Abstract

The aim of this work is to develop, improve and operate a domestic anaerobic digester as an open hardware apparatus to promote decentralized energy and nutrient recovery. A brief introduction to the concept of decentralized energy and nutrient recovery is presented and its connection to the Water-Food-Energy Nexus, which claims citizen participation in the process is highlighted. The construction and use of an Open Hardware anaerobic biodigester named Boitatá was based on communities of interest, so as to permit its replication in hackerspaces, fablabs, etc. The developed reactor was tested in real life conditions for a family of three people and their pets, and some improvements were proposed and implemented to make it easier to build and operate. During the field testing period it has managed to treat all the organic waste daily generated in the household (around 800 g) with a specific biogas production of around 0,710 Lbiogas/gSV, which covers about 21% of the family cooking energy demand, demonstrating the viability of the apparatus for the descentralized anaerobic digestion in urban households and small enterprises.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Despite the sanction of the National Solid Waste Policy in 2010 [1], which predicts the hierarchy in waste management of not generation, reduction, reuse, recycle and adequate final disposal, and considers energy recovery and composting as some of the adequate treatment technologies, municipal solid waste (MSW) management in Brazil has not achieved reasonable standards so far. Recycling rates are still at the level of around 3% [2] and almost 45% of the MSW collected in the country still have inadequate final disposal [3] consequently, there is an increasing demand for areas in the city outskirts for implementation of landfills or even illegal dumping sites.

Both aerobic (composting) and anaerobic digestion (AD) of the organic fraction of municipal solid waste (OFMSW) are techniques used to stabilize and convert this material in organic compost, with completely different characteristics from the OFMSW. Besides the stabilized material (digestate), AD also produces a methane rich gas (biogas), characterizing it as an energy recovery process. If the compost or digestate meets the requirements of the Normative Instruction n°61/2020 of the Ministry of Agriculture, Livestock and Supply, it is classified as a biofertilizer.

Biofertilizer is a fundamental input for food production, so, energy recovery through AD and nutrient recovery through both AD and composting allied to other aspects such as the land use in the peri-urban space and water management, allows characterizing the relationship between OFMSW, energy and food production within the Water-Energy-Food-Ecosystem nexus (WEFE) [4, 5], which is embedded in the framework of the United Nations Sustainable Development Goals (SDG). The WEFE nexus involves 14 of 17 SDGs [5] and its approach and methodology is a recognized way for the implementation of the SDGs.

The 4 pillars related to the WEFE nexus are complex, as they must consider the various stakeholders [4], thus, contrary to what is advocated by the neo/ultraliberal management model in which the minimum interference in the lives of citizens must be carried out, the resolution of the relationship between waste and energy must necessarily consider citizens’ participation.

The research area of decentralized energy and nutrient recovery (DENR) can thus be characterized, which is embedded in the WEFE nexus, seeking an environmentally and socially fair solution, since it considers a fundamental stakeholder: the citizens. There are several other stakeholders related to this nexus, such as governments and companies, which are also influenced by citizens.

Anaerobic digestion is an effective way to perform the DENR, for which anaerobic microreactors and the concepts of decentralized anaerobic digestion (DAD) are used [6, 7]. There are several substrates that can be used in urban space, FORSU, is among then but notably food waste (FW) has a good biochemical methane potential (BMP) [8,9,10].

However, there are great challenges present in DAD, such as the enormous variability in terms of quality and quantity in the generation of domestic food waste in an individual household, besides other relevant aspects such as variation in ambient temperature, reactor acidification, problems related to reactor odors, possibility of attracting unwanted animals, among others [6, 7].

One of the current ways in which people organize themselves is through communities of interest [11, 12], as can be seen in Hackerspaces, FabLabs, Makerspaces, among others. This practice usually occurs based on the construction of apparatuses and applying the concepts of open and citizen science, that is, with the use of free software, good documentation, encouraging spaces for interaction, as in the examples of the Open Source Hardware Association [13] and also the GOSH [14]. In general terms, the developed apparatus must be presented in such a way that any interested person can reproduce it.

The usual method applied in many spaces where interested communities meet (hackerspaces, fablabs, makerspaces, etc.) is based on “hands-on” activities [12], possibly derived from the long tradition of software development, notably straightforward methods such as the SCRUM [15]. There are several initiatives to transpose this method of software production to material production [16] and to scientific practice methods such as LabSCRUM [17].

A bibliographic survey was carried out using the “Web of Science” (WoS) database and binary search keys, using the search keys “decentrali* anaerobic digestion” AND (“Food Waste” OR “dog” OR “cat”) and “Micro-scale anaerobic digest*” [7].

