Abstract

This chapter gives an overview of the most popular methods for measurement of particle size and shape. It covers microscopy and image analysis, laser diffraction, dynamic light scattering and gravitational and centrifugal sedimentation. In view of its capability for measurements at high particulate concentrations, the ultrasound attenuation technique is also included. Moreover, measurement techniques for porosity, surface area and pore size distributions and zeta potential are examined. This chapter also contains sections on sampling and dispersion of dry powders, since either of the two often limits the accuracy of the measured data.

Particle size analysis is not an objective in itself,

it is a means to an end,

i.e. the application of such knowledge to

some manufacturing process or performance of some product.

H. Heywood [13].

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Dynamic Light Scattering

- Laser Diffraction

- Quality Aspect

- Concentrate Dispersion

- Diffusive Wave Spectroscopy

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

3.1 Introduction

Performance and quality of particulate products depend upon specific characteristics of the particles, viz. size distribution parameters, shape, surface area and/or – for suspensions – zeta-potential. Adequate definition and measurement of the relevant characteristics is essential for good quality control of the products. Note that particles may include any difference in phase between the ‘particles’ and their surroundings. In addition to the particle characteristics in dry powders and suspensions, are those in emulsions (liquid droplets in an immiscible liquid) and foams (gas bubbles in a liquid or solid material) that may all be subjects for measurement.

Given the importance of a large variety of particulate products and the wide range of particle sizes, many different techniques have been developed for size measurement. A selection is presented in Sect. 3.4; a full overview is presented in an earlier book [31]. All of the techniques interpret some size-related feature of the particles as an equivalent particle size. This may be, for example, the diameter of a particle’s projection, the size related to its sedimentation rate or an interpretation of the scattering signature of a group of particles. Thus, a series of ‘equivalent’ sizes exists in practice for non-spherical particles (see Sect. 3.4.1) [31]. This means that the ‘equivalent’ size distributions derived by different techniques may deviate from one another.

Moreover, the amounts of particles in the basis of the size distribution may be different. For example, microscopy yields size distribution results by counting the number of particles of specific measured sizes. This gives a number-basis for the size distribution. In other techniques, like laser diffraction, sedimentation and sieving, distributions have a more or less volumetric (or mass) basis. Since different techniques measure PSD’s from a different point of view (principle), it can also be concluded that they may supplement each others information for a collection of particles. In this way, data sets can be strengthened.

For spheres, the mathematical conversion of a number-based PSD into one based on e.g. area or volume, and vice versa, is straightforward since their area and volume relate to the diameter squared and cubed, respectively. For particles having another shape, however, the situation is different. Their size is derived from equivalent spheres, the diameter of which depends upon the principle used for measurement. Thus, a measured PSD offers only one aspect of reality and different techniques may lead to different PSDs.

Also the basis of the measurement is important, since measurement errors are transferred in the conversion in a relative manner. This causes, for example, the amount of the smallest particles in a broad PSD to be identified at better precision on a number-basis than on a volume-basis, since large particle numbers only take a relatively small volume.

At the upper end of broad PSDs, relatively small particle numbers represent a significant mass/volume (see below). Here, number statistics relate the precision of the measured PSD parameters to the minimum sample mass. In practice, the sample mass applied for the analysis often limits the overall precision of parameters at the upper PSD end.

The particle sizes of particulate products can cover many orders of magnitude. At the small size end, they may be in the nanometer range. At the upper end, they go up to centimeters. Also the width of the size distributions differs. Industrial products usually show a medium or broad distribution; few particulate materials have a narrow or ultra-narrow size distribution.

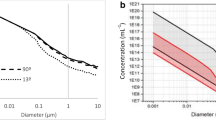

Size distributions are often shown in a graphical manner that can take different forms. Most often, differential or cumulative curves are used [16, 31]. An example of a cumulative undersize particle size distribution is presented in Fig. 3.1, in the form of a number-based and a volume-based distribution. It presents a log-normal size distribution of spheres having a geometric standard deviation s g = 2 and ln(s g ) = 0.693 around a mean size of 0.2 μm by number. Due to the width of this PSD example, there are large differences between both distribution types.

These cumulative size distributions allow easy estimation of percentile parameters such as the D 10 (10 % undersize), the median (D 50 at 50 %) and the D 90 (90 % undersize), as well as the undersize or oversize fraction at a given size. Some number-based percentile features of this PSD are median diameter D 50;0 = 0.20 μm, D 10;0 = 0.08 μm, D 90;0 = 0.49 μm and D 90;0 /D 10;0 = 5.9. More than 98 % n/n of the particles is smaller than 1 μm. Some volume-based characteristic features of this distribution are median diameter D 50;3 = 0.78 μm, D 10;3 = 0.33 μm, D 90;3 = 1.55 μm and D 90;3 /D 10;3 = 4.7.Footnote 1 Note that the D90 and the D10 in a normal Gaussian distribution are separated by about 2.6 times the standard deviation of that distribution.

The differences between the two types of distributions are obvious. For example, the D50;3 is about 4 times larger than the D50;0. Moreover, only about 2 % v/v is smaller than the D50;0; as much as 34 % v/v is larger than the D99;0 and only 0.05 % n/n corresponds to the largest 5 % v/v (i.e. is larger than the D95;3). These differences illustrate the need to be on your guard when reviewing particle size distribution data. Note that narrower distributions mean closer proximity between the two distribution types and vice versa.

A comparison of differential and cumulative curves is presented in Fig. 3.2. These figures show that resolution and sensitivity in terms of bimodality or shoulders are more easily identified in differential distribution curves than in cumulative ones. The cases shown have a fairly narrow overall size range of about 2:1. Here, the high resolution required for showing details is only possible with high-resolution techniques such as Electrical Sensing Zone, Image Analysis and Line-Start Disc Centrifuge.

Commercial products typically have a much broader size range, typically up to about 10:1 and they are analyzed by medium-resolution techniques, such as Laser Diffraction, Sieving and Ultrasound Attenuation. Also in these lower-resolution cases, differential curves show relatively more details than the cumulative curves. Note, however, that the measurement technique may introduce artefacts (e.g. broadening of the distribution or shoulders).

Fineness of particles and width of particle size distributions are defined differently in different fields of application. In the opinion of the author, it seems best to standardize [31]:

Fineness (D90;0): | PSD width (D90/D10 ratio)Footnote 2: | ||

|---|---|---|---|

Nanoparticles | < 0.1 μm | Monosized | < 1.02 (ideally: 1.00) |

Ultrafine | 0.1–1 μm | Ultra narrow | 1.02–1.05 |

Fine | 1–10 μm | Narrow | 1.05–1.5 |

Medium | 10–1,000 μm | Medium | 1.5–4 |

Coarse | 1–10 mm | Broad | 4–10 |

Very coarse | > 10 mm | Very broad | > 10 |

Adequate determination of PSD’s in relation to product quality requires six basic elements, viz. stated quantitative analysis criteria, good sampling, good dispersion/dilution of the measurement sample, well-trained analysts, good instrumentation and complete reporting of the measurement results [31].

The analysis criteria relate stated parameters of the PSD or particle shape or surface area to stated aspects of the product performance. This is often necessary to assist consistent production or adequate quality for the ultimate product, in a quantitative manner. This means that product performance characteristics have been translated into measurable parameters with a stated precision (repeatability, reproducibility) and resolution.

Inadequate sampling often limits the quality of characterization of a batch of product. Good sampling requires a measurement sample that is representative for the total batch of product and contains sufficient particles for measuring the most critical parameter (e.g. largest size or few deviating particle shapes) at the desired precision (see further Sect. 3.2).

