Abstract

The rationale of study of anaerobic digestion systems is considered, providing details of the working principles of anaerobic digestion systems for methane production as well as management of municipal solid waste, mainly kitchen waste. Background studies on the design of different types of biodigesters and theories of the production of methane gas from food waste are also discussed. The physical and chemical operating parameters for the process of methane gas production are also deliberated in this chapter since it is an essential part to be considered during design of an anaerobic biodigester. The environmental factors that have a major influence on production of methane gas from food waste and previous research work are analysed. Baseline design information is discussed to develop a suitable portable household food waste biodigester.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The lifestyles in cities as well as in villages are changing rapidly due to modernization and industrial revolutions. The result is an increase in the net demand for energy. Therefore, electricity as a source of energy plays an important role in a community’s daily life especially when most of the household appliances are electrical. According to a 2016 British Petroleum (BP) statistical report, primary energy consumption worldwide increased by 1.0% between the years 2014 and 2015. It is also found that about 33% of consumed energy came from fossil fuels, mainly from oil. The contribution of alternative energy was very limited at about 213 TW-h [1]. The main sources of alternative energy are wind, hydro, solar, biogas, etc. that are used globally. The energy generation or conversion cost mainly depends on the source of energy as well as technology. Among all the sources, the most economical abundant source is biogas since global solid waste mainly from municipalities exceeds 1.3 billion tonnes. According to World Bank 2012, on average, globally about 1.2 kg municipal solid waste is produced per capita per day, and it is projected to rise to 1.42 kg per capita per day by 2025. It is estimated that by 2025, about 2.2 billion tonnes of solid waste will need to be processed every day. This abundant source can contribute significantly to the energy sector. Poor management of municipal solid waste has a huge impact on the environment. Therefore, the effective use of these wastes may contribute a significant amount of energy generation as well as aid national development.

Malaysia is situated in the equatorial region, therefore receiving high solar radiation intensity as well as high relative humidity. This hot and humid climate contributes to the outbreak of any infectious diseases in Malaysia. As a result, the household sector needs more energy for ventilation and for cooling and Malaysia consumed a lot of electricity.

These household activities are mainly for cooling and heating and demand more energy than our ancestors would use. Hence, the consumption of energy is relatively high and might be insufficient in the near future. To overcome the demand for more energy, a sustainable solution is required within a short period of time. One of the most appropriate and valid solutions is implementation of alternative energy as replacement of non-renewable energy.

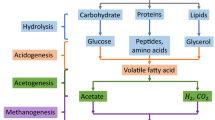

Biogas is one of the alternatives energy sources that can be used to replace non-renewable energy mainly fossil fuel. Biogas is not a single type of gas but it is a mixture of methane (CH4), carbon dioxide (CO2), nitrogen (N2), oxygen (O2), ammonia (NH3), hydrogen (H2), sulphur (S) compounds and carbon monoxide (CO) [2]. All kinds of biodegradable natural waste such as food waste, animal waste, forest and agriculture residues can be used to produce biogas. However, the production processes of biogas from the food wastes are different than other biomass and the conversion time also varies with types of waste [3]. The biogas production process can be speeded up by adding a suitable enzyme during the conversion process. The general biogas generation process is shown in Fig. 1.

Biogas can be produced under anaerobic (biodegradation process in the absence of oxygen) or aerobic (biodegradation process in presence of oxygen) conditions. In the anaerobic digestion system, a series of biological processes take place in the absence of oxygen. Microorganisms in the digestion tank break down the biodegradable material and produce biogas as a product. This is a combustible gas that can be used for electricity generation as well as a source of energy for domestic and industrial use. Therefore, the anaerobic digestion system depends on environmental conditions, the operation procedure and the start-up conditions. The most challenging issues are that the bacteria must break down organic material without oxygen, with the potential of hydrogen (pH) almost neutral (≈7.0); in addition, a suitable temperature and sufficient humidity, nutrients and alkalinity are needed [2]. In the anaerobic process, the organic materials are converted into biogas, which is a mixture of methane (55–75%) and carbon dioxide (25–45%) gases.