Both keys returned few publications (7 and 6 respectively) and with h-index equal to 4, however there is an increase in publications in the last 3 years, suggesting that despite being a small research area, there is a growing interest on the theme. It is also possible to observe that most of the articles published are outside the field of engineering, indicating a gap in the research and development of devices that can be used in the DENR concept, mainly in terms of anaerobic digestion.

The advantages of the DAD are still under scientific analysis [7, 21, 22], however in this work this practice is assumed to be advantageous due to the involvement of people, who are key stakeholders in the WEFE nexus.

The objective of this work is contribute to development of an open source hardware apparatus that can be applied for the DENR in households and other small scale organic waste generators in an urban or semi-urban context, and which can be replicated and improved by communities of interest.

2 Materials and Methods

As a more general conceptual framework for this research, the prototyping method was used, derived from SCRUM and the interest group method [12, 23], which implies focusing on solving a problem in a concrete way, even if the solution is partial.

Other three methods were used to achieve the objectives. The first is related to the long-term analysis of the reactor, which was carried out in the field and therefore with several limitations, including those resulting from the pandemic. The second refers to analyzes and characterizations of the substrates used, including the series of solids and BMP, which were carried out at the Laboratory of Processes and Production of Biogas (LPPB) at the São Bernardo do Campo, São Paulo, Brazil. UFABC (Federal University of ABC). Finally, a mathematical model was developed to optimize the reactor adaptation period.

2.1 The Boitatá Reactor

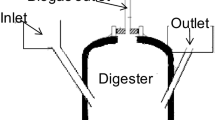

In 2018, some anaerobic digesters of the completely stirred tubular reactor (CSTR) type were built, named Boitatá, based on communities of interest [18] in the Baixada Santista (a metropolitan area on the coast, close to the city of São Paulo). Its design was based on a work presented by Peterson (2018) [18]. The materials used were readily available in the local market and total cost was approximately U$ 100,00. A general scheme can be seen in Fig. 1 and its main characteristics are presented in Table 1.

2.2 Field Analysis

With the worsening of the Sars-Covid-2019 pandemic, one of these reactors was transported and used by one of the researchers at his residence in the municipality of Praia Grande-SP. Over a period of 14 months (October 2020 to November 2021) the reactor was submitted to the steps of inoculation, start-up, adaptation and regular operation.

The reactor was inoculated with about 40 L of digestive liquid from a bovine manure reactor, and was fed daily until the level of 220 L was completed and the gas produced was able to maintain a flame (flame test), which was considered the end of the start-up phase.

During the adaptation phase the feed rate and composition of the substrate was kept constant during a month and increased and diversified monthly, as presented in Table 4. A kitchen scale with an accuracy of ±5 g was used to weight the substrate fed. A Philips-Walita blender model RI2008/3 L, with a maximum capacity of 1.5 L was used for grinding and homogenizing the FW. The measurement of pH and total alkalinity in the field was carried out using colorimetric strips for swimming pools (Hth brand) (alkalinity measurement in a 10% digestate solution).

A PVC bag with a volume of 75 L ± 10 was used for storage and estimation of the biogas produced.

A period of one month (month 5) was chosen to make a more detailed analysis of the Boitatá performance (period of analysis). Biogas production was monitored during this period using a gas flow micrometer (Ritter milligascounter MGC-1).

After the inoculation and start-up period, adaptation was carried out, which is a long period in which the complex system in the reactor acclimatizes to the substrate that is fed. This period was considered completed when all the daily organic residue available in the household was used to feed the reactor. Presently the reactor is being fed with FW from a family of 3 people and the waste of 2 dogs (Canis lupus familiaris) from Dachshund breed and 2 guinea pigs (Cavia porcellus) which represents an average of 800 g of waste daily.

During the adaptation phase, the main goal was to avoid acidification of the digester, since this is one of the main problems in the use of FW as substrate [19, 20].

The fundamental problem tackled was the feasibility of building and operating an anaerobic microreactor in urban space [24], for which a Boitatá reactor was used. The improvements of the apparatus followed the prototyping method derived from SCRUM.

Two iterations of development were made on the equipment: its assembly, the start-up and adaptation were carried out empirically, and an improvement (new iteration) in the adaptation of the reactor are presented in this work.

2.3 Characterization of the Substrates and of the Biogas

A total of 5 groups of waste were used, which were characterized separately: food waste (FW), dog waste, cat waste (Felis catus), guinea pig waste and white ginger lily (Hedychium coronarium), the latter was used as an unconventional food plant (UFP) by the family.

