Abstract

Basal reinforcement, where high tensile strength geogrids are employed beneath structures, is becoming an increasingly accepted construction technique along the eastern coast of southern Africa. The presence of compressible, soft, thin and shallow clay horizons usually associated with complex estuarine or lagoonal deposits are a major consideration when using basal reinforcement as a founding technique. In order to define the deformation behaviour under a wide platform load, three centrifuge tests were undertaken. These tests compared the behaviour of the clay horizon in three scenarios, namely (1) without reinforcement, (2) with a single layer of reinforcement, and (3) with a double layer of reinforcement. It was found that the inclusion of geogrid reinforcement increased the vertical load-bearing capacity of the system and the inclusion of an additional geogrid layer further increases the load bearing capacity. Additionally, the inclusion of geogrid reinforcement also changed the deformation mechanisms of the materials. Without reinforcement, deformation is localised to the portion of clay directly beneath the applied load from the platform. Whilst the inclusion of geogrid reinforcement allows the applied load to be spread to the sand beyond the platform, which contributes to an increase in load-bearing capacity, it comes at the disadvantage of deforming a wider portion of the clay horizon.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Harbours along the eastern coastline of southern Africa have been established on river estuaries where several rivers give rise to an interlinked lagoonal system, comprising complex unconsolidated deposits of sands, silts and clays. These sediments are typically characterised by extremely compressible, soft materials. The poor geotechnical nature of these deposits has lead to limitations on the type of foundation treatment that can be applied to various engineering structures. Accordingly, specialised foundation designs and construction techniques are required when constructing on these unfavourable materials. Initial development for structures constructed on these deposits primarily involved the construction of costly piling solutions. However, with the recent advancement of geosynthetics it has been possible to provide an alternative to traditional piling techniques using basal reinforcement, whereby suitable high tensile strength geogrids are employed. Moore et al. (2012) and Zannoni et al. (2012) have presented case studies where basal reinforcement techniques have been employed. The basal reinforcement utilized in both studies was specifically for warehouse structures whereby large platform loads developed as a result of product stockpiling. The major concern on site for both of the studies was the presence of compressible, soft, thin, shallow, clay horizons below the foundation footprint.

Understanding failure mechanisms are an important component of stability analysis of earth structures. It is therefore essential to have a thorough understanding of how the subsoil’s beneath the structure will behave, upon foundation loading. If reinforcement is used, the mechanisms become altered, and choosing the right mechanism for stability analysis may not always be straightforward (Michalowski and Shi 2003). Geotechnical centrifuge modelling provides a means to replicate a situation, which may exist in a prototype. Fundamentally, a geotechnical centrifuge allows reproduction of the same stress levels in a small-scale model as in a full-scale prototype, which is useful for analysing complex soil-structure interaction problems.

The present study focused on defining the behaviour of a compressible, soft, thin, shallow clay horizon, under a wide platform load. Accordingly, modelling of this situation in a geotechnical centrifuge allows for the mechanisms of deformation to be defined.

2 Geotechnical Centrifuge Model

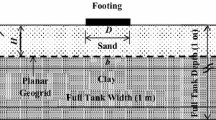

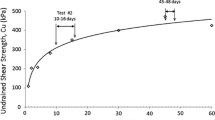

Three geotechnical centrifuge model tests were performed at a 1:50 scale using the 3 m radius balanced beam centrifuge housed in the Department of Civil Engineering at the University of Pretoria. The first model was tested without any reinforcement. The second and third models had a single and double layer respectively, of geogrid reinforcement present in the sand layer overlying the soft clay layer. Each model was constructed identically with the model set-up illustrated in Fig. 10.1. Initially, sand was pluviated to create a dense basal sand horizon of 100 mm thickness which was then carefully saturated from the base by introducing pore water via a header tank. Following which, the dry kaolin clay powder was prepared by mixing under partial vacuum with deionized water, to twice its liquid limit. The slurry was poured over the basal sand horizon, and allowed to consolidate in the centrifuge for 14 h at 50 G, under a load of approximately 25 kPa. This ensured the clay was normally consolidated and had a very soft consistency, with an undrained shear strength of approximately 6 kPa for each test. The clay horizon had a thickness of 60 mm for each centrifuge test. The geotechnical properties of the sand and clay are presented in Table 10.1. Finally, the reinforced sand was then pluviated over the clay to a thickness of 30 mm. For the second and third tests with reinforcing included, the sand pluviation was ceased temporarily to allow for placement of the geogrids within the reinforcing sand. The geogrids were placed at equally spaced vertical intervals within the sand layer, and extended the entire length of the centrifuge model box. The geogrids employed were polypropylene biaxial geogrids, which had an ultimate tensile strength of 20 kN/m, at 13 % strain, with a stiffness of approximately 154 kN/m.

