Abstract

This study presents a long-term performance analysis of a one-mega-watt power grid-connected PV plant installed on the rooftop of GITAM University, Visakhapatnam, Andhra Pradesh, India for 3 years. The 1000 kWp PV plant design, performance analysis, economic feasibility, and greenhouse gas reduction are provided. For 3 consecutive years (2018–2019, 2019–2020 and 2020–2021), the energy yields, performance ratio (PR), capacity utilisation factor (CUF) and efficiency are evaluated. The plant was established in 2018 with a peak power of 1000 kWp. The system feeds the state grid with all of the electricity it produces. The system is continuously monitored and analysed using yield, efficiency and performance parameters for 36 months (September 2018 to August 2021). Solar irradiation data has been collected from the National Renewable Energy Laboratory (NREL) database for these years. The system comprises 3078 PV modules, 23 inverters rating 20 kW/50 kW, a data logger and a Net-metering unit. The annual energy generation of the PV plant recorded during the study period is 1376.29 MWh, 1265.541 MWh and 1115.73 MWh. The annual average performance ratio for the first three consecutive years is observed as 0.68, 0.62 and 0.58, whereas the yearly average capacity factors are 15.5%, 14.11% and 12.72%, respectively. The overall system efficiency of the PV system during the study period is 11.39%. Compared to the country’s current conventional thermal power plants, we predict that rooftop PV systems may reduce CO2 emissions by 2145.406 tCO2eq for the base year, based on the electricity produced by this PV plant. The grid-integrated photovoltaic plant in this study is compared to other systems in the literature for performance assessment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Today, a green economy for meeting energy demands while avoiding global warming and environmental health impacts is becoming a primary concern. Significant evidence suggests that shifting to sustainable energy sources will solve ecological challenges such as emissions of greenhouse gases, air quality and environmental degradation to some level. This transformation is happening rapidly in emerging countries in all regions. In the recent decade, the renewable energy sector has grown significantly in India, which practically relies on renewable energy for its electricity. According to the Government of India, figures given by the Ministry of Power, renewable energy sources occupy a 25.2% share accounting a 98,883 MW in the whole energy generation (Power sector at a glance all India 2021).

The potential for solar energy in India is enormous. Solar energy is one of the most commonly available energy sources that can provide electric power profoundly cleanly. Solar energy has gained traction among renewable energies in India, owing to the country’s high level of solar radiation (one of the highest in the world). Around 5000 trillion kWh of incident energy is received by India’s land surface each year, with most places receiving 4 to 7 kWh/m2 each day (https://mnre.gov.in/solar/current-status). According to the National Institute of Solar Energy, the country has a solar potential of roughly 748 GW, assuming that 3% of the area of the wasteland will be covered with solar PV modules. The National Solar Mission (NSM) was launched on January 11, 2010, by the Indian government as a critical initiative to advance environmental sustainability and address the nation’s problems with energy security. The Mission targets 100 GW of grid-connected solar power plants installed by 2022. India’s intended nationally determined contributions (INDCs) set goals by 2030 for attaining roughly 40% of its installed electric power capacity from non-fossil fuel sources and a 33 to 35% reduction in the GDP’s emission intensity. To achieve the aforementioned goal, the Indian government has launched several programmes, such as the Solar Park Program, CPSU Program, VGF Programs, Defense Program, Canal Bank & Canal Top Program, Bundling Program, and Grid Connected Solar Rooftop Program. India recently overcame Italy to take over the 5th place globally in utilising solar energy. Solar power capacity increased from 2.6 to 40 GW by more than 11 times between March 2014 and March 2021. India’s solar pricing is currently highly competitive and has surpassed grid parity. Additionally, support from state and federal governments has fuelled the construction of solar farms, which mostly employ solar technology. Open areas, rooftops of buildings and water bodies are convenient for installing PV systems, substantial attention is drawn to developing and expanding solar technologies.

