Abstract

Agricultural residues are a major renewable source available on earth. In developing countries, food, agriculture, and forestry and industries produce high amounts of lignocellulosic wastes that cause disposal problems because these wastes are not easily degraded. Here we review the microbial synthesis of industrial products from lignocellulosic wastes. Lignocellulose is a complex compound of plant cell wall, composed of cellulose, hemicellulose, lignin, pectin and inorganics. As a consequence, feedstock pretreatments are required before the microbial production of industrial products through microbial intervention. Pretreatment techniques include physical, chemical, and biological methods. We discuss the microbial synthesis of industrial products such as enzymes, bioethanol, xylitol, and vinegar.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Lignocellulosic biomass

- Cellulose

- Hemicellulose

- Lignin

- Agricultural waste

- Pretreatment

- Hydrolysis

- Industrial products

- Xylitol

- Bioethanol

- Microorganisms

16.1 Introduction

Lignocellulose, mainly consists of cellulose, hemicellulose and lignin, is one of the key components of woody and non-woody plants. Lignocellulosic materials are obtained from three sources namely primary sources like short rotation energy plantations, sugar cane etc., secondary sources like corn cob, rice husk, straw, bagasse, and tertiary sources like sewage treatment sludge, municipal solid waste, and wood trimmings (Fischer and Schrattenholzer 2001). Primary sources have economic and social barriers for their utilization; hence, secondary and tertiary sources are commonly used as potential feed stocks for synthesis of industrial products. Lignocellulosic materials are produced in large amount annually by developing, and agricultural countries like India from food, agricultural, and forestry industries. These wastes cause serious disposal problems and cause harmful effects on environment because these wastes are often disposed of by burning in many developing countries (Demirbas 2008). Lignocellulose acts as major substrate for the production of enormous products of biotechnological value due to its chemical properties (Malherbe and Cloete 2003). The current focus of researchers is towards utilization of such renewable sources for microbial synthesis of industrial important products.

From the past few decades, considerable improvements have been made in green biotechnology by utilizing these lignocellulosic materials. These wastes are promising feedstocks for the production of numerous value-added products like animal feeds, amino acids, biofuels, chemicals, cheap energy sources, enzymes, organic acids, polyols, and human foods (Anwar et al. 2014; Sooch et al. 2019; Kauldhar et al. 2021; Lugani et al. 2019, 2021a, b). The global market of these bio-based products is enhancing at a very fast pace due to environmental concerns and continuous depletion of fossil fuels including petrol and diesel.

The major steps involved in production of industrial products using biomass as feedstocks are pretreatment, hydrolysis/saccharification, fermentation and purification. The schematic representation for biosynthesis of value-added industrial products from lignocellulosic biomass is shown in Fig. 16.1. The further steps vary with the type of product and form of its availability in the market. Pretreatment, hydrolysis, and purification are three major steps which regulate overall product market cost (Amiri and Karimi 2018). One of the major obstacles for using lignocellulosic materials is their recalcitrant nature due to their complex geometry, and hence, different pretreatment and hydrolysis methods are used to release fermentable sugars from these complex polysaccharides (Kumar and Sharma 2017). Different physical, chemical, biological, physico-chemical, thermo-chemical and thermo-physical methods are available for pretreatment of various feedstocks (Lugani et al. 2019, 2021b; Sooch et al. 2019; Mann and Sooch 2020; Kauldhar et al. 2021). The selection of pretreatment method relies on type of substrate, type of hydrolysis method, and type of microbial strain and fermentation mode. Hydrolysis can be achieved either by chemical or enzymatic methods but enzymatic methods appear to be more promising due to environmental and safety concerns.

Fermentation is an attractive approach for currently used green biotechnology in which microbial (bacteria, yeast, fungi and algae) strains are used for the synthesis of bio-products in the form of primary and secondary products (Box 16.1). Due to less productivity with the use of wild microbial strains, some improved approaches such as synthesis of genetically modified strains and use of computational models have been developed to produce industrial important strains in the past. Immobilization of biocatalyst is one of the alternative methods for development of continuous systems with reusability of enzymes.

Box 16.1 Primary and Secondary Metabolites Produced by Microorganisms

Primary metabolites | Examples |

Amino acids | L-alanine, L-arginine, L-glutamic acid, L-glutamine, L-histidine, L-proline, L-serine, L-valine, L-tyrosine, L-tryptophan, L-threonine, L-phenylalanine, L-leucine, L-isoleucine |

Organic acids | Acetic acid, butyric acid, citric acid, lactic acid, succinic acid, fumaric acid, Itaconic acid, Gluconic acid, Xylonic acid |

Alcohols | Ethanol, 1,3-Propanediol, 2,3-Butanediol |

Enzymes | Cellulase, protease, pectinase, lipase, xylanase, xylose reductase, laccase, peroxidase, arabinase, mannase |

Proteins | Single cell protein, Phycobiliproteins |

Vitamins | Riboflavin, ascorbic acid |

Trace elements | Ca, Fe, Mg, Zn, P, K, S, N, Mo, cl, Zn |

Sugars | Xylitol, mannitol, sorbitol |

Secondary metabolites | Examples |

Antibiotics | Penicillin, cephalosporin, cyclosporine A, neomycin, Oxytetracycline, Rifamycin A, tetracycline |

Phenolic compounds | Benzene, biphenyls, catechol, cyclohexane, toluene, xylene, lutein, Astaxanthin, zeaxanthin, β-carotene |

Essential oils | Docosahexaneoic acid, Eicosapentaneoic acid, terpenes, lactones, aldehydes, ketones, paraffin, monoterpenoid alcohols |

Chemicals | Furfural, ethylene, propylene, phenazines, quinolines, vanillin |

Polymers | Poly-3-hydroxybutyrate |

Separation and purification of product is generally carried out on the basis of the type of compounds being separated using various chromatographic techniques such as affinity chromatography, dye-ligand chromatography, gel permeation chromatography, high pressure liquid chromatography, hydrophobic interaction chromatography, ion exchange chromatography and gas chromatography (Coskun 2016). Deep eutectic solvents are used for the extraction of value-added components like flavones (apigein, luteolin), lignans (acetoxypinoresinol), phenolic acids, phenolic alcohols, secoiridoid derivative (aglycone, ligstroside), tocopherols and tocotrienols (Jablonsky et al. 2018). The current chapter enlightens the significance of lignocellulose biotechnology with emphasis on different pretreatment and hydrolysis steps, production of various value-added products and their current market status. Some other aspects like improved strategies for production of industrial products including development of genetically modified microbial strains, immobilization and computation techniques have also been reviewed in this chapter.

16.2 Types and Composition of Lignocellulosic Biomass

Lignocellulosic biomass is typically nonedible plant materials mainly comprises of cellulose (40–50%), hemicellulose (25–30%), lignin (15–20%), and traces of inorganic and nitrogen compounds along with pectin (Mori et al. 2015). Cellulose is the plentiful compound on earth with special features such as hydrophobicity, biocompatibility, and stereoregularity, and the framework of cell wall is determined by its structure (Tayyab et al. 2018). It is a linear syndiotactic, rigid, crystalline homopolymer in which D-glucose residues are linked together by β-1,4-glycosidic linkage. The non-covalent interactions (hydrogen bond and van der Walls forces) present help in packing of cellulose polymers into microfibrils. The hydrolysis of cellulose into monomeric sugars is influenced by its crystallinity and polymerization, and it varies with plant species (Gray et al. 2006). Hemicellulose is an amorphous structure which provides structural strength through linkage of cellulose fibers into micrifibrils, and their crosslinkage with lignin. It comprises of short, linear, heterogenous, highly branched chains, and it is a mixture of polysaccharides including pentose sugars (D-xylose, D-arabinose) and hexose sugars (D-glucose, D-galactose, and D-mannose) and uronic acids (Saha and Cotta 2007; Saha et al. 2017). Hemicellulosic component require a great variety of enzymes for complete hydrolysis into fermentable sugars due to diversity of hemicellulosic sugars (Limayem and Ricke 2012). This polysaccharide does not possess crystalline regions, and it has low degree of polymerization, therefore, it can be easily hydrolysed into monomeric units (Karimi and Taherzadeh 2016).

Lignin is a non-sugar based complex polymer of phenyl propanic alcohol (p-coumaryl, coniferyl, and sinapyl alcohol), which provides impermeability and structural support to plants. It also confers resistance against oxidative stress and microbial attack due to its distinctive properties such as water insolubility, optical inactivity, and amorphous nature (Howard et al. 2003). A great amount of energy is produced by burning lignin; hence, it is used in biorefinery for combined heat and power production in environmental-friendly manner (Bonawitz and Chapple 2010). Along with cellulose, hemicellulose, and lignin, the lignocellulosic materials contain small amount of ash, extractives (chlorophyll, nitrogenous materials, and waxes), proteins, and pectin (Kumar et al. 2009). There is great variation in composition of biomass constituents among different plant sources based on species, tissue, maturity of plant cell wall, variety, soil fertility, climate, and species. The composition of some lignocellulosic materials is shown in Table 16.1.