Good dispersion/dilution requires that the measured state of the particles agrees with the goals for measurement. Here, the dry powder dispersion must be distinguished from the dilution of concentrated dispersions. In the analysis of dispersed dry powders, the emphasis often lies in the PSD of the primary particles. For concentrated dispersions, the goal is to characterize the state of dispersion. Effective dispersion should not introduce a change of state and adequate care should be given that this goal is fully realized (see further Sect. 3.3).

Analysts who perform the measurements should be well trained. This means that they have been proven to be capable to perform the measurements, including laboratory sampling and dispersion/dilution, at the required quality and working according to written procedures. Furthermore, they should be capable to signal any deviation from the normal situation while doing this. Their qualification should be regularly tested and approved. Testing of analysts can be carried out with typical in-house products that have PSD parameters of known quality. Well characterized in-house products can be employed for comparative measurements to test for consistent results. Certified reference materials should be used for fundamental accuracy determinations of both apparatus and analysts.

Measurement techniques should be chosen that fulfill the quality requirements. The first quality requirement is for sufficient repeatability and reproducibility (precision), but also accuracy, resolution and sensitivity for discrimination between good and poor products is often important (see further Sect. 3.4).

Good reporting of measurement results means that it is done in accordance with given instructions, preferably in the form of a standard analysis sheet. Often, a short report gives only few basic measured parameters necessary for process or product control purposes. Extensive reports are useful in research and to investigate problems or unexpected results. All data should be stored in a computer memory or logbook that also contains data on instrument testing/qualification and that is accessible with authorization to both measurement personnel and users of the data. Minimum report requirements are: sample date and ID; analyst ID and date; instrument ID; measured characteristic values for size, shape and/or surface area plus their range for acceptance and potential analyst remarks on signaled deviations from normal. Maximum report contents are in addition to the above data: all measured values; sampling conditions; dispersion conditions; settings of both instrument and product parameters (e.g. RI, density) and sample concentration during measurement.

3.2 Sampling

A representative test sample is required for obtaining analysis results that are representative for the corresponding batch of product. The primary lessons for sampling are to always take a sample from a moving stream and to always take the sample from the full width of the moving stream. This ideal state is not always possible. For representative sampling of dry powders, it is usually necessary to take samples at different spots from any heaps or stock piles and/or at different times during product transport. The assembled sub-samples should be mixed carefully and then subdivided in an adequate laboratory riffler to obtain the test sample. For representative sampling of liquid dispersions, it is usually sufficient to mix them well and take the sample from the mixture whilst it is moving, thus preventing or at least limiting sedimentation or other types of systematic deviation (bias).

A fully representative sample of sufficient quantity is required for effective measurement. Only with such a representative sample can the properties of the particles in the sample be said to be characteristic of the full product. This sets two requirements to the sampling procedure of particulate products [31]:

-

(a).

The product shall be randomly sampled, or the samples or sample increments shall be collected over the full volume of the lot of product in order to account for potential segregation (related to the ‘segregation error’) and to give each particle the same chance of being sampled according to its proportion of occurrence.

-

(b).

The number of particles in the sample or sample increment shall be large enough for the precision required for the measured parameter (related to the ‘fundamental error’, which depends on number statistics).

Ad a: Fully random sampling of particles from a lot is virtually impossible. Neither is it possible to estimate the degree of segregation by a theoretical approach; only empirical estimation is possible. Therefore, the usual procedure is:

-

1.

To collect and analyze samples of sufficient amount (in view of fundamental error) from different locations in the lot (or at different times during product transport or from the production process). The resulting set of measurements can be used to calculate the degree of segregation from the result variations.

-

2.

To estimate the number of different locations (or times) required for the desired precision in view of occurring segregation.

-

3.

To use samples from those locations (or times) as sample increments to be combined into a collective sample. (Note that the collective sample may be further split up in the laboratory to form the test sample).

The segregation error (degree of segregation) can be approximated by the overall error provided that the segregation error is significantly greater than the fundamental error and the errors from dispersion and measurement are relatively insignificant. This overall error can be calculated for any parameter y from size measurements of N different samples through:

where:

-

s y = standard deviation of parameter y (overall)

-

y i = i-th measurement of y

-

<y> = mean measurement result for y

-

N = number of different samples taken for analysis of y

These calculations enable estimation of the minimum number of samples or sample increments to reach a defined standard deviation for any parameter of a size distribution.

Ad b: The minimum number of particles in a sample to reach a stated precision for a given characteristic PSD parameter can be calculated on the basis of number statistics. Large numbers of particles are required for high precision. Useful equations for this purpose in case of quasi-two-component mixtures arise from binomial statistics:

or from Poisson statistics:

where:

-

s p = standard deviation of p

-

p = number based proportion of particles in one of the two components of the mixture

-

1-p = number based proportion of particles in the other component of the mixture

-

s n = standard deviation of < n>

-

<n > = mean number of particles measured in a size class

Note that the uncertainty in the number fraction of particles is calculated above. It has to be divided by the slope of the size distribution at the corresponding point for calculation of the uncertainty in the corresponding size parameter.

The above calculations give the minimum sample size for reaching a defined standard deviation for any parameter of the size distribution. It holds for ideal, random mixtures or for ideal, fully random sampling.

For further information and some examples, reference is made to [20, 31]. The latter also gives information on sampling methods and devices.

3.3 Dispersion

Most solid particulate ingredients consist in the form of dry powders. Examples are cement, pigments, sand, sugar, ceramics and pharmaceutical powders. For measurement of their particle size distribution, the particles should present as individuals, i.e. they should be adequately dispersed. Sometimes, dry powders are dispersed in air. Such dry dispersion of powders is typically only feasible if the particles are larger than about 10 μm. Below this size, bonding in agglomerates is often too strong. The advantage of dry dispersion is that no liquid is necessary in which the particles can dissolve or swell.

Most often, however, dispersions in a liquid are prepared which can be diluted to the required particulate concentration for analysis. To achieve the desired dispersion an adequate liquid (zero solubility or swelling for the solid), a suitable dispersing agent (adequate wetting of the solid and stabilization of the suspension) and adequate dispersion energy (to break-up agglomerates) are all necessary. The advantage of liquid dispersions is that they allow much easier confirmation that the required state of dispersion has been achieved. For visual confirmation, e.g. a microscope may be used.

The general goals of dispersion are [5, 14, 21, 31, 32]:

-

The particles should be contained in the final dispersion as individual entities (‘primary particles’), i.e. free of agglomerates, aggregates and flocs

-

The individual primary particles should not undergo a change of size – by breakage, dissolution or swelling – during the dispersion or dilution process

-

The particulate concentration should be adequate for measurement

-

The dispersion state should not change during analysis or testing.

There are two fundamental steps for adequate dispersion of dry powders into a liquid, viz.:

-

Wetting of the solid particles by the liquid and displacement of present air. This requires a liquid of suitable, low surface tension, either or not by the addition of a surface-active agent (surfactant)

-

De-agglomeration of particle clusters through application of energy to the suspension by stirring, shaking or sonication.

Wetting of the surface of solid particles is the first step in their dispersion. The driving force for wetting is the difference in surface tension between the solid-vapor interface (γ SV ) and the solid–liquid interface (γ SL ). The resisting force is the energy required for increasing the surface area of the liquid drop. The balance between these forces is represented by the equation of Young-Dupré:

Adequate wetting is only possible if the contact angle Θ between solid and liquid is smaller than 90° (cos Θ > 0) and the driving force (γ SV – γ SL ) approaches γ LV . Compare, for example, water droplets on cars that are nicely waxed with the wet surface in the absence of the wax.

After wetting, much less energy is required for de-agglomeration.

