Abstract

This chapter presents the first-year (2014) performance analysis of a 276 kWp grid-connected roof-type solar photovoltaic (PV) plant located at the campus of Al-Ahliyya Amman University (AAU) in Jordan using monitored data. The plant is installed on the 3000 m2 roof of the arena building on the university’s campus. The array consists of 1176 modules with 2 orientations, 10° and 15°. The PV array is configured in such a way that the system includes 14 panels in parallel with 14 inverters. The plant is equipped with a monitoring system that is connected to the Internet and provides data on a daily basis. The study shows that the actual and estimated specific energy productions are 1639 and 1726 kWh/kWp/year, respectively. The annual capacity factor and performance ratio are found to be 18.7 and 87.5 %, respectively. The actual energy production is found to be 452,406 kWh/year, whereas the estimated annual energy production is found to be 476,467 kWh, as calculated using the PVsyst v6.32 software. The measured and estimated yields are in close agreement with each other, with a relative error of around 5 %. It is found that the actual yield is at its maximum in July and minimum in January. The analyzed plant is compared to PV plants worldwide, particularly in detail to a PV plant in Syria. The comparison shows that the overall performance of the AAU plant is excellent.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Al-Ahliyya Amman University (AAU) was established in 1990 as the first private university in Jordan. The university consists mainly of seven buildings, five female dormitories, and cultural foundation forums (Arena); the total built-up area of the university campus is 72,868 m2. The average specific electrical energy consumption of the university is around 4.5 kWh/m2/month. The annual electricity consumption is about 4 GWh [1]. The electrical use breakdown is shown in Fig. 61.1.

Electrical use breakdown of AAU [1]

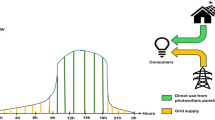

To reduce its electricity bill, AAU decided to install a solar photovoltaic (PV) plant with a capacity of 276 kWp on the roof of the Arena building, which has an area of 3000 m2 (Fig. 61.2).

Following the design stage, and after receiving confirmation of the university’s presidency, the installation of the system started and continued for around 10 days. After installing the system it was examined by Jordanian Electric Power Company, which released the necessary approvals to connect the system to the grid. This chapter presents measured system data for the year 2014 and a performance analysis of these data with the aim of showing whether this project is promising and inspires confidence for the university to install additional PV plants. Moreover, the plant’s behavior is compared with that of other plants in the region and worldwide.

2 Technical Description of System

The PV system is located in the As-Sarw area (between Amman and As-salt city), Jordan, at a latitude of +32.05 (32°03′00″N) and longitude of +35.72 (35°43′12″E). The module that was used is ET-P660235WW/ET-P660235WB with its data shown in Table 61.1.The array comprises 1176 modules configured as 14 subarrays. Each subarray consists of four strings with 21 modules connected in series for each string. The system is equipped with 14 subarray identical inverters SUN2000-20KTL from Huawei Technologies with technical specifications as shown in Table 61.2. The array orientation is fixed at two orientations: mixed tilt/azimuth of 15°/0° and 10°/0°. The plant is equipped with a monitoring system connected to the Internet and provides daily data that can be followed on the Web [2]. Figure 61.3 shows a schematic layout of the PV plant.

3 Actual and Estimated Energy Production

According to the monitored plant data from 1 January to 31 December 2014, the actual energy production was 452,506 kWh/year, with a specific final yield (Yf) of 1639 kWh/kWp. The minimum value was 16,898 kWh in January, while the highest value was 55,821 kWh in July (Fig. 61.4). The PV plant is simulated by the program PVsyst v6.32. The simulation results show that the expected energy fed into the grid was found to be 476,467, with a specific final yield of 1726 kWh/kWp, which is in good agreement with actual measurements, with a relative deviation of around 5 %. It is obvious from Fig. 61.4 that the actual values exceed the estimated values from April to August. In 2014, the PV plant saved approximately 331 tons of CO2, which would have been emitted by a crude oil fired thermal power plant generating the same amount of electricity.

