Abstract

Food nanotechnology involves the study of interactions between oil, water, surfactants and various ingredients such as active compounds, gelling agents, preservatives, chelating agents, flavors and colorants. In particular, the molecular structure and functions of nanoemulsions control the stability and organoleptic properties of nano-food products. For example, the overuse of surfactants to stabilize nanoemulsions may lead to toxicity of final food products. This review discusses methodical, logical and judicial selection of oils, surfactants, co-surfactants, active ingredients and other components. Ingredients for developing food-grade nanoemulsions are described.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Application of nanotechnology is an increasing trend in the field of nutraceutical, healthcare as well as in food. It includes formation of nanoemulsion, synthesis of nanoparticles, widely used in drug delivery system, nanopackaging in food industry and many others such as cosmetics, pharmaceuticals and material synthesis. Generally, nanoemulsions are kinetically stable liquid-in-liquid dispersions having droplet sizes ranges in order of 100 nm. Due to their small size, useful properties such as high surface area per unit volume, robust stability, optically transparent appearance and tuneable rheology are observed. For their preparation, various techniques are used such as application of high- and low-energy methods, including high-pressure homogenization, ultrasonication, phase-inversion temperature and emulsion inversion point, as well as recently developed approaches such as bubble bursting method, high-shear mixers (Gupta et al. 2016; Mohammadi et al. 2016; O’Sullivan et al. 2018).

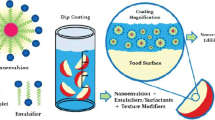

A number of food ingredients and additives have been emulsified and are available in the market. Depending upon the parameter to be incorporated into the food material such as food fortification or enhancing stability, appearance, taste or texture, various types of active constituents have been employed such as vitamins, minerals, flavorings, acidulants, preservatives, colorings and antioxidants (Mcclements and Jafari 2018). Proteins, fat and sugar molecules are also emulsified and added to food materials for increased uptake and absorption or improved bioavailability or additives such as benzoic acid, citric acid, ascorbic acid, vitamins A and E, isoflavones, beta-carotene, lutein, omega-3 fatty acids and coenzyme-Q10 (Ostertag et al. 2012). Different constituents to be emulsified are discussed further in each section (Fig. 1).

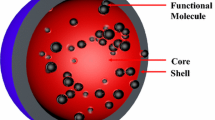

Nanoemulsion mainly consists of three components—oil, water and surfactant. A correct mix of these components determines the stability and property of emulsion. Various types of surfactants are used in food industries which have been approved by the Federal Drug Administration (FDA), but no single surfactant can be used for all food products. Thus, based upon the molecular characteristics a surfactant is chosen to give the desired effect. The surface-active nature of the component plays an important role in stabilizing the emulsion; hence, the surfactant used acts as stabilizing agent, emulsifying agent, solubilizing agent according to molecular characteristics and solution conditions, such as pH, ionic strength and temperature (McClements et al. 2017). The ratio of oil to water is very important criteria for fabrication of nanoemulsion. As oil molecules possess hydrophobic nature, higher solubility and dispersibility in aqueous media which reduce the organoleptic properties of the food system, there is growing interest in designing structured delivery systems to improve the dispersion stability and antimicrobial activity with examples being nanoemulsions, microemulsion and liposomes with the help of different methods as mentioned above (Sugumar et al. 2015a). Components used in the formation of nanoemulsion are either hydrophilic or lipophilic. Most of the bioactive components, flavors and pigments are lipophilic in nature (Fig. 2). This article is an abridged version of the chapter published by Dasgupta and Ranjan (2018) in the series Environmental Chemistry for a Sustainable World (http://www.springer.com/series/11480).

Oil phase

There has been growing interest in the development of food-grade colloidal delivery systems for encapsulating flavors, colors, micronutrients, nutraceuticals and antimicrobials which are lipophilic in nature (Mcclements 2018). There are many oil phase components used for fabrication of food-grade nanoemulsions which are shown in Fig. 3. The choice of oil is a highly important aspect in the case of food-grade materials or generally recognised as safe (GRAS).

Flavor oils

Oil-in-water nanoemulsions and microemulsions are two types of colloidal dispersions suitable for encapsulation and delivery of lipophilic components within the beverage industry (Rao and McClements 2012a). Generally, flavor oil contains characteristic aroma profiles with volatile constituents which are used as flavoring agents in the food and beverage industries, e.g., lemon, orange and peppermint oils. Additionally, it has been suggested that the use of natural flavor oils extracted from medicinal plant to develop health beneficial food or nutraceuticals may be termed as Nano-Ayurveda. Many phytonutrients are externally added in nanoemulsions in order to incorporate its biological activities, as reported by Jintapatanakit et al. (2018a). Additionally, folds/forms are developing in the flavor oil according to the differences in isolation and processing procedures; e.g., flavor oil extracted from cold processing is termed as single-fold oils, and further the use of different steps mainly distillations determines the folds of it. The fold of the flavor oils determines the chemical composition and physicochemical properties which ultimately has similar effects on nanoemulsions, its activities and properties (Lang and Buchbauer 2012; Baldissera et al. 2013). Notably, it has been established in our laboratory that higher-fold oils are suitable to develop nanoemulsions (Dasgupta et al. 2016b), and similarly it can be supported by the statement that lower-fold oils are suitable for microemulsion fabrication (Rao and McClements 2011; Jeirani et al. 2013).

Cloud oil

The cloud oil is mainly composed of non-flavor oils, e.g., terpene oils or triacylglycerol. Triacylglycerol oils are usually derived from natural resources as vegetable, corn, canola and sunflower oils, while terpene oils are typically extracted and purified by distillation of naturally occurring flavor oils. Nanoemulsion fabricated using cloud oils are known as cloud nanoemulsion as it shows a cloudy/milky appearance Because of very low water solubility, these oils are stable at Ostwald ripening—unlike flavor oil. Normally, they do not participate directly to increase the flavor properties of nanoemulsions, instead they obliquely manipulate nanoemulsions’ flavor because of their abilities to detach the flavor molecules among the oil, water and headspace regions (Vijayalakshmi et al. 2014; Jintapatanakit et al. 2018b; Teng et al. 2018). Generally, this kind of emulsion has wide application in beverage industry. The emulsion which provides only turbidity is termed as cloud emulsion (or clouding agent), and the other that provides both cloudiness and the aromas is denoted as flavor emulsion (Stounbjerg et al. 2017). Cloud oil physicochemical properties—mainly density, melting conditions and viscosity—have a critical role in fabrication and constancy of cloud oil nanoemulsions. The cloud oil density has important influence on their long-standing stability which further decides the creaming velocity of the nano-sized droplets. Its melting characteristics determine the partial crystallinity of cloud oil droplets and finally can be vulnerable for droplet aggregation and phase separation of nanoemulsions. Its viscosity controls the ability to fabricate small-sized droplets throughout the homogenization process, and the higher viscosities generally lead to large-sized droplets (Dickinson 2010).