During loading of the model, an aluminium platform of 200 mm width was attached to a jack and lowered at a constant rate of 0.081 mm/s. A load cell recorded the load achieved against the platform, while an LVDT measured the vertical displacement.

3 Analyses of Centrifuge Tests

Analyses of the centrifuge tests comprised the visual assessment of the material deformation, as well as evaluation of the load-displacement data. Camera’s installed on the centrifuge basket recorded the events in-flight. This was undertaken to compare the deformation at specific displacement intervals. An HBM Quantum system acquired data from the load cell and LVDT placed on the jack system.

3.1 Deformation Behaviour

The deformation of the centrifuge model, at 15 mm displacement is presented in Fig. 10.2. In the unreinforced test, a shear zone develops through the upper sand horizon at the edge of the platform. As such, the sand beneath the platform essentially behaves as a much deeper rigid platform, to the top of the clay horizon. The deformation of the clay horizon is confined to the portion below the overlying sand directly beneath the applied load from the platform. The clay is squeezed laterally, with little disturbance to the surface of the model, as the ‘bulging’ on the surface is limited.

With the inclusion of geogrid reinforcement, the mechanism of failure changes with the failure having a wider lateral impact. Huang and Tatsuoka (1990) termed this the ‘wide-slab’ effect, for their studies of reinforced sand loaded by footings. By including reinforcement beyond the platform footprint, the applied load is spread, mobilising the sand beyond the platform, and subsequently a wider portion of the clay deforms. This is visible by the surface deformation and ‘bulging’ of the clay horizon. When two layers of reinforcement are included, the effect is enhanced, as the sand is increasingly stiffened.

3.2 Load-Displacement

The load-displacement curves are presented in Fig. 10.3. At small displacements all three load-displacement gradients are almost identical, but with increased loading the reinforced curves differ in their relationship with the unreinforced curve. Both unreinforced and reinforced curves reach a load of approximately 0.8–0.9 kN, at approximately 1.5 mm displacement. Thereafter the reinforced gradients are much steeper than the unreinforced gradient. Both reinforced curves (1 and 2 geogrids) exceed a 2 kN load and stress of 40 kPa, when 15 mm displacement is achieved. At the same displacement the unreinforced test only reaches a load of 1.5 kN and a stress of 30 kPa. Similar load-displacement relationships exist for both the single and the double reinforcement conditions. However, the test with two geogrids installed, achieved an increase in vertical load-bearing capacity compared to the test with a single layer of geogrid reinforcement.

4 Conclusion

The addition of the geogrid reinforcement to sand under a wide platform load increases the vertical load-bearing capacity of the system. Furthermore, the addition of multiple layers of reinforcement further contributes to this increase in load-bearing capacity.

However, this resultant increase is only evident after a certain amount of vertical displacement, which is likely due to the reinforcement requiring a certain amount of strain in order to contribute to an increase in bearing capacity. The inclusion of geogrids changes the failure deformation of the clay layer. With no reinforcing present deformation is localised to the portion of clay directly beneath the footprint of the applied load from the platform. When reinforcement is included the applied load is spread and the sand beyond the platform contributes to the increase in load-bearing capacity, resulting in a wider portion of clay deforming.

References

Huang CC, Tatsuoka F (1990) Bearing capacity tests of reinforced horizontal sandy ground. Geotext Geomembr 9(1):51–81

Michalowski RL, Shi L (2003) Deformation patterns of reinforced foundation sand at failure. J Geotechn Geoenviron Eng 129(6):439–449

Moore L, Richter MV, Gilli A (2012). The use of wire mesh steel geogrids in South Africa. In: Proceedings of the 5th European geosynthetics congress, Valencia, Spain

Zannoni E, Freeman T, Richter MV (2012) Basal reinforcement over soft soil using high strength bonded geogrid at Agriport Maydon Wharf. Proceedings of the 5th European geosynthetics congress, Valencia, Spain

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this paper

Cite this paper

Jones, B.R., Van Rooy, J.L. (2014). Behaviour of a Thin Compressible Clay Horizon Under Geogrid Reinforced Sand with a Wide Platform Load. In: Lollino, G., Manconi, A., Locat, J., Huang, Y., Canals Artigas, M. (eds) Engineering Geology for Society and Territory – Volume 4. Springer, Cham. https://doi.org/10.1007/978-3-319-08660-6_10

Download citation

DOI: https://doi.org/10.1007/978-3-319-08660-6_10

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-08659-0

Online ISBN: 978-3-319-08660-6

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)