Abstract

Data on heat-resistant linear and crosslinked polymer materials containing mesogenic groups in their structure have been systematized. Principles of the macromolecular design of thermoplastic liquid-crystal (LC) polymers providing high performance characteristics and their relationship with the supermolecular organization and processing conditions have been discussed. Methods for synthesizing LC precursors with reactive terminal groups cured to form three-dimensional LC networks have been discussed; the effect of the chemical nature of the terminal groups on the thermal stability of the resulting material has been shown.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Since the date of synthesis of the first thermotropic liquid-crystal (LC) polymer based on 4-hydroxybenzoic acid (HBA), 4,4'-dihydroxy-1,1'-biphenyl, and terephthalic acid (1972), which predetermined the appearance of Xydar-type aromatic polyesters on the world market, a significant amount of data on the principles of synthesizing thermotropic macromolecules and the relationship of their structure with various properties has been published. In this context, using mostly the data published from 2010 to 2020, the authors of this review tried to describe the most relevant tendencies in the selection of the structure of macromolecular compounds that provide their mesomorphism in combination with high thermal and strength characteristics.

The LC state (mesomorphic state, mesophase) is considered to be the equilibrium phase state of matter, which combines both the fluidity of isotropic liquids and the ordering of crystalline solids. The appearance of an LC phase is associated with a strong asymmetry of the geometric parameters of the molecule, which is referred to as anisometry, as in the case of rod-shaped or disk-shaped molecules. In terms of the Flory theory [1], which describes the orientational ordering of solutions of rigid-chain polymers, the isotropic phase becomes thermodynamically unstable if the ratio between the length of the statistical segment of a linear macromolecule and the macromolecule diameter exceeds a certain maximum critical value. For polymers, the possibility of exhibiting LC properties is determined by the anisometry of the macromolecule chain segment that is close in value to the statistical segment length. Distinctive features of the existence of a mesophase are the anisotropy of the physical properties of the studied material and the orientational order in the arrangement of macromolecules in the absence of external impacts.

With respect to the mode of transition to the LC state, two types of polymers are distinguished, namely, thermotropic and lyotropic polymers. Thermotropic polymers represent a special type of macromolecular compounds that spontaneously form an LC phase in a certain temperature range. In addition to this type of polymers, there are lyotropic compounds, which transit into the mesomorphic state in a certain concentration range during dissolution.

A common structural feature for all LC compounds is the presence of rigid aromatic blocks (mesogens), as shown in Fig. 1; in addition, they can contain carboxyl, azomethine, azo, and other bridging groups with multiple bonds [2–5].

The topological structure of LC macromolecules can have a variety of variations: linear with mesogenic moieties in the backbone, comblike with mesogenic side groups, dendrimers with regular cascade-branched macrochains, hyperbranched with a dendrite-like irregular topological structure, and three-dimensional network polymers crosslinked via chemical or labile hydrogen bonding [9].

Several main types of mesophases are known for thermotropic polymers, namely, nematic ordering (N), which is characterized by an orientational order in the absence of a positional order; smectic ordering (Sm) with a layered arrangement of mesogenic blocks and the absence of a positional order; and cholesteric ordering formed by chiral molecules with a one-dimensional orientational order in an individual layer. The most common form of the LC state in polymers is the nematic mesophase.

LINEAR THERMOTROPIC POLYMERS

The mesomorphic properties of polymers were first discovered in 1956 in concentrated solutions of polypeptides forming a stable rodlike conformation [10]. In 1965, the research team of C.W. Stephens and S.L. Kwolek synthesized lyotropic poly(p-phenylene terephthalamide), which currently exists under the brands of high-strength fibers Kevlar (DuPont) and Twaron (Teijin Aramid) [11, 12]. As noted above, it is assumed that the origin of the history of thermotropic macromolecules is the synthesis of a polymer based on HBA, 4,4'-dihydroxy-1,1'-biphenyl, and terephthalic acid with a melting point of 395°C (trade name Ekkcel, Sumitomo Chemical; Xydar, Solvay Advanced Polymers) [13]. In 1973, thermotropic aliphatic–aromatic copolyesters synthesized from HBA and polyethylene terephthalate (trade name X7G, Eastman-Kodak) were patented [14]. A revolutionary—in terms of commercialization—discovery was the synthesis of a number of thermotropic nematics based on HBA and 6‑hydroxy-2-naphthoic acid with extremely high rigidity and strength in 1985 (Table 1); the nematics received a trade name of Vectra (Celanese); they are processed by conventional methods used for thermoplastics [15].

A significant contribution to the development of the basic science of macromolecular LCs was made by Russian scientists N.A. Plate, V.P. Shibaev, and S.Ya. Frenkel’, who are the authors of a set of papers “Physical Chemistry of Synthetic Liquid Crystal Polymers” [16–18]. The properties of low-molecular-weight LC compounds and rigid-chain mesomorphic polymers were studied by V.N. Tsvetkov [19]. The scientific foundations of the structural rheology of anisotropic polymer systems and their processing were developed by V.G. Kulichikhin [20].

