Abstract

Biofouling is the accumulation of several non-native species of organism such as algae, barnacles, and small animals. These non-native species usually grow on the surface of any material that is immersed in water for a long period of time such as a ship’s hull. The growth of this biofouling species on a ship’s hull will increase this ship’s drag and physical resistance which then leads to reduction of ship’s speed and velocities. With this being said, the fuel consumption of the ship will also increase. Various methods were introduced to control or reduce the growth of marine biofouling such as antifouling paint. An antifouling paint possesses a few characteristics which help in reducing the marine biofouling growth such as self-cleaning properties. This same characteristic can also be found in superhydrophobic materials. A superhydrophobic surface is a surface which is very difficult to get wet and can be found in natural superhydrophobic materials such as lotus leaf, taro leaf and banana leaf. This paper studies the effect of natural superhydrophobic materials mixed with paint when subjected to various types of parameters. Different types of parameters were chosen such as several types of natural superhydrophobic materials as binders, thickness of paint, underwater depth, and sun-orientation were compared and recorded over 60 days. Results of the experiment were observed and discussed. The aim of this experiment is to determine the most efficient and suitable natural superhydrophobic material between lotus leaf, taro leaf, centella leaf, banana leaf, and rose petal.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

8.1 Introduction

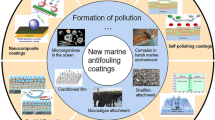

The biodiversity of species that lives in the ocean is infinite. Biofoulings consist of fewer type of non-native species such as microorganism, plants, algae, or small animals. These non-native species will start accumulating on the submerged part of the ship on the very second it contacts the water [1]. The physical resistance of the vessel will increase generated by the accumulation of the biofouling and increases the drag of the vessel. These processes increase the frictional resistance, which will lead to the reduction of the vessel speeds and velocities [2]. The weight of the vessel will increase according to the accumulation of the biofouling, which causes more fuel consumption to cover up the speed loss. In return for this action, more harmful emission will spawn and will directly connect to another environmental problems [3]. An additional consequence, a rise of dry-docking operations will occur. The methods used during dry-docking, not only take a lot of time and energy, they also release a huge amount of toxic waste [3]. The first process of biofouling is the presence of the marine biofilm. Biofilm is a group of microorganisms with made up of cells that can bind to each other and can attach to a surface, especially a ship’s hull. This biofilm is made of three major components that consist of extracellular polymeric substances (EPS), DNA, and protein. Microorganism life environment is represented by these major three components [4]. Biofilm can contain a single specie or several other microorganisms at one place together. This phenomenon usually takes place on a surface that they are attached among themselves, and they even share the nutrient among them and the birth of biofilm formation is on the very second the bacterium attached to the surface [4]. Besides all the problem from the marine biofouling, the prevention of this phenomenon also has long discovered by the Phoenicians in 1000 B.C.

Antifouling coatings are advanced paints that are applied to the hull of the ship to delay underwater marine development, which can impact the efficiency and stability of the vessels [5]. The hull coating will also serve as a shield against hull corrosion that can rust and weaken the metal, in addition to preventing marine growth. In both seawater and freshwater conditions, marine coating systems are applied to ships and offshore structures. They have the dual function of guarding against corrosion of the hull and maintaining the ships looking decent [6]. Moreover, the antifouling paints are divided into insoluble matrix paint and soluble matrix paint. The polymer matrix is insoluble in insoluble matrix paints, also referred to as touch leaching or constant contact, and did not wear down even after soaking it into the seawater. For example, using an elevated molecular weight, insoluble vinyl and acrylic are the regular polymers that were used. Right after the soluble pigments are dissolved, the organisms disperse by the film’s penetrating seawater and must pass through the interlinking pores [6]. Soluble matrix paints were produced by adding a binder that could be absorbed in seawater to prevent any degradation of antifouling quality as a result. The classical film-forming material contains strong concentrations of rosin in these methods [6]. The next one is about tributyltin self-polishing co-polymer paints (TBT-SPC). Tributyltin self-polishing co-polymer paints (TBT-SPC paints) are the most successful in mitigating biofouling on ships, among the various solutions proposed in navigation history. Controlled hydrolysis makes it possible to remove the organotin biocide from the film and hence provides an antifouling action. The partly reacting brittle polymer backbone can be quickly eroded by moving seawater and exposure to a constantly renewed bioactive surface until enough TBT molecules have been released. Unfortunately, the TBT-SPC applications have a detrimental effect on the environment [7]. The substances that have been used in antifouling paint have a lot of chemical mixture that can be harmful to the marine biodiversity. Hence, the idea of using natural Superhydrophobic materials came out.

