Abstract

The strength of material is an important parameter of the load-bearing capacity of building structures. Therefore, an objective assessment of the strength of building structures materials is of great importance for ensuring and calculating the reliability of structures and the proper justification of design standards. The temporary resistance and other mechanical characteristics of building materials have a statistical variance, which is well described by normal law, which has been repeatedly confirmed by test data of material samples. Relevance of regular statistical studies of material strength is linked to the constant revision of design standards. Factory tests of building material strength are performed for many years on a large scale, creating a significant array of statistical information. However, there is no common information database for these data. Some of them have been published in various scientific and technical journals, collections of articles, conference proceedings. Access to these publications is difficult. The translation into electronic form has taken place only for publications published after 2000. The article contains a systematic review of publications in leading scientific and technical journals on the problem of statistical description of the strength of structural materials such as concrete, brick, mortar, brickwork, wood. The main attention is paid to the selection of statistical strength characteristics of materials of different periods, such as mathematical expectation, standard deviation (standard), coefficient of variation, etc. Statistical approach took into account the statistical variability of material strength, allowed to reasonably control the resistance, identify total reserves and compare them for different structures on a common basis. The data presented in the article are intended for use in numerical calculations of structural reliability. In addition, the evolution of design standards for building structures is analyzed in the sense of justification of normative and design resistances and the involvement of experimental statistics.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Strength of concrete

- Strength of masonry

- Strength of wood

- Temporary resistance

- Normative resistance

- Design resistance

- Coefficient of homogeneity

1 Introduction

The strength of materials is a crucial parameter of the load-bearing capacity of building structures. Therefore, an objective assessment of material strength is of great importance for ensuring and calculating the reliability of structures and the proper justification of design standards. In particular, concrete is characterized by heterogeneity and statistical variability of strength and deformation properties. They depend on such random factors as cement activity, aggregate size, manufacturing and curing technology, service life, and so on. The strength of masonry also depends on many factors. They include: strength, size and shape of the stones; strength, ease of laying and elastic–plastic qualities of the solution; masonry quality. Less important factors in the work of masonry for compression are: bandaging masonry, adhesion of the mortar to the stone, filling with mortar vertical joints. Wood is an anisotropic structural material that has a heterogeneous structure, different nature of work in different stress states. Wood of different breeds has different strength. In addition, the strength of wood is affected by the presence of defects, humidity and service life. In the presence of such numerous factors that affect the strength of materials, it is natural that the strength indicators have a certain variability, a clear idea of which is given by statistical distribution curves of different characteristics of materials. The temporary resistance and other mechanical characteristics of modern materials have a statistical variance, which is well described by normal law, which has been repeatedly confirmed by test data of material samples. Therefore, the undoubted relevance of regular statistical studies of material strength is associated with the constant revision of design standards.

The initial data of the mechanical characteristics of building materials are obtained as a result of standard acceptance tests of samples in the laboratories of enterprises of the construction industry. The main purpose of these data is to assess the quality and rejection of substandard materials and structures. In addition, statistical test results of materials are used in the preparation and revision of design standards. Statistical studies of the concrete strength unfolded in the 50s of last century in connection with the adoption of the calculation method of limit states and continued in subsequent years [1–16]. Studies of the masonry strength and its components—brick and mortar—have been conducted since the 30s, and intensified in the 80s of last century [17,18,19,20]. Statistical studies of the mechanical characteristics of wood for building structures were constantly carried out [21,22,23,24,25,26,27,28]. This problem is actively discussed by foreign experts [29,30,31,32,33,34]. Reliable statistical parameters of material strength are especially needed to assess the reliability of building structures. This is emphasized, in particular, in the publications prepared by the scientific school “Reliability of building structures” of the National University “Yuri Kondratyuk Poltava Polytechnic” [35,36,37,38,39,40].

Factory tests of material strength are performed for many years on a large scale, creating a significant array of statistical information. However, there is no common information database for these data. Some of them have been published in various scientific and technical journals, collections of articles, conference proceedings. Access to these publications is difficult, especially since some institutions have begun to destroy paper magazines in recent years, citing the transition to electronic publications. However, in reality, the translation into electronic form has so far occurred only for publications published after 2000.

The article contains a systematic review of publications in leading scientific and technical journals on the problem of statistical description of the strength of main construction materials: concrete, brick, mortars, masonry, wood. The principal attention is paid to the selection of statistical strength characteristics of materials of different periods, such as mathematical expectation, standard deviation (standard), coefficient of variation, etc. These data are intended for use in numerical calculations of structure reliability. In addition, the evolution of the design norms of structures is analyzed in terms of changes in the purpose of normative and design resistances and the involvement of experimental statistics.

