Abstract

The process of food formulation entails a sufficient grasp of the physicochemical properties and transformations of emulsions in foods, which is essential in the development of appropriate food-grade naturally derived surfactants (NDSs) for stabilization and long-lasting structured food forms. Currently, food demand is growing at a rapid rate in correspondence with the human population increase worldwide, and therefore, the need to satisfy this quest for food sufficiency throughout the seasons of the year. Thus, the essence of food preparation, processing, formulation, or creation of special dietary foods with edible-type NDSs (having structural features identical to those existing in the natural system of the human body) is to ensure a high degree of food safety, digestibility, compatibility, utilization, efficacy, and optimal activity when ingested. Hence, the complement of the active working force between the hydrophilic and lipophilic components of consumable-type NDSs at the interface is the stimulating factor for their applications in diverse food process development and formulated food products as additives with functions such as stabilizing-emulsifier, shelf life–extender, lubricant, moisture-retainer, quality-improver, dispersant, wettability-enhancer, flavor-release agent, crystallization-inhibitor, and so on. This chapter discusses naturally derived surfactants for food formulation in relationship with their classification (cationic, anionic, nonionic, and zwitterionic); characterization (based on emulsions, micellization, hydrophilic-lipophilic balance, inter-micellar interactions); and utilization.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Amphipathic efficacy

- food formulation

- wellness-quality

- food emulsions

- micellization

- naturally derived surfactant for good health

- packing parameter

- stabilizing-emulsifier

8.1 Introduction

With the exponentials increase in human population worldwide, it is expected that global food demand will rise significantly and so the formulation of foods that are compatible with the body system is necessary in order to achieve food security and improved nutrition for the benefit of mankind, as well as food preservation and storage, while ensuring sufficiency of healthy food all round seasons of the year (Sustainable Development Goals—1, 2, 3, and 12) (Morton et al. 2017).

Food is an edible substance composed mainly of carbohydrates, proteins, fats, lipids, etc., which when consumed by living organisms provides the required nourishment for the sustenance of its existence. According to Nwaichi and Ntorgbo (2016), human health is largely determined by the diet and a recommendable diet should be able to provide sufficient nutrients and with tolerable levels of pathogenic microorganisms and chemical contaminants. Thus, formulated foods are those food materials prepared with ingredients which boost the supplemental influence of minerals, vitamins, and condiments to the body system on ingestion.

In addition to the nutriments gained from eating formulated foods, they furnish the body with nutraceutical benefits which in many cases support vascular function, maintain a healthy brain, enhance systemic circulation, rejuvenate body organs, promote muscular development, make up for dietary deficiencies, ensure vitality, energize body system interactions, and so on.

Food formulation, therefore, involves an assembled collection of microstructures of carbohydrates, proteins, fats, lipids, etc., stabilized with naturally derived surfactants mainly through the process of emulsification, solubilization, dispersion, foam formations, etc., which are specifically tailored to the nutritional needs of humans and other organisms. Some examples of formulated foods are margarine, oat, baking and wheat flour, mayonnaise, desserts, bread, confectioneries, tinned corn, canned tomatoes, etc. (Sharma 2014).

8.2 Naturally Derived Surfactants

Naturally derived surfactants (NDSs) designed for healthy food formulation are surface active-stabilizing molecules (of organic origin) with functionalized amphipathic efficacy at the surface or interface which are coherently free from artificial chemicals and certified by recognizable regulatory agencies. These functionalized NDSs could be applied as separable components (extracts/filtrates/exudates/isolates/distillates/concentrates/fermentates) or derivatives with edible-grade solvents. Some of the functional constituents inherent in parts of plants or animals which have contributed to the stability of complex colloids and emulsions in formulated foods are lecithin, glutens, amino acids, leucine, alkaloids, alanine, steroids, tannins, glycosides, lipids, phenolics, flavonoids, and aspartic-, glutamic-, and citric-acids (Holmberg 2001; Chhetri et al. 2009; Hosseinzadeh et al. 2013; Atta et al. 2021; Mehrjoo et al. 2022). These innate attributes of the dual-structured character of NDSs contribute to their wholesome interactions in the food formulation process as emulsifying, lubricating, stabilizing, shelf life–extending, dispersing, wetting, spreading, crystal-modifying, fermenting, conditioning, dough gas–retaining, strengthening, crystallization-inhibiting, aerating, stick-preventing, quality-improving, foaming/antifoaming, flavor-enhancing, gel-forming, and moisture-retaining agents or additives (Sharma 2014).