With the growing popularity of photovoltaic (PV) systems worldwide, it is essential to look at how they operate. Initially, a feasibility study assess the local climatic parameters influencing energy generation like atmosphere temperatures, wind velocities, humidity, solar radiation and dust. Additionally, PV technology, angle of inclination and installation method play an essential role in analysing the performance of PV systems. The authors (Nacer et al. 2016; Lee et al. 2016; Thotakura et al. 2020; Podder et al. 2021) presented their literature on the feasibility study of PV plants in various regions with an analysis with simulation models. The survey by authors (Pinho C et al. 2021) presented a simulation analysis of the one year operation of 1-hectare solar PV plant located in a coastal area of Benguela region, Angola. The study was conducted with a Vela Solaris Polysum Software and recorded a 1511.70 MWh annual AC electricity generation, with an average annual energy efficiency, exergy efficiency and Co2 emission reduction of 14.3%, 14.7% and 710.47 tCO2.. They considered DuoMax 365 PV modules made of Trina Solar. The authors (Faiz et al. 2021) have conducted the modelling and analysis of a solar PV plant of 3 MWp with a simulation tool PVSyst at a University campus in Bahawalpur, Pakistan. The study location has an average daily solar radiation of 5.9 kWh/m2. The authors highlighted that 15,369.3 kg of coal savings could be made daily. The performance ratio (PR) values, capacity utilization factor (CUF) and total energy generation are 83.8%, 16% and 4908 MWh/year, respectively. The article by Chowdhury et al. (2021) recommended a 5-MW grid-connected solar photovoltaic plant at two International Airports in Dhaka and Chittagong, Bangladesh performing mathematical and simulation studies. The findings of this study show an energy efficiency in the range of ~18.74 to 7.45% in both locations. Approximately 3926 tons of CO2/MWh gross reduction can be achieved in the study locations. A target-oriented evaluation of a 232.5-kWp grid-integrated solar PV plant is presented in reference Saleheen et al. (2021), which is erected on a business building in Malaysia. From the solar data logger, the data is retrieved in a 5-min interval for 2019 to analyse the performance matrices. An average temperature between 26.9 and 28 °C, and a moderate global solar irradiation of ~ 4.21 to 5.06 kWh/m2 are recorded in the study location with a rainfall of ~2300 mm annually. The PR, CUF, levelized energy cost, system and inverter efficiency are 85.4%, 14.85%, 0.396 MYR/kWh, 9.51% and 98%, respectively. The losses in the system (system losses) are observed to change between 0.017 and 2.98 h/d, as the temperatures at the water’s surface in the centre and east-central equatorial regions have been rising regularly.

Even though solar photovoltaic performance can be evaluated using simulation and analytical methodologies, the perfect way is to investigate the actual performance of such systems under real-world conditions at a given site. Operations research on existing on-grid PV systems is needed to evaluate the performance of local features such as geographical location and climate categorisation. A detailed overview of the performance of solar PV plants established in various regions worldwide is highlighted by researchers (Srivastava et al. 2020). The review is carried out and summarised by covering many aspects like essential location, year of commissioning, the technology used and their performance. The authors concluded that the majority of countries throughout the world had installed PV plants, and those installations have been found to produce satisfactory results and also pointed out that PV module material and panel tilt angle were the critical factors in the design of a PV plant. The authors (Behura et al. 2021) presented an article on a 248-kW rooftop photovoltaic system developed at an educational institute (Vellore) in India. The authors proposed a new design to overcome the shading loss to increase the energy efficiency of the existing PV plant. The performance ratio and panel efficiency are 79.1% and 12–18%. A simulation study is also carried out with the PV system design tool, correlated with the measured values and found to be in good agreement.

The work by Bansal et al. (2021) presented a techno-economic study, analysis of deterioration and performance evaluation of a 5-MW grid-connected solar photovoltaic (PV) plant for 7 consecutive years from 2013 to 2019, located in hot and dry climatic conditions in Gujarat, India. During the 7-year operations, hot spots, junction box melting, encapsulant discolouration, snail trails, corrosion of metallisation and connection corrosion, owing to moisture ingression as the principal deterioration modes and problems on the PV modules are identified. Between 2013 and 2016, the annual average for performance ratio, capacity factor and efficiency of inverter and system were approximately 73%, 17–18%, 96% and 10.29–10.41%, respectively. Later years show a higher degradation rate of roughly 2–2.5%, with yearly average PR, CUF and PV system efficiency varying between 62–70%, 14–16%, and 8–9%, respectively, from 2017 to the year 2019. Since being installed, the facility has reduced CO2 emissions by 57,869 mt through 2019. The authors presented the operating performance of a 2-MWp solar PV plant in the rain-dominant tropical monsoon climates of Kerala, India (Sudhakar et al. 2021). The efficiency of the PV plant varies in the range of 11.51–12.78%. The highest capture loss of 45.18 kW/kWh per month is recorded during April (summer), and the lowest of 26.88 kWh/kWp is noted during July (rainy month). The performance assessment of a large-scale 50-MWp solar park for 2 years (2018–2020) located in Sakunala, Andhra Pradesh, India is addressed by Boddapati et al. (2021). The maximum average solar irradiation at the study location is 7.38 kWh/m2/day, while the lowest irradiation recorded was 4.48 kWh/m2/day. During 2018–2019, a PR (77.9%), CUF(24%) and energy yield of 107,326.4 MWh and in the next year, 2029–2020, a PR(80%), CUF (24%) and energy yield of 106,022 MWh are recorded. The simple payback period of the plant is expected to be 4 years and 7 months, based on the economic assessment.

