Abstract

In recent years considerable interest has developed in the properties of thermotropic liquid crystalline polymers (LCPs). This is a consequence not only for their scientific interest but also from an industrial point of view. LCPs have many attractive properties, particularly when compared with engineering polymers (EPs). LCPs are mechanically stronger than EPs, have lower thermal expansivities, and are also stable at higher temperature. Ordinary equipment for thermoplastic processing can be used for LCPs or an addition of a LCP to an EP can lower the viscosity of the latter by two orders of magnitude. Thus, offering an attractive combination of physical, chemical and mechanical properties deemed favourable to a diverse array of technological applications, LCPs or their blends are materials of the future. The motivation behind the scientific and industrial interests in LCP is the wide applications of LCPs in industry and their unique properties.

Although LCPs are assuming an increasingly important role in numerous technologically advanced applications, the complex relationships between chemical constitution and properties of these materials are still far from being completely clarified. Liquid-crystalline materials are unique in their behaviour with certain properties characteristic of liquids while others are characteristic of crystals. This duality results from the presence of both long-range order and disorder which makes the study of LCPs both fascinating as well as challenging.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

16.1 Introduction

Liquid crystals (LCs) or orientationally ordered liquids have been considered as the fourth state of matter (Saeva 1979; Kelker and Hatz 1980). Although the phenomenon of liquid crystallinity was discovered in 1888 and the term “liquid crystals” was first used in 1890 (Kelker and Hatz 1980), liquid crystallinity has attained prominence only in the last two decades or so.

In 1888, Austrian botanist Friedrich Reinitzer noted that, when melted, the cholesteryl esters form colourful-opaque liquids, which become clear at higher temperatures. Reinitzer sent a sample of cholesteryl esters to a German scientist Otto Lehmann, who was studying the crystallisation properties of various substances. Lehmann had constructed a polarising microscope that allowed him to observe the crystallisation of his samples. Lehmann investigated Reinitzer’s sample with his polarising microscope and noted its similarity to some of his own samples and first referred to them as ‘soft crystals’. By 1889 Lehmann was describing the material as ‘flowing crystals’. Later Lehmann used the term ‘crystalline fluids’, but when he became more convinced that the opaque phase was a uniform phase of matter sharing properties of both liquids and solids, he began to call them ‘liquid crystals’ (Coolings 1990).

LCs are anisotropic materials whose flow properties strongly depend on their structure and molecular orientation. Molecules in crystalline solid state are positionally and orientationally ordered in three dimensions, but in the isotropic liquid state these orders are completely destroyed. Whereas LCs exhibit a degree of macroscopic orientational order that is found between the boundaries of crystalline solid state and the isotropic, ordinary liquid, state (Donald and Windle 1992; Collyer 1996). Consequently, the properties of LCs are intermediate between those of an isotropic liquid and those of a crystalline solid.

Schematic representation of molecular order in the crystalline, isotropic and liquid crystalline phases is given in Fig. 16.1.

As shown in Fig. 16.2, when a sample of crystalline solid material is heated, it is expected sooner or later to melt into an isotropic liquid losing both the long range orientational and positional order. The temperature at which the melting takes place is called melting temperature, Tm, or crystalline-isotropic transition temperature , TC−I. When the isotropic liquid (melt) is subsequently cooled, it is expected to solidify again.

However, some of the materials do not behave as expected: they do not show a single transition from solid to liquid, but rather a cascade of transitions involving new phases. Thus, referring to Fig. 16.3, for a certain substance the crystalline solid melts into an intermediate phase only partially losing its ordering. In this case the melting temperature coincides with the crystalline-liquid crystalline transition temperature , TC−LC. Such materials can exhibit one or more intermediate phases. These intermediate phases are mostly referred to as liquid crystalline phases, also known as crystalline liquid phases, mesophases or mesomorphic phases (Hurduc and Pavel 1999; Guerriero et al. 2011; Wenyi and Shi 2012). Consequently, the properties of these phases are intermediate between those of a liquid and those of a crystal.

At higher temperatures, this mesophase further loses its partial ordering and it is transformed into an ordinary isotropic liquid, this phenomenon is called liquid crystalline-isotropic transition (LC-I) (Brostow 1992). The temperature at which LC-I takes place (TLC−I) is called clearing temperature, Tc, also known as isotropisation temperature, Ti.

When the isotropic liquid of liquid-crystalline material is cooled, it is expected to exhibit an isotropic-liquid crystalline transition and then to solidify again. The temperature at which the isotropic-liquid crystalline transition takes place is called TI−LC, and the temperature at which the liquid crystalline-crystalline transition takes place is called TLC−C.

The liquid crystalline phase is thermodynamically stable and represents a condition of incomplete melting. As illustrated in Fig. 16.3, Tm (or TC−LC) and Tc define the temperature range in which the liquid crystalline phase is thermodynamically stable.

There are two main types of liquid crystals: thermotropic and lyotropic. The LCs that exhibit various liquid crystalline phases as a function of temperature are called thermotropic (Fig. 16.3). They are formed by heating to the temperature above which the crystal lattice is no longer stable. Thermotropic LCs exhibit liquid crystallinity in a particular temperature range: between TC−LC or Tg (glass transition temperature in the cases where the crystallinity is absent) and Tc (Donald and Windle 1992; Wang et al. 1996). Thermotropic LCs are very stable and exhibit very large mesomorphic ranges, sometimes several hundred degrees.

The thermotropic liquid crystalline materials are further divided into two subgroups: thermodynamically stable—enantiotropic and unstable—monotropic (Blackwell and Biswas 1987; Bhowmik and Lenz 1994). The mesophase of enantiotropic LCs is observed by either raising the temperature of a solid crystalline phase or lowering the temperature of a liquid phase, whereas the mesophase of monotropic LC is only observed by lowering the temperature of a liquid phase.