Nutraceutical lipids

The nutraceutical lipids—polyunsaturated fats, carotenoids, fat-soluble vitamins and fat-soluble antioxidants, phytosterols and fat-soluble colorants—have attracted the food market for its incorporation in commercial nano-foods. They are incorporated into nanoemulsions, fabricated by high-/low-energy approaches such as high-speed homogenization, sonicators, phase-transition methods, and/or encapsulated into the foods (Anandharamakrishnan 2014). Since the nutraceutical lipids are prone to several factors for its chemical or physical degradation, so, using the same in commercial nano-food is still a major challenge (Akhavan et al. 2018). It can be noted that specific lipid nutraceutical has specific confronts which ultimately depend on their physicochemical properties—chemical stability solubility, melting point and oil–water partition coefficient (McClements et al. 2009; McClements and Li 2010). Henceforth, they should be fabricated with extreme care and the fabrication protocol should be selected wisely to maintain the specific physicochemical properties of particular nutraceutical lipids used in the nanoemulsions (Stellavato et al. 2018).

Polyunsaturated fats

The potential health benefits of polyunsaturated fatty acids (PUFAs) are the major driving force to grow the interest of their use in food and beverage sector, especially ω − 3 fatty acid. It is noted that it lowers the risk of different types of cancers, cardiovascular disease, as well as it improves the brain functioning (Rubio-Rodríguez et al. 2010; Ryckebosch et al. 2012; Filipović et al. 2015; Ranjan et al. 2016a; Sánchez-Salcedo et al. 2016; Azizi et al. 2018). These properties have attracted the food manufacturers to incorporate such PUFAs and fortify the nanoemulsions based foods. As the nano-level droplet size ranges, it will provide efficient delivery and activities (Katouzian et al. 2017). It can be noted that PUFAs are highly vulnerable for oxidative degradation and ultimately cause problem in long-term storage; additionally, they are extremely susceptible at smaller size of nanorange (van de Rest and de Groot 2014). It is advised to follow the preventive measures and protocol to have the long-term stability of PUFA-based nanoemulsions which include deactivation of pro-oxidants, i.e., oxygen and transition metals, controlling quality of the initial ingredient, interfacial engineering and addition of antioxidants to have stable nanoemulsions.

Carotenoids

Carotenoids are intensely colored liposoluble pigments synthesized by plants and microorganisms and are present in many foods, particularly fruit, vegetables, and fish which are used as colorants to provide colors, especially red, yellow and orange. Many of the researches have claimed their health benefits too. Oxygen-containing carotenoids called as xanthophylls—e.g., lutein and zeaxanthin—have been claimed to have properties to decrease age-related cataract and macular degeneration. Similarly, carotenoids without oxygen known as carotenes—e.g., β-carotene and lycopene—have the potential to decrease the risk of prostate cancer. Nevertheless, there is some limitation with the carotenoids incorporation into many food and beverage products. These include poor water solubility due to their high hydrophobicity, melting point and susceptibility to chemical degradation as they are highly unstable (Chaari et al. 2018). Therefore, carotenoids have a poor intake in the body. Due to their properties, carotenoids have the growing interest to be used in food and beverages; in recent days, the interest is to use them in nanoemulsions (Bou et al. 2011; Arunkumar et al. 2013; Jo and Kwon 2014; Uzun et al. 2016).

Vitamins

To improve the nutritional value of nanoemulsion-based foods, there has been increased interest to incorporate vitamins (mainly A, D, E and K) and nutraceuticals (e.g., flavonoids, curcumin and sterols) (Hormann and Zimmer 2016). Vitamin E is a natural antioxidant, and its most bioactive form is α-tocopherol which is having wide applications in cosmetics, pharma and food industries (Campardelli and Reverchon 2015). Researchers have claimed that the nanoemulsified vitamin E is used in drug delivery system for reducing diabetes, cancer, cardiovascular diseases, etc. (Li et al. 2015). For these reasons, there has been huge interest in fortifying many foods and beverages with vitamin E. In a recent study, it has been cited that the alpha–tocopherol nanoemulsion is used for the wound healing (Bonferoni et al. 2018). Vitamins are being emulsified to increase its bioavailability in organisms. As it is unstable in nature, nanoemulsions are prepared with the help of nonionic surfactant, water-soluble co-solvent such as glycerol, and sometimes different oil phases are used followed by continuous stirring and homogenization (Saberi et al. 2013; Ozturk et al. 2015; Dasgupta et al. 2016b; Morais and Burgess 2014; Zheng et al. 2016).

Other vitamins such as vitamin C and D are also loaded with emulsifier and mixed surfactant with different oil phase components to produce nanoemulsion having a droplet diameter of 2.0–3.0 μm which was stable for more than 30 days (Khalid et al. 2013a, b; Ziani et al. 2012). A patent has been filed—US20130189316 A1—for nanoemulsion of vitamin K that can therapeutically replace phytonadione injectable emulsion (vitamin K in aqueous solution with a strong detergent to solubilize it). The drug sometimes causes hypersensitive reaction if injected intravenously or intramuscularly (Andrew 2013).

Vitamin E is becoming lost during processing, utilization and storage of the commercial food and beverage products—oxidation is the major cause for vitamin E instability (Cheng et al. 2016). To achieve higher oxidative stability, vitamin E acetate has been advised to be used in commercial food and beverages rather than vitamin E. It can be noted that in the gastrointestinal tract, action of pancreatic esterase causes the breaking of vitamin E acetate to vitamin E (Mayer et al. 2013; Yang and McClements 2013). The higher lipophilic behavior of vitamin E restricts its direct dispersion into aqueous solutions (Fuchs-Godec and Zerjav 2015). Further, its efficient delivery is necessary, wherein it should be transported using colloidal system for which a number of previous studies have proved the efficient emulsion-based delivery system, e.g., emulsions (Gonnet et al. 2010), microemulsions (Zhou et al. 2015) and nanoemulsions (Mehmood 2015). For enhancing the biological and physicochemical properties of vitamin E in the drug delivery system, D-α-tocopheryl polyethylene glycol succinate (vitamin E TPGS or TPGS) has been approved by FDA as a safe adjuvant which is a water-soluble derivative of natural vitamin E. It possesses multiple advantages in drug delivery such as high biocompatibility, enhancement of drug solubility, improvement of drug permeation and selective antitumor activity (Yang et al. 2018).

Antioxidants, flavors and colorants

Bioactive substances are commonly lipophilic components such as antioxidants, vitamins, phytosterols, fatty acids and probiotics, which are potentially unstable against environmental stresses; encapsulation and emulsification are attractive technologies frequently used to slow down their oxidative degradation, increase their activity and functionality, enhancing the shelf life of nanoemulsion-based foods (Rabelo et al. 2018). It can be noted that the chemical degradation of the above-discussed sensitive nutraceuticals—mainly PUFAs and carotenoids—can be avoided using lipophilic antioxidants (McClements 2016; Sotomayor-Gerding et al. 2016). Few of the active lipophilic antioxidants used at industrial level are: ascorbylpalmitate, rosemary extracts, gallic acid, tert-butyl hydroquinone (TBHQ), butylatedhydroxy toluene (BHT), butylatedhydroxy anisole (BHA), and alpha-tocopherols (Budilarto and Kamal-Eldin 2015; Mohammadi et al. 2016).

