Abstract

Microplastics’ sorption capability has been studied over the last decade to better understand the potential impacts that they have on the ecosystems and human health. However, the role of plastic aging, in which the polymer’s physical and chemical properties are changed due to exposure to environmental agents, such as weathering, has been overlooked. Consequently, there is a need to explore the role of the aging processes in the interaction of microplastics with other pollutants, and the potential risk of an enhanced capacity of microplastics carrying co-occurring pollutants between environmental compartments and ecosystems. Thus, the main goal of this study was to evaluate the changes in the sorption capacity after aging microplastics of LDPE – low-density polyethylene, PET – poly(ethylene terephthalate), and uPVC – unplasticized poly(vinyl chloride). Through sorption experiments, virgin and aged (by ozone exposure or 3 months of rooftop weathering) microplastic particles of the three polymers were exposed to ten organic contaminants (pesticides or pharmaceutical substances) at trace concentrations, including both priority substances and contaminants of emerging concern. The results show increased sorption of these contaminants on the aged microplastic particles, which is dependent on the affinity between each polymer and organic contaminant, and the effectiveness of the aging treatment. A better understanding of the interaction between these different pollutants was reached due to the analysis of the sorption experiments results when accounting for modifications of the chemical structure, surface morphology and/or crystallinity of the microplastic particles identified after the aging processes. This study supports the hypothesis that microplastics can be transport vectors for other pollutants and demonstrates the major role of the aging degree in the sorption process. Thus, it provides further evidence of the pressing need to study microplastics in more realistic conditions, in which they undergo aging and interact with other pollutants.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

14.1 Introduction

Microplastics are considered as contaminants of emerging concern [1] since large quantities started to be frequently and in a widespread manner found in several environmental compartments and ecosystems [2]. In order to better understand the behavior and impacts of microplastics, their sorption capacities started to be studied, but the role of plastic aging on the sorption processes has been overlooked [3]. Polymer degradation, by abiotic and/or biotic pathways, is usually a slow process under natural environmental conditions, which creates physical and chemical modifications, such as crazing, cracking, the introduction of oxygen-containing surface groups, and discoloration [4]. These modifications are expected to change the behavior of microplastics over time, influencing their interaction with co-occurring contaminants and biota [5, 6]. Consequently, there is a need to explore the role of the aging processes in the interaction of microplastics with other pollutants, and the subsequent potential risk of an enhanced sorption capacity and a trojan horse vector effect [7].

Although several pesticides and pharmaceutical substances are already considered priority substances under the European Union (EU) environmental legislation, new substances continue to be developed and pose new threats to the environment. These substances, yet to have Environmental Quality Standards [8], are classified as contaminants of emerging concern. Therefore, research is necessary on the interaction of these substances with microplastics to identify affinities between the different polymers and substances and the potential threats of this combo in the environment [9].

Thus, the goals of this study were to (i) assess the modifications on the chemical structure, surface morphology and crystallinity of microplastic particles of 3 polymers after different aging treatments; (ii) evaluate the changes in the sorption capacity after aging and link those with the modifications detected, and (iii) identify affinities between 10 organic contaminants (4 pesticides and 6 pharmaceutical substances) with microplastic particles of the selected polymers.

14.2 Experimental

14.2.1 Materials

Microplastic particles (MPPs) of LDPE – low-density polyethylene (average particle diameter of 509 ± 221 µm), PET – poly(ethylene terephthalate) (161 ± 79 µm) and uPVC – unplasticized poly(vinyl chloride) (159 ± 43 µm) were purchased from Goodfellow (UK).

Ten organic contaminants were selected for the study, including both priority substances and contaminants of emerging concern, at trace concentrations: (i) pesticides – alachlor, clofibric acid, diuron, pentachlorophenol; and (ii) pharmaceutical substances – citalopram, diclofenac, florfenicol, tramadol, trimethoprim, and venlafaxine. These substances were purchased from Sigma-Aldrich (Germany) or Supelco (Germany) in powder form.