Sometimes liquid crystalline phases are formed by mesomorphic molecules in a non-mesomorphic solvent (Kelker and Hatz 1980; Donald and Windle 1992; Hintze-Bruening et al. 2011; Hatakeyama et al. 2011), so a true solution is not obtained, but the resulting state exhibits liquid crystalline properties. Further increase of the amount of non-mesogenic solvent molecules beyond a critical concentration leads to a transition to the isotropic liquid phase. Thus, the LCs that are formed when the concentration of the solvent is changed are called lyotropic (Fig. 16.4).

Lyotropic LCs play a very important role mostly in biological systems (Coolings 1990; Hintze-Bruening et al. 2011; Liang et al. 2010). However, this kind of LCs will not be discussed further, since it is beyond the scope of this chapter, the subject of which is restricted to thermotropic LCs.

16.2 Nature of Liquid Crystalline Polymers

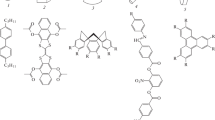

Macromolecules are also capable of forming similar liquid crystalline mesophases if the mesogenic groups are linked by flexible spacers (i.e., in this study the spacers are propylene, diethyletheric (oxydiethylene) and oxetane ring). Such macromolecules are called liquid crystalline polymers (LCPs) . The mesogenic units of LCPs are usually made up of a rigid core of two or more aromatic rings, therefore, the LCPs are frequently aromatic polymers. These stiff regions along the chain allow the polymer to retain a high degree of orientational order in the liquid/melt state. Similar to ordinary liquid crystals, LCPs exhibit fluidity while possessing order like structure of a solid crystal (Kelker and Hatz 1980; Collyer 1996). LCPs are also anisotropic materials whose flow properties depend on their molecular structure and orientation. Liquid crystalline behavior during melting results in lower viscosity, because the rigid polymeric mesophases align themselves in the direction of the flow, so LCPs are easier to process compared with isotropic polymers. Considering their direct applicability in technology, LCs have been intensively considered, and several thousands of such compounds have been synthesized in the past few decades. However, related aspects for LCPs are still in their infancy and are in the area of continuing research interest. Scientific and technological interest in LCPs was first sparked by the development and commercialization of DuPont “KEVLAR” poly(p-phenylene terephthalamide) (PPTA) fibre in the 1970s which can be manufactured as stiff and strong as steel (Hall and Tiddy 1992; Donald and Windle 1992). An important goal of polymer science now is to design polymers with the necessary structure to form a mesophase, yet with sufficient chain flexibility to be processed. In general, for normally flexible polymers to exhibit liquid crystalline properties, mesogenic molecules such as rod-like, disc-like, pyramid-like or phasm-like have to be incorporated into or onto their chains. It is noteworthy that the mesogenic groups are incorporated into or onto the main-chain polymer almost exclusively by covalent bonds.

As liquid crystals, liquid crystalline polymers can also be thermotropic and lyotropic. Yet in terms of position of the mesogenic groups, liquid crystalline polymers can be classified as main-chain, side-chain, combined main-chain/side-chain and cross-linked.

The first type of LCPs, main-chain, is formed when the mesogenic groups are incorporated in the backbone of the polymer (Damman and Mercx 1993; Hurduc and Pavel 1999). The liquid crystalline phases are formed by the polymer chains folding in a way analogous to what occur when polymers crystallize. Linear main-chain thermotropic LCPs tend to form nematic phases in particular and helical main-chain thermotropic LCPs tend to form discotic phases (Davies and Ward 1988; Donald and Windle 1992). A main-chain LCP is schematically represented in Fig. 16.5.

The second type of LCPs, side-chain or comb-like, is formed when the mesogenic groups are attached covalently as side-chains onto the polymer main-chain (Finkelmann 1991; Mulligan et al. 1996; Cook et al. 2012). The mesogenic groups can be directly attached to the backbone of the polymer, or connected through a flexible spacer. This is schematically represented in Fig. 16.6.

In the last few years, scientific research has concentrated on the synthesis and characterisation of new polymers with special properties. Among these, side chain liquid crystalline polymers (SCLCPs) are distinguished by their properties as materials in a range of advanced electro-optical technologies, but also because they present a demanding challenge to our understanding of self-assembly in molecular systems. The main reason is that SCLCPs could combine the unique properties of low-molar mass liquid crystals and polymers together, which made it easier to form film during material processing. Although a large amount of experimental data has been available on the properties of side chain liquid crystalline polymers, the fundamental understanding of their behavior at a molecular and atomic level is still limited.

An important goal in the synthesis of SCLCPs is to design molecules with the necessary order to form a mesophase yet with sufficient chain flexibility so that the crystal melting temperature (Tm) is reached within the range of normal processing temperatures (Yu et al. 2013). One of the distinguishing structural properties of these polymers is the ease to form film during material processing. Therefore, SCLCPs offer potential solutions for problems that low-mass-molecular liquid crystals are unable to solve, and possible applications arise where the combination of these properties are basic requirements. These applications range from electrical-electronic components, chemical processing, transportation (including automotive and aerospace) and telecommunications, and more recently to optical and electro-optical display devices, optical computing and medical science as diagnostic aids.

Small molecule modified macromolecules (SMMM) have been used extensively to obtain functional polymers with special properties (Pankaj Kumar et al. 2011; Su et al. 2011; Wang et al. 2013). This method is preferred due to the absence of side reactions that can induce the appearance of branched polymers.

As with small-molecule liquid crystals, the appearance of a mesophase is associated with long-range organisation of the molecular orientations. For small molecules this order may arise from the packing requirements of the rodlike molecules, from anisotropic attractive forces or some combination of both. Models to predict orientational order in liquid-crystalline polymers are well known, the earliest being the lattice theory of Flory and co-workers. The lattice theory depends on aspect ratio of polymer chains (the ratio of length to diameter) as the only molecular parameter. In the particular treatment of Flory and Ronca, for example, it is predicted that the critical aspect ratio for a polymer to exhibit liquid crystallinity is 6.42.