The ability of liquids to wet the particles is dictated by their surface tension, which must be smaller than that of the solid. Adequate wetting properties of a liquid are shown by a low contact angle between solid and liquid. Dispersions of poor quality often show low stability with time, where e.g. a sediment layer or floating particle clusters can be seen by the eye. For clusters of small particles, microscopic examination may be necessary.

Most industrial liquid based particulate products are concentrated dispersions, either during processing and/or as end product. However, very few techniques are capable of measuring concentrated dispersions. Therefore, most product dispersions are diluted before measurement of their particle size distribution. Particle characteristics should not alter during dilution. Note that most industrial emulsions and suspensions contain emulsifiers and/or stabilizers for adequate performance. Such particle dispersions lose their stability upon dilution with mere solvent, and flocs and/or agglomerates are formed. Supplementing these stabilizing components during dilution is, therefore, essential but no guarantee of avoiding flocculation and agglomeration.

More dispersion background is provided in the references [5, 14, 21, 31, 32].

3.4 Overview of Most Popular Techniques for Size Measurement

3.4.1 Introduction

The measurement techniques for particle size distributions (PSD) show two basic differences:

-

(a).

The principle that is employed for measurement

-

(b).

The way of quantification of the relative amounts of particles of given sizes.

Many different principles are used for size measurement, which can be grouped into fingerprint techniques, separation techniques and particle-ensemble techniques.

In the fingerprint techniques, each individual particle provides a size related to a signal that comes from some kind of detection forming a ‘fingerprint’. The numbers obtained from these signals are classified into size classes, often after a process of calibration. Examples are microscopy and image analysis.

In the separation techniques, particles of different size are physically separated. The size fractions are quantified e.g. by weighing or extinction of electromagnetic radiation. Examples are sieving and sedimentation techniques.

In the particle-ensemble techniques, a set of signals arising from an ensemble of particles is mathematically converted to a best-fitting size distribution, using some kind of model for particle behavior. In the ensemble method both size and quantity information are derived from the same set of signals. Examples are dynamic light scattering and laser diffraction.

All techniques should yield, in principle, the same results for ensembles of spherical particles. For non-spherical particles, equivalent sizes are obtained, however the sizes reported depend upon the principle used for the determination. Note that all techniques, except microscopy, assume in their modelling that all particles have the same physical properties, e.g. density or refractive index.

Some examples of equivalent sizes are:

-

Equivalent projected area diameter, i.e. diameter of a circle with the same area as the particle

-

Equivalent settling diameter (or Stokes’ diameter), i.e. diameter of a sphere with the same settling rate as the particle

-

Equivalent sieve diameter, i.e. diameter of a particle with the same size as the sieve opening

-

Equivalent surface area diameter, i.e. diameter of a sphere with the same surface area as the particle

-

Equivalent volume diameter, i.e. diameter of a sphere with the same volume as the particle

Aerodynamic (for aerosols) and hydraulic particle size (for sediments) represent special types of Stokes’ diameter. Particle density for these cases is assumed to be 1,000 and 2,650 kg/m3, respectively. These standard values are useful for settling of particle mixtures that have unknown or different densities. If the test sample density is different from the standard value then the size distribution is only a relative guide.

Note that aerodynamic sizes are, sometimes, calculated from other equivalent sizes than from the Stokes’ diameter.

An overview of all particle size measurement techniques is given by Merkus [31]. In this chapter, only a summarized background is presented on some modern and popular techniques, of microscopy/image analysis, laser diffraction, dynamic light scattering (DLS), sedimentation and ultrasound attenuation. More detailed information and information on other techniques is given in the same book [31]. Note that most techniques do not allow size distribution measurements in concentrated dispersions, although DLS may provide some ‘structural’ information. If PSD information is required in such dispersions, e.g. if dilution results in changes of the distribution, then only sieving and currently less popular techniques such as nuclear magnetic resonance, small angle X-ray scattering and ultrasound attenuation can be used.

3.4.2 Microscopy and Image Analysis

3.4.2.1 Microscopy

Microscopy allows the direct inspection of individual particles. It provides not only information on particle size but also on particle shape. The size scale is calibrated by means of suitable reference scales or materials; the quantity information is gathered by counting the particles in relation to size. Digital image analysis is used for size analysis (see section “Image Analysis”), but direct measurement by an operator is also carried out. The experience and quality of training of the operator are important. In the following section only optical microscopy and electron microscopy are described.

Optical microscopy of resting particles is most commonly used. It uses visible light and a lens system for magnification of the particles image. Maximum magnification is about 1,500 times. Such high magnification can only be achieved using the oil immersion method. Particles can be visualized at sizes larger than about 0.3 μm; quantitative size measurement is possible from about 3 μm onwards. For quantification, both manual procedures and image analysis can be used. Information about fine structure of particle shape requires larger particles, as the ability to recognize fine structure depends on the number of picture points available at the particle’s contour. In ‘manual’ procedures for shape recognition, usually reference shapes are used for comparison.

Optical microscopy can also be used for moving particles, e.g. in a process stream. This is becoming increasingly popular as it provides direct process information. Measurement periods should then be short in comparison to the particle velocity in the stream in order to get sharp pictures (e.g. through using flash illumination and/or short shutter times). Moreover, concentration should be low to avoid overlapping of particles in the image. In this application, maximum magnification is about 5-fold lower than in the static case.

For static images requiring large magnification, scanning or transmission electron microscopy (SEM or TEM) is used, with or without image analysis. SEM allows magnifications up to about 100,000 times, TEM up to about 1,000,000. In electron microscopy, electron beams (wavelength about 0.04 nm) are used instead of light and electromagnetic lenses instead of optical ones. The technique requires substantial particle preparation involving vacuum deposition of a gold coating and depositing onto a suitable filter or grid.

3.4.2.2 Summary of Quality Aspects

An advantage of optical microscopy is that it allows a quick impression of particle size range, particle shape, and particle dispersion quality. This method also enables images to be recorded for further inspection and later reference.

Type of information. Typically, a number-based size distribution is obtained of equivalent area diameters or linear size parameters, related to the images shown. Shape information can be obtained as well.

Sample type. The measurements can be performed in emulsions, powders, suspensions and dry particles on a surface. The only requirement is that the refractive index of the particles differs from that of the surrounding medium.

The overall size range of optical microscopy is about 0.3–500 μm. In the range 0.3–3 μm only qualitative or semi-quantitative inspections are possible. For SEM the size range is about 10 nm–500 μm, for TEM about 1 nm–5 μm. At a single magnification, the range for quantitative measurement is about a factor 30 between the largest and the smallest particle.

The typical particle number per image for quantitative measurement is about 5–50. The number is limited by the requirement that individual particles should not show a significant degree of overlap and have a sufficient magnification. For qualitative inspection, the number per image may be greater. For measurement of size distributions, large numbers of particles – i.e. many images – have to be analyzed in view of repeatability.

The measurement time is typically about 1 min to several hours. It depends on whether qualitative or quantitative information is required and which quality is required for that information.

The repeatability of size measurement on a single particle is about 0.5–2 %. This precision requires adequate magnification to provide a suitable number of image pixel elements for the smallest particle and good operator performance [40]. For size distributions, repeatability also depends on the number of particles counted; reasonable precision requires sizing of (often many) thousands of particles governed by the range of particle sizes within the distribution.

Good accuracy and absence of bias strongly depend upon proper calibration of the magnification and upon proper focusing for sharp images. Overlap of particles may also lead to bias, if the combination is taken as a single particle. Finally, dirty lenses and insufficient contrast between particles and background together with lack of uniform illumination of the background, may cause biased results.