2 Basic Material and Results

The content of the article is an organized review of publications of such scientific and technical journals as “Industrial and civil construction” (formerly “Construction industry” and “Industrial construction”), “Industrial construction and engineering structures”, “Construction mechanics and calculation of structures”, “University News. Construction and architecture”, “Building materials”, “Concrete and Reinforced Concrete”, “Concrete and Reinforced Concrete in Ukraine”, “Lesnoy Zhurnal”, etc. The review is compiled for the period from the 40s of the twentieth century to the present. The paper version was mainly used for journals published before 2000, which were in the scientific and technical library of the National University “Poltava Polytechnic Yuri Kondratyuk”, one of the most complete book storages in Ukraine. Information on later editions digitized from electronic libraries and electronic versions of journals.

2.1 Statistical Characteristics of Concrete Strength

The initiator of statistical studies of concrete strength was KE Tal, one of the developers of the new method of limit states, an employee of the Research Institute of Reinforced Concrete Structures (NDIZB). In one of the first publications on the parameters justification of the method of limit states, he compared the then average and defective values of concrete strength with the newly introduced design resistances (Table 1) [1].

It was emphasized that the calculation according to the new method is based on the design resistance of concrete, which is equal to the lowest probable value of resistance, and not on the allowable stresses, as it was the case with the previous norms of NiTU 3–49 “Norms and technical conditions of concrete structures”. Under production conditions, the strength of concrete was controlled by tests, but taking into account the selectivity of these tests, the defective values of concrete resistance were taken to be much higher than the design resistance (Table 1).

Then KE Tal stated that the strength of concrete has a statistical variance, which is well described by normal law [2]. Tests showed that for concrete brand 200 the average value of compressive strength in bending was 22.3 MPa, the standard 2.7 MPa with “good” quality of work (3700 samples-cubes) and 4.9 MPa with “poor” quality of work (675 samples). The coefficient of variation was 0.121 and 0.219, respectively.

In NiTU 123–55 “Norms and technical conditions for the design of concrete and reinforced concrete structures” for the normative resistance of concrete

it was taken as the average (or close to it) value of its compressive strength in bending \(\overline{\sigma }_{b}\). The design resistance was determined by providing 0.999 at a distance of three standards \(\hat{\sigma }_{b}\) from the average value. Accordingly, the theoretical value of the homogeneity coefficient, greater than one, was defined as

it was taken as the average (or close to it) value of its compressive strength in bending \(\overline{\sigma }_{b}\). The design resistance was determined by providing 0.999 at a distance of three standards \(\hat{\sigma }_{b}\) from the average value. Accordingly, the theoretical value of the homogeneity coefficient, greater than one, was defined as

Statistically substantiated homogeneity coefficients, introduced in NiTU 123–55 after some adjustment and rounding, are given in Table 2.

In Table 2, line A corresponds to the automatic or semi-automatic dosing of concrete components; line B—when there is no automatic dosing.

A similar concept of the purpose of normative and design resistances and homogeneity coefficients of concrete was implemented in the following general norms of SNiP II-A.1062 “Building structures and foundations. Basic design provisions”.

With the development of statistical substantiation of design standards of reinforced concrete structures, attention was paid not only to the average strength of concrete, but also to its variability, which is estimated by the coefficient of variation V. Statistical evaluation of this coefficient was performed on several ZBK of Moscow [3].

The results of tests on 20 technological lines were considered, 28 representative samples were composed and more than 10 thousand results were processed. The obtained statistical characteristics of concrete are given in Table 3.

The obtained coefficient of variation of concrete strength was in the range of 8.1–20.0%. It was confirmed that it depends mainly on the variability of the properties of the materials and the composition of the mixture. As can be seen from Table 3, the coefficient of variation is practically independent of the heat treatment of concrete at its stable mode. It is shown that the coefficient of variation with the set of concrete strength, as a rule, decreases due to the lag of growth of the strength standard from the increase of the average value.

In 1972, new standards were introduced in the form of SNiP II-A.1071 “Building structures and foundations. Basic design provisions”. Designing norms of reinforced concrete structures were developed under the direction of prof. A.A. Gvozdev on their basis. They reflected achievements in the field of the calculation theory of reinforced concrete for the last 12 years and were vigorously discussed in the scientific and technical periodical [4,5,6]. According to the codes of SNiP II-2175 “Concrete and reinforced concrete structures” the normative resistance of concrete was provided not less than 0.95. Therefore, it was determined by Eq. (2).

where \(\overline{R}\) is the average value of strength; \(V\)—coefficient of variation; 1.64—a factor corresponding to the security of 0.95 when applying the normal law for the concrete strength.