In the anaerobic process, the microorganisms break down biodegradable material through a series of biological processes before the useful end product is produced. The processes are involved hydrolysis, acidogenesis, acetogenesis and methanogenesis [4]. The pH value changes through each stage due to particular function of microorganism that desires a specific pH value. If the environment is too acidic or alkaline, the function of the microorganisms might be reduced or failed to function. It will delay the complete decomposition of the biodegradable material and reduce produced biogas. Alternatively, aerobic digestion is a biological process where bacteria in the presence of oxygen break down natural organic and biological waste, resulting in the overall reduction of natural organic material and the generation of limited quantity of stabilised cell mass as well as discharging ammonia-N and phosphate. The performance of aerobic digestion depends on solids retention time, temperature, pH value, mixing, types of solids and biodegradable material configuration.

Animal manure and human sewage sludge can be decomposed using the anaerobic digestion process. Nowadays, this process can also use to compost some municipal solid waste (MSW) as well as green waste. However, aerobic digestion can be used to process any type of organic materials. For an effective composting through aerobic digestion, the right blend of ingredients and conditions are essential, namely, that the moisture content is about 60–70% and the C/N (carbon to nitrogen) ratio is approximately 30/1. The variation in ingredients and environmental conditions might alter the performance of the aerobic digestion system. Furthermore, to ensure the presence of oxygen throughout the process a ventilation system, either passive or forced ventilation is needed to introduce air.

2 Potential of the Anaerobic Digestion Process

Malaysia is one of the fastest developing countries in Southeast Asia. Energy consumption is increasing significantly with the gross domestic product (GDP). In 2010, the GDP of Malaysia was $15,385 per capita with the economy and industry mushrooming [5]. The relationships of GDP with electricity consumption have been correlated [6]. Malaysia generates most of its electrical energy by using fossil fuel. With those inextricable relationships, it could be concluded that increases in GDP means an increase in energy demand. In correlation to that, the fluctuating constantly increasing fossil fuel price and the emission of greenhouse gases (GHG), push the development of Malaysia towards the renewable energy field. The government have started up renewable energy-powered systems and created renewable energy policies [5].

There is another knotty problem in Malaysia, which is to manage solid waste from households, which requires a well-thought-out solution. Currently, landfills are used as the main disposal place for managing those households’ solid wastes, and this gradually increases every year. However, this is not a sustainable way for household waste management [7]. There is insufficient land to place those waste in near future in Malaysia [7, 8]. On average, a Malaysian creates 1.2 kg of wastes per day, of which about 74% is food waste, approximately 21% plastic and 5% other wastes [9]. Most of the solid waste produced actually comes from the kitchen, which is daily food waste. The food waste generates a high percentage of methane gas, which can be used as a source of energy [3]. In addition, the combustion of methane gas is clean and environmental friendly [10].

Methane gas could bring the benefit of a greener living environment as a useful energy source and also a sustainable way to deal with those food wastes. By contrast, it could be a reason to produce harmful greenhouse gases and may cause global warming if it is not handled properly [11]. Studies have shown that the Earth’s temperature is increasing annually and the Arctic sea ice is melting due to climate changes [12]. This is a warning sign from our mother Earth. The micro level solution, using less energy at household level, is a valid and suitable option to reduce the emission of greenhouse gases as well as reduce the effect of climate change.

In contemplation of solving the problems, energy can be generated from household waste with an efficient and portable biodigester [3]. In the biodigester, the daily kitchen food waste is applied as input materials. Generally, food waste consists of cooked, uncooked and raw vegetables and fruits. The wastes are decomposed inside a confined inner compartment and generate methane gas. The gas is stored in a gas storage chamber. The end product, methane gas is required to burn with the presence of sufficient oxygen in furtherance of clean combustion [10].

This technique will help to reduce CO2 emissions and limit the emission of one of the greenhouse gases—methane, especially from animal manure, like cow dung. In addition, during biogas production, the digested slurry is also produced as a by-product that is a micro- and macro-nutrients rich fertiliser suitable for plants.

3 Energy

In thermodynamics, energy is represented the capacity of a physical system to produce work and heat that appears in different forms. Energy cannot be destroyed but it can be transferred from one form to another form. The growth of world population and living standards in developing and developed countries are giving pressure on global energy consumption which increases on average by 2% every year [10, 13]. It is estimated that in 2025, about 8.4 billion people will live on the Earth and need a huge amount of energy [14]. This energy is harvested mainly from the renewable and non-renewable sources of energy. Unfortunately, the contribution of renewable energy is still small compared to non-renewable energy. The use of energy mainly depends on the efficiency of energy production, levels of energy conversion and the expected standard of the population [15].

