Abstract

Different types of nanomaterials and different strategies could be used in the betterment of the overstressed agriculture. We have tried to focus on the different characterisation techniques involved in nanomaterial synthesis like UV-Vis spectroscopy, scanning electron microscopy (SEM), X-ray diffraction (XRD), transmission electron microscopy (TEM), atomic force microscopy (AFM) and Fourier transform infrared spectroscopy (FTIR). Further, the limitations of physical and chemical methods have also been discussed. We have talked about the organic strategies in detail, like microorganisms and plant-intervened biosynthesis of nanomaterials.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

6.1 Introduction

Nanotechnology is the link between physical and biological sciences. The plan and improvement of nanomaterials result from information on material designing and its exercises, explored by knowing natural science (Majeed et al., 2020). The rapidly growing field of nanotechnology is the interdisciplinary research and developmental field in physics, chemistry and biology. It explores the design, manufacture, assemblage and characterisation of materials that are more modest than 100 nanometres in size, just as the utilisation of scaled-down useful frameworks got from these materials (Nadaroglu et al., 2017). Nanotechnology has expected a colossal part in the agriculture industry, named nano-agribusiness, which infers that this advancement is regularly used to fabricate the yield (Duhan et al., 2017). Metal nanoparticles pulled in scientists due to their wide application and advances in various zones (Herlekar et al., 2014; Zhang et al., 2018). The main drawback of conventional methods is their environmental toxicity; therefore, the requirement for alternatives is increasing faster (Kaur et al., 2014). The nanoparticles synthesised through plants is a straightforward and eco-friendly approach to reduce toxicity, time and cost. There are various assessments subjected to plant-interceded biosynthesis of nanoparticles (Gupta et al., 2018), e.g. TiO2 NPs impel spinach seed germination and plant improvement (Zheng et al., 2005), and ZnO nanoparticles significantly improve the transport and metabolic processes in plants (Jayarambabu et al., 2014). Similarly, Ag NPs obtained from neem (A. indica), dark tulsi (Ocimum tenuiflorum) and banana (Musa balbisiana) applied on mung bean (Vigna transmit) demonstrate a fundamental augmentation in shoot and root lengths (Banerjee et al., 2014). In this chapter, the main focus has been on collecting studies focused on plant-mediated nanomaterial synthesis and its essential function in agriculture.

6.2 Types of Different Nanoparticles (NPs)

The NPs can be categorised into different types:

-

(i)

Inorganic-based nanomaterials.

-

(ii)

Organic-based nanomaterials.

-

(iii)

Carbon-based nanomaterials.

-

(iv)

Composite-based nanomaterials.

6.2.1 Inorganic-Based Nanomaterials

The inorganic NMs consist of metal oxide and metal NPs. The metallic nanoparticles include Ag, Zn, Au, etc., while the metal oxide nanomaterials include TiO2 and ZnO and semiconductors like ceramics and silicon.

6.2.2 Organic-Based Nanomaterials

These nanomaterials are made mainly from organic matter. The use of weak interactions (noncovalent) for design and molecular self-assemblage helps in turning organic NMs into structures such as liposomes, polymer, dendrimers and desired micelle NPs (Jaison et al., 2018).

6.2.3 Carbon-Based Nanomaterials

These NMs are found in different morphologies like hollow tubes, spheres or ellipsoids and contain carbon. The carbon-based NMs include MXene, carbon nanotubes (CNTs), graphene, fullerenes, carbon nanofibers and carbon black (C60). The methods for the preparation of carbon-based nanomaterials include laser ablation, chemical vapour deposition (CVD) and arc discharge (Kumar & Kumbhat, 2016; Paul et al., 2020; Syamsai & Grace, 2020).

6.2.4 Composite-Based Nanomaterials

Composite-based NMS are materials with at least one of the phases in the nanometre range. They comprise an assemblage of two materials of different types, allowing us to obtain a material of greater quality. Composite-based nanomaterials are a combination of carbon, organic or metal nanomaterials and some forms of polymer bulk, metal or ceramic materials (Jaison et al., 2018).

6.3 Techniques for the Readiness of Nanoparticles

Nanomaterials can be blended top-down and bottom-up methodologies, which are additionally partitioned into various strategies.

6.3.1 Top-Down Approach

This method involves the destruction of bulk materials into smaller molecules, which are later converted into NMs. Physical vapour deposition, milling or grinding are a few examples of the top-down approach.

6.3.2 Bottom-Up Approach

The bottom-up approach is a type of constructive strategy, opposite to that of the top-down approach. In this approach, NMs are obtained through simpler substances. Some examples of the bottom-up approach include sol-gel, pyrolysis and biological synthesis (Yadav et al., 2009).

6.4 Methods of Nanoparticle Production

6.4.1 Physical Methods

Physical methods for NM synthesis employ mechanical strain, high-energy radiations, electrical energy or thermal energy that leads materials to evaporation, condensation, abrasion or melting to produce nanoparticles. Based on physical procedures for NM preparation, they are usually divided into the following types:

6.4.1.1 Mechanical Attrition

Mechanical methods employ the technique of mechanical alloying that gained huge attention over a long time to manufacture various kinds of nanomaterials. Mechanical alloying is considered one of the novel techniques that can be carried out at room temperature. The strategy includes completed force plants, diffusive plants and vibratory industrial facilities (Dhand et al., 2015).

6.4.1.2 Condensation of Inert Gas

It is based on the application of inert gases like helium or argon and sometimes liquid nitrogen on the substrate to synthesise nanomaterials. The nanomaterials, after being evaporated, are transported along with the inert gases over the substrate, which gets condensed with liquid nitrogen. This method was first used by Ward et al. (2006) for the amalgamation of Mn nanomaterials.

6.4.1.3 Physical Vapour Deposition

The physical vapour deposition process is a group of techniques that are widely utilised for nanomaterial synthesis. They help in the formation of thin layers of nanomaterials of a few nanometres. Physical vapour deposition methods are environmentally safe and include three basic steps: vaporisation of materials, transport of vaporised materials and their nucleation to grow them into thin fibres.