The design resistance of concrete on compression is now determined by dividing by the “safety factor for concrete”

. In particular, for heavy concrete, this factor was

. In particular, for heavy concrete, this factor was

, the coefficient of variation was \(V = 0.135.\)

, the coefficient of variation was \(V = 0.135.\)

This approach took into account the statistical variability of concrete strength, allowed to reasonably control the strength, identify total reserves and compare them for different structures on a common basis. Now, in industries that produce concrete with high homogeneity (low value of the variation coefficient), the average strength could be lower than the design brand with the corresponding savings in cement. On the contrary, productions with the high coefficient of variation were forced to assign an average concrete strength above the design brand [7].

It should be noted that the variation coefficient of concrete strength is accepted in the design standards equal to \(V_{b}\) = 0.135 as the average value for a large number of plants which produce reinforced concrete structures. Meanwhile, studies of technological lines at reinforced concrete plants have shown that the coefficient of variation can deviate significantly in both larger and smaller directions and is \(V_{b}\) = 0.05…0.25 (data from AS Lychev [8]). With increasing strength of concrete, its structure is compacted, which leads to increased homogeneity and reduced coefficient of variation.

This is confirmed by the data in Table 4, which shows the results of laboratory tests conducted in ODASA by MM Zastava (462 tests, 14,320 samples), adjusted for the impact of production conditions on the recommendations of AP Kudzis (Vilnius Technical University).

The statistical scatter of concrete strength significantly depends on the level of manufacturing technology and construction of structures (Table 5).

The scatter of concrete strength is significantly affected by the variability and possible inaccuracy of dosing of its components, which may be within the following limits:

-

strength of cement \(\pm \left( {6...25} \right)\)%;

-

strength of aggregates \(\pm \left( {15...50} \right)\)%;

-

cement content \(\pm \left( {5...15} \right)\) t%;

-

water content \(\pm \left( {8...23} \right)\)%;

-

content of fillers \(\pm \left( {5...10} \right)\)%;

-

moisture content in the filler \(\pm \left( {1...21} \right)\)%.

Mass statistical studies of compressive strength of concrete were performed in 1979–82 by leading research institutes—NDIZB and CNDIPromzdanii [9]. Data from 67 production lines of reinforced concrete plants of different cities were collected. In total, about 17 thousand test results of control series of samples were processed, representing 2.5 million m3 of concrete after heat treatment at the age of 18 days. This was a large-scale test of the effectiveness of the statistical strength control which was recently introduced according to GOST 18,105–80.

According to the entire study information, it was found that the average strength of concrete in 89% of cases exceeds the design strength and in 11% of cases exceeds the design strength with the provision of 95%. The average variation coefficient of strength was 0.057–0.083, ie it was more than twice less than the value of 0.135, regulated by SNiP II-21-75.

The calculation of the provision of normative concrete resistances

for the studied technological lines was performed. The average value of the safety characteristics was quite high –\(\beta = 5.25\), in all cases \(\beta > 2\). To identify the possibility of increasing the standard resistance of concrete, a safety estimate

for the studied technological lines was performed. The average value of the safety characteristics was quite high –\(\beta = 5.25\), in all cases \(\beta > 2\). To identify the possibility of increasing the standard resistance of concrete, a safety estimate

was calculated, which gave values \(\beta\) greater than 1.64 according to SNiP, for all technological lines. When assessing security

was calculated, which gave values \(\beta\) greater than 1.64 according to SNiP, for all technological lines. When assessing security

, it was found that in 17% of production lines the index \(\beta\) is less than regulated. These conclusions clearly confirm the data of Table 6, inwhich all probabilistic indicators (except one) significantly exceed the normative provision of 0.95.

, it was found that in 17% of production lines the index \(\beta\) is less than regulated. These conclusions clearly confirm the data of Table 6, inwhich all probabilistic indicators (except one) significantly exceed the normative provision of 0.95.

Although in some cases the distribution curves had a right-hand (positive) asymmetry, the strength of concrete was described by the normal law of distribution, which did not lead to significant errors.

The authors of the article [9] concluded that the obtained results open the possibility of increasing the normative and design resistances of precast concrete by 5–10% in comparison with norms SNiP. However, given that the study was conducted only at the plants of large industrial centers with a fairly high culture of production, this proposal was not included in the design standards of reinforced concrete structures. Perhaps it is now rational to return to these conclusions.