They acquire thermodynamic and kinetic stabilities through their preferential orientation at the surface or interface of colloidal systems, with the polar (hydrophilic, lipophobic, or oleophobic) head portion and non-polar (hydrophobic, lipophilic, or oleophilic) tail portion (Fig. 8.1) aligning towards aqueous and organic phases, respectively.

8.3 Classification of Naturally Derived Surfactants

Naturally derived surfactants are classified based on the capacity of their hydrophilic head groups to exercise influential attraction for ionic moieties in colloidal fluid. The four major classes of NDSs (Fig. 8.2) are the naturally derived cationic surfactant, naturally derived anionic surfactant, naturally derived nonionic surfactant, and naturally derived zwitterionic surfactant (Schramm et al. 2003; Massarweh and Abushaikha 2020; Atta et al. 2021; Isaac et al. 2022).

8.3.1 Naturally Derived Cationic Surfactant

Naturally derived cationic surfactant (NDCS) carries a positively charged head group with compositions such as ammonium salts of fatty acids, fatty diamine salts, diester amine quaternary salts, and simple fatty amine salts.

8.3.2 Naturally Derived Anionic Surfactant

Naturally derived anionic surfactant (NDAS) bears a negatively charged head group with components made up of carboxylates, sulfates, sulfonates, and phosphates.

8.3.3 Naturally Derived Nonionic Surfactant

Naturally derived nonionic surfactant (NDNS) possesses zero net charged head group with common constituents such as alkylphenol ethoxylates, poly-propoxylated alcohols, and poly-ethoxylated alcohols.

8.3.4 Naturally Derived Zwitterionic Surfactant

Naturally derived zwitterionic surfactant (NDZS) has both positively and negatively charged head groups, with the cationic part of the hydrophile serving as the link to the hydrophobic chain. Acids of sulfonate, phosphate ester, carboxylate, and sulfate groups are instances of a charged center for the anionic part, while amines and quaternary ammonium are examples of functional group components that make up the charged center for the cationic part of NDZS.

For instance, as part of the structural activity of NDSs in the food formulation process (Sharma 2014):

-

(a)

Arginine and lysine exhibit their cationic feature through the influence of the amino group-head portion at the interface of colloidal dispersion.

-

(b)

Aspartic and glutamic acids contain carboxyl groups at the side chains which enhance their anionic behavior in colloidal solution at the interface.

-

(c)

Alanine and leucine possess aliphatic side chains with non-polar hydrophile-controlled character at the interface in the fluidous colloidal system.

8.4 Characterization of Naturally Derived Surfactants

With the adsorption of NDSs, the interfacial (surface) tension and free energy of the system are relatively reduced by proportions which are connected to the added surfactant quantity; thus, the unification of the two immiscible aqueous and oily phases start at the attainment of a particular concentration to form micelles (micellization).

Naturally derived surfactant molecules are characterized based on their:

-

(a)

Active influence at the surface or interface of the system.

-

(b)

Polar head and nonpolar tail structural frame of the moiety.

-

(c)

Self-organized association between the amphiphilic components.

The principles governing food emulsions, micelle formation, hydrophilic-lipophilic balance, and inter-micellar interactions are the main characteristic considerations before the application of NDSs for healthy food formulation.

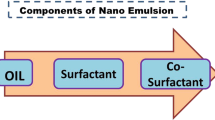

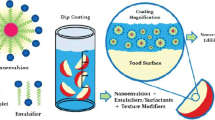

8.4.1 Emulsions in Food Formulation

The prolonging of shelf life under the condition of enduring stability of formulated food structural forms is dependent on the thorough grasp of the physicochemical characteristics and transformational behavior of emulsions in foods, as well as its implementation in the developmental pattern of consumable-type NDSs for food formulation. The dispersion of an immiscible liquid (dispersion phase) into another liquid (dispersion medium or continuous phase) with which it is stabilized by a suitable food-grade NDS is referred to as emulsion in food formulation. Oil-in-Water (O/W), Water-in-Oil (W/O), and Water-in-Oil-in-Water (W/O/W) emulsions are the prevalent type of emulsions governing the food formulation process (Fig. 8.3) (Schramm et al. 2003; Kralova and Sjöblom 2009; Sharma 2014).

8.4.1.1 Oil-in-Water Emulsion

This is a colloidal system which involves an oily phase dispersed in a continuous phase of water. The applied NDSs and any impurity present in the water phase dictate the physicochemical behavior of the emulsion. Some examples of O/W emulsion in formulated foods are creamers, cream liqueur, whipped toppings, ice cream mixes, and mayonnaise.