The characterization of the substrates and biogas was carried out with samples collected during a period of one month. The substrates were analyzed according to Standard Methods EPA 2540G/1997 for the total solids, volatile solids and fixed solids, and according to the technical guidance of the German engineers (VDI 4630/2006) for the realization of the biochemical methane potential (BMP) test.

All weight measurements were made using a Shimadzu model BL320H scale with an error of 0.01 g. For pH measurements, the DIGIMED pHmeter model DM 22 was used. For the analysis of the biogas composition, the Landtec GEM5000 portable gas analyzer was used, which measures CH4, CO2, O2, CO and H2S, with an accuracy of ±0.5% (vol) (CO2 and CH4) and 1% (O2) and 2% (H2S) [25].

The BMP was performed using the Automatic Methane Potential Test System (AMPTS II) from Bioprocess Control Systems, with a repeatability of ±1% for the methane measurement [26]. Specific methane production data are presented with an experimental error equivalent to the standard deviation of the mean of triplicate measurements (according to VDI 4630/2006 guidelines).

2.4 Optimized Adaptation

The reactor adaptation process was based on previous experiences of small laboratory bench reactors. The experimental data obtained were subjected to data processing, and an optimized substrate consumption rate was obtained, and an improved initial feed rate was proposed.

During the adaptation process, the reactor feed was started with a very low organic load rate (OLR) that was increased monthly. The pH and alkalinity were measured weekly using a colorimetric tape used for swimming pool water analysis. The pH was maintained between 6.5 and 8 and total alkalinity between 1000 and 2500 ppm. There was a need for pH correction in two episodes, using calcium carbonate (CaCO3) at a dosage of 500 mg/Lreator. Biogas production was also monitored, since in stable operation of the reactor, there is an increase in biogas production during the 24 h after feeding.

Empirical data from the adaptation period of the Boitatá digester analyzed served as the starting point for the optimization.

Despite the limitations due to the variability of the substrate and the conditions surrounding the reactor, a simplified modeling was made by fitting the experimental data to a function, based on the cell growth function. In general terms, it can be assumed that the population increase is proportional to the substrate consumption by the population, according to Eq. 1, so the modeling of the substrate feed rate (considering that all the substrate fed is consumed) is proportional to the population increase rate [27].

The solution and linearization of Eq. 1 using the least square method (LSM) for fitting it to the experimental data is presented in Eq. 2. The increase rate of maximum substrate feeding was obtained (η_max) using the free software Calc.

3 Results and Discussion

The results of total and volatile solids can be seen in Table 2.

The BMP results of the 5 tested substrates is presented in Table 3. They are presented in descending order and it is noticeable the high potential of the FW and also of the dog waste.

During the analysis period (5th month), the weight of the 5 groups of fed substrates was registered separately, which is shown in Fig. 2. Based on these data, the average volatile solids content of 0.23 gSV/g of the substrate used to feed the reactor was estimated. The total production of biogas in the period was 818.35 L, so the specific production of biogas in the period was estimated at 0.710 Lbiogas/gSV. The average concentration of methane in the biogas was 63,1%.

During the adaptation period, the reactor was fed by keeping the mass and composition of the substrate approximately constant for a month and gradually increasing it monthly, as can be seen in Table 4. In the first month, simple substrates such as rice and beans were used. Gradually, with the increase in mass, a greater variety of substrate was offered. From the 5th month on, the variety of substrates shown in Table 2 was offered, and from the 7th month on, all types of organic domestic wastes were fed, with the mass control still being carried out. From the 13th month onward, feeding was carried out without any mass or variety control, using all the organic waste produced by the household, just avoiding some substrates (orange and lemon peel) and large quantities of a single type of waste, by portioning it to the subsequent days. The daily input mass (diluted substrate) has been limited by the volume of the blender cup (1.5 L).

3.1 Reactor Design Improvements

Three improvements were made to the reactor design. The first was the insertion of a ball valve at the exit of the digestate, as can be seen in Fig. 3. Originally it was designed so that the exit of the digestate was made by increasing the level in the reactor, by communicating vessels, thus ensuring a mass balance process in a steady state operation of the reactor. In the original design a PVC cap was used to seal the digestate outlet, however this made the operation difficult, requiring constant lubrication with vaseline. A good seal in all parts of the reactor [6] is essential to prevent the entry and proliferation of vectors.

