Abstract

Nanosized ferrites and magnetic nanocrystals have attracted significant attention owing to their vast applications in various fields, such as magnetic resonance imaging (MRI) contrast agents, magnetic memory, efficient hyperthermia for cancer therapy, and catalysts. Magnetic nanoparticles (MNPs) have been prepared by ferrite nanoparticles, MFe2O4 (M = Mn, Co, Ni, Zn, Mg, Fe, for example). Because of their applications in medical diagnosis technology, sensor technology, information storage, cooling technology, and magnetic warming, MNPs have attracted considerable interest in the last few years. The magnetic properties of MNPs strongly depend on the size of the MNPs. Therefore, MNPs with a controlled size are crucial in controlling properties for different applications in the biomedical field. The efficacy of dopant ions in modifying the resultant MNPs’ size and shape could be directly related to variations in the rate of crystal growth and thermodynamic and kinetic considerations. In some situations, particle growth is due to the existence of some other physicochemical phenomenon like passivation of the nanoparticle surface, charging of the nanoparticles, and compartmentalization of nanoparticles in different zones. Various methods involved in the crystal growth of MNPs are also discussed in this chapter.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

2.1 Introduction

Magnetic phenomena at the atomic scale were discovered in the early twentieth century, whereas the discovery of the first known magnetic material (Fe3O4) revolutionized the field of magnetism. The magnetic properties of a material depend on temperature, the applied magnetic field, and pressure. A change in these variables will result in the existence of two or more forms of magnetism. Ferro- and ferrimagnetic materials like Fe3O4 and some of their alloys have particles whose shape is asymmetrical when they are obtained by the grinding of bulk materials, whereas they can possess a spherical shape only when manufactured through plasma atomization or wet chemistry or when in aerosol and gas phases. Depending on the procedure used to form particles, they can be crystalline or amorphous spherical in shape. To a large extent, the synthesis process determines the degree of impurities in a particle, as well as the presence of structural defects, and, hence, the division of these defects inside the particle structure can be used to discover its magnetic properties [1, 2].

Magnetization depends on the number of unpaired valence electrons present in the atoms of solids and on the relative orientations of the neighboring magnetic moments [3]. Two types of motion of electrons in atoms are responsible for magnetism. One is the spin of electrons around the atom’s axis, and the other is the motion of electrons in an orbit around the nucleus. Iron (Fe), nickel (Ni), manganese (Mn), and cobalt (Co) are magnetic materials that have a net magnetic moment. In transition metal atoms, the magnetic moment is due to electron spin [4].

2.1.1 Classification of Magnetic Materials

In solids, materials may be categorized by their response to an externally applied magnetic field. There are five basic types of magnetism, paramagnetism, diamagnetism, ferromagnetism, ferrimagnetism, and antiferromagnetism. The magnetic properties of a material are governed by the electronic structure of the atoms within the material. They vary from weakly magnetic (diamagnetic) to permanently magnetic (ferromagnetic).

The most important property of a magnetic material is the magnetic susceptibility (χ), defined by

where M is the magnetization and H the magnetic field, both of which are measured in units of A/m. In general, the magnetic susceptibility is different for each material, temperature dependent (except in diamagnetic materials), and of the form

2.1.1.1 Diamagnetism

Diamagnetism is a basic property of all matter, but it is an extremely weak property. The susceptibility (χ) is negative and on the order of approximately 10−5. The other characteristic behavior of diamagnetic materials is that their susceptibility is independent of temperature. The origin of diamagnetism is due to the noncooperative behavior of orbiting electrons when exposed to an applied external magnetic field. Diamagnetic materials are composed of atoms having no net magnetic moments (i.e., all the orbital shells are filled and there are no unpaired electrons). When a small field is applied, a small negative magnetization is generated that is proportional to the applied field strength (Fig. 2.1a).

2.1.1.2 Paramagnetism

Because of the magnetic field generated by unpaired electrons, atoms may behave like magnets under the influence of an external magnetic field. However, when the applied magnetic field is removed, the thermal fluctuations would cause the magnetic moment of paramagnetic atoms to move randomly. In the presence of a relatively low magnetic field, this effect can be described by Curie’s law,

where C is the Curie constant. The expected behaviors of paramagnetic materials with an applied external magnetic field and with temperature are shown in Fig. 2.1b. In general, the response of a material to a magnetic field, that is, the magnetic susceptibility (χ), is on the order of 10−3–10−5.

2.1.1.3 Ferromagnetism

Ferromagnetic materials exhibit parallel alignment of magnetic moments to one another, resulting in a large net magnetization, even in zero magnetic fields, known as spontaneous magnetization. The atomic dipole moments in these materials are characterized by very strong positive interactions produced by electronic exchange forces, which results in a parallel alignment of atomic moments. The two distinct features of ferromagnetic materials are a magnetic ordering temperature and spontaneous magnetization.

Ferromagnetism is strongly temperature dependent, and the magnetization of a ferromagnetic material is inversely proportional to temperature by the Curie–Weiss law:

The Curie temperature is the temperature above which exchange forces cease to be present, that is, above that temperature a ferromagnetic material randomizes owing to the thermal energy, as in paramagnetic systems (Fig. 2.1c). They have relatively large susceptibilities, and in general, magnetic saturation is achieved through fields lower than for paramagnetic systems by a factor of 104.

2.1.1.4 Antiferromagnetism

Antiferromagnetic materials are characterized by a weak magnetic susceptibility of the order of paramagnetic materials. In a simple antiferromagnetic material, the atoms can be divided into two sublattices, where magnetic dipole moments are aligned antiparallel, which causes a small magnetic susceptibility in these materials. The temperature above which antiferromagnetic order ceases to exist is called the Neel (T N) temperature (Fig. 2.1d). Above T N, antiferromagnetic materials have a slight positive susceptibility comparable to that of paramagnetic materials. Below T N, however, antiferromagnetic materials have a spontaneous magnetization in the absence of an external field that causes the magnetic dipole moments of sublattices to align antiparallel to each other.

2.1.1.5 Ferrimagnetism

Ferrimagnetic materials, like ferromagnetic materials, have a spontaneous magnetization below a critical temperature called the Curie temperature (T C). The magnitude of the magnetic susceptibility (χ) of ferro-/ferrimagnetic materials is identical, while the alignment of magnetic dipole moments is drastically different (Fig. 2.1e). The magnetic dipole moments in a ferrimagnetic material are divided into two sublattices and classified as a subset of antiferromagnetic materials. Each sublattice can be treated as a ferromagnetic material, and the difference between the magnetic dipole moments for the sublattices results in a net magnetization for ferrimagnetic materials. The major difference between ferrimagnetic and antiferromagnetic materials is that either the magnitude or the number of moments of sublattices is different.

The most important crystalline ferrimagnetic substances are double oxides of iron, as in MO.Fe2O3, where M is a divalent metal. These are based on the spinel structure; the protypical example is magnetite, Fe3O4. As the temperature rises, the alignment of the spins is disturbed by thermal energy and the magnetization decreases. At a certain temperature, called the Curie temperature T C, this alignment becomes completely disordered and the magnetization vanishes.

2.1.1.6 Superparamagnetism

Superparamagnetic materials are a special class of magnetic materials. They are single-domain particles that behave like ordinary ferromagnetic materials below T C because they have rather large magnetic susceptibilities, are saturated in moderate magnetic fields, and display coercivity and remanence. Above T C, however, superparamagnetic materials behave like ordinary paramagnetic materials in that they display no hysteresis (i.e., no coercivity or remanence).

The idea of superparamagnetism was first developed and proposed by Neel [5, 6] to describe the possibility of thermal fluctuations in single-domain ferromagnetic clusters. In general, the magnetic anisotropy energy of a particle is proportional to its volume. In a given crystal of volume V, the magnetic anisotropy energy is given by

where K is the anisotropy energy constant and θ the angle between the magnetization vector and easy axis of nanoparticles [7]. When the volume of a single-domain cluster is small enough, the magnetic anisotropy energy of the cluster approaches its thermal energy, causing the magnetization to flip between easy axes through an anisotropy barrier in the same way as in a classical paramagnetic system [8] but, with a giant magnetic moment, that of a single atom, hence the term superparamagnetism.