In Malaysia, the growth of energy demand is very significant. In 1991, the primary energy supply was 20,611 kilotonne of oil equivalent (ktoe) and it increased to 50,658 ktoe in 2000 and 54,194 ktoe in 2013. At the same time, electricity demand also increased from 22,273 gigawatts hour (GWh) in 1991 to 60,299 GWh in 2000 and further increased to 71,159 GWh in 2003. This is mainly due to the growth of the economy and industry in Malaysia, and there is an inseparable relation between GDP with GWh [6].

3.1 Potential Sources of Energy

Malaysia is located in Southeast Asia whose energy demand increased more than 50% from 2000 to 2013. The energy demand is going to approximately double its value by 2040. Fossil fuels are the primary source of energy in Malaysia and it is predicted to increase more than 90% in 2040 [16]. In 1993, the energy source for Malaysia was only from natural gas (44.4%), crude oil (53.1%), coal and coke (0.4%) and hydropower (2.1%). Oil reserves were predicted to be finished in 15 years, if the usage of crude oil was controlled at 2.9 million barrels per day. Therefore, the Malaysia government has implemented a number of energy policies since 1974. Later in 2013, a few renewable energy sources such as biodiesel and biomass were added to the policy to strengthen it. Malaysia also has potential to use solar, municipal solid waste, small and mini-hydro, fuel cells, wind energy and geothermal power as a source of renewable energy. Palm Oil Mill Effluent (POME) can be used as the main source of biomass and biogas. It has been estimated to generate roughly 1750 MW by 2028 [5].

3.2 Biomass Sources Energy

Biomass refers to any type of animal or plant, which can be converted to energy and it can be divided into three categories: wastes, standing forests and energy crops [17]. Biomass energy resources are produced in areas where plantations are grown for fuel or heating purposes [18]. The biomass resources and its potential for producing bioenergy is still not yet fully utilised today [19]. Biomass could be the most powerful and ideal energy source in the near future if it is fully utilised. Properly managed it minimises harm to the environment. Biomass is categorised as an energy source that does not emit carbon dioxide (CO2) to the environment when decomposed. The carbon cycle is a complex global process when biomass is breaking down and the organic carbon is recycled. Through this, the CO2 produced is able to be absorbed by the plants during growth [14].

Energy can be harvested from biomass resources either by mechanical or natural processes. These techniques are used to convert biomass resources into liquid or gaseous fuel [19]. The converted biomass fuel can be used efficiently to run vehicles or generate electricity as a replacement for fossil fuel. Figure 2 summarises the forms of biomass conversion pathways.

3.2.1 Mechanical Process

Most of the biomass is required to be preprocessed such as compression, chopping, preheating, etc. before it can be put it into a conversion process [14]. Thermochemical processes such as combustion, gasification and pyrolysis are used to convert biomass into fuel. Thermal conversion takes place effectively if the moisture content in biomass is less than 15%. Combustion of biomass is a process to produce steam and power. Direct combustion of biomass is efficient if the moisture content is more than 15%. Gasification is one of the most suitable techniques to ensure efficient biomass combustion. A gasifier is used to convert biomass into producer gas that contains mainly carbon monoxide, hydrogen, carbon dioxide, methane and nitrogen. A gasifier is a chemical reactor where biomass goes through several complex physical processes and chemical reactions take place under an incomplete supply of air. As a result, producer gases are generated which can be used for heating water to produce steam and run a power plant to generate electricity. The producer gas is not a single type of gas it is a mixture of combustible and non-combustible gases. The volume of combustible and non-combustible gases depends on the types of biomass that is used a raw material. The heating value of the producer gas varied from 4.5 to 6 MJ/m3, it also depends on the biomass material. Therefore, the gasifier, gas flow direction and capacity are considered. Gasifiers are classified into three groups: updraft, downdraft and cross-draft.

During the gasification process, biomass goes through drying, oxidation, pyrolysis and mass reduction processes. Among the processes, pyrolysis is known as a thermochemical process, which helps decomposes biomass material. Biomass materials can be converted into a liquid that can be applied in transportation or as a type of chemical feedstock [10]. Furthermore, biomass waste such rice husk, sawdust and leaves have a high bulk volume. Hence, it is very hard to transport from one place to another place. In addition, the heating values of loose biomass per unit volume are very low compare to other fuels. The loose biomass can be compressed and increased the heating value per unit volume which is known briquetting [19].