Resolution of microscopic measurement can be high, provided that large particle images are available created by a significant number of pixels.

Sensitivity. Particles that deviate from the typical population can be fairly easily recognized. Quantitative interpretation of such quality requires an experienced operator.

The traceability of microscope techniques is good, since it is very direct and certified standards for calibration are available.

On-/in-line capability. Most applications are off-line. On- and in-line application of optical microscopy is feasible with special equipment. In-line measurement is only possible for product streams, which have a low particulate concentration.

Note that non-representative sampling is often a major error source. One advantage is that optical microscopy can show the presence of agglomerates due to inadequate dispersion.

3.4.2.3 Image Analysis

Image analysis can be understood to mean two different things. In its basic form, it is a subjective, qualitative description of images by an observer, with or without comparison with standard images. The quality of results strongly depends on the experience and quality of the observer. In the early days of microscopy, a.o. Van Leeuwenhoek (1632–1723) reported on his objects by describing what he saw. Especially when standard references are used, this approach is still fast and powerful but only a limited number of particles are generally observed. Nowadays, it usually requires digital analysis of images by computer software. For very small particles, the images are usually produced after magnification in a microscope (optical, SEM, TEM). After threshold detection, digitization and restoration, the images are processed according to some code and algorithms employed to yield size and shape information. The quality of results depends strongly on the degree of magnification (i.e. the number of pixels per particle image [40]), the quality of the image (especially contrast and uniformity), the number of images included and the quality of the algorithms.

3.4.2.4 Summary of Quality Aspects

Type of information. A number-based size distribution is obtained of equivalent area diameters or linear size parameters, related to the particle images shown. Shape information can be obtained from the images as well, often as a ratio of linear size parameters.

Sample type. The measurements can be carried out in any images coming from emulsions, suspensions and – with limitations – aerosols.

The overall size range of quantitative image analysis is determined by the microscope technique used for magnification of the particle images.

The typical particle number per image for quantitative measurement is about 5–50. The number is limited by the requirement that individual particles should not show a significant degree of overlap as well as have a sufficient magnification. Thus, the statistical significance of size distribution results can only be obtained by measurement of a large number of images.

The measurement time is typically about 1–60 min. It strongly depends on the degree of automation for change of image fields.

The repeatability of size measurement on a single particle can be about 0.5–2 %. For this precision, adequate magnification is required. Typically, area-based size has better precision than linear size. For size distributions, repeatability also depends on the number of particles counted; reasonable precision requires sizing of thousands of particles.

Good accuracy and absence of bias strongly depend upon proper calibration and segmentation and upon the creation of sharp images. Overlap of particles may also lead to bias, if segmentation is insufficient and the combination is taken as a single particle.

Resolution and sensitivity of image analysis results depend strongly on the number of pixels in the particle images and on the number of particles measured.

The traceability of image analysis in combination with a microscope is good, since certified standards for calibration are available.

On-/in-line capability. Measurements can be done off-line, on-line and in-line, provided that sharp images of good quality are available.

3.4.3 Laser Diffraction

The laser diffraction technique uses a monochromatic light source, typically a laser, to illuminate a flowing collection of particles, either dispersed in air or in a transparent liquid within a specified concentration range. The angular light scattering pattern is measured by a series of light sensitive detector elements in forward and backward directions. This pattern is converted to a PSD by means of some optical model for light scattering of (usually spherical) particles. Various optical models can be chosen. The model based on the Mie theory which is exact for all sizes of spherical particle is most often used. Its application requires information on the real and the imaginary part of the refractive index of both particles and dispersion medium. The model based on Fraunhofer diffraction theory, is often used for larger and/or opaque particles. The Fraunhofer approximation does not require information on the refractive index. The technique can be used in the laboratory as well as in processes, provided that the particle concentration is neither too high nor too low. Above the maximum concentration allowed, multiple scattering occurs that yields biased size distributions. At too low concentrations, signal to noise ratio becomes too small. Note that, with some assumptions, some macroshape information may be obtained [7, 28, 29, 31].

3.4.3.1 Summary of Quality Aspects

Type of PSD information. A volume-based size distribution is obtained of diameters of spheres that show the same scattering pattern.

Sample type. The measurements can be implemented for emulsions, suspensions (in both air and liquid), sprays and aerosols.

The overall size range for laser diffraction instruments is about 0.1–10,000 μm. Per measurement the dynamic range is usually about a factor 1,000.

The typical concentration range is about 0.001–1 % v/v (5–30 % optical concentration). It depends on particle size.

The measurement time ranges from about 0.01 to 30 s.

The repeatability of laser diffraction results can be excellent (about 0.5 % relative), provided that representative samples are being analyzed in sufficient quantities and after adequate dispersion. Poor repeatability is often caused by the use of non-representative or poorly dispersed samples.

Biased results – for non-spherical particles meaning results that deviate systematically from standard results – may be caused by sub-standard use of this method, due to application of inadequate optical models, to input of incorrect refractive index parameters, to drifted detector sensitivity (fully eliminated in current apparatus) or to application of too high particulate concentrations. It is essential to describe the input data in operating procedures and to qualify the instrument and operator performance through regular measurement of a reference material, for which adequate data is available. Note that particle shape has a significant influence upon the reported particle size, since spheres are assumed in the models.

The resolution of the technique is usually medium. Size differences of about 10–40 % are typically taken for the limits of the size classes. This resolution may be improved to some extent in special cases with special hardware and software as it depends upon the size and number of detector elements and the degree of smoothing applied in the deconvolution procedure. The standard size classes are satisfactory for most applications.

The sensitivity of laser diffraction is satisfactory to medium (better than about 5 % m/m).

Traceability. Laser diffraction is a first principles technique but due to the additional uncertainty and errors induced by dispersion, sampling, material properties and operator parameter choices calibration is necessary to ensure traceability.

On-/in-line capability. Off-line as well as on- and in-line application is feasible. In-line measurement is possible for product streams, which have a suitable (low to medium) particulate concentration in a transparent medium.

3.4.4 Dynamic Light Scattering(DLS) or Photon Correlation Spectroscopy (PCS)

As in laser diffraction, an ensemble of particles, dispersed in a transparent liquid, scatters light from a laser beam. In DLS the variation of the scattered light intensity with time, at some defined angle, is measured.Footnote 3 The rate of change of this intensity is related to the diffusion coefficient of the particles, which in turn is related to hydrodynamic particle size by the Stokes-Einstein equation (see also Chap. 2).

where:

-

= diffusion coefficient

= diffusion coefficient -

k B = Boltzmann constant

-

T = absolute temperature

-

η L = liquid viscosity

-

D h = (apparent) hydrodynamic particle size

Several mathematical methods are used for conversion of the intensity-time relationship to a PSD. Signal processing can be carried out either with a digital Correlator or by Spectrum analysis. From either of the signal processors a further mathematical conversion is required. Such data is regarded as ill-conditioned and has a poor signal-to-noise ratio which limits the amount of PSD information that can be obtained. Usually, the polynomial ‘cumulants’ method is favored for data analysis. It leads to a mean size and a value for PSD width. Other methods claim to lead to a PSD, but often results are not stable.

There are two versions for measurement. The conventional technique operates usually at a fixed angle of 90°, or another specified angle, at very low concentration. New techniques, such as fiber-optics quasi-elastic light scattering (FOQELS) and diffusive wave spectroscopy, use back-scattered light and may operate at higher concentration. At higher concentrations particle-particle interactions often influence the particle movement and, thus, the sizing result. However, a correlation with product quality may be found provided that the particulate concentration is kept constant.

A variant of the technique can also be used for measurement of the zeta-potential (see Sect. 3.7).