2.1.2 Ferrites

Ferrites are considered a very important class of oxides with significant magnetic properties. Ferrites have been widely studied and applied over the past several decades. To say that ferrites have magnetic properties means they will attract magnets of opposite polarity and iron-based alloys and repel magnets of similar polarity. Ferrites also possess dielectric properties, which mean that they do not conduct electricity when electromagnetic waves pass through them. In various applications, this gives them an advantage over Ni, Fe, and transition metals that possess magnetic properties (“ferromagnetic”) because these metals conduct electricity when electromagnetic waves pass through them [9]. The phenomenon of ferromagnetic ferrites is the converse of ferromagnetic metals. In ferrimagnetism, there is not just one arrangement but distinct alignments of perpendicular and parallel magnetic moments. It is these alignments that give them their remarkable properties. This property can be attained through various crystal structures [10].

2.1.2.1 Applications of Ferrites

Ferrites have applications in such devices as antenna cores, transformers and tuned inductors, compasses, injection pumps, starter motors, loudspeakers, antilock braking systems, microphones, eddy current brakes, telephone rings, switches, alternators, stepping motors, drills, clocks, printers, washing machines, computers, sensors, dampers, energy meter discs, electrochemical transducers, nuclear magnetic resonance spectrometers, DC motors for magnetic devices, magnetic bearings, robotics, clutches and brakes, coupling, orthodontics, instrumentation, lifting apparatus, cancer cell separators, wound closures, magnetic resonance imaging (MRI) body scanners, and ferromagnetic probes. Ferrites are mainly used as inductive components in electronic circuits like impedance matching networks, filters, and low-noise amplifiers. Ferrites have various power applications, such as video and TV systems, computers, and both medium-sized and small gadgets [11, 12].

2.1.2.2 Types of Ferrites

Ferrites are mainly categorized into two major groups, hard ferrites and soft ferrites. In 1945, the first so-called soft ferrite was produced by J. L. Snoek in the Netherlands for commercial purposes [13]. Ferrites are produced in specific sizes and shapes and used for antenna applications, and soft ferrites have multiplied in number and in terms of shapes and sizes. Ferrites have wide applications in electronics, and ferrite devices are the best choice for both modern and conventional applications because of their low cost and because of the continuous improvements being made in their material properties [14].

The magnetic field strength of soft ferrites decreases with time, so their magnetization is temporary. Soft ferrites have numerous applications, such as in inductors, radio frequency interference filters, and transformers [15]. Soft ferrites are a type of black and gray ceramic material and are brittle, inert, and hard. Soft ferrites possess a spinel structure. The usual composition of ferrites is MeFe2O4, where Me denotes one or more divalent metals like Mg, Mn, Cu, Ni, Fe, and Zn. Soft magnets can become magnetized when drawn toward another magnet, that is, they possess an obvious magnetism only when they are in a magnetic field. They are not permanently magnetized and are used in applications such as cores of distribution power transformers, rotor and stator materials for generators, and motors and electronic transformers [16].

Magnetite (Fe2O3) is a weak hard ferrite. Hard ferrites have a basically permanent magnetism. Over time, artificial hard ferrites with fine characteristics were acquired but in the laboratory, with an analogous soft magnetic material being fabricated. A hard magnet attracts other magnetized materials to itself. It retains this obvious magnetism, more or less permanently.

Hard ferrites are mostly used as permanent magnets in brushless and synchronous motors, loudspeakers, and telephone receivers. Hard magnets or hard ferrites also behave as permanent magnets. Hard ferrites are magnetic materials that retain their magnetism after being magnetized. Generally such materials have a very high coercivity (>10 kA/m) [17].

Currently, the most significant use of ferrites is as a medium for the transmission of microwaves. At very high frequencies (above approximately 500 MHz, and in the range of 1–30 GHz), some ferrites show a nonreciprocal effect. This means that electromagnetic waves passing through ferrites behave differently and travel in different directions. This phenomenon is used to construct one-way transmission lines, junctions to control microwave “traffic,” and other microwave-controlled appliances. Today, the latest telecommunications systems would not be possible without ferrites. Ferrites are studied extensively, for example, because of their applications at high frequencies and in low eddy current losses, their usefulness at microwave frequencies and mechanical stiffness, and the high coercivity of selected ferrites; in addition, ferrites are used as insulators with magnetic properties, and some ferrites have square hysteresis loops. On the basis of their crystalline structure, ferrites are categorized into four main classes: cubic or spinel ferrites, hexaferrites, orthoferrites, and garnets [18].

2.2 Structural and Magnetic Properties of Nanomaterials

This section aims to provide an understanding of the structural properties of nanomaterials since their technologically relevant properties depend on their structure at the nanoscale.

2.2.1 Crystal Structures

For iron, there are 16 different forms of oxide. In 13 compounds, iron is in its trivalent form, while in the three remaining compounds, −FeO, −Fe(OH)2, and Fe3O4, it is in divalent form. All oxides, hydroxides, and oxide hydroxides (or oxyhydroxides) of iron have a crystalline structure. Iron oxides are usually arranged in close packed lattices in hexagonal (hcp) or cubic (ccp) arrangements, where interstitial sites are partially filled by Fe2+ or Fe3+, mostly in octahedral sites, and in a few cases in a tetrahedral geometry. The iron oxide structures are described here.

2.2.1.1 Magnetite (Fe3O4)

Magnetite occurs in nature as magnetic ore, known as lodestone. Magnetite differs from the majority of other iron oxides in that it contains both trivalent and divalent iron ions. Both magnetite and maghemite have an inverse spinel structure, and differentiating between the two structures in diffraction patterns remains a challenge [19]. Magnetite has a face-centered cubic (fcc) structure on 30 O2− ions arranged in a cubic close-packed arrangement in accordance with [20] in a regular pattern. The lattice parameter of the unit cell is a = 0.839 nm. There are eight crystal motifs per unit cell [21]. Its chemical formula can be described as A[AB]O4, where A = Fe3+, B = Fe2+, and brackets indicate octahedral sites. In an inverse spinel structure, all the Fe2+ and half of the Fe3+ cations occupy octahedral sites and the remaining half of the trivalent iron occupy tetrahedral sites [22, 23]. The distribution of Fe3+ cations at the tetrahedral sites suggests the degree of disorder λ in the spinel structure, and the value of λ for an inverse spinel is λ = 1/2. Figure 2.2 shows the order of the Fe and O layers along the (001) direction.

Atomic structure and diffraction of inverse spinel magnetite simulated with JEM software [24]: (a) 3-D crystal structure along [001] zone axis (gray spheres oxygen atoms, purple spheres iron atoms). (b) Diffraction pattern oriented along [001] zone axis. (c) Powder electron diffraction pattern of inverse spinel magnetite or maghemite (angle described in powder electron diffraction is 2θ). The indexes of the diffraction peaks are given in red. (Note that chemically disordered maghemite would exhibit the same diffraction patterns as b and c; see next section). Space group: Fd3m. Atomic positions: Fe1: 0.125, 0.125, 0.125; Fe2: 0.5, 0.5, 0.5; O: 0.254, 0.254, 0.254. Lattice parameters: a = 0.839 nm

The Fe2+ cations can be substituted with other metal cations, which produce different types of metal ferrites, such as CoFe2O4, MnFe2O4, ZnFe2O4, and NiFe2O4. The substituting ions are adjusted by the expansion or contraction of the oxygen framework to compensate the size difference from Fe2+ [25,26,27,28].

2.2.1.2 Maghemite γ-Fe2O3

Maghemite nanoparticles are broadly applicable in biomedicine owing to their excellent magnetic properties. At the same time, they can be made biocompatible and produce low toxicity [29, 30]. Maghemite occurs in nature as a weathering product of structurally related magnetite. The iron oxide γ-Fe2O3 is typically described both in a cubic system (space group P43 32) with disordered Fe vacancy or in a tetragonal system (space group P41212) with full site ordering and c/a ≈ 3. Magnetite and maghemite have a similar spinel crystalline structure and, hence, identical electron diffraction patterns. Nevertheless, the latter have both Fe3+~and Fe2+ cations, whereas in maghemite, all the iron ions are in the trivalent state. The charge neutrality of the unit cell is compensated by the existence of cation vacancies. The cubic form of maghemite has a lattice parameter, a = 0.834 nm. Each unit cell of maghemite contains 32 oxygen ions, 21 1/3 ferric ions, and 2 1/3 vacancies. Eight Fe ions are located in the tetrahedral sites, and the remaining is randomly distributed over the octahedral sites, whereas vacancies occupy only the octahedral sites. Thus, maghemite’s chemical formula can be changed to A [AΔ] O3, where A = Fe3+, Δ = vacancies, and brackets indicate octahedral sites [31]. This structure can also be described using the Fd3m cubic space group.