Linear thermotropic polymers are synthesized by polycondensation methods: under low-temperature conditions via the Schotten–Baumann reaction between acid chlorides of aromatic carboxylic acids and aromatic diols [21–23] or the exchange reaction between aromatic diols and fluorine-containing monomers [24] and at high temperatures via melt or solution transesterification [25–28]. In the latter case, acylated bifunctional phenols or aromatic hydroxyacids, bifunctional aromatic acids, dimethyl esters of aromatic carboxylic acids [25], and phenyl esters of carboxylic acids are used as the monomers [26, 27]. For use under laboratory conditions, it was proposed that the reaction of trimethylsiloxy derivatives of aromatic carboxylic acids with aromatic diols [28] or an esterification reaction involving boric anhydrides [29] should be used.

In terms of the Flory theory, the highest degree of anisometry takes place in linear LC polymers with the smallest possible macromolecule diameter, which corresponds to the absence of lateral substituents and linking of the monomer units together through functional groups at the para-position. Examples of these polymers are poly(p-oxybenzoate) and poly(p-phenylene terephthalate), which, however, do not form an LC phase. Their melting occurs at extremely high temperatures (600 and 610°C, respectively) [30], whereas thermal degradation begins in a range of 400–450°C; this fact indicates a high stability of the crystal lattice. Methods to impede a close packing of macromolecules into crystalline structures can be the formation of an irregular spatial structure of the macromolecule and the introduction of bulky substituents.

In actual practice, the first approach is implemented via introducing comonomers with different lengths of mesogenic moieties into the polymer chain. In this case, the melting point decreases without adversely affecting the ability to form a mesophase, as shown in [13, 31] using the example of polymers of the Xydar and Vectra families. The commonly used comonomers are multinuclear aromatic compounds, such as naphthyl [32], biphenylene [33], p-quaterphenyl [24], furan [33–35], and 9,10-diphenylanthracene moieties [36] (Table 2). The thermal stability of the polymers based on these comonomers can be fairly high, because multiple bonds in aromatic rings are energetically stronger than a single σ-bond.

The introduction of geometrically kinked moieties linked together via functional groups at the ortho- or meta-position, in addition to units linked to each other at the para-position, into the structure of aromatic polyesters [37, 38] complicates the formation of a regular crystal lattice and has an ambiguous effect on mesomorphism. Furthermore, the incorporation of kinked moieties into a macromolecule changes their conformational characteristics and contributes to an increase in chain flexibility. At a certain content of these units, the ability of the polymer to mesomorphism disappears. Some authors propose that 3-hydroxybenzoic acid should be introduced into the polymer composition together with HBA [38]. The new monomers exhibiting high thermal stability include biphenyl-3,4′-dicarboxylic [39] and 3-amino-4-hydroxybenzoic acids [40].

In addition, it is common practice to introduce flexible-chain spacers into the macromolecule structure to separate mesogenic blocks, such as aliphatic, polyester, and polydimethylsiloxane moieties. Recently, compounds synthesized from various aromatic monomers with the incorporation of aliphatic carboxylic acids [23, 34, 41–43], triethylene glycol [44, 45], and aliphatic [46, 47] or aromatic diols into the structure [48, 49] have been studied. An increase in the content of covalent carbon–carbon bonds in the copolymers leads to a significant decrease in their thermal stability, which, however, can be avoided via using various bisphenols as spacers.

Lateral substituents, which are bulk structural moieties attached to the polymer backbone, contribute to a decrease in the intermolecular interaction and packing density of macromolecules. This approach was implemented in [50], where aromatic thermotropic polyesters with alkoxy side groups were synthesized from 2,5-diethoxyterephthalate, 2,5-dibutoxyterephthalate, and 2,5-dihexyloxyterephthalate monomers. Halogen-substituted compounds, such as bis[4-hydroxy benzoyloxy]-2-chloro-1,4-benzene, were introduced into the structure of thermotropic polymers as a mesogen with lateral substituents [23]. A set of thermotropic copolyesters in which the lateral bulk substituent was a phosphorus-containing heterocycle exhibiting high thermal stability (above 360°C) was proposed in [51, 52]. The 4,4'-(phenylphosphoryl)dicarboxylic acid monomer with a noncoplanar structure was introduced into the composition of mesogenic blocks in [53].

To predict the rheological behavior of thermotropic polymers during the manufacture of products (injection molding and extrusion), a necessary condition is to study the flow curves of the processed materials (Fig. 2a). The rheological properties of LC polymers with a nematic mesophase have been studied in the most detail [58]. For these polymers, upon the achievement of the crystalline phase–mesophase phase transition temperature, even in the region of relatively low shear rates, an abrupt decrease in the apparent viscosity of the melt is observed; it indicates the orientation of rod-shaped macromolecules along the flow direction. It is only natural to assume that the processing of LC polymers in this mode requires significantly lower energy costs than those for a more viscous isotropic state. In this case, with an increase in the shear rate at a constant temperature, some of the macromolecules from the nematic phase can transit into the isotropic phase and thereby increase the apparent viscosity. Therefore, the selection of optimum conditions for the processing of LC polymers is extremely important to provide both the energy efficiency of the processing procedure and the manufacture of finished products with desired properties.

