Abstract

Bioalcohols produced by microorganisms from renewable materials are promising substitutes for traditional fuels derived from fossil sources. For several years already ethanol is produced in large amounts from feedstocks such as cereals or sugar cane and used as a blend for gasoline or even as a pure biofuel. However, alcohols with longer carbon chains like butanol have even more suitable properties and would better fit with the current fuel distribution infrastructure. Moreover, ethical concerns contradict the use of food and feed products as a biofuel source. Lignocellulosic biomass, especially when considered as a waste material offers an attractive alternative. However, the recalcitrance of these materials and the inability of microorganisms to efficiently ferment lignocellulosic hydrolysates still prevent the production of bioalcohols from these plentiful sources. Obviously, no known organism exist which combines all the properties necessary to be a sustainable bioalcohol producer. Therefore, breeding technologies, genetic engineering and the search for undiscovered species are promising means to provide a microorganism exhibiting high alcohol productivities and yields, converting all lignocellulosic sugars or are even able to use carbon dioxide or monoxide, and thereby being highly resistant to inhibitors and fermentation products, and easy to cultivate in huge bioreactors. In this review, we compare the properties of various microorganisms, bacteria and yeasts, as well as current research efforts to develop a reliable lignocellulosic bioalcohol producing organism.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

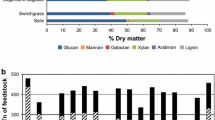

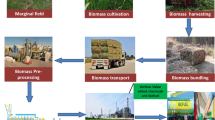

The demand for sustainable alternative transportation fuels based on renewable resources is already high today but will dramatically increase in the future. Todays biofuel industry primarily produces ethanol from corn starch or sugar cane, and biodiesel is generated from vegetable oils and animal fats. However, these first generation biofuels, especially ethanol produced from starch, are in competition with the food and animal feed industry. In contrast, lignocellulosic biomass like crop wastes, forestry residues and municipal solid waste offers a high potential as feedstock for biofuels because it is the most abundant sustainable raw material worldwide and occurs as byproduct without competing uses.

However, the process of conversion of lignocellulosic biomass to biofuels is more complicated than that of starch-based biofuels. This is due to the technical challenges resulting from the rigid and complex molecular polymeric structure of cellulosic biomass that makes lignocellulose highly resistant to chemical attack, solubilisation and bioconversion (Himmel et al. 2007). Irrespective of the microorganism used for the conversion of the biomass to biofuels, it is required to overcome this recalcitrance by (thermo-) chemical pretreatment which breaks down the lignocellulosic structures and thereby enhance the enzymatic accessibility (Taherzadeh and Karimi 2007a; Hendriks and Zeeman 2009). Then follows the hydrolysis and fermentation step. For the hydrolysis step, usually a mixture of cellulases, hemicellulases and glucosidases is used to convert the cellulose and hemicellullose into the sugar monomers. There are basically three different modes on how the hydrolysis step can be done (Taherzadeh and Karimi 2007b). In the first two variants, the hydrolytic enzymes are produced in a separate operation unit by a specific microorganism e.g. the fungi vs. Trichoderma. The obtained enzyme mixtures are then used for the hydrolysis either in a seperate vessel (separate hydrolysis and fermentation (SHF)) and afterwards the biofuel producing micororganism is added, or the hydrolysis is performed simultaneously with the fermentation (simultaneous saccharification and fermentation (SSF)). The SHF process allows hydrolysis and fermentation to be performed at their individual optimal conditions. The SSF process avoids end-product inhibition of cellulolytic enzymes by sugars because they are immediately consumed by the microorganisms. In the third variant, the hydrolytic enzymes are coproduced together with the alcohol in the same reaction vessel either by a single microorganism or a coculture of microorganisms (consolidated bioprocessing (CBP)). Which of these three strategies will work economically in the future still remains an open question and will depend on whether the drawbacks of the respective technologies can be overcome by new developments (Wingren et al. 2003).

Currently, industry is also developing new processes for the production of advanced biofuels to substitute for ethanol. The focus is on higher alcohols which are more suitable for the existing fuel infrastructure concerning storage, distribution and engines. Compared with ethanol, they have a higher energy density, lower vapour pressure, are less hygroscopic and therefore less corrosive. These beneficial properties allow the blending with conventional fuels at any ratio. However, a drawback of these advanced biofuels is that they are highly toxic to the microorganisms. Therefore further engineering of the microbes to improve their resistance or the development of specific continous extraction methods are required to circumvent this toxicity. The preferred higher alcohol is isobutanol but also 1-butanol, 2-methyl-1-butanol, 3-methyl-1-butanol and isopentenol have been identified as interesting compounds (Lee et al. 2008a; Connor and Liao 2009). In addition, terpenoids derived from the isoprenoid pathway, fatty-acid esters or long-chain alkanes have been suggested to be produced by microorganisms as sustainable replacements for diesel and jetfuels (Peralta-Yahya and Keasling 2010; Steen et al. 2010).

The majority of potential biofuels are naturally produced by various microorganisms as side products. However, the deciding factor for a successful and cost-competitive fermentation process is the economics. Therefore, to be a feasible substitute of fossil fuels it is required that they can be produced in large quantities at low costs. Recent calculations indicate that at least 100 g/l with a minimal productivity of 2 g/l per hour and a yield of 95% of the theoretical yield is required (Sheridan 2009). In this review, we want to concentrate on the production of lignocellulosic ethanol and butanol as these two will most probably enter the advanced biofuel market at first. We will provide an overview of recent advances in the metabolic engineering of various microorganisms for their production (Fig. 1).

Microbial biocatalysts

Lignocellulosic hydrolysates are complex mixtures of hexose and pentose sugars together with other compounds some of which can act as fermentation inhibitors. The optimal microbial cell for the production of advanced biofuels should combine the following properties: efficient fermentation of both, hexose and pentose sugars, preferentially simultaneously, high tolerance to fermentation inhibitors and fermentation products, resistance against microbial contamination e.g. bacteriophage infections, high productivities and yields. Moreover, secretion of cellulolytic and hemicellulolytic enzymes would be a benefit. These properties can either be natural properties or they can be obtained via genetic engineering. A variety of microorganisms, both prokaryotic and eukaryotic, are presently in the focus of research. We will start describing the prokaryotic organisms and continue with different yeasts.

Bacteria

Escherichia coli

The ability of E. coli to utilize hexoses as well as pentoses makes this microorganism an interesting host for biofuel production from lignocellulosic biomass (Feldmann et al. 1992). Pentoses such as d-xylose and l-arabinose are the most abundant sugars in hemicelluloses and can make up more than 30% of plant biomass. For an economically viable manufacturing process of biofuels from lignocellulosic biomass, pentose utilization is required. Moreover, E. coli is already used in other industrial processes (e.g. recombinant protein production). The engineering of E. coli for homoethanolic fermentations by expressing pyruvate decarboxylase and alcohol dehydrogenase genes (PET operon) of Zymomonas mobilis was one of the first successful applications of metabolic engineering (Ingram et al. 1987, 1998). More recently, various E. coli strains for the production of more advanced bioalcohol fuels such as isopropanol (Hanai et al. 2007), n-butanol (Atsumi et al. 2008a), n-propanol (Shen and Liao 2008), isobutanol, 2-methyl-1-butanol and 3-methyl-1-butanol (Atsumi et al. 2008b) have been constructed. Furthermore, new pathways for the production of fatty-acid-derived fuels (Steen et al. 2010) or isoprenoid-based fuels (Peralta-Yahya and Keasling 2010) have been expressed in E. coli but productivities and yields are not yet high enough for industrial use.

A major challenge in engineering E. coli for fermentation of biomass sugars is the simultaneous consumption of all lignocellulose-derived sugars (Jojima et al. 2010). The utilization of sugars like xylose or arabinose in E. coli is normally repressed in the presence of glucose, due to carbon catabolite repression (Görke and Stülke 2008). With this system, glucose effectively blocks the expression of sugar-specific transporters and key enzymes needed for the metabolism of alternative sugars. Enabling coutilization is an important step in increasing the fermentation rate (e.g. Nichols et al. 2001), and the glucose-inhibited uptake of pentoses has been mainly made responsible for the lack of cofermentation. However, recently, a glucose facilitator from Z. mobilis which also transports xylose was evolved to eliminate glucose inhibition on xylose uptake. Through random mutagenesis and partial deletions the evolved transporter showed an improved xylose transport activity in the presence of glucose. Nevertheless, no obvious advantage in xylose consumption was observed when cofermented with glucose which might be attributed to an inhibition of the intracellular xylose metabolism by glucose (Ren et al. 2009). In another investigation, Yomano and coworkers deleted the methylglyoxal synthase gene (mgsA) in an ethanologenic E. coli strain, which enabled this strain to coutilize a 10% mixture of mannose, glucose, arabinose, xylose and galactose (2% each) within 72 h (Yomano et al. 2009).