3.4.4.1 Summary of Quality Aspects

Type of PSD information. Typically, a size distribution is obtained for diffusion coefficient related diameters, for which the quantity axis relates to scattered light intensity. For particles less than 100 nm scattering intensity reduces as the 6th power of particle diameter. In liquid dispersions, these hydrodynamic diameters may be (slightly) larger than the actual particle size as they include a layer of attached ions often needed to stabilize the dispersion. This additional layer of ions is described as the Stern layer [31].

Note: The extended layer caused by the attached ions increases the surface drag of the particle causing it to diffuse more slowly which is then reported by DLS as a larger hydrodynamic particle size.

Sample type. The measurements can be executed as emulsions, lipids, colloids and suspensions and – with substantial limitations – to aerosols.

The overall size range of the technique in liquids is about 0.005–1 μm. The lower size limit depends upon the intensity of the illuminating light source since the scattered light intensity for very small particles drops with the 6th power of particle size. It also depends upon the difference in the refractive index of the test sample particles compared with the suspending liquid. The upper size limit depends upon the density of the test material, i.e. the onset of sedimentation, together with the low number of large particles with their attendant long diffusion times. These combined influences may result in a practical upper size limit being well below 1 μm. Best results are obtained for fairly narrow size distributions.

The typical concentration range for measurement is around 10−2–10−3 % v/v. In FOQELS and diffusive wave spectroscopy, higher concentrations may be used. Then, the resulting ‘size’ is dependent on particle-particle interactions.

The typical measurement time is about 0.1–5 min.

The repeatability of the mean DLS diameter is very good if the cumulants procedure is applied, viz. better than about 2 % relative. Repeatability of the polydispersity index is typically poor, viz. about 20 % relative. Precision, due to the intensity weighting, remains limited in general and quite variable if other information extraction procedures are used for obtaining size distributions.

The bias of the mean intensity weighted DLS diameter obtained in the cumulants procedure is, at optimum conditions, less than about 2 % relative. Note that bias is to be interpreted for non-spherical particles as systematic deviation from standard results by this technique. However, DLS is vulnerable to distortions and artefacts caused by applying different de-convolution procedures, increased particulate concentrations (due to particle-particle interactions and multiple scattering), too low concentrations (due to fluctuations of the number of particles in the measurement zone) and presence of one or few relatively large particles (‘dust’) or air bubbles. Validation of results is recommended at regular time intervals and whenever it seems necessary. It can ensure proper functioning of the instrument as well as competence of the operator.

The resolution of the technique is low. The cumulants procedure only delivers a mean DLS diameter together with a polydispersity index for PSD width. Special mathematical procedures such as CONTIN and MEM claim that they are capable to extract more PSD information. The results, however, have low resolution and are very sensitive to noise.

Sensitivity for small changes in the PSD is very poor due to the limited resolution. In fact, changes can usually only be identified through changes in the mean size or the polydispersity index.

Traceability of the DLS technique is good, since first principles are applied. Of course, this only holds within the limits of proper application.

On-/in-line capability. Off-line measurement is preferred, since any flow influences the diffusion. Stop-flow on-line measurement is only possible, if this is not the case. Furthermore, on-line measurement requires a product stream, which has a (very) low particulate concentration. Note that relative product performance parameters may be extracted at high concentrations, if the concentration is kept constant.

3.4.5 Ultrasound Attenuation

In this technique, the attenuation of ultrasound and/or retardation of ultrasound velocity by an ensemble of particles suspended in a liquid is measured at a series of frequencies. Similar to laser diffraction, the measured pattern is then converted to a PSD by a mathematical deconvolution through the use of a matrix that contains attenuation patterns per unit volume of particles in defined size classes. This matrix is either calculated from a theoretical model or obtained in an empirical way from measurements of known size fractions of the same material. In order to construct the model-based matrix, various properties of both particulate phase and dispersion medium have to be known. These relate to thermodynamic, mechanical and transport behavior. These models are sometimes simplified through an assumption of some kind of model size distribution (e.g., normal or log-normal). At increased concentration, particle–particle interactions and overlap of acoustical fields of different particles may become significant in relation to attenuation (depending on material properties). In such cases adaptation of the model is required to compensate for these effects, or specific parts of the ultrasound attenuation spectrum is used (in case of process control).

A new instrument operates as a particle counter. A single transducer is used as transmitter and receiver. Signals are classified by their amplitude and then converted to particle size.

3.4.5.1 Summary of Quality Aspects

Type of PSD information. A volume-based size distribution is obtained modeled upon spherical particles that shows the same ultrasound attenuation pattern.

Sample type . The measurements can be performed in emulsions and suspensions.

The overall size range for ultrasound attenuation is about 0.01–3,000 μm. This range can often be met without changing the instrument. The range of frequencies covered by an instrument determines the measurement range.

The typical concentration range is about 0.5–70 % (v/v). For the newly developed counting instrument it is about 1–1,000 ppmv.

The measurement time is about 1–10 min.

Repeatability of characteristic sizes in between D10 and D90 is typically within 3 % (coefficient of variation).

Bias of particle size distributions – for non-spherical particles meaning results that deviate systematically from standard results – may be caused by sub-standard use of this method. Typically, bias may be smaller than about 3 %. Application of inadequate models/model parameters in the matrix that relates extinction spectrum to PSD and particulate concentration or inaccurate calibration may lead to more severe bias. Regular qualification of instruments is recommended.

The resolution of the technique is low. Typically, particle size distributions are presented as log-normal distributions, i.e. as the mean size and the standard deviation of such distributions.

The sensitivity of the technique is, in relation to resolution, also low. Often, US attenuation at one or few specific frequencies is used for control purposes.

The direct traceability of sizing results is poor, due to the complex theory behind it and the deconvolution procedure. Both attenuation spectra and PSDs can be validated through use of appropriate reference materials at appropriate conditions.

On-/in-line capability. Measurements can be carried out off-line as well as on- and in-line. In-line measurement is possible for product streams, which have a medium to very high particulate concentration.

3.4.6 Gravitational and Centrifugal Sedimentation

Sedimentation is applied for particle sizing in suspensions within various types of instruments. The instruments differ, first in the force field that is applied for sedimentation, viz. gravity or a centrifugal field. A second difference is that either a line start or a homogenous start is applied. A third difference is the way of detection of particle quantity after size separation. All techniques require a known liquid viscosity, a constant temperature, absence of sources of vibration and knowledge of effective particle density.

A short overview of gravitational sedimentation and centrifugal sedimentation is given below.

3.4.6.1 Gravity Sedimentation

The terminal settling velocity of spherical particles in suspensions due to gravity is the basis for this technique. Viscous – creep flow conditions and dilute liquid dispersions are assumed (i.e. Reynolds number for settling particles < 0.25) and Stokes’ law is applied to convert this velocity to particle size (see also Chap. 2).

where:

-

v = terminal settling velocity of a particle

-

H s = settling height

-

t = time for settling over height H

-

ρ P = effective particle density

-

ρ L = liquid density

-

g = gravitational acceleration constant

-

D St = equivalent Stokes’ diameter of a particle

-

η L = liquid viscosity

Effective particle density must be known for this conversion (in addition to liquid viscosity and liquid density). The word ‘effective’ means that it takes into consideration the effects coming from gas or liquid present within potential closed and open pores of the particles, which decrease their true solid density. Its measurement should be described in a written procedure that guarantees both optimum dispersion and pore filling. ‘Hydraulic’ particle size assumes a particle density of 2,650 kg/m3. Generally, one starts with a homogenous suspension of particles. In the most simple (pipette) version of the technique, samples are taken at predefined times at a fixed or a variable height in the dispersion, and then dried and weighed. In the instrumental version, X-rays, visible light or a balance is used to obtain remaining particle mass concentration or settled mass reported against time.