In 1986 SNiP 2.03.01–84 “Building constructions. Concrete and reinforced concrete structures” came into force, which introduced the concept of “concrete strength class “as the main indicator in the design and manufacture of reinforced concrete structures. As always when changing design standards, this transition was actively discussed in the publications of scientific and technical journals [10, 11]. Previously, in SNiP II-21-75, the strength of concrete was characterized by a brand that corresponded to the average value \(\overline{R}\) of the strength of the reference concrete cubes. Now the concrete class B was introduced, equal to the standard cube strength

with a provision of 0.95. It was determined, as in the previous edition of the rules, by Eq. (2), from which the average strength was

with a provision of 0.95. It was determined, as in the previous edition of the rules, by Eq. (2), from which the average strength was

When using the class as a characteristic of the concrete strength, the normative resistance

is set, according to which Eq. (3) determines the average value of the cubic strength \(\overline{R}\) depending on the actual coefficient of variation \(V\).

is set, according to which Eq. (3) determines the average value of the cubic strength \(\overline{R}\) depending on the actual coefficient of variation \(V\).

In the article [12] it was shown that if in Eq. (2) to substitute the normative coefficient of variation \(V = 0.135\) according to SNiP II-21-75 for heavy concrete, we obtain

Accordingly, the average strength of concrete is

A new situation has arisen when, depending on the value of the coefficient of variation, the average strength of concrete, corresponding to a certain class, can vary widely. For example, according to Eq. (3), with a variation coefficient of concrete strength of 20%, the average strength is 150% of the class. Obviously, it makes no sense to compare the brand and class by the average values of cubic strength.

The authors of the article [12] reasonably believed (and this was confirmed in practice) that the transition to concrete classes will not make significant changes in the design. At the same time for technologists it will lead to fundamental changes in the technique of appointment of standard strength at selection of concrete structure and its control on production. It is no coincidence that numerous articles published over many years have been devoted to the organization and improvement of statistical control of concrete strength in plants of reinforced concrete structures [11, 13, 14].

Publications of the 2000s summarize the long-term evolution of the rationing of the calculation of reinforced concrete structures for 70–80 years [15] and the application of the probabilistic method [16].

2.2 Statistical Characteristics of Masonry Strength

As can be seen from publications from the 1930s [17], the greatest influence on the masonry strength has the strength of stones and mortars, which have a statistical scatter.

Strength of Mortars.

Statistical studies of the mortars strength on various binders were conducted by CNDIBK in the period 1980–85 at construction companies and construction laboratories in Moscow and the Moscow region [18]. According to the norms, the mortars were distributed by compressive strength by 8 brands, the most common of them are listed in Table 7. The mortar brand \(\overline{R}\) corresponded to the average strength of the mortar after curing for 28 days. The number of tests of mortar brands was 500–8000.

Processing of test results of mortars revealed a statistical scatter of results and showed (Table 7) that for brands M50, M75 and M100 the actual strength \( \bar{R}_{\phi } \) is almost equal to the standard strength, and for brands M150 and M200—lower by 10%. The strength of mortars with a provision of 0.95 is lower than the normative by 30–40%. The coefficient of variation was obtained in the range of 18–35%. It was found that the actual strength distributions of the mortars are asymmetric and slightly different from the normal distribution. Therefore, an attempt was made to involve Pearson curves of different types. However, the difference in results compared to the normal law was insignificant. Therefore, the authors of the publication [18] concluded that it is possible to apply the normal law to describe the strength of the mortars.

The obtained statistics on the mortar strength were used to assess the strength of brickwork [20]. Based on the research, the authors proposed to replace the strength division of mortars by brands with the division by classes. The basic parameter is the strength with a provision of 0.95 (Table 7), and the main statistical characteristics are mathematical expectation and coefficient of variation.

Strength of Brick.

Statistical studies of the bricks strength (ordinary clay) were conducted by CNDIBK in the period 1980–85 years according to the data of construction laboratories in Moscow and the Moscow region [19].

According to the codes, bricks were distributed by strength by 9 brands, more common were brands M75 and M100. The brand of brick corresponded to the average compressive and tensile strength at bending (Table 8). The tests number of brick brands was 595–1915.

Processing of brick test results revealed a statistical scatter of results and showed (Table 8) that for brands M75 and M100 the actual compressive and tensile strength of the brick in bending almost meets the requirements of the norms. The strength of bricks with a provision of 0.95 is lower than the norm by 30–40%. The coefficient of variation was obtained in a fairly high range of 33.6–40.4%, which is due to the large diversity of raw materials and the instability of the technological process. It was found that the actual distributions of brick strength are asymmetric with left-handed asymmetry; they therefore differ from the normal distribution. Therefore, Pearson curves of different types were involved.

The obtained statistics on the bricks strength were used to assess the strength of brickwork [20]. On the basis of the conducted researches the author has made the offer to replace division of brick durability on brands on division on classes with maintenance of statistical control of brick durability that was not introduced in norms.

Strength of Masonry.