Compared with other commonly used industrial production hosts like yeasts, E. coli is less robust against several factors, like changes in pH, salt concentration or temperature. Additionally, E. coli exhibits lower ethanol tolerance than yeast (e.g. homoethanologenic KO11 cannot grow in the presence of more than 35 g/l ethanol (Yomano et al. 1998)) and cannot tolerate more than 2% (v/v) butanol (Knoshaug and Zhang 2009). To increase the tolerance of E. coli against these fermentation-related stresses, random and rational improvements have been carried out (e.g. Alper and Stephanopoulos 2007; Miller and Ingram 2007), but to be an industrial relevant biofuel producer, strains still have to be further improved.

Z. mobilis

Z. mobilis is a Gram-negative bacterium that had attracted attention early in the development of ethanol fuel technology. The microorganism has a homoethanol fermentation pathway and tolerates up to 120 g/l ethanol. Its specific ethanol productivity is 2.5-fold higher than that of Saccharomyces sp., and its ethanol yield approaches 97% of the theoretical maximum at an optimal temperature of 30°C (Rogers et al. 1982). The high ethanol yield and productivity are a consequence of its unique physiology. Z. mobilis metabolizes glucose using the Entner-Doudoroff pathway, producing less ATP than glycolysis. Therefore, Z. mobilis produces less biomass than e.g. yeasts and more carbon is funneled to fermentation products.

Despite this advantage, Z. mobilis is not well suited for biomass conversion because it can ferment only glucose, fructose and sucrose. It lacks some of the glycolytic and pentose phosphate pathway enzymes which are necessary to ferment other sugars like xylose and arabinose. To broaden its limited substrate range, various catabolic genes have been transferred into Z. mobilis. Introduction and expression of heterologous xylose isomerase, xylulokinase, transaldolase and transketolase led to a functional metabolic pathway that converts xylose to central intermediates of the Entner–Douderoff pathway for fermenting xylose to ethanol (Zhang et al. 1995). Introduction and expression of heterologous arabinose isomerase, ribulokinase, ribulose-5-phosphate-4-epimerase, transaldolase and transketolase enabled Z. mobilis to assimilate arabinose (Deanda et al. 1996). Coconsumption analysis in mixed sugar fermentation demonstrated that there is a preferential order of sugar utilization. Glucose is rapidly used, followed by xylose and then arabinose. One major problem with the improved pentose-utilizing strains is a low tolerance to acetic acid which is commonly found in biomass hydrolysates (Lawford and Rousseau 2002; Mohagheghi et al. 2002). The introduction of a bacterial β-glucosidase gene fused to a secretion signal peptide for translocation across the cytoplasmic membrane enabled a Z. mobilis strain to utilize cellobiose (Yanase et al. 2005). Furthermore, processes with Z. mobilis to ferment cellulose or starch to ethanol via SSF have been investigated. In both cases carbon sources were fermented to ethanol with productivities of 1.5 g/(l * h) for sugarcane bagasse and 10 g/(l * h) for starch under described conditions (Rebroš et al. 2009; da Silveira dos Santos D et al. 2010).

Recently, the company DuPont Danisco Cellulosic Ethanol (DDCE) has established a cellulosic ethanol demonstration facility based on a genetically modified Z. mobilis. The facility in Vonore (Tennessee) has a annual production capacity of 250,000 gallons of ethanol. The plant produces ethanol from agricultural residue and bioenergy crops, including corncobs and switchgrass (http://www.ddce.com).

Clostridia

Ethanol

Clostridium phytofermentans is a Gram-positive, anaerobic and spore-forming prokaryote isolated from forest soil. Its optimal growth temperature is 35–37°C at pH values ranging from 6.0 to 9.0 (Warnick et al. 2002). Like many other Clostridia, this bacterium is able to saccharify and ferment a variety of polysaccharides (e.g. cellulose, pectin, polygalacturonic acid, starch, xylan), oligosaccharides (e.g. cellobiose, gentiobiose, lactose, maltose) and monomeric sugars like hexoses (e.g. glucose, fructose, galactose, mannose) and pentoses (e.g. arabinose and xylose). The major end products of fermentation are ethanol and minor amounts of acetate, formate, lactate and H2. Most bacteria of the genus Clostridia secrete many carbohydrate-degrading enzymes (Lee et al. 1985; Bronnenmeier and Staudenbauer 1993; Maki et al. 2009).The C. phytofermentans genome encodes the highest number of enzymes for modification and breakdown of complex carbohydrates among clostridial genomes sequenced to date. It comprises genes for 161 carbohydrate-active enzymes, which include 108 glycoside hydrolases spread across 39 families (Cantarel et al. 2009). Therefore, it might be an interesting organism for consolidated bioprocessing processes.

For its commercial use, the microbe has still to be improved to reach industrial standards. Currently, it is under investigation by the company Qteros, a startup based in Hadley Massachusetts, which plans pilot and demonstration plants for producing ethanol by fermenting biomass with C. phytofermentans (http://www.technologyreview.com/business/21777/?a=f).

1-Butanol

Other Clostridia species especially Clostridium acetobutylicum are interesting organisms because they naturally produce acetone, butanol and ethanol with typical ratios of 3:6:1 (Jones and Woods 1986; Awang et al. 1988; Dürre 2008). The process is also known as ABE fermentation and has already intensively been used in times of insufficient oil supply. Typical ABE fermentations undergo first an acidogenic phase characterized by the production of acetate and butyrate which are converted in the solventogenic phase into the respective solvents (Maddox et al. 2000). In the past, efforts have been made to improve the productivity of the respective solvents. To date, the best results were obtained by inactivation of the putative transcriptional repressor solR and overexpression of the bifunctional alcohol/aldehyde dehydrogenase (aad) leading to production levels of 8.2 g/l acetone, 2.2 g/l ethanol and 17.6 g/l butanol, which were 66%, 194% and 51% higher compared with the wild-type strain (Nair et al. 1999; Harris et al. 2001). Many strategies also focussed on the improvement of the selective production of butanol. However, overexpression of enzymes involved in butanol production did not improve selective butanol production. In contrast, Tummala et al. (2003a, b) used an antisense RNA strategy for knock-down of the acetone producing enzyme CoA transferase (ctfB) in combination with overexpression of butanol producing enzyme (aad). Using this approach the butanol/ acetone ratio was increased more than twofold, although the butanol titer decreased slightly to ∼9.8 g/l compared with the wild-type with ∼10.2 g/l.

There have been numerous more investigations to understand the regulation of metabolite production, metabolite tolerance, stress tolerance and carbohydrate utilization of solventogenic clostridia (Lee et al. 2008b; Papoutsakis 2008; Ezeji et al. 2010). However, the developments have been basically hampered by the lack of efficient genetic tools. Recently, a universal gene knock-out system was developed (Heap et al. 2007). This new tool will certainly be very helpful for further engineering of the Clostridia for improved performance. Nevertheless, Clostridia have several disadvantages in industrial production processes that till date have just partly been solved or are generally hard to overcome by metabolic engineering. For example, Clostridia are strictly anerobic and have a slow growth rate. They rapidly degenerate and loose their ability for solvent production, and in addition most of them are sensitive to bacteriophage infection (Kashket and Cao 1993; Jones et al. 2000). Moreover, the bacteria have a high butanol sensitivity (Hermann et al. 1985; Lee et al. 2005). Even though there have been several achievements that already improved the solvent resistance (Ezeji et al. 2010), it seems that continuous product recovery during fermentation will be required which is usually very expensive. Therefore, the focus is also on the introduction of the clostridial butanol pathways into more user-friendly organisms like yeast and E. coli (Atsumi et al. 2008a; Inui et al. 2008; Steen et al. 2008).

Syngas fermentations

In contrast to the biochemical conversion of biomass into bioalcohols by enzymatical hydrolysis and fermentation, alcohols can also be produced by a combination of thermochemical and fermentative pathways. Biomass can be gasified to synthesis gas (syngas) by heating it with a controlled level of oxygen, and converting it into a mixture of carbon monoxide and hydrogen. A huge advantage of this process is that gasification can use almost all parts of biomass, including the lignin portion, and it is not limited to lignocellulosic biomass, but many other forms of organic materials may be substituted. Syngas can then be converted into ethanol either by catalytic conversion or bacterial fermentation. The advantages of bacterial over catalytic conversion are that microbes are less sensitive to syngas impurities like sulfur and normally produce specific alcohols instead of mixtures (Munasinghe and Khanal 2010).