The third type of LCPs, combined main-chain/side-chain, also known as double or combined (Brostow 1992) is formed when the mesogenic groups are both incorporated into and attached onto the polymer main chain. The side-chain mesogenic groups can be attached to the main-chain mesogenic groups, or connected to the flexible spacer of the main chain of the polymer. This is schematically represented in Fig. 16.7. The presence of mesogenic groups in both side and main chain positions can have a significant effect on the properties and organisation of the mesophase (Petr et al. 2013).

Super-strong (SS) polymers are specially-designed combined LCPs in which the side chains of one molecule are designed to pack between the side chains of neighboring molecules, thus leading to molecular self-reinforcement and enhanced molecular ordering compared with main-chain LCPs (Dowell 1990).

The fourth type of LCPs, cross-linked, also known as network or thermoset (Fig. 16.8), is a result of a cross-linking reaction of LCPs that are functionalized with reactive groups (cross-linkable LCPs) allowing a network formation via the cross-linking reaction (Hoyt et al. 1990; Zentel et al. 1990).

If the crosslinking reaction is performed in the liquid crystalline phase, an anisotropic network structure becomes chemically locked in, which results in obtaining ordered three-dimensional systems with exceptionally high mechanical resistance (Donald and Windle 1992; Pavel et al. 1999a, b). Moderate cross-linking of LCPs (10–20 %) has no effect on the nature of the mesophases compared with an analogous homopolymer, but tends to lower all phase transition temperatures by a few degrees (Simmonds 1992).

Liquid crystalline networks combine both high dimensional stability and mechanical orientability typical of polymer networks with the unique anisotropic behaviour of liquid crystals. Depending on the cross-link density, i.e., the average length between two contiguous cross-links along the molecular backbone, the materials may exhibit reversible transitions from the liquid crystalline to the isotropic state.

Great attention has been devoted to the liquid crystal networks during the last few years due to their use as optical switches, waveguides, non-linear optical materials and advanced composites, as well as because of a great potential to generate a new class of polymers with outstanding properties for new applications. Therefore, their ‘building blocks’—cross-linkable LCPs—are also of a great interest.

Recently, more novel LCs are obtained from carbon nano-tubes materials (Nano News), these LCs are expected to have better thermo-mechanical properties:

16.3 Liquid Crystalline Phases

The common feature of LCs is a rigid backbone that is responsible for the formation of the liquid crystalline phase. The essential molecular requirement for the formation of a liquid crystalline phase is a highly geometrically anisotropic shape, i.e., the molecules are anisometric (Pavel et al. 1997, 1999a, b). This means that one of the molecular dimensions is usually much larger (rod-like molecules) or much smaller (disc-like molecules) than the other two. Although theoretically any molecule that has a non-spherical symmetry should be able to exhibit a mesophase, only 3–4 % of these organic molecules are found to have mesogenic behavior.

Liquid crystalline molecules always have a rigid segment (a group of atoms), called a mesogenic group (often an aromatic core) which is rod-like or disc-like and a flexible spacer. The mesogenic group increases the anisotropic interactions between the constituent molecules, and therefore increases the clearing temperature. Unlike the mesogens, the flexible spacers increase the number of conformations that the molecules can adopt and hence the entropy of melting. Consequently, the TC−LC will be reduced. An additional requirement for a stable liquid crystalline phase is that its Tc is above the TC−LC and below decomposition temperature, Td.

The tendency of the molecules to order and align themselves in a common direction with their long axes more or less parallel is referred in general as the orientational property of LCPs. The orientational property is fundamental for LCPs: for example, mechanical properties of LCPs are strongly dependent upon the degree of orientational order (molecular orientation) (Hamley et al. 1996). This degree of order is responsible for the unique behaviour of liquid crystalline materials. The direction about which the degree of orientational order is defined is usually characterised by a unit vector n (Allen et al. 1996), which satisfies the physically reasonable condition n ≡ −n. The vector n is called the director, or optical axis (Noel 1992; Sarman 1996). The average molecular orientation described by the director should not be confused with the individual molecular orientation. The director n is determined by relatively weak forces, such as magnetic and electric fields or the action of flow.

The director n determines only the direction of the preferred orientation of the molecules and indicates nothing about the degree of orientational order in the liquid crystalline phase. The degree of the orientational order is quantified and characterised by a scalar quantity S, varying from zero to unity. S is called an order parameter, also known as Hermans orientation function (Pavel et al. 1999a, b), and it is calculated using the following equation (Schmidt-Rohr and Hong 1996):

The angular brackets around the cosine term in this equation denote a thermal average over all of the unit molecules and θ is the orientational angle between the structural unit vector (mesogen) of the polymer chain and the director n.

The value of S equal to 0 (< cos2θ> = 1/3) indicates total absence of orientational order—isotropy. There are some exceptions for which S may be negative (Yoon et al. 1990; Rusing et al. 1993). The value of S equal to 1 corresponds to the case of the perfect order with all molecules strictly parallel to one another (Bosch et al. 1983). This ideal order would be possible near to absolute zero point of temperature only if the material would not freeze.

-

1.

The order parameter of a material varies inversely with temperature as a result of kinetic molecular motion (Bosch et al. 1983). The actual value of S represents a compromise between the ordering effect of the mesogenic interaction and the disordering contribution of temperature (Marrucci 1996). In a typical LCP, S decreases as the temperature is raised, so S varies from around 0.43 at clearing temperature, Tc, to about 0.8–0.9 at much lower temperatures (Keller et al. 1990; Khoo 1995). For combined main-chain/side-chain macromolecules, two order parameters are to be calculated to describe the state of the polymer, one for the main-chain and one for the side-chains.

The order parameter is also known as the anisotropy factor. Anisotropy means that the properties of a material depend on the direction in which they are measured. Thus, liquid crystalline materials are optically anisotropic: for example, the propagation of a ray of light through the medium depends on its orientation.