(a) Dependence of the viscosity of LC polymers and isotropic polymers on shear rate and (b) the rheological curve of an LC polymer according to the Onogi and Asada hypothesis [59].

A significant effect on the processing of LC polymers is exerted by individual characteristics of the mesophase. Liquid crystal macromolecules undergo orientation under the action of external forces (electromagnetic field or mechanical impacts); this is a key factor responsible for a decrease in the melt viscosity [59]. Figure 2a shows typical flow curves of an LC polymer in the anisotropic and isotropic states.

The rheology of polymers exhibiting mesomorphic properties is non-Newtonian and fundamentally different from the flow of low-molecular-weight liquids and polymers; therefore, in this case, the Newton and Ostwald–de Waele laws of viscosity are not applicable. The theoretical flow curve of a linear LC polymer proposed by S. Onogi and T. Asada [60] is shown in Fig. 2b. Three flow regions can be distinguished in this curve: (1, 3) regions with variable viscosity at low and high shear rates and (2) a plateau with a constant viscosity value.

To interpret the pattern of change in the viscosity characteristics of mesomorphic substances, the Leslie–Ericksen theory [61, 62] and the Doi molecular model [63] were developed in terms of continuum mechanics. Additional difficulties in the description of these systems are introduced by the domain supermolecular structure and the presence of defects in the ordering of melts of LC polymers. At the same time, in the region of low shear rates, the relationships predicted by the molecular theory are in good agreement with the experimental data. According to this theory, the molecular dynamics of rod-shaped molecules can be described by the following equation [64]:

where ηs is the viscosity of the isotropic medium, L is the length of the rod-shaped polymer molecule, K is the Frank elastic constant, and α3 and α2 are the Leslie coefficients.

The effect of the domain structure of LC polymers is taken into account in the modified molecular theory proposed in [65], which is applicable to regions 1 and 2 of the flow curve.

Measurements of dynamic rheological properties make it possible to study the solid–fluid transitions of a polymer system under the action of deformation. Under conditions of dynamic testing in the oscillation mode, the sample is subjected to harmonic shear vibrations. Dynamic properties are expressed in terms of dynamic shear storage modulus G ' and loss modulus G ''. The test result is a relaxation spectrum, which describes the rearrangement of structural elements of the polymer system under dynamic conditions. The evolution of the morphology of the LC state over time for polymers can be traced from the dynamic complex viscosity. It is noteworthy that a characteristic increase in viscosity with temperature was observed for LC melts [66]. This anomaly can be interpreted as follows. In the case of monodispersed LC macromolecules, it is reasonable to expect an abrupt increase in viscosity upon transition from the mesophase to the isotropic state. A polydisperse distribution of LC molecules implies the presence of fractions with different molecular weights, the low-molecular-weight portion of which begins to transit into an isotropic melt at lower temperatures than the other fractions do. As a consequence, an increase in temperature in polydisperse systems leads to a gradual increase in viscosity (Fig. 3).

Dependence of the viscosity of LC polymers on (a) oscillation frequency and (b) temperature [66]: (a) T = (1) 330, (2) 340, (3) 350, (4) 360, (5) 380, (6) 400, and (7) 420°C and (b) frequency (1) 0.628, (2) 1256, (3) 3.14, (4) 6.28, (5) 12.56, (6) 25.12, and (7) 62.8.

Linear LC polymers with mesogens in the backbone are characterized by a unique combination of strength properties, thermal stability, processibility, chemical resistance, a low coefficient of thermal expansion, and antifriction properties. In this context, interest in these materials from research laboratories and manufacturers of electronics, aircrafts, and industrial equipment has been observed in recent decades [59, 67–70].

The method of processing of LC thermoplastics is responsible for the anisotropy of the properties of the materials, in particular, physicomechanical properties. Cast products and fibers exhibit a pronounced anisotropy of strength properties, which is shown in Table 3 using the example of X7G and in Fig. 4. The presence of solvent molecules in the polymer matrix can lead to a further decrease in strength, owing to the plasticization effect.

Effect of processing method on the strength properties of LC polyesters: (1) fiber spinning, (2) injection molding, (3) solution casting (with subsequent heat treatment), and (4) solution casting (without a heat treatment) [55].

The existence of oriented rigid-chain macromolecules arranged parallel to each other in the bulk of a polymer material improves the crystalline structure of the material, while increasing the strength and elasticity of the polymer. The high strength characteristics of linear thermotropic polymers are attributed to a hierarchical supermolecular structure formed during the processing of oriented macromolecules. It is known that, at temperatures exceeding the melting point of the material, rigid-chain moieties of thermotropic polymers undergo self-organization into LC domains. In general, in the mesophase of the polymer at rest, a single direction of orientation of individual domains does not exit. The further flow of the LC melt through the technological equipment during processing under the action of shear forces aligns the domains along the flow direction. Immediately after the molding process, the finished polymer product is subjected to a significant temperature difference and quenching; this process provides the fixation of the oriented supermolecular organization of the LC melt in the bulk of the finished product.