3.4.6.2 Summary of Quality Aspects

Type of PSD information. A mass-based size distribution is obtained of Stokes’ diameters. Note that the method of detection may set limits to the mass determination.

Sample type. The measurements are executed in suspensions, in which there is sufficient (positive) density difference between particles and medium.

The overall size range for gravity sedimentation in aqueous suspension is about 0.3–200 μm. For particles larger than about 65 μm or smaller ones having a high density, more viscous liquids other than water must be used in order to sustain viscous-creep flow conditions. When a major part of the particles is smaller than about 1 μm, centrifugal sedimentation is recommended.

The typical concentration for gravity sedimentation is smaller than about 0.2 % v/v, in order to avoid particle-particle interactions.

The measurement time is about 0.5–8 h, depending on the rate of settling and operational conditions.

At optimum conditions of settling rate and particulate concentration, the repeatability (standard deviation) of the results is better than 1 % w/w at the same Stokes’ diameter. Precision of manual operations depends strongly on the skills of the operator.

Biased results are obtained when standard conditions are not met, e.g. if a too high concentration is used. Note that bias is to be interpreted for non-spherical particles as systematic deviation from standard results by this technique. At the lower size end, Brownian motion may shift the sizing results to lower sizes, since it counteracts sedimentation. Regular validation of both instrument and procedure with certified reference materials can expose this.

Size resolution is about 5–10 %; instrumental methods are better than manual ones.

The sensitivity of the technique for fractional mass is typically better than 2 % w/w. For sedimentation instruments it depends on the net extinction by the particles and the stability of the extinction signal.

Traceability of the technique is good, since first principles are applied and the total equipment can be calibrated and validated. Note that an equivalent sedimentation or Stokes’ diameter is obtained.

On-/in-line capability. Measurements can only be carried out off-line.

3.4.6.3 Centrifugal Sedimentation

Centrifugal sedimentation uses the centrifugal force for more rapid settling (within the Reynolds number limit) of the particles in a liquid than occurs under gravitational conditions.Footnote 4 It is recommended when a major part of the particle distribution is smaller than about 1 μm, where the influence of Brownian motion becomes significant in gravity sedimentation. Centrifuge speeds of 500–24,000 rpm are used, where smaller particles require higher speeds. Two types of instruments are used, viz. the disc centrifuge and the cuvette centrifuge. A line start is applied in the disc, a homogenous start in the cuvette. White or monochromatic light or X-rays are used for detection of particle concentration against time at a given position. Here, an adapted Stokes’ law is applied for conversion of settling rate to particle size.

where:

-

D St = equivalent Stokes’ (hydrodynamic) particle diameter

-

η L = liquid viscosity

-

R d = distance between detector and center of rotation

-

R i = distance between injected sample layer and center of rotation

-

ρ P = effective particle density

-

ρ L = liquid density

-

ω = angular velocity of centrifuge (2π N c /60), radians/s

-

t = sedimentation time

-

N c = centrifuge speed, rpm

3.4.6.4 Summary of Quality Aspects

Type of PSD information. A mass-based size distribution is obtained of Stokes’ (hydrodynamic) diameters, which may include a layer of adsorbed dispersant molecules. The quantity axis depends on the technique of concentration measurement (light or X-rays).

Sample type. The measurements are carried out in suspensions, in which there is sufficient (positive) density difference between particles and medium.

The size range for centrifugal sedimentation in water is about 0.02–10 μm. This can only be met in a single analysis if the centrifuge speed is programmed with time.

The particulate concentration should be typically smaller than about 0.2 % v/v, in order to avoid particle-particle interactions.

The measurement time is about 10–20 min.

At optimum conditions the repeatability of results (standard deviation) is better than 1 % w/w at the same hydrodynamic diameter. Precision of manual operations depends strongly on the skills of the operator.

Biased results are obtained when analysis conditions systematically deviate from standard conditions. Note that bias is to be interpreted for non-spherical particles as systematic deviation from standard results by this technique. Regular validation of both instrument and procedure with certified reference materials can show this.

Resolution capability depends on the technique and conditions used. An optimum disc design allows a size resolution of about 5 %; the cuvette technique is slightly worse, about 10 %.

The sensitivity of the centrifugal sedimentation technique is usually better than 2 % w/w. It is worse for particles, which have a low extinction coefficient.

Traceability of the technique is good, since first principles are applied and the total equipment can be calibrated and the procedure validated.

On-/in- line capability. Measurements can only be carried out off-line.

3.5 Particle Shape and Its Measurement

3.5.1 Introduction

Besides particle size, particle shape may have a significant effect on the properties of a particulate product. This influence is sometimes dominant. This is, for example, the case for fibers, flakes and platelets in relation to flow, packing and scattering behavior.

Conceptually, particle shape is the pattern of all points on the boundary of a particle. Thus, it includes every aspect of external morphology of the particle and consequently exhibits a wide variety of aspects. Three scales of shape can be discriminated: macroscale, mesoscale and microscale:

-

The macroscale is related to the general 3-dimensional form of particles, for example the ratio of their main three dimensions as used in aspect ratio, elongation and flakiness.

-

The mesoscale regards the general aspects of the roundness and angularity of the particle’s contour.

-

The microscale involves surface rugosity or smoothness as well as porosity and other structural heterogeneities.

-

An overview of shape characteristics and their measurement is given in [17, 31].

3.5.2 Shape Measurement

A qualitative or semi-quantitative description for particle shape on macroscale and mesoscale can be given through their evident properties on the eye. The US Pharmacopoeia [34] gives such descriptions for pharmaceutical particles; BS 2955 [6] provides similar descriptors (e.g. acicular/needle shape, angular, dendritic, plate, rod, rounded). These descriptions can be used to express an expectation of the behavior of powders and/or particles. For example, the flow behavior of a powder and the vulnerability of particles to breakage or attrition during processing. The usual procedure is to magnify a suitably dispersed set of particles and to compare the particle images by the eye, with a standard set of images. If this exercise is conducted manually, then it will be clear that good direct observation by the eye of many particles requires both experience and time.

A quantitative description for particle shape on the macro- and mesoscale arises after magnification by optical or electron microscopy, from image analysis (see Sect. 3.4.2). Note that large magnifications are required to reach sufficient accuracy for all parameters involved in the shape parameters [17].

The determination of parameters such as e.g. length, breadth, perimeter and contour angles is mostly used, which are then related to e.g. aspect ratio and angularity.

In the so-called R-theta method, the distance of the center of gravity of a particle’s projection to its contour is measured in many directions (i.e. over a large number of directions) [4, 27, 31]. In this way, the contour is ‘unrolled’. The results are then compared to a library of given shapes, or they are evaluated in a Fourier series:

where:

-

F(Θ) = Fourier function in polar coordinates; R/<R > as a function of angle Θ

-

Θ = (polar) angle for measurement of R

-

A 0 = mean radius < R>

-

A k = Fourier coefficients (harmonic amplitudes in shape function)

-

R = distance between center of gravity and contour of particle projection

-

<R > = mean value of R (radius of circle with the same area as the particle projection)

-

k = harmonic number in Fourier shape function

-

φ k = phase angle of the k-th harmonic

In this equation, the lower-order harmonics (lower frequencies) reflect the aspects of macroscopic shape, the higher-order elements surface angularity and rugosity. At increasing k, more detail of the contour is revealed (note that this is only possible if the number of measured data points is large).