The digestate outlet valve presented important advantages: greater ease of operation and increased reactor level allowing the use of fatty substrates that form a supernatant that needs a longer retention time. There is no evidence of disturbance or instability of the reactor due to the use of this valve, the removal of the digestate follows approximately the same volume of diluted substrate added.

The second important improvement was in the reactor feed inlet. In the original design the feeding was made directly into the 50 mm tube, however during the operation several times the diluted substrate ended up falling out of the tube, causing a bad smell and fly larvae proliferation outside the reactor. The improvement of the feeding system was the insertion of the PVC adapter from 50 to 100 mm diameter, which can be seen in Fig. 3, and which generated a small elevation, improving the dynamics of the insertion. To effect the sealing, a cap without rubber was used, which caused a noticeable reduction in the smell.

Finally, a common type of accident can happen due to the blockage of the biogas outlet (when the biogas bag is full) which can cause the digestive liquid to leak through both the mixer seal and the feeder. To avoid this, a safety valve was adapted to depressurize the reactor. Such a valve is built with a PVC bottle and a hose tee, as can be seen in Fig. 3 (center). The materials needed for the proposed improvements and those suppressed, in relation to the original design can be seen in Table 5.

3.2 Modeling the Feeding Rate of Adaptation Period

The adaptation period can be characterized between the end of the start-up and the stable use of all available substrate. In terms of cell growth it could be recognized between the lag phase and the exponential phase, but still far from the theoretical the carrying capacity limit of the reactor (maximum OLR) (2.5 gVS/L.day).

From the empirically obtained data of feed rate used in the adaptation period (Table 4) it was possible to fit the linearized model proposed in Eq. 2 for the substrate consumption rate, presented in Fig. 4.

Fitting of experimental data to linearized model of Eq. 2.

The use of Eq. 2 with the same empirically obtained data of Table 5 made it possible to obtain η_max = 0.13067 with S(t = 0) ≊ 118g. This shows that the initial feed rate used, of 40 g/day could have been three times higher. The correlation between the experimental data and the modeling finds a good fitting (R2 = 0.879), which can be seen in Fig. 5.

In Table 5 and Fig. 5 it is possible to observe an inflection between months 8 and 10, which correspond to the winter months, this has been reported as a great challenge for microdigesters, which consists of having strategies that allow them to operate with the same range of substrate consumption during the whole year.

3.3 Conclusion

The results of this research point to the feasibility of DAD, since a low-cost microreactor has been developed and successfully operated digesting the domestic waste of a 3 people household, which demonstrates that this practice can be carried out successfully. It is necessary, though, to think about new relationships between university research and extension and the spaces of interest groups. People interested in having a food waste biodigester in their family must have access to the necessary instructions to build and operate it and to share its development.

Traditional innovation pathways have a lot of development steps while a citizen-driven approach through communities of interest, open hardware, WEFE Nexus and stakeholders participation, as presented in this article, tend to be more straightforward in solving people’s demands. This approach has proved adequate in this case of biodigester for decentralized anaerobic digesters.

The biogas produced is used daily for cooking, using an adapted stove directly connected to the PVC biogas bag though a plastic hose. Due to the low pressure (controlled through the use of weights disposed on the bag) and the small amount of gas stored (75 L representing the same amount of energy in 100 ml of ethanol) no extra safety requirements were necessary than those usually taken in a regular kitchen.

Considering the period of one month, the biogas produced represented 18,53 MJ, produced from 3,59 kg of organic family waste, which means a rate of 5,2 MJ/kg of residue. A 13 kg bottle of liquified petrol gas (LPG), commercialized in Brazil has an energy content of 600 MJ, so, using anaerobic digestor Boitatá with a daily waste production of 0,8 kg, it would be possible to substitute around 21% of the LPG needs of the family.

Boitatá has succeeded in providing a reasonable part of the cooking energy requirements for a 3 people family, an adequate treatment for the stabilization of the FORSU and a biofertilizer for improving productivity of the vegetable organic family garden.

The developed open source hardware Boitatá has shown to be a viable alternative for DENR, based on citizen-driven approach. It also proved to be a powerful tool to make waste segregation at the generation point which can be used for households and other small scale organic waste generators.