The above holds true for the latest processing methods, such as 3D printing [70, 71]. It should be noted that, in the published studies, the issue of selecting a polymer composition for 3D printing is still at the initial stage of development and requires the formation of theoretical foundations to reveal the relationship between the process parameters and the properties of the finished products. Polylactide–LC polymer and polyphenylene sulfide–LC polymer blends were proposed as promising recyclable materials for additive processing methods [72]; these blends can be subjected to repeated recycling with the preservation of the initial strength characteristics [73, 74].

LIQUID CRYSTALLINE THERMOSETS

An alternative concept for designing heat-resistant high-strength materials involves the use of reactive LC monomers or oligomers, which are transformed into a three-dimensional network structure via the reaction of terminal groups, rather than the use of thermoplastics. Liquid crystal binders are cured under the action of high temperatures after the transition of the substance into the mesophase state to provide the fixation of the ordered mesomorphic supermolecular organization in the bulk of the crosslinked polymer material. There are published data on the reactivity of thermotropic compounds with different terminal groups, namely, maleimide and maleimide derivatives [75–78], ethynyl-substituted [79–85], epoxy resins [86–96], and benzoxazines [97–100]. The synthetic aspects of the reactions to form these compounds and their curing are discussed below.

The synthesis of LC binders with amide groups in the mesogen and maleimide terminal groups was described in [58]. The process is run as follows: terminal groups are synthesized separately from carboxylic acid anhydride (maleic, nadic, methylenadic) and 4‑aminobenzoic acid; the resulting adduct is converted to acid chloride and blended with aromatic diamine. In monomers with amide groups, the transition to the mesophase is observed at high temperatures; this fact is attributed to the strong intermolecular interaction of the amide groups.

Lower phase transition temperatures are observed for thermosets with ester bridging groups, which are formed via the reaction of one equivalent of an aromatic diol with two equivalents of aromatic carboxylic acid chlorides and subsequent functionalization with maleimide groups.

Ethynyl derivatives of aromatic oligoesters are formed via the reaction of the terminal carboxyl groups of the mesogenic moiety with p-ethynylbenzoyl chloride [101]. Propargyl groups are introduced into the macromolecular composition owing to the action of propargyl chloride on the mesogen functionalized with hydroxyl groups:

Phenylethynyl derivatives of thermotropic thermosets are synthesized using precursors (4-phenylethynylphthalic anhydride) for the terminal groups that were presynthesized via the reaction of 4-bromophthalic anhydride with phenylacetylene [102]. The compound reacts with 4-aminophenol or 4‑aminobenzoic acid to form N-(4-hydroxyphenyl)-4-phenylethynylphthalimide or N-(4-acetoxyphenyl)-4-phenylethynylphthalimide, respectively. The precursor synthesized by this method is added as a comonomer to the polymer-forming system during synthesis [102].

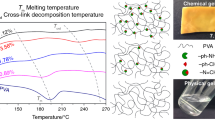

Thermotropic thermosets with terminal groups containing multiple bonds are cured thermally; the curing is accompanied by the opening of multiple C‒C bonds to form a crosslinked polymer.

Mesomorphic properties, such as the temperature of transition to the LC phase, the isotropization temperature, and the range of existence of the mesophase, are determined by the structure of the mesogenic unit and the chemical nature of the terminal groups. Any lateral substituents in the mesogenic moiety and in the terminal group destabilize the ordered intermolecular organization and thereby decrease the temperature of phase transitions and narrow the temperature range of the mesomorphic state.

A similar effect is exerted by spacers, such as a propargyl group. According to Table 4, the introduction of terminal functional groups leads to a significant decrease in the temperature of transition to the mesophase; however, it does not affect the heat resistance.

In terms of increasing the thermal properties of polymer materials, it is of interest to introduce heteroatoms, particularly heterocycles, with a high carbon–heteroatom bond energy into the structure of LC binders [78]:

The synthesis of LC epoxy resin thermosets is discussed in detail in [2]. Thermosets of this type are synthesized from aromatic diols under the action of epichlorohydrin and cured with aromatic diamines or anhydrides:

Analysis of the published data on thermotropic epoxy resin thermosets and compounds used to cure the binders suggests that the kinetic parameters of the reaction depend on the phase state of the polymer composite material. A common tendency for LC epoxy resins is a decrease in the curing temperature with an increase in the basicity of the curing agent [2].

The elaborated design of the macromolecular structure of thermosets makes it possible to control the elastic–strength properties and morphology of the mesomorphic state of crosslinked polymers. Thus, an increase in the length of a flexible-chain moiety leads to a decrease in the fragility of the material and a simultaneous decrease in the strength characteristics. The replacement of alkyl moieties with siloxane moieties leads to a decrease in the temperature of transition to the LC state and extends the temperature range of existence of the mesophase [103]. In addition, it becomes possible to control the degree of ordering of LC domains in the thermoset owing to the action of external forces (mechanical, electromagnetic) [104].