LCs and LCPs can exhibit nematic, smectic, columnar, cholesteric and/or blue mesophase(s) due to their degree of molecular order. With rod-like molecules, nematic, smectic, blue and cholesteric mesophases are observed, whereas with disc-like (or discotic) molecules, the phases that are clearly identified fall into two categories: the columnar and the nematic. A smectic mesophase with discotic molecules has also been reported, but the precise arrangement of the molecules in each layer has not been fully investigated (Marrucci 1996).

The nematic phase is the least organized and the most common type of liquid crystalline phases. This phase is characterized when molecules are ordered in one dimension and the average directions of the long axes of the molecules (described by director n) are parallel (Noel 1992; Islam et al. 2014). The nematic phase possesses long range orientational order but only short-range positional order (Davies and Ward 1988; Mulligan et al. 1996). Therefore, the nematic phase is very liquid-like. Optically, nematic liquid crystals constitute a uniaxial material. Unlike the classical nematic phase of rod-like molecules, the nematic phase of discotic molecules is optically negative. Schematic representation of the structure of nematic phase is shown in Fig. 16.9.

The smectic liquid crystalline phase is characterised when molecules possess a degree of long range orientational order as well as long range positional order: the molecules are parallel and arranged in layers which stack on top of each other (Fig. 16.10) (Davies and Ward 1988). If nematic and smectic phases occur within one compound, the smectic phases will occur at lower temperatures. The higher order of smectic phases causes them to be more viscous than nematic phases.

Many smectic phases have been observed, and they have been named in chronological order of discovery, i.e. smectic A, A1, A4, B, C, D, E, F, G, H, I, J, K phases (the least ordered smectic phase is smectic A). The smectic phases arise from differences within the layers of molecules. All of the smectic phases are characterised by the possession of a layered structure where the molecule ends are aligned next to each other. The ideal classification has yet to be achieved. The smectic phases also tend to be highly polymorphic and in some instances smectic liquid crystalline materials will transform between a number of sub-classes, i.e. A, A1, A4, B, C during heating or cooling (Davies and Ward 1988; Lan et al. 2013). In compounds where smectic polymorphism occurs, higher ordered phases always occur at lower temperature than lower ordered ones.

Columnar phases are formed on heating/cooling of compounds composed of disc-shaped molecules that can pack together to form flexible cylinders or columns of different type (resembling stacks of coins). The arrangement of disc-shaped molecules within an individual column can be either ordered or random. The columns themselves can be grouped into hexagonal or orthogonal lattices (Davies and Ward 1988; Stoeva et al. 2013). A schematic representation of the ordered hexagonal structure of columnar phase is given in Fig. 16.11.

In some cases, compounds that form columnar phases do not have a disc-like shape by themselves, but may aggregate into disc-like formations. Therefore, the often used term ‘discotic phase’ is not quite correct for the columnar phase, since it refers to building blocks that are not necessary prerequisite for obtaining this two-dimensional order. The columns are two-dimensionally ordered with nematic-like, hexagonal, rectangular or oblique packing. This distinct class of mesophase has only been recognised for a few years. In practice, columnar phases are relatively rare since a special disc-like geometry of the mesogen is required. The research effort on this phase is still somewhat limited, but increasing steadily.

The cholesteric liquid crystalline phase is often referred to as “twisted nematic” or “chiral nematic” phase. The cholesteric phase is characterised by layers of nematic oriented molecules where each layer is twisted with respect to the ones above and below it (Blackwell and Biswas 1987; Davies and Ward 1988). A schematic representation of the structure of the cholesteric phase is illustrated in Fig. 16.12. The director n in the cholesteric phase is not constant in space but, rather, twists periodically about an axis normal to n, forming a helix. The distance over which the director turns exactly 360° is called the pitch of the helix. The helical arrangement also introduces new optical properties, particularly in the propagation and reflection of light from cholesteric liquid crystalline materials. The cholesteric phase possesses only orientational order, but neither long range order nor positional order of the molecules.

The blue phases appear between the cholesteric (helicoidal) liquid crystalline phase and the isotropic liquid phase, as the temperature is lowered (Hess et al. 1991). They are called ‘blue’ phases for historical reasons, so the adjective blue does not prevent them from looking bright yellow or red in some instances. The blue phases occur in cholesteric systems of sufficiently low pitch, less than about 5000 Å (Brostow and Walasek 1998). The temperature region in which the blue phases are thermodynamically stable is relatively narrow, usually about 1 K. This fact has limited the progress of study of blue phases in contrast to other mesophases (Blackwell and Biswas 1987).

Three distinct blue phases have been identified: BP I (a body-centred cubic lattice), BP II (a simple cubic lattice) and BP III (probably amorphous) occurring in that order with increasing temperature (Brostow and Walasek 1998). The question of the molecular arrangement within the blue phases remained unsolved, so, it is impossible to provide a schematic representation of the phase at present. In practice, only nematic, cholesteric, smectic A and smectic C phases are commonly observed for LCPs, other higher-order smectic mesophases being comparatively rarer.

16.4 Theories of Liquid Crystalline Polymers

The anisotropic interactions between linear LCP macromolecules will be considered in this section. Two theoretical models, taking into account such applications, namely those of Flory and de Gennes, have found widespread use.

Flory’s lattice model and his theory of liquid crystallinity in LCP systems were formulated in 1956. The theory was later amplified by Flory, his co-workers and students (Finkelmann 1991). Flory considered a system of unconnected linear semiflexible LCP chains, such that each macromolecule consists of flexible and LC sequences. The flexible sequences can coil and have high internal conformational entropy. The LC sequences are represented by rigid rods with low internal entropy, but they can interact anisotropically. As discussed in some, Flory developed an ingenious combinatorial procedure allowing the placement of LC sequences at any angle to the lines of the lattice. The procedure is based on the fact that macromolecules cannot penetrate each other.