A case study by Abdullah and Nishimura (2021) presents an economic performance of a 40.1-kWp PV system integrated into the grid after 8 years of generation. It has been operating since 2012, and the data is monitored for 2019. The expected energy of 48,521 kWh has to be generated, where only 38,071 kWh of energy generated was injected into the grid in 2019. The annual PR, CUF, capture losses and system losses are recorded as 68.1%, 10.61%, 0.85 and 0.39, respectively. Kumar and Sudhakar (2015) presented the design, operation and maintenance of a 10-MWp solar plant at Ramagundam, Telangana State, India. The location has an average solar radiation of 4.97 kW h/m2/day and an average temperature of roughly 27.3 °C. The monitored results are compared with the PYSyst and Solar GIS PV planner results. The conclusions from the study indicated peak and minimum output powers of 10.34 and 40.83 MW during round operation in a year. For 1 year, from April 2014 to March 2015, the total energy generation with PVsyst, Solar GIS PV planner and the monitored data was 16,047 MWh, 16,403 MWh and 15,605.908 MWh, respectively. The PR average in a year is with measured and PVsyst tool are noted as 85.12% and 76.20%, respectively. The plant’s CUF varies between 12.67 and 20.04%, with an annual average value of approximately 17.68%. The overall energy loss is 23.4%. The study offers knowledge on the location and appropriate PV structure for India’s large-scale solar photovoltaic system implementation. The authors in ref. Malvoni et al. (2017) investigated the performance of a PV system of capacity 960 kWp for 43 months in southern Italy. The results are as follows: average reference yield and array yield range from 2.2 to 7.1 h/d and 1.9 to 5.9 h/d, respectively. The average PR, capacity factor, module efficiency and system efficiency in a year are 84.4%, 15.6%, 15.3% and 14.9%, respectively, while the capture and system losses are 0.6 and 0.1 h/d. A classical seasonal decomposition method estimates the degradation rate as 1.48%/year. Using two PV simulators: SAM3 and PVsyst, the PV system’s actual performance is compared with the projected outcomes. The result comparison between the monitored and simulation data (SAM and PVsyst) exemplifies an underestimated value of 3.5 and 3.3% for AC energy output. In contrast, the SAM tool overestimated the PR, and the PVsyst overestimated the capture and system losses.

The authors perform 4 years (September 2013–August 2017) analysis using monitored and simulation data (Banda et al. 2019) for an 830-kWp grid integrated solar PV plant at Malawi Kamuzu International Airport. A total of 3540 modules with rating 235 Wp, made with thin layer technology are used. The 4-year annual average efficiencies (array, inverter and overall) and PR are 15.3%, 95.2%, 14.6% and 79.5%, respectively. The capacity factor noted annually is 17.7%. The typical ranges of the PR and CF are 75–85% and 15–17.7%, and the performance values attained from the analysis are within the range. The performance is compared with the PVsyst tool, where a ± 5% normalised mean bias error is observed with reliable measured data. The solar PV plant examined in the study by authors Mensah et al. (2019) is located in Navrongo, Upper East Region of Ghana, where the location experiences two seasons: wet season during June to October; from November to May, it is the dry season. In the performance study made from June 2013 to May 2016, the following observations are made for that period: A total of 10,643.3 MWh of energy is generated, the annual PR and capacity factor (CF) is 70.6% and 16.2%, and over 3852 mt of CO2 emission is avoided. A practical study was conducted on a 10-MWp Oryx PV plant by authors Rezk et al. (2019) installed in Ma’an, Jordan. The PV plant supplied approximately 24.157 GWH in a year (May 2017 to April 2018), with annual energy efficiency, performance ratio and CF of 12.1%, 78.14% and 26.34%, respectively. The yield factor and reference yield are 2307.7 kWh/kWp and 2983 h. The authors mentioned a minor increase in PV due to the wind-cooling solar modules during the summer, which is caused by the growth of wind speed. However, the module will turn horizontal when the speed hits 12 m/s, which will render another factor, such as the soling rate, to impair the efficiency of the PV. Hence, they provided insight into renewable sources on the PV system’s ability to produce electricity. Using several temperature models the article by (Thotakura and Kondamudi 2022) forecasted the operational temperature of the 1-MWp rooftop photovoltaic plant located in the tropical dry and wet climate in India. The observations reveal that module efficiency and output power are linearly dependent on temperature. The literature discussed here provide a broad overview of how PV systems performed in India and various regions under different environmental conditions.