6.4.2 Chemical Methods

These are the methods using certain chemical elements for the synthesis of nanomaterials. Different specialist substances like sodium borohydride, hydrazine and hydrogen are utilised for the synthesis (Egorova & Revina, 2000). In light of nanomaterials’ compound union, they can also be isolated into two principle types: (i) gas-phase synthesis and (ii) liquid-phase synthesis.

6.4.3 Gas-Phase Synthesis

Gas-phase synthesis is a type of bottom-up approach of nanomaterial synthesis, and among this type of synthesis, gas pyrolysis and gas condensation are the most common types. In gas pyrolysis, the aerosol droplets resulting from metal salt are formed by flame heating. Droplets disperse in the gas, and dehydration decreases their size. Another method is gas condensation, which involves the evaporation of metal salts inside the chamber by different heat sources like laser beams, electron or radio frequencies, etc. The vapours are being pushed into the cooler chamber consisting of inert gases and after that collected from the chamber. The major drawback associated with this method is the agglomeration and amalgamates of nanomaterials (Naveed Ul Haq et al., 2017).

6.4.4 Liquid-Phase Synthesis

It is one of the precipitation methods in which inorganic alkalis act as reducing agents and is reacting with the metal salts to form an insoluble or soluble precipitated product. The product is washed and calcinated at a suitable temperature to produce a particular nanomaterial with variable morphology. With this method, the size can be tailored by optimising synthetic conditions. The liquid-phase synthesis can be divided into different types like sol-gel synthesis and colloidal, hydrothermal and solvothermal methods (Rai et al., 2013). Figure 6.1 shows the different physical and substance systems for nanomaterial synthesis.

6.5 Limitations of Chemical and Physical Methods

Though nanomaterials’ physical and chemical syntheses are popular, they are also associated with a large number of risks. Using physical methods, we may obtain nanomaterials of high purity, but they typically require refined equipment, chemical materials, radiations and high energy consumption, leading to high operating costs. Again, the chemical synthesis generates many toxic chemicals that are non-biodegradable and harmful and can restrict the manufacturing process. In addition, certain toxic materials may contaminate the surface of nanomaterials and make them unsuitable for different applications. In this context the researcher’s main focus is to formulate the alternate route for nanomaterial synthesis to defeat the restrictions of substances and actual strategies (Khandel et al., 2018).

6.6 Characterisation of Nanomaterials

Nanomaterials are characterised by different methods, including UV-Vis spectroscopy, X-ray diffraction (XRD), transmission electron microscopy (TEM), atomic force microscopy (AFM), scanning electron microscopy (SEM) and Fourier transmission infrared spectroscopy (FTIR).

6.6.1 UV-vis Spectroscopy

This is the most straightforward technique used to check the construction of nanoparticles. Different nanoparticles show different peaks, which confirm the structure of NPs in the aqueous medium. The UV-Vis spectroscopy works based on the intensity of light. It detects, analyses and investigates the nanomaterials’ optical properties. This method is usually used to check the particles’ distribution size (Rajasekaran & Raghavan, 2020; Velappan et al., 2020).

6.6.2 Scanning Electron Microscopy (SEM)

The SEM is one of the versatile techniques used to check the texture, morphology and size of nanoparticles. In this technique, electrons are used instead of light to scan the specimen surface to generate various signals, which give detailed information about the interaction, nature, composition and structure of materials (Raghavan et al., 2020; Sitaaraman et al., 2020).

6.6.3 X-Ray Diffraction (XRD)

The XRD is another technique for nanomaterial characterisation. It gives detailed information about the crystalline structure, crystalline size and lattice parameter of materials. However, this technique only uses the dried powder samples for characterisation. The data obtained from XRD analysis is compared with reference patterns from the Joint Committee on Powder Standards (JCPDS) (Krupa et al., 2019; Mourdikoudis et al., 2018).

6.6.4 Transmission Electron Microscopy (TEM)

Transmission electron microscopy is another quantitative technique used to characterise the morphology and homogeneity of nanomaterials. TEM gives the actual size of nanomaterials and accurate images of the nanoparticles. In TEM the uniform electron beam touches the samples and diffuses through them. The formation of images by TEM analysis is due to the interaction of samples with an electron, wherein the imaging device further magnifies the samples. We can get the maximum resolution through TEM than other characterisation techniques. The information about size, structure, shape, morphology and agglomeration is only possible through this technique (Chakravorty et al., 2020).

6.6.5 Fourier Transmission Infrared Spectroscopy (FTIR)

It is one of the analytical techniques used to study the different kinds of practical gatherings present in the biomolecules. During nanomaterials, the functional groups that act as capping and reducing agents are studied through this technique. It gives information about the molecular structure, nature of bonds and the functional groups involved in nanomaterial biosynthesis. It works on an electromagnetic absorption spectrum and wavelength ranging from 400 to 4000 cm−1 (Busó-Rogero et al., 2016).

6.6.6 Atomic Force Microscopy

Atomic force microscopy is one of the microscopic techniques that can produce three-dimensional pictures of the sample surfaces. The basic principle of atomic force microscopy is the interaction of forces involved between samples and fine probe. AFM gives the detailed size, shape and surface area of nanomaterials.

6.7 Biological Synthesis of Nanomaterials

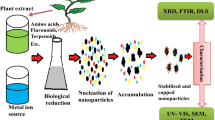

The biological process of nanomaterial synthesis is the alternative to the physical and chemical methods (Fig. 6.2). It is a cheap, non-toxic, environmentally friendly option of nanomaterial synthesis compared to its physical and chemical counterparts. Nanomaterials with different sizes and shapes can be prepared through biological synthesis (Shah et al., 2015). The synthesis of nanomaterial through biological routes leads to safer, ecologically appropriate and non-toxic nanomaterial through the involvement of bacteria, fungi and plants (Nayantara & Kaur, 2018).