Syngas can be utilized as a carbon and energy source by numerous microorganisms. Some of them, e.g. Clostridium ljungdahlii and Clostridium carboxidivorans can convert it into ethanol or butanol. In these organisms, CO is oxidized to CO2 via an enzyme called carbon monoxide dehydrogenase providing reducing power. This or the H2 present in the syngas can then be used to reduce CO to acetyl-CoA via the Wood–Ljungdahl pathway and then further to alcohols (Datar et al. 2004; Oelgeschläger and Rother 2008).

One major problem with syngas fermentation is that syngas does not dissolve well in water and therefore is not easily accessible to the bacteria. However, bioreactors have recently been designed which obviously can solve this problem; e.g. the company Coskata has developed a bioreactor in which bacteria grow in dense biofilms on porous membranes which separate syngas from the bacteria-growing medium. Syngas is pushed through the membrane and converted by the bacteria on the membranes into ethanol which is released into the liquid medium. Challenges, however, might be up-scaling to a commercial scale, high capital costs and low ethanol tolerance of the bacteria.

Corynebacterium glutamicum

C. glutamicum is well known as an industrial organism for the production of amino acids (Hermann 2003). Inui et al. 2004 engineered this Gram-positive bacterium to produce ethanol by introducing the heterologous pyruvate decarboxylase and alcohol dehydrogenase genes from Z. mobilis under control of the endogenous ldhA promoter, which is induced under oxygen-deprived conditions. Although not growing under these conditions, C. glutamicum was now able to produce ethanol with byproducts acetate, lactate and succinate resulting in glucose conversion yields of 79% for ethanol and organic acids, ethanol accounting for 20%. After deletion of the endogenous lactate dehydrogenase and addition of pyruvate to the media a productivity of 29.5 g ethanol/l/h could be achieved corresponding to a glucose conversion yield of 53% for ethanol (Inui et al. 2004). Interestingly, under oxygen-deprived conditions C. glutamicum is quite resistant to phenols and furans which are typically found in acid-pretreated lignocellulosic hydrolysates (Sakai et al. 2007).

Unlike E. coli, most C. glutamicum strains are not naturally able to utilize pentoses (Kawaguchi et al. 2009). By introduction of genes from E. coli essential for utilization of arabinose and xylose, C. glutamicum was able to utilize both sugars under aerobic and oxygen-deprived conditions (Kawaguchi et al. 2006, 2008). By overexpression of an arabinose transporter gene, the consumption rate of both sugars could be enhanced (Sasaki et al. 2009). Interestingly, the presence of glucose did not influence xylose or arabinose consumption, which is a clear advantage compared with other bacteria, e.g. E. coli. Recently, a platform strain for C. glutamicum-based mixed sugar utilization was constructed (Sasaki et al. 2009). This strain expresses araBAD for arabinose metabolism, xylAB for xylose metabolism, bglF317A (cellobiose permease), bglA (beta-glucosidase) and araE (pentose uptake), which were all integrated in the chromosomal DNA. Under oxygen-deprived conditions in mineral medium containing a sugar mixture of glucose, xylose, arabinose and cellobiose the strain consumed all sugars simultaneously and completely. Recently, Smith et al. (2010) engineered C. glutamicum for isobutanol production, resulting in an isobutanol yield of 4 g/l after 96 h.

Thermophilic bacteria

A main disadvantage of SHF processes is the product inhibition of cellulases by glucose. This can be circumvented using SSF. One of the major challenges in SSF processes are the different temperature optima for cellulases (>50°C) and fermenting organisms (e.g. <35°C for yeast). If a thermophilic organism could be used for fermentation the whole process can take place at higher temperatures. This can reduce production costs (e.g. no cooling of the hydrolysation broth needed) and product inhibition (e.g. glucose is simultaneously consumed). There are several interesting thermophilic organisms known, including the genera Clostridium, Thermoanaerobacter or Thermoanaerobacterium, which are able to produce ethanol from biomass-derived sugars (Zeikus et al. 1981; Lynd et al. 2005). In 2008, Lynd and coworkers engineered Thermoanaerobacterium saccharolyticum, a thermophilic anaerobic bacterium, which is able to utilize xylan and sugar monomers, for the production of ethanol. Deletion of genes involved in organic acid formation resulted in a strain producing 37 g ethanol/l in fed batch culture and 33 g/l in continuous culture, consuming xylose and glucose simultaneously (Shaw et al. 2008). Other candidates like Geobacillus thermoglucosidasius (Fong et al. 2006) are currently investigated and steadily new thermophiles are discovered, exhibiting interesting properties like a broad substrate spectrum and coproduction of ethanol and hydrogen (e.g. Koskinen et al. 2008).

Besides the higher temperature optimum compared with mesophilic organisms like yeasts, an additional advantage of thermophilic bacteria is their metabolic diversity to degrade a great variety of carbohydrates derived from lignocellulosic feedstocks. Because some of the thermophilic species like Clostridium thermocellum, Thermomonospora sp. N-35, and Anaerocellum thermophilum, exhibit cellulolytic activities, they have been considered for CBP (Lynd et al. 2002). Using an engineered strain in SSF experiments at 50°C allowed a 2.5-fold reduction in cellulase loading compared with using Saccharomyces cerevisiae at 37°C (Shaw et al. 2008). Until now, production rates of thermophilic bacteria are far away from those of currently used fermenting organisms like S. cerevisae or Z. mobilis. Besides the low glucose conversion rate, another major limitation of most thermophilic organisms is their low ethanol tolerance, which is generally in the range of 2% (v/v). Using classical strain improvement methods the ethanol tolerance for those strains could be increased (e.g. Mikkelsen and Ahring 2007), but are still far away from current industrial requirements.

Cyanobacteria

A characteristic of biomass fermentations is that they are rather indirect. First, the energy of the sun is used by plant cells via photosynthesis to build up sugars or even more complex biopolymers like starch or lignocellulosic polymers. Then these compounds have to be collected, deconstructed, hydrolysed and finally fermented into the bioalcohols by microorganisms. It would be quite advantageous to combine these separated phototrophic and chemotrophic modes of metabolism into a kind of “photofermentative” metabolism in one and the same organism (Hellingwerf and Teixeira de Mattos 2009). This means that solar energy is directly used by a photosynthetic (micro)-organism to drive the production of bioalcohols from H2O and CO2 instead of cell mass and storage carbohydrates.

Many microalgae have metabolic pathways to ethanol, but to couple ethanol production to photoautotrophic metabolism has not been shown (Radakovits et al. 2010). On the other hand, cyanobacteria like Synechocystis sp. seem to be very promising for photofermentative bioalcohol production as they are well characterized, naturally transformable, relatively fast and robustly growing, with no specific nutritional demands. Indeed, by expressing a bacterial pyruvate decarboxylase and alcohol dehydrogenase in the cyanobacterium Synechococcus sp. PCC 7942, the recombinant microorganism produced up to 230 mg/l ethanol directly from CO2 within 4 weeks of growth (Deng and Coleman 1999). Moreover, a genome-scale Synechocystis sp. PCC 6803 metabolic network model was used to improve cyanobacterial ethanol production up to 690 mg/l in 1 week (Fu 2009). Even more intriguingly, expression of an isobutanol-fermentation pathway in Synechococcus elongates PCC7942 together with overexpression of the rate-limiting CO2-fixating ribulose 1,5-bisphosphate carboxylase (Rubisco) resulted in a photofermentative bacterium that produced up to 450 mg/l isobutanol in 6 days with a maximal productivity of about 3 mg/l/h (Atsumi et al. 2009).

However, the final alcohol titers are far below those values calculated for cost- and energy-efficient distillation processes normally used for product recovery which minimally are about 40–50 g/l for ethanol. Therefore, Atsumi et al. (2009) considered isobutyraldehyde as a more promising fermentation product. Its high vapour pressure allows in situ product recovery, and therefore its continuous evaporation reduces toxicity to cells and prolong the production phase. Isobutyraldehyde is a precursor for the synthesis of isobutanol and other chemicals and can be easily converted either biologically or chemically to them. Interestingly, S. elongates PCC7942 expressing the isobutanol-fermentation pathway without an alcohol dehydrogenase produced 1.1 g/l isobutyraldehyde over 8 days with a production rate of about 6 mg/l/h. Although the volumetric productivities of the photofermentative recombinant organisms seem to be quite low compared with traditional microbial fermentations, the areal productivities expressed as litre of biofuel produced per unit of surface area (hectare) per year are significantly higher (Sheehan 2009). Nevertheless, like in biodiesel production from algae the many technical problems of large-scale culturing and high capital cost will remain a severe hurdle for commercialisation.