In the current study, the research tries to assess the solar PV system performance under actual weather circumstances because the system’s performance under STC cannot be guaranteed. We conduct the long-term performance of a one-megawatt power PV system in the southeast coastal region of India, established on the rooftops of a University campus. Utilising real-time data collected over 3 years (September 2018–August 2021) considering seasonal variation, the operation of solar installation on institutional buildings in terms of their performance parameters, plant efficiency and other system losses were examined. The impact of meteorological conditions on solar PV plant performance in tropical wet and dry temperate climates is also discussed. In the literature, no study has addressed about the performance of rooftop PV plants in the present study location and also in the tropical wet and dry temperature climatic conditions. Hence, the main intention is to explore the performance of various solar configurations (rooftop, ground mount, floating and tracking PV), where initially the rooftop is chosen for assessment. The results of this study will help system designers, technologists and installers predict the economic and energy performance of similar projects on PV plants in India’s climate, mainly in coastal regions.

Case study

Solar power plant location and project description

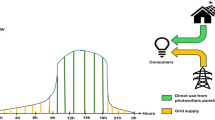

The present system is installed in Visakhapatnam City, India (17° 48′ 8.208″ N, 83° 23′ 6.54″ E ) with a capacity of one-megawatt power in the year September 2018. Visakhapatnam City is located in Andhra Pradesh; the region comes under the southeast coastal area of the Bay of Bengal, which falls under tropical wet and dry climate conditions. There are various PV arrays in the PV system at the study location to complete the one mega-watt power configuration. The PV arrays are installed in multiple building rooftops of the university campus connected in series, with 3078 modules, each of a capacity of 325 Wp. The installation has equipment with 23 inverters and a data logger that records energy generated (W), voltage (V), current (A) and module temperature (°C), at an interval of 5 min. The inverters installed here have ratings of 20 and 50 kW, and the modules connected to each inverter vary based on the space available on each rooftop to position the solar modules. The data logger continuously monitors the energy sent into the grid from the solar PV plant. The PV modules are free from the effect of shading and are cleaned twice a month. The PV modules are installed with a 15° southward slant. The complete PV system is supported by metal frames installed on concrete pillars. The full specifications of the PV system are presented in Table 1. The aerial view of the solar PV plant in the study location is illustrated in Fig. 1. The schematic shown in Fig. 2 gives the complete layout of PV plant on the the rooftops connected to the grid.

Data collection

The PV system’s most sensitive and volatile parameter is sun irradiation. Solar irradiation and ambient (air) temperature are collected from metrological data from NREL worldwide energy resources (NREL:Asia/Pacific Himawari database). The values recorded are for 36 months, from September 2018–August 2021. It is observed that solar irradiation and ambient temperature are high from March to May in all 3 years due to the summer season and low during August and September due to the rainy season. The overall discussion of these parameters is made in the “Results and Discussion” section, along with figures. The solar PV plant commenced its operation in September 2018. The energy generation is tracked over 3 years, from the plant’s inception in September 2018 to August 2021, from the PV system inverters. A data logger is maintained to record the data from every inverter for 5 min throughout the day. As per the track record, it is observed that the data is loaded from sunrise time (approx. at 6 am) to sunset time (approx. till 6 pm). The performance indicators are calculated based on the monitored values.

Analysis methods

To assess the technical performance of the current rooftop solar PV system, numerous works have used the parameters specified and classified in IEC 61724 standards (Photovoltaic system performance monitoring — guidelines for measurement, data exchange and analysis, IS/IEC 61724:1998), such as yield parameters, efficiency parameters, quality factors, loss parameters and economic indicators. A precise and reliable system evaluation helps improve the installation of PV plants in developing countries and these parameters are also used to identify operational problems. This article will discuss the yield parameters, efficiency parameters, quality factors and economic indicators by considering the real-time measured values gathered during 36 months from September 2018 to August 2021.

Yield parameters

Yield parameters characterise the performance of the overall photovoltaic plant concerning energy produced, solar resources and the effect of losses. These parameters are array, final, reference and thermal yield.

Array yield (Yay). The ratio of direct current energy production from a PV array (Eay,DC, kWh) over a specific time (day, month or year) to its rated power (Pr, kW) is known as the array yield and can be calculated as given in Eq. (1). It shows how long the photovoltaic array needs to produce DC electricity at its nominal power.

Yield factor (Yyf). The final factor is calculated as the system’s daily, monthly and yearly alternating current energy production (EAC, kWh) divided by the rated power (Pr, kW) of the installed PV array’s under standard test conditions (STC) of 1 kW/m2 solar irradiation and 25 °C cell temperature.

Reference yield (Yref). It is defined as the ratio of daily solar irradiation (HT, kWh/m2/day) on the area of the PV module to the array reference irradiance (Gref, W/m2). It is the duration of time expended under the reference irradiance and expressed as in Eq. (3).

Thermal reference yield (Yt). It is the corrected reference yield (Yref, h/d) with module and ambient temperature effect (Tc, °C).

where α is the temperature coefficient of power in %/°C.

Efficiency parameters

Efficiency is one of the critical parameters for analysing the system or plant performance. It ensures the system is running up to its capacity. In this long-term study of PV Plant, individual array, inverter and system efficiency were calibrated. The mathematical expressions for these efficiencies are given in this section, along with a brief description.