6.7.1 Bacteria-Mediated Biosynthesis of Nanomaterials

Research has been heavily based on prokaryotes as the easy and ideal ways to synthesise different nanoparticles. Because of their ability to adjust to extreme conditions and their abundance in the environment, microbes are decent contenders in nano-research. They can be handily controlled as they are fast-growing and inexpensive to cultivate in large quantities. Their growth conditions, including oxygen, incubation and temperature, can be easily monitored, and controlling such parameters can produce nanoparticles of different sizes (Pantidos & Horsfall, 2014). Different strains of bacteria like yeast, moulds and microalgae have been utilised to integrate metallic and non-metallic nanoparticles (Hulkoti & Taranath, 2014). Different types of nanomaterials like gold, silver and selenium with different properties and different purposes like imaging, biosensors, in vitro antibacterial, anticancer, antioxidant and anticoagulant activities have been synthesised from bacteria over time (Grasso et al., 2019). Bacillus species have been widely considered because of their ability to bioaccumulate metals (Pantidos & Horsfall, 2014). Microbe-intervened amalgamation of nanomaterials can be classified into intracellular or extracellular by the guide of chemicals or proteins present in microorganisms which can go about as lessening specialists and convert metal salts into specific nanomaterials (Nadaroglu et al., 2017). Different bacteria like Pseudomonas stutzeri, Pseudomonas aeruginosa, Escherichia coli and Vibrio cholera have been utilised to combine diverse metallic nanoparticles through intracellular and extracellular strategies (Nayantara & Kaur, 2018; Srinath & Ravishankar Rai, 2015). Extracellular is the simplest method as it occurs outside the bacterial cells and does not involve the breakdown of the cell wall. It includes the usage of bacterial biomass, supernatant and cell-free extracts. The extracellular synthesis is preferred over intracellular synthesis as it does not involve complex downstream processes. The main challenge in microbe-based nanomaterials is the selection of choosing the right microbe, depending on its essential properties like replication, growth rate and biochemical pathways to be studied. Another aspect of microbe-interceded nanomaterials is reducing the temperature, which can control their size and mono dispersion (Ovais et al., 2018).

6.7.2 Fungal-Mediated Nanomaterials

Fungi have a great potential for the manufacture of different nanomaterials; around 6400 bioactive substances have been separated from the filamentous organisms and their connected species. Because of the substantial metal resilience and ability to disguise and bio-gather metals, organisms go about as significant balancing out and decreasing specialists. In addition, fungi can be quickly grown on a large scale and can produce size-controlled nanomaterials with definite morphologies (Guilger-Casagrande & de Lima, 2019). Fungus is a great contender for nanomaterial synthesis as it goes about as apparatus for a huge amount of proteins and quick and simple combination of nanomaterials (Alghuthaymi et al., 2015). The extracellular enzymes produced by several fungi are considered to play an essential role in nanomaterial biosynthesis. The enzymes include cellobiohydrolase D, glucosidase, acetyl xylan esterase and β-glucosidase. The enzyme nitrate reductase, released by fungi, acts as a reducing agent in nanomaterial production. Silver and gold nanoparticles have been produced from Fusarium oxysporum (Ovais et al., 2018).

Similarly, Duggingyonia flagans are used to synthesise silver nanoparticles by using insect carapaces as a source of substrate for fungi (Costa Silva et al., 2017). A. alternata can be used to synthesise silver nanoparticles (Ibrahim & Hassan, 2016). The microbial-assisted synthesis of nanomaterials has been found to be very easily scalable, co-friendly and consistent. Still, the production is more expensive because of extended time maintenance of cultures, and chances of contamination are very high. Moreover, microbial-based techniques require high aseptic conditions and maintenance that are not appropriate for nanomaterials’ large-scale production, so plant-based nanomaterial production is preferred over microbial-based. The key advantage of bio-based methods over physical and chemical methods is that large-scale nanomaterials involve environmentally friendly, simple and one-step processes rather than chemicals, high temperature and pressure (Khandel et al., 2018).

6.7.3 Plant-Based Nanomaterials

Plants are the bio-factories for many active compounds like flavonoids, terpenes, alkaloids, enzymes and proteins, acting as capping and balancing out specialists for the nanomaterial synthesis (Fig. 6.3). The mechanism of nanoparticle synthesis from plants is the same as that of microbial synthesis, but it’s cheap, less costly and environmentally friendly (Khandel et al., 2018). Different parts of plants like leaves, roots, stem, bark, shoots, latex, seeds, peels, oils, natural products and so on can be utilised for the nanomaterial combination, as they can go about as great wellsprings of phytochemicals (Dauthal & Mukhopadhyay, 2016). Diverse metal oxide nanoparticles have been set up through a green approach. Zinc oxide nanoparticles use different plant extracts like Cassia alata, Bauhinia tomentosa and Catharanthus roseus (Happy et al., 2019; Gupta et al., 2018; Sharmila et al., 2018). Spherical-shaped nanoparticles were synthesised from various plant parts like A. calamus roots and A. dentata leaves (Kumar et al., 2014; Nakkala et al., 2014). Different types of plants like clove buds, cardamom, black pepper and saffron have been used for various types of nanomaterial synthesis (Chakravorty et al., 2020).

Plant-based selenium nanoparticles (SeNPS) have been carried out using different plant extracts like Citrus reticulate , Catharanthus roseus, Leucas lavandulifolia, Allium sativum, Aloe vera and Asteriscus graveolens (Anu et al., 2017; Deepa & Ganesan, 2015; Fardsadegh & Jafarizadeh, 2019; Kirupagaran et al., 2016; Sasidharan et al., 2014; Zeebaree et al., 2020). Euphrasia officinalis leaf extract mediated biosynthesis of gold nanoparticles (AuNPs) and silver nanoparticles (AgNPs) (Singh et al., 2018), and Ziziphus leaf extract mediated gold nanoparticles (Aljabali et al., 2018). Indigofera tinctoria leaf extract mediated silver (AgNPs), and gold nanoparticles (AuNPs) are a major highlight of the plant-based nanomaterials (Vijayan et al., 2018).