8.4.1.2 Water-in-Oil Emulsion

This system is a colloidal suspension of droplets of water (dispersion phase) in an insoluble mixture with an oily dispersion medium. The physicochemical properties of the NDSs and the purity level of the lipids used determine the stability of the W/O emulsion. Some examples of W/O emulsions in formulated foods include butter, margarine, and fat-based spreads.

8.4.1.3 Water-in-Oil-in-Water Emulsion

This is a colloidal system made up of an oil phase suspended an in aqueous phase, with the oil phase having small droplets of water dispersed in it. In order to have a significantly stable W/O/W emulsion, the NDS, water, and oil used should be free of foreign materials. Many bakery products belong to this class of emulsion.

8.4.2 Micellization of Naturally Derived Surfactants

Micellization is a key behavior of all surfactants, and the concentration of surfactants above which micelles are formed is termed the “critical micelle concentration” (CMC) (De et al. 2015; Massarweh and Abushaikha 2020; Mehrjoo et al. 2022). The measurements of surface or interfacial tension plotted as a function of surfactant concentrations are often applied in evaluating the CMC of NDSs. The concentration of surfactant which coincides with the breakoff point from the slopy-line plot depicts the CMC of that particular NDSs (Fig. 8.4).

The pre-micellar region in Fig. 8.4 denotes the interval of preferential orientation of surfactant molecules at the interface with an increase in its quantity, followed by the attendant degree of reduction of interfacial tension in this circumstance. Thus, with further increase and as time goes on, the saturation of surfactant concentration at the interconnection point of the phases is reached when the self-generation of micelles begins to occur which is depicted as CMC (0.034 mg/L). The post-CMC (plateau) region signifies the period in which more micelles are formed with further addition of surfactant molecules; followed by an abrupt change in the physicochemical properties with relatively no noticeable variation in parameters such as electrical conductivity, thermal resistivity, and interfacial/surface tension. This shows that they do not rely on an increase in the concentration of surfactants any longer, but that extra surfactant molecules self-organize at a specific quantity to form more micelles.

8.4.3 Hydrophilic-Lipophilic Balance

The ability to generate suspension between two immiscible liquids and how the stabilizing magnitude of NDS molecules influences the behavior of hydrophilic and lipophilic moieties are made known by the hydrophilic-lipophilic balance (HLB) value. The HLB values are scaled from 0 to 20, which reveals the spontaneous tendency towards oil or water emulsion (Kralova and Sjöblom 2009). Thus, a low value of HLB points to NDS’s high capacity for oil emulsion, while a high value of HLB is an indication of NDS’s high capacity for water emulsion. Table 8.1 shows the range of HLB values for emulsifying capabilities of NDS applications (Massarweh and Abushaikha 2020).

Thus, the HLB values of NDSs (separable components, intermixtures, or formulations) can be evaluated experimentally using the formula in Eq. 8.1:

where S and A are the saponification and acid values, respectively.

8.4.4 Inter-Micellar Interactions of Naturally Derived Surfactants

In the inter-particle interactions of colloidal fluids, the capacity of the tail moieties to produce a hydrophobic effect and the power of electrostatic or steric repulsion exerted between the hydrophilic portions are the main contending forces that control the micellar aggregation and size, respectively; while the hydrophobic and hydrophilic groups of the individual surfactant particle determine the shape of the micelle (Goyal and Aswal 2001). In order to group micellar aggregation intelligibly along a systematic sequence, the idea of molecular packing parameter advanced by Israelachvili et al. (1977) was generally applied to describe the implication of the geometric relationship between the tail (volume and length) and head (area) features to the self-organization of surfactant molecules in fluidous colloids.

Research scientists and industrial technologists in the field of food processing and formulation have within the past two and half decades applied the molecular packing parameter as a means of providing uncomplicated and perceptive insight into the multimolecular assemblage of structured shapes (spherical, cylindrical, vesicles, planar bilayers, and reverse) formed in colloidal solutions (Fig. 8.5), which have impacted value over rheological property, emulsification capacity, solubilization performance, and dispersion capability of NDSs in the food formulation industry.

The molecular packing parameter (P) is expressed as (Nagarajan 2002; Stuart and Boekema 2007; Yan et al. 2007; Massarweh and Abushaikha 2020):

where v and l are the surfactant’s tail volume and length, respectively, while ae is the equilibrium area per molecule at the aggregate interface.

The v and l parts of the expression are consistent variables for a particular NDS molecule, and since they are determined from the innate features of the molecular structure, the ratio of v to l will remain constant. However, the surface area is a product of compilation from the circumference, radius, and height of the formed structure due to inter-micellar interactions, which is dependent on the extent of surface accessed by the head group of NDS molecule at the interface of the hydrophobic core-hydrophilic media under equilibrium condition. Thus, modifications in micellar solution conditions (such as temperature, pH, ionic strength, and concentration) will likely alter the value of P through the influence over the surface area variable and, in turn, lead to the aggregate morphology transition.