Other bacteria

Several other bacteria have been investigated for their potential as biofuel producers, all exhibiting different properties which could be beneficial for the fermentation process. Klebsiella oxytoca, a Gram-negative bacterium genetically similar to E. coli, has the inherent ability to utilize all monomeric sugars and also cellobiose and cellotriose (Wood and Ingram 1992). Integration of the Z. mobilis PET operon enabled this bacterium to produce ethanol from a variety of substrates (Wood and Ingram 1992; Wood et al. 1998). However, compared with E. coli, K. oxytoca is less efficient in ethanol production, which could be due to its low ethanol tolerance. The PET operon has also been successfully expressed in strains of Erwina chrysanthemi which have the native ability to secrete endoglucanase, express phosphotransferase systems for cellobiose and cellotriose utilization and secrete pectate lyases and other enzymes that depolymerize cell wall carbohydrates (Ingram and Beall 1993).

Bi et al. (2009) isolated Enterobacter asburiae JDR-1 from colonized wood. This bacterium ferments both methylglucuronoxylose and xylose in acid hydrolysates of sweet gum xylan. Introduction of the PET operon led to homoethanol fermentation with acetate as byproduct. Additional deletion of the pyruvate formate lyase resulted in a strain producing ethanol from xylan hydrolysate with 99% of theoretical yield and a rate of 0.11 g ethanol per gram per hour (Bi et al. 2009).

Yeasts

S. cerevisiae

Ethanol

The yeast S. cerevisiae (commonly referred to as the “yeast”) is among the best known microorganisms and wide sets of genetic tools exist to modify the cells. Yeast cells have a high robustness, are highly resistant to toxic inhibitors and fermentation products and they ferment sugars at low pH values, which minimizes the contamination risk. Hence, yeast is used already today in food and beverage industry as well as for industrial production of specialty chemicals and bioethanol. However, S. cerevisiae cannot naturally ferment pentose sugars like xylose and arabinose (Olofsson et al. 2008). Therefore various approaches were carried out to integrate xylose and arabinose utilization pathways into S. cerevisiae (van Maris et al. 2007).

Anaerobic xylose fermentation by S. cerevisiae was first demonstrated by heterologous expression of the genes XYL1 and XYL2 encoding xylose reductase and xylitol dehydrogenase from Pichia stipitis converting xylose into xylitol and xylulose, respectively (Kötter and Ciriacy 1993). Xylulose is then phosphorylated by yeast xylulokinase and channelled into the pentose phosphate pathway (Ho et al. 1998). However, a large amount of xylitol was produced in these recombinant strains reducing ethanol yields. This has been primarily attributed to the difference in coenzyme specificities between the strictly NAD+-dependent xylitol dehydrogenase and the mainly NADPH-dependent xylose reductase, resulting in an intracellular cofactor imbalance (Kötter and Ciriacy 1993). During the last 20 years several approaches have been made to solve the imbalance problem. Examples are the heterologous expression of a transhydrogenase which converts NADH to NADPH (Nissen et al. 2001) or alterations in the coenzyme specificity of xylose reductase and/or xylitol dehydrogenase by protein engineering (Jeppsson et al. 2006).

Major progress was recently made by the heterologous expression of genes encoding xylose isomerase in S. cerevisiae which in the beginning had been difficult (Matsushika et al. 2009). Most bacterial xylose isomerase turned out to be inactive in yeast. The first functional xylose isomerase was that from Thermus thermophilus, with the drawback of its temperature optimum at 85°C. Xylose isomerases from the fungi Piromyces (Kuyper et al. 2003) and Orpinomyces (Madhavan et al. 2009) have also been functionally expressed. The xylose isomerase from C. phytofermentans was the first bacterial xylose isomerase highly active in S. cerevisiae at its normal growth temperature (Brat et al. 2009). This enzyme offered the advantage that it is less inhibited by xylitol than the eukaryotic enzymes. Xylitol is always produced in yeast cells by unspecific aldose reductases. The ethanol production rates and yields of various fermentations with media containing xylose with the numerous developed recombinant yeast strains have been summarized in the review of Matsushika et al. (2009).

Expression of a multi-step oxidoreductive fungal arabinose pathway in S. cerevisiae resulted in a strain with only marginal ethanol production. This phenotype was attributed also to cofactor imbalances as well as limitations in the uptake of arabinose (Richard et al. 2002). In contrast, the bacterial pathway for arabinose fermentation was successfully integrated in S. cerevisiae by heterologous expression of the genes araA from B. subtilis or B. licheniformis and araB and araD from E. coli (Becker and Boles 2003; Wiedemann and Boles 2008) or with all three genes from Lactobacillus plantarum (Wisselink et al. 2007).

For optimal pentose fermentation in S. cerevisiae, overexpression of the genes of the non-oxidative part of the pentose phosphate pathway turned out to be beneficial (Kuyper et al. 2005). Furthermore, there is a high demand for specific pentose transporters to improve coconsumption of glucose and pentoses (Hahn-Hagerdal et al. 2007). To improve recombinant S. cerevisiae for utilizing of mixed sugar substrates an intriguing new evolutionary engineering approach was recently developed (Wisselink et al. 2009). The yeast cells were successively cultivated in various mixtures of arabinose, xylose and glucose medium, allowing them to evolve longer time periods on the less preferred carbon sources without loosing performance on the other carbon sources. A strain was evolved which was able to completely ferment a synthetic mixture of 30 g/l glucose, 15 g/l xylose and 15 g/l arabinose in about 35 hours. Unfortunately, this laboratory strain did not perform well under conditions simulating lignocellulosic hydrolysates containing acetic acid at low pH values (Bellissimi et al. 2009). For commercial lignocellulosic ethanol production engineering of highly robust industrial yeast strains is necessary which might be further optimised to resist the lignocellulose-derived inhibitors like acetic acid, furfural, hydroxymethylfurfural and various lignin-degradation products (Hahn-Hagerdal et al. 2007).

Butanol

Recently, a S. cerevisiae strain was described engineered for 1-butanol production by introduction of a clostridial 1-butanol pathway (Steen et al. 2008). However, 1-butanol yields and productivities were only very low although several improvements were made. In contrast, isobutanol production seems to be more suitable with yeast. Although no scientific article has yet been published various companies like DuPont, Gevo and Butalco are working on the genetic engineering of yeasts for isobutanol production as judged from several patent applications (e.g. PCT/US2006/041602 and PCT/EP2009/001191), press releases and conference contributions.

Intriguingly, isobutanol is already produced by wild-type S. cerevisiae as a degradation product of valine metabolism (Hazelwood et al. 2008). Valine is produced from ketoisovalerate which is derived from pyruvate via three mitochondrial enzyme reactions. To increase isobutanol production in yeast cytosolic overexpression of native or heterologous enzymes of the ketoisovalerate pathway has been suggested together with overexpression of ketoacid decarboxylase and alcohol dehydrogenase. To avoid cofactor imbalances between glycolytically derived NADH and the NADPH requirements of the isobutanol pathway engineering of cofactor specificities of the involved oxidoreductases was proposed. Ethanol formation can be blocked by the deletion of pyruvate decarboxylase genes. The resulting cytosolic acetyl-CoA requirements can be overcome by expression of a bacterial pyruvate formate lyase together with formate dehydrogenase (patent application PCT/EP2009/000181). It is difficult to judge how far the engineering of commercial isobutanol producing S. cerevisiae strains is progressed but this interesting route to the synthesis of lignocellulosic bioalcohols seems to be very promising.

P. stipitis

P. stipitis is one of the few naturally xylose fermenting yeasts and thus is a promising candidate for ethanol production from lignocellulosic materials. P. stipitis is also able to ferment glucose, galactose and cellobiose (Parekh and Wayman 1986) and as the recently completed genome sequence revealed, it also possesses different cellulases and hemicellulases (Jeffries et al. 2007). This could be of use in SSF set-ups although the optimal growth temperature of this yeast is around 30°C. Xylose is metabolized by xylose reductase and xylitol dehydrogenase. The cofactor imbalance between these two enzymes in P. stipitis and the resulting xylitol accumulation is less drastic than in other yeasts because of the less stringent cofactor specificity of xylose reductase, which can use NADH and NADPH, with a preference for the latter (Verduyn et al. 1985). Additionally P. stipitis possesses a non-cytochrome electron transport chain (SHAM-sensitive pathway) which can resolve cofactor imbalances (Jeppsson et al. 1995). Recently the cofactor specificity of the P. stipitis xylose reductase could be shifted almost completely to NADH, which might improve xylose utilization in P. stipitis and, after heterologous expression, in S. cerevisiae (Zeng et al. 2009).