6.8 The Role of Nanoparticles in Agriculture

Human beings obtain their food directly or indirectly from the agriculture sector and keep in view the overgrowing world population. It is imperative to use new technologies like bio- and nanotechnology in the agricultural industry. In developing countries, the development of agribusiness is seen as a context for development. The field of nanotechnology has not just improved current horticultural practices by making them more secure, specialised and powerless yet, in addition, raised the nature of farming items by making them exceptionally nutritious and infection safe. The use of nanotechnology in horticulture has helped create work openings, new rural items, stockpiling/bundling techniques and the longer timeframe of realistic usability and, in a manner, has also improved the nature of water. The field of nanotechnology can improve the production and quality of food. A report published by Wheeler (2005) suggested that modern techniques can meet growing food demands and boost health, economic and environmental sectors as well. Lately, the significance of nanotechnology in the farming area has been acknowledged, although its examination started some 50 years back (Mukhopadhyay, 2014). In developing countries, more than 60% of the people earn their livelihood directly or indirectly from agriculture, thus acting as a backbone of their economy (b; Brock et al., 2011; Qamar et al., 2014; Rai & Ingle, 2012a). In the rural area, nanotechnology has arisen as one of the best basic instruments, and soon, it might turn into an anticipated thrust. To improve crop productivity, nanotechnology employs different approaches that involve the use of novel delivery systems and chemical agents posing a lesser threat to the welfare of living beings. Nanotechnology offers answers for the current issues in farming regions and gives trust in improving yield efficiency by better administration and protection programmes. Due to the extraordinary physicochemical properties of nanoparticles, nanotechnology offers incredible breadth to fulfil the food needs of the rising total populace. These nanoparticles control a broad scope of utilisations, essentially their utilisation in treating human sicknesses and in the agricultural area. In the rural area, nanoparticles have different applications as depicted in Fig. 6.4.

However, the most important aim of nanomaterials that is of a greater significance is to improve crop productivity and plant protection as discussed below.

6.8.1 Crop Productivity

Nanomaterials have been utilised to improve crop profitability and effectiveness. In the agricultural sector, a new strategy based on nanoparticle use has been commonly employed to address crop yield and efficiency problems. For supportable farming, nanotechnology can expand world food production, improve the nature of foods, screen plant development, distinguish sicknesses of plants/animals and give insurance to plants and capacity to decrease squanders (Biswal et al., 2012; Ditta, 2012; Frewer et al., 2011; Gruere et al., 2011; Perez-de-Luque & Hermosín, 2013; Prasad et al., 2014; Sonkaria et al., 2012). The plants hereditarily incited by nanomaterial-based substances can assume a vital part in expanding agrarian efficiency (Kuzma, 2006; Scott, 2007). In plants and animals at cellular/molecular levels, the induction of molecules by gene delivery, site-specific drug delivery and nano-array-based gene modifications have been used (Maysinger, 2007). The factors that determine nanoparticle efficiency include size, chemical composition, reactivity and surface area. On plant development and improvement, nanoparticles may display both positive and negative impacts. A study on tomato seeds (Khodakovskaya et al., 2009) reported that the inserted carbon nanotubes (CNTs) increased their germination efficiency multiple times because CNTs improved the capacity of water take-up (Khodakovskaya et al., 2009). The growth of spinach increased with the use of TiO2 nanoparticles, which enhanced the activity of the Rubisco enzyme and improved the absorbance of light (Hong et al., 2005; Yang et al., 2006). It was found that Tio2 nanoparticles enhanced nitrogen metabolism, which ultimately improved spinach growth (Yang et al., 2007). A study reported by DeRosa et al. (2010) found that in corn and ryegrass, seed germination was inhibited by ZnO nanoparticles. The use of ZnO-based nanomaterial left some porous spaces in the roots of these plants, thus creating a potential route for nutrient delivery systems.

Other nanoparticles that have been discovered to be significant for plant development and advancement are listed in Table 6.1.

6.8.2 Plant Protection

In addition to enhancing crop productivity, nanoparticles are also known to protect plants from various diseases. Several approaches have been used to manage crop diseases, particularly genetic breeding, sanitation schemes, new pesticides and integrated pest management. New insights have been provided by nanotechnology for improving and modifying present crop management methods. Techniques such as spraying and broadcasting are conventionally used for applying plant protection chemicals and nutrients. However, the minimum required amounts of chemicals/nutrients do not reach the target site because of leaching, hydrolysis and microbial degradation. The conventional methods of crop protection generally involved the use of large-scale herbicides, insecticides and fungicides. Over 90% of the pesticides used for pest control were either lost in the environment or were unable to reach the target sites (Nuruzzaman et al., 2016). The utilisation of pesticides expanded the cost expenses and caused degradation of the general climate. In this regard, a better initiative that was needed in the agricultural sector to protect plants from microbial diseases was the development of nanoformulations or encapsulation of pesticides. These nanoformulations contain a small number of tiny particles with pesticides as active ingredients. Nanoparticles of carbon, silver, silica and alumina silicates have been used to control plant diseases caused by various phytopathogens. The epitomised nanoformulations encourage the controlled arrival of dynamic fixings into the objective zones of plants and hence give better outcomes. The pesticides of conventional origin have various limitations like limited solubility, increased resistance and nanoformulations; these problems are decreased (Dwivedi et al., 2016). Therefore, to accomplish higher harvest creation, the criticalness of nanotechnology has expanded dramatically. A study reported by Petosa et al. (2017) showed that the pesticide nanoformulations boosted crop yield by enhancing the efficacy of pesticides by regulating their transport potential. Their study combined polymeric nanocapsules with pyrethroid bifenthrin (Ncap-BIF), which ended up being a promising conveyance vehicle for plant security. The catalytic activity of trypsin, known as a viral protease, was reduced by fabricated bioactive AuNPs, thereby proving effective in controlling insects. This change in catalytic activity was believed to be due to the interaction of proteins with metallic nanoparticles (Patil et al., 2016). For instance, to control the growth of Penicillium expansum, Alternaria alternate, Rhizopus stolonifer, A. flavus, Fusarium graminearum and pathogenic bacteria, ZnO nanoparticles have proven to be effective (Dwivedi et al., 2016; Vanathi et al., 2016). Further, Si and TiO2 have shown a promise in suppressing crop diseases through its antimicrobial activity. In sustainable agriculture development, nanomaterial-encapsulated pesticides, herbicides and fungicides have shown a tremendous scope.