The combination of a large number of random factors that affect the strength of the masonry, give it a random character and the ability to study by statistical methods. The initial data for assessing the strength of masonry were obtained in 1932–1958 in the tests of many thousands of large samples of various masonry from brick, concrete stones, large blocks, rubble, ceramic stones and more. Tests were performed on different types of resistance [17]. Proposed by prof. L.I. Onishchik empirical formula allowed to determine the strength of the masonry for different combinations of its strength components:

where \(R,\,\,R_{1} ,\,\,R_{2}\)—the compressive strength of masonry, brick (stone) and mortar; \(a,b\)—empirical coefficients, which depend on the type of masonry; \(\eta\)—correction factor for masonry with a mortar of low brands.

To assess the accuracy of Eq. (4), the tests results of 747 samples of brickwork were processed. The distribution of deviations of the average breaking strength of experimental samples from the values calculated by Eq. (4) was constructed, which was well described by the normal law. The coefficient of variation of these deviations was equal to 9% taking into account the actual strength of the mortar (class of work A) and 14.7%—if the strength was determined by the composition of the mortar (class of work B) [17].

When determining the homogeneity coefficient of the masonry, the following factors were taken into account:

-

a)

the necessary provision of the design resistance of the masonry (based on the rule of “three sigma”):

-

for class of work A \(k^{\prime} = 1 - 3V_{A} = 1 - 3 \cdot 0.09 = 0.73\);

-

for class of works B \(k^{\prime} = 1 - 3V_{B} = 1 - 3 \cdot 0.147 = 0.56\);

-

-

b)

possible reduction in the quality of masonry \(k^{\prime\prime} = 0.9\);

-

c)

possible decrease in the masonry strength \(k^{\prime\prime\prime} = 0.95\).

The resulting homogeneity coefficient of the masonry was as follows:

-

for the case of class of works A \(k = 0.73 \cdot 0.9 \cdot 0.95 = 0.6\);

-

for the case of class of works B \(k = 0.56 \cdot 0.9 \cdot 0.95 = 0.48 \approx 0.5\).

At the suggestion of prof. S.A. Sementsov [17] these coefficients were taken into account in the norms of SNiP II-22-81 “Stone and reinforced stone structures” when assigning the design resistances of masonry. It should be noted that at the stage of implementation of the calculation method of limit states, the system of correction factors for the strength of masonry was considered cumbersome and difficult to use in the calculations. Therefore, the rationing of calculations of masonry, starting from the 40s of the twentieth century, did not fit into the general procedure of the method of limit states, and remained based on the calculated characteristics of strength.

In the late 80's of the twentieth century in CNDIBK under the leadership of prof. V.D. Raizer an attempt was made to translate the calculation of stone structures into the format of the method of limit states. To do this, statistical studies of the masonry strength were realized [20]. They showed that the actual average strength of brickwork is slightly higher than strength calculated by the Eq. (4) of LI Onishchik) (Table 9). This is due to the fact that the average compressive strength of the brick is greater than that required by the standard.

The largest sample of test results of M100 brickwork samples with M25 mortar was considered separately. The normative and design values of the strength of this masonry were evaluated. With a provision of 0.995, the experimental value of the masonry strength of 2.1 MPa was 1.5 times higher than the above 1.42 MPa; with a provision of 0.95, the corresponding values were 2.12 MPa and 1.7 MPa. Taking into account the correction factors included in the homogeneity coefficient, the value of the design resistance of 1.30 MPa contained in the standards was confirmed for the specified sample of material strengths.

To expand the combinations of the original components of the masonry strength VD Raizer applied statistical modeling. The test results obtained in this case differ slightly from the calculations by the Eq. (4) by LI Onishchik. The conclusion about the possibility of increasing the calculated strength of the masonry by reducing the variation coefficient of the mortar is substantiated. The general offer is made: a) to accept values with provision not less than 0.995 for design values of masonry resistance at compression taking into account the gained experience (results are in article [20]); b) to equalize the provisions of resistances and in some cases to increase them essentially (to 20%), c) to enter the normative resistance of masonry with provision of 0.95. To date, these proposals are not included in the design standards. The current norms for stone structures have no normative values of strength characteristics and give only the design values of these values.

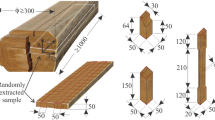

2.3 Statistical Characteristics of Wood Strength

The strength of wood is evaluated by the results of tests of small pure samples of wood (so-called “pure wood”). Some of the published generalized statistical data on the wood strength of different species of the former USSR are given in Tables 10 and 11 (humidity 12%) [21, 22].