A non-lattice approach was proposed by de Gennes and then developed by Walasek (Brostow 1992). De Gennes assumed a representation of the LCP system by a three-chain cell, with mutually perpendicular end-to-end distances. A chain consisted of freely-jointed segments with internal orienting interactions between them; thus, the chain was not fully flexible. The semiflexibility was determined by the intensity of the segment-segment interaction forces. One of the chains was parallel to the system symmetry axis while the other two were perpendicular to that axis. The distribution function of chain segment orientations was obtained by requiring that the Helmholtz function, with respect to the distribution function, became a conditional minimum. Conditions resulted from an independent definition of chain end-to-end distances; these distances were defined by border conditions imposed upon the system. Chains in the three-chain cell were connected via one end at a point. Necessarily, the model did not contain any information on the topological structure (such as loops, defects, etc.) present in a network of a large number of chains connected by copious junctions.

Brostow and Walasek considered a system of linear LCPs (Brostow 1992). Each macromolecule constituted an alternating copolymer of flexible and LC sequences. The macromolecules could be either unconnected, or else connected into a LCP network. The system was characterized with respect to local orientation. Competition between energetic effects of anisotropic orienting interactions between LC sequences and entropic effects determined mainly by flexible parts was considered. The Maier and Saupe mean-field approach (Klein et al. 1996) was assumed for the representation of LC interactions.

Since flexible chains can coil and create a large number of conformational microstates, their entropy is large. By contrast, in the theories under discussion, a LC sequence is represented by a hard rod and its internal entropy is equal to zero. Of course, the LC part as a whole has an entropy pertaining to the realization of orientational microstates, but its value is much smaller than the entropy of the flexible part.

Brostow and Walasek consider the LCP system in which the only orientation came from the presence of LC sequences in the chains. Orienting interactions between LC sequences were assumed. Interactions within flexible parts of the system and/or between flexible and LC parts were assumed to be much weaker than interactions between mesogenic LC particles. The segment + system interactions were imposed only by the topological structure of the LCP linear chain and by the structure of the network of chains, the latter if the system of chains was connected by junctions. These authors considered the order parameter, S, since it is related to the uniaxial orienting interaction potential between LC units—as demonstrated long ago by Maier and Saupe and recently by Donald and Windle (Simmonds 1992). The more complicated potentials including pitch, chirality, etc., can presumably be introduced later. Brostow and Walasek found that the LC part was dominated by energetic effects related to orienting interactions. The competition between energetic and entropic effects led them to a general formula for the system Helmholtz function for arbitrary types of orienting interactions between LC sequences. It was found that all transitions were of the first order. They represented thermodynamical and structural parameters of the system at phase transition points by phase diagrams.

Both original Flory and de Gennes theories involve uniaxial nematic-like interactions between LC sequences. As a result, they predicted in LCPs, the transition from S = 0 to S > 0 only, as it takes place in molecular liquid crystals (MLCs) with uniaxial interactions.

Differences in S between LCPs and MLCs were qualitative only. However, experiments (Marrucci 1996; Saeva 1979) suggested possibilities of other types of transitions such as from S = 0 to S < 0 or from S < 0 to S > 0. Brostow and Walasek also showed that biaxiality of LC interactions in LCP systems was not a necessary condition for such transitions. This is contrary to the situation observed in MLCs in which the biaxiality is the necessary condition (Davies and Ward 1988).

16.5 Applications of Liquid Crystalline Polymers

LCPs present a unique balance of orientational, mechanical, magnetic, optical and electrical properties, high toughness, low die swell, easy flowability, outstanding chemical and thermal resistance, high modulus, and excellent dimensional stability. Therefore, LCP materials offer potential solutions for problems that conventional materials are unable to solve, and possible applications arise where the combination of these properties are basic requirements. These applications range from electrical-electronic components, chemical processing, transportation (including automotive and aerospace) and telecommunications, to high tensile strength polymeric fibers and components, thermography, holography and more recently to optical and electro-optical display devices, optical computing and medical science as diagnostic aids (Allen et al. 1996; Hoyt et al. 1990; Lee et al. 2012; Yagi et al. 2014; Cho et al. 2014; Morimoto et al. 2014; Huang et al. 2013; Jeong et al. 2013; Carter et al. 2014). Each of these areas requires different sets of properties that are summarized in Table 16.1.

In terms of performance requirements, cost factors and processing needs, LCPs can compete against other high-performance thermoplastics, ceramics and metals. Moreover, as new properties and types of LCPs are investigated and researched, these materials are sure to gain increasing importance in industrial and scientific applications and to become one of the most promising areas of material science.

References

Allen MP, Warren MA, Wilson MR, Sauron A, Smith W (1996) J Chem Phys 105(7):2850–2858

Baur G (1982) Polymer liquid crystals. Academic, New York, pp 309–327

Bhowmik PK, Lenz RW (1994) J Polym Sci A Polym Chem 32:651–659

Biswas S, Fukushima H, Drzal LT (2011) Mechanical and electrical property enhancement in exfoliated graphene nanoplatelet/liquid crystalline polymer nanocomposites. Compos A Appl Sci Manuf 42(4):371–375

Blackwell J, Biswas A (1987) In: Ward IM (ed) Developments in oriented polymers, vol 2. Elsevier, London, pp 153–198

Blinov LM (1983) Electro-optical and magneto-optical properties of liquid crystals. Wiley, Chichester

Bobrovsky A, Ryabchun A, Shibaev V (2011) Liquid crystals photoalignment by films of side-chain azobenzene-containing polymers with different molecular structure. J Photochem Photobiol A Chem 218(1):137–142

Bosch AT, Maissa P, Sixou P (1983) Phys Lett 94A:6–7, 298–300

Brostow W (1979) Science of materials. Wiley, New York, pp 65–71

Brostow W (1992) Liquid crystal polymers: from structures to applications, polymer liquid crystals series, 1. In: Collyer AA (ed) Elsevier applied science. Elsevier, London, pp 1–30

Brostow W, Walasek J (1998) J Chem Phys 108:6484–6496

Carter BM, Wiesenauer BR, Noble RD, Gin DL (2014) Thin-film composite bicontinuous cubic lyotropic liquid crystal polymer membranes: effects of anion-exchange on water filtration performance. J Membr Sci 455:143–151