6.9 Conclusions

Nanotechnology has emerged as the most innovative science with widespread applications. It has solved many agriculture-related issues like nutrient uptake efficiency, insect pest control and crop production. The synthetic pesticides available in the markets have negatively impacted the environment due to their toxic and persistent nature. To avoid the limitations of these synthetic pesticides, pest management could be done by involving nanotechnology-based nanopesticides. The nanopesticides are non-toxic and safe to use. To beat the impediments of biological or green synthesis methods, nanoparticles are favoured as eco-friendly, less toxic and healthy alternatives. In this regard, we will understand the role of green synthesised nanoparticles in agriculture management in this chapter.

References

Alghuthaymi, M. A., Almoammar, H., Rai, M., Said-Galiev, E., & Abd-Elsalam, K. A. (2015). Myconanoparticles: synthesis and their role in phytopathogens management. Biotechnology & Biotechnological Equipment, 29(2), 221–236.

Aljabali, A. A. A., Akkam, Y., Al Zoubi, M. S., Al-Batayneh, K. M., Al-Trad, B., Abo Alrob, O., … Evans, D. J. (2018 March). Synthesis of gold nanoparticles using leaf extract of Ziziphus zizyphus and their antimicrobial activity. Nanomaterials, 8(3), 174. https://doi.org/10.3390/nano8030174

Anu, K., Singaravelu, G., Murugan, K., & Benelli, G. (2017 January 1). Green-synthesis of selenium nanoparticles using garlic cloves (Allium sativum): Biophysical characterisation and cytotoxicity on vero cells. Journal of Cluster Science, 28(1), 551–563. https://doi.org/10.1007/s10876-016-1123-7

Banerjee, P., Satapathy, M., Mukhopahayay, A., & Das, P. (2014 December 1). Leaf extract mediated green synthesis of silver nanoparticles from widely available Indian plants: Synthesis, characterisation, antimicrobial property and toxicity analysis. Bioresources and Bioprocessing, 1(1), 3. https://doi.org/10.1186/s40643-014-0003-y

Barrena, R., Casals, E., Colón, J., Font, X., Sánchez, A., & Puntes, V. (2009). Evaluation of the ecotoxicity of model nanoparticles. Chemosphere, 75(7), 850–857. https://doi.org/10.1016/j.chemosphere.2009.01.078

Biswal, S. K., Nayak, A. K., Parida, U. K., & Nayak, P. L. (2012). Applications of nanotechnology in agriculture and food sciences. IJSID, 2(1), 21–36.

Brock, D. A., Douglas, T. E., Queller, D. C., & Strassmann, J. E. (2011). Primitive agriculture in a social amoeba. Nature, 469(7330), 393–396. https://doi.org/10.1038/nature09668

Busó-Rogero, C., Brimaud, S., Solla-Gullon, J., Vidal-Iglesias, F. J., Herrero, E., Behm, R. J., & Feliu, J. M. (2016 February 15). Ethanol oxidation on shape-controlled platinum nanoparticles at different pHs: A combined in situ IR spectroscopy and online mass spectrometry study. Journal of Electroanalytical Chemistry, 763, 116–124. https://doi.org/10.1016/j.jelechem.2015.12.034

Chakravorty, A., Rather, G. A., Ali, A., Bhat, B. A., Sana, S. S., Abhishek, N., & Nanda, A. (2020). Nano approach: Indian spices as antimicrobial agents. In Advances in medical diagnosis, treatment, and care (pp. 205–241). IGI Global. https://doi.org/10.4018/978-1-7998-2524-1.ch016

Costa Silva, L. P., Oliveira, J. P., Keijok, W. J., da Silva, A. R., Aguiar, A. R., Guimarães, M. C. C., … Braga, F. R. (2017). Extracellular biosynthesis of silver nanoparticles using the cell-free filtrate of nematophagous fungus Duddingtonia flagrans. International Journal of Nanomedicine, 12, 6373–6381. https://doi.org/10.2147/IJN.S137703

Dauthal, P., & Mukhopadhyay, M. (2016 September 14). Noble metal nanoparticles: Plant-mediated synthesis, mechanistic aspects of synthesis, and applications. Industrial and Engineering Chemistry Research, 55(36), 9557–9577. https://doi.org/10.1021/acs.iecr.6b00861

Deepa, B., & Ganesan, V. (2015). Bioinspiredsynthesis of selenium nanoparticles using flowers of Catharanthus roseus (L.) G. Don. And Peltophorum pterocarpum (DC.) backer ex Heyne–a comparison. Int. J. Chem. Technol. Res., 7, 725–733.

DeRosa, M. C., Monreal, C., Schnitzer, M., Walsh, R., & Sultan, Y. (2010). Nanotechnology in fertilisers. Nature Nanotechnology, 5(2), 91–91. https://doi.org/10.1038/nnano.2010.2

Dhand, C., Dwivedi, N., Loh, X. J., Jie Ying, A. N., Verma, N. K., Beuerman, R. W., … Ramakrishna, S. (2015). Methods and strategies for the synthesis of diverse nanoparticles and their applications: A comprehensive overview. RSC Advances, 5(127), 105003–105037. https://doi.org/10.1039/C5RA19388E. PubMed: 105003

Dhoke, S. K., Mahajan, P., Kamble, R., & Khanna, A. (2013). Effect of nanoparticles suspension on the growth of mung (Vigna radiata) seedlings by foliar spray method. Nanotechnology Development, 3(1). https://doi.org/10.4081/nd.2013.e1

Dimkpa, C. O., McLean, J. E., Latta, D. E., Manangón, E., Britt, D. W., Johnson, W. P., … Anderson, A. J. (2012). CuO and ZnO nanoparticles: Phytotoxicity, metal speciation, and induction of oxidative stress in sand-grown wheat. Journal of Nanoparticle Research, 14(9), 1–15. https://doi.org/10.1007/s11051-012-1125-9

Ditta, A. (2012). How helpful is nanotechnology in agriculture? Advances in Natural Sciences: Nanoscience and Nanotechnology, 3(3). https://doi.org/10.1088/2043-6262/3/3/033002. PubMed: 033002.