The methods for determining chemical composition of biomass have been developed by some global organizations like Technical Association of the Pulp and Paper Industry, National Renewable Energy and Laboratory, and American Society for Testing and Materials. The purest sources of cellulose are cotton (80–95%), flax and chemical pulp (60–80%), however, approximately 45% cellulose is present in hardwoods, and softwoods (Demirbas 2005). Monterey pine is a preferred substrate for production of industrial products due to its rapid growth, high cellulose content (48%), and compositional uniformity (Dong et al. 2018). Hemicellulosic content is found maximum in crop residues like wheat straw, rice straw, and corn stover (Foody and Foody 1991). The main hemicelluloses in hardwood species are glucuronoxylans (O-acetyl-4-O-methyl-D-glucuronoxylan), and in softwood species are galactoglucomannans (O-acetyl-galactoglucomannans). Hardwood species have higher xylan and lower mannan content than softwood; therefore, softwood species are more recalcitrant to enzymatic action (Alvarez et al. 2016). Lignin content is highest in softwood barks (30–60%), followed by hardwood barks (30–55%), whereas, minimum lignin content is found in grasses (10–30%), and agricultural residues (3–15%) (Demirbas 2005). The complex chemical structure of lignocellulosic biomass is the major challenge for their utilization to develop and commercialize value-added industrial products (Tayyab et al. 2018). Hence, it is necessary to select suitable, cost-effective and economic pretreatment method for their utilization as raw materials with minimum formation of by-products.

16.3 Pretreatment and Hydrolysis of Lignocellulosic Biomass

Pretreatment and saccharification/ hydrolysis are two crucial steps used for the release of monomeric sugars from polysaccharides. Pretreatment causes alteration in the structure, and chemical composition of biomass resulting in improved substrate porosity by decreasing cellulose crystallinity, increasing surface area, size reduction, and lignin removal (Zhu et al. 2009). The fermentable sugars are released from pretreated biomass either by enzymatic hydrolysis or acid hydrolysis (Azhar et al. 2017).

16.3.1 Methods of Pretreatment

There are many physical, chemical, biological, electrical, physico-chemical, thermo-physical, and thermo-chemical methods available for pretreatment of lignocellulosic materials, and each method has some merits and demerits. Figure 16.2 shows different methods available for pretreatment of lignocellulosic biomass but none of these methods could be adapted successfully at industrial scale, and researchers are still focusing on development of some cost and energy efficient pretreatment method. The physical methods used for the disruption of recalcitrant biomass are size reduction (Maurya et al. 2015), microwave irradiation (Amin et al. 2017), and pyrolysis (Den et al. 2018). These methods do not use chemicals and disrupt the biomass by reducing its size by mechanical forces (milling, grinding, and chipping), generating heat from magnetic and electrical components, and rapid decomposition by producing gaseous products (Amin et al. 2017). However, physical pretreatment methods are not economical for commercial use due to high power consumption, and slow rate of reaction.

Different chemicals such as acids (Wyman et al. 2005), alkali (Kumar et al. 2009), ionic liquids (Capolupo and Faraco 2016), organic solvents (Monavari et al. 2009), surfactants (Qing et al. 2010), and lime (Sierra et al. 2009) are used in chemical pretreatment. The most conventional chemical pretreatment method is acid hydrolysis in which acids like H2SO4, HNO3, HCl, and H3PO4 are used for disrupting covalent and non-covalent interactions. Dilute acid treatment methods are simple with less generation of toxic products (Wyman et al. 2005). Alternatively, the pretreatment method using concentrated acids result in rapid extraction of reducing sugars from diverse feedstocks; however, reducing sugars are easily degraded by this method (Zhu et al. 2009). Hemicellulose fraction is rapidly hydrolysed by alkaline agents like KOH, NaOH, NH4OH, and Ca(OH)2 (Mosier et al. 2005). Simultaneous hydrolysis and delignification for hardwood and softwood can be achieved by using organic solvents (ethanol, methanol, tetrahydrofurfuryl alcohol, acetone, ethylene glycol) (Pan et al. 2005), however, this method is expensive, and leads to synthesis of toxic inhibitors (Eggeman and Elander 2005). Surfactants possess both hydrophilic and hydrophobic properties, and the most commonly used surfactants are polyethylene glycol 4000, polyethylene glycol 6000, Tween 20, and Tween 80 (Zhang et al. 2016a).

Biological pretreatment method is energy-saving and environment friendly. It is conducted at mild temperature and pressure conditions using microbial cells or enzymes as biocatalyst (Tayyab et al. 2018). The major drawbacks for using this method at industrial scale are requirement of chemical mediators, large space, and long residence time with optimum growth conditions. Pulsed electrical field is electrical pretreatment method which needs simple equipment, and ambient conditions (Ammar et al. 2011). Ozonolysis is a physico-chemical method which is conducted at mild temperature, and pressure, and effective for lignin removal, however, this method is expensive and leads to production of toxic inhibitors (Cubero et al. 2009). Hot water (Banerjee et al. 2009), ultrasound (Ivetic et al. 2017), and steam explosion (Pielhop et al. 2016) are thermo-physical methods in which physical and chemical forces cause loosening of lignocellulose materials which become highly susceptible to hydrolysis (Den et al. 2018). The methods used in thermo-chemical pretreatment are alkaline wet oxidation (Monavari et al. 2009), supercritical CO2 (Kumar et al. 2009), ammonia recycle percolation (Chaturvedi and Verma 2013), and ammonia fiber explosion (Kim 2018), and these methods are reported to be more effective for biomass containing high lipid fraction (Kumar et al. 2009).

16.3.2 Factors Affecting the Pretreatment

There are various factors affecting the pretreatment of lignocellulosic materials and particle size is an important factor of size reduction pretreatment process because it affects the power requirement, and high-power consumption can make the process economically non-feasible (Hendriks and Zeeman 2009). High decomposition rate of biomass can be achieved using pyrolysis at low temperature in the presence of sodium carbonate or zinc chloride as catalyst (Singh et al. 2011). Dielectric properties of lignocellulosic material influence the performance of microwave irradiation (Amin et al. 2017). Dilute acid pretreatment is an economical method and used with abroad range of feedstocks like agricultural waste materials, hardwood, herbaceous crops, municipal solid waste, and softwood for complete removal of hemicelluloses. The temperature-time combination is very crucial during selection of method for pretreatment, this can be carried out at high temperature (180 °C) for short time or low temperature (120 °C) for long time (Myat and Ryu 2016). The efficiency of pulsed electric field pretreatment method relies on various parameters such as electric field strength, treatment time, and pulse parameters, and moisture distribution of plant tissue (Barba et al. 2015). The major factors like temperature, particle size, and residence time affect the efficacy of pretreatment by steam explosion method.

There is enhanced removal of hemicellulose from solid fraction and cellulose digestibility at higher temperature (Oliva et al. 2003). High frequency ultrasonic waves are used in ultrasound pretreatment, and the effectiveness of this method is governed by ultrasonic frequency, reactor geometry, and type of solvent used (Den et al. 2018). In organosolv process, different organic acids like salicylic, acetyl salicylic, and oxalic acid are used as catalyst, however, the use of catalyst is insignificant for satisfactory delignification at high temperature i.e., above 185 °C (Aziz and Sarkanen 1989). Steam explosion pretreatment method is economic and environment friendly which used high pressure saturated steam for explosive decompression of hemicelluloses.

Ammonia fiber expansion is an ammonia-based pretreatment method aimed to improve the susceptibility of lignocellulosic biomass for enzymatic action. In this process, ammonia load and residence time are the critical factors affecting the economics of the process. The conditions optimized for this method are like temperature of 90 °C, liquid ammonia dosage of 1–2 Kg ammonia/Kg dry biomass, and residence time of 30 min (Sun and Cheng 2002). The energy consumption by steam explosion method affects the energy efficiency ratio. The energy efficiency ratio is less (0.26 Kg sugar/ MJ) for steam explosion than organosolv (0.31–0.40 Kg sugar/ MJ) (Zhu et al. 2010), hence steam explosion pretreatment method is a method of choice for wide variety of feedstocks including industrial hump (Sipos et al. 2010), wheat straw (Erdei et al. 2012), wood chips (Pielhop et al. 2016), and corn stover (Walker et al. 2018; Sulzenbacher et al. 2021).

16.3.3 Methods for the Hydrolysis of Pretreated Feedstock

The fermentable sugars are released from pretreated biomass using saccharification/hydrolysis, which is generally conducted by acid or enzymatic treatment (Azhar et al. 2017). Acid hydrolysis is carried out through dilute or concentrated acids (Kim et al. 2005). Organic acids, phosphoric acid, nitric acid, sulfuric acid and hydrochloric acid are commonly used for acid hydrolysis (Zhou et al. 2013). Enzyme hydrolysis, also known as biological hydrolysis, is another method for hydrolysis of pretreated materials in which biocatalysts (cellulases, and hemicellulases) are used, and biological method is observed to be more promising over acid hydrolysis for commercial applications due to less chemical and energy requirement, less generation of toxic by-products, and high product yield (Madadi et al. 2017). The factors affecting enzymatic hydrolysis involve enzyme mediated factors such as source of enzymes, combined action of two or more enzymes and adsorption of enzymes in addition to lignin content, and substrate related factors such as accessible surface area, cellulose crystallinity, hemicellulose content, particle size and specific surface area ratio and degree of polymerization (Lukajtis et al. 2018). Other physical and chemical parameters like temperature, pH, substrate concentration, enzyme dosage, and treatment time also affect the enzyme mediated hydrolysis (Kamzon et al. 2016).