Compared with S. cerevisiae, sugar consumption rates in P. stipitis are lower and this seem partly to be related to sugar transport (Ligthelm et al. 1988; Agbogbo and Coward-Kelly 2008). As opposed to S. cerevisiae, mainly proton-symporters are responsible for sugar uptake in P. stipitis, which might be disadvantageous for efficient and complete xylose fermentation due to energetic constraints. Glucose is the preferred carbon source and in glucose/xylose mixtures xylose transport is inhibited. Recent studies focused on increasing inhibitor and ethanol tolerance by UV mutagenesis and genome shuffling as well as nutritional demands and their effects on ethanol yields and inhibitor tolerance (Bajwa et al. 2009, 2010; Slininger et al. 2009). In optimized defined media containing 150 g/l xylose a maximum of 61 g/l ethanol with a yield of 0.41 g ethanol/g xylose could be achieved (Slininger et al. 2006). Especially the nitrogen source has a big influence on ethanol production and is a prerequisite for non-growth-associated ethanol production. For an industrial application, this causes the need for a suitable nitrogen source. Furthermore, P. stipitis shows optimal ethanol production only under microaerophilic conditions and under aerobic conditions no ethanol production is observed, even with sugar excess. Ethanol productivity has been assessed in many different hydrolysates with yields ranging from 0.31 to 0.48 g ethanol/g sugar consumed (for an overview see Agbogbo and Coward-Kelly (2008)).

Kluyveromyces

In the genus Kluyveromyces the two species Kluyveromyces lactis and Kluyveromyces marxianus are of major interest for biotechnological applications, but so far the main focus is directed to applications like heterologous protein production (van Ooyen et al. 2006). This is due to the strong crabtree-negative nature of Kluyveromyces species and the low tendency to form ethanol when exposed to excess of sugar. Ethanol production in this more aerobic and respiring yeasts is linked to oxygen limitation (Bellaver et al. 2004). Nevertheless, some traits especially of K. marxianus make this yeast an interesting organism for converting biomass to ethanol. One advantage is the thermotolerance which enables K. marxianus to grow at up to 52°C (Banat et al. 1992) and to ferment at elevated temperatures above 40°C. In an industrial scale this could reduce cooling costs and the risk of contamination, simplify the removal of ethanol and is advantageous for SSF processes because it suits the optimum temperatures of cellulolytic enzymes. A higher fermentation temperature also increases the productivity of the plant. Additionally, K. marxianus shows a high degree of intraspecies variation, with many diverse isolates with a broad substrate spectrum. Currently many isolates are characterized for their ability to grow on and ferment different sugars or substrates (e.g. Suryawati et al. 2008; Wilkins et al. 2008; Kumar et al. 2009). Despite promising results in fermentation of glucose at temperatures above 40°C with up to 98% of the theoretical yield (Banat et al. 1992), fermentation of xylose to ethanol is poor. Instead xylose is converted to xylitol to a great extent, which is undesirable for economic production of ethanol from lignocellulosic feedstocks. As mentioned elevated temperatures for fermentation are feasible but also have a negative effect on ethanol yield, cell viability and ethanol tolerance. So far there are only few studies on the biochemistry and physiology of K. marxianus and although recombinant DNA technologies are available, no attempts have been reported to engineer Kluyveromces strains for more efficient ethanol production.

Hansenula polymorpha

H. polymorpha is another thermotolerant, naturally xylose fermenting yeast and therefore shares some advantages of K. marxianus, like the prospect of SSF at elevated temperatures. Optimal growth temperature for this yeast is 37°C and fermentation is still possible at up to 48°C. Successful attempts were made to improve this thermotolerance even further (Ryabova et al. 2003; Ishchuk et al. 2009). Xylose conversion is accomplished by the two-step oxidoreductive process. Different approaches were taken to increase the efficiency of xylose fermentation, including heterologous expression of the E. coli xylose isomerase, additional cooverexpression of endogenous xylulokinase and changing the cofactor specificity of xylose reductase to avoid cofactor imbalances (Voronovsky et al. 2005; Dmytruk et al. 2008a, b). Furthermore, the pyruvate decarboxylase gene PDC1 was overexpressed to direct pyruvate towards ethanol formation instead of respiration (Ishchuk et al. 2008). Although xylose fermentation in H. polymorpha could be improved by each of these optimisations, the ethanol production rate is still low. This might be due to inefficient uptake of xylose into the cells or limitations in the pentose-phosphate-pathway. Recently, the tolerance of H. polymorpha against ethanol and l-azetidine-2-carboxylic acid could be increased by heterologous expression of S. cerevisiae N-acetyltransferase MPR1. Its role is still unclear but it has been proposed that this protein reduces intracellular ROS levels or acetylates toxic compounds (Ishchuk et al. 2010). Moreover, the heterologous expression of amylolytic and xylanolytic enzymes conferred ability to grow on starch and xylan as sole carbon source, respectively (Voronovsky et al. 2009).

Perspectives

It is difficult to predict which of these microorganisms finally will be used in commercial lignocellulosic biofuel production. Probably, there will be not only one super-bug doing all the work but in different processes different species will be used. Of course, there will always be the potential to further improve these organisms by classical methods or genetic engineering. At the moment the two species S. cerevisiae and Z. mobilis have the best chances to be used in the first commercial plants for lignocellulosic bioalcohol production. The big advantage of S. cerevisiae is the fact that it is used already today in large-scale first generation bioethanol production. The yeast process is well established and simple, the organism is robust and well known, and most parts of the technology of current ethanol production plants can be used also for the next generation technologies. To establish bioalcohol production technologies for new kinds of species seems to be difficult in the short term due to the huge dimensions of the production plants.

Also it is difficult to judge when the more advanced biofuels will take over. Bioethanol technologies are already well established in many countries since several years and therefore bioethanol, both first and second generation, will probably dominate the biofuel market still for many years. Probably the next prominent biofuel will then be isobutanol, produced with yeasts, as the production process will be very similar to the bioethanol production process. The production of fermentative fatty-acid-derived and isoprenoid biofuels might be more difficult in large scale as their biochemical synthesis needs energy requiring aeration of the fermentation vessels.

A serious problem in the production of butanol is its toxicity. It is very unlikely that the producing microorganisms can be engineered to resist more than 7–8% butanol after which phase separation will occur. This would be really beneficial for its isolation. However, it is more likely that more advanced downstream technologies will be developed that continuously remove the butanol out of the fermentation broth.

Nevertheless, the commercial production of second generation bioalcohols is very close. Recently, the companies Novozymes and Danisco/Genencor announced that commercial enzyme mixtures for lignocellulose hydrolysis are available. Also, the first industrial S. cerevisiae and Z. mobilis strains for cofermentation of hexose and pentose sugars seem close to their completion as recently announced by the companies Butalco and DuPont Danisco Cellulosic Ethanol. Several companies worldwide are already constructing lignocellulosic ethanol production plants. It is obvious that the first drops of commercial lignocellulosic bioethanol will not be produced in a completely optimised process but continuous improvements will make lignocellulosic bioalcohols more and more competitive with fossil fuels.

References

Agbogbo FK, Coward-Kelly G (2008) Cellulosic ethanol production using the naturally occurring xylose-fermenting yeast, Pichia stipitis. Biotechnol Lett 30:1515–1524

Alper H, Stephanopoulos G (2007) Global transcription machinery engineering: a new approach for improving cellular phenotype. Metab eng 9:258–267

Atsumi S, Cann AF, Connor MR, Shen CR, Smith KM, Brynildsen MP, Chou KJY, Hanai T, Liao JC (2008a) Metabolic engineering of Escherichia coli for 1-butanol production. Metab eng 10:305–311

Atsumi S, Hanai T, Liao JC (2008b) Non-fermentative pathways for synthesis of branched-chain higher alcohols as biofuels. Nature 451:86–89

Atsumi S, Higashide W, Liao JC (2009) Direct photosynthetic recycling of carbon dioxide to isobutyraldehyde. Nat Biotech 27:1177–1180

Awang GM, Jones GA, Ingledew WM (1988) The acetone-butanol-ethanol fermentation. Crit Rev Microbiol 15(Suppl 1):S33–S67

Bajwa PK, Shireen T, D'Aoust F, Pinel D, Martin VJ, Trevors JT, Lee H (2009) Mutants of the pentose-fermenting yeast Pichia stipitis with improved tolerance to inhibitors in hardwood spent sulfite liquor. Biotechnol Bioeng 104:892–900

Bajwa PK, Pinel D, Martin VJ, Trevors JT, Lee H (2010) Strain improvement of the pentose-fermenting yeast Pichia stipitis by genome shuffling. J Microbiol Methods 81:179–186

Banat IM, Nigam P, Marchant R (1992) Isolation of thermotolerant, fermentative yeasts growing at 52°C and producing ethanol at 45°C and 50°C. World J Microbiol Biotechnol 8:259–263

Becker J, Boles E (2003) A modified Saccharomyces cerevisiae strain that consumes l-arabinose and produces ethanol. Appl Environ Microbiol 69:4144–4150

Bellaver LH, de Carvalho NM, Abrahao-Neto J, Gombert AK (2004) Ethanol formation and enzyme activities around glucose-6-phosphate in Kluyveromyces marxianus CBS 6556 exposed to glucose or lactose excess. FEMS Yeast Res 4:691–698