The measurement and estimation (simulation) of PV energy production is a fundamental issue in PV system engineering. Measurement and monitoring is generally simpler than estimation, which is dependent on weather. Monitoring and estimation of PV can be used for various purposes, for example, to conduct a financial analysis. Whatever the goal, the processes and methods are critical to the technical and financial viability of PV technology and its integration into the utility grid. Simulation of PV systems differs from monitoring. The input may be either measured or calculated. The output is not measured; it is calculated. Simulation is a two-part process entailing the use of a set of input parameters and a model or transfer function of the physical plant used to calculate the performance of a PV system [3].

4 Performance Ratio

4.1 Definition

One of the key evaluation criteria of the PV system is the performance ratio (PR) of a grid-connected PV plant. The PR is an indicator of the effectiveness of the plant in transforming the solar energy captured by PV arrays into AC energy delivered to the utility grid. The PR is defined for a period of time (usually a month or a year) as the ratio of the measured generated AC energy fed into the point of common coupling (PCC) to the potential array output DC energy under standard test conditions. The calculation of annual and monthly PR percentage can be performed by Eqs. (61.1) and (61.2), respectively [4–6]:

4.2 Performance Ratio Calculation:

-

$$ \mathrm{Active}\kern0.5em \mathrm{array}\kern0.5em \mathrm{area}\;\left(\mathrm{Area}\kern0.5em \mathrm{of}\kern0.5em \mathrm{module}\kern0.5em \mathrm{cells}\right)=0.156*0.156*60*1176=1717.148\kern0.5em {\mathrm{m}}^2. $$

-

The solar data of a plant’s location are assumed to be those of Amman and is adopted from NASA’s Surface Meteorology and Solar Energy satellite included in the database of the PVsyst v6.32 software. Based on horizontal values, the global monthly average insolation in the collector plane is computed using the PVsyst v6.32 software; the results are represented in Fig. 61.5. The yearly average global insolation in the collector plane is 5.71 kWh/m2 day.

The plant annual PR is calculated using Eq. (61.1):

In modern solar PV plants, the performance ratio should typically be around 80 % in the starting year. According to the National Renewable Energy Laboratory (NREL) (Golden, CO), the standard performance ratio for a new PV system is around 77 %, and over time the PR will degrade [7]. Thus, the PR value of over 87 % for the new university PV system shows the excellent quality of the system. The PR value indeed evaluates the total losses of the system, less than 13 % for our system. These losses account for, among things, mismatched modules, differences in ambient conditions, dirty collectors, inverter efficiency, wiring losses, system availability, diodes, and connections.

It is a good practice to calculate the monthly PRs in order to be aware of the losses that occur each month, which can help in deciding on measures to reduce them. The calculation process is illustrated by an example for March 2014:

The results are shown graphically in Fig. 61.6.

It is obvious from Fig. 61.6 that the PR is at its minimum in January (62.45 %), at its maximum in December (98.40 %), and over 90 % for more than 6 months. The performance ratio for the whole year is found to be 87.544 %, as calculated earlier.

4.3 Performance Ratio Levels Worldwide [8]

Many studies have been conducted [9–12] to analyze the performance of PV systems installed in different countries at different times. An increasing trend of the annual PR values has been observed over the years (Table 61.3). The average PR values increased from about 65 % in the 1990s to over 80 % in the 2000s. Compared to average PR levels for PV plants worldwide, the AAU plant is among those plants with the best PR.

5 Capacity Factor

5.1 Definition

The other key parameter for evaluating PV plants is the capacity factor (CF). The CF of a power plant is the ratio of its actual generated energy over a period of time to its potential output if it could operate at full nameplate capacity. The main difference between the PR and CF is that the CF ignores environmental conditions affecting the plant, while the PR accounts for these conditions. The CF may be, however, a value that serves as a comparison criterion for evaluating power stations with different fuels. Renewable power plants or conventional power plants with high fuel costs that are usually operating at peak load periods have relatively low capacity factors. Table 61.4 shows average CFs for different power plants in the UK [13].