It should be emphasized that the minimum difference between the temperature of transition to the LC phase and the curing temperature of the polymer composite material is important for preserving the mesophase state in the finished products and imparting an improved set of properties to them, regardless of the selected thermoset type [77].

Benzoxazine thermosets are aminophenol–formaldehyde resins whose synthesis methods are based on the example of reactions of phenol derivatives with primary amines in the presence of paraformaldehyde:

Benzoxazine thermosets are polymerized in accordance with the mechanism of cationic polymerization accompanied by the opening of the benzoxazine ring. Benzoxazine systems are comparable to epoxy resins with respect to strength properties and to bismaleimides with respect to thermal properties; therefore, they are regarded as a promising alternative to the most commonly used heat-resistant thermosetting plastics.

The upper limit of operating temperature recommended for most epoxy resin systems is 80–110°C; at 250–300°C, this material loses 10% of weight [105]. In LC epoxy resin binders, the oncet degradation temperature increases with the mesogenic moiety length and can achieve 350°C (Table 4). A disadvantage of epoxy resin polymer composite materials is low fire resistance; it can be eliminated, for example, via introducing phosphorus-containing compounds into the macromolecular structure. However, with respect to thermal stability and the set of mechanical properties, epoxy resins are significantly inferior to the family of heat-resistant thermosetting resins based on bismaleimides. The latter are capable of withstanding long-term mechanical loads at 230–290°C. The formation of an ordered mesomorphic supermolecular organization in bismaleimide systems not only increases the heat resistance, but also provides a high fracture energy of the material. Finally, benzoxazine resins, which exhibit higher thermal stability, fire resistance, and insulating properties than the respective parameters of epoxy resins, are thought of as being promising heat-resistant matrices for composite materials used in electronics, for carbon plastics, and as high-temperature adhesives. The imparting of LC properties to these thermosets, as in the case of other types of plastics, has a positive effect on deformation stability during heating.

CONCLUSIONS

Scientific and practical interest in LC polymer materials intended for construction purposes remains at a stable high level. The peak of publication activity on LC thermoplastics was observed in the 1970–1980. Recently, it has slightly decreased; however, the design of composite materials based on LC thermoplastics is still being dynamically developed. In addition, a new direction is the processing of LC thermoplastics by additive methods providing the manufacture of products with complex geometric shapes for various types of equipment.

The thermal properties of linear LC polymers change symbatically with the content of chemical bonds with high dissociation energies—aromatic moieties, multiple bonds, and carbon–heteroatom bonds—in the macromolecules. The mesomorphic properties of thermotropic are affected by the structure and length of the mesogen, the chemical nature and number of lateral substituents, the structure and linear dimensions of flexible chains, the presence of hydrogen bonds, and other factors. A general relationship characteristic of macromolecular LCs is an increase in the stability of the crystal lattice with an increase in the mesogen length and the strengthening of the intermolecular bonds. The main solutions for decreasing the phase transition temperatures of LC polymers in a temperature range acceptable for processing, which impede a close packing of macromolecules into crystalline structures, can be the formation of an irregular spatial structure of the macromolecule, the introduction of bulk or polar lateral substituents, and a deviation from the geometrically linear shape of the macromolecules.

Another tendency is observed for LC thermosetting compounds and crosslinked polymer materials based on them. In this case, the strategies for selecting the macromolecular structure are fundamentally different from those for thermoplastic polymers. The most important condition for the further use of thermoplastic polymers is a fairly high temperature of transition to the LC state, which indicates the upper limit of the temperature regime of operation of the material, whereas to synthesize LC thermosets, it is necessary to provide the condition of equality of the temperature of transition to the mesophase and the curing temperature. Only in this case, the resulting crosslinked polymer will maintain a mesomorphic ordering in the structure and exhibit an improved set of properties. The future of thermosetting LC resins is associated with the synthesis of heat-resistant composite materials, crosslinkers, and adhesives for high-tech industries imposing stringent requirements for the stability of properties over a wide temperature range and a decrease in the weight of the finished products. A large amount of research should be conducted to provide an effective development of these directions.

REFERENCES

P. J. Flory, Proc. R. Soc. A 234 (1196), 73 (1956).

M. Kisiel and B. Mossety-Leszczak, Eur. Polym. J. 124, 109507 (2020).

T. Ube, Polym. J. 51, 983 (2019).

Liquid Crystalline Polymers, Ed. by V. K. Thakur and M. R. Kessler (Springer, Cham, 2016).

T. Kato, J. Uchida, T. Ichikawa, and B. Soberats, Polym. J. 50, 149 (2018).

V. P. Shibaev and A. Yu. Bobrovskii, Russ. Chem. Rev. 86, 1024 (2017).

D.-Y. Kim, L. Wang, Y. Cao, X. Yu, S. Z. D. Cheng, S.‑W. Kuo, D.-H. Song, S. H. Lee, M.-H. Lee, and K.‑U. Jeong, J. Mater. Chem. 22, 16382 (2012).