Fractal analysis of the contour of the particle’s projection offers another method for shape determination. Different length scales λ are then used to evaluate the contour length (perimeter, P(λ)). In a given contour, decreasing length scales lead to increased perimeters, as they are capable of showing more and more detail of the fine structure, provided that a picture of high resolution is available [26, 31]. A straight line on a double-logarithmic plot of P(λ) against λ relates to a self-similar structure, whose slope is the so-called fractal dimension δ. Small values of δ relate to simple structures (e.g. linear shape in 2-dimensional images), large values to complex information.

Sometimes, shape information is derived from the ratio between sizing results coming from different techniques. For the so-called Waddell sphericity factor, shape is defined by the ratio of surface area of a sphere with the same volume as the particle, compared to the actual surface area. Shape information may also be derived from theoretical behavior, such as in measurement results from the angular scattering pattern in laser diffraction [7, 31, 39].

3.6 Porosity, Surface Area and Pore Size Distributions and Measurement

3.6.1 Introduction

Porosity, surface area and the pore size distribution are cardinal properties in the capacity and selectivity of particles for absorption, adsorption, catalysis and separation. These same properties may also affect the flow of dry powders. For solid products, large pores and inter-particle voids are often the instigator of cracking of the product.

3.6.2 Porosity and Measurement

3.6.2.1 Porosity of Dry Powder Beds

Rocks and powdered rock are similar in that they are both solids, but differ in the fact that the rock is typically in one piece but the powdered rock consists of many particles. In between these particles, empty spaces or voids exist. The porosity of dry powders in a bed or batch typically considers only the fraction of voids in between the particles. Thus, void fraction is easily derived from the difference between effective bulk density and particle density if the particles do not contain pores.

where:

-

ε = void fraction in powder bed (powder bed porosity)

-

V V = volume of voids

-

V B = volume of powder bed (=V P + V V )

-

V P = volume of particles in bed

-

ρ B = effective bulk density of powder bed

-

ρ e = envelope particle density (including all intra-particle pores)

-

M = mass of powder bed

Two types of powder bed porosity (powder bulk density) can be distinguished, viz. porosity of loose powder packing (usually measured under standardized conditions), and porosity after tapping until a constant volume is achieved.

Sometimes, the particles contain pores. For the proper calculation of the void fraction, the volume of all pores should be included in the envelope particle density. Note that the sizes of pores and voids may show overlap.

Note: Solid materials, e.g. concrete or pottery, often exhibit porosity that results from voids in between particles being created as they are formed. If the porosity is significant and the pores large, then cracks can be formed weakening the structure. These pores, if open, may be measured through mercury penetration or similar techniques (see section “Mercury Penetration Technique”).

3.6.2.2 Porosity of Particles

Porosity of particles may have different functions. If the pores are open and accessible, they can provide access to a large active surface area for e.g. catalytic reactions, ion exchange and adsorption. In other cases, pores may be closed and, thus, in-accessible. With closed pores the effective density will be (much) smaller than the true density of the material. This may result in e.g. light-weight materials with increased insulation properties.

3.6.2.3 Measurement of Void Volume and Total Pore Volume

The total volume of open pores and voids in a dry powder can be determined by titration with a non-viscous liquid that is capable of wetting the solid, e.g. water or ethanol for hydrophilic powders or linseed oil for pigments. Titration involves liquid being added dropwise to a known mass of powder in a small container, while mixing with a spatula [2, 3]. Initially, the open pores in the particles are filled and the powder’s appearance remains dry. As soon as all open pores are filled, the appearance changes into wet. This point represents the volume of the open pores. Continued addition of liquid fills the voids and the particles start forming small lumps. The titration end point occurs when the lumps have formed a single ‘ball’ and liquid start smearing the wall of the container. The volume of liquid used at that point is an indicator of the total pore volume.

The total volume of open pores and voids in a dry powder can also be derived from the measurement results of pore size distributions (see Sect. 3.6.4).

The presence and volume of in-accessible pores can only be determined by comparing the effective particle density with the true material density or by visual inspection or image analysis of cross-sections of particles or materials.

3.6.3 Surface Area and Measurement

The surface area of solid particles reflects both the external surface and the surface of the accessible pore walls. The external surface of solid, non-porous, spherical particles can be easily derived from its inverse relationship with their diameter:

where:

-

S = specific surface area (usually expressed in m2/g adsorbent)

-

D = particle diameter

-

ρ = true particle density

The total surface area of porous particles is often much larger than the external surface. It is usually measured by the gas adsorption method. In this method, the fraction of gas molecules adsorbed at the surface at constant temperature is determined at various relative gas pressures (adsorption isotherm). Most often, nitrogen or argon is used as the adsorptive at liquid nitrogen temperature (about – 196 °C). At some point on the isotherm, a complete monolayer of adsorbed molecules (adsorbate) is assumed to have formed. At this point the corresponding surface area is calculated from the amount of adsorbate together with the known cross-sectional area of the gas molecules adsorbed [1, 18, 30]. Typically, the BET equation (Brunauer-Emmett-Teller) is used for evaluation:

where:

-

P = actual pressure during measurement

-

P 0 = saturation pressure of adsorptive

-

V = volume of adsorbate at pressure P (usually expressed in mole, or cm3 at standard T and P)

-

V m = monolayer of adsorbate (usually expressed in mole, or cm3 at standard T and P)

-

C = constant (related to adsorbent-adsorbate interaction energy; dependent on type of porous material)

This Eq. 3.11 results for suitable materials in straight line plots of P/V(P 0 –P) against P/P 0 . The slope of this line is (C–1)/V m · C, with the intercept being 1/(V m · C). They are calculated by linear regression or determined graphically. The BET equation usually holds for type II and type IV isotherms and relative pressures P/P 0 of 0.05–0.35. Subsequently, V m is calculated from slope and intercept. and, the specific surface area S(BET) by using Avogadro’s number, the cross-sectional area of the adsorbate molecule and the amount of adsorbent used in the determination. If V m is expressed in moles, Eq. 3.12 can be used for the calculation:

where:

-

S(BET) = specific surface area according to the BET method (here in m2/g)

-

V m = monolayer of adsorbate (here in mole)

-

a m = cross-sectional area of adsorbate (e.g. for N2: 0.162 · 10−18 m2)

-

N A = Avogadro’s number (6.022 · 1023 mol−1)

-

M = mass of adsorbent (here in g)

For C-values much larger than 1, the BET plots can be assumed to go through the origin and single-point measurement may be done at a fixed relative pressure (P/P 0 usually about 0.3).

Microporous materials show very strong adsorption. They exhibit a Langmuir type of isotherm (type I), since the size of the pores restricts adsorption to one or a few layers of adsorbate.

Frequently volumetric methods are used for the determination of adsorption isotherms of gases. These are the same methods as used for pore size distributions (see Sect. 3.6.4).

The repeatability of surface area measurements is about 1 % relative ± 0.1 m2/g.

The BET method can only be used if some inflection point at complete monolayer coverage of the surface is visible in the adsorption isotherm, i.e. if there is adequate attraction between the surface of the adsorbent and the adsorptive. This is not the case if the C-value is near to 1 or negative. Neither is the method applicable in the case of micropores, where pore volume rather than monolayer coverage sets limits to the adsorption.

Complete ‘outgassing’ of the samples is essential for good results.

Various standard reference materials are available for validation of instruments and measurement results.

3.6.4 Pore Size Distribution and Measurement

Porous materials typically show a distribution of pore sizes. They are classified in three categories, viz. [37]:

-

Macropores, with pore diameters larger than 50 nm

-

Mesopores, with pore diameters in the range 2–50 nm

-

Micropores, with pore diameters smaller than 2 nm.

Pore size distributions are determined by either gas adsorption methods (section “Gas Adsorption Methods”) or mercury penetration (section “Mercury Penetration Technique”).