Chandrasekhar S (1992) Liquid crystals, 2nd edn. Cambridge University Press, Cambridge

Chen S, Shu X, Xie H-L, Zhang H-L (2013a) Synthesis and liquid crystalline behavior of 2,5-disubstituted styrene-based random copolymers: effect of difference in length of the rigid core on the mesomorphic behavior of mesogen-jacketed liquid crystalline polymers. Polymer 54(14):3556–3565

Chen S, Luo H, Xie H-L, Zhang H-L (2013b) Synthesis of mesogen-jacketed liquid crystalline polymers with long symmetry mesogenic core containing two biphenyls. Polymer 54(7):1794–1802

Cho W, Lee JW, Gal Y-S, Kim M-R, Jin SH (2014) Improved power conversion efficiency of dye-sensitized solar cells using side chain liquid crystal polymer embedded in polymer electrolytes. Mater Chem Phys 143(3):904–907

Collyer AA (1996) In: Acierno D, Collyer AA (eds) Rheology and processing of liquid crystal polymers, polymer liquid crystals series, vol 2. Charman & Hall, London, pp 1–29

Cook AG, Inkster RT, Martinez-Felipe A, Ribes-Greus A, Hamley I, Imrie CT (2012) Synthesis and phase behavior of a homologous series of polymethacrylate-based side-chain liquid crystal polymers. Eur Polym J 48(4):821–829

Coolings PJ (1990) Liquid crystals: nature’s delicate phase of matter. Princeton University Press, Princeton

Damman SB, Mercx PM (1993) J Polym Sci B 31:1759–1767

Davies GR, Ward IM (1988) High modules polymers: approaches to design and development, plastic engineering, 17. Marcel Dekker, New York, pp 37–70

De Gennes PG, Prost J (1993) The physics of liquid crystals. Clarendon, Oxford, pp 509–586

Demeuse MT, Kiss G (2014) 5—Liquid crystal polymers (LCPs) as a reinforcement in high temperature polymer blends. In: Demeuse MT (ed) High temperature polymer blends. Woodhead, Kidlington, pp 141–164

Donald AM, Windle AH (1992) Liquid crystalline polymers. Cambridge University Press, Cambridge, pp 50–59

Dowell F (1990) Liquid-crystalline polymers. American Chemical Society, Washington, DC, pp 335–358

Fakirov C (2012) Molecular liquid crystalline polymers reinforced polymer composites: the concept of “Hairy Rods”. In: Bhattacharyya D, Fakirov S (eds) Synthetic polymer–polymer composites. Hanser, Tampa, pp 281–299

Finkelmann H (1991) Liquid crystallinity in polymers: principles and fundamental properties. VCH, New York, pp 315–340

Flory PJ, Ronca G (1979) Mol Cryst Liq Cryst 54:289–310

García T, Larios-López L, Rodríguez-González RJ, Martínez-Ponce G, Solano C, Navarro-Rodríguez D (2012) Liquid-crystalline polymers bearing phenylene(azobenzene) moieties substituted with an electron-donor or electron-acceptor lateral group. Synthesis, mesomorphic behavior and photo-induced isomerization. Polymer 53(10):2049–2061

Gökçen M, Köysal O (2011) Effect of frequency on dielectric properties of liquid crystal doped with side-chain liquid crystalline polymer. Mater Chem Phys 129(3):1142–1145

Guerriero G, Alderliesten R, Dingemans T, Benedictus R (2011) Thermotropic liquid crystalline polymers as protective coatings for aerospace. Prog Org Coat 70(4):245–251

Ha SM, Lee HL, Lee S-G, Kim BG, Kim YS, Won JC, Choi WJ, Lee DC, Kim J, Yoo Y (2013) Thermal conductivity of graphite filled liquid crystal polymer composites and theoretical predictions. Compos Sci Technol 88:113–119

Hall PJ, Tiddy GJT (1992) Liquid crystal polymers: from structures to applications, polymer liquid crystals series, vol 1. Elsevier Applied Science, London, pp 237–272

Hamley W, Garnet S, Luckhurst GR, Roskilly SJ, Pendersen JS, Richardson RM, Seddon JM (1996) J Chem Phys 104(24):10046–10054

Hashimoto H, Hasegawa M, Horie K, Yamashita T, Ushiki H, Mita I (1993) J Polym Sci B 31:1187–1196

Hatakeyama ES, Gabriel CJ, Wiesenauer BR, Lohr JL, Zhou M, Noble RD, Gin DL (2011) Water filtration performance of a lyotropic liquid crystal polymer membrane with uniform, sub-1-nm pores. J Membr Sci 366(1–2):62–72

Hatui G, Sahoo S, Das CK, Saxena AK, Basu T, Yue CY (2012) Effect of nanosilica and polyphosphazene elastomer on the in situ fibrillation of liquid crystalline polymer (LCP) and thermo-mechanical properties of polybutylene terephthalate (PBT)/LCP blend system. Mater Des 42:184–191

Hess S, Frenkel D, Allen MP (1991) Mol Phys 74(4):765–774

Hintze-Bruening H, Anne-Lise T, Leroux F (2011) Layered particle based polymer composites for coatings: part III—textured coatings obtained via lyotropic liquid crystals. Prog Org Coat 70(4):240–244

Hornreich RM, Shtrikman S (1980) Liquid crystals of one- and two-dimensional order. In: Helfrich W, Heppke G (eds) Springer series in chemical physics. Springer, Berlin, pp 185–195

Hoyt AE, Benicewicz BC, Huang SJ (1990) Liquid-crystalline polymers. American Chemical Society, Washington, DC, pp 198–206

Hsu T-C, Lu C-H, Huang Y-T, Shih W-P, Chen W-S (2011) Concentric polymer-dispersed liquid crystal rings for light intensity modulation. Sensors Actuators A Phys 169(2):341–346