L. Wang, D. Huang, L. Lam, and Z. Cheng, Liq. Cryst. Today 26 (4), 85 (2017).

D. Andrienko, J. Mol. Liq. 267, 520 (2018).

C. Robinson, Trans. Faraday Soc. 52, 571 (1956).

E. F. Hoegger, J. R. Schaefgen, and C. W. Stephens, US Patent No. 3575933 (1971).

S. L. Kwolek, US Patent No. 3600350 (1971).

S. G. Cottis, J. Economy, and B. E. Nowak, US Patent No. 3637595 (1972).

H. F. Kuhfuss and W. J. Jackson, Jr., US Patent No. 3778410 (1973).

G. W. Calundann, US Patent No. 4161470 (1979).

V. P. Shibaev and N. A. Plate, Vysokomol. Soedin., Ser. A 19, 923 (1977).

N. Plate and V. Shibaev, Comb-Shaped Polymers and Liquid Crystals (Plenum Press, New York; London, 1987).

E. E. Pashkovskii, A. Yu. Bilibin, S. S. Skorokhodov, and S. Ya. Frenkel’, Vysokomol. Soedin., Ser. B 29, 74 (1987).

V. N. Tsvetkov and N. V. Tsvetkov, Russ. Chem. Rev. 62, 851 (1993).

V. G. Kulichikhin, E. P. Plotnikova, A. K. Tereshin, A. V. Subbotin, and L. A. Tsamalashvili, Polym. Sci., Ser. C 42, 129 (2000).

S. Ozden, A. M. Charayev, A. H. Shaov, and R. C. Bazheva, J. Appl. Polym. Sci. 107, 2459 (2008).

S. Zhou, M. Zhang, R. Wang, J. Ping, X. Zhang, N. Zhao, J. Xu, Z. Shen, and X. Fan, Polymer 109, 49 (2017).

N. Manurkar, S. More, K. Mulani, N. Ganjave, and N. Chavan, J. Chem. Sci. 129, 1461 (2017).

F. O. Oladoyinbo, D. F. Lewis, D. J. Blundell, and H. M. Colquhoun, Polym. Chem. 11, 75 (2020).

M. Uchimura, R. Ishige, M. Shigeta, Y. Arakawa, Y. Niko, J. Watanabe, and G.-I. Konishi, Res. Chem. Intermed. 39, 403 (2013).

P. K. Kaicker, S. Tyagi, S. Khanna, and A. M. Khan, in Frontiers of Polymer Research (Springer, Dordrecht, 1991).

J. Economy, R. S. Storm, V. I. Matkovich, S. G. Cottis, and B. E. Nowak, J. Polym. Sci., Part A: Polym. Chem. 14, 2207 (1976).

G. Lieser, G. Schwarz, and H. R. Kricheldorf, J. Polym. Sci., Polym. Phys. Ed. 21, 1599 (1983).

M. Kihara, S.-I. Kohama, S. Umezono, K. Wakabayashi, S. Yamazaki, and K. Kimura, J. Polym. Sci., Part A: Polym. Chem. 49, 1088 (2011).

A. Pegoretti and M. Traina, Handbook of Properties of Textile and Technical Fibres (Woodhead Publ., Duxford; Cambridge; Kidlington, 2018).

S.-X. Cheng, T.-S. Chung, and S. Mullick, Chem. Eng. Sci. 54, 663 (1999).

L. Zeng, R. Li, P. Chen, J. Xu, and P. Liu, J. Appl. Polym. Sci. 133, 43800 (2016).

C. H. R. M. Wilsens, B. A. J. Noordover, and S. Rastogi, Polymer 55, 2432 (2014).

C. H. R. M. Wilsens, J. M. G. A. Verhoeven, B. A. J. Noordover, M. R. Hansen, D. Auhl, and S. Rastogi, Macromolecules 47, 3306 (2014).

G. de Kort, N. Leone, E. Stellamanns, D. Auhl, C. Wilsens, and S. Rastogi, Polymers 10, 935 (2018).

M. Uchimura, R. Ishige, M. Shigeta, Y. Arakawa, Y. Niko, J. Watanabe, and G.-I. Konishi, Res. Chem. Intermed. 39, 403 (2013).

K. V. Heifferon, R. J. Mondschein, S. J. Talley, R. B. Moore, S. R. Turner, and T. E. Long, Polymer 163, 125 (2019).

V. Babacan, S. Aksoy, Z. Yerlikaya, and H. Altinok, Polym. Int. 59, 749 (2010).

K. V. Heifferon, G. A. Spiering, S. J. Talley, M. Hegde, R. B. Moore, S. R. Turner, and T. E. Long, Polym. Chem. 10, 4287 (2019).