There are many lipophilic colorants which are naturally available and used in food—such as paprika, lycopene, β-carotene and other carotenoids. Because of their origin from natural sources, they can be used as pigments or colorants in food (Meléndez-Martínez et al. 2015; Kiokias et al. 2016). These natural colorants are unstable, hence prepared with the help of emulsifier and stabilizer (Patil et al. 2017) such as β-carotene, lycopene, lutein and astaxanthin which are prepared using different carrier materials.

β-carotene has been emulsified by various methods, such as lipid carrier/liposomes (Pardeike et al. 2009), casein micelles (Dalgleish 2011) or by β-lactoglobulin complexes (Ron et al. 2010) which form stable emulsion with minimum droplet size of 8–15 nm (Poonia et al. 2016). Other carotenoids being emulsified include lycopene, lutein and astaxanthin. Lycopene emulsions have been prepared by high-pressure homogenizer, and its thermal stability is evaluated in emulsion systems (Ax et al. 2003; Boon et al. 2008). Astaxanthin was also prepared by high-pressure homogenization with mean diameter of the dispersed ranged from 160 to 190 nm (Kim et al. 2012). Another study includes improving stability of acidic model beverage astaxanthin by loading nanostructured lipid carriers along with α-tocopherol and EDTA as antioxidants. This nanoemulsion shows particle size 94 nm with better stability (Tamjidi et al. 2018). Nanoencapsulated lutein is developed using chitosan to improve its bioavailability. It was observed that lutein absorption was higher from nanoencapsules than mixed micelles (Arunkumar et al. 2013).

Plant essential oil and active compounds

Plant oils are mainly used as oil phase for making food-grade nanoemulsions rather than encapsulating. The detailed application of plant essential oil is summarized in Table 1. Phytosterols and phytostanols are the plant-derived lipid which shows bioactivity (Otoni et al. 2014; Bhargava et al. 2015; Topuz et al. 2016). It has the potential to inhibit the dietary cholesterol, because of its capability to reduce the low-density cholesterol as well as total cholesterol, so there is a growing interest in food and beverage industry (Nicolosi and Wilson 2015). It is an experimentally established fact that 1.6 g phytosterols per day intake is able to reduce the LDL by 10% (Augustin and Sanguansri 2014). Few properties such as tendency to form crystals, low oil solubility, low water solubility and high melting point are the main hurdles while incorporating phytosterols and phytostanols into nanoemulsified food products and their susceptibility for oxidative degradation Esterification of phytosterols with polyunsaturated fatty acids can be done to overcome these hurdles. The esterified esterification of phytosterols will be digested in gastrointestinal tract and produces free fatty acids and phytosterols (Smoliga and Blanchard 2014; McClements 2015; McClements et al. 2015; Yao et al. 2015; Zou et al. 2015).

Minerals

Minerals exist in food material in various forms such as ions, compounds, complexes or as chelates. Like vitamins, minerals also play an important role in body metabolism, and their solubility depends upon their functional properties. To overcome the deficiency of vitamin and minerals, direct fortification into food may induce chemical degradation, change the level of bioavailability or decrease the sensory quality of food products such as undesirable color and flavor change. This direct addition may accelerate the undesirable chemical reaction which lowers down the nutrition profile of the food product. To solve this hurdle, water-in-oil-in-water (W/O/W) emulsions as encapsulation system is a suitable alternative (Prichapan and Klinkesorn 2014).

High concentrations of minerals, especially Ca2+, can have an adverse effect on the aggregation stability of O/W emulsions containing electrostatically stabilized droplets due to electrostatic screening and ion-binding effects. Certain mineral ions such as iron and copper ions may also promote undesirable chemical reactions such as lipid oxidation that leads to product deterioration. In these systems, it is usually necessary to add chelating agents to sequester the mineral ions and prevent them from causing chemical instability. Certain types of minerals influence the functional properties of other food ingredients. For example, the ability of many biopolymers to thicken or gel a solution is strongly dependent on the type and concentration of mineral ion present (Mungure et al. 2018). Careful selection and control of the mineral ions present in food emulsions are therefore equally important when formulating a successful product (McClements and Li 2010; Piorkowski and McClements 2014).

Weighing agents

Weighing agents are the additives that are added to nanoemulsions in order to minimize the separation of oil droplets. It can be noted that the densities of vegetable and flavor oils are significantly lower than those of the aqueous phase as well as the aqueous sugar solutions, and the nanoemulsions containing these oil droplets tend to move upward. The upward movement of oil droplets in aqueous solutions leads to ringing—oil droplet ring formation at the product surface. The best way to minimize ringing can be possible by using the hydrophobic higher density materials other than the oil droplets. These higher density materials are the weighing agents which increase the density of oil droplets and match with aqueous phase. Generally, weighing agents are used to prevent the creaming in nanoemulsion with low-density oil phase. In addition, such weighing agent reduces the turbidity of the emulsion and increases their cloudiness as well as the refractive index of the emulsion. Ester gum, protein, sucrose acetate isobutyrate (SAIB) and damar gum are used as a weighing agent for increasing the density of oil phase (Stounbjerg et al. 2017).

Emulsifiers

Emulsifiers are surface-active molecules which are mainly used for easing the droplet breakup using top-down approach—thus helping in smaller droplet size formation—and ever for prevention of aggregation—further maintaining long-term stability (Ranjan et al. 2014, 2016a, b; Dasgupta et al. 2015, 2016a; Komaiko et al. 2016; Jain et al. 2018). During the fabrication of nanoemulsions, the emulsifiers get absorbed in the O/W interface which ultimately reduces the interfacial tension causing ease in disruption of droplets. After facilitating the droplet disruption, the emulsifiers must play a role of a protective coating around the oil droplets to prevent aggregation and coagulation. It can be importantly noted that the concentration of emulsifiers should be appropriate to cover all the O/W interfaces, and rate of coating around the oil droplets by emulsifiers must be faster (Komaiko et al. 2016; Artiga-artigas et al. 2018).

Sweeteners

Nanoemulsions get sweetened by natural (preferably) or artificial compounds which interact with tongue taste receptors, giving sensitivity of sweetness—primarily sugar-based compounds are such compound to give perception of sweetness for mammals (Komaiko and McClements 2015; Puri et al. 2015). Compared to number of such compounds, sucrose has been considered, having sweetness of 100 which is additionally responsible for the increase in density of emulsion, while non-nutritive or artificial sweetener reduces their density (Stounbjerg et al. 2017; Kheynoor et al. 2018). Once compared with sugars (glucose, fructose, sucrose, etc.) and sugar alcohols (sorbitol, xylitol, mannitol and erythritol), the latter is considered useful for the development of reduced calorie product (Carrillo-inungaray et al. 2018; Kheynoor et al. 2018). The reason behind this statement is that the human body breaks down sugar alcohol with slower rate and lesser efficiency, which results in the lesser calories per gram in them. Other than sugar alcohols, many of the high-intensity sweeteners are there with favorable flavor profile, low-/medium-calorie nanoemulsions, e.g., natural sweetener such as Stevia and artificial sweeteners such as: saccharin, aspartame, cyclamate, sucralose, neotame and acesulfame K (Delaveau et al. 2015; Al-Nemrawi and Dave 2016; Baker Jr. et al. 2016). In gelatine-based dessert, generally a sweetening agent is incorporated for a thermodynamically stable emulsion (Komaiko and McClements 2015).