3.2.2 Natural Process

This process is also known as a biological process, which involves a series of biochemical reactions in the presence of enzymes or enzymatic reactions [10]. The biochemical process is very sensitive and perceptive towards the surrounding environment. This process is particularly depended on the presence of enzymes, microorganisms or bacteria, which are used for breaking down the complex substances into their simplest form. Enzymes act like key for a padlock and only the right key can be used to open the specialised padlock. There are two main types of biochemical processes that can be used to turn biomass resources into synthetic fuels. The biochemical processes are known as fermentation and anaerobic digestion [18]. The differences between them are the involvement of oxygen throughout the process. The operational parameters are different according to the specific process on the grounds of how the enzymes work [21].

3.3 Biomass and Biogas

Many developing and underdeveloped countries in the world, mainly in rural areas, use biomass as a source of energy [21]. The efficiency of direct combustion of biomass varies from 10 to 15% depending on the moisture content in the biomass. The combustion efficiency can be increased up to 30% by using improved stoves. However, the direct combustion of biomass generates harmful carbon monoxide (CO) and hydrogen (H2) gas (Fig. 3). Biomass can be used to produce biogas. In the biogas production process, biodegradable raw materials are decomposed either in the presence or absence of oxygen. The produced biogas can be used as a source of energy. The process is more commonly named as aerobic or anaerobic digestion, respectively.

3.3.1 Anaerobic Digestion

During anaerobic digestion, biogas is produced that is an end product from biomass raw material which has a high volume of carbon compound [22]. Food wastes, palm oil wastes, animal manures, aquatic and woods can be used as input materials for the anaerobic digestion process [23]. The biogas that is produced during the digestion processes is predominantly a mixture of methane and carbon dioxide with a negligible amount of nitrogen, hydrogen, hydrogen sulphide, ammonia and oxygen [10]. The performance of the biodigester can be determined from the amount of collected gases. Studies showed that the biogas is only flammable when methane gas is >45% in the producer gas [24]. Methane is a colourless, odourless gas and gives a blue flame during burning. The combustion of biogas, mainly the burning of methane gas, with sufficient presence of oxygen becomes water (H2O) and carbon dioxide (CO2) [10, 22]:

The combustion of biogas is clean; therefore, it is known as an environmentally friendly source of energy and can be used as a fuel for electricity generation plants. Therefore, the effective use of biogas can contribute to national development.

3.3.2 Solid Waste Digestion Processes

Anaerobic digestion is a suitable option to decompose biodegradable waste, crop waste and wastewater to generate energy. It is a decomposition process under controlled conditions and in the absence of oxygen. Mesophilic or thermophilic temperatures are suitable for anaerobic digestion and facultative anaerobic bacteria and archaea species occur naturally, which able to convert the wastes to biogas [25, 26].

Anaerobic digestion is a microbial process of decomposition of organic matter, in sealed reactors tanks, that reduces the percentages of the organic waste and creates biogas and fertiliser [27]. The advantages of using anaerobic digestion over aerobic digestion are that anaerobic decomposition requires a lower energy and operation cost. On the other hand, anaerobic digestion needs a long period of time; thus, a larger hydraulic retention time is demanded [28].

3.4 Principles of Anaerobic Digestion

There are four different steps during anaerobic digestion for the deterioration of carbon-based raw material which are hydrolysis, acidogenesis, acetogenesis and methanogenesis [25]. The stages of the anaerobic process are shown in Fig. 4.

Hydrolysis

In this process, with the help of exoenzymes and bacterial cellulosomes, the complex carbohydrates, fats and proteins are hydrolysed to their monomeric forms [21]. The enzymes act as a catalyst to speed up the digestion process, where carbohydrates become simple glucose, proteins hydrolyse to amino acids and lipids to long-chain fatty acids [29, 30].

Acidogenesis

This step is also known as fermentation since glucose, amino acids, fatty acids and peptides are fermented to volatile fatty acids by anaerobic bacteria [10]. Volatile fatty acids such as acetic acid, propionic acid, butyric acid, isobutyric acid, valeric acid, isovaleric acid, caprionic acid, alcohols, hydrogen and carbon dioxide are produced through this process [21]. The acidogens reproduce at a rapid rate which causes the pH to drop which is harmful if the volatile acids produced are not removed by the next stage [31].

Acetogenesis

The higher volatile fatty acids and other organic compounds are transformed to acetic acid, hydrogen and carbon dioxide by the acetogenic bacteria [31].