14.2.2 Methods

The MPPs were first aged by ozone exposure or rooftop weathering, being characterized before and after aging. Then, sorption batch experiments were conducted with both virgin and aged samples of MPPs. Finally, the solutions were filtered to remove the MPPs from suspension and the pesticides and pharmaceutical substances in solution were quantified by liquid chromatography.

14.2.2.1 Aging Treatments

For the ozone gas MPP aging, the virgin MPPs of each polymer received a 150 Ncm3 min−1 flow rate of 50 gO3 Nm−3 for 1 h [10]. For the rooftop (RT) weathering experiment, the virgin MPPs of each polymer were exposed to real conditions of weathering regarding air humidity and temperature, sunlight, and precipitation (under a temperate climate, during the period of the year with the maximum hours of sunlight per day and higher UV index, in the city of Porto, Portugal). Two types of weathering samples were obtained after 3 months (13 weeks): RT1 – the MPPs underwent aging due to natural solar exposure and temperature variations; RT2 – same as RT1 but filtered rainwater collected was additionally added to these samples of MPPs, following the precipitation pattern [10].

14.2.2.2 Sorption Experiments

Two series of sorption batch experiments were performed to study the MPP sorption capacities and affinity to the organic contaminants [11]: (i) sorption kinetics of a mix of the 10 organic contaminants on virgin MPPs; (ii) sorption with the same mix of the 10 organic contaminants but using aged MPPs to study this effect.

For this, 250 mg of MPPs (LDPE, PET, or uPVC) and 25 mL of the solution with the 10 organic contaminants (pH ca. 5.8, ca. 100 µg L−1 of each substance) were added to 50 mL bottles. The bottles were shaken at 150 strokes per minute and kept at 25 °C for the duration of the experiment. All samples with MPPs were run in triplicates and had control bottles without the MPPs. After that, the samples underwent vacuum filtration (pore size of 1.2 µm) to remove the MPPs from suspension. The filtered samples were stored in HPLC vials at −18 °C until analyzed.

For the kinetics experiments, the following time intervals were used: 2, 4, 8, 16, 24 and 30 h. For the other type of experiments, the samples were shaken for 24 h.

14.2.2.3 Analytical Techniques

The MPPs were characterized using a particle size analyzer, Attenuated Total Reflection – Fourier transform infrared (ATR-FTIR) spectroscopy, Scanning Electron Microscopy (SEM), and X-ray diffraction (XRD) analysis [10].

The organic substances were quantified using an ultra-high-performance liquid chromatography-tandem mass spectrometry (UHPLC-MS/MS) analytical method [11].

14.2.2.4 Data Analysis

Carbonyl Index (CI) was estimated by Eq. 14.1 for LDPE and uPVC [10]. The ATR-FTIR spectra were used to obtain the transmittance, which was converted to absorbance (A), of the carbonyl group and methylene group peaks maximum height. CI was not calculated for PET, since this polymer has a characteristic infrared absorption peak at 1714 cm−1 due to C = O stretching of the carboxylic acid group, disabling the possible detection of the growth of the carbonyl group peak height as aging modifies the polymer. The average and standard deviation were calculated for all the results.

The XRD diffractograms were analyzed using the HighScore 4.8 software, in this way determining the crystalline and amorphous areas and, consequently, the degree of crystallinity [10].

The sorption capacity q (µg g−1) was calculated by Eq. 14.2, where Ccontrol is the concentration of each organic substance (µg L−1) in the control bottle liquid phase, Csample is the concentration of each organic substance (µg L−1) in a sample bottle liquid phase, V is the volume (L) of the solution added to each bottle, and m is the mass (g) of MPPs added to the bottle.