Bacteria and fungi can be easily grown under laboratory conditions due to their rapid growth and less generation time, and species of Aspergillus, Clostridium, Cellulomonas, Fusarium, Neurospora, Penicillium and Trichoderma possess the ability for production of cellulases and hemicellulases (Chandel et al. 2007). Cellulase mediated hydrolysis has been conducted by synergistic action of three enzymes namely, endo-glucanase, exo-glucanase and β-glucosidase, and three major steps are involved in this process for production of monomeric sugars from polysaccharide cellulose (Madadi et al. 2017). A complex group of hemicellulases involving endo-β-1,4-xylanase (EC 3.2.1.8), α-D-galactosidase (EC 3.2.1.22), acetyl xylan esterase (EC 3.1.1.72), β-xylosidase (EC 3.2.1.37), α-L-arabinofuranosidase (EC 3.2.1.55), α-D-glucuronidase (EC 3.2.1.139), and ferulic acid esterase (EC 3.1.1.73) was employed for degradation of complex hemicellulose structure (Ivetic et al. 2017).

16.4 Production of Industrial Products from Lignocellulosic Biomass

Lignocellulosic biomass is found to be one of the primary raw materials for renewable fuels, chemicals, and different value-added products (Liu et al. 2014), and the major sources of lignocellulosic biomass are agricultural sources like crop residues, perennial grasses and woody crops, logging and wood processing mill waste, and biomass from forest waste (Wahlstrom and Suurnakki 2015). It has been reported that more than 200 value-added compounds have been obtained from lignocellulosic biomass by development of novel cost-effective technique (Kumar et al. 2018a). There are different microbial factories which have been involved in biotransformation of lignocellulosic biomass into value-added products. The major factors influencing rate of microbial growth and production of different primary and secondary metabolites are temperature, pH, inoculum size, inoculum age, aeration rate, type and concentration of carbohydrate, concentration of salt, osmolarity, and ethanol concentration (Sooch and Lugani 2017). The three major steps involved in transformation of lignocellulosic biomass into high value compounds are pre-treatment, hydrolysis and fermentation (Kumar et al. 2018b). Different value-added industrial products produced by bioconversion of lignocellulosic biomass have been described in Table 16.2.

16.4.1 Production of Industrial Enzymes

Enzymes are proteinaceous biomolecules which enhances the rate of reaction by lowering the activation energy. Enzyme production is one of the central parts of global industrial biotechnology, and utilization of low-cost lignocellulosic biomass as substrate is an appropriate approach for production of proficient enzymes. Different bacteria (Acidothermus, Acidobacterium, Bacillus, Clostridium, Cellulomonas, Corynebacterium, Enterobacter, Pseudomonas, Staphylococcus), fungi (Aspergillus, Cephalosporium, Fusarium, Humicola, Mucor, Neurospora, Penicillium, Rhizopus, Trichoderma), and yeasts (Candida, Cryptococcus, Debaryomyces, Hansenula, Kloeckera, Kluyveromyces, Monilia, Pichia, Rhodotorula, Saccharomyces, Torulopsis, Trichosporon) are involved in the production of industrially important enzymes (Shahriarinour et al. 2011; Lugani et al. 2015; Sooch et al. 2019).

Actinomycetes constitute an important group of microbial population for production of novel enzymes having commercial potential due to their extreme stability, ability to decompose various materials, and unusual substrate specificity. Many commercially relevant enzymes like amylase, cellulase, chitinase, glucose oxidase, lipase, lipoxygenase, pectinase, phytase, peroxidase, protease, and xylanase have been reported to be produced from lignocellulosic biomass (Table 16.2) by different genera of actinomycetes including Actinomadura, Cellulomonas, Microbiospora, Nocardiopsis, Streptomyces, Thermoactinomycees, Thermobifida, Thermomyces, Thermomonospora (Prakash et al. 2013). Among all the enzymes, cellulases and hemicellulases have tremendous applications in different industrial sectors like agriculture, animal feed, brewery and wine, chemicals, food, fuel, laundry, paper, pulp, and textiles (Beauchemin et al. 2003).

The two major fermentation strategies used for production of enzymes are solid-state fermentation and submerged fermentation, and there is different genetic expression of microbes under different fermentation modes (Gonzalez 2012; Sirohi et al. 2018). Solid state fermentation leads to utilization of solid substrate for the production of industrial enzymes from different fungal species like ascomycetes, basidiomycetes, and deuteromycetes (Batche et al. 2014) and lignocellulosic materials are found suitable for production of many industrial enzymes. This method promises less downstream processing, minimum effluent production, high volumetric productivity, and increased product concentration (Singhania et al. 2010). However, there are several limitations also associated with this method like there is limited reproducibility of results, and it is not able to standardize process parameters such as temperature and aeration which may lead to enzyme inactivation (Holker and Lenz 2005).

The second fermentation strategy is submerged fermentation which utilizes aqueous medium to maintain uniform temperature, pH, aeration and agitation conditions within the vessel, and this method is commonly used for large scale enzyme production (Ravindran and Jaiswal 2016). There is strict control of different parameters within this system; hence, there are minimum chances of contamination, and less byproducts production like metal ions, butylated hydroxytoluene and hydrogen peroxide (Roukas 2016). Hence, submerged fermentation is commonly used for the fermentative production of different enzymes and bioactive compounds from bacteria, and filamentous fungi using lignocellulosic biomass. However, there are many reports which clearly revealed that submerged fermentation is not an economical mode of enzyme production at large scale because there is a need of sophisticated and large equipment in this mode. Previously, Zhang et al. (2012) showed that capital investment for submerged fermentation is 78% more than solid state fermentation. Research work of various enzyme producing industries is now focusing towards isolation of novel extremophilic and recombinant microbial strains with enhanced enzyme production from lignocellulosic biomass.

Different agricultural lignocellululosic materials like wheat straw (Sumantha et al. 2005), rice straw, rice bran (Virupakshi et al. 2005), coffee by-products (Murthy and Naidu 2010), oil palm empty fruit bunch (Shahriarinour et al. 2011), chocory Dahlia (El-Hersh et al. 2011), wheat bran (Kumar and Sushma 2012), pine apple (Thangaratham and Manimegalai 2014), banana waste (Dabhi et al. 2014), sugarcane bagasse (Kaur et al. 2015), corn cob (Barathikannan et al. 2016), sugarcane industrial waste (Ellila et al. 2017), and wastewater (Zouaoui and Bouziane 2018) were used as feedstocks for production of industrial important enzymes. Different lignocellulosic materials like bajra straw, Trifolium hay, sorghum straw, maize straw, oat hay, and wheat straw were screened for production of thermostable xylanase production from Trichoderma viride, and the maximum enzyme production was achieved with maize straw under submerged fermentation (Goyal et al. 2008). Detoxified sugarcane bagasse hydrolysate was used for production of xylose reductase from Candida guilliermondii FTI 20037, and the maximum enzyme production (2.5 U/mg of protein) was found under microaerobic conditions (Milessi et al. 2011).

Lignocellulosic feedstocks like date seeds, grasses and palm leaves were also tested for the production of different hydrolytic enzymes (α-amylase, pectinase, xylanase) under solid state fermentation from Bacillus megatherium, and wheat bran was found to be the best among all the substrates used for production of different hydrolytic enzymes (El-Shishtawy et al. 2014). In another study, carrot peel was used for pectinase production by Bacillus mojavensis I4 in submerged fermentation using two statistical methods i.e., Taguchi design (for key ingredients) and Box-Behnken design for optimizing different parameters, and maximum pectinase production of 64.8 U/mL were obtained under optimized conditions with 6.5% (w/v) carrot peel powder (Ghazala et al. 2015). In another study, among all the seven fungal strains tested for lipase production, the maximum enzyme activity of 5.12 ± 0.0059 U/mL was attained with Aspergillus niger at 30 °C after fermentation period of 72 h using olive oil as substrate (Mukhtar et al. 2015).

Different forms of cellulases i.e., endoglucanase, exoglucanase and β-glucosidase were produced by Aspergillus flavus Linn after utilizing freshly ripe tomato fruit under solid state fermentation (Damato et al. 2010), and by Bacillus subtilis from molasses sawdust and bagasse under submerged fermentation (Singh et al. 2016). Response surface methodology was adopted for production of protease from different substrates (corncob and coffee pulp waste) using Box-Behnken design and the maximum enzyme yield of 920 U/mL was attained with 3 g/L and 2 g/L of coffee pulp waste and corncob, respectively at 37 °C after 60 h of fermentation (Kandasamy et al. 2016). Extracellular lipase activity of 140 U/mL was also obtained from novel Bacillus stratosphericus using coconut dregs as feedstock in submerged fermentation, and the resultant enzyme was observed to be active under wide range of pH and temperature conditions in the presence of detergents (Zin et al. 2017).

16.4.2 Production of Bioethanol

Bioethanol is a clean, environment-friendly, and alternate fuel for future generation, which results in less emission of green house gases, and hence considered as an alternative strategy for reducing global warming (Joshi et al. 2011). Based on type of raw material, biofuels are classified into four generations i.e., first generation biofuels from edible agricultural crops, second generation biofuels from non-edible lignocellulosic feedstocks, third generation biofuels from algal biomass, and fourth generation biofuels from metabolically engineered algal strains (Meneses et al. 2017). Currently, sucrose and starch-based grains are utilized for industrial level bioethanol production (Asgher et al. 2013); whereas it may generate a competition between food production and fuel ethanol for future generations (Gnansounou 2011). Hence, to avoid such situation, one of the alternative potential approaches is utilization of different agricultural lignocellulosic residual materials for low-cost fermentation production (Iqbal et al. 2013; Lugani et al. 2019). The major steps involved in biofuel production are pretreatment, hydrolysis, fermentation and distillation (Mosier et al. 2005).