Thickening agents

Thickening agents are the polymeric compounds which are used in nanoemulsions to increase the viscosity of aqueous phase which ultimately leads to a decrease in the rate of droplet creaming, as well as alters the mouthfeel, acting as an emulsifier as well as stabilizing agent. Some emulsifiers are used in combination with thickening agent to improve the mechanical strength of emulsions (Meng et al. 2018). These are the biocompatible polymers which get dissolved in the aqueous phase and cover the larger volume than original polymer chain. The oxidative stability of the polymer and their molecular characteristics (molecular weight, interactions and confirmation) are the main parameters. Also, the addition of thickening agent slows down the rate of flocculation and coalescence in the desired nanoemulsion system (Stounbjerg et al. 2017).

Phase diagram

Emulsion is a complex system which includes micelles, colloids and gel network of components involved in it. Phase diagram is used to determine the existence zone of nanoemulsion. It graphically depicts the ratios of the three variables as positions in an equilateral triangle. Usually, only three components are used to form a nanoemulsion (oil phase, water phase and surfactant), as three different sides of the triangle. The three components are each found at apex of the triangle, where their corresponding volume fraction is 100%. Moving away from that corner reduces the volume fraction of that specific component and increases the volume fraction of one or both of the two other components. These points combine to form regions with boundaries between them, representing the “phase behavior” of the system at constant temperature and pressure (Kumar et al. 2012).

To produce such diagrams, a large number of samples of different compositions are prepared. To construct a phase diagram, oil phase is first mixed with surfactant (and co-surfactant) in different ratios. Then, this mixture is titrated with distilled water until a clear, isotropic and thermodynamically stable dispersion with low viscosity is obtained. The ternary phase diagram is constructed by plotting the different values obtained from the experiment. The titration begins by fixing two components and varying the third component. The titration procedure begins with zero loading of water and ends at a point of 100% water loading. Usually, three different forms of phases are observed while constructing a ternary phase diagram—emulsion state, liquid crystal and coarse emulsion. Emulsion state is the area of our interest and can be easily identified by its transparent appearance. Liquid crystal is a translucent gel-like state where partition between oil and water phase can be still visible. Coarse emulsions are the unstable emulsions and appear as milky white. The boundary lines between the three states are drawn according to their appearance (Wang and Pal 2014).

Conclusion

Nanoemulsions are colloidal nano-sized emulsions, which are fabricated for improving the delivery of bioactive ingredients in food, pharmaceutical and cosmetic industry. These are the thermodynamically stable isotropic system in which two immiscible liquids are mixed to form a single phase by means of an emulsifying agent, i.e., surfactant and co-surfactant as discussed above. The droplet size of nanoemulsion falls typically in the range 20–200 nm. With the help of a number of techniques such as high-energy approaches (high-pressure homogenization, ultrasonication), low-energy approaches (low-energy emulsification, phase-inversion method), it is easy to form the nanoemulsion for achieving stability (Anandharamakrishnan 2014). The above-discussed ingredients are used to prepare nanoemulsion; depending upon the requirement, suitability and solubility of the component in both oil and aqueous phases, they are mixed.

References

Ahmadi Lakalayeh G, Faridi-Majidi R, Saber R et al (2012) Investigating the parameters affecting the stability of superparamagnetic iron oxide-loaded nanoemulsion using artificial neural networks. AAPS PharmSciTech 13:1386–1395. https://doi.org/10.1208/s12249-012-9864-6

Akhavan S, Assadpour E, Katouzian I, Mahdi S (2018) Trends in food science & technology lipid nano scale cargos for the protection and delivery of food bioactive ingredients and nutraceuticals. Trends Food Sci Technol 74:132–146. https://doi.org/10.1016/j.tifs.2018.02.001

Al-Edresi S, Baie S (2009) Formulation and stability of whitening VCO-in-water nano-cream. Int J Pharm 373:174–178. https://doi.org/10.1016/j.ijpharm.2009.02.011

Alfaro L, Hayes D, Boeneke C et al (2015) Physical properties of a frozen yogurt fortified with a nano-emulsion containing purple rice bran oil. LWT Food Sci Technol 62:1184–1191. https://doi.org/10.1016/j.lwt.2015.01.055

Al-Nemrawi NK, Dave RH (2016) Formulation and characterization of acetaminophen nanoparticles in orally disintegrating films. Drug Deliv 23:540–549

Anandharamakrishnan C (2014) Techniques for nanoencapsulation of food ingredients. Food Sci Nutr. https://doi.org/10.1007/978-1-4614-9387-7

Andrew XC (2013) Nanoemulsion composition containing vitamin K

Artiga-artigas M, Guerra-rosas MI, Morales-castro J, Salvia-trujillo L (2018) Food Hydrocolloids Influence of essential oils and pectin on nanoemulsion formulation: a ternary phase experimental approach. Food Hydrocoll 81:209–219. https://doi.org/10.1016/j.foodhyd.2018.03.001

Arunkumar R, Prashanth KVH, Baskaran V (2013) Promising interaction between nanoencapsulated lutein with low molecular weight chitosan: characterization and bioavailability of lutein in vitro and in vivo. Food Chem 141:327–337

Augustin MA, Sanguansri L (2014) Challenges and solutions to incorporation of nutraceuticals in foods. Annu Rev Food Sci Technol 6:1–15. https://doi.org/10.1146/annurev-food-022814-015507

Ax K, Mayer-Miebach E, Link B et al (2003) Stability of lycopene in oil-in-water emulsions. Eng Life Sci 3:199–201. https://doi.org/10.1002/elsc.200390028

Azizi M, Kierulf A, Connie Lee M, Abbaspourrad A (2018) Improvement of physicochemical properties of encapsulated echium oil using nanostructured lipid carriers. Food Chem 246:448–456. https://doi.org/10.1016/j.foodchem.2017.12.009

Baker Jr JR, Hemmila MR, Wang SC et al (2016) Nanoemulsion therapeutic compositions and methods of using the same. PCT International Applications

Baldissera MD, Da Silva AS, Oliveira CB et al (2013) Trypanocidal activity of the essential oils in their conventional and nanoemulsion forms: in vitro tests. Exp Parasitol 134:356–361. https://doi.org/10.1016/j.exppara.2013.03.035

Bernardi DS, Pereira TA, Maciel NR et al (2011) Formation and stability of oil-in-water nanoemulsions containing rice bran oil: in vitro and in vivo assessments. J Nanobiotechnol 9:44. https://doi.org/10.1186/1477-3155-9-44

Bhargava K, Conti DS, da Rocha SRP, Zhang Y (2015) Application of an oregano oil nanoemulsion to the control of foodborne bacteria on fresh lettuce. Food Microbiol 47:69–73