Bellissimi E, JPv D, Pronk JT, AJAv M (2009) Effects of acetic acid on the kinetics of xylose fermentation by an engineered, xylose-isomerase-based Saccharomyces cerevisiae strain. FEMS Yeast Res 9:358–364

Bi C, Zhang X, Ingram LO, Preston JF (2009) Genetic engineering of Enterobacter asburiae strain JDR-1 for efficient production of ethanol from hemicellulose hydrolysates. Appl Environ Microbiol 75:5743–5749

Brat D, Boles E, Wiedemann B (2009) Functional expression of a bacterial xylose isomerase in Saccharomyces cerevisiae. Appl Environ Microbiol 75:2304–2311

Bronnenmeier K, Staudenbauer WL (1993) Molecular biology and genetics of substrate utilization in Clostridia. Biotechnol 25:261–309

Cantarel BL, Coutinho PM, Rancurel C, Bernard T, Lombard V, Henrissat B (2009) The carbohydrate-active enzymes database (CAZy): an expert resource for glycogenomics. Nucleic Acids Res 37:D233–D238

Connor MR, Liao JC (2009) Microbial production of advanced transportation fuels in non-natural hosts. Curr Opin Biotechnol 20:307–315

da Silveira dos Santos D, Camelo A, Rodrigues K, Carlos L, Pereira N (2010) Ethanol production from sugarcane bagasse by Zymomonas mobilis using simultaneous saccharification and fermentation (SSF) process. Appl Biochem Biotechnol 161:93–105

Datar RP, Shenkman RM, Cateni BG, Huhnke RL, Lewis RS (2004) Fermentation of biomass-generated producer gas to ethanol. Biotechnol Bioeng 86:587–594

Deanda K, Zhang M, Eddy C, Picataggio S (1996) Development of an arabinose-fermenting Zymomonas mobilis strain by metabolic pathway engineering. Appl Environ Microbiol 62:4465–4470

Deng M-D, Coleman JR (1999) Ethanol synthesis by genetic engineering in cyanobacteria. Appl Environ Microbiol 65:523–528

Dmytruk OV, Dmytruk KV, Abbas CA, Voronovsky AY, Sibirny AA (2008a) Engineering of xylose reductase and overexpression of xylitol dehydrogenase and xylulokinase improves xylose alcoholic fermentation in the thermotolerant yeast Hansenula polymorpha. Microb Cell Fact 7:21

Dmytruk OV, Voronovsky AY, Abbas CA, Dmytruk KV, Ishchuk OP, Sibirny AA (2008b) Overexpression of bacterial xylose isomerase and yeast host xylulokinase improves xylose alcoholic fermentation in the thermotolerant yeast Hansenula polymorpha. FEMS Yeast Res 8:165–173

Dürre P (2008) Fermentative butanol production: bulk chemical and biofuel. Ann N Y Acad Sci 1125:353–362

Ezeji T, Milne C, Price ND, Blaschek HP (2010) Achievements and perspectives to overcome the poor solvent resistance in acetone and butanol-producing microorganisms. Appl Microbiol Biotechnol 85:1697–1712

Feldmann SD, Sahm H, Sprenger GA (1992) Cloning and expression of the genes for xylose isomerase and xylulokinase from Klebsiella pneumoniae 1033 in Escherichia coli K12. Mol Gen Genet 234:201–210

Fong JCN, Svenson CJ, Nakasugi K, Leong CTC, Bowman JP, Chen B, Glenn DR, Neilan BA, Rogers PL (2006) Isolation and characterization of two novel ethanol-tolerant facultative-anaerobic thermophilic bacteria strains from waste compost. Extremophiles 10:363–372

Fu P (2009) Genome-scale modeling of Synechocystis sp. PCC 6803 and prediction of pathway insertion. J Chem Technol Biotechnol 84:473–483

Görke B, Stülke J (2008) Carbon catabolite repression in bacteria: many ways to make the most out of nutrients. Nat Rev Microbiol 6:613–624

Hahn-Hagerdal B, Karhumaa K, Fonseca C, Spencer-Martins I, Gorwa-Grauslund MF (2007) Towards industrial pentose-fermenting yeast strains. Appl Microbiol Biotechnol 74:937–953

Hanai T, Atsumi S, Liao JC (2007) Engineered synthetic pathway for isopropanol production in Escherichia coli. Appl Environ Microbiol 73:7814–7818

Harris LM, Blank L, Desai RP, Welker NE, Papoutsakis ET (2001) Fermentation characterization and flux analysis of recombinant strains of Clostridium acetobutylicum with an inactivated solR gene. J Ind Microbiol Biotech 27:322–328

Hazelwood LA, Daran J-M, van Maris AJA, Pronk JT, Dickinson JR (2008) The Ehrlich pathway for fusel alcohol production: a century of research on Saccharomyces cerevisiae metabolism. Appl Environ Microbiol 74:3920

Heap JT, Pennington OJ, Cartman ST, Carter GP, Minton NP (2007) The ClosTron: a universal gene knock-out system for the genus Clostridium. J Microbiol Methods 70:452–464

Hellingwerf KJ, Teixeira de Mattos MJ (2009) Alternative routes to biofuels: light-driven biofuel formation from CO2 and water based on the ‘photanol’ approach. J biotechnol 142:87–90

Hendriks ATWM, Zeeman G (2009) Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour Technol 100:10–18

Hermann T (2003) Industrial production of amino acids by coryneform bacteria. J Biotechnol 104:155–172

Hermann M, Fayolle F, Marchal R, Podvin L, Sebald M, Vandecasteele JP (1985) Isolation and characterization of butanol-resistant mutants of Clostridium acetobutylicum. Appl Environ Microbiol 50:1238–1243

Himmel ME, Ding S-Y, Johnson DK, Adney WS, Nimlos MR, Brady JW, Foust TD (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Sci 315:804–807

Ho NWY, Chen Z, Brainard AP (1998) Genetically engineered Saccharomyces yeast capable of effective cofermentation of glucose and xylose. Appl Environ Microbiol 64:1852–1859

Ingram LO, Beall DS (1993) Genetic engineering of soft-rot bacteria for ethanol production from lignocellulose. J Ind Microbiol Biotech 11:151–155

Ingram LO, Conway T, Clark DP, Sewell GW, Preston JF (1987) Genetic engineering of ethanol production in Escherichia coli. Appl Environ Microbiol 53:2420–2425

Ingram, Gomez, Lai, Moniruzzaman, Wood, Yomano, York (1998) Metabolic engineering of bacteria for ethanol production. Biotechnol Bioeng 58:204–214

Inui M, Kawaguchi H, Murakami S, Vertès AA, Yukawa H (2004) Metabolic engineering of Corynebacterium glutamicum for fuel ethanol production under oxygen-deprivation conditions. J Mol Microbiol Biotechnol 8:243–254

Inui M, Suda M, Kimura S, Yasuda K, Suzuki H, Toda H, Yamamoto S, Okino S, Suzuki N, Yukawa H (2008) Expression of Clostridium acetobutylicum butanol synthetic genes in Escherichia coli. Appl Microbiol Biotechnol 77:1305–1316

Ishchuk OP, Voronovsky AY, Stasyk OV, Gayda GZ, Gonchar MV, Abbas CA, Sibirny AA (2008) Overexpression of pyruvate decarboxylase in the yeast Hansenula polymorpha results in increased ethanol yield in high-temperature fermentation of xylose. FEMS Yeast Res 8:1164–1174

Ishchuk OP, Voronovsky AY, Abbas CA, Sibirny AA (2009) Construction of Hansenula polymorpha strains with improved thermotolerance. Biotechnol Bioeng 104:911–919

Ishchuk OP, Abbas CA, Sibirny AA (2010) Heterologous expression of Saccharomyces cerevisiae MPR1 gene confers tolerance to ethanol and l-azetidine-2-carboxylic acid in Hansenula polymorpha. J Ind Microbiol Biotech 37:213–218

Jeffries TW, Grigoriev IV, Grimwood J, Laplaza JM, Aerts A, Salamov A, Schmutz J, Lindquist E, Dehal P, Shapiro H, Jin YS, Passoth V, Richardson PM (2007) Genome sequence of the lignocellulose-bioconverting and xylose-fermenting yeast Pichia stipitis. Nat Biotechnol 25:319–326

Jeppsson H, Alexander NJ, Hahn-Hagerdal B (1995) Existence of cyanide-insensitive respiration in the yeast Pichia stipitis and its possible influence on product formation during xylose utilization. Appl Environ Microbiol 61:2596–2600

Jeppsson M, Bengtsson O, Franke K, Lee H, Hahn-Hägerdal B, Gorwa-Grauslund MF (2006) The expression of a Pichia stipitis xylose reductase mutant with higher K M for NADPH increases ethanol production from xylose in recombinant Saccharomyces cerevisiae. Biotechnol Bioeng 93:665–673