The first of superhydrophobicity was found in the vast nature on a lotus leaf and few other plant or leaf (e.g., lotus leaf and taro leaf) which did not get wet by the water. The lotus leaf has its unique surface structure and the presence of low surface energy material which is becoming the reason of this phenomenon. The surface must have a hierarchical micro- and nano-roughness and low surface energy at the same time to implement a superhydrophobic surface or coating [8]. Air that is trapped on the surface of the lotus leaf by the hierarchical micro- and nanoscale roughness is allowing the rise of the water contact angle and low surface energy can limit water’s ability to bind with the leaf surface. The natural and exciting phenomenon of the lotus leaf has been given a special name: “the lotus effect”. Superhydrophobic surfaces show outrageously high-water repellency, where the droplet of water rain down on the surface of the leaf, rolling with a minimal force of application and bouncing if dropping from a height on the surface of the lotus leaf [8]. A huge amount of attention has been given to the incredible water repellency, superhydrophobicity of a certain plant. There are various species of plant that contain the superhydrophobic characteristic, including Nelumbo nucifera (lotus), Brassica oleracea, Colocasia esculenta, and several others, as well as the wings of butterflies and the legs of water striders. The wettability of superhydrophobic material can be evaluated based on the contact angle. Most of the superhydrophobic surface has identical contact angle of around 160°, the lotus leaves rise above any other plants in state of improved stability and perfection as water repellent. If the hydrophobic effect of superhydrophobic materials is to be dynamically assessed, the rolling angle will be considered. The rolling angle at which the liquid falls on the solid surface corresponds to the critical angle α at which the solid surface tilts as, under the influence of gravity, the liquid falls on the solid surface [9]. The applications of superhydrophobic surfaces can be divided into several different parts such as oil water separation, corrosion resistance surfaces, self-cleaning properties, anti-bacterial properties, and drag reduction [10].

8.2 Methodology

8.2.1 Procedures

This section of the paper shows and explains all the flow of this experiment, including the steps and procedures to conduct this experiment to achieve the expected outcome as shown in Fig. 8.1. The flowchart is purposely made for the reader to understand the steps for the experiment to be performed perfectly. Parameters that lead to field testing, materials used, and the selection of equipment chosen to conduct a field test are based on ASTM D3626-78a (Standard Test Method for Testing Antifouling Panels in Shallow Submergence). Sensitive data analysis was used in this experiment to gain precise data collection. The planning, preparation, data collection, and data analyzing will be shown to make the methodology complete.

8.2.2 Experimental Planning

In this section, it shows the planning of the whole experiment starting from the parameters, the equipment, and the devices or tools selection for the experiment. The material chosen for the test specimen is fiberglass. Three different materials underwent a preliminary test to determine which is one of these materials attracts the most marine biofouling growth and the result is that the fiberglass has the most percentage of marine biofouling growth. Fiberglass can be produced with fiberglass mat, catalyst, and raisin. Then, the fiberglass is dried under the sun for at least 6 h for the fiberglass to completely dry and harden.

Next, the powder of the natural superhydrophobic material as shown in Fig. 8.2 will be mixed with the Kossan marine paint as shown in Fig. 8.3 and stirred until it is fully mixed which each other. The amount of the natural superhydrophobic material was measured 10% from the volume of the paint. The painted plate will be left to dry about 8–12 h according to the paint manufacturer’s guide.

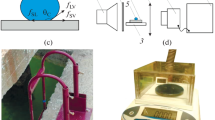

Besides that, the floating frame as shown in Fig. 8.4 is used to hang the test specimen underwater and was made from 5 cm diameter of PVC pipes. Four PVC pipes and four PVC elbows were used to connect and made the floating frame. The floating frame will be tested for floating ability and every end of the elbows will be covered with the special PVC glue.

8.2.3 Parameters of the Experiment

Parameters, also known as variables, were chosen and used for the experiment. The parameters will be described below for further understanding. Table 8.1 is the list of the parameters in this experiment.

8.2.3.1 Binders

Types of natural superhydrophobic materials that have been chosen are Lotus leaf, Taro leaf, Centella leaf, Banana leaf, and rose petal. These five mains natural superhydrophobic materials play an important rule for the experiment. All five natural superhydrophobic materials will be dried out and will be grinded until they become a powder. The powder then will be mixed with the Kossan marine paint with accurate measurement of volume.

8.2.3.2 Thickness of Paint

The mixture of Kossan marine paint with the natural superhydrophobic material will be painted with different thicknesses and will be used to evaluate the effectiveness of the mixture for a given thickness. The thickness or the layer of the paint will be based on ASTM D3623-78a and paint manufacturer guidelines.