According to the NREL, the CF of PV plants over a year is calculated as follows:

5.2 Calculation of AAU Plant Capacity Factor

The annual capacity factor of AAU plant is calculated using Eq. (61.3):

Monthly CFs are calculated and represented graphically in Fig. 61.7, which shows that the CF is at its minimum in January (8.23 %) and at its maximum in July (27.18 %). The average CF for the entire year is 18.7 %. According to [13], the CFs of evaluated PV plants in the USA and UK are as foll

ows:

PV solar in Massachusetts 13–15 %, PV solar in Arizona 19 %, PV solar in UK 8.6 %. The annual CF of a PV plant in Egypt is 18.12 % [14]. Compared to the CF values in some countries, our plant possesses a very high CF, which again indicates excellent performance.

6 Effect of Ambient Temperature on Power Output of Array and Inverter

Cell temperatures change not only as a result of variations in ambient temperatures but also because of insolation changes on the cells. Manufacturers often provide a parameter called nominal operating cell temperature (NOCT), which can be used for considering the changes in cell performance with temperature. The NOCT is the cell temperature in a module under the following conditions: ambient temperature of 20 °C, solar irradiance of 0.8 kW/m2, and wind speed of 1 m/s. To account for other ambient conditions, the following expression may be used [15]:

where Tcell is the cell temperature (°C), Tamb is the ambient temperature (°C), and S is the actual solar irradiance (kW/m2).

The approximate calculation of the power output of the array (PDC) and power output of inverters (PAC) can be carried out as follows.

-

From given monthly average ambient temperatures, the average Tcell is determined for each month using Eq. (61.5):

-

$$ {P}_{\mathrm{DC}}=276\left[1-0.0044\left({T}_{\mathrm{cell}}-25\right)\right]\mathrm{kW}, $$(61.6)

-

$$ {P}_{\mathrm{AC}}={\eta}_{\mathrm{conversion}}*{P}_{\mathrm{DC}}\kern1em \mathrm{kW}. $$(61.7)

The results are shown in Fig. 61.8.

As can be seen in Fig. 61.8, when cells heat up and, consequently, the cell temperature increases, both maximum DC power available and AC output power decrease. The minimum value occurs in August with 14.5 % less than rated power, and the maximum is found to be in January with a 6.4 % rated power drop. Given this significant variation in performance as the cell temperature changes, it should be quite apparent that the temperature needs to be included in any estimate of array performance.

7 AAU PV Plant Versus a Syrian PV Plant

To compare the quality of our plant with PV plants in the region, a grid-connected PV system in Syria is briefly analyzed and compared to the AAU PV plant. The considered Syrian PV plant is a grid-connected plant operating since 9 November 2010. It is installed in Damascus on the roof of one of the Electricity Ministry buildings. The PV array consists of 45 modules with a rated power of 90 W each. The module made in Syria has an efficiency of 13.56 % and 36 cells connected in series. The cell area is 156.25 cm2. The array orientation is fixed at a tilt angle of 35°. Based on the measured solar insolation on a horizontal surface in Damascus [16], the monthly values on the tilted collector are computed and represented in Fig. 61.9, along with the insolation in Amman as well. The yearly average insolation in Damascus is 5.56 kWh/m2/day, whereas that value is 5.71 in Amman.

According to the measured data of the Syrian PV plant [17], the energy production in 2013 (the third year of operation) was 6177 kWh and the specific yield was 1525 kWh/kWp, which is less than the specific yield of our Jordanian plant by around 7 %. The lowest specific yield was found to be in January (92.59 kWh/kWp), while the highest value was in May (150.12 kWh/kWp). The specific yield of the Syrian plant exceeds that of the Jordanian plant in November and winter months (Fig. 61.10). This result is due to the higher array tilt angle (35°) of the Syrian plant compared to the 10° to 15° of the Jordanian plant.

The annual PR of the Syrian plant is 88.2 %, which is slightly greater than the PR of the Jordanian plant (87.5 %). It is calculated using Eq. (61.1):

The CF of the Syrian plant is 17.4 %, which is less than the CF of the Jordanian plant by around 7 %. It is calculated using Eq. (61.3):

The comparison results are summarized in Table 61.5.