Jojima T, Omumasaba CA, Inui M, Yukawa H (2010) Sugar transporters in efficient utilization of mixed sugar substrates: current knowledge and outlook. Appl Microbiol Biotechnol 85:471–480

Jones DT, Woods DR (1986) Acetone-butanol fermentation revisited. Microbiol Rev 50:484–524

Jones DT, Shirley M, Wu X, Keis S (2000) Bacteriophage infections in the industrial acetone butanol (AB) fermentation process. J Mol Microbiol Biotechnol 2:21–26

Kashket ER, Cao Z-Y (1993) Isolation of a degeneration-resistant mutant of Clostridium acetobutylicum NCIMB 8052. Appl Environ Microbiol 59:4198–4202

Kawaguchi H, Vertès AA, Okino S, Inui M, Yukawa H (2006) Engineering of a xylose metabolic pathway in Corynebacterium glutamicum. Appl Environ Microbiol 72:3418–3428

Kawaguchi H, Sasaki M, Vertès AA, Inui M, Yukawa H (2008) Engineering of an l-arabinose metabolic pathway in Corynebacterium glutamicum. Appl Microbiol Biotechnol 77:1053–1062

Kawaguchi H, Sasaki M, Vertes AA, Inui M, Yukawa H (2009) Identification and functional analysis of the gene cluster for l-arabinose utilization in Corynebacterium glutamicum. Appl Environ Microbiol 75(11):3419–3429

Knoshaug EP, Zhang M (2009) Butanol tolerance in a selection of microorganisms. Appl Biochem Biotechnol 153:13–20

Koskinen PEP, Beck SR, Orlygsson J, Puhakka JA (2008) Ethanol and hydrogen production by two thermophilic, anaerobic bacteria isolated from Icelandic geothermal areas. Biotechnol Bioeng 101:679–690

Kötter P, Ciriacy M (1993) Xylose fermentation by Saccharomyces cerevisiae. Appl Microbiol Biotechnol 38:776–783

Kumar S, Singh SP, Mishra IM, Adhikari DK (2009) Ethanol and xylitol production from glucose and xylose at high temperature by Kluyveromyces sp. IIPE453. J Ind Microbiol Biotech 36:1483–1489

Kuyper M, Harhangi HR, Stave AK, Winkler AA, Jetten MS, de Laat WT, den Ridder JJ, Op den Camp HJ, van Dijken JP, Pronk JT (2003) High-level functional expression of a fungal xylose isomerase: the key to efficient ethanolic fermentation of xylose by Saccharomyces cerevisiae? FEMS Yeast Res 4:69–78

Kuyper M, Hartog MM, Toirkens MJ, Almering MJ, Winkler AA, van Dijken JP, Pronk JT (2005) Metabolic engineering of a xylose-isomerase-expressing Saccharomyces cerevisiae strain for rapid anaerobic xylose fermentation. FEMS Yeast Res 5:399–409

Lawford H, Rousseau J (2002) Performance testing of Zymomonas mobilis metabolically engineered for cofermentation of glucose, xylose, and arabinose. Appl Biochem Biotechnol 98–100:429–448

Lee SF, Forsberg CW, Gibbins LN (1985) Xylanolytic activity of Clostridium acetobutylicum. Appl Environ Microbiol 50:1068–1076

Lee J, Mitchell WJ, Tangney M, Blaschek HP (2005) Evidence for the presence of an alternative glucose transport system in Clostridium beijerinckii NCIMB 8052 and the solvent-hyperproducing mutant BA101. Appl Environ Microbiol 71:3384–3387

Lee SK, Chou H, Ham TS, Lee TS, Keasling JD (2008a) Metabolic engineering of microorganisms for biofuels production: from bugs to synthetic biology to fuels. Curr Opin Biotechnol 19:556–563

Lee SY, Park JH, Jang SH, Nielsen LK, Kim J, Jung KS (2008b) Fermentative butanol production by Clostridia. Biotechnol Bioeng 101:209–228

Ligthelm ME, Prior BA, Preez JC, Brandt V (1988) An investigation of d-1-13C xylose metabolism in Pichia stipitis under aerobic and anaerobic conditions. Appl Microbiol Biotechnol 28:293–296

Lynd LR, Weimer PJ, van Zyl WH, Pretorius IS (2002) Microbial cellulose utilization: fundamentals and biotechnology. Microbiol Mol Biol Rev 66:506–577, table of contents

Lynd LR, van Zyl WH, McBride JE, Laser M (2005) Consolidated bioprocessing of cellulosic biomass: an update. Curr Opin Biotechnol 16:577–583

Maddox IS, Steiner E, Hirsch S, Wessner S, Gutierrez NA, Gapes JR, Schuster KC (2000) The cause of “acid-crash” and “acidogenic fermentations” during the batch acetone-butanol-ethanol (ABE-) fermentation process. J Mol Microbiol Biotechnol 2:95–100

Madhavan A, Tamalampudi S, Ushida K, Kanai D, Katahira S, Srivastava A, Fukuda H, Bisaria VS, Kondo A (2009) Xylose isomerase from polycentric fungus Orpinomyces: gene sequencing, cloning, and expression in Saccharomyces cerevisiae for bioconversion of xylose to ethanol. Appl Microbiol Biotechnol 82:1067–1078

Maki M, Leung KT, Qin W (2009) The prospects of cellulase-producing bacteria for the bioconversion of lignocellulosic biomass. Int J Biol Sci 5:500–516

Matsushika A, Inoue H, Kodaki T, Sawayama S (2009) Ethanol production from xylose in engineered Saccharomyces cerevisiae strains: current state and perspectives. Appl Microbiol Biotechnol 84:37–53

Mikkelsen TIGMJ, Ahring BK (2007) High ethanol tolerance of the thermophilic anaerobic ethanol producer Thermoanaerobacter BG1L1. Cent Eur J Biol 2:364–377

Miller EN, Ingram LO (2007) Combined effect of betaine and trehalose on osmotic tolerance of Escherichia coli in mineral salts medium. Biotechnol Lett 29:213–217

Mohagheghi A, Evans K, Chou YC, Zhang M (2002) Cofermentation of glucose, xylose and arabinose by genomic DNA-integrated xylose/arabinose fermenting strain of Zymomonas mobilis AX101. Appl Biochem Biotechnol 98:885–898

Munasinghe PC, Khanal SK (2010) Biomass-derived syngas fermentation into biofuels: opportunities and challenges. Bioresour Technol 10:5013–5022

Nair RV, Green EM, Watson DE, Bennett GN, Papoutsakis ET (1999) Regulation of the sol Locus Genes for Butanol and acetone formation in Clostridium acetobutylicum ATCC 824 by a putative transcriptional repressor. J Bacteriol 181:319–330

Nichols NN, Dien BS, Bothast RJ (2001) Use of catabolite repression mutants for fermentation of sugar mixtures to ethanol. Appl Microbiol Biotechnol 56:120–125

Nissen TL, Anderlund M, Nielsen J, Villadsen J, Kielland-Brandt MC (2001) Expression of a cytoplasmic transhydrogenase in Saccharomyces cerevisiae results in formation of 2-oxoglutarate due to depletion of the NADPH pool. Yeast 18:19–32

Oelgeschläger E, Rother M (2008) Carbon monoxide-dependent energy metabolism in anaerobic bacteria and archaea. Arch Microbiol 190:257–269

Olofsson K, Bertilsson M, Liden G (2008) A short review on SSF—an interesting process option for ethanol production from lignocellulosic feedstocks. Biotechnol Biofuels 1:7

Papoutsakis ET (2008) Engineering solventogenic Clostridia. Curr Opin Biotechnol 19:420–429

Parekh S, Wayman M (1986) Fermentation of cellobiose and wood sugars to ethanol by Candida shehatae and Pichia stipitis. Biotechnol Lett 8:597–600

Peralta-Yahya PP, Keasling JD (2010) Advanced biofuel production in microbes. Biotechnology Journal 5:147–162

Radakovits R, Jinkerson RE, Darzins A, Posewitz MC (2010) Biofuels from Eukaryotic Microalgae. Eukaryotic Cell EC 00364-00309

Rebroš M, Rosenberg M, Grosová Z, Krištofíková Lu, Paluch M, Šipöcz M (2009) Ethanol production from starch hydrolyzates using Zymomonas mobilis and glucoamylase entrapped in polyvinylalcohol hydrogel. Appl Biochem Biotechnol 158:561–570

Ren C, Chen T, Zhang J, Liang L, Lin Z (2009) An evolved xylose transporter from Zymomonas mobilis enhances sugar transport in Escherichia coli. Microb Cell Fact 8:66

Richard P, Putkonen M, Vaananen R, Londesborough J, Penttila M (2002) The missing link in the fungal l-arabinose catabolic pathway, identification of the l-xylulose reductase gene. Biochem 41:6432–6437