The character and extent of arranging iron vacancies in octahedral sites have been studied by researchers for many years. Vacancy ordering depends on the nature of the precursor, the size of the crystallite, and the amount of iron ions in the structure. The space group Fd3m suggests a random distribution of cation vacancies over octahedral sites like magnetite, but vacancy ordering with 2 2/3 vacancies per unit cell is not permissible owing to the fractional number of vacancies. Thus, it is necessary to extend the cell three times along c, which ends in a tetragonal space group (P41212), giving a formula of Fe3+ 24 [Fe3+ 4O8] O96. The lattice parameters are a = 0.833 nm and c = 2.501 nm. Usually, the tetragonal maghemite is associated with an ordered form and the cubic with a disordered form, but cubic phases with vacancy ordering still exist [32]. Figure 2.3 shows the chemically ordered maghemite crystalline structure and diffraction pattern simulated by JEMS software. By comparing the simulated diffractions of Figs. 2.2 and 2.3, we can observe additional superstructure reflections in the diffraction of the chemically ordered maghemite structure (Fig. 2.3). This chemical order allows us to differentiate between maghemite and magnetite using electron diffraction on HRTEM.

Atomic structure and diffraction of chemically ordered maghemite simulated with JEMS for chemically ordered maghemite [24]: (a) 3-D crystalline structure along [001] zone axis (gray spheres oxygen atoms, purple spheres iron atoms). (b) Diffraction pattern oriented along [001] zone axis. (c) Powder electron diffraction pattern of chemically ordered maghemite (angle described in powder electron diffraction is 2θ). The indexes of the diffraction peaks are given in red. Space group: P41212. Atomic positions: Fe: (0.742, 0.992, 0.039), (0.2579, 0.0079, 0.2057), (0.492, 0.7579, 0.1224), (0.615, 0.615, 0), (0.385, 0.385, 0.166), (0.375, 0.135, 0.08 ), (0.865, 0.625, 0.0867), (0.875, 0.365, 0.003), (0.125, 0.125, 0) and O: (0.611, 0.861, −0.0047), (0.361, 0.889, 0.0787), (0.389, 0.139, 0.162), (0.122, 0.377, 0.0003), (0.877, 0.378, 0.0837), (0.878, 0.623, 0.166), (0.374, 0.628, 0.0007), (0.128, 0.126, 0.084), (0.626, 0.372, 0.1673), (0.373, 0.376, 0.0843), (0.624, 0.627, 0.0843), (0.124, 0.873, 0.001). Lattice parameters: a = 0.83 nm, c = 2.501 nm

In brief, maghemite contains cation vacancies, which may be ordered (tetragonal superstructure), partially ordered (cubic structure), or totally disordered with a high possibility of the vacancies being aggregated [33].

2.2.1.3 Hematite α-Fe2O3

Hematite has remarkable applications in the field of gas sensors, magnetic storage media, solar cells, water splitting, and environmental treatment due to its nontoxicity, biodegradability, low corrosion, and low processing expenses [34,35,36,37,38]. It also serves as a starting material for synthesizing maghemite and magnetite [39].

Hematite can be described in a hexagonal (rhombohedral) R\( \overline{3} \)c space group. In hexagonal unit cells, the lattice parameters are a = 0.5034 nm and c = 1.375 nm. The number of crystal motifs per unit cell is six. For hexagonal symmetry, the Miller index is (hkil), where it is usually equal to −(h+k).

The crystallographic structure of hematite is similar to α-Al2O3, corundum. The anions form a hexagonal close-packed structure differentiated by the regular successive change in two layers; the atoms in both layers occupy the vertices of a sequence of equilateral triangles, and the atoms in one layer are located directly over the centers of the triangles in the neighboring layers. The cations occupy two-thirds of the octahedral sites [21]. In other words, the oxygen ions occupy hexagonal sites and the Fe cations are located only in the adjacent octahedral sites, though the six adjacent neighboring oxygen ions of an iron ion are slightly misaligned. Moreover, the four iron ions around each oxygen ion are not arranged in a regular tetrahedron [40]. Figure 2.4 shows a 3-D view of the structure of hematite consisting of hcp arrays of oxygen ions placed along the [001] direction; Fe3+ occupy two-thirds of the sites, arranged in a regular pattern, with two filled sites accompanied by one unoccupied site in the (001) plane.

Atomic structure and diffraction of hematite simulated with JEMS [24]: (a) 3-D crystalline structure along [001] zone axis (gray spheres oxygen atoms, purple spheres iron atoms). (b) Diffraction pattern oriented along [001] zone axis. (c) Powder electron diffraction pattern of hematite (angle described in the powder electron diffraction is 2θ). The indexes of the diffraction peaks are given in red. Space group: R\( \overline{3} \)c. Atomic positions: Fe: 0, 0, 0.3553 and O: 0.3059, 0, 0.25. Lattice parameters: a = 0.503 nm, c = 1.375 nm

2.2.1.4 Ferrihydrite

Ferrihydrite (Fh) is an extensive hydrous ferric oxyhydroxide mineral present on the Earth’s surface [41, 42]. It has been reported that ferrihydrite also occurs in the core of the ferritin protein in living entities and serves to store excess iron [43]. Although we have not observed ferrihydrite in ferritins of ex vivo mice samples, we discuss the structure of ferrihydrite here. Ferrihydrite is a poorly crystalline iron oxyhydroxide. It has an estimated composition of 5Fe2O3.9H2O, although the actual formula for ferrihydrite is still not established owing to a lack of accurate knowledge of its water content. The degree of crystallinity of ferrihydrite is classified as two-line, four-line, and six-line ferrihydrite because it is well known that the number and width of X-ray diffraction (XRD) peaks are directly linked to crystallinity. Figure 2.5a shows the 3-D arrangement of atoms in ferrihydrite that has a hexagonal structure with unit cell parameters of a = 0.296 nm and c = 0.949 nm. The space group of this structure is P31c [21]. Figure 2.5b, c shows the diffraction pattern along the [001] direction and powder electron diffraction pattern obtained by JEM software [37], respectively.

Atomic structure and diffraction of ferrihydrite simulated with JEMS [24]: (a) 3-D crystalline structure along [001] zone axis (gray spheres oxygen atoms, purple spheres iron atoms). (b) Diffraction pattern oriented along [001] zone axis. (c) Powder electron diffraction pattern of ferrihydrite (angle described in the powder electron diffraction is 2θ). The indexes of the diffraction peaks are given in red. Space group: P31c. Atomic positions: Fe: 0.333, 0.666, 0.136, O (OH): 0, 0, 0, and O (OH): 0.666, 0.333, 0.25. Lattice parameters: a = 0.295 nm, c = 0.937 nm

2.2.1.5 Cobalt Ferrite (Cobalt Ferrite Nanoparticles)

Cobalt ferrites belong to the so-called hard ferrites and have many applications in the fields of medicine, permanent magnets, catalysts, microwave devices, and high-density information storage [44,45,46,47]. They are crystallized in an inverse spinel structure just like magnetite, except that divalent iron ions are replaced by cobalt ions [48]. As the ionic radii of divalent Fe and Co are the same, there is no change in the lattice parameter (i.e., a = 0.839 nm) of the unit cell.

2.3 Nucleation, Growth, and Arrested Growth

2.3.1 Introduction

The isolation of solid states from liquid phases is an ancient method, but currently it plays a key role in various industrial procedures. To attain the quality of fine products, for economic reasons and environmental effects, the optimization of this phase is necessary [49].

To attain this goal, various theoretical and experimental principles or procedures have been developed. In physical chemistry the following procedures are studied: solubility product, crystal growth, supersaturation, common ion effect, filtration, crystallization, heterogeneous and homogeneous nucleation, precipitation, and coprecipitation. In addition to the effects of pressure, temperature, and additives, the kinetic, thermodynamic, and statistical features of nucleation, precipitation, and crystallization are verified. Some significant methods, such as crystal growth and nucleation, are mostly used in different environments like alloys, vapor phases, interfaces, and glass matrices. The most common approach for the analysis of these methods is to develop a specific treatment. In the liquid phase, the main conditions for the appropriate precipitation procedure are purity and the recovery of the majority of the final product [9].