Bonferoni MC, Riva F, Invernizzi A et al (2018) Alpha tocopherol loaded chitosan oleate nanoemulsions for wound healing. Evaluation on cell lines and ex vivo human biopsies, and stabilization in spray dried Trojan microparticles. Eur J Pharm Biopharm 123:31–41. https://doi.org/10.1016/j.ejpb.2017.11.008

Boon CS, Xu Z, Yue X et al (2008) Factors affecting lycopene oxidation in oil-in-water emulsions. J Agric Food Chem 56:1408–1414. https://doi.org/10.1021/jf072929+

Bou R, Boon C, Kweku A et al (2011) Effect of different antioxidants on lycopene degradation in oil-in-water emulsions. Eur J Lipid Sci Technol 113:724–729. https://doi.org/10.1002/ejlt.201000524

Budilarto ES, Kamal-Eldin A (2015) The supramolecular chemistry of lipid oxidation and antioxidation in bulk oils. Eur J Lipid Sci Technol 117:1095–1137. https://doi.org/10.1002/ejlt.201400200

Campardelli R, Reverchon E (2015) α-Tocopherol nanosuspensions produced using a supercritical assisted process. J Food Eng 149:131–136. https://doi.org/10.1016/j.jfoodeng.2014.10.015

Carrillo-inungaray ML, Trejo-ramirez JA, Reyes-munguia A, Carranza-alvarez C (2018) Use of nanoparticles in the food industry: advances and perspectives. Impact Nanosci Food Ind. https://doi.org/10.1016/b978-0-12-811441-4/00015-7

Chaari M, Theochari I, Papadimitriou V et al (2018) Encapsulation of carotenoids extracted from halophilic Archaea in oil-in-water (O/W) micro- and nano-emulsions. Colloids Surf B Biointerfaces 161:219–227. https://doi.org/10.1016/j.colsurfb.2017.10.042

Chen H, Guan Y, Zhong Q (2015) Microemulsions based on a sunflower lecithin-tween 20 blend have high capacity for dissolving peppermint oil and stabilizing coenzyme Q10. J Agric Food Chem 63:983–989. https://doi.org/10.1021/jf504146t

Cheng K, Niu Y, Zheng XC et al (2016) A comparison of natural (D-α-tocopherol) and synthetic (DL-α-tocopherol Acetate) vitamin E supplementation on the growth performance, meat quality and oxidative status of broilers. Asian-Australas J Anim Sci 29:681

Dalgleish DG (2011) On the structural models of bovine casein micelles—review and possible improvements. Soft Matter 7:2265

Dasgupta N, Ranjan S (2018) Ingredients and components of nanoemulsions. In: An introduction to food grade nanoemulsions. Springer, Singapore, pp 63–82. https://doi.org/10.1007/978-981-10-6986-4_4

Dasgupta N, Ranjan S, Mundekkad D et al (2015) Nanotechnology in agro-food: from field to plate. Food Res Int 69:381–400

Dasgupta N, Ranjan S, Chakraborty AR et al (2016a) Nanoagriculture and water quality management. Nanosci Food Agric 1(1):1–18. https://doi.org/10.1007/978-3-319-39303-2_1

Dasgupta N, Ranjan S, Mundra S et al (2016b) Fabrication of food grade vitamin E nanoemulsion by low energy approach, characterization and its application. Int J Food Prop 19:700–708. https://doi.org/10.1080/10942912.2015.1042587

Delaveau J, Minost A, Fessi H et al (2015) Long-acting nanoencapsulated coumarin arthropod repellent formulations and methods of use thereof

Dickinson E (2010) Food emulsions and foams: stabilization by particles. Curr Opin Colloid Interface Sci 15:40–49

Duarte JL, Amado JRR, Oliveira AEMFM et al (2015) Evaluation of larvicidal activity of a nanoemulsion of Rosmarinus officinalis essential oil. Rev Bras Farmacogn. https://doi.org/10.1016/j.bjp.2015.02.010

Filipović J, Pezo L, Filipović V et al (2015) The effects of ω − 3 fatty acids and inulin addition to spelt pasta quality. LWT Food Sci Technol 63:43–51

Fuchs-Godec R, Zerjav G (2015) Corrosion resistance of high-level-hydrophobic layers in combination with Vitamin E-(α-tocopherol) as green inhibitor. Corros Sci 97:7–16

Gadkari PV, Balaraman M (2015) Extraction of catechins from decaffeinated green tea for development of nanoemulsion using palm oil and sunflower oil based lipid carrier systems. J Food Eng 147:14–23. https://doi.org/10.1016/j.jfoodeng.2014.09.027

Ghosh V, Mukherjee A, Chandrasekaran N (2013) Formulation and characterization of plant Essential oil based nanoemulsion: evaluation of its larvicidal activity against aedes aegypti. Asian J Chem 25:18–20

Gonnet M, Lethuaut L, Boury F (2010) New trends in encapsulation of liposoluble vitamins. J Control Release 146:276–290

Gupta A, Eral HB, Hatton TA, Doyle PS (2016) Nanoemulsions: formation, properties and applications. Soft Matter 12:2826–2841. https://doi.org/10.1039/C5SM02958A

Homayoonfal M, Khodaiyan F, Mousavi SM (2014) Optimization of walnut oil nanoemulsions prepared using ultrasonic emulsification: a response surface method. J Dispers Sci Technol 35:685–694

Hormann K, Zimmer A (2016) Drug delivery and drug targeting with parenteral lipid nanoemulsions—a review. J Control Release 223:85–98

Hwang TL, Fang CL, Chen CH, Fang JY (2009) Permeation enhancer-containing water-in-oil nanoemulsions as carriers for intravesical cisplatin delivery. Pharm Res 26:2314–2323. https://doi.org/10.1007/s11095-009-9947-6

Jain A, Ranjan S, Dasgupta N, Ramalingam C (2018) Nanomaterials in food and agriculture: an overview on their safety concerns and regulatory issues. Crit Rev Food Sci Nutr 58(2):297–317. https://doi.org/10.1080/10408398.2016.1160363

Jeirani Z, Mohamed Jan B, Si Ali B et al (2013) Formulation, optimization and application of triglyceride microemulsion in enhanced oil recovery. Ind Crops Prod 43:6–14

Jiang SP, He SN, Li YL et al (2013) Preparation and characteristics of lipid nanoemulsion formulations loaded with doxorubicin. Int J Nanomed 8:3141–3150. https://doi.org/10.2147/IJN.S47708

Jintapatanakit A, Hasan HM, Junyaprasert VB (2018a) Center of excellence in innovation drug delivery and nanomedicine, faculty of pharmacy. J Drug Deliv Sci Technol. https://doi.org/10.1016/j.jddst.2017.12.018

Jintapatanakit A, Hasan HM, Junyaprasert VB (2018b) Vegetable oil-based nanoemulsions containing curcuminoids: formation optimization by phase inversion temperature method. J Drug Deliv Sci Technol. https://doi.org/10.1016/j.jddst.2017.12.018

Jo Y-J, Kwon Y-J (2014) Characterization of β-carotene nanoemulsions prepared by microfluidization technique. Food Sci Biotechnol 23:107–113