8.2.3.3 Underwater Depth

The test specimens will undergo the immersion at various underwater depths. The justification for this action is to evaluate the efficiency of the natural superhydrophobic material at different level of depths. The depth of the immersion is also based on ASTM D3623-78a which is 1, 1.5, and 2 m.

8.2.3.4 Sun-Orientation

The immersed specimens will be placed and divided into 2 parts. One side of the test specimen will be exposed to the sunlight while the other side of the specimen will remain away from the sunlight. The purpose of adding sun-orientation in this parameter is to verify whether the presence of sunlight helps the growth of biofouling or does not have any effect for the growth of biofouling.

8.2.4 Data Table

Test specimens were evaluated and calculated for surface fouling physical condition of the paint for an interval of three days using the data table in Table 8.2.

Fouling Rating (F.R.) is the fouling presence on the test specimen which is intact during inspection. The procedure to calculation the F.R. is described in the following. Award each test specimen which is free from any biofouling a percentage rating of 100. Reduce the rating to 95 when there is any biofouling occurring. If mature forms of fouling are present, obtain the rating by subtracting from 95 the sum of the number of individuals’ present and percent surface covered by.

Antifouling rating (A.F.) is the condition of the antifouling coating and it records qualitative descriptions of the coating. The procedure to calculate the A.F. is described in the following. Award an antifouling coating test specimen having no defect a percentage rating of 100. Subtract the percent surface affected by the coating from 100 to obtain the rating of imperfect films.

Overall performance (O.P.) is the lowest percent rating of the two preceding values.

8.2.5 Method of Collecting Data

The process of collecting data in this experiment is referring to the flowchart as shown in Fig. 8.5. Total period of the immersion is 60 days, and the specimen will be taken out from the water every 3 days to calculate the marine biofouling growth on the plate. Figure 8.6 acts as the tool to calculate the marine biofouling growth on the surface of the specimen. The tool will be placed on top of the specimen and visually can calculate the bow that has marine biofouling on it. The data calculation will be following the ASTM D3623-78a which consists of the fouling rating (F.R.), antifouling rating (A.F.), and overall performance.

8.3 Results and Discussion

Over the period of 60 days, data of the test specimen were calculated and tabulated using the sensitive analysis. Then, the whole data was narrowed down to a specific target so that a graph can be easier plotted. The graph will be plotted based on the chosen parameters and will be compared between days and the overall performance. The overall performance was chosen instead of fouling rating (F.R.) and anti-fouling rating (A.F.) because it is the lowest percent rating of the two others preceding values. Most critically, each of the parameters brings out different outcome and clearly shown their effect in the plotted graph based on the growth of marine biofouling on top of the test specimens.

Figure 8.7 shows the lotus leaf as binders with 3 different layers of thickness and constant immersion depth at 2 m underwater. The specimens were all having the sunlight facing them for 60 days. Two layers of coating show the worst degradation of overall performance and one layer of coating has the least growth of marine biofouling.

Based on the graph shown in Fig. 8.8, it shows five different types of natural superhydrophobic materials as binders with 3 layers thickness of paint and constant depth of immersion which is at 2 m underwater. Cantella leaf shows the worst degradation of overall performance and lotus leaf shows the most effective binders compared to the others. Lotus leaves have the highest contact angle among others which exceeds 160°and the graph proves that lotus is the suitable binder to avoid marine biofouling growth. The result shows taro leaf, centella leaf, banana leaf, and rose petal almost have the same outcome at the end of the experiment which is all below 20%.

Figure 8.9 shows the Taro as binder with three different depths or immersion underwater with two layers of paint thickness and the specimen were facing the sunlight. 2 m depth of immersion shows the worst degradation of overall performance and 1 m depth of immersion has the least growth of marine biofouling. The result shows that, the deeper the depth of immersion, the growth of marine biofouling will increase compared to others. The graph is the evidence that 2 m of immersion attract more marine biofouling growth than 1 and 1.5 m of immersion.

Based on the graph shown in Fig. 8.10, it shows five different types of natural superhydrophobic materials as binders with 2 layers of paint thickness and a constant depth of immersion which is at 1.5 m underwater. Rose shows the worst degradation of overall performance and lotus leaf shows the most effective binders compared to the others. Based on the graph, all the binders have different effect on the marine biofouling growth and at 1.5 m of immersion the differential marine biofouling growth is not that far compared to each other especially on the last day of experiment.