14.3 Results and Discussion

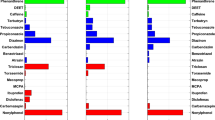

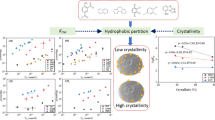

Of the 3 polymers selected, LDPE was the most impacted by the aging treatments studied Fig. 1a. Both the ozone treatment and rooftop weathering lead to modifications in the chemical structure of the polymer. The most substantial modification was the formation of carbonyl species (C = O), enabling to quantify the degree of aging with the estimation of the CI increase from 0.004 ± 0.001 (virgin) to 0.100 ± 0.002 (ozone), 0.243 ± 0.011 (RT1) and 0.246 ± 0.006 (RT2) [10]. While being more difficult to assess the aging degree of PET using ATR-FTIR data, it was possible to detect a broader 1714 cm−1 peak base for the ozone samples (Fig. 1b). The weathering treatments were the most effective in introducing changes in the chemical structure of uPVC, as suggested by the highest increase in carbonyl species Fig. 1c. The uPVC CI increased from 0.73 ± 0.15 (virgin) to 0.85 ± 0.06 (ozone), 4.82 ± 0.27 (RT1) and 3.37 ± 0.12 (RT2) [10]. Another noteworthy modification identified is the formation of hydroxyl species (O–H) for the weathering samples of the 3 polymers, although much more subtle. Overall, LDPE was shown to be more susceptible, than PET and uPVC, to crystallinity changes under the aging treatments conducted and for the exposure times tested, particularly after weathering.

The SEM analysis of the surface morphology of LDPE, PET and uPVC revealed that most of the aging treatments lead to no major morphological changes. The most relevant modifications detected occurred for LDPE after weathering, as shown by the observation of randomly distributed cracks on the surface of LDPE weathered samples, that were more pronounced for the RT2 samples, which were in contact with rainwater [10].

The sorption kinetics of the mixture of the 10 organic contaminants were studied for each polymer virgin MPPs, allowing to define an adequate contact time for the rest of the sorption experiments. These first experiments show that only alachlor (for LDPE) and pentachlorophenol (for the 3 polymers but mainly for LDPE) were discernibly sorbed on virgin MPPs. An apparent equilibrium was reached between 16 and 24 h. Thus, 24 h was considered enough to reach equilibrium, under the conditions tested.

Following this, the effect of aging on the sorption capacities of the polymers was studied (Fig. 14.2). The results revealed higher sorption of several organic substances on aged MPPs, when compared to virgin MPPs, i.e. the sorption capacity increased from one or two sorbed substances (maximum 3 µg g−1 per sorbate) up to nine after aging (maximum 10 µg g−1 per sorbate). As predicted, considering the characterization of the aged samples, LDPE sorption capacities were the most impacted by aging. The weathering exposure led to the highest increases in the sorption capacities of LDPE and uPVC, but ozone exposure proved to be more effective for PET due to pentachlorophenol sorption on the ozone-aged MPPs of this polymer.

The increase in the amount of the oxygen-containing functional groups through aging is known for affecting the surface hydrophobic properties of the plastics and allowing additional interactions [12]. Thus, the previously identified modifications can be linked to the increment of the sorption capacity for certain substances. For instance, the overall higher sorption capacity observed for uPVC RT1 samples over RT2 samples matches the higher CI obtained for RT1 over RT2. Likewise, the similar CI obtained for RT1 and RT2 samples of LDPE matches the similar sorption capacities between these two samples.

Despite the fact that RT1 and RT2 samples of LDPE show similar sorption capacities for most substances and similar modifications in their chemical structure, they are different regarding their surface morphology, i.e. RT2 is more aged in that regard. This suggests that the affinity and consequent sorption of most of the studied substances on LDPE MPPs were mainly governed by the surface chemical structure.

Even after aging, pentachlorophenol remains the most sorbed substance for all LDPE samples and ozone-aged PET. Another noteworthy affinity encountered was the trimethoprim sorption on the PET RT2 samples, which might be related to the formation of hydroxyl species during aging. No affinity was found, even after aging, between tramadol and venlafaxine for LDPE and PET, and between clofibric acid and uPVC.