Joe MM, Chauhan PS, Bradeeba K et al (2012) Influence of sunflower oil based nanoemulsion (AUSN-4) on the shelf life and quality of Indo-Pacific king mackerel (Scomberomorus guttatus) steaks stored at 20 °C. Food Control 23:564–570. https://doi.org/10.1016/j.foodcont.2011.08.032

Journal B, Nikolovski BG, Sovilj MN (2016) How to formulate a stable and monodisperse water-in-oil nanoemulsion containing pumpkin seed oil: the use of multiobjective. Braz J Chem Eng 33:919–931

Jufri M, Azmi N, Shamsuddin AF (2012) Effects of intravenous palm oil-based lipid nanoemulsion on fat metabolism in rabbits. Asian Pac J Trop Dis. https://doi.org/10.1016/s2222-1808(12)60297-

Katouzian I, Faridi A, Mahdi S, Akhavan S (2017) Trends in Food Science & Technology Formulation and application of a new generation of lipid nano-carriers for the food bioactive ingredients. Trends Food Sci Technol 68:14–25. https://doi.org/10.1016/j.tifs.2017.07.017

Katzer T, Chaves P, Bernardi A et al (2014) Castor oil and mineral oil nanoemulsion: development and compatibility with a soft contact lens. Pharm Dev Technol 19:232–237. https://doi.org/10.3109/10837450.2013.769569

Khalid N, Kobayashi I, Neves MA et al (2013a) Preparation and characterization of water-in-oil emulsions loaded with high concentration of l-ascorbic acid. LWT Food Sci Technol 51:448–454. https://doi.org/10.1016/j.lwt.2012.11.020

Khalid N, Kobayashi I, Neves MA et al (2013b) Preparation and characterization of water-in-oil-in-water emulsions containing a high concentration of L-ascorbic acid. Biosci Biotechnol Biochem 77:1171–1178. https://doi.org/10.1271/bbb.120870

Kheynoor N, Mohammad S, Hosseini H et al (2018) Encapsulation of vitamin C in a rebaudioside-sweetened model beverage using water in oil in water double emulsions. LWT Food Sci Technol. https://doi.org/10.1016/j.lwt.2018.05.066

Kim DM, Hyun SS, Yun P et al (2012) Identification of an emulsifier and conditions for preparing stable nanoemulsions containing the antioxidant astaxanthin. Int J Cosmet Sci 34:64–73. https://doi.org/10.1111/j.1468-2494.2011.00682.x

Kiokias S, Proestos C, Varzakas T (2016) A review of the structure, biosynthesis, absorption of carotenoids-analysis and properties of their common natural extracts. Curr Res Nutr Food Sci J 4:25–37

Komaiko J, McClements DJ (2015) Food-grade nanoemulsion filled hydrogels formed by spontaneous emulsification and gelation: optical properties, rheology, and stability. Food Hydrocoll 46:67–75. https://doi.org/10.1016/j.foodhyd.2014.12.031

Komaiko J, Sastrosubroto A, McClements DJ (2016) Encapsulation of w-3 fatty acids in nanoemulsion-based delivery systems fabricated from natural emulsifiers: sunflower phospholipids. Food Chem 203:331–339. https://doi.org/10.1016/j.foodchem.2016.02.080

Kumar S, Talegaonkar S, Negi LM, Khan ZI (2012) Design and development of ciclopirox topical nanoemulsion gel for the treatment of subungual onychomycosis. Indian J Pharm Educ Res 46:303–311

Lang G, Buchbauer G (2012) A review on recent research results (2008–2010) on essential oils as antimicrobials and antifungals. A review. Flavour Fragr J 27:13–39

Li YJ, Li LY, Li JL et al (2015) Effects of dietary supplementation with ferulic acid or vitamin E individually or in combination on meat quality and antioxidant capacity of finishing pigs. Asian Australas J Anim Sci 28:374–381. https://doi.org/10.5713/ajas.14.0432

Liang R, Xu S, Shoemaker CF et al (2012) Physical and antimicrobial properties of peppermint oil nanoemulsions. J Agric Food Chem 60:7548–7555. https://doi.org/10.1021/jf301129k

Mayer S, Weiss J, McClements DJ (2013) Behavior of vitamin E acetate delivery systems under simulated gastrointestinal conditions: lipid digestion and bioaccessibility of low-energy nanoemulsions. J Colloid Interface Sci 404:215–222. https://doi.org/10.1016/j.jcis.2013.04.048

McClements DJ (2015) Enhancing nutraceutical bioavailability through food matrix design. Curr Opin Food Sci 4:1–6

McClements DJ (2016) Recent progress in hydrogel delivery systems for improving nutraceutical bioavailability. Food Hydrocoll 68:238

Mcclements DJ (2018) Function enhanced delivery of lipophilic bioactives using emulsions: a review of major factors affecting vitamin, nutraceutical, and lipid bioaccessibility. Food Funct. https://doi.org/10.1039/c7fo01515a

Mcclements DJ, Jafari SM (2018) General aspects of nanoemulsions and their formulation. Elsevier, Amsterdam

McClements DJ, Li Y (2010) Structured emulsion-based delivery systems: controlling the digestion and release of lipophilic food components. Adv Colloid Interface Sci 159:213–228. https://doi.org/10.1016/j.cis.2010.06.010

McClements DJ, Decker EA, Park Y, Weiss J (2009) Structural design principles for delivery of bioactive components in nutraceuticals and functional foods. Crit Rev Food Sci Nutr 49:577–606. https://doi.org/10.1080/10408390902841529

McClements DJ, Li F, Xiao H (2015) The nutraceutical bioavailability classification scheme: classifying nutraceuticals according to factors limiting their oral bioavailability. Annu Rev Food Sci Technol 6:299–327

McClements DJ, Bai L, Chung C (2017) Recent advances in the utilization of natural emulsifiers to form and stabilize emulsions. Annu Rev Food Sci Technol 8:205–236. https://doi.org/10.1146/annurev-food-030216-030154

Mehmood T (2015) Optimization of the canola oil based vitamin E nanoemulsions stabilized by food grade mixed surfactants using response surface methodology. Food Chem 183:1–7. https://doi.org/10.1016/j.foodchem.2015.03.021

Meléndez-Martínez AJ, Mapelli-Brahm P, Benítez-González A, Stinco CM (2015) A comprehensive review on the colorless carotenoids phytoene and phytofluene. Arch Biochem Biophys 572:188–200

Meng Z, Qi K, Guo Y et al (2018) Effects of thickening agents on the formation and properties of edible oleogels based on hydroxypropyl methyl cellulose. Food Chem 246:137–149

Mohamed Salama M, Ahmad Mustafa ME (2013) Formulation and evaluation of avocado oil nanoemulsion hydrogels using sucrose ester laureate. Adv Mater Res (Durnten-Zurich, Switzerland) 812:246–249. https://doi.org/10.4028/www.scientific.net/AMR.812.246

Mohammadi A, Jafari SM, Esfanjani AF, Akhavan S (2016) Application of nano-encapsulated olive leaf extract in controlling the oxidative stability of soybean oil. Food Chem 190:513–519. https://doi.org/10.1016/j.foodchem.2015.05.115

