillain C, Fontenot Q, Kilgen MB (2007) Biological treatment of low-salinity shrimp aquaculture wastewater using sequencing batch reactor. Int Biodeterior Biodegradation 59:16–19

Bratvold D, Browdy CL (1999) Disinfection, community establishment and production in a proto-type biosecure shrimp pond. J World Aquaculture Soc 30:422–432

Browdy CL (1998) Recent developments in penaeid broodstock and seed production technologies: improving the outlook for superior captive stocks. Aquaculture 164:3–21

Browdy CL, Moss SM (2005) Shrimp culture in urban, super-intensive closed systems. Urban Aquac 6:173–185

Browdy CL, Stokes AD, Hopkins JS, Sandifer PA (1995) Improving sustainability of shrimp pond water resource utilization. In: 3rd Ecuadorian aquaculture conference, Guayaquil, Ecuador

Brune DE, Schwartz G, Eversole AG, Collier JA, Schwedler TE (2003) Intensification of pond aquaculture and high rate photosynthetic systems. Aquac Eng 28:65–86

Castille FL, Lawerence AL (1998) The effect of salinity on osmotic, sodium, and chloride concentrations in the hemolymph of euryhaline shrimp of the genus Penaeus. Comp Biochem Physiol 68A:75–80

Cerra FJ, Maisel JW (1979) Wastewater engineering treatment, disposal, reuse. McGraw-Hill Inc., New York, p 228

Cohen JM, Samocha TM, Fox JM, Gandy RL, Lawrence AL (2005) Characterization of water quality factors during intensive raceway production of juvenile Litopenaeus vannamei using limited discharge and biosecure management tools. Aquac Eng 32:425–442

Cripps SJ, Bergheim A (2000) Solids management and removal for intensive land-based aquaculture production systems. Aquac Eng 22:33–56

Csavas L (1994) Important factors in the success of shrimp farming. World Aquaculture 25:34–56

Deng LW, Zheng P, Chen ZA (2006) Anaerobic digestion and post-treatment of swine wastewater using IC-SBR process with bypass of raw wastewater. Water Sci Technol 41:965–969

Fang HP, Yeong CY, Book KM, Chiu CM (1993) Removal of COD and nitrogen in wastewater using a sequencing batch reactor with fibrous packing. Water Sci Technol 28:125–131

Federal Register (2004) Effluent limitations guidelines and new source performance standards for the concentrated aquatic animal production point source category; final rule. 40 CFR Part 451. Monday, 23 Aug 2004. http://epa.gov/guide/aquaculture

Fernandes L, McKyes E, Warith M, Barrington S (1991) Treatment of liquid swine manure in the sequencing batch reactor under aerobic and anaerobic conditions. Can Agr Eng 33:373–379

Fontenot Q, Bonvillain C, Kilgen MB, Boopathy R (2007) Effects of temperature, salinity, and carbon: nitrogen ratio on sequencing batch reactor treating shrimp aquaculture wastewater. Biores Technol 98:1700–1703

Goldburg R, Triplett T (1997) Murky waters: environmental effects of aquaculture in the US. http://www.environmentaldefense.org/documents/490_AQUA.pdf

Hach D (1999) Hach DR/2000 spectrophotometer handbook. Loveland, Colorado, USA

Hagopian DS, Riley JG (1998) A closer look at the bacteriology of nitrification. Aquac Eng 18:223–244

Holloway M (2002) Blue revolution. Discover 23:56–63

Hopkins JS (1994) An apparatus for continuous removal of sludge and foam fractions in intensive shrimp ponds. Progressive Fish Culturist 56:135–139

Irwine RL, Ketchum LH (1989) Sequencing batch reactors for biological wastewater treatment. CRC Crit Rev Environ Control 18:255–294

Jang JD, Bradford JP, Rennebery R (2004) Application of biochemical oxygen demand (BOD) biosensor for optimization of biological carbon and nitrogen removal from synthetic wastewater in a sequencing batch reactor. Biosens Bioelectron 19:805–812

Jory DE (2000) Shrimp—potential for development of marine shrimp farming in Florida. Aquac Mag 26:72–80

Juteau P, Tremblay D, Villemur R, Bisaillon JG, Beaudet R (2005) Analysis of the bacterial community inhabiting an aerobic thermophilic sequencing batch reactor (AT-SBR) treating swine waste. Appl Microbiol Biotechnol 66:122–155

Kargi F, Uygur A (2005) Improved nutrient removal from saline wastewater in an SBR by Halobacter supplemented activated sludge. Environ Eng Sci 22:170–171

Kinne PN, Samocha TM, Jones ER, Browdy CL (2001) Characterization of intensive shrimp effluent and preliminary studies on biofiltration. North Am J Aquac 63:25–33

Keithly WR, Diop H, Kazmierczak RF, Travis MD (2005) An economic analysis of the southeast US shrimp processing industry responses to an increasing import base. Proc Gulf Caribb Fish Inst 56:133–149

Landesman L (1994) Negative impacts of coastal aquaculture development. World Aquaculture 25:12–17

Lin Y, Chen J (2001) Acute toxicity of nitrite on Litopenaeus vannamei (Boone) juveniles at different salinity levels. Aquaculture 244:193–201