In Tables 10 and 11 coniferous and deciduous wood species are considered as separate statistical aggregates. This allowed to significantly expand the range of studied characteristics of pure wood. Each variant represents the arithmetic mean for a number of values that characterize the species and growing area. Judging by the values of asymmetry and excess, all data sets, without exception, obey the normal distribution law. The generalized average values of wood strength were higher for deciduous species, the standard and coefficient of variation was lower for conifers that characterize the variability of wood strength. The coefficient of variation is different for different stress states of wood. The tensile strength of pure wood with average values of about 100 MPa and maximum more than 200 MPa, commensurate with some grades of steel. The average compressive strength of wood along the fibers is twice less. The average tensile strength in static bending occupies an intermediate position between tension and compression.

Statistical data of Tables 10 and 11 gave a general probabilistic picture of the wood strength and served as a basis for its rationing. It should be emphasized that the method of substantiation of normative and design resistances of wood is much more complicated than other materials. The average values of the strength of pure softwood from Table 10 were included in the norms of SNiP II-25-80 “Wooden structures” (marked as

). Normative values of the strength limit of pure wood

). Normative values of the strength limit of pure wood

, determined by the standard method at a distance of 1.64 standards from the average value, were also given. In the specified codes the average

, determined by the standard method at a distance of 1.64 standards from the average value, were also given. In the specified codes the average

and normative resistances

and normative resistances

of lumber were resulted with essential reduction taking into account influence of wood defects and the sizes of working section of wooden elements.

of lumber were resulted with essential reduction taking into account influence of wood defects and the sizes of working section of wooden elements.

The fact is that yard lumber is a qualitatively new statistical set, another material, the mechanical properties of which are determined not so much by the numerous elements of the wood microstructure, but by the presence of a large defect such as a knot, all characteristics of which are very different from pure wood. Therefore, the variability of lumber is higher than that of pure samples, as the presence of defects adds additional variance to the results. It is noteworthy that the absolute values of tensile strength of lumber along the fibers are 2–4 times lower than strength of small samples. The compressive strength of pine and spruce lumber along the fibers is approximately the same and twice less than strength of small pure samples [23].

For the transition to the design resistance, the coefficient of long-term resistance of wood \(m_{mp}\) and the coefficient of reliability \(\gamma = {{\left( {1 - \beta_{n} V} \right)} \mathord{\left/ {\vphantom {{\left( {1 - \beta_{n} V} \right)} {\left( {1 - \beta V} \right)}}} \right. \kern-\nulldelimiterspace} {\left( {1 - \beta V} \right)}}\) were introduced, where \(\beta_{n}\) = 1.64 is the coefficient (safety characteristic), which corresponds to the provision of 0.95 of the normative resistance; \(\beta = 2,33\)—coefficient that took into account the provision of 0.99 of the design resistance. Let us illustrate these transformations with the example of the tensile strength of softwood along the fibers: pure wood—average value

, normative value

, normative value

; 1st grade lumber—average value

; 1st grade lumber—average value

, normative value

, normative value

; stretched elements of the 1st grade—design resistance \(R_{p}\) = 10 MPa. Thus, the design resistance of lumber was much less than the initial strength of small pure samples. In addition, the design resistance is adjusted by a number of lowering coefficients, taking into account the operating conditions and features of the structures.

; stretched elements of the 1st grade—design resistance \(R_{p}\) = 10 MPa. Thus, the design resistance of lumber was much less than the initial strength of small pure samples. In addition, the design resistance is adjusted by a number of lowering coefficients, taking into account the operating conditions and features of the structures.

The strength characteristics of wood are influenced by numerous factors, including growth conditions and the actual age of the trees from which the structural wood is obtained. In this regard, it is interesting to compare the strength characteristics of softwoods belonging to different construction periods—the nineteenth century. (“old” wood) and the late twentieth century (“new” wood)—on the example of pine wood of the Arkhangelsk region, one of the main forestry regions of the European part of Russia [24]. For this purpose, during the restoration of wooden architecture objects, the specialists of the Moscow State University (MSU) selected samples of structural “old” and “new” wood aged 75 and 110 years. The test results of the obtained samples of pure wood, processed by statistical methods, are given in Table 12.

Experimentally obtained average and normative resistances of wood of different ages for compression and bending are illustrated, which are compared with each other and with resistances according to SNiP II-25-80. Note that for the “new” wood, the coefficients of variation of compressive and bending resistances are 7.7% and 12–14%, respectively.

As can be seen from Table 12, in all cases, the strength of wood of the XIX century which aged 75 and 110 years is more than 1.00–1.31 times the strength of modern wood of the appropriate age. Obtained as a result of tests of small samples of pure wood and subsequent statistical processing, the normative resistance of compression along the fibers is more than established by current standards: for wood under 75 years—by 7 and 25%, for wood under 110 years—by 32 and 45% for modern wood and wood of the XIX century respectively. Normative bending resistances of modern wood and wood of the XIX century are more than the resistances established by norms for wood up to 75% of age—by 1%; for wood up to 110%—by 22 and 42% respectively. This shows that wood belonging to the construction periods of the nineteenth century and present, can be used as a structural building material.