Array efficiency (ηarry). In terms of converting solar energy into electrical energy, it describes how effectively solar PV modules do so. Its definition is the relationship between the DC energy output (ET, kWh) of a module and the product of the entire area of the array (Aarry, m2) and daily solar radiation (HT, kWh/m2/day).

System efficiency (ηSys). It was stated as a percentage of the overall electric energy output (EAC, kWh) to net solar energy input. The net solar energy is calculated based on the solar radiation (HT, kWh/m2/day) spreading on the area’s total area (Aarry, m2) (Navothna and Thotakura 2022).

Inverter efficiency (ηinv). The amount of AC power output to input AC power is used to quantify it. It is derived by Equation (7) as:

Performance indicators

The performance ratio (PR) and capacity factor (CF) are two performance indicators of a PV system that describes the characteristics of design. These indicators are also termed as quality parameters.

PR. The performance ratio (PR) assesses a photovoltaic system’s capacity to produce energy. It is expressed as the ratio between the final (Yyf, h/d) and reference yields (Yref, h/d), and it displays the losses incurred by the PV system during the conversion of DC electricity to AC electricity. Due to the unstable operating environment and the system’s features, the PR value of photovoltaic plants ranges between 60 and 85%. The PR expression is given by Navothna and Thotakura (2022):

CF. This parameter measures how much energy the photovoltaic plant would produce, if operating for 24 h straight at its maximum recommended power. The capacity factor change depending on global solar radiation and the number of sunny days (Miskat et al. 2023).

Environmental indicators

India primarily relies on thermal power facilities to supply its electricity needs, which produce greenhouse gas emissions. Solar PV systems benefit society by reducing the number of greenhouse gases released into the atmosphere.

CO2 emission. It reflects the overall emissions created when manufacturing the photovoltaic system’s parts. According to the literature, the polycrystalline silicon modules’ life cycle CO2 emissions are 0.053 kg CO2 eq./kWh. An assessment is made for CO2 emission during a PV system’s lifetime and annually.

In Eq. (10), ‘Y’ is the lifetime of the photovoltaic system; generally, a solar system’s life is 25 years, and the symbol ‘r’ denotes the polycrystalline PV module’s deterioration, which is assumed to be 0.6% per year (Kumar and Sudhakar 2015).

CO2 mitigation. The number of CO2 emissions reduced by the system’s yield produced by the coal-fired power plant to produce the same amount of energy. The mean CO2 emission for 1 unit of electricity production is 0.98 kg from a coal-fired power plant. According to India’s grid emission factor, abbreviated as GEF, losses in transmission and distribution result in per-unit CO2 emissions of 1.58 kg. A PV system’s net CO2 mitigation is calculated using the disparity between its lifetime CO2 emission and mitigation.

Earned carbon credits. In general, the term “carbon credit” is an offset that gives value to the mitigation of emissions of greenhouse gases. Trading 1 tCO2e results in the receipt of one carbon credit on the global market. Carbon credits are priced at €16.32/tCO2e (NASDAQ, 2018), where €1 = INR 86.23 (Dec 7, 2022).

Results and discussion

Weather analysis

Climate factors like solar radiation, atmosphere (air) temperature, wind, annual precipitation and relative humidity impact how well PV systems operate. Analysing these parameters is crucial for determining how well the PV system performs. Nation’s meteorological department adheres to the four-season international norm with certain local modifications of Winter (December–February), Summer (March–May), Monsoon or Rainy (June–September) and Autumn (October–November). The coldest months of the year are December and January, where the lowest atmospheric temperature of 25–27 °C and the hottest months are April and May, with the highest (air) temperature of 32–35 °C are recorded during the study period. The performance of a solar photovoltaic module is directly impacted by solar irradiation and cell temperature. The cell temperature, air temperature and monthly average total solar radiation on the PV module’s surface at the study location recorded for 36 months (September 2018–August 2021) are displayed in Fig 3. Summer being the hottest season, the temperatures are high.

Total energy generation

Hourly and daily energy production

The solar photovoltaic plant installed in the present study started its operation in September 2018. Energy from the solar PV plant is injected into the grid and continuously measured by the data logger every day, in regular intervals of 5 min. Figure 4 shows the variation of energy produced in a single day from 6.19 a.m. to 5.53 p.m. at an array connected to a 50-kW inverter of the PV system on January 5, 2019, plotted at an interval of 15 min. A peak energy of 260.70 kWh is recorded during midday around 1.23 p.m., and a lowest of 246.7 kWh at 6.44 a.m. The average daily energy output by the one mega-watt PV plant during its first year of operation (Oct. 2018–Sept. 2019) is shown in Fig. 5. The schematic indicated the highest energy production of 5325 MWh on April 23, 2019 and the lowest value of 1880.5 MWh on August 30, 2019.