M. A. Ali, H. Shimosegawa, A. Nag, K. Takada, and T. Kaneko, J. Polym. Res. 24, 214 (2017).

M. E. Bloom, J. Vicentin, D. S. Honeycutt, J. M. Marsico, T. S. Geraci, and M. J. Miri, J. Polym. Sci., Part A: Polym. Chem. 56, 1498 (2018).

Y. Wang, G. Lu, W. Wang, M. Cao, Z. Luo, N. Shao, and B. Wang, e-Polym. 17, 199 (2017).

G. Yao and Y. Gu, Chin. Chem. Lett. 20, 1510 (2009).

A. Martinez-Gómez, E. Pérez, and A. Bello, Colloid Polym. Sci. 288, 859 (2010).

A. Martinez-Gómez, E. Pérez, and A. Bello, Macromol. Chem. Phys. 212, 1971 (2011).

N. S. Al-Muaikel and K. I. Aly, Open J. Org. Polym. Mater. 3, 19 (2013).

K. I. Aly, M. A. Hussein, and M. M. Sayed, Liq. Cryst. 40, 1570 (2013).

C. D. Ruijter, J. B. H. Boerstoel, and T. J. Dingemans, J. Polym. Sci., Part A: Polym. Chem. 46, 6565 (2016).

P. Wei, M. Cakmak, Y. Chen, X. Wang, Y. Wang, and Y. Wang, J. Appl. Polym. Sci. 131, 40487 (2014).

G. T. Park, J.-H. Chang, and A. R. Lim, Polymers 11, 992 (2009).

D. Serbezeanu, T. Vlad-Bubulac, C. Hamciuc, and M. Aflori, Macromol. Chem. Phys. 211, 1460 (2010).

X. Zhang, M. Yang, Y. Shen, H. Wu, S. Guuo, and Y. Wang, Liq. Cryst. 43, 886 (2016).

R. Yang, L. Chen, R. Jin, and Y.-Z. Wang, Polym. Chem. 4, 329 (2013).

P. Wei, L. Wang, X. Wang, Y. Chen, Y. Wang, and Y. Wang, High Perform. Polym. 26, 935 (2014).

C. H. R. M. Wilsens, Y. S. Deshmukh, W. Liu, B. A. J. Noordover, Y. Yao, H. E. H. Meijer, and S. Rastogi, Polymer 60, 198 (2015).

H. M. de Oca, J. E. Wilson, A. Penrose, D. M. Langton, A. C. Dagger, M. Anderson, D. F. Farrar, C. S. Lovell, M. E. Ries, I. M. Ward, A. D. Wilson, S. J. Cowling, I. M. Saez, and J. W. Goodby, Biomaterials 31, 7599 (2010).

Q. V. Nguyen, J. Y. Bae, and H. S. Le, Chem. Eng. Commun. 204, 1 (2019).

R. W. Lusignea, in Applications of High Temperature Polymers, Ed. by R. R. Luise (CRC Press, Boca Raton, 1997), Chap. 3, p. 41.

E. Glowińska, P. Parcheta, and J. Datta, in Rheology of Polymer Blends and Nanocomposites. Theory, Modelling and Applications (Elsevier, Amsterdam; Oxford; Cambridge, 2020).

Rheology, Ed. by G. Astarita, G. Marrucci, and L. Nicolais (Springer, Boston, 1980).

J. L. Ericksen, Arch. Ration. Mech. Anal. 9, 371 (1962).

F. M. Leslie, Arch. Ration. Mech. Anal. 28, 265 (1968).

M. Doi, J. Polym. Sci., Polym. Phys. Ed. 19, 229 (1981).

E. A. Kirsanov and V. N. Matveenko, Non-Newtonian Behavior of Structured Systems (Tekhnosfera, Moscow, 2016) [in Russian].

K. M. Kim, T. K. Kim, S. Kim, and I. J. Chung, Korean J. Chem. Eng. 14, 8 (1997).

Y. Fan, D. Shaocong, and I. R. Tanner, Korea-Aust. Rheol. J. 15, 109 (2003).

High-Performance and Specialty Fibers, Ed. by Society of Fiber Science and Technology (Springer Japan, Japan, 2016).

100+ Years of Plastics. Leo Baekkeland and Beyond, Ed. by E T. Strom and S. C. Rasmussen (Am. Chem. Soc., Washington, DC, 2011).

Yu. A. Mikhailin, Thermostable Polymers and Polymer Materials (Professiya, St. Petersburg, 2006) [in Russian].

S. Gantenbein, K. Masania, W. Woigk, J. P. W. Sesseg, T. A. Tervoort, and A. R. Studart, Nature 561 (7722), 226 (2018).

C. Zhang, X. Lu, G. Fei, Z. Wang, H. Xia, and Y. Zhao, ACS Appl. Mater. Interfaces 11, 44774 (2019).

M. Q. Ansari, M. J. Bortner, and D. G. Baird, Addit. Manuf. 29, 100814 (2019).

G. W. de Kort, L. H. C. Bouvrie, S. Rastogi, and C. H. R. M. Wilsens, ACS Sustainable Chem. Eng. 8, 624 (2020).

G. W. de Kort, S. Rastogi, and C. H. R. M. Wilsens, Macromolecules 52, 6005 (2019).

B. Fache, B. Gallot, M. P. Gelin, J. C. Milano, and Q. T. Pham, J. Appl. Polym. Sci. 127, 3798 (2013).

H.-G. Moon, M.-S. Jung, and J.-H. Chang, Macromol. Res. 19, 2 (2011).