8 Conclusions

A performance analysis of the 276 kWp grid-connected PV plant at AAU in Jordan was carried out in terms of main performance criteria such as specific final yield (Yf), performance ratio (PR%), and capacity factor (CF%). The values of Yf, PR, and CF were found to be 1639 kWh/kWp, 87.5 %, and 18.7 %, respectively. The plant was simulated using the program PVsyst v6.32. The estimated energy injected into the grid was found to be in good agreement with the actual energy production, with a relative deviation of around 5 %. A comparison of these values with evaluation parameters of reported PV plants in some countries revealed that our plant is among the best. A relatively extended comparison was conducted with a grid-connected PV plant in the region (Syria), which was briefly analyzed, and showed that the performance of both plants is approximately similar. Thus, the overall performance of the AAU PV plant was found to be excellent during the first year of operation, and the studied PV system represents a successful project in Jordan and in the region, which will help to justify installing more plants at the university and elsewhere.

References

EcoSol (2014) Complete energy solutions—practical case study. Presentation conducted at Al-Ahliyya Amman University

James M Bing (2015) Application note predicting and monitoring PV energy production. ECI Publication No Cu0207. www.leonardo-energy.org, Jan 2015

SMA Solar Technology AG, Performance ratio, Technical information Perfratio-UEN100810. http://files.sma.de/dl/7680/Perfratio-UEN100810.pdf

Cristian P, Chioncel, Ladislau Augustinov, et al. (2009) Performance ratio of a photovoltaic plant. Bulletin of Engineering, Copyright © University Politehnica Timisoara/Fascicule 2/April–June/Tome Ii, pp 555–58

Ebenezer NyarkoKumi, Abeeku Brew-Hammond. Design and analysis of a 1MW grid-connected solar PV system in Ghana. African Technology Policy Studies Network, ATPS 2013 ATPS Working Paper No. 78

Ralf Muenster, National Semiconductor. Watts matter: maintaining the performance ratio of PV systems. http://www.solarindustrymag.com/

Jahn U, Nasse W (2004) Operational performance of grid connected PV systems on buildings in Germany. Prog Photovolt Res Appl 12(6):441–448

Leloux J, Narvarte L, Trebosc D (2012) Review of the performance of residential PV systems in France. Renew Sustain Energy Rev 16(2):1369–1376

Leloux J, Narvarte L, Trebosc D (2012) Review of the performance of residential PV systems in Belgium. Renew Sustain Energy Rev 16(1):178–184

Huang HS, Jao JC, Yen KL, Tsai CT (2011) Performance and availability analyses of PV generation systems in Taiwan. World Academy of Science, Engineering and Technology, vol 54

Reich NH, Mueller B, Armbruster A, van Sark WGJHM, Kiefer K, Reise C (2012) Performance ratio revisited: is PR > 90% realistic? Prog Photovolt Res Appl 20(6):717–726

CHROSIS Sustainable Solutions (2012) Whitepaper on PR vs. CUF. http://chrosis.de/wp-content/uploads/2012/12/PR-vs-CUF-WP.pdf

Elhodeiby AS, Metwally HMB, Farahat MA (2011) Performance analysis of 3.6 kw rooftop grid connected photovoltaic system in egypt. International Conference on Energy Systems and Technologies (ICEST 2011), Cairo, 11–14 March 2011

Masters GM (2004) Renewable and efficient electric power systems, Stanford University, Wiley

Al-Mohamad A (2004) Global, direct and diffuse solar-radiation in Syria. Appl Energy 79:191–200, www.elsevier.com/locate/apenergy

Private communication with National Energy Research Center (NERC), Syria

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing Switzerland

About this paper

Cite this paper

Hamzeh, A., Hamid, S., Sandouk, A., Al-Omari, Z., Aldahim, G. (2017). First-Year Performance of a PV Plant in Jordan Compared to PV Plants in the Region. In: Sayigh, A. (eds) Mediterranean Green Buildings & Renewable Energy. Springer, Cham. https://doi.org/10.1007/978-3-319-30746-6_61

Download citation

DOI: https://doi.org/10.1007/978-3-319-30746-6_61

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-30745-9

Online ISBN: 978-3-319-30746-6

eBook Packages: EnergyEnergy (R0)