Figure 8.11 shows that Rose as binder on different sun-orientation with 1 layer of paint thickness at constant depth which is 1.5 m underwater. The graph shows that the different sun-orientations have only in a slight difference. The factor that affects this result is due to the condition of the surrounding where the specimen is left. The specimen is left alongside a pontoon that might block the sun from getting in contact and affecting the specimen. Another possible factor is the sizing of the plate, the size of the plate might be too small for the sun to take effect.

8.4 Conclusion

This paper reported on the research investigations to determine the effect of five different natural superhydrophobic materials on marine biofouling growth with four types of parameters. The growth of marine biofouling can be very troublesome especially on ship’s owner and even can be dangerous to the sea ecosystem. Based on the result of the experiment, between five different binders that have been chosen, lotus leaf has proven that it is the best binder which can control and reduce the marine biofouling growth on the fiberglass compared to taro leaf, centella leaf, banana leaf, and rose petal. Next, is the thickness of paint. The mixture of marine paint with the natural superhydrophobic material with three different thickness and was used to evaluate the effectiveness of the mixture for a given thickness and the result shows inconsistencies between one layer and three layers thickness of paint. Another parameter in this experiment is the depth of immersion, the test specimens underwent the immersion at various underwater depths. The justification for this action is to evaluate the efficiency of the natural superhydrophobic material at different levels of depth. Based on the result accumulated, 2 m depth of underwater immersion has the worst degradation compared to the depth of 1 and 1.5 m. Lastly is the sun-orientation. The immersed specimens were placed and divided into two parts. One side of the test specimen was exposed to the sunlight while the other side of the specimen was remained away from the sunlight. This parameter has only small differences on the result and the parameter has also proven to have an effect on the test specimens.

The experiment is a total success as the main objective of the experiment has been achieved which is to determine whether the natural superhydrophobic material has an impact on the growth of marine biofouling. The efficiency of the natural superhydrophobic material has different result based on the different parameters that have been subjugated to them and the result from the field testing has been analyzed. This experiment has proven that natural superhydrophobic material can control and reduce marine biofouling growth on fiberglass.

References

Yebra DM, Kiil S, Dam-Johansen K (2004) Antifouling technology—past, present and future steps towards efficient and environmentally friendly antifouling coatings, In: Prog Org Coatings 50(2):75–104. https://doi.org/10.1016/j.porgcoat.2003.06.001.

Demirel YK, Uzun D, Zhang Y et al (2017) Effect of barnacle fouling on ship resistance and powering. Biofouling 33(10):819–834. https://doi.org/10.1080/08927014.2017.1373279

Alghamdi SA, Quijada R (2019) The maritime commons: digital repository of the world maritime the impact of biofouling on marine environment: a qualitative review of the current antifouling technologies. Impact Biofouling Marine Environ 91

Callow ME, Callow JA (2002) Marińe biofouling: a sticky problem. Biologist 49(1):10–14

NRL (1952) The history of the prevention of fouling. Mar Fouling Its Prev 580:211–222

Woods Hole Oceanographic Institute (1952) Characteristics of antifouling coatings. Mar Fouling Its Prev 580:313–322

Qureshi AS, Ramaswamy R (2018) Evolution of antifouling paints. Int J Sci Res 7(1):433–443. https://doi.org/10.21275/ART20179277

Darmanin T, Guittard F (2015) Superhydrophobic and superoleophobic properties in nature. Mater Today 18(5):273–285. https://doi.org/10.1016/j.mattod.2015.01.001

Barati DG, Aliofkhazraei M, Khorsand S et al (2020) Science and engineering of superhydrophobic surfaces: review of corrosion resistance, chemical and mechanical stability. Arab J Chem 13(1):1763–1802. https://doi.org/10.1016/j.arabjc.2018.01.013

Sayre N (2015) Investigation of boat hull performance with superhydrophobic coating. Mater Sci

Acknowledgements

This research is conducted as one of the requirements that must be completed by the researcher that supported by UNIKL MIMET with guidance from experts and for this, we would like to express our gratitude to anyone who was deliberately or inadvertently involved in the completion of this study. We also thank the readers for their positive feedback and helpful ideas in writing this paper

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Zoolfakar, M.R., Zahari, M.Z., Azaim, F.Z.Z. (2022). Natural Superhydrophobic Material as Alternative Substance in Antifouling Paint. In: Ismail, A., Dahalan, W.M., Öchsner, A. (eds) Advanced Materials and Engineering Technologies. Advanced Structured Materials, vol 162. Springer, Cham. https://doi.org/10.1007/978-3-030-92964-0_8

Download citation

DOI: https://doi.org/10.1007/978-3-030-92964-0_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-92963-3

Online ISBN: 978-3-030-92964-0

eBook Packages: EngineeringEngineering (R0)