2.3.1.1 Thermodynamic Considerations

The thermodynamic stability of a substance A in a solution with respect to the pure crystalline solid phase depends on the difference (Δμ) between the chemical potential (μA) of A in both phases:

If Dμ < 0, then some portion of species A will develop a solid phase moving from the solution to the solid phase until Dμ = 0 and a dynamic equilibrium is established between A in both the solid and liquid phases. On the other hand, if Dμ > 0, in saturated solution (a A,sat solution), if the activity of A in the state of equilibrium with pure A is more than that in the actual solution (a A,solution), the material will remain completely molecularly isolated in the liquid phase. Also, the system will be thermodynamically stable and have a single phase. Because of these main properties, Dμ is also known as the driving force behind crystallization.

For sparingly soluble solutes, the driving force (Dμ) is associated with entropy (∆S) and enthalpy (∆H):

The preceding equation highlights the relationship between entropic and energetic terms used to control the factors of the crystallization method. Various thermodynamic equations are used to predict the pressure and temperature dependency of the driving force (Dμ) [50]. Also, when the activity coefficients in the liquid and solid phases are known, thermodynamics establishes the relationship between the driving force (Dμ) and the solubility of nonionic and ionic solutes [51].

2.3.1.2 Kinetic Considerations

Usually, above the solubility limit, crystallization or precipitation occurs rapidly in the presence of a solid phase established due to different substances (heterogeneous nucleation) or the same substance (secondary nucleation). The existence of a solid phase that interacts with the solution offers a surface on which molecules of species A could grow as well as nucleate [52, 53]. In this situation, the factors that control the rate of the entire procedure are (1) the nature and area of the solid phase exposed to the solution; (2) the appearance of the species on the surface of the solid phase and vice versa by mechanical agitation, thermal diffusion, or convection currents; and (3) the incorporation rate of the precursors to the crystal lattice [54, 55]. The incorporation phase contains the partial release of solvating species, the adsorption of a precursor, and a useful setup in the lattice. Usually, anisotropic morphologies are examined when fewer or more molecules are trapped in specific crystal faces.

In homogeneous nucleation, the creation of a solid phase cannot take place owing to the absence of a preexisting solid phase, and the liquid system will be stable kinetically [56,57,58]. The creation of a crystalline phase is not a single-step process; it is a multistep process that requires the strengthening of molecular groups of cumulative size according to the scheme

or, in agglomeration processes,

At the molecular level, Brownian diffusion of species is a driving force behind these methods that allows their random occurrence. For this purpose, a thermodynamics property must be considered to know whether the solid phase will be established or not from ionic or molecular precursors. The free energy of formation of a nucleus comprised of N molecules, DG f , given by

The preceding equation is comprised of the term \( N{\varDelta}_{\mu }=\mathrm{NkT}\ \ln \frac{a_{\mathrm{A},\mathrm{sat}.\mathrm{solution}}}{a_{\mathrm{A},\mathrm{solution}}} \), which includes the thermodynamic driving force for the growth of aggregate, and the other term ΔG S is a result of the formation of a boundary between the surroundings and the aggregate. The last term of the preceding equation is given by

where A N represents the aggregate surface (A N = KNN2/3) and γ s is the interfacial energy per unit surface.

According to the molecular approach, the interfacial energy ΔG s determines the difference in the energetic state between the species situated in the interior and at the particle surface. This should be positive because at the surface, the energetic state of a species must be greater than that in bulk; then the boundary would be enhanced indefinitely [51].

If the molecules are at the surface or in a bulk, the time average of all the forces acting on them is zero. The strength and number of chemical bonds formed at the surface is smaller than that of bulk species. Embryos are thermodynamically unstable against abnormal growth.

Here, two states, such as bulk and surface species, have been considered. But it must be taken into account that when two phases interact with each other, an imprecise and interfacial domain is produced [54]. In a particle, this indicates the presence of more than two states of A. The first term for the supersaturated solutions (aA,solution > aA,sat.solution) will be negative, but the second term will always be positive. In these conditions, the dependency of such contributions and of ∆G f on N is shown in Fig. 2.6.

N dependence of free energy of formation of a nucleus (∆G f ), bulk crystal (N∆ μ ), and interface (∆G S ). Figure reprinted/adapted with permission from [51]

The value of N* corresponding to the maximum ∆G f is known as the critical aggregation number. Aggregates with N > N* are known as nuclei; they grow naturally because a decrease in free energy increases their size. Aggregates with N < N* are known as embryos; they decompose because a decrease in the system free energy decreases N.

2.3.2 Growth Mechanism and Size Control

According to kinetic and thermodynamics properties, above the supersaturation threshold, the boundless growth of a nanoparticle is a natural process, and the growth rate can be managed by changing some factors such as temperature, supersaturation degree, and additive presence. To place a constraint on this process, other phenomena must play a role. The proper use of these parameters can lead to thermodynamic or kinetic refined nanoparticles of a controlled size [59]. The important types will be further discussed in the following subsections.

2.3.2.1 Nanoparticle Size Dependence on Time

In supersaturated solutions, the possibility of critical aggregate formation is very important in homogeneous conditions. There are three different methods that describe crystal growth, competitive and normal growth and nucleation. Moreover, other processes occur, such as aggregation, crystal growth, agglomeration, recrystallization, nucleation, time aging, induction time, solid-phase transitions, and amount of solid phase. Overlapping zones occur because not all phases are well isolated in time [60,61,62].

When the concentration of precursor becomes negligibly small, competitive growth controls the whole process. During this step, a movement of mass from minute particles to bigger particles takes place, and the following equation describes the time dependency of a cluster size:

It must be pointed out that the preceding equation represents the tendency toward an indefinite growth of crystal size. Mostly, when the size of a particle attains a system-acquired value as a result of the association of smaller aggregates or a growing process, it manages to isolate from the liquid state under the influence of the gravitational force that arises owing to Brownian movements.

In these conditions, a lower or upper solid phase depending on the bulk medium and the density of particles is developed. From homogeneous solutions, the precipitation of scarcely soluble materials results in an extensive particle size distribution owing to the random growth of a crystal [63]. After precipitation, various secondary processes can take place, such as aging, recrystallization, and aggregation. These processes involve additional changes in the structure, size, effectivity, and shape of crystals [64].

2.3.2.2 MNP Growth Inhibition and Size Control

In some situations, the growth of a particle is due to the existence of some other phenomenon. Various physicochemical methods allow one to control the size of nanoparticles:

-

Passivation of nanoparticle surface by adsorption of suitable species,

-

Charging of nanoparticles,

-

Compartmentalization of nanoparticles in different zones.

Every mechanism has its own uniqueness and drawbacks that must be considered when selecting a synthesis process [65]. The stability of particles is due to the presence of a net charge and the establishment of an electric double layer surrounding the particle. In polar solvents, this is a very common phenomenon because the particle can adsorb ionic species of the solution, or species placed on the particle surface can separate, emitting ions to the adjacent medium. A double layer that surrounds the particle is generated by these methods along with an electrostatic effect on other neighboring ionic species. Owing to electrostatic forces, particles having similar charges or bounded by an electrical double layer repel each other. In such circumstances, when the particle–particle repulsive force overcomes attractive forces, such as hydrogen bonding and van der Waals forces, a stable scattering takes place. Electrostatic stabilization is powerfully reactive in the presence of electrolyte solution, to their charge and concentration, and at relatively low concentrations of nanoparticles, stable scattering can occur [66]. In particular, two contradictory results can be observed: ions resulting from electrolyte dissociation can be selectively adsorbed, creating a charge on the surface of a nanoparticle or neutralizing preexisting charges. It must be taken into account that when two particles come into contact with each other, the charge distribution around each particle is changed as a result of the charge mobility on the particle surface, electrostatic forces, or the charged double layer coating the particles (Fig. 2.7). The subsequent charge distribution involves a reduction in the repulsive forces, so the particles will be able to approach each other and other distance dependent interactions can play their role. In addition, other attractive forces, for example, capillary forces and chemical bonds, can become effective at small distances [67]. For instance, it has been observed that negatively charged silica particles are easily deposited in the presence of negatively charged polymer latexes [68].