Duhan, J. S., Kumar, R., Kumar, N., Kaur, P., Nehra, K., & Duhan, S. (2017 September 1). Nanotechnology: The new perspective in precision agriculture. Biotechnology Reports, 15, 11–23. https://doi.org/10.1016/j.btre.2017.03.002

Dwivedi, S., Saquib, Q., Al-Khedhairy, A. A., & Musarrat, J. (2016). Understanding the role of nanomaterials in agriculture. In D. P. Singh, H. B. Singh, & R. Prabha (Eds.), Microbial inoculants in sustainable agricultural productivity (pp. 271–288). Springer.

Egorova, E. M., & Revina, A. A. (2000 July 31). Synthesis of metallic nanoparticles in reverse micelles in the presence of quercetin. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 168(1), 87–96. https://doi.org/10.1016/S0927-7757(99)00513-0

Fardsadegh, B., & Jafarizadeh-Malmiri, H. (2019). Aloe vera leaf extract mediated green synthesis of selenium nanoparticles and assessment of their in vitro antimicrobial activity against spoilage fungi and pathogenic bacteria strains. Green Processing and Synthesis, 8(1), 399–407.

Frewer, L. J., Norde, W., Fischer, A. R. H., & Kampers, F. W. H. (2011). Nanotechnology in the Agri-food sector: Implications for the future. Wiley-VCH Press.

Grasso, G., Zane, D., & Dragone, R. (2019 January). Microbial nanotechnology: Challenges and prospects for green biocatalytic synthesis of nanoscale materials for sensoristic and biomedical applications. Nanomaterials, 10(1), 11. https://doi.org/10.3390/nano10010011

Gruere, G., Narrod, C., & Abbott, L. (2011). Agriculture, food, and water nanotechnologies for the poor: Opportunities and constraints. Policy brief 19. International Food Policy Research Institute.

Guilger-Casagrande, M., & de Lima, R. (2019). Synthesis of silver nanoparticles mediated by fungi: A review. Frontiers in Bioengineering and Biotechnology, 7, 287. https://doi.org/10.3389/fbioe.2019.00287

Gupta, M., Tomar, R. S., Kaushik, S., Mishra, R. K., & Sharma, D. (2018 September 3). Effective antimicrobial activity of green ZnO Nano particles of Catharanthus roseus. Frontiers in Microbiology, 9, 2030. https://doi.org/10.3389/fmicb.2018.02030

Happy, A., Soumya, M., Kumar, S. V., Rajeshkumar, S., Sheba, R. D., Lakshmi, T., & Nallaswamy, V. D. (2019). Phyto-assisted synthesis of zinc oxide nanoparticles using Cassia alata and its antibacterial activity against Escherichia coli. Biochemistry and Biophysics Reports, 17, 208–211.

Herlekar, M., Barve, S., & Kumar, R. (2014). Plant-mediated green synthesis of iron nanoparticles. Journal of Nanoparticles, 2014, 1–9. https://doi.org/10.1155/2014/140614

Hong, F., Zhou, J., Liu, C., Yang, F., Wu, C., Zheng, L., & Yang, P. (2005). Effect of Nano-TiO2 on photochemical reaction of chloroplasts of spinach. Biological Trace Element Research, 105(1–3), 269–279. https://doi.org/10.1385/BTER:105:1-3:269

Hulkoti, N. I., & Taranath, T. C. (2014 September 1). Biosynthesis of nanoparticles using microbes—A review. Colloids and Surfaces B, Biointerfaces, 121, 474–483. https://doi.org/10.1016/j.colsurfb.2014.05.027

Ibrahim, H. M. M., & Hassan, M. S. (2016 October 20). Characterization and antimicrobial properties of cotton fabric loaded with green synthesised silver nanoparticles. Carbohydrate Polymers, 151, 841–850. https://doi.org/10.1016/j.carbpol.2016.05.041

Jaison, J., Barhoum, A., Chan, Y. S., Dufresne, A., & Danquah, M. K. (2018). Review on nanoparticles and nanostructured materials: History, sources, toxicity and regulations. Beilstein Journal of Nanotechnology.

Jayarambabu, N., Kumari, B. S., Rao, K. V., & Prabhu, Y. T. (2014). Germination and growth characteristics of mungbean seeds (Vigna radiata L.) affected by synthesised zinc oxide nanoparticles. International Journal of Current Engineering and Technology, 5161(4(5)), 2347.

Juhel, G., Batisse, E., Hugues, Q., Daly, D., van Pelt, F. N., O’Halloran, J., & Jansen, M. A. (2011). Alumina nanoparticles enhance growth of Lemna minor. Aquatic Toxicology, 105(3–4), 328–336. https://doi.org/10.1016/j.aquatox.2011.06.019

Kaur, P., Jain, P., Kumar, A., & Thakur, R. (2014 June 1). Biogenesis of PbS nanocrystals by using rhizosphere fungus ie, Aspergillus sp. isolated from the rhizosphere of chickpea. BioNanoScience, 4(2), 189–194. https://doi.org/10.1007/s12668-014-0135-8

Khandel, P., Yadaw, R. K., Soni, D. K., Kanwar, L., & Shahi, S. K. (2018). Biogenesis of metal nanoparticles and their pharmacological applications: Present status and application prospects. Journal of Nanostructure in Chemistry, 8(3), 217–254. https://doi.org/10.1007/s40097-018-0267-4

Khodakovskaya, M., Dervishi, E., Mahmood, M., Xu, Y., Li, Z., Watanabe, F., & Biris, A. S. (2009). Carbon nanotubes are able to penetrate plant seed coat and dramatically affect seed germination and plant growth. ACS Nano, 3(10), 3221–3227. https://doi.org/10.1021/nn900887m

Khodakovskaya, M. V., Kim, B. S., Kim, J. N., Alimohammadi, M., Dervishi, E., Mustafa, T., & Cernigla, C. E. (2013). Carbon nanotubes as plant growth regulators: Effects on tomato growth, reproductive system, and soil microbial community. Small, 9(1), 115–123. https://doi.org/10.1002/smll.201201225

Kirupagaran, R., Saritha, A., & Bhuvaneswari, S. (2016 December 31). Green synthesis of selenium nanoparticles from leaf and stem extract of leucas lavandulifolia sm. And their application. NanoScience and Technology, 224–226.