Different fermentation modes for bioethanol production are batch, fed-batch and continuous mode. The most traditional method of ethanol production is batch fermentation in which high initial substrate concentration is used (Olsson and Hagerdal 1996). In a continuous system, there is constant addition of nutrients and substrate with removal of biomass and metabolites, and the merits associated with this mode of fermentation are easy to control, less labor intensive, high productivity, and elimination of undesired products (Sanchez and Cardona 2008). Fed-batch system is a combination of batch and continuous process in which substrate is added intermittently, which results in shorter fermentation time, higher ethanol productivity, high dissolved oxygen and low toxicity of media components (Cheng et al. 2009). In another study, ethanol productivity of 0.44 g/L/h, and ethanol concentration of 53.3 g/L was obtained from wheat meal and wheat straw in fed batch system at 32 °C for 120 h under agitation conditions (300 rpm) using Saccharomyces cerevisiae TMB3400 (Erdei et al. 2012). The ethanol productivity of 3.8 g/L/h was obtained in a continuous system with a dilution rate of 0.131/h using nonlinear model predictive controller algorithm (Ajbar and Ali 2017).

Various previous reports have been published on ethanol production by utilizing different lignocellulosic feedstocks such as water hyacinth (Kumar et al. 2009), cassava powder (Choi et al. 2010), grass silage (Sieker et al. 2011), spent coffee grounds (Mussatto et al. 2012), coffee processing waste (Kefale et al. 2012), poplar (Wang et al. 2012), grasses (Scordia et al. 2014), douglas fir (Inoue et al. 2016), rice straw (Wi et al. 2013; Phitsuwan et al. 2017), waste paper (Nishimura et al. 2017), pine needle (Vaid et al. 2018), and pine slurry (Dong et al. 2018). In one previous study, ethanol was produced from cotton hydrolysate using Saccharomyces cerevisiae var. ellipsoideus at 30 °C under agitation conditions (Nikolic et al. 2016). In a similar study, maximum ethanol production of 33.7 g/L was observed after 96 h of fermentation at 34 °C from corn stover pretreated with ethylenediamine using simultaneous saccharification and co-fermentation strategy (Qin et al. 2018). The ethanol yield is very less with wild microbial strains; hence many recombinant strains have been developed for improved production of ethanol (Cavalheiro and Monteiro 2013; Sar et al. 2017; Ko et al. 2018; Lopez-Hidalgo et al. 2021).

There are some fermentation integrated strategies such as simultaneous saccharification and fermentation, simultaneous saccharification and co-fermentation and consolidated bioprocessing, which are adopted for bioethanol production to overcome the drawbacks of traditional fermentation systems. Simultaneous saccharification and fermentation system allows use of a single vessel for simultaneous hydrolysis and fermentation, which allows ease of process operation, less chances of contamination, and economical ethanol production in short duration. Simultaneous saccharification and co-fermentation method is one step complete simultaneous hydrolysis and fermentation of both pentoses and hexoses into ethanol in short duration (Nikolic et al. 2016). The most upgraded highly integrated approach is consolidated bioprocessing in which single microbial community brings all the processes in a single step including sugar production, enzyme hydrolysis and fermentation (Lynd et al. 2005).

Previously, waste newspaper was used as substrate for ethanol production in simultaneous saccharification and fermentation using thermotolerant yeast Saccharomyces cerevisiae KNU5377 at 50 °C, and the maximum ethanol production of 8.4% was attained after 72 h of fermentation (Park et al. 2010). 82.1 g/L ethanol was produced from 25% (w/w) undetoxified pile slurry in simultaneous saccharification and fermentation system (Dong et al. 2018). Simultaneous saccharification and co-fermentation system was used previously by many researchers for the production of ethanol (Liu and Chen 2016; Sharma et al. 2018; Qin et al. 2018). In a recent study, the maximum ethanol yield of 0.148 g/g after 72 h of fermentation was obtained from pine needle biomass using Saccharomyces cerevisiae and Pichia stipitis through consolidated bioprocessing (Vaid et al. 2018).

16.4.3 Production of Xylitol

Xylitol is an industrially important polyol sugar having tremendous applications in different industrial sectors such as food, bakery, confectionery, cosmetic, odontological, pharmaceutical, and medical sectors (Lugani and Sooch 2017, 2018, 2020; Lugani et al. 2017, 2020; Baptista et al. 2018). The unique properties of xylitol such as negative heat of dissolution, improvement of taste and color of food, and bakery products, absence of Maillard reaction, low calorie sugar, insulin independent metabolism, enhanced remineralization of carious lesions, and ability to retain moisture make this alcoholic sugar an attractive choice for industrial applications (Albuquerque et al. 2014), and the global market of xylitol is supposed to be USD 6.30 billion by 2022 (Markets and Markets 2016). Biotechnological methods (fermentative and enzymatic), being environment friendly, are currently explored to produce xylitol to meet its increasing global demand. Fermentation method, also known as microbial method, uses whole microbial (bacterial, yeast, and fungal) cells for xylitol production at ambient temperature, and pressure conditions with enhanced product yield and productivity, and there is minimum synthesis of by-products during this process (Tran et al. 2004; Lugani et al. 2021a).

Yeasts are the primary candidate of choice for xylitol production due to improved yield and productivity compared to bacteria and fungal strains, and Candida boidinii, C. guillermondii, C. tropicalis, C. parapsilosis, C. boidinni, Pichia sp., Pachysolen sp., Kluyveromyces marxianus, Kloeckera sp., Saccharomyces sp., Rhodotorula sp., Hansenula sp., Torulopsis sp., Trichosporon sp., Cryptococcus sp., and Debaromyces hansenii have been extensively utilized by many researchers for xylitol production from various agricultural waste materials (Cortez and Roberto 2014; Tamburini et al. 2015; Zahed et al. 2016; Dasgupta et al. 2016; Xavier et al. 2018). Various genera of bacteria such as Acetobacter, Gluconobacter, Achromobacter, Actinomadura, Agrobacterium, Arthrobacter, Azotobacter, Brevibacterium, Corynebacterium, Erwinia, Flavobacterium, Micrococcus, Nocardia, Planococcus, Pseudomonas, Rhodococcus, Morganella,Streptomyces, and Gluconobacter (Takeuchi et al. 2001; Sugiyama et al. 2001; Lugani and Sooch 2020), and fungi Neurospora, Penicillium, Aspergillus, Rhizopus, Gliocladium, Byssochlamys, Myrothecium (Sampaio et al. 2003; Mudaliyar et al. 2011) are also reported for xylitol production.

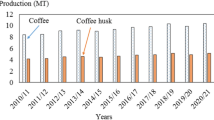

Different agricultural wastes such as walnut shell (Tran et al. 2004), sugarcane bagasse (Santos et al. 2005), spent brewing grain (Carvalho et al. 2005), rice straw (Zeid et al. 2008), sorghum straw (Sene et al. 2011), groundnut shells, glass straw (Mudaliyar et al. 2011), rice bran (Martinez and Santos 2012), coffee husks, moungbean hull, oat hull, peanut hull, corncob (Jeevan et al. 2011; Tada et al. 2012), sago trunk (Mohamad et al. 2013), coconut husk (Neeru et al. 2013), banana peel (Rehman et al. 2013), pomegranate peel (Barathikannan et al. 2016), oil palm empty fruit bunch (Kresnowati et al. 2016), beech wood, and cocoa pod husk (Santana et al. 2018) have been used as raw material of xylose for xylitol production. Two agricultural wastes such as beech wood and walnut shells were screened for xylitol production by Candida tropicalis IFO0618, and the maximum xylitol yield (50%) was obtained with beech wood hydrolysed solution mixed with glucose (1%, w/v) (Tran et al. 2004).

Agricultural wastes such as coconut husks, groundnut shells, grass straw, Eucalyptus leaves, Eucalyptus wood, and Jambulina leaves have been tested for production of xylitol by Aspergillus niger, and the maximum xylitol production (0.300 g/L) has been attained with Eucalyptus leaves (Mudaliyar et al. 2011). The maximum xylitol production of 35 g/L was obtained from corn cob hydrolysate (containing 40 g/L xylose) by Pichia sp. under stirring conditions (150 rpm) at temperature of 28 °C and pH of 6.0 after 72 h of fermentation (Jeevan et al. 2011). Xylitol was produced from cocoa pod husk hemicellulose hydrolysate by Candida boidinii XM02G, and the highest xylitol yield of 0.52 g/g was observed at the end of fermentation and the yeast strain was also observed to tolerate phenolic compounds present in hemicellulose hydrolysate up to 6 g/L (Santana et al. 2018). Recently, Lugani et al. (2021b) have utilized rice straw as feedstock for the production of xylose reductase (a xylitol producing enzyme), from novel isolated Pseudomonas putida BSX-46. Some attempts have been made for improved xylitol production using industrially efficient recombinant microbial strains produced by mutagenesis and recombination DNA technology (Peng et al. 2012; Pal et al. 2013; Zhang et al. 2015; Kogje and Ghosalkar 2017; Baptista et al. 2018). Other polyol like sorbitol is also produced fermentativly using rice bran from Lactobacillus plantarum NCIM 2912 with 5.3 g/L yield (Jan et al. 2017).