Mechanisms allowing nanoparticle size stabilization. Figure reprinted/adapted with permission from [68]

The double layer electrostatic repulsion and the presence of a net charge on the surface can regulate the stability of particle diffusion in polar and aqueous media [69, 70]. Some particular mechanisms, like proton exchange between surrounding medium and particle surface, are used to sustain surface charges in solvents with small dielectric constants [71]. Particles can also be stabilized by the deliberate use of suitable capping agents. From a molecular approach, molecules that show a chemical or physical affinity for species located at the surface of nanoparticles and form a shielding layer that makes the nanoparticle surface unreactive against precursor incorporation and agglomeration are known as capping agents. The action of capping agents depends on their particular structure. In particular, they have an unreactive moiety attracted toward the environment and another type of molecular moiety exhibiting an affinity for the surface of nanoparticles. In the presence of unreactive additives or electrolytes, stabilization achieved through surface capping is usually not responsive. For nanoparticles, capping with chemically bonded species may serve as a catalyst.

In different domains, particles can be stabilized against abnormal growth by compartmentalization or segregation. This approach depends on the material exchange method and the inhibition of nanoparticle encounters. This strategy can be attained by scattering particles in a solid matrix or chemically attaching them to the surface of an appropriate substrate. In these situations, particle growth can be avoided by suspending diffusive methods. In various applications (catalysis or optical), this strategy has been extensively used in the preparation of nanoparticles.

Owing to the synthesis of nanoparticles in microheterogeneous systems, a stable-sized nanoparticle can be attained. Compared to the aforementioned mechanisms, this approach has unique characteristics. The formation of nanoparticles takes place in two steps: (1) slow growth of nuclei and (2) fast growth. At high concentrations, separation is obvious [72, 73].

In microheterogeneous systems, specific stabilization mechanisms are observed. Such microheterogeneous systems are used to stabilize nanoparticles. The nanoscopic domains of microhetrogeneous systems serve as a physical border that prevents nanoparticles and precursor diffusion, agglomeration, and encounters. In homogeneous media, the rate of formation of nanoparticles is generally faster than in microheterogeneous systems. This is similar to what is observed in biological systems, such as liposomes or biological membranes.

When a collection of molecules is restricted in a nano-sized area, some additional factors that play a role in the stability of the system could originate from the following sources:

-

1.

Owing to the adsorption on the aggregate surface of a monolayer of surfactant molecules, the particle interfacial energy changes. It must be determined whether the aggregate surface is lipophilic or hydrophilic, as this feature controls the alignment of micellar aggregate or surfactant on the particle surface. If a nanoparticle is isolated in water, a subsequent layer of surfactant molecules is usually created, coating the primary layer and creating a bilayer surrounding the particle, and the surface is known as hydrophilic [74].

-

2.

The encounter frequency decreases owing to the screening effect of the surfactant layer on internanoparticle attractive interactions and to the diffusion of micelles in the solvent medium.

-

3.

A significant reduction in the particle growing process owing to the drastic decrease of the diffusion rate provides sufficient time for various other processes, for example, particle coating with a special type of molecule allowing for stabilization and regulation of small-sized particles.

-

4.

Inhibition of heterogeneous nucleation occurs owing to the coating effect of a monolayer of surfactant molecules on particles or possible solid surfaces in the system.

-

5.

An adjustment takes place in the microscopic processes that make it possible to control the growth and formation of nanoparticles.

-

6.

Thermodynamic and kinetic factors vary in confined spaces.

2.3.3 Novel Synthesis Methods for Size-Controlled MNPs

Spinel ferrites have remarkable magnetic and electrical properties. The sintering and synthesis of ferrites is considered a powerful technique in current ceramic research, and spinel ferrites have notable applications. Because of their low coercivity and high resistance, spinel ferrites have been extensively used in transformers and microwave appliances. The spinel structure is based on a fcc arrangement of oxygen atoms with the stuffing of cations in either octahedral or tetrahedral spaces within this arrangement; in a unit cell 8 out of 64 tetrahedral sites and 16 out of 32 octahedral sites are occupied. These kinds of compounds have both inverse and normal spinel structures. For a normal spinel structure, the octahedral holes are filled by Fe3+ ions and the tetrahedral holes are occupied by transition metal ions [75]. In an inverse spinel structure, half the Fe ions pack all the tetrahedral sites and the transition metal ions and the other half of the Fe ions fill all the octahedral sites.

Various chemical methods applied to synthesize magnetic nanoparticles (MNPs) have been presented [76], including the polyol method [77], flow injection synthesis [78], and electrochemical techniques [79, 80]. Because of the colloidal nature of superparamagnetic nanoparticles, it is difficult to synthesize them [60]. Comprehensive studies on the synthesis of small MNPs with well-defined shapes have been conducted by many researchers [21, 81].

2.3.3.1 Classical Synthesis by Coprecipitation

In chemical routes of preparation of nanoparticles with preferred physical properties, the structural and chemical properties of the elements also play an important role. Fine chemical homogeneity can be attained by mixing constituents at the molecular level. Moreover, this makes it possible to control the shape and size distribution during synthesis. Chemical methods of preparation have emerged as an important technique and are used for the synthesis of spinel ferrite nanoparticles [82].

The coprecipitation process is the most proficient technique used for the synthesis of MNPs. This technique involves mixing ferrous and ferric ions in a molar ratio of 1:2 in a solution at room temperature or higher. The formation of ferric oxide can be achieved under the following chemical reaction:

The reaction is controlled by changing the solution pH. The growth of a ferric oxide nucleus is comparatively simple when the pH of the solution is greater than 11, while the nucleation of a ferric oxide nucleus is comparatively simple when the solution pH is less than 11 [83]. Coprecipitation has been examined mostly in the preparation of ferric oxide nanoparticles because of its ease of use in gram-scale fabrication (Fig. 2.8) [84]. Many researchers have reported the extensive coprecipitation synthesis of ferric oxide nanoparticles, where their magnetic properties and morphology at various different temperatures were examined [85]. Various modified coprecipitation processes have been developed. Many researchers have reviewed the advancements and developments in this field over the last decade [83]. In the presence of oxygen, magnetite (Fe3O4) oxidizes and converts to maghemite:

Coprecipitation method. (a) Traditional synthesis. (b) Inverted synthesis. MNPs synthesized by coprecipitation and modified with sodium dodecyl sulfate (SDS) in a postsynthesis step. Inverted coprecipitation was carried out by adding the Fe2+/Fe3+ aqueous solution containing the proper amount of SDS to the alkali solution. Figure reprinted/adapted with permission from [86]

This equation shows that iron ions are desorbed from the Fe3O4 surface, producing cationic holes and forming γ-Fe2O3. Hence, the oxidation of Fe3O4 involves the oxidation–reduction of the surface of magnetite (Fe3O4). Maghemite and magnetite differ from each other in terms of the distribution of iron ions in the tetrahedral and octahedral sites of the spinel structure [79].

In an octahedral site, maghemite (γ-Fe2O3) has cationic holes. The ordering of vacancies is related to the synthesis process, which results in symmetry lowering and perhaps superstructures. The vacancies may be partially or completely random or absolutely well arranged. According to the results of XRD and Fourier transform infrared (FTIR) spectroscopy, vacancy ordering occurs only for particles greater than 5 nm in size [87].

The coprecipitation method is used for the fabrication of nanoparticles on a large scale. However, kinetic factors control only the crystal growth while the particle size distribution cannot be definitively measured. The mechanism of this process can be described by the two phases [88, 89]; First, when the concentration of reactant approaches critical supersaturation, an initial short nucleation occurs. Second, due to the dispersion of solutes to the crystal’s surface, regular growth of nuclei takes place. Several parameters are used to control the surface and magnetic properties, shape, and size of iron oxide nanoparticles (IONPs). By varying the temperature, pH, Fe2+/Fe3+ ratio, and ionic strength, the shape and size of IONPs can be modified [79].

Many researchers have examined the effect of the main parameters on the production of IONPs using the coprecipitation technique. For instance, in [90] the effect of the Fe2+/Fe3+ ratio on the magnetic properties, size, and morphology of coprecipitated nanoparticles is discussed.

The effect of iron concentration and iron media have been examined [91]. The Fe2+/Fe3+ ratio is the main parameter used to attain the desirable yield and size of IONPs during synthesis. Increasing the Fe2+/Fe3+ ratio reduces the preparation yield and enhances the mean particle size.

Moreover, the ionic strength and acidity of the precipitation agent are the main factors on which the mean size of magnetic nanoparticles depends [92]. Narrow particle size distribution and small particle size can be attained under elevated ionic strength [93].