For instance, the salt added to ionic micellar solution shields the colloidal fluid from the repulsive force between two positive or two negative charges and, hence, allows the modification of surface area which will alter the P value. Thus, transform the inter-micellar interactions to the aggregate morphology that yields the desired products with properties like longer shelf-life and improved quality. Furthermore, variation in micellar solution to a higher temperature can moderate the performance of non-ionic NDSs to a new value of the corresponding P due to hydrogen bonding interaction at the interface; thereby achieving the product of the required structural form (Goyal and Aswal 2001).

8.5 Utilization of Naturally Derived Surfactants

The surfactant’s amphipathic structure and chain length, ionic strength, impurities, approximate molecular weight, pH, temperature, concentration, etc., are the major factors which influence the CMC of a given NDS; hence, NDSs should be purified (to the best level possible) for the purpose of quality control and assured healthy standard and their specification ascertained with requisite condition(s) for replicability before utilization.

Structurally, the hydrophilic portion is made of carbohydrate, glycerol, amino acid, sorbitol, sucrose, phosphate or cyclic peptide, and propylene glycol or polyglycerol; while the hydrophobic portion is composed of long-chain fatty acids or fatty acid derivatives of fats and oils such as palm kernel, rapeseed, soybean, and coconut oils (Ranasalva et al. 2014; Sharma 2014). Most of these NDSs perform additional functions (Table 8.2) in their different applications (WHO 1974; Zobel 1976; Saltmarsh 2020), and some commonly utilized NDSs with their amphipathic structures are presented in Table 8.3. The combination of selected NDSs tends to render more functional amphipathic efficacy as they provide a compatible blend of properties in the formulation of food. For example, a mixture of NDSs composed of mono- and di-glycerides of fatty acids will yield bakery products with stably fermented and well-conditioned dough, which adds nutritive value to the body when consumed (Sharma 2014).

8.6 Conclusion

Naturally derived surfactants patterned for healthy food formulation are a distinct set of organic compounds with peculiar interfacial stabilizing activity between the hydrophilic and hydrophobic portions of the immiscible colloidal system, and as such display their characteristic additive functions in the establishment and development of long-lasting structured edible forms by acting as emulsifiers, dispersants, shelf life-extenders, solubilizers, lubricants, moisture-retainers, quality-improvers, wettability-enhancers, flavor-release agents, crystal-modifiers, foaming agents, and so on. Hence, as human population increases globally with its attendant rise in food requirement, the process of food formulation or creation of special dietary food products with consumable-type NDSs (having structural features identical to those existing in the natural system of the human body) becomes paramount, so as to guarantee sustainable food systems and high level of food security, wellness-quality, availability, digestibility, compatibility, optimal-utility, preservability, nutrimental-activity, sufficiency, and affordability for different classes of the populace (Sustainable Development Goals – 1, 2, 3, and 12).

References

Alhajj MJ, Montero N, Yarce CJ, Salamanca CH. Lecithins from vegetable, land, and marine animal sources and their potential applications for cosmetic, food, and pharmaceutical sectors. Cosmetics. 2020;7(4):87.

Atta DY, Negash BM, Yekeen N, Habte AD. A state-of-the-art review on the application of natural surfactants in enhanced oil recovery. J Mol Liq. 2021;321:114888.

Chhetri AB, Watts KC, Rahman MS, Islam MR. Soapnut extract as a natural surfactant for enhanced oil recovery. Energy Sources Part A Recov Utilization Environ Effects. 2009;31(20):1893–903.

De S, Malik S, Ghosh A, Saha R, Saha B. A review on natural surfactants. RSC Adv. 2015;5:65757–67.

EFSA Panel on Additives and Products or Substances used in Animal Feed (FEEDAP). Safety and efficacy of polyoxyethylene (20) sorbitan monooleate as a feed additive for all animal species. EFSA J. 2016;14(3):4443.

EFSA Panel on Food Additives and Nutrient Sources added to Food (ANS). Scientific opinion on the re-evaluation of sodium stearoyl-2-lactylate (E 481) and calcium stearoyl-2-lactylate (E 482) as food additives. EFSA J. 2013;11(5):3144.

European Food Emulsifier Manufacturers Association (2019). EFEMA index of food emulsifiers.