16.4.4 Production of Vinegar

Vinegar is a sharp and sour liquid produced by double fermentation of sugar containing solution and is used as condiment and preservation of food. According to Food and Drug Administration, USA, vinegar is produced by two step fermentation process i.e., splitting of sugar into alcohol followed by bioconversion of alcohol into acetic acid. Different processes which have been adapted for production of acetic acid from past decades are Orleans/generator process, submerged fermentation and quick process, and the last two processes are used presently for commercial production of vinegar. Different steps involved in commercial vinegar production are fermentation, filtration, clarification, distillation, pasteurization, and bottling (Oyetoro et al. 2017). Traditionally, different types of raw materials like apples, berries, fruit juices, grapes, grains, honey, plant extracts, rice, sugars, whey have been utilized for production of different types of vinegar. However, in the recent past, different agricultural materials like banana peels (Bazirake et al. 2014), decomposed fruits (Diba et al. 2015), pineapple wastes (Raji et al. 2012; Krusong and Vichitraka 2010; Roda et al. 2014), star fruit juice (Minh 2014), and wood (Donald et al. 2009) have been utilized as substrate for vinegar production.

16.4.5 Other Products

Synthesis of various value-added products like vanillin and gallic acid from lignin-based materials by Phanerochaete chrysosporium was reported in literature (Ribbons 1987). Vanillin has potential applications in different industrial products like anti-foaming agents, drugs, herbicides, and household products (Priefert et al. 2001). Furfural is another value-added product produced by bioconversion of xylose containing lignocellulosic feedstock, and it is used for manufacturing of furfural-phenol plastics, pesticides and varnishes (Peleteiro et al. 2016).

The other products produced by lignocellulosic materials are antibiotics, methane, phenolic compounds, polysaccharides, and single cell proteins (Howard et al. 2003). In a recent study, a novel yeast strain Candida intermedia FL021 was reported to produce single cell protein by consuming lignocellulosic hydrolysate (Wu et al. 2018). Some organic chemicals such as benzene, ethylene, propylene, toluene, and xylene are also produced by lignocellulosic materials (Pothiraj et al. 2006), and these chemicals are in turn required for the synthesis of different chemical products like resins and polymers (Coombs 1987). Lignocellulosic waste is also utilized for the synthesis of high value byproducts like amino acids, organic acids, vitamins, bacterial and fungal polysaccharides such as xanthan (Pothiraj et al. 2006). In a previous study, L-lysine was produced by both wild and engineered strains of Corynebacterium glutamicum using acid pretreated detoxified biorefinery waste stream (Christopher et al. 2016). Chemicals such as 2,3-butanediol (2,3-BD) (Okonkwo et al. 2017), 1,3-propanediol (1,3-PD) (Vivek et al. 2018), and organic acids like lactic acid (Zhang et al. 2018; Juturu and Wu 2018), fumaric acid (Liu et al. 2017), itaconic acid (Saha et al. 2017), butyric acid (Wei et al. 2012; Fu et al. 2017; Xiao et al. 2018) gluconic acid, xylonic acid (Zhang et al. 2016b) and succinic acid (Cimini et al. 2016; Alexandri et al. 2016) have been reported to be produced by microbial fermentation by utilizating lignocellulosic feedstocks. The biodegradable polymer poly-3-hydroxybutyrate was also produced previously by utilizing xylose rich lignocellulosic wastes (Raposo et al. 2017).

Various valuable components such as polysaccharides, vitamins and trace elements like Ca, Fe, Mg, Zn, produced by lignocellulosic materials, improved digestibility of feedstuffs in animals (Zhu et al. 2012). Some previous authors have utilized lignocellulosic materials like corncob, corn stover, eucalyptus, rice straw, spent grain, and sugarcane bagasse for the synthesis of renewable and marketable bio-chemicals like benzene, biphenyls, catechol, cyclohexane, guaiacols, phenols, syringaldehyde, vanillin and vanillic acid (Messaoudi et al. 2017; Ji et al. 2012; Varanasi et al. 2013). Apart from bioethanol, other environment friendly clean biofuels, such as bio-butanol (Nilsson et al. 2015; Maiti et al. 2018) and bio-hydrogen (Abdul et al. 2013; Sen et al. 2016) are also produced by lignocellulosic biomass. During the past few years, some research has been directed towards development of bio-based composites with different functionalities of interest from lignocellulosic waste residual materials (Bajpai et al. 2013), and production of medium-density fiber board is one of the successful attempts in this research (Li et al. 2013).

Agricultural lignocellulosic wastes like cassava peel, coconut oil cake, corn cob, corn husk, corn steep waste, peanut shells, rice husk, rice straw, sugarcane bagasse, sugarcane molasses, and wheat bran flour have been utilized previously for the production of various antibiotics like cephalosporin, cyclosporine A, neomycin, oxytetracycline, rifamycin A, and tetracycline using solid state fermentation (Kaur et al. 2014). In a previous study, corn stover was utilized to produce succinic acid from Basfia succiniproducens and a final productivity of 0.43 g/L/h was obtained (Salvachua et al. 2016). In another study, Actinobacillus succinogenes and Basfia succiniproducens was used for biotransformation of spent sulphite liquor into succinic acid production and 39 g/L yield was achieved. Along with succinic acid, lignosulphonates (32.4 g/L), and phenolic rich extract (1.15 g) was also produced after fractionation (Alexandri et al. 2016). Many industrial valuable products such as astaxanthin, biohydrogen, β-carotene, docosahexaneoic acid, eicosapentaneoic acid, lutein, lycopene, phycobiliproteins, and zeaxanthin are produced by microalgal biomass (Bhalamurugan et al. 2018).

16.5 Improved Strategies for the Production of Industrial Products

The yield and productivity of industrially important valuable products is very less with wild microbial strains, and hence these methods can’t be adapted at commercial level for production of energy and cost-effective bio-based products. Hence, the focus of researchers is towards development of different strategies like genetic and metabolic engineering, immobilization methods and in silico computational techniques to reduce the cost of products produced by utilization of lignocellulosic biomass.

16.5.1 Development of Genetically-Modified Strains

Major techniques used to produce recombinant microorganisms are genome-based strain reconstruction, metabolic engineering, protein engineering, genome-wide transcript expression analysis, molecular breeding, genome mining, recombination DNA technology, whole genome shuffling and genome mining (Adrio and Demain 2010; Yang et al. 2017; Yang et al. 2018). One of the emerging fields of recombinant DNA technology is metabolic engineering to improve the production of novel products, accelerating rate determining step, engineer enzyme activities and shift metabolic flux towards synthesis of desired product by modulating transport of sugar, gene regulation and enzyme expression. In this process, there is introduction of heterologous genes or regulatory elements for developing novel metabolic configuration (Joshi et al. 2011). Various attempts have been made for adopting genetic engineering techniques for development of industrially efficient microbial strains which can show enhanced gene expression, produce improved product yield and tolerate high temperature and low pH.

The genetically engineered strains of S. cerevisiae and Zymomonas mobilis have been employed by DuPont Dannisco Cellulosic Ethanol and Butalco for commercial production of ethanol (Weber et al. 2010). Protein engineering is another advance in biotechnology for construction of tailored biocatalysts with desired functions using directed evolution or rational design strategies. The other techniques of protein engineering are semi-rational design (Lutz 2010), truncation and fusion (Yang et al. 2014) and structure-based designs using site-specific or non-specific chemical modifications (Davids et al. 2013). Various genetically modified fungal strains have been developed which possess the ability for production of large-scale hydrolytic enzymes such as cellulose, hemicellulase and xylanase and fermentable sugars from agricultural waste materials such as corn stover, straw, sugarcane bagasse, and switchgrass (Deswal et al. 2014).

However, genetically modified microorganisms possess several environmental and public health risks when used in large-scale fermentation systems (Limayem and Ricke 2012). Hence, to avoid such risks associated by exposure of genetically modified microorganisms, microbial risk assessment modeling approach is used for risk assessment of microbial dissemination in four steps namely hazard identification, hazard characterization, exposure assessment and risk characterization (Haas et al. 2004). Nanotechnology is one of the emerging fields of industrial biotechnology for generation of recombinant microbial strains by site-specific insertion of desired gene (Chekol and Gebreyohannes 2018).

16.5.2 Immobilization Strategies

Biocatalysts show tremendous applications to produce industrial important products from lignocellulosic materials by accelerating the rate of reaction at optimum conditions. However, there are some limitations for their use at commercial scale like easy solubility in aqueous media, high cost, less stability, and availability in small amounts (Sarrouh et al. 2012). Immobilization is one of the attractive approaches as an alternate which makes the enzyme immobilize onto insoluble matrix for retaining its geometry and economic reuse under stabilized conditions. Enzymes can be immobilized on supports either reversibly using adsorption, affinity, ionic and metal binding or irreversibly using entrapment and covalent binding. Different immobilization techniques used to bind the enzymes are shown in Fig. 16.3.

Enzymes bind to different carrier support materials through various functional groups (amine, alcoholic, carboxylic, guanidine, imidazole, phenol, thioester and thiol) by physical (hydrophobic and van der Waals interactions), covalent or ionic interactions. Covalent interactions are observed to be strongest and ionic interactions are weakest among different types of enzyme-carrier interactions (Ali et al. 2017; Kauldhar et al. 2016). Adsorption, cross-linking, encapsulation and entrapment are traditional immobilization strategies, whereas, protein engineering, nano-techniques and affinity tags are considered as modern strategies for biocatalyst immobilization (Ali et al. 2017). Protein engineering for enzyme immobilization is done by site-directed protein modification techniques such as enzymatic modification, native chemical ligation, auxotrophic expression and nonsense suppression.