References

Brasil Política Nacional de Resíduos Sólidos (2010)

MMA Planares - Plano Nacional de Resíduos Sólidos (2020)

ABRELPE Panorama Dos Resíduos Sólidos No Brasil 2020 (2021)

FAO: The Water-Energy-Food Nexus A New Approach in Support of Food Security and Sustainable Agriculture (2014)

Implementing the Water–Energy–Food-Ecosystems Nexus and Achieving the Sustainable Development Goals; UNESCO, IWA, UE: Italy (2021)

Heeb, F.: Decentralised anaerobic digestion of market waste, Case study in Thiruvananthapuram, India; Dubendorf, Switzerland (2009)

Ntostoglou, E., Khatiwada, D., Martin, V.: The potential contribution of decentralized anaerobic digestion towards urban biowaste recovery systems: a scoping review. Sustainability 13, 13435 (2021)

Zhang, R., et al.: Characterization of food waste as feedstock for anaerobic digestion. Biores. Technol. 1, 929–935 (2007)

Oliveira, B.P., Santos Oliveira, L.H., Martins, G.: Anaerobic Digestion of Food Waste, pp. 902–906. Stockholm, Sweden (2017)

Souza, A.C.C.L., Martins, G.: Biogas from food waste: possibilities and challenges of small anaerobic reactors. In: Proceedings of the Energy and Sustainable Development: Brazil Facing the Global Challenges of Energy Transition, São Bernardo do Campo (2019)

Kera, D.: Maker culture liminality and open source (science) hardware: instead of making anything great again, keep experimenting! Liinc em Revista 13, 7–28 (2017)

Menezes, K., Pretto, N.L.: Pirâmide Da Pedagogia Hacker: De Sonhos Coletivos a Engajamentos Reais. Teias 20, 148–166 (2019)

OSHWA Certification. A guide to the best practices to ensure your project is open source compliant (2022)

GOSH GOSH Manifesto. Gathering for Open Science hardware (2022)

Sutherland, J.: SCRUM: A Arte de Fazer o Dobro Do Trabalho Na Metade Do Tempo; Leya: São Paulo (2016)

Abrudan, C.I., Baru, P.E., Lungu, R.: Applying scrum methodology into the production processes of a logistic equipment producer. Int. J. Curr. Sci. Res. Rev. 2, 76–81 (2019)

May, L., Runyon, T.: LabScrum: a case study for agility in academic research labs. Cutter Bus. Technol. J. 32, 15–20 (2019)

Peterson, E.C., Villegas, M.F., Langeveld, J.W.A., Quist-Wessel, P.M.F.: Evaluation of low-cost enhanced biodigesters for public use in rural societies in Colombia. Stockholm, Sweden (2017)

Cheah, Y.K., Vidal-Antich, C., Dosta, J., Mata-Alvarez, J.: Study of the effects of temperature and ph on acidogenic fermentation process from organic fraction of municipal solid waste. NAXOS (2018)

Braguglia, C., Gallipoli, A., Gianico, A., Pagliaccia, P.: Anaerobic bioconversion of food waste into energy: a critical review. Biores. Technol. 248, 37–56 (2018)

Tian, H., et al.: life cycle assessment of food waste to energy and resources: centralized and decentralized anaerobic digestion with different downstream biogas utilization. Renew. Sustain. Energy Rev. 150, 111489 (2021)

Weidner, T., Yang, A., Hamm, M.W.: Consolidating the current knowledge on urban agriculture in productive urban food systems: learnings, gaps and outlook. J. Clean. Prod. 209, 1637–1655 (2019)

Pearce, J.M.: Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs. Elsevier, Amsterdam (2013)

Souza, A.C.L.L.: Os Biodigestores Em Microescala No Contexto de Práticas Sociais Urbanas. Dissertação apresentada ao Programa de Pós-Graduação em Energia da UFABC, UFABC: Santo André (2021)

QED, E.S.: GEM 5000 Gas Analyzer: Operating Manual (2018)

BIOPROCESS AMTPS II - Technical Specifications (2014)

Velázques-Martí, B., Meneses-Quelal, W., Gaibor-Chavez, J., Niño-Ruis, Z.: Review of mathematical models for the anaerobic digestion process. In: Anaerobic Digestion, Interchopen (2019)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

de Souza, A.C.C.L., de Campos Leite Tonelli, J.T., Martins, G. (2023). Improvements in the Construction, Start-Up and Use of a Domestic Food Waste Digester. In: Pereira, L., Krus, P., Klofsten, M. (eds) Proceedings of IDEAS 2022. IDEAS 2022. Design Science and Innovation. Springer, Cham. https://doi.org/10.1007/978-3-031-29129-6_14

Download citation

DOI: https://doi.org/10.1007/978-3-031-29129-6_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-29128-9

Online ISBN: 978-3-031-29129-6

eBook Packages: EngineeringEngineering (R0)