Some authors believe that the parameters of defects do not fully characterize the strength and deformability of structural lumber, and in this aspect a statistical approach may be promising [25]. As an argument for the statistical assessment of the strength of the beams proposed defect index \(V\)%—the relative total volume of knots of the fracture site—which is defined as the ratio of the sum of the volumes of knots located on the beam length equal to the width of the beam to the volume of this sample. To obtain the initial data, tests were performed on samples of spruce wood of the 1st grade and pine of the 2nd grade, the results are given in Table 13.

Statistical indicators of wood strength of the tested samples of spruce and pine, as in previous tests (Tables 10, 11 and 12), correspond to the values of normative and temporary resistances of SNiP II-25-80. The values of the new indicator of wood defects are of the following order: 1st grade—average value \(\overline{V} \approx 3\)%, standard \(\hat{V}\) \(\approx\) 2%; 2nd grade—average value \(\overline{V} \approx 8\)%, standard \(\hat{V}\)\(\approx\) 5%. The correlation analysis revealed a linear decrease in wood strength with increasing V at a correlation coefficient \(\rho\) = 0.5–0.7.

As shown above, in all tests, the strength characteristics of wood were well described by the normal distribution law. But it should be noted that the initial distributions of the limit strength of whip wood deteriorate with prolonged storage of raw materials in stacks in warehouses, in interoperable stocks after dimensional sorting of logs, in drying stacks and stacks of finished products. Therefore, the limit strength distribution of lumber can take the form of the sum of four normal distributions with their arithmetic means and standard deviations [26].

In modern design standards DBN B.2.6–161: 2017 “Wooden structures. Basic provisions” wood is divided into strength classes separately for coniferous and deciduous species depending on the characteristic values of strength, stiffness and density. The designations of the classes coincide with the characteristic bending strength of wood, expressed in N/mm2.

In parallel with the development of probabilistic substantiation of the parameters of the method of calculation of wooden structures by limit states, the calculation of reliability of such structures was developed, and the lognormal distribution law was used to describe the strength of wood [27, 28].

3 Conclusions

A systematic review of work is carried out on the problem of statistical description of the strength of building materials. Structural materials such as concrete, brick, mortar, brickwork, wood are considered. The main attention is paid to the statistical characteristics of the materials strength of different periods, such as mathematical expectation, standard deviation, coefficient of variation, etc. These data are intended for use in numerical calculations of reliability of structures. The evolution of design norms of building structures is analyzed in the part of changes of purpose and provision of normative and design resistances and utilization of experimental statistical data.

References

Tal KE (1956) Some questions of the calculation of reinforced concrete structures according to new standards. Concr Reinforced Concr 4:139–142

Tal KE (1961) On the reserve factors in reinforced concrete structures. In: Materials of the International meeting on the calculation of building structures (Moscow, December 1958), pp 60–70. Gosstroyizdat, Moscow

Khayutin YuG, Kozlov ED (1970) On the strength of concrete under different modes of hardening. Concr Reinforced Concr 12:20–21

Gvozdev AA, Dmitriev SA, Lessig NN (1971) On the structure and general provisions of new standards for design of structures. Concr Reinforced Concr 5:1–4

Tal KE (1971) Normative and design characteristics of concrete. Concr Reinforced Concr 5:4–6

Sychev VI (1976) On the design standards for concrete and reinforced concrete structures. Concr Reinforced Concr 6:2–5

Yashin AV (1976) On new requirements for the standardization of the basic design characteristics of concrete. Concr Reinforced Concr 6:12–14

Lychev AS (2001) Statistical information for calculating the reliability of elements of building systems. Univ News Constr 5(509):17–20

Sapozhnikov NYa, Berdichevsky GI, Brusser MI (1983) Statistical analysis of the strength of concrete at the age of 28 days (according to factory tests). Concr Reinforced Concr 5:27–29

Tal KE (1977) On the improvement of standardized methods for calculating of reinforced concrete structures. Concr Reinforced Concr 5:20–21

Gvozdev AA, Krakovsky MB, Brusser MI, Igoshev VL, Dorer VA (1985) Relationship of statistical control of concrete strength with the reliability of reinforced concrete structures. Concr Reinforced Concr 3:37–38

Gushcha YuP, Brusser MI, Krakovsky MB, Serykh RL, Skubko VM (1985) On the transition from grades to concrete strength classes. Concr Reinforced Concr 10:39–40

Ratz EG (1968) Statistical control of concrete strength in reinforced concrete factories. Concr Reinforced Concr 10:5–10

Danilenko EL, Sadovich MA (1975) Statistical control and quality management of concrete. Concr Reinforced Concr 1:35–37