Morais DJM, Burgess J (2014) Vitamin E nanoemulsions characterization and analysis. Int J Pharm 465:455–463. https://doi.org/10.1016/j.ijpharm.2014.02.034

Mungure TE, Roohinejad S, Bekhit AE et al (2018) Accept ecrt. Curr Opin Food Sci. https://doi.org/10.1016/j.cofs.2018.01.011

Nguyen MH, Hwang IC, Park HJ (2013) Enhanced photoprotection for photo-labile compounds using double-layer coated corn oil-nanoemulsions with chitosan and lignosulfonate. J Photochem Photobiol B Biol 125:194–201. https://doi.org/10.1016/j.jphotobiol.2013.06.009

Nicolosi RJ, Wilson T (2015) Compositions and methods for making and using nanoemulsions. https://patents.google.com/patent/WO2009121069A2

Noori S, Zeynali F, Almasi H (2018) Antimicrobial and antioxidant efficiency of nanoemulsion-based edible coating containing ginger (Zingiber officinale) essential oil and its effect on safety and quality attributes of chicken breast fillets. Food Control 84:312–320. https://doi.org/10.1016/j.foodcont.2017.08.015

O’Sullivan JJ, Drapala KP, Kelly AL, O’Mahony JA (2018) The use of inline high-shear rotor-stator mixing for preparation of high-solids milk protein-stabilised oil-in-water emulsions with different protein: fat ratios. J Food Eng 222:218–225. https://doi.org/10.1016/j.jfoodeng.2017.10.015

Ofokansi KC, Chukwu KI, Ugwuanyi SI (2009) The use of liquid self-microemulsifying drug delivery systems based on peanut oil/Tween 80 in the delivery of griseofulvin. Drug Dev Ind Pharm 35:185–191. https://doi.org/10.1080/03639040802244292

Ostertag F, Weiss J, McClements DJ (2012) Low-energy formation of edible nanoemulsions: factors influencing droplet size produced by emulsion phase inversion. J Colloid Interface Sci 388:95–102. https://doi.org/10.1016/j.jcis.2012.07.089

Otoni CG, Pontes SFO, Medeiros EAA, Soares NdeFF (2014) Edible films from methylcellulose and nanoemulsions of clove bud (Syzygium aromaticum) and oregano (Origanum vulgare) essential oils as shelf life extenders for sliced bread. J Agric Food Chem 62:5214–5219

Ozturk B, Argin S, Ozilgen M, McClements DJ (2015) Formation and stabilization of nanoemulsion-based vitamin E delivery systems using natural biopolymers: whey protein isolate and gum arabic. Food Chem. https://doi.org/10.1016/j.foodchem.2015.05.005

Pant M, Dubey S, Patanjali PK et al (2014) Insecticidal activity of eucalyptus oil nanoemulsion with karanja and jatropha aqueous filtrates. Int Biodeterior Biodegrad 91:119–127. https://doi.org/10.1016/j.ibiod.2013.11.019

Pardeike J, Hommoss A, Müller RH (2009) Lipid nanoparticles (SLN, NLC) in cosmetic and pharmaceutical dermal products. Int J Pharm 366:170–184

Patil A, Bhide S, Bookwala M et al (2017) Mini-review stability of organoleptic agents in pharmaceuticals and cosmetics. AAPS PharmSciTech. https://doi.org/10.1208/s12249-017-0866-2

Piorkowski DT, McClements DJ (2014) Beverage emulsions: recent developments in formulation, production, and applications. Food Hydrocoll 42:5–41. https://doi.org/10.1016/j.foodhyd.2013.07.009

Poonia N, Kharb R, Lather V, Pandita D (2016) Nanostructured lipid carriers: versatile oral delivery vehicle. Futur Sci OA 2:FSO135. https://doi.org/10.4155/fsoa-2016-0030

Prichapan N, Klinkesorn U (2014) Factor affecting the properties of water-in-oil-in-water emulsions for encapsulation of minerals and vitamins. Songklanakarin J Sci Technol 36:651–661

Puri R, Mahajan M, Sahajpal NS et al (2015) Self-nanoemulsifying drug delivery system of docosahexanoic acid: development, in vitro, in vivo characterization. Drug Dev Ind Pharm. https://doi.org/10.3109/03639045.2015.1107089

Rabelo CAS, Taarji N, Khalid N et al (2018) Formulation and characterization of water-in-oil nanoemulsions loaded with açaí berry anthocyanins: insights of degradation kinetics and stability evaluation of anthocyanins and nanoemulsions. Food Res Int. https://doi.org/10.1016/j.foodres.2018.01.017

Ramisetty KA, Pandit AB, Gogate PR (2015) Ultrasound assisted preparation of emulsion of coconut oil in water: understanding the effect of operating parameters and comparison of reactor designs. Chem Eng Process Process Intensif 88:70–77. https://doi.org/10.1016/j.cep.2014.12.006

Ranjan S, Dasgupta N, Chakraborty AR et al (2014) Nanoscience and nanotechnologies in food industries: opportunities and research trends. J Nanoparticle Res 16:1–23. https://doi.org/10.1007/s11051-014-2464-5

Ranjan S, Nandita D, Lichtfouse E (2016a) Nanoscience in food and agriculture 2, 1st edn. Springer, Switzerland

Ranjan S, Nandita D, Lichtfouse E (2016b) Nanoscience in food and agriculture 1, 1st edn. Springer, Switzerland

Rao J, McClements DJ (2011) Food-grade microemulsions, nanoemulsions and emulsions: fabrication from sucrose monopalmitate & lemon oil. Food Hydrocoll 25:1413–1423. https://doi.org/10.1016/j.foodhyd.2011.02.004

Rao J, McClements DJ (2012a) Food-grade microemulsions and nanoemulsions: role of oil phase composition on formation and stability. Food Hydrocoll 29:326–334. https://doi.org/10.1016/j.foodhyd.2012.04.008

Rao J, McClements DJ (2012b) Lemon oil solubilization in mixed surfactant solutions: rationalizing microemulsion & nanoemulsion formation. Food Hydrocoll 26:268–276. https://doi.org/10.1016/j.foodhyd.2011.06.002

Ricaurte L, Perea-Flores M de J, Martinez A, Quintanilla-Carvajal MX (2016) Production of high-oleic palm oil nanoemulsions by high-shear homogenization (Microfluidization). Innov Food Sci Emerg Technol. https://doi.org/10.1016/j.ifset.2016.04.004

Ron N, Zimet P, Bargarum J, Livney YD (2010) Beta-lactoglobulin–polysaccharide complexes as nanovehicles for hydrophobic nutraceuticals in non-fat foods and clear beverages. Int Dairy J 20:686–693

Roy A (2018) Formulation and characterization of betel leaf (Piper betle L.) essential oil based nanoemulsion and its in vitro antibacterial efficacy against selected food pathogens. J Food Process Preserv. https://doi.org/10.1111/jfpp.13617

Rubio-Rodríguez N, Beltrán S, Jaime I et al (2010) Production of omega-3 polyunsaturated fatty acid concentrates: a review. Innov Food Sci Emerg Technol 11:1–12