3.6.4.1 Gas Adsorption Methods

In the gas adsorption method, the fraction of gas molecules adsorbed at the surface at constant temperature is determined at various relative gas pressures in a so-called adsorption isotherm. Nitrogen and argon are most often used as adsorptive at liquid nitrogen temperature (about 77 K or – 196 ºC). The volumetric measurement method is most popular. Initially a known amount of sample is ‘outgassed’ (i.e. all adsorbed molecules and air removed) by high vacuum and/or elevated temperature and the dead space of the equipment filled with test sample determined (with the aid of a known volume of helium at known pressure). Starting again from vacuum, known volumes of adsorptive are added stepwise and the resulting pressure determined after adsorption equilibrium is attained, until saturation pressure and related full pore filling is reached. Subsequently, the desorption isotherm may be determined by gradual decrease of the pressure. Both the adsorption and the desorption isotherm can be used as the basis for calculation of pore size distributions. The choice depends on several factors, viz. the type of pore system, whether relatively small pores are the only entrance and exit for larger pores and the presence of a tensile strength effect. Often, the type of hysteresis loop provides information on the shape of the accessible pores. This data may also give an indication whether the adsorption or the desorption isotherm is to be preferred [12, 37]. Most often, cylindrical pores (or, in some specific cases, slit pores) are assumed at whose walls the adsorbate exists as a liquid layer. For these the Kelvin equation leads to calculation of pore size [1, 23, 24, 30, 36].

For cylindrical pores:

and for slit pores:

where:

-

d p = diameter of cylindrical pore

-

W = width of slit pore

-

r = radius or half-width of pore after some space has been occupied by liquid layer t

-

t = thickness of adsorbed liquid layer at pore wall

-

V l = molar volume of the liquid condensate

-

γ = surface tension of the liquid condensate

-

R = gas constant

-

T = absolute analysis temperature

The thickness t of the adsorbate layer can be derived in most cases from the ‘common’ t-curve, which gives the average layer thickness independent of relative pressure for a variety of materials. Typically, t is in the order of 0.5–4 nm.

3.6.4.2 Summary of Quality Aspects

The size range for measurement of pore diameters is about 0.5–200 nm.

The repeatability of the measurements is about 3 % relative.

Complete ‘outgassing’ of the samples is essential for good results. This is especially true when micropores are present, in which adsorption can be strong. Note that the presence of some adsorbates (e.g. water) at vulnerable, large surfaces at high temperatures may decrease surface area by sintering.

3.6.4.3 Mercury Penetration Technique

This technique uses the principle that a non-wetting liquid can enter the accessible pores of a particulate system only when forced by pressure. Mercury is one of the very few liquids that provides the required property of non-wetting, regardless of the pore wall material. Thus, the pore size is determined by forcing mercury into an evacuated sample under increasing pressure, while measuring the volume of mercury intruded as a function of pressure. Measurements occur at each stepwise increasing pressure. Sometimes, they are followed by measurements at decreasing pressures, for example to check whether the pores have changed through the influence of the pressure applied. Pore size is calculated by means of the Washburn equation, which assumes free access of the mercury to cylindrical pores [1, 22, 30]:

where

-

d p = diameter of a cylindrical pore

-

γ m = surface tension of mercury

-

Θ = contact angle of mercury at the pore surface

-

P = applied pressure

A pressure range of about 0.001–400 MPa is covered in instruments, which allows pore diameter measurements of about 800 μm to about 4 nm. The Washburn equation shows an inverse relationship between pore size and pressure. Thus, the large pores are intruded at low pressure; the small pores require high pressures. At pressures near ambient pressure, small pressure variations have a significant influence on pore size. Thus, size resolution is low here. Note that voids are included in the measurement.

If the access to wide pores or voids is constrained by narrow channels, as in e.g. ink bottle-type pores (having a narrow entrance and a wider body afterwards) and voids in between particles, then the mercury intrusion occurs at the higher pressure relating to the narrow entrance. In these cases the total intruded volume is only attributed to the size of the entrance, and the inner size of the pores or voids remains undetected. The inner void size is often important, for example in relation to the strength of concrete, where cracks find their origin in the larger voids (see Chap. 7). Intrusion of Wood’s metal at elevated temperature instead of mercury, which has a similar contact angle, may be applied to circumvent the limitation of the entrance. This metal has a melting point of about 66 °C and, thus, is a solid at room temperature. This permits the making of product sections, followed by quantitative image analysis of their electron microscopic images (see Sect. 3.4.2). This method clearly show the void sizes [10, 38, 41].

3.6.4.4 Summary of Quality Aspects

The repeatability of the mercury intrusion measurements is about 3 % relative.

The maximum volume of intruded mercury gives the pore (and void) volume in the meso- and macropore range. If high pressures are applied, then it may also include volumetric changes of the sample induced by the pressure (e.g. for compressible materials, originating from elasticity or structural collapse).

Good removal of adsorbed species from the samples by ‘outgassing’ before analysis is essential for good results.

Note: Mercury is poisonous. Therefore, its use is restricted in most countries.

3.7 Zeta-potential and Its Measurement

3.7.1 Zeta-potential

The zeta-potential (ζ-potential) plays an important role in the stability of colloidal suspensions and emulsions. It is defined as the electrostatic potential at the surface of shear of a particle suspended in a liquid. The electric charges result from ionization of hydroxyl groups at the particle surface through the influence of the pH and/or by adsorption of ions at this surface. The distribution of charges is affected by the dielectric constant of the dispersion medium. In aqueous dispersions, there is also adsorption of some water molecules in the boundary layer. These adsorbed species are so strongly bonded to the surface that they go with the particle if this moves.Footnote 5 The electrostatic potential results in repulsive forces between particles, which limit their free movement and prevent them from coming in close vicinity (see also Sect. 2.6). At somewhat higher concentration, it may lead to some ‘structure’ in the dispersion.

3.7.2 Measurement

Zeta-potential is not directly measured but is calculated via the electrophoretic mobility. The relationship between zeta-potential and electrophoretic velocity in an electric field is provided by the following equation [9, 11, 14, 15, 19].

where

-

v el = electrophoretic velocity of dispersed particle

-

ε d = dielectric constant of dispersion medium

-

ζ = zeta-potential of dispersed particle

-

E = strength of electric field applied

-

u el = electrophoretic mobility of dispersed particle (= v el /E)

-

a = particle radius

-

κ = inverse statistical thickness of double layer around particle

-

F(κa) = Henry’s function (depends on particle shape)

Henry’s function F(κa) relates to the ratio of the particle radius and the statistical thickness of the double layer (or Debije Length; DL = 1/κ). Large values indicate a relatively thin double layer and vice versa. The value of F(κa), in aqueous dispersions of high electrolyte concentration is often taken to equal 1.5. The Helmholtz-Smoluchowski approximation which assumes the electric field to be uniform and parallel to the particle surface, is valid for κa > 200. In non-aqueous dispersions, with a low-dielectric constant, F(κa) may be assumed to equal 1 (Hückel approximation, which disregards the deformation of the electrical field in the neighborhood of the particle; and valid for κa < 0.3). Values in the intermediate range may be calculated from Henry’s function [33]. Some values are presented in [15, 35]. Note that Rahaman [35] gives values for (F(κa)–1).

The electrophoretic velocity can be measured in several ways:

-

(a).

Directly under a microscope

-

(b).

In dynamic light scattering instruments by measurement of the Doppler shift of the frequency of the scattered light (caused by the movement of the particles; LDE = Laser Doppler Electrophoresis) or by measurement of its phase shift (PALS = Phase Analysis Light Scattering)

-

(c).