Biocompatibility and aggregation are major hindrances in biomedical applications of IONPs. In the coprecipitation process, various biomolecules and surfactants are directly inserted. The coprecipitation technique is one of the most established and effective techniques used in the synthesis of IONPs with high saturation magnetization, and to overcome the limitations of this technique more attention should be devoted, for instance, to the use of a strong base in reactions and a wide particle size distribution [83].

2.3.3.2 Synthesis by Hydrothermal Method

The hydrothermal method is one of the well-known techniques that have attracted scientific community for nanomaterial synthesis. This is due to its simple and easy synthesis mechanisms. This technique is economical and highly efficient and has potential for large-scale production. In general, the hydrothermal method uses an aqueous medium in a reaction reactor under high temperature and pressure. The size and shape of the particles can be accurately controlled by adjusting the synthesis parameters such as temperature, pressure, reaction time, concentrations and ratio of reactants, type of solvent, and reaction path. In the hydrothermal method, the size of the particle is usually controlled by the crystal growth and rate of nucleation [94]. Generally, nanomaterials synthesized by the hydrothermal method do not need further calcination at high temperatures, which minimizes the risk of nanomaterial reclustering. The hydrothermal method can be used to synthesize a wide range of nanostructured materials [95, 96]. A generalized hydrothermal method for various types of nanomaterial synthesis can be explained as shown in Fig. 2.9.

Generalized hydrothermal method for various types of nanomaterial synthesis. Reproduced with permission from [96]

Magnetic nanoparticles have also been synthesized using the hydrothermal technique. In this regard, octahedral NiFe2O4 ferrites were synthesized by hydrothermal reaction under mild conditions. FTIR spectroscopy and XRD were employed for constitution measurements and composition of these ferrites. Morphological measurements were done by scanning electron microscopy and these were found octahedral in morphology having mean particle size of ca 40 nm. Crystallite size from XRD analysis was obtained as 39 nm, which is in good agreement with scanning electron microscopy (SEM) results. Electron diffraction and consequent transmission electron microscopy studies confirmed the single crystalline nature and morphology of the octahedral nanoparticles. Magnetic behavior was also investigated, and it was shown that NiFe2O4 octahedrons had the same coercivity because of the lower morphological anisotropy [97]. TEM investigations revealed that cobalt oxide nanorods have a nanoporous structure, involving the aggregations of nanorods. Magnetic properties indicate that cobalt oxide nanorods have a lower Ne transition temperature, around 35 K. The optical properties of cobalt oxide nanorods were investigated by ultraviolet-visible and Raman spectroscopy [98].

Various properties of cobalt ferrite (CoFe2O4) nanoparticles have been examined. The hydrothermal technique via a polyethylene glycol (PEG) was used for the synthesis of cobalt ferrite nanoparticles. TEM and XRD analysis were used to investigate the morphological, structural properties of the prepared nanoparticles, and a vibrating sample magnetometer (VSM) was used to examine the magnetic properties. The formation of a pure spinel phase was verified by XRD analysis and the crystallite size was in the range of 10.0–32.0 nm. An increase in the average size of the cobalt ferrite (CoFe2O4) nanoparticles was also reported as the hydrothermal temperature increased. The size and morphology of the nanoparticles were affected by the hydrothermal temperature, and the morphology of the cobalt ferrite (CoFe2O4) nanoparticles transformed into an octahedral from a spherical shape as the hydrothermal temperature increased. The characterization of the magnetic properties showed that the coercivities and saturation magnetization of the synthesized cobalt ferrite (CoFe2O4) nanoparticles become enhanced as the mean size of the cobalt ferrite (CoFe2O4) nanoparticles increases [99].

Nanoparticles of magnetite (Fe3O4) were synthesized using the hydrothermal technique. A contrast agent was used in these nanoparticles to study their applications in MRI. Ferric chloride (FeCl3) and ferrous chloride tetrahydrate (FeCl2.4H2O) were used as precursors, with sodium hydroxide as reducing agent to start the precipitation of magnetite (Fe3O4). Then a layer of chitosan (CHIT) was deposited on the surface of the magnetite’s (Fe3O4) nanoparticles to increase its biocompatibility and stability. TEM was used to investigate the size distribution of the prepared magnetite (Fe3O4) nanoparticles. XRD analysis confirmed the formation of a cubic inverse spinel structure of magnetite (Fe3O4) nanoparticles. The FTIR spectrum showed the presence of CHIT on the surface of the synthesized magnetite. The magnetic properties of the magnetite nanoparticles were characterized using a VSM at room temperature. A customized phantom study of MRI proved that the Fe3O4 nanoparticles showed better results as contrast agent [100].

The cause of the inhibition of the surfactant was studied for NiFeO4 nanoparticles prepared by the hydrothermal method. The sample was prepared in the presence of sodium dodecyl sulfate and glycerol. XRD, inductively coupled plasma atomic emission spectrometer (ICP-AES), transmission electron microscopy (TEM), and vibrating sample magnetometer (VSM) techniques were employed to investigate the specimens. The crystallinity was increased by increasing the temperature. In the presence of surfactants, the crystallinity of the NiFe2O4 nanoparticles was decreased. Furthermore, all of the ferrite nanoparticles were highly paramagnetic at room temperature [101].

2.3.3.3 Polyol Method

Currently, the polyol method has become a preferred technique in the preparation of uniform MNPs. The polyol technique is widely used at high levels of biomedical applications as a tool of investigation; for example, MRI is a polyol technique [102]. Polyols [e.g., ethylene glycol (EG), diethylene glycol (DEG)] are used to reduce metal salts to small-sized metal particles [103]. This process has been used for the production of inorganic compounds [104]. The polyol method was first used for the preparation of noble metals (Pt, Ru, and Au) and other metals like cobalt (Co), copper (Cu), and nickel (Ni) [105, 106]. Nowadays, this synthesis method is being used to synthesize several metals, such as iron-based alloys [107], that can be used in various applications such as in biomedicine.

The polyol method [108] is similar to a sol-gel process. In a sol-gel process, an oxidation reaction is involved, but in the polyol method, a reduction reaction is involved [60], and such a reduction reaction is useful for the synthesis of both microparticles and nanoparticles with well-described shapes and a narrow range of sizes [109]. Polyols such as PEG possess some remarkable properties. They serve as solvents owing to their relatively high dielectric constant and their high boiling point (BP), they occur in a wide temperature range (25 °C to BP) for the preparation of inorganic mixtures [110].

Polyols do not just act as solvents and reducing agents but also serve as stabilizers to manage particle sizes and are used to prevent particle accumulation. In the polyol synthesis method, a metal precursor mixture is suspended in a liquid polyol. First, the suspension is stirred and then heated to a relatively high temperature; this temperature should be as high as the BP of polyols [60, 111]. The narrow size and well-defined shape of nonagglomerated metal nanoparticles can be attained by controlling the kinetics of precipitation [102]. By raising the temperature of reaction or inducing heterogeneous nucleation, some particles, like those of submicrometer-size, can be synthesized. Iron nanoparticles can also be obtained by disproportionation of Fe(OH)2 in organic medium [108].

Recently, Cai and Wan [104] presented a simple process by modifying the polyol process to directly attain nonaggregated MNPs. [104]. The four major kinds of polyols are ethylene glycol (EG), diethylene glycol, triethylene glycol, and tetraethylene glycol [104, 111]. Cuboid iron-manganese oxide nanoparticles with unprecedented dimensions as large as 33 ± 5 nm (average body-centered diagonal) were obtained in monodisperse form by varying the ester content. The shape and size of these unusually large MNPs can be controlled simply by varying the surfactant composition, leading to increased control over the dimensions of the nanoparticles (Fig. 2.10).

Shape variation of iron-manganese oxide nanoparticles. Figure reprinted/adapted with permission from [20]

Only the reaction with triethylene glycol produced nonagglomerated MNPs of small size and uniform shape (Fig. 2.9). This result shows that the polyol solvent performs a vital role in determining the colloidal stability and morphology of the obtained particles [104]. The occurrence of polyol ligands on the surface of MNPs can be confirmed by FTIR spectroscopy analysis [60]. When sodium hydroxide (NaOH) and Fe (II) chloride reacts with EG, precipitation arises at a low temperature of 80–100 °C [102].