Methanogenesis

Methanogens convert the intermediate products into methane and carbon dioxide [21]. There are two types of methanogens process in this stage: one type is acetoclastic methanogens that nurture along with acetic acid and generate about 70% of methane gas, and the other type is hydrogen exploiting methanogens that reduced carbon dioxide and hydrogen [31].

3.4.1 Operational Conditions in Anaerobic Digestion

Methane production from biomass involves varies types of microorganisms. The performance of the anaerobic digestion processes depends mainly on the volume of biomass, temperature, mixing, carbon–nitrogen ratio, hydraulic retention time and the potential of hydrogen (pH). These parameters are also important to maintain the balance of microorganisms in the digestion system [21].

Volume

The total reactor volume used for batch tests is inversely related to the number of replicate samples that could be tested at the same time using a fixed amount of sludge and substrate. The useful reactor for biochemical methane potential (BMP) evaluation was always less than 1L [23].

Temperature

There is a wide range of temperature where anaerobic digestion can occur, which are classified into three groups, namely, as psychrophilic (below 20 °C), mesophilic (optimum 30–40 °C) and thermophilic (above 50 °C) [31]. Mesophilic and thermophilic are more favoured compared to psychrophilic because the reaction rate is higher at both temperature ranges [31]. Mesophilic anaerobic processes are common due to the stable reaction process, high in microbial activities and easy to start up [10].

Mixing Substrate

It is important to retain consistent substrate concentration, temperature and other environmental factors to avert scum formation and solids deposition. Mixing through gas circulation and mechanical stirrers are depending on the final total solids concentrations of the systems [32].

Carbon–Nitrogen Ratio (C/N Ratio)

The performance of the anaerobic digestion process relies on the concentrations of carbon and nitrogen, where carbon is the energy source for the microorganisms and nitrogen enhances microbial growth. It is generally lost as ammonia gas when the amount of nitrogen exceeds the microbial requirement. For the ideal condition, the ratio of carbon to nitrogen is about 30:1 in the raw material [32].

Hydraulic Retention Time (HRT)

Hydraulic retention time is defined as the period the raw material remains in the digester and is a key design parameter used that depends on the chemical oxygen demand (COD) and biochemical oxygen demand (BOD) of the feedstock and slurry. The optimal hydraulic retention time for full biological conversion using mesophilic digestion is 15–30 days [33].

where

- \(V_{\text{r}}\) :

-

Volume of reactor (m3),

- Q :

-

Influent flow rate.

The Potential of Hydrogen (pH) Value

The pH value of the digester environment is a very important factor and plays an important role in biomass digestion and methane gas production. Bacteria are very sensitive towards acidic conditions. The pH value for each stage is different due to the volatile fatty acids, carbon dioxide and small chain carbonates; therefore, a buffer solution such as lime may be added to stabilise the pH at a neutral value [33].

3.5 Anaerobic Biodigester

Biodigesters such as fixed dome, floating drum and plug flow are used to produce methane gas and usually are of large size. There are a few types of small-scale biodigesters suitable for households’ waste [21]. The biodigester is a waterproof, sealed chamber usually cubical or cylindrical and built using brick, concrete, steel or plastic, to allow the process of transforming organic waste into biogas to take place [24].

3.5.1 Fixed Dome Digester

A fixed dome digester is known as ‘Chinese’ or ‘hydraulic’ digester. In this digester, biomass raw material is fed through the inlet pipe, the biogas produced accumulates at the upper part of the digester and the gas pressure formed compresses the slurry to the outlet pipe [21, 34]. Figure 5 shows the fixed dome digester and its different parts. There are two different types of fixed dome digester models; Janata model and Deenbandhu model are commonly used. The main difference between Janata model and Deenbandhu model is the shape of the floor bottom. The digestion tank of Deenbandhu model is designed as a hemispherical shape, while Janata model has a flat bottom. The disadvantage of these biodigesters is once installed, it is hard to move or replace them [21]. In addition, the digester tank leaks easily when a high gas pressure develops in the biogas chamber [35, 36].

The advantages of fixed dome digesters are lower construction cost, they do not contain moving and rust-prone steel parts, longer lifetime, less temperature variation and more space-saving [35, 36].