14.4 Conclusions

This study demonstrates the major role of the aging degree of MPPs in the sorption process, with impact on the interaction between most of the studied organic contaminants and the MPPs of LDPE, PET and uPVC. The differences between the sorption capacities of each polymer before and after aging can be linked to the chemical and physical modifications identified, providing essential information on the behavior of microplastics in the environment, particularly when predicting their affinity with a diversity of co-occurring contaminants. For LDPE and uPVC, the CI can be a valuable indicator in a preliminary estimation of the global sorption capacities of aged MPPs, although it is not valid for every single substance.

References

The European Parliament and the Council of the European Union (2020) Directive (EU) 2020/2184 on the quality of water intended for human consumption (recast) 435:1–62

Miranda MN, Silva AMT, Pereira MFR (2020) Microplastics in the environment: A DPSIR analysis with focus on the responses. Sci Total Environ 718:134968

Alimi OS, Claveau-Mallet D, Kurusu RS, Lapointe M, Bayen S, Tufenkji N (2022) Weathering pathways and protocols for environmentally relevant microplastics and nanoplastics: What are we missing? J Hazard Mater 423:126955

Singh B, Sharma N (2008) Mechanistic implications of plastic degradation. Polym Degrad Stab 93(3):561–584

Liu P et al (2020) Effect of aging on adsorption behavior of polystyrene microplastics for pharmaceuticals: Adsorption mechanism and role of aging intermediates. J Hazard Mater 384:121193

Vroom RJE, Koelmans AA, Besseling E, Halsband C (2017) Aging of microplastics promotes their ingestion by marine zooplankton. Environ Pollut 231:987–996

UNEP (2016) Marine plastic debris and microplastics: Global lessons and research to inspire action and guide policy change. Nairobi. Available: https://wedocs.unep.org/handle/20.500.11822/7720

The European Parliament and the Council of the European Union (2013) Directive 2013/39/EU of the European Parliament and of the Council of 12 August 2013 amending Directives 2000/60/EC and 2008/105/EC as regards priority substances in the field of water policy 226:1–17

Vieira Y, Lima EC, Foletto EL, Dotto GL (2021) Microplastics physicochemical properties, specific adsorption modeling and their interaction with pharmaceuticals and other emerging contaminants. Sci Total Environ 753:141981

Miranda MN, Sampaio MJ, Tavares PB, Silva AMT, Pereira MFR (2021) Aging assessment of microplastics (LDPE, PET and uPVC) under urban environment stressors. Sci Total Environ 796:148914

Miranda MN, Lado Ribeiro AR, Silva AMT, Pereira MFR (2022) Can aged microplastics be transport vectors for organic micropollutants? – Sorption and phytotoxicity tests. Sci Total Environ 850:158073

Liu G, Zhu Z, Yang Y, Sun Y, Yu F, Ma J (2019) Sorption behavior and mechanism of hydrophilic organic chemicals to virgin and aged microplastics in freshwater and seawater. Environ Pollut 246:26–33

Acknowledgments

This work was financially supported by: LA/P/0045/2020 (ALiCE), UIDB/50020/2020 and UIDP/50020/2020 (LSRE-LCM), funded by national funds through FCT/MCTES (PIDDAC). M.N.M. acknowledges the PhD research grant from Fundação para a Ciência e a Tecnologia (FCT) (Ref. PD/BD/137730/2018, extended by COVID/BD/152633/2022), funded by national funds and by the European Union (EU) through the European Social Fund (ESF). The authors are grateful for the contributions of Ana R. Lado Ribeiro, Maria J. Sampaio, and Pedro B. Tavares.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Miranda, M.N., Silva, A.M.T., Pereira, M.F.R. (2023). Evaluation of the Role of Plastic Aging on the Sorption of Pesticides and Pharmaceutical Substances on Microplastics. In: Cocca, M., Ambrogi, V., Avolio, R., Castaldo, R., Errico, M.E., Gentile, G. (eds) Proceedings of the 3rd International Conference on Microplastic Pollution in the Mediterranean Sea. ICMPMS 2022. Springer Water. Springer, Cham. https://doi.org/10.1007/978-3-031-34455-8_14

Download citation

DOI: https://doi.org/10.1007/978-3-031-34455-8_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-34454-1

Online ISBN: 978-3-031-34455-8

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)