Lin Y, Chen J (2003) Acute toxicity of ammonia on Litopenaeus vannamei boone juveniles at different salinity levels. J Exp Mar Biol Ecol 259:109–119

Lo KV, Liao PH, Van Kleeck RJ (1991) A full scale sequencing batch reactor treatment of dilute swine wastewater. Can Agric Eng 33:193–195

Masse DI, Masse L (2000) Treatment of slaughterhouse wastewater in anaerobic sequencing batch reactors. Can Agric Eng 42:131–137

Mazik PM, Parker NC (2001) Semi-controlled systems. In: Wedemeyer GA (ed) Fish hatchery management, 2nd edn. American Fisheries Society, Bethesda, Maryland, pp 241–284

McGraw WJ (2002) Utilization of heterotrophic and autotrophic bacteria in aquaculture. Global Aquac Advocate 12:82–83

Menz A, Blake BF (1980) Experiments on the growth of Penaeus vannamei boon. J Exp Mar Biol Ecol 48:99–111

Morgenroth E, Wilder PA (1998) Sequencing batch reactor technology: concepts, design and experiences. Water Environ Manag 12:314–321

Murat S, Genceli EA, Tasli R, Artan N, Orhon D (2002) Sequencing batch reactor treatment of tannery wastewater for carbon and nitrogen. Water Sci Technol 46:219–227

Ng WJ, Kho K, Ong SL, Sin TS, Ho JM, Tay SH (1993) Preliminary estimation of tropical ornamental fish metabolite production rates. Aquaculture 110:263–269

Ostrowski A, Warren A, Atwood H, Browdy C, Boopathy R, Lotz JM, Lawrence A, Lightner D, Moss S (2005) Strategies and focus of the U.S. marine shrimp farming program in a changing world market. Paper presented at the aquaculture America 2005 conference, New Orleans, 17–20 Jan 2005

Otoshi CA, Arce SM, Moss SM (2003) Growth and reproductive performance of broodstock shrimp reared in a biosecure recirculating aquaculture system versus a flow-through pond. Aquac Eng 29:93–107

Peters M, Newland M, Seviour T, Broom T, Bridle T (2004) Demonstration of enhanced nutrient removal at two full-scale SBR plants. Water Sci Technol 50:115–120

Pruder GD (2004) Biosecurity: application in aquaculture. Aquac Eng 32:3–10

Remde A, Conrad R (1990) Production of nitric oxide in Nitrosomonas europea by reduction of nitrite. Arch Microbiol 154:187–191

Rijn VJ (1995) The potential for integrated biological treatment systems in recirculation fish culture—a review. Aquaculture 139:181–201

Ritchie GA, Nicholas DJ (1972) Identification of the sources of nitrous oxide produced by oxidative and reductive processes in Nitrosomonas europaea. Biochem J 126:1181–1191

Statistical Analysis System (SAS) Institute (2003) Version 9.1. SAS Institute, Cary, North Carolina

Sauthier N, Grasmick A, Blancheton JP (1998) Biological denitrification applied to a marine closed aquaculture system. Water Res 32:1932–1938

Sharma B, Ahlert RC (1977) Nitrification and nitrogen removal. Water Res 11:897–925

Summerfelt S, Bebak-Williams J, Tsukuda S (2001) Controlled systems: water reuse and recirculation. In: Wedemeyer GA (ed) Fish hatchery management, 2nd edn. American Fisheries Society, Bethesda, Maryland, pp 285–397

Sundermeyer-Klinger H, Meyer W, Warninghoff B, Brock E (1984) Memebrane-bound nitrite oxidoreductase of Nitrobacter: evidence for a nitrate reductase system. Arch Microbiol 140:153–158

Tanaka Y, Fukumori Y, Yamanaka T (1983) Purification of cytochrome a1c1 from Nitrobacter agilis and characterization of nitrite oxidation system of the bacterium. Arch Microbiol 135:265–271

Weirich CR, Browdy CL, Bratvold D, McAbee BJ, Stokes AD (2002) Preliminary characterization of a prototype minimal exchange super-intensive shrimp production system. In: Proceedings of the IVth international conference on recirculating aquaculture, Virginia Tech University, Blacksburg, July 2002. pp 255–270

Williams AS, Davis DA, Arnold CR (1996) Density-dependent growth and survival of Penaeus setiferus and Penaeus vannamei in a semi-closed recirculating system. J World Aquac Soc 27:107–112

Zhu S, Chen S (2001) Effects of organic carbon on nitrification rate in fixed film biofilters. Aquac Eng 25:1–11

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG, part of Springer Nature

About this chapter

Cite this chapter

Boopathy, R. (2018). Waste Treatment in Recirculating Shrimp Culture Systems. In: Hai, F., Visvanathan, C., Boopathy, R. (eds) Sustainable Aquaculture. Applied Environmental Science and Engineering for a Sustainable Future. Springer, Cham. https://doi.org/10.1007/978-3-319-73257-2_10

Download citation

DOI: https://doi.org/10.1007/978-3-319-73257-2_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-73256-5

Online ISBN: 978-3-319-73257-2

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)