3.5.2 Floating Drum Digester

This type of digester is designed with a movable inverted drum, which is known as a gas collector and able to move up and down depending on the gas produced at the top of the digester tank (Fig. 6). The gas pressure can be increased by adding load to the inverted drum that is needed for the gas flow through the piping, for further usage. In this digester, the amount of gas accumulated can be predicted from the position of the drum. The average size of the digester tank is around 1.2 m3. The difference between a floating drum digester and fixed dome digester is the gas collection part. The floating drum digester uses a floating drum, steel, gas collector; however, the fixed dome digester uses a fixed steel gas collector. The drum can rust over time and reduce the movement of the drum as well as reduce the performance of the digester [21, 37].

3.5.3 Plug Flow Digester

This type of digester is designed as a long and narrow horizontal tank in which biomass is constantly added at the influent. Continuous digestion takes place in the plug flow digester; therefore, the production of gas is continuous. Usually, the plug flow digester vessel is five times longer than it is wide. It is made of concrete, steel or fibreglass [38]. The inlet and outlet of the digester are put at two different ends and placed above the ground; the other parts of the digester are buried inclined in the ground as shown in Fig. 7. The main advantage of plug flow is simple, easy to operate and economical to instal [38].

According to Cheng et al. [28] and Deng et al. [35], the fixed dome, floating drum and plug flow digesters can be used for food waste. All the digesters have advantages and disadvantage as presented in Table 1.

3.6 Food Waste

The bio-methanisation of food waste is divided into four main categories based on the food waste main components such as proteins, lipids, carbohydrates and celluloses. The rate of production of methane is highest from food wastes that have excess lipids but the reaction needs a longer time. Food waste with proteins takes a little longer, then celluloses and lastly carbohydrates [33]. Food waste has a high content of organic matter, comprising crude lipid (22.8–31.45%), crude protein (14.71–28.64%) and carbohydrates on a dry matter basis [39]. Household food wastes categories are rich in proteins and lipids from meat, egg, cheese and fish or high in carbohydrates from bread, flour and potatoes. Vegetables and fresh fruits are usually rich in carbohydrates except for mushroom, spinach and dry fruits which are full of proteins [33].

3.7 Biodigester for Food Waste

According to Deng et al. [35] and Tapase et al. [40], the fixed dome biodigester can be used successfully under mesophilic condition for food waste digestion. A floating drum anaerobic biodigester under mesophilic condition can also be used for food waste [41]. To produce methane effectively, Asmare [42] combined food waste with human waste before putting it into the fixed dome digester tank under mesophilic conditions. Lama et al. [43] pretreated the floating drum biodigester with cow dung before placing food waste in it. This study showed that the numbers of microorganisms were increased significantly after pretreatment. The anaerobic digestion of the food waste at mesophilic temperature was faster and a specific amount of methane gas is produced under this process [43]. Ogur and Mbatia [3] selected only uncooked kitchen waste as their organic matter to put into the biodigester and operated it under mesophilic conditions. The experiment accumulated 24 m3/day biogas for an input of waste of approximately 100 kg. Vij [44] chose cooked rice, vegetables and vegetable waste as the source of organic matter and managed to produce methane gas in only 52 h. The summary of the outcome of these experiments is presented in Table 2.

3.8 Conclusion and Future Remarks

The huge amounts of food waste and other biodegradable biomass are responsible for severe environmental pollution in many countries in the world. Therefore, food waste management is becoming a major issue for every city as well as for society. Nowadays, it is of serious economic and environmental concern; hence, many organisations are working for effective solution for food waste management. Many researchers all over the world are putting their efforts into finding a sustainable solution and conversion technologies to manage this waste. The main components of food wastes are proteins, lipids, carbohydrates and celluloses. There are many different ways food waste can be managed. Among all the management methods, the anaerobic digestion process is one of the valid options that can manage food waste effectively as well as generate a by-product, biogas that can be used as a source of energy. In the anaerobic digestion process, the microorganisms effectively break down the natural biomass materials and food waste in the absence of the oxygen and produce biogas, mainly methane. The methane gas is an appropriate solution for rural household energy supply, mainly for cooking and heating. This methane gas can also be used as a source fuel for generators to generate electricity or as a vehicular fuel but the biogas needs to fulfil certain condition of combustion. The performance of the anaerobic digestion can be improved significantly by reviewing several physical, thermochemical, biological or combined pretreatments. The food waste digestion performance also depends on the rate of reaction in the digestion chamber and hydrolysis process. Food waste with others biomass significantly enhances the production of biogas, mainly methane. In the anaerobic digestion system, the percentage of combustible gas mainly methane and non-combustible gas mainly CO2 are about 69 and 29%, respectively [45].