Huang W, Liu Y, Hu L, Quanquan M, Peng Z, Yang C, Xuan L (2013) Second-order distributed feedback polymer laser based on holographic polymer dispersed liquid crystal grating. Org Electr 14(9):2299–2305

Hull JB, Jones AR (1996) Rheology and processing of liquid crystal polymers, polymer liquid crystals series, 2. Chapman & Hall, London, pp 245–246

Hurduc N, Pavel D (1999) Liquid crystalline polymers. Junimea, Iasi

Hurduc N, Stoleru A, Pavel D, Simionescu CI (1996a) J Therm Anal 47:735–741

Hurduc N, Scutaru D, Barboiu V, Simionescu CI, Buisine JM, Daoudi A (1996b) J Macromol Sci Pure Appl Chem A 33:1745–1754

Hurduc N, Daoudi A, Busine JM, Barboiu V, Simionescu CI (1998) Eur Polym J 34:123–125

Iseki T, Kawabata K, Kawashima H, Goto H (2014) Catalysis direction selective asymmetric polymerization in chiral liquid crystal medium. Polymer 55(1):66–72

Islam MT, Kamal T, Shin T, Seong B, Park S-Y (2014) Self-assembly of a liquid crystal ABA triblock copolymer in a nematic liquid crystal solvent. Polymer 55:16

Jeong J, Lee SW, Min KS, Kim SJ (2013) A novel multilayered planar coil based on biocompatible liquid crystal polymer for chronic implantation. Sensors Actuators A Phys 197:38–46

Jia L, Pierre-Antoine A, Cicco AD, Cao A, Li M-H (2011) Self-assembly of amphiphilic liquid crystal block copolymers containing a cholesteryl mesogen: effects of block ratio and solvent. Polymer 52(12):2565–2575

Kakiuchida H, Tazawa M, Yoshimura K, Ogiwara A (2013) Optical diffractometry of anisotropic holographic structure composed of liquid crystal and polymer phases with extended Bragg modes. Thin Solid Films 571:431–436

Kelker H, Hatz R (1980) Handbook of liquid crystals. Verlag Chemie, Weinheim, pp 593–602

Keller A, Ungar G, Percec V (1990) Liquid crystalline polymers. American Chemical Society, Washington, DC

Khoo IC (1995) Liquid crystals: physical properties and nonlinear optical phenomena. Wiley, New York, pp 67–70

Kim SE-UM, Lee S, Na J-H, Lee S-D (2014) Tunable liquid crystal lens array by encapsulation with a photo-reactive polymer for short focal length. Opt Commun 313:329–332

Klein PG, Evans BW, Ward IM (1996) Liquid-crystalline polymer systems: technology advances, vol 632, ACS Symposium Series. American Chemical Society, Washington, DC, pp 249–258

Kuwahara Y, Kaji M, Okada J, Kim S, Ogata T, Kurihara S (2013) Self-alignment and photomechanical properties of alternative multi-layered films containing azobenzene polymer liquid crystal and polyvinyl alcohol layers. Mater Lett 113:202–205

Lai Y-T, Kuo J-C, Yang Y-J (2014) A novel gas sensor using polymer-dispersed liquid crystal doped with carbon nanotubes. Sensors Actuators A Phys 215(15):83–88

Lan Y-F, Tsai C-Y, Lu J-K, Sugiura N (2013) Mechanism of hysteresis in polymer-network stabilized blue phase liquid crystal. Polymer 54(7):1876–1879

Lee SY, Park K-IL, Huh C, Koo M, Yoo HG, Kim S, Chil Seong AH, Sung GY, Lee KJ (2012) Water-resistant flexible GaN LED on a liquid crystal polymer substrate for implantable biomedical applications. Nano Energy 1(1):145–151

Li J, Turunen M, Niiranen S, Chen H, Paulasto-Kröckel M (2012) A reliability study of adhesion mechanism between liquid crystal polymer and silicone adhesive. Microelectron Reliab 52(12):2962–2969

Liang X, Lu X, Yu M, Cavanagh AS, Gin DL, Weimer AW (2010) Modification of nanoporous supported lyotropic liquid crystal polymer membranes by atomic layer deposition. J Membr Sci 349(1–2):1–5

Liu D, Wu Q, Chang PR, Gao G (2011) Self-assembled liquid crystal film from mechanically defibrillated chitosan nanofibers. Carbohydr Polym 84(1):686–689

Liu H, Zi-En F, Xu K, Hua-Lun C, Liu X, Chen M-C (2012) Preparation and characterization of high performance Schiff-base liquid crystal diepoxide polymer. Mater Chem Phys 132(2–3):950–956

Maier M, Saupe A (1959) Naturforsch 14A:882

Malik P, Raina KK (2010) Dichroic dye-dependent studies in guest—host polymer-dispersed liquid crystal films. Phys B Condens Matter 405(1):161–166

Marrucci G (1996) Rheology and processing of liquid crystal polymers, polymer liquid crystals series, vol 2. Chapman & Hall, London, pp 30–48

Morimoto M, Makino Y, Gonda J, Misaki M, Ishida K, Ueda Y, Kubono A (2014) Electrorheological response of the interfacial layer between a liquid crystal and a polymer alignment sublayer. Thin Solid Films 558:227–230

Moritsugu M, Sun-Nam K, Kubo S, Ogata T, Nonaka T, Sato O, Kurihara S (2011) Photoswitching properties of photonic crystals infiltrated with polymer liquid crystals having azobenzene side chain groups with different methylene spacers. React Funct Polym 71(1):30–35

Mulligan DR, Imrie CT, Larcey P (1996) J Mater Sci 31:1985–1989

Noel C (1992) Liquid crystal polymers: from structures to applications, polymer liquid crystals series, vol 1. Elsevier Applied Science, London, pp 31–102

Pankaj Kumar, Neeraj S-WK, Lee SH, Raina KK (2011) Analysis of dichroic dye-doped polymer-dispersed liquid crystal materials for display devices. Thin Solid Films 520(1):457–463