Gombač Z, Osojnik Črnivec IG, Skrt M, Istenič K, Knez Knafelj A, Pravst I, Poklar Ulrih N. Stabilisation of lutein and lutein esters with polyoxyethylene sorbitan monooleate, medium-chain triglyceride oil and lecithin. Foods. 2021;10(3):500.

Goyal PS, Aswal VK. Micelle structure and inter-micellar interactions in micellar solutions: results of small angle neutron scattering studies. Curr Sci. 2001;80(8):972–9.

Holmberg K. Natural surfactants. Curr Opin Colloid Interface Sci. 2001;6(2):148–59.

Hosseinzadeh R, Khorsandi K, Hemmaty S. Study of the effect of surfactants on extraction and determination of polyphenolic compounds and antioxidant capacity of fruits extracts. PLoS One. 2013;8(3):e57353.

Isaac OT, Pu H, Oni BA, Samson FA. Surfactants employed in conventional and unconventional reservoirs for enhanced oil recovery—a review. Energy Rep. 2022;8:2806–30.

Israelachvili JN, Mitchell DJ, Ninham BW. Theory of self-assembly of lipid bilayers and vesicles. Biochim Biophys Acta. 1977;470:185–201.

Kralova I, Sjöblom J. Surfactants used in food industry: a review. J Dispers Sci Technol. 2009;30(9):1363–83.

List GR. Soybean lecithin: food, industrial uses, and other applications. Polar lipids. 2015:1–33.

Massarweh O, Abushaikha AS. The use of surfactants in enhanced oil recovery: a review of recent advances. Energy Rep. 2020;6:3150–78.

Mehrjoo H, Riazi M, Norouzi-Apourvari S. A comprehensive review on the use of eco-friendly surfactants in oil industry. Chemical Methods. 2022:357–99.

Morton S, Pencheon D, Neil Squires N. Sustainable development goals (SDGs), and their implementation: a national global framework for health, development and equity needs a systems approach at every level. Br Med Bull. 2017;124:81–90.

Nagarajan R. Molecular packing parameter and surfactant self-assembly: the neglected role of the surfactant tail. Langmuir. 2002;18(1):31–8.

Nwaichi EO, Ntorgbo SA. Assessment of PAHs levels in some fish and seafood from different coastal waters in The Niger Delta. Toxicol Rep. 2016;3:167–72.

Ranasalva N, Sunil R, Poovarasan G. Importance of biosurfactant in food industry. IOSR J Agric Veterinary Sci. 2014;7(5):06–9.

Saltmarsh M. Food additive regulations in Europe. London: Saltmarsh’s Essential Guide to Food Additives; Royal Society of Chemistry; 2020. p. 40–51.

Schramm LL, Stasiuk EN, Marangoni DG. Surfactants and their application. Annual Report on the Progress of Chemistry, Section C. 2003;99:03–48.

Sharma RK. Surfactants: basics and versatility in food industries. PharmaTutor. 2014;2(3):17–29.

Stuart MCA, Boekema EJ. Two distinct mechanisms of vesicle-to-micelle and micelle-to- vesicle transitions are mediated by the packing parameter of phospholipid-detergent systems. Biochim Biophys Acta. 2007;1768:2681–9.

Teixeira GL, Züge LCB, Silveira JLM, Scheer ADP, Ribani RH. The impact of polyoxyethylene sorbitan surfactants in the microstructure and rheological behaviour of emulsions made with melted fat from Cupuassu (Theobroma grandiflorum). J Surfactant Deterg. 2016;19(4):725–38.

World Health Organization (1974). Toxicological evaluation of some food additives including anticaking agents, antimicrobials, antioxidants, emulsifiers and thickening agents.

Yan Y, Xiong W, Xiaosong L, Lu T, Huang J, Li Z, Fu H. Molecular packing parameter in bolaamphiphile solutions: adjustment of aggregate morphology by modifying the solution conditions. J Phys Chem B. 2007;111:2225–30.

Zobel M. Toxicological evaluation of some food additives including anticaking agents, antimicrobials, antioxidants, emulsifiers and thickening agents. WHO food additives series, no. 5. 520 seiten. Geneva 1974. Preis: Sw. Fr. 23; 1976: pp. 681–682.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Ibezim-Ezeani, M.U. (2023). Naturally Derived Surfactants for Healthy Food Formulation. In: Nwaichi, E.O. (eds) Modernity in Health and Disease Diagnosis: The Account from STEM Women. Sustainable Development Goals Series. Springer, Cham. https://doi.org/10.1007/978-3-031-34963-8_8

Download citation

DOI: https://doi.org/10.1007/978-3-031-34963-8_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-34962-1

Online ISBN: 978-3-031-34963-8

eBook Packages: MedicineMedicine (R0)