Krupa, N. D., Grace, A. N., & Raghavan, V. (2019 February 13). Process optimisation for green synthesis of ZnO nanoparticles and evaluation of its antimacrofouling activity. IET Nanobiotechnology, 13(5), 510–514. https://doi.org/10.1049/iet-nbt.2018.5396

Kumar, V., Guleria, P., Kumar, V., & Yadav, S. K. (2013). Gold nanoparticle exposure induces growth and yield enhancement in Arabidopsis thaliana. Science of the Total Environment, 461–462, 462–468. https://doi.org/10.1016/j.scitotenv.2013.05.018

Kumar, N., & Kumbhat, S. (2016). Essentials in nanoscience and nanotechnology (pp. 189–236). John Wiley & Sons,. Nanomaterials, C.-B.

Kumar, D. A., Palanichamy, V., & Roopan, S. M. (2014 June 5). Green synthesis of silver nanoparticles using Alternanthera dentata leaf extract at room temperature and their antimicrobial activity. Spectrochimica Acta. Part A, Molecular and Biomolecular Spectroscopy, 127, 168–171. https://doi.org/10.1016/j.saa.2014.02.058

Kuzma, J. (2006). Moving forward responsibly: Oversight for the nanotechnology-biology interface. Journal of Nanoparticle Research, 9(1), 165–182. https://doi.org/10.1007/s11051-006-9151-0

Lin, D., & Xing, B. (2007). Phytotoxicity of nanoparticles: Inhibition of seed germination and root growth. Environmental Pollution, 150(2), 243–250. https://doi.org/10.1016/j.envpol.2007.01.016

López-Moreno, M. L., De La Rosa, G., Hernández-Viezcas, J. A., Castillo-Michel, H., Botez, C. E., Peralta-Videa, J. R., & Gardea-Torresdey, J. L. (2010). Evidence of the differential biotransformation and genotoxicity of ZnO and CeO2 nanoparticles on soybean (Glycine max) plants. Environmental Science and Technology, 44(19), 7315–7320. https://doi.org/10.1021/es903891g

Ma, C., Chhikara, S., Xing, B., Musante, C., White, J. C., & Dhankher, O. P. (2013). Physiological andmolecular response of Arabidopsis thaliana (L.) to nanoparticle cerium and indium oxide exposure. ACS Sustainable Chemistry and Engineering, 1(7), 768–778. https://doi.org/10.1021/sc400098h

Mahmoodzadeh, H., Nabavi, M., & Kashefi, H. (2013). Effect of nanoscale titanium dioxide particles on the germination and growth of canola (Brassica napus). Journal of Ornamental Horticulture Plants, 3, 25–32.

Majeed, S., Danish, M., Ibrahim, M. N., Sekeri, S. H., Ansari, M. T., Nanda, A., & Ahmad, G. (2020 September 4). Bacteria mediated synthesis of iron oxide nanoparticles and their antibacterial, antioxidant, cytocompatibility properties. Journal of Cluster Science, 1–2.

Maysinger, D. (2007). Nanoparticles and cells: Good companions and doomed partnerships. Organic and Biomolecular Chemistry, 5(15), 2335–2342. https://doi.org/10.1039/b704275b

Morla, S., Ramachandra Rao, C. S. V., & Chakrapani, R. (2011). Factors affecting seed germination and seedling growth of tomato plants cultured in vitro conditions, J Chem bio. Physiological Sciences, B1, 328–334.

Mourdikoudis, S., Pallares, R. M., & Thanh, N. T. K. (2018). Characterisation techniques for nanoparticles: Comparison and complementarity upon studying nanoparticle properties. Nanoscale, 10(27), 12871–12934. https://doi.org/10.1039/c8nr02278j

Mukhopadhyay, S. S. (2014). Nanotechnology in agriculture prospects and constraints. Nanotechnology, Science and Applications, 7, 63–71. https://doi.org/10.2147/NSA.S39409

Nadaroglu, H., Güngör, A. A., & Selvi, İ. N. (2017 August). Synthesis of nanoparticles by green synthesis method. International Journal of Innovative Research and Reviews, 1(1), 6–9.

Nakkala, J. R., Mata, R., Gupta, A. K., & Sadras, S. R. (2014 October 6). Biological activities of green silver nanoparticles synthesised with Acorous calamus rhizome extract. European Journal of Medicinal Chemistry, 85, 784–794. https://doi.org/10.1016/j.ejmech.2014.08.024

Naveed Ul Haq, A., Nadhman, A., Ullah, I., Mustafa, G., Yasinzai, M., & Khan, I. (2017 April 18). Synthesis approaches of zinc oxide nanoparticles: The dilemma of ecotoxicity. Journal of Nanomaterials, 2017, 1–14. https://doi.org/10.1155/2017/8510342

Nayantara, P., & Kaur, P. (2018 January 1). Biosynthesis of nanoparticles using eco-friendly factories and their role in plant pathogenicity: A review. Biotechnology Research and Innovation, 2(1), 63–73. https://doi.org/10.1016/j.biori.2018.09.003

Nuruzzaman, M., Rahman, M. M., Liu, Y. J., & Naidu, R. (2016). Nanoencapsulation, nano-guard for pesticides: A new window for safe application. Journal of Agricultural and Food Chemistry, 64(7), 1447–1483. https://doi.org/10.1021/acs.jafc.5b05214

Ovais, M., Khalil, A. T., Ayaz, M., Ahmad, I., Nethi, S. K., & Mukherjee, S. (2018 December). Biosynthesis of metal nanoparticles via microbial enzymes: A mechanistic approach. International Journal of Molecular Sciences, 19(12), 4100. https://doi.org/10.3390/ijms19124100

Pantidos, N., & Horsfall, L. E. (2014 September 1). Biological synthesis of metallic nanoparticles by bacteria, fungi and plants. Journal of Nanomedicine and Nanotechnology, 5(5), 1.