Rogers PLK, Lee J, Skotnicki ML, Tribe DE (1982) Ethanol production by Zymononas mobilis. Advances Biochem Eng 23:37–84

Ryabova OB, Chmil OM, Sibirny AA (2003) Xylose and cellobiose fermentation to ethanol by the thermotolerant methylotrophic yeast Hansenula polymorpha. FEMS Yeast Res 4:157–164

Sakai S, Tsuchida Y, Nakamoto H, Okino S, Ichihashi O, Kawaguchi H, Watanabe T, Inui M, Yukawa H (2007) Effect of lignocellulose-derived inhibitors on growth of and ethanol production by growth-arrested Corynebacterium glutamicum R. Appl Environ Microbiol 73:2349–2353

Sasaki M, Jojima T, Kawaguchi H, Inui M, Yukawa H (2009) Engineering of pentose transport in Corynebacterium glutamicum to improve simultaneous utilization of mixed sugars. Appl Microbiol Biotechnol 85:105–115

Shaw AJ, Podkaminer KK, Desai SG, Bardsley JS, Rogers SR, Thorne PG, Hogsett DA, Lynd LR (2008) Metabolic engineering of a thermophilic bacterium to produce ethanol at high yield. Proc Natl Acad Sci USA 105:13769–13774

Sheehan J (2009) Engineering direct conversion of CO2 to biofuel. Nat Biotech 27:1128–1129

Shen CR, Liao JC (2008) Metabolic engineering of Escherichia coli for 1-butanol and 1-propanol production via the keto-acid pathways. Metab Eng 10:312–320

Sheridan C (2009) Making green. Nat Biotech 27:1074–1076

Slininger PJ, Dien BS, Gorsich SW, Liu ZL (2006) Nitrogen source and mineral optimization enhance d-xylose conversion to ethanol by the yeast Pichia stipitis NRRL Y-7124. Appl Microbiol Biotechnol 72:1285–1296

Slininger PJ, Gorsich SW, Liu ZL (2009) Culture nutrition and physiology impact the inhibitor tolerance of the yeast Pichia stipitis NRRL Y-7124. Biotechnol Bioeng 102:778–790

Smith KM, Cho KM, Liao JC (2010) Engineering Corynebacterium glutamicum for isobutanol production. Appl Microbiol Biotechnol (in press)

Steen E, Chan R, Prasad N, Myers S, Petzold C, Redding A, Ouellet M, Keasling J (2008) Metabolic engineering of Saccharomyces cerevisiae for the production of n-butanol. Microbial Cell Factories 7:36

Steen EJ, Kang Y, Bokinsky G, Hu Z, Schirmer A, McClure A, Del Cardayre SB, Keasling JD (2010) Microbial production of fatty-acid-derived fuels and chemicals from plant biomass. Nature 463:559–562

Suryawati L, Wilkins MR, Bellmer DD, Huhnke RL, Maness NO, Banat IM (2008) Simultaneous saccharification and fermentation of Kanlow switchgrass pretreated by hydrothermolysis using Kluyveromyces marxianus IMB4. Biotechnol Bioeng 101:894–902

Taherzadeh MJ, Karimi K (2007a) Acid-based hydrolysis processes for ethanol from lignocellulosic materials: a review. Bioresour 2:472–499

Taherzadeh MJ, Karimi K (2007b) Enzyme-based hydrolysis processes for ethanol from lignocellulosic materials: a review. Bioresour 2:707–738

Tummala SB, Welker NE, Papoutsakis ET (2003a) Design of antisense RNA constructs for downregulation of the acetone formation pathway of Clostridium acetobutylicum. J Bacteriol 185:1923–1934

Tummala SB, Junne SG, Papoutsakis ET (2003b) Antisense RNA downregulation of coenzyme A transferase combined with alcohol-aldehyde dehydrogenase overexpression leads to predominantly alcohologenic Clostridium acetobutylicum fermentations. J Bacteriol 185:3644–3653

van Maris AJ, Winkler AA, Kuyper M, de Laat WT, van Dijken JP, Pronk JT (2007) Development of efficient xylose fermentation in Saccharomyces cerevisiae: xylose isomerase as a key component. Adv Biochem Eng Biotechnol 108:179–204

van Ooyen AJ, Dekker P, Huang M, Olsthoorn MM, Jacobs DI, Colussi PA, Taron CH (2006) Heterologous protein production in the yeast Kluyveromyces lactis. FEMS Yeast Res 6:381–392

Verduyn C, Van Kleef R, Frank J, Schreuder H, Van Dijken JP, Scheffers WA (1985) Properties of the NAD(P)H-dependent xylose reductase from the xylose-fermenting yeast Pichia stipitis. Biochem J 226:669–677

Voronovsky AY, Ryabova OB, Verba OV, Ishchuk OP, Dmytruk KV, Sibirny AA (2005) Expression of xylA genes encoding xylose isomerases from Escherichia coli and Streptomyces coelicolor in the methylotrophic yeast Hansenula polymorpha. FEMS Yeast Res 5:1055–1062

Voronovsky AY, Rohulya OV, Abbas CA, Sibirny AA (2009) Development of strains of the thermotolerant yeast Hansenula polymorpha capable of alcoholic fermentation of starch and xylan. Metab Eng 11:234–242

Warnick TA, Methe BA, Leschine SB (2002) Clostridium phytofermentans sp. nov., a cellulolytic mesophile from forest soil. Int J Syst Evol Microbiol 52:1155–1160

Wiedemann B, Boles E (2008) Codon-optimized bacterial genes improve l-arabinose fermentation in recombinant Saccharomyces cerevisiae. Appl Environ Microbiol 74:2043–2050

Wilkins MR, Mueller M, Eichling S, Banat IM (2008) Fermentation of xylose by the thermotolerant yeast strains Kluyveromyces marxianus IMB2, IMB4, and IMB5 under anaerobic conditions. Process Biochemistry 43:346–350

Wingren A, Galbe M, Zacchi G (2003) Techno-economic evaluation of producing ethanol from softwood: comparison of SSF and SHF and identification of bottlenecks. Biotechnol Prog 19:1109–1117

Wisselink HW, Toirkens MJ, del Rosario Franco Berriel M, Winkler AA, van Dijken JP, Pronk JT, Van Maris AJA (2007) Engineering of Saccharomyces cerevisiae for efficient anaerobic alcoholic fermentation of l-arabinose. Appl Environ Microbiol 73:4881–4891

Wisselink HW, Toirkens MJ, Wu Q, Pronk JT, van Maris AJ (2009) Novel evolutionary engineering approach for accelerated utilization of glucose, xylose, and arabinose mixtures by engineered Saccharomyces cerevisiae strains. Appl Environ Microbiol 75:907–914

Wood BE, Ingram LO (1992) Ethanol production from cellobiose, amorphous cellulose, and crystalline cellulose by recombinant Klebsiella oxytoca containing chromosomally integrated Zymomonas mobilis genes for ethanol production and plasmids expressing thermostable cellulase genes from Clostridium thermocellum. Appl Environ Microbiol 58:2103–2110

Wood LO, Ingram K, Ohta BE (1998) Recombinant cells that highly express chromosomally integrated heterologous genes. US Patent 5821093

Yanase H, Nozaki K, Okamoto K (2005) Ethanol production from cellulosic materials by genetically engineered Zymomonas mobilis. Biotechnol Lett 27:259–263

Yomano LP, York SW, Ingram LO (1998) Isolation and characterization of ethanol-tolerant mutants of Escherichia coli KO11 for fuel ethanol production. J Ind Microbiol Biotechnol 20:132–138

Yomano LP, York SW, Shanmugam KT, Ingram LO (2009) Deletion of methylglyoxal synthase gene (mgsA) increased sugar co-metabolism in ethanol-producing Escherichia coli. Biotechnol Lett 31:1389–1398

Zeikus JG, Ben-Bassat A, Ng TK, Lamed RJ (1981) Thermophilic ethanol fermentations. Basic Life Sci 18:441–461

Zeng QK, Du HL, Wang JF, Wei DQ, Wang XN, Li YX, Lin Y (2009) Reversal of coenzyme specificity and improvement of catalytic efficiency of Pichia stipitis xylose reductase by rational site-directed mutagenesis. Biotechnol Lett 31:1025–1029

Zhang M, Eddy C, Deanda K, Finkelstein M, Picataggio S (1995) Metabolic engineering of a pentose metabolism pathway in ethanologenic Zymomonas mobilis. Sci 267:240–243

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Weber, C., Farwick, A., Benisch, F. et al. Trends and challenges in the microbial production of lignocellulosic bioalcohol fuels. Appl Microbiol Biotechnol 87, 1303–1315 (2010). https://doi.org/10.1007/s00253-010-2707-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-010-2707-z