Patnaiks S, Plimpton S, Pacher R, Adams WW (1995) Liq Cryst 19:213–220

Pavel D, Ball J, Bhattacharya S, Shanks R, Hurduc N (1997) Polymer 38(A):7–11

Pavel D, Ball J, Bhattacharya S, Shanks R, Hurduc N (1999a) J Polym Sci B Phys 37:2334–2352

Pavel D, Ball J, Bhattacharya S, Shanks R, Hurduc N (1999b) J Comput Theor Polym Sci 9:1–19

Petr M, Helgeson ME, Soulages J, McKinley GH, Hammond PT (2013) Rapid viscoelastic switching of an ambient temperature range photo-responsive azobenzene side chain liquid crystal polymer. Polymer 54(12):2850–2856

Rusing I, Dedier J, Filliatre C, Godinho MH, Varichon L, Sixou P (1993) J Polym Sci Phys 31:595

Saeva D (1979) Liquid crystals—the fourth state of matter. Marcel Dekker, New York

Sarman S (1996) J Chem Phys 104(1):342–350

Schmidt-Rohr K, Hong M (1996) J Phys Chem 100:3861–3866

Simmonds DJ (1992) Liquid crystal polymers: from structures to applications, polymer liquid crystals series, vol 1. Elsevier Applied Science, London, pp 349–406

Sordi D, Orlanducci S, Tamburri E, Passeri D, Lucci M, Terranova ML (2011) Self organisation and photoinduced charge transfer in single-wall carbon nanotubes embedded in a thermotropic liquid crystal polymer. Carbon 49(7):2227–2234

Stoeva Z, Lu Z, Ingram MD, Imrie CT (2013) A new polymer electrolyte based on a discotic liquid crystal triblock copolymer. Electrochim Acta 93:279–286

Su Y-C, Chu C-C, Chang W-T, Hsiao VKS (2011) Characterization of optically switchable holographic polymer-dispersed liquid crystal transmission gratings. Opt Mater 34(1):251–255

Suga Y, Takahama T (1996) Polym Mater Sci Eng 74:268–269

Sun XH, Tao XM (2011) Switchable photonic crystal for polymer dispersed liquid crystal. Opt Laser Technol 43(4):820–824

Sung S-J, Jung E-AE, Sim K, Kim D-H, Cho KY (2013) Structure control of lattice-patterned liquid crystals—polymer composites prepared by polarization-selective UV-curing through the addition of a fluorinated acrylate monomer. Microelectr Eng 103:42–48

Takahashi C, Yoshihara S, Kang S, Sakajiri K, Watanabe J, Tokita M (2014) Decrease in the isotropization temperature and enthalpy of main-chain polymer smectic liquid crystals as a result of the inclusion of chain ends. Polymer 55(10):2609–2613

Tu M, Han W, Zeng R, Best SM, Cameron RE (2012) A study of surface morphology and phase separation of polymer/cellulose liquid crystal composite membranes. Colloids Surf A Physicochem Eng Asp 407:126–132

Walasek J (1990) J Polym Sci Phys 28:2473–2485

Wang S, Yang Z, Mo Z, Zhang H, Feng Z (1996) Polymer 37(19):4397–4402

Wang B, You Y, Huo Y (2011) Opto-thermo actuation of multilayered liquid crystal polymer films. Thin Solid Films 519(15):5310–5313

Wang L, Meng F, Sun Y, Yang H (2013) Effect of surfactant-modified ZnS:Mn nanoparticles on the electro-optical properties of composite polymer-dispersed liquid crystal films. Compos B Eng 45(1):780–784

Wenyi H, Shi ER (2012) High-performance thermotropic starch-based liquid crystalline polymer. Carbohydr Polym 90(1):703–708

Wright RV, Hakemi G, Kirby PB (2011) Integration of thin film bulk acoustic resonators onto flexible liquid crystal polymer substrates. Microelectr Eng 88(6):1006–1009

Yagi R, Katae H, Kuwahara Y, Kim S-N, Ogata T, Kurihara S (2014) On-off switching properties of one-dimensional photonic crystals consisting of azo-functionalized polymer liquid crystals having different methylene spacers and polyvinyl alcohol. Polymer 55(5):1120–1127

Yang K-J, Yoon D-Y (2011) Electro-optical characteristics of dye-doped polymer dispersed liquid crystals. J Ind Eng Chem 17(3):543–548

Yao K, Chen L, Hu T, Chen Y (2012) Photocrosslinkable liquid–crystalline polymers for stable photovoltaics by adjusting side-chains spacing and fullerene size to control intercalation. Org Electr 13(8):1443–1455

Yilmaz Canli N, Safak-Boroglu M, Bilgin-Eran B, Günes S (2014) Bilayer polymer/fullerene solar cells with a liquid crystal. Thin Solid Films 560:71–76

Yoon DY, Masiocchi N, Depero LE, Viney C, Parrish W (1990) Macromalecules 23:1793–1798

Yu L, Wei W, Xiong H (2013) Polyether based side-chain liquid crystalline polymers. Anionic polymerization and phase structures. Polymer 54(24):6572–6579

Zentel R, Brehmer M (2012) 8.06—Electroactive liquid crystalline polymers. In: Krzysztof M, Martin M (eds) Polymer science: a comprehensive reference. Elsevier, Amsterdam, pp 129–145

Zentel R, Kapitza H, Kremer F, Vallerien SU (1990) Liquid-crystalline polymers. American Chemical Society, Washington, DC, pp 207–217

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Pavel, D. (2016). Introduction to Liquid Crystalline Polymers. In: Thakur, V., Kessler, M. (eds) Liquid Crystalline Polymers. Springer, Cham. https://doi.org/10.1007/978-3-319-22894-5_16

Download citation

DOI: https://doi.org/10.1007/978-3-319-22894-5_16

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-22893-8

Online ISBN: 978-3-319-22894-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)