Additionally, there are a few parameters that need to be considered to improve the performance of the anaerobic digestion process. First, a large volume of digester tank should be used with centralised gas storage. This will increase the methane gas concentration at the outlet. Furthermore, suitable enzymes can be used to enhance the reaction rate for the digestion of food waste. Different combinations of food waste and biomass material have a significant effect on the digestion rate. Therefore, the enzyme can be suitable for all kind of food wastes, which has altered C–H–O–N ratio.

References

Statistical Review of World Energy (SRWE) (2016) BP Statistical review of world energy 2016, 65th edn, vol 5

Schirmer WN, Jucá JFT, Schuler ARP, Holanda S, Jesus LL (2014) Methane production in anaerobic digestion of organic waste from recife (Brazil) landfill: evaluation in refuse of different ages. Braz J Chem Eng 31(2):373–384

Ogur EO, Mbatia S (2013) Conversion of kitchen waste into biogas. Int J Eng Sci (IJES) 11(2):70–76

Vinnerås B, Schönning C (2011) Microbial risks associated with biogas and biodigestor sludge. In: Encyclopedia of environmental health, pp 757–764

Mekhilef S, Barimani M, Safari A, Salam Z (2014) Malaysia’s renewable energy policies and programs with green aspects. Renew Sustain Energy Rev 40:497–504

Jafar AH, Al-Amin AQ, Siwar C (2008) Environmental impact of alternative fuel mix in electricity generation in Malaysia. Renew Energy 33(10):2229–2235

Moh Y, Abd Manaf L (2017) Solid waste management transformation and future challenges of source separation and recycling practice in Malaysia. Resour Conserv Recycl 116:1–14

Fauziah SH, Agamuthu P, Municipal solid waste management in Malaysia: strategies in reducing the dependency on landfills http://repository.um.edu.my/27036/1/Banda%20Aceh%20Fullpaper.pdf

Budhiarta I, Siwar C, Basri H (2012) Advanced science information technology current status of municipal solid waste generation in Malaysia. Int J Adv Sci Eng Inf Technol 2(2):16–21

Cheng J (ed) (2010) Biomass to renewable energy processes. Taylor & Francis Group, Raleigh, North Carolina

Prasad PVV, Thomas JMG, Narayanan S (2017) Global warming effects. In: Encyclopedia of applied plant sciences, pp 289–299

Matishov GG, Dzhenyuk SL, Moiseev DV, Zhichkin AP (2016) Trends in hydrological and ice conditions in the large marine ecosystems of the Russian Arctic during periods of climate change. Environ Dev 17:33–45

Ngô C, Natowitz J (2016) Our energy future: resources, alternatives and the environment. Wiley

Golus̆in M, Dodić S, Popov S (2013) Sustainable energy management. Academic Press

Kreith F, Kreider JF, Krumdieck S (2010) Principles of sustainable energy: mechanical and aerospace engineering series. CRC Press

Birol F, Bromhead A, Blasi A, Ikeyama S (2015) Southeast Asia energy outlook—world energy outlook special report 2015. www.iea.org/publications/freepublications/publication/WEO2015_SouthEastAsia.pdf

Schobert H (2014) Energy: the basics. Routledge

Cassedy ES, Grossman PZ (1998) Introduction to energy: resources, technology and society, 2nd edn. Cambridge University Press, Cambridge, UK

Letcher TM (2008) Future energy: improved, sustainable and clean options for our planet. Elsevier Science

Rajendran K, Aslanzadeh S, Taherzadeh MJ (2012) Household biogas digesters—a review. Energies 5(8):2911–2942

Ingole NW (2015) Development and design of biogas plant for treatment of kitchen waste. Int J Res Eng Sci Technol (IJRESTs)—Civ Eng 1:1–5

Raposo F, De La Rubia MA, Fernández-Cegrí V, Borja R (2012) Anaerobic digestion of solid organic substrates in batch mode: an overview relating to methane yields and experimental procedures. Renew Sustain Energy Rev 16(1):861–877

Ghosh R, Bhattacherjee S (2013) A review study on anaerobic digesters with an Insight to biogas production 2(3):8–17