The tags used for affinity immobilization are His (Histidine), GST (glutathione-S-transferase), FLAG (epitope tag), HA (hemagglutinin), myc, biotin and DNA mediated tags (Redeker et al. 2013). Some attempts have already been made by previous authors for development of cost-effective immobilization system for production of various bio-based products from lignocellulosic biomass; still minimum success has been achieved from previous studies for generation of commercial immobilization system. Development of multi-enzyme immobilization system is one of the promising alternate strategies which can be utilized for production of valuable products from lignocellulosic biomass. Hence, further studies and research is required to develop enzyme-based immobilization systems by understanding properties of proteins, their stability, conformational changes under different conditions and interactions involved in their immobilization.

16.5.3 Computational Strategies

Several genome sequence databases such as GenBank, European Nucleotide archive and Saccharomyces genome database, and protein sequence databases such as Swiss-Prot, Universal Protein Resource, TrEMBL, Protein Information Resource, worldwide Protein Data Bank are available for in silico computational studies. Other commonly used databases for protein-protein interactions, membrane transporters and carbohydrate-modifying enzymes are Molecular Interaction database, Transporters Classification Database and Carbohydrate-Active enzyme database. Molecular interactions are studied using Docking, AUTODOCK, High Ambiguity Driven Protein-Protein Docking and GRID (Mehmood et al. 2014). COMPOSER (Sutcliffe et al. 1987), 3D-IIGSAW (Bates and Sternberg 1999) and MODELLER (Sali and Blundell 1994) are used for molecular modelling of proteins.

For evaluation of potential stabilizing mutations, computational high-throughput screening methods have been observed to attract more attention (Goldenzweig et al. 2016). Molecular dynamics and quantum mechanics studies are used to understand the effect of every single amino acid on protein structure and function (Kaushik et al. 2016). Computational approaches have been integrated with metabolic engineering for developing models for improved prediction of metabolic fluxes and their regulation by metabolite concentration, gene expression and protein expression (Strauer et al. 2009). Different methods such as pathway-based approaches, optimization-based approaches, kinetic modeling approaches and many other bioinformatics tools are being used for the production of desired products from microorganisms (Reed et al. 2010; Sooch et al. 2016). Computational tools have also been used for development of engineered enzymes having novel and improved activities (Damborsky and Brezovsky 2014). Machine learning is one of the advanced techniques of metagenome analysis and this technique can be used in future for the selection of efficient wild and genetically modified microbial strains producing large amount of industrial important compounds in considerable good amount from lignocellulosic biomass.

16.6 Current Status of the Green Technology

The global market of industrial important enzymes like amylase, cellulase, protease, lipase and phytase is found to be increased by 6.30 billion USD by 2022 (Industrial Enzymes Market 2018).The major players in global market for production of industrial enzymes are Advanced Enzyme Technologies Ltd., Aumgene Biosciences, PAC Bio Fungbact Pvt. Ltd. (India), Amano Enzyme Inc., Asahi Kasei Pharma Corporation, Hayashibara Company (Japan), AB Enzyme GmbH, BASF SE, Direvo Biotech AG (Germany), BioResource International, Inc., Codexis, Inc., DuPont Nutrition and Health, Enzymatic Deinking Technologies LLC, Enzyme Innovation, Thermo Fischer Scientific, Inc. (USA), Chr. Hansen A/S, Novozymes A/S (Denmark), Royal DSM (The Netherlands) (Research and Markets 2018).

The major companies producing bioethanol in India from biomass are Aatmiya Biofuels Pvt. Ltd., D1 Oil Plc, Godrej Agrovet, Emami Group, Gujarat Oelo Chem Ltd., Jain Irrigation System Ltd., Nova Bio Fuels Pvt. Ltd., Reliance Industries Ltd., Sagar Jatropha Oil Extraction Pvt. Ltd. The main focus of their research work is towards establishment of cost-effective biofuels (butanol, ethanol, dimethylether, hydrogen, biodiesel and hydrocarbons). Different research centers which have been developed in India with prime interest towards biofuel generation using renewable resources are located in Delhi (International Centre of Genetic Engineering, Biotechnology Centre for Advanced Bioenergy Research), Faridabad (Centre for Advanced Bioenergy Research: Indian Oil Corporation Ltd. and Department of Biotechnology Institute), Mumbai (Institute of Chemical Technology) and Indian Institute of Technology located at Mumbai, Kharagpur, Guwahati, Roorkee and Jodhpur (Lali 2016).

The market of petroleum and natural gas sector was found to be USD 7 billion in June 2018 (IBEF 2018). Xylitol is one of the important industrial products which has shown tremendous applications in various industrial sectors and its global market is expected to be USD1 billion by 2020. The major companies of xylitol production are CSPC Shengxue Glucose Company Limited, Roquette Freres, Cargill Incorporation, Novagreen Incorporation, DFI Corporation, S2G Biochem, Dupont Nutrition and Health, Ingredion Incorporation, Shandong Futaste Company Limited, O’laughlin Industries Company Limited, Xylitol Canada Incorporation, Mitsubishi Shoji Foodtech Company Limited, Shandong Longlive Bio-Technology Company Limited, Shandong Lujian Biological Technology Company Limited, Thomson Biotech Company Limited, Zichem Incorporation, Zhejiang Huakang Pharmaceuticals Company Limited. DuPont Dansico is one of the global leading players of xylitol production with three production plants in USA, China and Finland with their sweetener business of Danisco USA Incorporation, Danisco Sw. Anyang Company Limited and Danisco Sweeteners Oy (Markets and Markets 2016).

The key global manufacturers of vinegar are AcetificiItaliani Modena, Australian Vinegar, Bizen Chemical, Fleischmann’s Vinegar, Krafet Heinz, Mizkan and Shanxi Shuita Vinegar (Marketers Media 2018). Deloitte Touche Tohmatsu Ltd. has published a report in 2017 entitled ‘The chemical multiverse 4.0’ on market size of chemical industry, and in this report ethylene capacity is observed to be enhanced in 2018 by US and China. The maximum chemical mergers and acquisitions activity is found in US followed by China, UK, Germany, India, France, Brazil and Switzerland. In the same report in silico experimentation and machine learning are found to be two major computational techniques for development of novel chemicals in this competitive market (Deloitte 2017). United States Department of Agriculture has given a report on bio-based chemicals containing commodity chemicals (6–10%), polymers (10%) and fine chemicals (45–50%) in 2025 (USDA 2008).

The sales of DuPont’s industrial biotechnology products increased to USD 1 billion in 2015 from USD 200 million in 2009. A joint venture was developed between DuPont and Tate & Lyle which was focused on production of propanediol from corn and other feedstocks by fermentation (www.duponttateandlyle.com). The global players of single cell proteins market are NOW Food Health LLC., Willows Ingredients, Devenish Nutrition Ltd., BIOMIN Holding GmbH, PRO SOLO SPA, Aumgene Biosciences, BIO-CAT, Novozymes, Alltecch Inc., Nutreco N.V. (Market Research 2018), and the market size of single cell proteins is expected to be USD 8.7 billion by 2023 with commercial success of Chlorella and Spirulina (P & S Market Research 2018).

16.7 Conclusion

It has been concluded from the present studies that lignocellulosic biomass can be exploited to produce numerous industrial important value-added products namely ethanol, vinegar, xylitol, industrial enzymes and chemicals (organic solvents, olefins and plastics), drink softner solvents and fermentable sugars. Lignocellulosic biomass is an important renewable source present in abundance in nature and its use for production of value-added products provides various environmental benefits. The major bottleneck for production of value-added chemicals at commercial scale is chemical complexity of lignocellulosic biomass, complex metabolic pathways of microorganisms, less product yield from wild strains and presence of inhibitors in lignocellulosic biomass hydrolysate. Development of improved pretreatment strategies, fermentation processes and recovery of value-added products by efficient methods may reduce their capital and operating costs.

Media and process engineering through statistical tools is one of the alternate methods to improve economic production of different products. System biology combines experimental and computational research, and it involves integration of many disciplines such as biology, engineering, computer science, chemistry and physics for understanding complex biological systems and network behavior between gene, protein and informational pathways. Hence, system biology can be adapted in future to understand microbial metabolic pathways for development of commercial biological systems which can carry out all the required steps (pretreatment, hydrolysis and fermentation of both pentose and hexose sugars) in a single pot.

Solid state fermentation is also a promising approach over submerged fermentation to use lignocellulosic biomass for the production of industrial products. Therefore, by adapting combinational advanced techniques like biodiversity studies, meta-genomics, system biology, protein engineering, developing research for regulating different media and process parameters, high automation for regulation of parameters during operation, it will become a reality in near future to produce renewable and pollution free value-added fuels and chemicals by utilizing cost effective lignocellulosic materials.