Y.-H. Ahn, M.-S. Jung, and J.-H. Chang, Mater. Chem. Phys. 123, 177 (2010).

M. Hasegawa, K. Shigeta, and J. Ishii, Polym. Adv. Technol. 30, 128 (2019).

T. Huang, Q. Guan, L. Yuan, G. Liang, A. Gu, Ind. Eng. Chem. Res. 57, 7090 (2018).

Y. Dai, X. Bi, T. J. Dingemans, and Q. Guan, High Perform. Polym. 31, 631 (2019).

Y. Tang, L. Yuan, G. Liang, and A. Gu, Composites, Part B 181, 107554 (2020).

M. Iqbal, S. J. Picken, and T. J. Dingemans, High Perform. Polym. 26, 381 (2014).

Q. Guan, B. Norder, L. Chu, N. A. M. Besseling, S. J. Picken, and T. J. Dingemans, Macromolecules 49, 8549 (2016).

Q. Guan, B. Norder, and T. J. Dingemans, J. Appl. Polym. Sci. 134, 44774 (2017).

K. Wang, Y. Wang, P. Chen, L. Xia, and X. Xiong, Adv. Polym. Technol. 37, 281 (2018).

Y. Liu, J. Chen, Y. Zhang, S. Gao, Z. Lu, and Q. Xue, J. Polym. Sci., Part B: Polym. Phys. 55, 1830 (2017).

Y. Li, P. Badrinarayanan, and M. R. Kessler, Polymer 54, 3017 (2013).

M. Harada, J. Ando, M. Yamaki, and M. Ochi, J. Appl. Polym. Sci. 132, 41296 (2015).

S. Kawamoto, H. Fujiwara, and S. Nishimura, Int. J. Hydrogen Energy 41, 7500 (2016).

I. Jeong, C. B. Kim, D.-G. Kang, K.-U. Jeong, S. G. Jang, N.-H. You, S. Ahn, D.-S. Lee, and M. Goh, J. Polym. Sci., Part A: Polym. Chem. 57, 708 (2019).

D.-W. Zhou, L.-Y. Liang, and M.-G. Lu, Polym. Bull. 66, 1111 (2011).

Y.-L. Liu, Z.-Q. Cai, W.-C. Wang, X. Wen, P. Pi, D. Zheng, J. Cheng, and Z. Yang, Macromol. Mater. Eng. 296, 83 (2011).

Z. Lin, Y. Cong, B. Zhang, and H. Huang, Liq. Cryst. 46, 1467 (2019).

J.-M. Pin, N. Sbirrazzuoli, L. Sacarescu, and A. Mija, Polym. Chem. 7, 1221 (2016).

H. Wang, Y. Zhang, L. Zhu, Z. Du, B. Zhang, and Y. Zhang, Thermochim. Acta 521, 18 (2011).

R. Balamurugan and P. Kannan, J. Mater. Sci. 45, 1321 (2010).

T. Kawauchi, Y. Murai, K. Hashimoto, M. Ito, K. Sakajiri, and T. Takeichi, Polymer 52, 2150 (2011).

P. Velez-Herrera and H. Ishida, J. Polym. Sci., Part A: Polym. Chem. 47, 5871 (2009).

M. Ito, T. Kawauchi, K. Sakajiri, and T. Takeichi, React. Funct. Polym. 73, 1223 (2013).

M. Hasegawa, N. Suyama, N. Shimoyama, H. Aoki, T. Nunokawa, and T. Kimura, Polym. Int. 60, 1240 (2011).

D. A. Langlois, B. C. Benicewicz, and E. P. Douglas, Chem. Mater. 10, 3393 (1998).

A. Knijnenberg, E. S. Weiser, T. L. StClair, E. Mendes, and T. J. Dingemans, Macromolecules 39, 6939 (2006).

M. Harada, M. Hirotani, and M. Ochi, J. Appl. Polym. Sci. 136, 47891 (2019).

W. Shen, L. Wang, T. Zhong, G. Chen, C. Li, M. Chen, C. Zhang, L. Zhang, K. Li, Z. Yang, and H. Yang, Polymer 160, 53 (2019).

High Performance Polymers and Engineering Plastics, Ed. by V. Mittal (Scrivener Publ. LLC, Massachusetts, 2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by M. Timoshinina

Rights and permissions

About this article

Cite this article

Deberdeev, T.R., Akhmetshina, A.I., Karimova, L.K. et al. Heat-Resistant Polymer Materials Based on Liquid Crystal Compounds. Polym. Sci. Ser. C 62, 145–164 (2020). https://doi.org/10.1134/S1811238220020034

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1811238220020034