Monthly energy generation

The monthly average energy output of the megawatt power solar plant is shown in Fig. 6, with a combination of average solar irradiation for the month during its first 36 months of operation. In the first month of its operation, the generation is around 81.78 MWh. The plant experienced the highest generation of 139.22 MWh in March 2018 during the first month of the hottest season (summer), where an average solar radiation of 199.97 kWh/m2 was recorded. During July, 2021, it was observed that the plant could generate 72.29 MWh of energy which is the lowest value in its 36 months of operation. The yearly energy generation of the plant during the study period is noted as 1376.29 MWh (1st year), 1265.541 MWh (2nd year), 1115.73 MWh (3rd year), whereas 3757.553 MWh of energy is fed into the grid in its first 36 months (Sept. 2018–Aug. 2021) of operation.

Yields

The rooftop PV system’s average monthly reference, array and final yield are shown in Fig. 7. The average monthly reference, final and array yields fluctuate from 2.28 to 6.89 h/d, with an aggregate for the 36-month study period are recorded as 3.35 h/d, 3.42 h/d and 5.29 h/d, respectively. The highest reference yield is observed from March to June in every year due to the hot summer season, with a maximum of 6.89 h/d recorded in April 2019. The maximum final and array yield of 4.64 h/d and 4.54 h/d were recorded during March 2019, and minimum values of 2.33 h/d and 2.28 h/d in July 2021, respectively. Solar irradiation directly affects reference and final yields, and a high reference yield corresponds to more extended sun irradiation.

Efficiency

Climate factors like atmospheric temperature, radiation, soiling, humidity and air affect the array’s efficiency. The variation in the system, array and inverter efficiencies for 36 months are presented in Fig. 8. The highest array efficiency is observed during November (13.97% (1st year), 13.18% (2nd year)) in the first 24 months of its operation due to low temperatures in the autumn season. The plant experienced the most melancholy and highest array efficiency of 9.38% (March 2021) and 13.97% (November 2018). Nearly a drop of 4.59% is observed due to seasonal variation. The efficiency of the inverter of the megawatt solar PV plant fluctuates between 94.8 and 98%. The system’s efficiency will peak when the module and inverter’s performance are at their best. The plant showed 8.85% system efficiency in the first month of operation (September 2018), later, it reached its maximum value of 13.69% (November 2018) in autumn. The current rooftop system claimed an average monthly system efficiency of 11.16% during the period of September 2018–August 2021.

PR and CF

The plant’s performance ratio (PR) reveals how effectively it turns solar power into electricity. Due to inevitable losses, the plant’s rated performance ratio cannot be realised in the actual environmental circumstances. PR of the PV plant varied between 51.21 and 79.3% over the 3 years. Due to the initial state of operation, it exhibited low PR in the first month; later, the lowest PRwas recorded at 53.36% at a cell temperature of 28.63 °C and a maximum of 79.3% at 27.47 °C in November 2018. The fluctuation in average monthly PR caused by cell temperature is depicted in Fig. 9. The overall average monthly PR of the PV plant was 64.72% during the study period.

Throughout the study time (36 months), the current system’s capacity factor (CF) fluctuates between 9.7 and 19.33%. Figure 10 shows a minimum of 9.71% in July 2021 and a maximum of 19.33% in March 2019. The CF monthly average figure for the 3 years is 14.25. %. Seasonally, the average capacity factors of the present plant are 16.67. % (Summer), 14.27% (Winter), 12.24% (Monsoon) and 13.8% (Autumn). Seasonally, maximum CF is recorded in summer and minimum in monsoon.

Environmental economics

The payback period is a measurement metric used to estimate how long it will take for a system to recoup its actual investment. It is frequently used to evaluate the viability of PV system economically and is assessed using net current value. The payback period is determined by the time required to bring the system’s net present worth to zero. To determine the initial investment’s payback period, we need information on the capital cost of the system’s construction and maintenance. The solar modules account for 68% of the PV system’s overall capital cost. The total PV system’s cost breakdown is provided in Fig. 11. The present study’s capital cost of the one-megawatt rooftop PV system is INR 3,71,40,000.00. The polycrystalline Si-modules, as shown in Fig. 11, add INR 2,52,00,000.00 to the overall cost of the installed system. A cost of Rs 1,00,000 with additional taxes from the Indian government is spent on monthly maintenance of the PV plant. The existing system’s payback period is calculated using total annual savings and the system’s initial cost. A solar PV system emits greenhouse gases due to the energy it provides. Since the polycrystalline silicon module’s life cycle CO2 emissions are anticipated to be 0.053 kgCO2-eq./kWh, the net CO2 emission of the PV system over its 25-year lifespan has been calculated to be 1538.559 tCO2e.The system exhibits 2145.406 tCO2e of annual CO2 mitigation. As per the yearly energy generation data, annual savings in the earned carbon credits is INR. 24,67,770.76.