References

Abdul PM, Jahim JM, Harun S, Markom M, Hassan O, Mohammad AW, Asis AJ (2013) Biohydrogen production from pentose-rich oil palm empty fruit bunch molasses: a first trial. Int J Hyd Energy 38(35):15693–15699. https://doi.org/10.1016/j.ijhydene.2013.05.050

Adrio JL, Demain AL (2010) Recombinant organisms for production of industrial products. Bioeng Bugs 1(2):116–131. https://doi.org/10.4161/bbug.1.2.10484

Ajbar AH, Ali E (2017) Study of advanced control of ethanol production through continuous fermentation. J King Saud Uni-Eng Sci 29(1):1–11. https://doi.org/10.1016/j.jksues.2015.10.005

Albuquerque TL, Silva IJ Jr, Macedo GR, Rocha MVP (2014) Biotechnological production of xylitol from lignocellulosic wastes: a review. Process Biochem 49(11):1779–1789. https://doi.org/10.1016/j.procbio.2014.07.010

Alexandri M, Papapostolou H, Komaitis M, Stragier L, Verstraete W, Danezis GP, Koutinas AA (2016) Evaluation of an integrated biorefinery based on fractionation of spent sulphite liquor for the production of an antioxidant-rich extract, lignosulphonates and succinic acid. Bioresour Technol 214:504–513. https://doi.org/10.1016/j.biortech.2016.03.162

Ali S, Zafar W, Shafiq S, Manzoor M (2017) Enzyme immobilization: an overview of techniques, support materials and its applications. Int J Sci Technol Res 6(7):64–72

Alvarez C, Sosa FMR, Diez B (2016) Enzymatic hydrolysis of biomass from wood. Microbiol Biotechnol 9(2):149–156. https://doi.org/10.1111/1751-7915.12346

Amin FR, Khalid H, Zhang H, Rahman S, Zhang R, Liu G, Chen C (2017) Pretreatment methods of lignocellulosic biomass for anaerobic digestion. AMB Expr 7:1–12. https://doi.org/10.1186/s13568-017-0375-4

Amiri H, Karimi K (2018) Pretreatment and hydrolysis of lignocellulosic wastes for butanol production. Chall Persp 270:702–721. https://doi.org/10.1016/j.biortech.2018.08.117

Ammar JB, Lanoiselle JL, Lebovka NI, Hecke E, Vorobiev E (2011) Impact of a pulsed electric field on damage of plant tissues: effects of cell size and tissue electrical conductivity. J Food Sci 76(1):90–97. https://doi.org/10.1111/j.1750-3841.2010.01893.x

Anwar Z, Gulfraz M, Irshad M (2014) Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: a brief review. J Rad Res Appl Sci. 7(2):163–173. https://doi.org/10.1007/s13205-018-1188-0

Asgher M, Ahmad Z, Iqbal HMN (2013) Alkali and enzymatic delignification of sugarcane bagasse to expose cellulose polymers for saccharification and bioethanol production. Ind Crop Prod 44:488–495. https://doi.org/10.1016/j.indcrop.2012.10.005

Azhar SHM, Abdulla R, Jambo SA, Marbawi H, Gansau JA, Faik AAM, Rodrigues KF (2017) Yeasts in sustainable bioethanol production: a review. Biochem Biophy Rep 10:52–61. https://doi.org/10.1016/j.bbrep.2017.03.003

Aziz S, Sarkanen K (1989) Organosolv pulping – a review. TAPPI J 72(3):169–175

Bajpai PK, Singh I, Madaan J (2013) Tribological behaviour of natural fiber reinforced PLA composites. Weae 297(1–2):829–840. https://doi.org/10.1177/0731684417747742

Banerjee S, Sen R, Pandey RA, Chakrabarti T, Satpute D, Giri BS, Mudliar S (2009) Evaluation of wet air oxidation as a pretreatment strategy for bioethanol production from rice husk and process optimization. Biomass Bioenergy 33(12):1680–1686. https://doi.org/10.1016/j.biombioe.2009.09.001

Baptista SL, Cunha JT, Romani A, Domingues L (2018) Xylitol production from lignocellulosic whole slurry corn cob by engineered industrial Saccharomyces cerevisiae PE-2. Bioresour Technol 267:481–491. https://doi.org/10.1016/j.biortech.2018.07.068

Barathikannan K, Khusro A, Paul A (2016) Simultaneous production of xylitol and ethanol from different hemicellulose waste substrates by Candida tropicalis strain LY15. J Bioprocess Biotech. 6:1–8. https://doi.org/10.4172/2155-9821.1000289

Barba FJ, Parniakov O, Pereira SA, Wiktor A, Grimi N, Boussetta N, Saraiva JA, Raso J, Belloso OM, Rajchert DW, Lebovka N, Vorobiev E (2015) Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res Int 77(4):773–798. https://doi.org/10.1016/j.foodres.2015.09.015

Batche H, Solano CV, Martinez RH (2014) Production of conidiospores in solid-state fermentation of Trichoderma harzianum and T. asperellum isolated from grapevine in Baja California. Phytopathology 104(3):S3.179. https://doi.org/10.1094/PHYTO-104-11-S3.179

Bates PA, Sternberg MJ (1999) Model building by comparison at CASP3: using expert knowledge and computer automation. Prot Suppl 3:47–54. https://doi.org/10.1002/(SICI)1097-0134

Bazirake GWB, Byarugaba W, Tumusiime M, Kimono DA (2014) The technology of producing banana wine vinegar from starch of banana peels. Afr J Food Sci Technol 5(1):1–5. https://doi.org/10.14303/ajfst.2013.062

Beauchemin KA, Colombatto D, Morgavi DP, Yang WZ (2003) Use of exogenous fibrolytic enzymes to improve animal feed utilization by ruminants. J Anim Sci 81(14):E37–E47. https://doi.org/10.1080/09712119.2017.1399135

Bhalamurugan GL, Valerie O, Mark L (2018) Valuable bioproducts obtained from microalgal biomass and their commercial applications: a review. Environ Eng Res 23(3):229–241. https://doi.org/10.4491/eer.2017.220

Bharathiraja B, Sudharsanaa T, Bharghavi A, Sowmeya GS, Yuvaraj D, Kumar RP, Chozhavendhan C, Arulraj JV (2015) Biobutanol production from cellulose rich agricultural waste using clostridium species. J Chem Pharm Res 7(3):2463–2469

Bonawitz ND, Chapple C (2010) The genetics of lignin biosynthesis: connecting genotype to phenotype. Annu Rev Genet 44:337–363. https://doi.org/10.1146/annurev-genet-102209-163508

Brosse N, Hage RE, Sannigrahi P, Ragauskas A (2010) Dilute sulphuric acid and ethanol organosolv pretreatment of Miscanthus giganteus. Cellulose Chem Technol 44(1–3):71–78

Capolupo L, Faraco V (2016) Green methods of lignocellulose pretreatment for biorefinery development. Appl Microbiol Biotechnol 100(22):9451–9467. https://doi.org/10.1007/s00253-016-7884-y,9467

Carvalho W, Santos JC, Canhila L, Silva SS, Pergo P, Converti A (2005) Xylitol production from SCB hydrolysate: metabolic behaviour of Candida guillermondii cells entrapped in a calcium alginate. Biochem Eng J 25:25–31. https://doi.org/10.1016/j.bej.2005.03.006

Cavalheiro AA, Monteiro G (2013) Solving ethanol production problems with genetically modified yeast strains. Braz J Microbiol 44(3):665–671. https://doi.org/10.1590/s1517-83822013000300001

Chakraborty K, Saha J, Raychaudhuri U, Chakraborty R (2015) Feasibility of using corncob as the substrate for natural vinegar fermentation with physicochemical changes during the acetification process. Food Nutr Sci 6:935–943. https://doi.org/10.4236/fns.2015.610097

Chandel AK, Chan ES, Rudravaram R, Narasu ML, Rao LV, Ravindra P (2007) Economics and environmental impact of bioethanol production technologies: an appraisal. Biotechnol Mol Biol Rev 2(1):14–32

Chaturvedi V, Verma P (2013) An overview of key pretreatment processes employed for bioconversion of lignocellulosic biomass into biofuels and value added products. 3 Biotech 3(5):415–431. https://doi.org/10.1007/s13205-013-0167-8

Chekol C, Gebreyohannes M (2018) Application and current trends of biotechnology: a brief review. Austin J Biotechnol Bioeng 5(1):1–7

Cheng NG, Hasan M, Kumoro AC, Ling CF, Tham M (2009) Production of ethanol by fed-batch fermentation. J Sci Technol Pertanika 17(2):399–408

Chmielarz M, Blomqvist J, Sampels S, Sandgren M, Passoth V (2021) Microbial lipid production from crude glycerol and hemicellulosic hydrolysate with oleaginous yeasts. Biotechnol Biofuels 14(1):1–11

Choi GW, Um HJ, Kim M, Kim Y, Kang HW, Chung BW, Kim YH (2010) Isolation and characterization of ethanol-producing Schizosaccharomyces pombe CHFY0201. J Microbiol Biotechnol 20(4):828–834. https://doi.org/10.4014/jmb.0910.10003

Christopher M, Anusree M, Mathew AK, Nampoothiri KM, Sukumaran RK, Pandey A (2016) Detoxification of acidic biorefinery waste liquor for production of high value amino acid. Bioresour Technol 213:270–275. https://doi.org/10.1016/j.biortech.2016.03.054

Cimini D, Argenzio O, D’Ambrosio S, Lama L, Finore I, Finamore R, Pepe O, Faraco V, Schiraldi C (2016) Production of succinic acid from Basfia succiniproducens up to the pilot scale from Arundo donax hydrolysate. Bioresour Technol 222:355–360. https://doi.org/10.1016/j.biortech.2016.10.004

Coombs J (1987) EEC resources and strategies. Phil Trans R Soc London Ser A. 321:405–422. https://doi.org/10.1098/rsta.1987.0019

Cortez DV, Roberto IC (2014) Optimization of D-xylose to xylitol biotransformation by Candida guilliermondii cells permeabilized with triton X-100. Biocatl Biotransform 32(1):34–38. https://doi.org/10.3109/10242422.2013.870558