2.3.3.4 Electrochemical Method

The electrochemical process has been used extensively to prepare different phases of iron oxide nanoparticles like Fe3O4 or γ-Fe2O3 [58]. In this process, a current is passed through a cathode and anode placed in an electrolyte. In an electrolyte, the anode can be oxidized into a metal ion and the cathode can then be reduced to a metal in the presence of stabilizers. At the electrode–electrolyte boundary, synthesis occurs. The electrosynthesis process has various specific characteristics. The electrochemical process occurs near the electrode with a relatively high potential gradient (105 Vcm−1) [79]. Under these conditions, the reactions form products that cannot be obtained using other techniques. The product formed in this reaction is deposited on an electrode, known as a thin film. If a properly shaped electrode is immersed in an electrolyte, a uniform polarization is acquired. The temperature should be moderate and not be as high as the BP of the electrode [79]. The electrochemical process relies on both oxidation and reduction reactions; by changing and regulating the cell potential, the power of both oxidization and reduction can be selected and regularly altered. This unique characteristic cannot be achieved by other synthesis methods. The structure of the thin film or coating can be measured by altering the bath composition [79]. However, this technique has some limitations, for example, all reactions take place at room temperature, and the electrosynthesis process forms rough products. X-ray characterization of synthesized products formed in this process reveals amorphous impurities [79].

The electrochemical synthesis of maghemite nanoparticles was carried out in an organic medium. Using this method, 3–8 nm γ-Fe2O3 particles were prepared from an Fe electrode in a liquid medium of a cationic surfactant [58, 112]. The size of maghemite (γ-Fe2O3 ) nanoparticles can be adjusted by the current density [102]. Under oxidizing conditions, electrochemical deposition has been used for the production of Fe2O3 and Fe3O4 nanoparticles [113].

In this method, the particle size can be managed by changing the current density or potential. Moreover, it is possible to avoid the aggregation of magnetic nanoparticles if the synthesis is carried out in the presence of surfactants [80]. Some work has been done in this field. Using a conventional process, a size of 20 or 30 nm of Fe3O4 nanoparticle is difficult to obtain. The electrochemical synthesis of magnetite (Fe3O4) is carried out in an aqueous solution [80]. The particles generated in this process are hydrophobic, and the surface of these particles can easily be changed by an exchange reaction with specific biomolecules. Various techniques, such as TEM, IR spectroscopy, and XRD, have been used mostly for the characterization of generated nanoparticles [80].

2.3.3.5 Flow Injection Technique

The flow injection synthesis (FIS) technique is an adapted form of the coprecipitation process [83]. In various “matrices” like emulsion, the reaction zone confinement is mostly utilized to obtain small nanoparticles. Moreover, a particular pattern of a device can serve as a substitute for the “matrix” confinement [60, 114]. The synthesis of MNPs depends on the flow injection synthesis method. This method is comprised of segmented or continuous mixing of substances in a capillary vessel. In the reaction, various precursors can be inserted by injecting an adjustable amount of flow. Flow injection synthesis has some advantages, for example, high mixing homogeneity and reproducibility. Alvarez studied the impact of chemical factors on the characteristics of various materials [115]. MNPs with a size of 2–7 nm can be obtained in this process [60, 116].

2.4 Strategies to Control the Size and Shape

The morphology and size control of nanoparticles is an important topic for researchers and represents a challenge [117,118,119]. This topic has further specified applications that might be used more proficiently in different areas. For example, different in vivo properties have been detected using needle or spherically shaped MNPs [120]. Likewise at the cellular level, it seems essential to know MNPs’ surface charge for interpreting their uptake capability [121].

Using expensive, complex, and energy-intensive procedures like the acetyl acetanoate of Fe, a polyol, the preparation of identical and nearly individual MNPs can be achieved; however, coprecipitation is proposed when a low-cost, non-time-consuming, and simple method is desired. This popular method includes aqueous salt solutions of iron (Fe2+/Fe3+) and a base used as precipitant medium. In inert atmosphere, this process is normally carried out at comparatively very high temperatures, 70–90 °C [122]. The particles formed as a result of the process normally possess an arbitrary size and morphology. An additional constraint is connected to the accumulation trend in the coprecipitation agents. Particles of iron oxide can form large clusters owing to the anisotropic dipolar attraction, thereby displaying the particular properties connected to single-domain magnetic nanostructures [123].

Comparable studies are also found in other fields; for example, Roth et al. have investigated the impact of numerous experimental variables (e.g., reaction temperature, salt concentration, ratio of Fe3+/Fe2+, and ratio of hydroxide ions to iron ions). They focused largely on the influence of those variables on the size and the magnetization. In this respect, it was found that by adjusting the Fe2+/Fe3+ ratio and raising the concentration of iron salts, the saturation magnetization can be improved. The concentration of iron salt and the ratio of hydroxide ions to iron ions affected the particle size [124].

Fang et al. estimated that by using the coprecipitation process, the MNP size was affected by the temperature and the base addition rate [125]. Quick mixing significantly affected the size of particles. It was also found that temperature further affected the size of particles. The influence of the variety of the base was observed by Mascolo et al. These writers tested three different types of base, (C2H5)4NOH, NaOH, and KOH, carrying out coprecipitation at room temperature. They revealed a connection between the pH established in coprecipitation media and the tendency of magnetic nanoparticles to agglomerate. That pH is strongly influenced by the alkali nature [126].

The existence of additives, for instance surfactants, was an additional variable that has been widely studied. In this work, MNPs were manufactured by the process of coprecipitation and was improved using SDS in the postsynthesis step. Nanoparticles were consumed for the recovery and removal of nickel, zinc, and copper from industrial wastewater. This research showed that high adsorption capabilities might be obtained in less time thanks to the high surface area and also short diffusion route of SDS-coated Fe3O4 MNPs [127].

The current work was applied to perform a control of three significant properties of MNPs: surface change, shape, and size. The aim was to attain monodomain MNPs that were tunable by varying only the experimental conditions related to the methodology of preparation. Progress in nanotechnology is linked with nanoscale accuracy. MNPs are being used in an increasing number of commercial applications. The present work has the ability to control the crystallinity, shape, and size of MNPs and the development of new production methods [60, 128] by accurately adjusting the array magnitudes together with the crystallization of MNPs. The position and properties of MNPs on surfaces can be controlled using biomineralization proteins. Naturally, complex synthetic functions are performed by proteins. Biomineralization proteins yield an inorganic mineral structure within biological organisms. Biomineralization proteins have been produced for millions of years to regulate the variety of ore below slightly aqueous states [7]. Numerous other biomineralizing biomolecules have been found or improved to prepare desirable materials in vitro and to shape the creation of abiotic materials (including silver, CoPt, and FePt [129,130,131,132].

Magnetotactic bacteria can develop extremely uniform MNPs constituted of magnetite, that is, magnetic iron oxide, Fe3O4, within the distinctive lipid organelles called magnetosomes. The crystallization of magnetite MNPs is controlled by the biomineralization proteins that remain inside the magnetosome membrane. Numerous proteins were discovered firmly bound to MNPs of the magnetite in the magnetotactic bacterium Magnetospirillum magneticum AMB-1 by Arakaki et al. [133]. One protein in particular, Mms6, comprises a hydrophobic N-terminal region for incorporation into the magnetosome membrane and an acidic C-terminal region that can powerfully fix iron ions; it is supposed to nucleate and regulate the development of magnetite in vivo [134]. It has also been revealed that refined Mms6 is able to regulate the development of MNPs of magnetite in vitro (Fig. 2.11) [135].

SEM pictures of gold surfaces covered with whole layer of cysteine-tagged Mms6 protein patterned by interferometric lithography (IL) at a disclosure dose of 100 J cm−2. Figure reprinted/adapted with permission from [136]

The method of synthesis of nanomaterials shows some very important measures that will regulate the particular size, size distribution, shape, the surface chemistry of particles, and, thus, their magnetic properties. The nanoparticles of iron oxide have been synthesized by a coprecipitation reaction between ferric and ferrous salts having inorganic bases, very strong bases, NaOH, and somewhat mild bases like NH4OH. All these schemes indicate that magnetic behavior is similar to that of superparamagnetic materials. Using the aforementioned method, MNPs have been produced that are very small, 1–2 nm, and that have a precise uniform size; the standard deviation is less than 10%. A very uniform coating of silica (1 nm thin) is made using base-catalyzed hydrolysis and the reaction of polymerization of TEOS in microemulsion. It is very important to mention that the insignificant particle size of composites makes it a less acceptable candidate for in vivo applications [9].