PV plant performance evaluation in comparison to other systems

An analysis is done on solar PV plants of different installed capacities, installed locations, monitored period, measured annual parameters, performance ratio (PR) (%) and capacity factor (CF) (%). Figure 12 presents the performance evaluation from the operating results of the wide range of PV systems addressed in literature at different locations and different climatic conditions.

Conclusion

The current study comprehensively evaluates the behaviour of a one-megawatt power rooftop solar photovoltaic system operating for 3 years in Andhra Pradesh, India. The study has considered a 36-month monitoring period, from September 2018 to August 2021, where the plant commenced its operation in September 2018. The metrics developed and specified in the International Electrotechnical Commission standard IEC 61724-1 are used to analyse the current solar PV plant’s long-term performance. The results and methodology applied in this study demonstrate how a grid-integrated rooftop system operates in respect to the intended energy under real weather circumstances and may be applied globally. The effectiveness of the rooftop system was evaluated in comparison to other PV systems that have been installed around the world. Following is a presentation of the critical finding of the technical analysis:

-

The monthly average reference yield (Yref), array yield (Yay) and final yield (Yyf) of the megawatt PV system during the study period were recorded as 5.29 h/d, 3.35 h/d and 3.41 h/d, respectively.

-

Overall average PR and CF of the plant are 64.71% and 14.25%. Figure 12 demonstrates the current system’s performance (PR and CF values), comparable to those of other plants deployed in various places with diverse meteorological conditions and capacities.

-

The rooftop solar PV system installation’s total energy output during the study period is 3757.561 MWh with an annual average energy of 1252.517 MWh/year.

-

The average array loss of the system is 1.86 h/d.

-

The PV system’s cumulative net CO2 emissions during its 25-year lifespan have been calculated to be 1538.559 tCO2e.

-

The system shows an annual CO2 mitigation of 2145.406 tCO2e with yearly savings in earned carbon credits, according to annual energy generation data, is INR. 24,67,770.76 (30,056.75 USD as of Dec 7, 2022).

Our findings imply that rooftop PV panels can provide green electricity in affordable structures for various applications, including education, health, construction and residential structures. This approach would benefit businesses that offer services for PV systems, customers, system designers, technologists and other stakeholders to assess comparable projects’ energy and financial performance on grid-integrated rooftop solar PV systems on buildings in similar temperate climates using the analysis’s guide. By analyzing the performance of existing rooftop PV solar plants, engineers and planners can gain insights into the challenges and opportunities that are unique to these types of installation. This study can be extended to include the power forecasting, fault identification in rooftop PV plants, applying machine learning to rooftop PV solar systems to optimize performance, improve reliability and reduce cost.

References

Abdullah G, Nishimura H (2021) Techno-economic performance analysis of a 40.1 kWp grid-connected photovoltaic (GCPV) system after eight years of energy generation: a case study for Tochigi, Japan. Sustain 13(14):7680. https://doi.org/10.3390/su13147680

Banda MH, Nyeinga K, Okello D (2019) Performance evaluation of 830 kWp grid-connected photovoltaic power plant at Kamuzu International Airport-Malawi. Energy Sustain Dev 51:50–55. https://doi.org/10.1016/j.esd.2019.05.005

Bansal N, Pany P, Singh G (2021) Visual degradation and performance evaluation of utility scale solar photovoltaic power plant in hot and dry climate in western India. Case Studies in Thermal Engineering 26:101010. https://doi.org/10.1016/j.csite.2021.101010

Behura AK, Kumar A, Rajak DK, Pruncu CI, Lamberti L (2021) Towards better performances for a novel rooftop solar PV system. Solar Energy 216:518–529. https://doi.org/10.1016/j.solener.2021.01.045

Boddapati V, Nandikatti ASR, Daniel SA (2021) Techno-economic performance assessment and the effect of power evacuation curtailment of a 50 MWp grid-interactive solar power park. Energy Sustain Dev 62:16–28. https://doi.org/10.1016/j.esd.2021.03.005

Chowdhury H, Chowdhury T, Hossain N, Chowdhury P, dos Santos Mascarenhas J, Bhuiya MMK (2021) Energy, emission, profitability, and sustainability analyses of a grid-connected solar power plant proposed in airport sites of Bangladesh: a case study. Environ Sci Pollut Res 28(43):61369–61379. https://doi.org/10.1007/s11356-021-14973-5

Faiz FUH, Shakoor R, Raheem A, Umer F, Rasheed N, Farhan M (2021) Modeling and analysis of 3 MW solar photovoltaic plant using PVSyst at Islamia University of Bahawalpur, Pakistan. Int J Photoenergy 2021:1–14. https://doi.org/10.1155/2021/6673448