Coskun O (2016) Separation techniques: chromatography. North Clin Istanb 3(2):156–160. https://doi.org/10.14744/nci.2016.32757

Cubero MTG, Benito GG, Indacoechea I, Coca M, Bolado S (2009) Effect of ozonolysis pretreatment on enzymatic digestibility of wheat and rye straw. Bioresour Technol 100(4):1608–1613. https://doi.org/10.1016/j.biortech.2008.09.012

Dabhi BK, Vyas RV, Shelat HN (2014) Use of banana waste for the production of cellulolytic enzymes under solid substrate fermentation using bacterial consortium. Int J Curr Microbiol Appl Sci. 3(1):337–346

Damato G, Vivona G, Stoller M, Bubbico R, Bravi M (2010) Cellulase production from olive processing residues. Chem Eng Tran 20:978–988. https://doi.org/10.3303/CET1020013

Damborsky J, Brezovsky J (2014) Computational tools for designing and engineering enzymes. Curr Opin Chem Biol 19:8–16. https://doi.org/10.1016/j.cbpa.2013.12.003

Dasgupta D, Ghosh D, Bandhu S, Agarwal D, Suman SK, Adhikari DK (2016) Purification, characterization and molecular docking study of NADPH dependent xylose reductase from thermotolerant Kluyveromyces sp. IIPE453. Process Biochem 51(1):124–133. https://doi.org/10.1016/j.procbio.2015.11.007

Davids T, Schmidt M, Bottcher D, Bornscheuer UT (2013) Strategies for the discovery and engineering of enzymes for biocatalysis. Curr Opin Chem Biol 17(2):215–220. https://doi.org/10.1016/j.cbpa.2013.02.022

Deloitte (2017) The chemical multiverse 4.0 report. Promising future for the strong, decisive, and persistent. pp 1–40. https://www2.deloitte.com/content/dam/Deloitte/de/Documents/consumer-industrialproducts/The%20Chemical%20Multiverse%204.0_Report2017.pdf

Demir H, Tari C (2014) Valorization of wheat bran for the production of polygalactouronase in SSF of Aspergillus sojae. Ind Crop Prod 54:302–309. https://doi.org/10.1016/j.indcrop.2014.01.025

Demirbas A (2005) Bioethanol from cellulosic materials: a renewable motor fuel from biomass. Energy Sources 27(4):327–337. https://doi.org/10.1080/00908310390266643

Demirbas A (2008) Conversion of corn stover to chemicals and fuels. Energy Sources 30(9):788–796. https://doi.org/10.1080/15567030600817811

Den W, Sharma VK, Lee M, Nadadur G, Varma RS (2018) Lignocellulosic biomass transformations via greener oxidative pretreatment processes: access to energy and value added chemicals. Front Chem 6:1–23. https://doi.org/10.3389/fchem.2018.00141

Deswal D, Gupta R, Nandal P, Kuhad RC (2014) Fungal pretreatment improves amenability of lignocellulosic material for its saccharification to sugars. Carbohydr Polym 99:264–269. https://doi.org/10.1016/j.carbpol.2013.08.045

Diba F, Alam F, Talukder AA (2015) Screening of acetic acid producing microorganisms from decomposed fruits for vinegar production. Adv Microbiol. 5:291–297. https://doi.org/10.4236/aim.2015.55028

Donald G, Barbara JWM, Raymond CC, Mares FA (2009) Potential markets for chemicals and pharmaceuticals from woody biomass: a report. In: Forest research LLC, Orono, Maine 04473. www.forestresearchllc.com

Dong C, Wang Y, Zhang H, Leu SY (2018) Feasibility of high concentration cellulosic bioethanol production from undetoxified whole Monterey pine slurry. Bioresour Technol 250:102–109. https://doi.org/10.1016/j.biortech.2017.11.029

Eggeman T, Elander RT (2005) Process and economic analysis of pretreatment technologies. Bioresour Technol 96(18):2019–2025. https://doi.org/10.1016/j.biortech.2005.01.017

El-Hersh MS, Saber WIA, El-Naggar NEA (2011) Production strategy of inulinase by Penicillium citrinum AR-IN2 on some agricultural by products. Microbiol J 1(3):79–88. https://doi.org/10.3923/mj.2011.79.88

Ellila S, Fonseca L, Uchima C, Cota J, Goldman GH, Saloheimo M, Sacon V, Siikaaho M (2017) Development of a low-cost cellulase production process using Trichoderma reesei for Brazilian biorefineries. Biotechnol Biofuels 10(30):1–17. https://doi.org/10.1186/s13068-017-0717-0

El-Shishtawy RM, Mohamed SA, Asiri AM, Gomaa AB, Ibrahim IH, Al-Talhi HA (2014) Solid fermentation of wheat bran for hydrolytic enzymes production and saccharification content by a local isolate bacillus megatherium. BMC Biotechnol 14:1–8. https://doi.org/10.1186/1472-J396750-14-29

Erdei B, Franko B, Galbe M, Zacchi G (2012) Separate hydrolysis and co-fermentation for improved xylose utilization in integrated ethanol production from wheat meal and wheat straw. Biotechnol Biofuels 5:1–12. https://doi.org/10.1186/1754-6834-5-12

Fischer G, Schrattenholzer L (2001) Global bioenergy potentials through 2050. Biomass Bioenergy 20(3):151–159. https://doi.org/10.1016/S0961-9534(00)00074-X

Foody BE, Foody KJ (1991) Development of an integrated system for producing ethanol from biomass. In: Klass DL (ed) Energy from biomass and waste. Institute of Gas Technology, Chicago, pp 1225–1243. https://doi.org/10.3923/biotech.2010.274.282

Fu H, Yang ST, Wang M, Wang J, Tang IC (2017) Butyric acid production from lignocellulosic biomass hydrolysates by engineered clostridium tyrobutyricum over expressing xylose catabolism genes for glucose and xylose co-utilization. Bioresour Technol 234:389–396. https://doi.org/10.1016/j.biortech.2017.03.073

Ghazala I, Sayari N, Romdhane MB, Chaabouni SE, Haddar A (2015) Assessment of pectinase production by Bacillus mojavensis I4 using an economical substrate and its potential application in oil sesame extraction. J Food Sci Technol 52(12):7710–7722. https://doi.org/10.1007/s13197-015-1964-3

Gnansounou E (2011) Assessing the sustainability of biofuels: a logic-based model. Energy 36(4):2089–2096. https://doi.org/10.1016/j.energy.2010.04.027

Goldenzweig A, Goldsmith M, Hill SE, Gertman O, Laurino P, Ashani Y, Dym O, Unger T, Albeck S, Prilusky J, Lieberman RL, Aharoni A, Silman I, Sussman JL, Tawfik DS, Fleishman SJ (2016) Automated structure- and sequence-based design of proteins for high bacterial expression and stability. Mol Cell 63(2):337–346. https://doi.org/10.1016/j.molcel.2018.03.035

Gonzalez JB (2012) Solid-state fermentation: physiology of solid medium, its molecular basis and applications. Process Biochem 47(2):175–185. https://doi.org/10.1016/j.procbio.2011.11.016

Goyal M, Kalra KL, Sareen VK, Soni G (2008) Xylanase production with xylan rich lignocellulosic wastes by a local soil isolate of Trichoderma viride. Braz J Microbiol 39(3):535–541. https://doi.org/10.1590/S1517-838220080003000025

Gray KA, Zhao L, Emptage M (2006) Bioethanol. Curr Opin Chem Biol 10(2):141–146. https://doi.org/10.4137/MBI.S10878

Guimaraes JL, Frollini E, Silva CGD, Wypych F, Satyanarayana KG (2009) Characterization of banana, sugarcane bagasse and sponge gourd fibers of Brazil. Ind Crop Prod 30(3):407–415. https://doi.org/10.1016/j.indcrop.2009.07.013

Haas CN, Rose JB, Gerba CP (2004) Quantitative microbial risk assessment, 2nd edn. Wiley-Blackwell. https://doi.org/10.1002/9781118910030

Hakim A, Bhuiyan FR, Iqbal A, Emon TH, Ahmed J, Azad AK (2018) Production and partial characterization of dehairing alkaline protease from Bacillus subtilis AKAL7 and Exiguobacteriumindicum AKAL11 by using organic municipal solid wastes. Heliyon 4(6):1–27. https://doi.org/10.1016/j.heliyon.2018.e00646

Hendriks ATWM, Zeeman G (2009) Pretreatment to enhance the digestibility of lignocellulosic biomass. Bioresour Technol 100(1):10–18. https://doi.org/10.1016/j.biortech.2008.05.027

Holker U, Lenz J (2005) Solid state fermentation-are there any biotechnological advantages? Curr Opin Microbiol 8(3):301–306. https://doi.org/10.1007/s00253-003-1504-3

Howard RL, Abotsi E, Rensburg ELJ, Howard S (2003) Lignocellulose biotechnology: issues of bioconversion and enzyme production. Afr J Biotechnol 2(12):602–619. https://doi.org/10.3923/biotech.2014.1.21

IBEF (2018) India brand equity foundation. Oil & Gas Industry in India. https://www.ibef.org/industry/oil-gas-india.aspx

Industrial Enzymes Market (2018) Industrial enzymes market worth 6.30 billion USD by 2022. https://www.marketsandmarkets.com/PressReleases/industrial-enzymes.asp