2.5 Safety and Surface Stability of Magnetic Nanoparticles

The frequent use of nanomaterials in industrial and medical fields raises questions about their safe use and requires a comprehensive understanding of their life cycle in the body after exposure. Scientists claim that biodegradable nanoparticles are more suitable for biomedical applications because of their efficient metabolization. However, at the nanoscale, properties depend on the particles’ size or shape (owing to a large surface-to-volume ratio) and as a result of physical and chemical transformations, the technologically relevant properties of nanoparticles can be changed drastically [137]. Therefore, it is important to provide an extensive understanding about the interactions of nanoparticles with biological environments. Additionally, the evaluation of degraded products is still very challenging owing to the complex phenomena in vivo [138]. For example, the dissolution of crystals can liberate toxic soluble ions, such as Fe2+ and Zn2+. On the other hand, other factors, such as a coating polymer, can reduce crystal dissolution and increase the circulation time and persistence of nanoparticles. Recently various research groups have focused on these important issues to understand the life cycle of nanoparticles in vivo [139].

MNPs have less liberty for rotation and translation owing to dipole–dipole magnetic interactions at the cellular level. This reduces magnetic susceptibility and increases the blocking temperature. Consequently, the specific absorption rate of nanoparticles might fall after internalization if an AC magnetic field is applied. It is observed that degradation is a step-by-step dissolution process controlled by surface reaction processes. The physical transformations of nanoparticles indicate the loss of magnetic properties over time. Functionalization or coating of nanoparticles is one of the important factors used to control degradation mechanisms. Organic polymers or inorganic shells can be used as coating [140]. Organic polymers have been used to make nanoparticles biocompatible. This kind of polymer can also serve as a first barrier to control degradation. However, the nature and distribution of the polymer plays an important role in the dissolution of a crystal. An inorganic shell is also a potential candidate to control degradation mechanisms. For inorganic coatings, a complete shell is necessary to control the loss of the core part, in other words, a better cover rate of the core is an important factor. Additionally, an inorganic shell, for example gold, can lend its plasmon properties to nanoparticles. As a result, thermotherapy and plasmon therapy can be used simultaneously from a single nanoparticle. In conclusion, we need degradable nanoparticles, but the process of biodegradation should be delayed so that nanoparticles can be employed for the required application for a specified time [141].

2.6 Applications

2.6.1 Industrial Applications

Magnetic iron oxides (MIOs) are mostly used in porcelain, ceramics, and paints as synthetic pigments. They have attracted much attention in industry and other fields. These materials are attractive and useful in materials science and have vast applications in different fields [142, 143]. Both hematite and magnetite are used as catalysts for various reactions, for instance, in high-temperature water–gas shift reactions and in the preparation of ammonia. The synthesis of butadiene, the oxidation of alcohols, and Fishere–Tropsch synthesis for hydrocarbons are other reactions [144, 145].

2.6.2 Environmental Applications

For in situ applications, IONPs exhibit great flexibility. Supported and catalyzed NPs have been synthesized to increase their efficacy and speed of remediation [146]. Due to some unresolved ambiguities related to the use of IONPs, these substances are recognized as very useful tools in the rectification of various kinds of pollutants in air, soil, and water at both field and experimental levels [31]. Currently, various MNPs have been examined for the removal of both inorganic and organic contaminants.

2.6.3 Organic Pollutants

MNPs are used for the removal of excessive concentrations of organic mixtures [147, 148]. Dyes usually exist in wastewater flows in various branches of industry, for example, in the paint industry, tanneries, and textiles. Hence, MNPs could be suitable for the handling of textile waste.

2.6.4 Inorganic Pollutants

The main feature in metal toxin removal is the formation of functionalized sorbents for affinity or selective removal of harmful metal ions from complex matrices. For the removal of metal ions, MNPs are mostly used as sorbents. Because of the high surface area, MNPs exhibit high [149, 150] efficacy and ability in the removal of various metal ions. These results could be utilized to plan a suitable adsorption treatment for the recovery and removal of metal ions from wastewater.

2.6.5 Analytical Applications

-

1.

Fluorescence techniques. Magnetic luminescent nanoparticles present a higher surface area-to-volume ratio owing to their small size than recently employed microbeads that result in faster reaction kinetics and an effective reaction homogeneity. Thus, the formation of magnetic fluorescent particles, such as silica nanoparticles embedded with quantum dots (QDs) and iron oxide, and Fe2O3 particles coated with dye-doped silica shells, shells of QDs or polystyrene magnetic beads with entrapped organic dyes or quantum dots [151], is quite simple. But, the application of MNPs is restricted generally to biological applications, for instance cellular imaging.

-

2.

Encapsulation of MNPs in polymeric matrixes. The encapsulation of inorganic particles in organic polymers provides the particles with significant properties that bare, uncoated particles lack [152]. A polymer coating on these particles decreases their susceptibility to leaching, increases their compatibility with other organic constituents, and shields the surfaces of particles from oxidation.

Encapsulation of MNPs in inorganic matrixes. Magnetic properties can be controlled by a simple heating method, and silica has been described to be an efficient approach to controlling magnetic properties [153]. A surface enriched in silica is indicative of surface silanol groups that can simply react with silane coupling agents and alcohols to produce dispersions [154].

2.6.6 Biomedical Applications

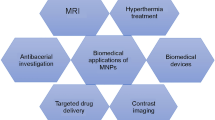

There are various biological and clinical applications of MNPs such as in vitro and in vivo applications. For in vivo applications, MNPs are used for diagnostic applications such as MRI as well as in therapies such as drug targeting and hyperthermia, while for in vitro applications, MNPs are mostly used in diagnostic selection, separation, and magnetorelaxometry [155, 156].

2.6.7 In Vivo Applications

For in vivo applications, two main factors, the surface and size functionality of MNPs, play a vital role. Even without affecting surface ligands, superparamagnetic iron oxide (SPIO) nanoparticle diameters greatly affect in vivo biodistribution. Ultrasmall SPIOs and particles with diameters 10–40 nm play a vital role for the prolonged circulation of blood [76].

-

1.

Therapeutic applications. Hyperthermia: Employing SPIOs in varying-current magnetic fields arbitrarily reverses the direction of magnetization between both parallel and antiparallel directions. In the form of heat it allows for the transfer of magnetic energy to particles. For in vivo applications, a property that can be used to enhance the temperature of malignant cells is known as hyperthermia. Cancerous cells are very responsive to an elevated temperature than healthy cells [157]. Also, the use of nanometer-sized magnetic particles is preferred instead of micron-sized magnetic particles because at reasonable AC magnetic fields, nanoparticles absorb much more power [158, 159], which is largely dependent on particle shape and size, and allows for the use of precise synthetic methods for fabricating uniform particles.

-

2.

Drug delivery. For drug delivery, drug targeting is a very recent development. Over the last decade, the applications of IONPs in drug targeting have taken on great importance [160]. Magnetic NPs in combination with an external magnetic field allow for the delivery of particles to the required target locations, fix them at the local site while the medication is released, and act locally (magnetic drug targeting) [161]. The transport of drugs to a specific location can reduce side effects and diminish the required dose.

2.6.8 In Vitro Applications

-

1.

Diagnostic applications

-

a.

Separation and selection. Currently solid-phase extraction has attracted a lot of attention. Solid phase extraction (SPE) is a technique to isolate and preconcentrate required constituents from a sample matrix. SPE is used for the determination of trace pollutants in ecological samples. Nowadays, nanoparticles have undergone significant advancements and have a considerable effect on sample extraction. This technique is considered the best substitute for the usual sample concentration processes [162,163,164].

-

b.

Magnetorelaxometry. Two relaxation procedures are Neel relaxation and Brownian relaxation. In Neel relaxation, the internal magnetization vector of the nanoparticles decreases in the direction of the axis inside the core [165]. In Brownian relaxation, particles achieve rotational diffusion in a carrier liquid. Brownian and Neel relaxation can be determined by their distinct relaxation times [166]. Moreover, Neel relaxation does not depend on the dispersal of nanoparticles, whereas Brownian relaxation occurs only in liquids, magnetorelaxometry is based on the hydrodynamic size and core size [167]. For magnetorelaxometry application, the advantage of decreasing the size of particles to the nanometer size is virtually identical to those explained for selection and separation applications.

-

c.