Kumar BS, Sudhakar K (2015) Performance evaluation of 10 MW grid connected solar photovoltaic power plant in India. Energy Rep 1:184–192. https://doi.org/10.1016/j.egyr.2015.10.001

Lee J, Chang B, Aktas C, Gorthala R (2016) Economic feasibility of campus-wide photovoltaic systems in New England. Renew Energy 99:452–464. https://doi.org/10.1016/j.renene.2016.07.009

Malvoni M, Leggieri A, Maggiotto G, Congedo P, De Giorgi M (2017) Long term performance, losses and efficiency analysis of a 960 kWP photovoltaic system in the Mediterranean climate. Energ Conver Manage 145:169–181. https://doi.org/10.1016/j.enconman.2017.04.075

Mensah LD, Yamoah JO, Adaramola MS (2019) Performance evaluation of a utility-scale grid-tied solar photovoltaic (PV) installation in Ghana. Energy Sustain Dev 48:82–87. https://doi.org/10.1016/j.esd.2018.11.003

Miskat MI, Sarker P, Chowdhury H, Chowdhury T, Rahman MS, Hossain N et al (2023) Current scenario of solar energy applications in Bangladesh: techno-economic perspective, policy implementation, and possibility of the integration of artificial intelligence. Energies 16(3):1494. https://doi.org/10.3390/en16031494

Nacer T, Hamidat A, Nadjemi O, Bey M (2016) Feasibility study of grid connected photovoltaic system in family farms for electricity generation in rural areas. Renew Energy 96:305–318. https://doi.org/10.1016/j.renene.2016.04.093

Navothna B, Thotakura S (2022) Analysis on large-scale solar PV plant energy performance–loss–degradation in coastal climates of India. Front Energy Res 301. https://doi.org/10.3389/fenrg.2022.857948

Photovoltaic system performance monitoring — guidelines for measurement, data exchange and analysis, IS/IEC 61724: 1998.

Pinho C, Ramos L, Mourão Z (2021) Performance analysis of a hypothetical 1-hectare PV plant in the Benguela Region. The first year of operation. Angolan Mineral, Oil & Gas Journal 2(2):32–39. https://doi.org/10.47444/amogj.v2i2.6

Podder AK, Habibullah M, Roy NK, Pota HR (2021) A chronological review of prospects of solar photovoltaic systems in Bangladesh: feasibility study analysis, policies, barriers, and recommendations. IET Renew Power Gener 15(10):2109–2132. https://doi.org/10.1049/rpg2.12165

Rezk H, Mazen AO, Gomaa MR, Tolba MA, Fathy A, Abdelkareem MA et al (2019) A novel statistical performance evaluation of most modern optimization-based global MPPT techniques for partially shaded PV system. Renew Sustain Energy Rev 115:109372. https://doi.org/10.1016/j.rser.2019.109372

Saleheen MZ, Salema AA, Islam SMM, Sarimuthu CR, Hasan MZ (2021) A target-oriented performance assessment and model development of a grid-connected solar PV (GCPV) system for a commercial building in Malaysia. Renew Energy 171:371–382. https://doi.org/10.1016/j.renene.2021.02.108

Srivastava R, Tiwari A, Giri V (2020) An overview on performance of PV plants commissioned at different places in the world. Energy Sustain Dev 54:51–59. https://doi.org/10.1016/j.esd.2019.10.004

Sudhakar K, Ngui W, Kirpichnikova I (2021) Energy analysis of utility-scale PV plant in the rain-dominated tropical monsoon climates. Case Stud Therm Eng 26:101123. https://doi.org/10.1016/j.csite.2021.101123

Thotakura S, Kondamudi SC, Xavier JF, Quanjin M, Reddy GR, Gangwar P, Davuluri SL (2020) Operational performance of megawatt-scale grid integrated rooftop solar PV system in tropical wet and dry climates of India. Case Stud Therm Eng 18:100602. https://doi.org/10.1016/j.csite.2020.100602

Thotakura S, Kondamudi SC (2022) Operating temperature prediction and comparison for rooftop PV arrays in coastal climates of India. Environ Sci Pollut Res 29:43532–43545. https://doi.org/10.1007/s11356-022-20068-6

Author information

Authors and Affiliations

Contributions

Conceptualization: Sandhya Thotakura; data curation: Bhogula Navothna; formal analysis and investigation: Bhogula Navothna; writing: Bhogula Navothna; writing — review and editing: Sandhya Thotakura; Supervision: Sandhya Thotakura.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Navothna, B., Thotakura, S. Long-term performance of grid-integrated solar photovoltaic system on institutional buildings in tropical wet and dry climates of India — a practical study. Environ Sci Pollut Res 30, 88036–88048 (2023). https://doi.org/10.1007/s11356-023-28444-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-28444-6