Ryckebosch E, Bruneel C, Muylaert K, Foubert I (2012) Microalgae as an alternative source of omega-3 long chain polyunsaturated fatty acids. Lipid Technol 24:128–130. https://doi.org/10.1002/lite.201200197

Saberi AH, Fang Y, McClements DJ (2013) Fabrication of vitamin E-enriched nanoemulsions: factors affecting particle size using spontaneous emulsification. J Colloid Interface Sci 391:95–102. https://doi.org/10.1016/j.jcis.2012.08.069

Sánchez-Salcedo EM, Sendra E, Carbonell-Barrachina ÁA et al (2016) Fatty acids composition of Spanish black (Morus nigra L.) and white (Morus alba L.) mulberries. Food Chem 190:566–571

Sharma A, Kumar N, Srivastava A et al (2018) Industrial crops & products clove and lemongrass oil based non-ionic nanoemulsion for suppressing the growth of plant pathogenic Fusarium oxysporum f. sp. lycopersici. Ind Crop Prod 123:353–362. https://doi.org/10.1016/j.indcrop.2018.06.077

Smoliga JM, Blanchard O (2014) Enhancing the delivery of resveratrol in humans: if low bioavailability is the problem, what is the solution? Molecules 19:17154–17172

Sotomayor-Gerding D, Oomah BD, Acevedo F et al (2016) High carotenoid bioaccessibility through linseed oil nanoemulsions with enhanced physical and oxidative stability. Food Chem 199:463–470. https://doi.org/10.1016/j.foodchem.2015.12.004

Stellavato A, Virginia A, Pirozzi A et al (2018) In vitro assessment of nutraceutical compounds and novel nutraceutical formulations in a liver-steatosis-based model. Lipids Health Dis. https://doi.org/10.1186/s12944-018-0663-2

Stounbjerg L, Vestergaard C, Andreasen B, Ipsen R (2017) Beverage clouding agents: review of principles and current manufacturing. Food Rev Int. https://doi.org/10.1080/87559129.2017.1373286

Sugumar S, Nirmala J, Ghosh V et al (2013) Bio-based nanoemulsion formulation, characterization and antibacterial activity against food-borne pathogens. J Basic Microbiol 53:677–685. https://doi.org/10.1002/jobm.201200060

Sugumar S, Ghosh V, Nirmala MJ et al (2014) Ultrasonic emulsification of eucalyptus oil nanoemulsion: antibacterial activity against Staphylococcus aureus and wound healing activity in Wistar rats. Ultrason Sonochem 21:1044–1049. https://doi.org/10.1016/j.ultsonch.2013.10.021

Sugumar S, Mukherjee A, Chandrasekaran N (2015a) Nanoemulsion formation and characterization by spontaneous emulsification: investigation of its antibacterial effects on listeria monocytogenes. Asian J Pharm. https://doi.org/10.4103/0973-8398.150033

Sugumar S, Mukherjee A, Chandrasekaran N (2015b) Eucalyptus oil nanoemulsion-impregnated chitosan film: antibacterial effects against a clinical pathogen, Staphylococcus aureus, in vitro. Int J Nanomed 10:67–75. https://doi.org/10.2147/IJN.S79982

Tabibiazar M, Davaran S, Hashemi M et al (2015) Design and fabrication of a food-grade albumin-stabilized nanoemulsion. Food Hydrocoll 44:220–228

Tamjidi F, Shahedi M, Varshosaz J, Nasirpour A (2018) Stability of astaxanthin-loaded nanostructured lipid carriers in beverage systems. J Sci Food Agric 98:511

Teng J, Hu X, Wang M, Tao N (2018) Fabrication of chia (Salvia hispanica L.) seed oil nanoemulsions using different emulsifiers. J Food Process Preserv 42:1–9. https://doi.org/10.1111/jfpp.13416

Topuz OK, Özvural EB, Zhao Q et al (2016) Physical and antimicrobial properties of anise oil loaded nanoemulsions on the survival of foodborne pathogens. Food Chem 203:117–123. https://doi.org/10.1016/j.foodchem.2016.02.051

Uzun S, Kim H, Leal C, Padua GW (2016) Ethanol-induced whey protein gels as carriers for lutein droplets. Food Hydrocoll 61:426–432

van de Rest O, de Groot C (2014) The impact of omega-3 fatty acids on quality of life. In: Omega-3 fatty acids in brain and neurological health. Elsevier, Amsterdam, pp 81–85

Vijayalakshmi G, Mukherjee A, Chandrasekaran N (2014) Eugenol-loaded antimicrobial nanoemulsion preserves fruit juice against, microbial spoilage. Colloids Surf B Biointerfaces 114:392–397. https://doi.org/10.1016/j.colsurfb.2013.10.034

Vyas TK, Shahiwala A, Amiji MM (2008) Improved oral bioavailability and brain transport of Saquinavir upon administration in novel nanoemulsion formulations. Int J Pharm 347:93–101. https://doi.org/10.1016/j.ijpharm.2007.06.016

Wang Z, Pal R (2014) Enlargement of nanoemulsion region in pseudo-ternary mixing diagrams for a drug delivery system. J Surfactants Deterg 17:49–58

Yang Y, McClements DJ (2013) Vitamin E bioaccessibility: influence of carrier oil type on digestion and release of emulsified α-tocopherol acetate. Food Chem 141:473–481. https://doi.org/10.1016/j.foodchem.2013.03.033

Yang C, Wu T, Qi Y, Zhang Z (2018) Recent advances in the application of vitamin E TPGS for drug delivery. Theranostics 8:464–485. https://doi.org/10.7150/thno.22711

Yao M, McClements DJ, Xiao H (2015) Improving oral bioavailability of nutraceuticals by engineered nanoparticle-based delivery systems. Curr Opin Food Sci 2:14–19

Zhang X (2013) Tea tree oil nanoemulsion and its preparation method thereof. Faming Zhuanli Shenqing

Zheng N, Gao Y, Ji H et al (2016) Vitamin E derivative-based multifunctional nanoemulsions for overcoming multidrug resistance in cancer. J Drug Target 24:663–669

Zhou Q, Xu J, Yang S et al (2015) The effect of various antioxidants on the degradation of O/W microemulsions containing esterified astaxanthins from haematococcus pluvialis. J Oleo Sci 64:515

Ziani K, Fang Y, McClements DJ (2012) Fabrication and stability of colloidal delivery systems for flavor oils: effect of composition and storage conditions. Food Res Int 46:209–216. https://doi.org/10.1016/j.foodres.2011.12.017

Zou L, Liu W, Liu C et al (2015) Utilizing food matrix effects to enhance nutraceutical bioavailability: increase of curcumin bioaccessibility using excipient emulsions. J Agric Food Chem 63:2052–2062. https://doi.org/10.1021/jf506149f(2018)AcceptedMuspt

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Dasgupta, N., Ranjan, S. & Gandhi, M. Nanoemulsion ingredients and components. Environ Chem Lett 17, 917–928 (2019). https://doi.org/10.1007/s10311-018-00849-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-018-00849-7