Bensah EC, Ahiekpor J, Antwi E, Ribeiro J (2015) A study of the effluent quality of excrement-based biogas plants in Ghana. Int J Sci Eng Appl Sci (IJSEAS) 1(6)

Suanon F, Sun Q, Li M, Cai X, Zhang Y, Yan Y, Yu C-P (2017) Application of nanoscale zero valent iron and iron powder during sludge anaerobic digestion: impact on methane yield and pharmaceutical and personal care products degradation. J Hazard Mater 321:47–53

Jyothilakshmi R, Prakash SV (2016) Design, fabrication and experimentation of a small scale anaerobic biodigester for domestic biodegradable solid waste with energy recovery and sizing calculations. Proc Environ Sci 35:749–755

Cheng S, Li Z, Mang HP, Huba EM, Gao R, Wang X (2014) Development and application of prefabricated biogas digesters in developing countries. Renew Sustain Energy Rev 34:387–400

Sørensen B (1991) A history of renewable energy technology. Energy Policy 19(1):8–12

Twidell J, Weir T (2015) Renewable energy resources. Routledge

Minteer SD (2011) Biochemical production of other bioalcohols: biomethanol, biopropanol, bioglycerol, and bioethylene glycol. In: Handbook of biofuels production, pp 258–265

Hilkiah Igoni A, Ayotamuno MJ, Eze CL, Ogaji SOT, Probert SD (2008) Designs of anaerobic digesters for producing biogas from municipal solid-waste. Appl Energy 85(6):430–438

Mir MA, Hussain A, Verma C (2016) Design considerations and operational performance of anaerobic digester: a review. Cogent Eng 28(1):1–20

Kaur H, Sohpal VK, Kumar S (2017) Designing of small scale fixed dome biogas digester for paddy straw. 7(1)

Deng L, Liu Y, Zheng D, Wang L, Pu X, Song L, Long Y (2016) Application and development of biogas technology for the treatment of waste in China. Renew Sustain Energy Rev 70(2017):845–851

Kalia AK, Kanwar SS (1998) Long-term evaluation of a fixed dome Janata biogas plant in hilly conditions. Bioresour Technol 65(1):61–63

Kalia AK, Singh SP (1999) Case study of 85 m3 floating drum biogas plant under hilly conditions. Energy Convers Manage 40(7):693–702

Ramatsa IM, Akinlabi ET, Madyira DM, Huberts R (2014) Design of the bio-digester for biogas production : a review, vol II, pp 22–24

Meng Y, Luan F, Yuan H, Chen X, Li X (2017) Enhancing anaerobic digestion performance of crude lipid in food waste by enzymatic pre-treatment. Bioresour Technol 224:48–55

Tapase R, Phutane S, Pawar P, Sonawane P, Chavan VM (2016) Design of fixed dome domestic bio digester for degradation of kitchen waste using mesophilic & thermophilic reactions (anaerobic). Int J Mech Eng Technol (IJMET) 7(2):52–58

Voegeli Y, Lohri C, Kassenga G, Baier U, Zurbrügg C (2009) Technical and biological performance of the Arti compact biogas plant for kitchen waste-case study from Tanzania. In: Margherita di Pula S (ed) 12th international waste management and landfill symposium. Cagliari, Italy, pp 5–9

Asmare M (2014) Design of cylindrical fixed dome bio digester in the condominium houses for cooking purpose at Dibiza site East Gojjam, Ethiopia. Am J Energy Eng 2(1):19–22

Lama L, Lohani SP, Lama R, Adhikari JR (2012) Production of biogas from kitchen waste, vol 2, pp 14–18

Vij S (2011) Biogas production from kitchen waste. In: A seminar report submitted in partial fulfillment of the requirements for Bachelor of Technology (Biotechnology), unpublished. Seminar report, Department of Biotechnology and Medical Engineering, National Institute of Technology, Rourkela, July

Cheng J (ed) (2009) Biomass to renewable energy processes. CRC press

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Rahman, M.M., Lee, Y.S., Tamiri, F.M., Hong, M.G.J. (2018). Anaerobic Digestion of Food Waste. In: Horan, N., Yaser, A., Wid, N. (eds) Anaerobic Digestion Processes. Green Energy and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-10-8129-3_7

Download citation

DOI: https://doi.org/10.1007/978-981-10-8129-3_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-8128-6

Online ISBN: 978-981-10-8129-3

eBook Packages: EnergyEnergy (R0)