Zvezdov AI, Zalesov AS, Mukhamediev TA, Chistyakov EA (2002) 75th Anniversary of the Design Standards of concrete and reinforced concrete structures. Ind Civil Constr 9:10–15

Rastorguev BS, Vanus DS (2016) Calculation of reinforced concrete structures for limit states using the probabilistic method. Ind Civil Constr 7:11–15

Sementsov SA (1961) Modern methods of stone structures calculating in the USSR. In: Materials of the International meeting on the calculation of building structures (Moscow, December 1958), pp 234–248. Gosstroyizdat, Moscow

Raizer VD, Kruchinin NN (1988) On the normalization of the mortars strength. Struct Mech Struct Calc 4:50–53

Kruchinin NN (1987) On the statistical assessment of brick strength. Struct Mech Struct Calc 3:59–63

Raizer VD, Kruchinin NN (1990) To standardizing of the bearing capacity of masonry. Struct Mech Struct Calc 2:80–86

Ryumina EB, Uspenskaya GB (1992) Confidence level of standardized strength indicators of structural sawn timber. Lesnoy Zhurnal (Russ Forestry J) 2:81–86

GSSD 69–84 (1985) Standard reference data tables. Wood. Indicators of physical and mechanical properties of small clean samples. Publishing House of Standards, Moscow

Tuturin SV (2004) Mechanical strength of wood. Phys Mesomech 7(6):85–88

Linkov NV (2018) To the issue of comparing the physico-mechanical characteristics of structural timber of the XIX and XX centuries. Ind Civil Eng 1:58–62

Byzov VE (2016) Melekhov VI (2016) Structural sawn timber: resource enhancement. Mag C.E. 65(5):67–76

Dounaev VF (2014) Variability of young’s modulus and wood tensile strength in the work cycle. Lesnoy Zhurnal (Russ Forestry J) 3:106–113

Gromatsky VA, Turkovsky SB, Filimonov MA (2011) On the assessment of the reliability of wooden structure elements. Struct Mech Struct Calc 6:22–25

Denesh ND, Sukhov DYu, Andreev OO (1988) On the use of the lognormal load distribution law in assessing the reliability of wooden structures. Struct Mech Struct Calc 4:8–9

Mirza SA, Mac Gregor JG, Hatzinikovas M (1979) Statistical description of strength of concrete. J Struct Div 6(105):1021–1037

Indelicato F (1999) In-place compressive strength of concrete: statistical methods to evaluate experimental data. Mater Struct 32:394–399

Kausay T, Simon T (2007) Acceptance of concrete compressive strength. Concr Struct (Ann J Hung Group fib Budapest) 8:54–63

Kabantsev O (2015) Modeling nonlinear deformation and destruction masonry under biaxial stresses. Part 1. Masonry as simulation object. Appl Mech Mater 725–726:681–696

Grishchenko AI, Semenov AS, Semenov SG, Melnikov BE (2014) Influence of structural parameters of the masonry on effective elastic properties and strength. Mag Civil Eng 5(49):95–106

Foschi RO, Folz BR, Yao FZ (1989) Reliability-based design of wood structures. Structural research series. Rep No 34 Dep of Civil Eng, Univ of British Columbia, Vancouver, Canada

Perelmuter AV, Pichugin SF (2017) On one safety characteristic of buildings. J Civil Eng Arch Res 5(4):2035–2044

Pichugin SF (2018) Reliability estimation of industrial building structures. Mag Civil Eng 83(7):24–37

Pichugin SF (2019) Scientific school«reliability of building structures»: new results and perspectives. Acad J Ser Ind Mach Build Civil Eng 2(53):5–12

Pichugin S (2017) Probabilistic description of ground snow loads for Ukraine. In: Snow engineering 2000: Recent advances and developments, pp 251–256. https://doi.org/10.1201/9780203739532

Pichugin SF, Makhin’Ko AV (2009) Calculation of the reliability of steel underground pipelines. Strength Mater 41(5):541–547. https://doi.org/10.1007/s11223-009-9153-0

Pichugin S, Severin V (2004). Reliability of structures under snow load in ukraine. In: Snow engineering, pp 67–72

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Pichugin, S. (2022). Statistical Strength Characteristics of Building Structures Materials. In: Onyshchenko, V., Mammadova, G., Sivitska, S., Gasimov, A. (eds) Proceedings of the 3rd International Conference on Building Innovations. ICBI 2020. Lecture Notes in Civil Engineering, vol 181. Springer, Cham. https://doi.org/10.1007/978-3-030-85043-2_30

Download citation

DOI: https://doi.org/10.1007/978-3-030-85043-2_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-85042-5

Online ISBN: 978-3-030-85043-2

eBook Packages: EngineeringEngineering (R0)