Patil, C. D., Borase, H. P., Suryawanshi, R. K., & Patil, S. V. (2016). Trypsin inactivation by latex fabricated gold nanoparticles: A new strategy towards insect control. Enzyme and Microbial Technology, 92, 18–25. https://doi.org/10.1016/j.enzmictec.2016.06.005

Paul, A. M., Sajeev, A., Nivetha, R., Gothandapani, K., Bhardwaj, P., K, G., … Grace, A. N. (2020 April 28). Cuprous oxide (Cu2O)/graphitic carbon nitride (g-C3N4) nanocomposites for electrocatalytic hydrogen evolution reaction. Diamond and Related Materials, 107. https://doi.org/10.1016/j.diamond.2020.107899, PubMed: 107899.

Perez-de-Luque, A., & Hermosín, M. C. (2013). Nanotechnology and its use in agriculture. In D. Bagchi, M. Bagchi, H. Moriyama, & F. Shahidi (Eds.), Bio-nanotechnology: A revolution in food, Bomedical and health sciences (pp. 299–405). Wiley-Blackwell, West.

Petosa, A. R., Rajput, F., Selvam, O., Öhl, C., & Tufenkji, N. (2017). Assessing the transport potential of polymeric nanocapsules developed for crop protection. Water Research, 111, 10–17.

Prasad, R., Kumar, V., & Prasad, K. S. (2014). Nanotechnology in sustainable agriculture: Present concerns and future aspects. African Journal of Biotechnology, 6, 13705–13713.

Prasad, T. N. V. K. V., Sudhakar, P., Sreenivasulu, Y., Latha, P., Munaswamy, V., Reddy, K. R., … Pradeep, T. (2012). Effect of nanoscale zinc oxide particles on the germination, growth and yield of peanut. Journal of Plant Nutrition, 35(6), 905–927. https://doi.org/10.1080/01904167.2012.663443

Qamar, Z., Nasir, I. A., & Husnain, T. (2014). In-vitro development of cauliflower synthetic seeds and conversion to plantlets. Advances in Life Sciences, 1(2), 34–41.

Raghavan, V., Deb, A., & Grace, A. N. (2020 June 19). Honokiol-camptothecin loaded graphene oxide nanoparticle towards combinatorial anticancer drug delivery. IET Nanobiotechnology.

Rai, M., & Ingle, A. (2012a). Role of nanotechnology in agriculture with special reference to management of insect pests. Applied Microbiology and Biotechnology, 94(2), 287–293. https://doi.org/10.1007/s00253-012-3969-4

Rai, M., & Ingle, A. (2012b). Role of nanotechnology in agriculture with special reference to management of insect pests. Applied Microbiology and Biotechnology, 94(2), 287–293. https://doi.org/10.1007/s00253-012-3969-4

Rai, P., Kwak, W. K., & Yu, Y. T. (2013 April 24). Solvothermal synthesis of ZnO nanostructures and their morphology-dependent gas-sensing properties. ACS Applied Materials and Interfaces, 5(8), 3026–3032. https://doi.org/10.1021/am302811h

Rajasekaran, S. J., & Raghavan, V. (2020 November 1). Facile synthesis of activated carbon derived from Eucalyptus globulus seed as efficient electrode material for supercapacitors. Diamond and Related Materials, 109. https://doi.org/10.1016/j.diamond.2020.108038. PubMed: 108038.

Sasidharan, S., Sowmiya, R., & Balakrishnaraja, R. (2014). Biosynthesis of selenium nanoparticles using citrus reticulata peel extract. World Journal of Pharmaceutical Research, 4, 1322–1330.

Scott, N. R. (2007). Nanoscience in veterinary medicine. Veterinary Research Communications, 31(Suppl. 1), 139–144. https://doi.org/10.1007/s11259-007-0083-7

Shah, M., Fawcett, D., Sharma, S., Tripathy, S. K., & Poinern, G. E. J. (2015 November). Green synthesis of metallic nanoparticles via biological entities. Materials, 8(11), 7278–7308. https://doi.org/10.3390/ma8115377

Sharmila, G., Muthukumaran, C., Sandiya, K., Santhiya, S., Pradeep, R. S., Kumar, N. M., … Thirumarimurugan, M. (2018 September 1). Biosynthesis, characterisation, and antibacterial activity of zinc oxide nanoparticles derived from Bauhinia tomentosa leaf extract. Journal of Nanostructure in Chemistry, 8(3), 293–299. https://doi.org/10.1007/s40097-018-0271-8

Sheykhbaglou, R., Sedghi, M., Shishevan, M. T., & Sharifi, R. S. (2010). Effects of nano-iron oxide particles on agronomic traits of soybean. Notulae Scientia Biologicae, 2(2), 112–113. https://doi.org/10.15835/nsb224667

Singh, H., Du, J., Singh, P., & Yi, T. H. (2018 August 18). Ecofriendly synthesis of silver and gold nanoparticles by Euphrasia officinalis leaf extract and its biomedical applications. Artificial Cells, Nanomedicine, and Biotechnology, 46(6), 1163–1170. https://doi.org/10.1080/21691401.2017.1362417

Sitaaraman, S. R., Santhosh, R., Kollu, P., Jeong, S. K., Sellappan, R., Raghavan, V., … Grace, A. N. (2020 October 1). Role of graphene in NiSe2/graphene composites-Synthesis and testing for electrochemical supercapacitors. Diamond and Related Materials, 108. PubMed: 107983.

Sonkaria, S., Ahn, S. H., & Khare, V. (2012). Nanotechnology and its impact on food and nutrition: A review. Recent Patents on Food, Nutrition and Agriculture, 4(1), 8–18. https://doi.org/10.2174/2212798411204010008

Srinath, B. S., & Ravishankar Rai, V. R. (2015 October 1). Biosynthesis of highly monodispersed, spherical gold nanoparticles of size 4–10 nm from spent cultures of Klebsiella pneumoniae. 3 Biotech, 5(5), 671–676. https://doi.org/10.1007/s13205-014-0265-2

Syamsai, R., & Grace, A. N. (2020 March 1). Synthesis, properties and performance evaluation of vanadium carbide MXene as supercapacitor electrodes. Ceramics International, 46(4), 5323–5330. https://doi.org/10.1016/j.ceramint.2019.10.283

Vanathi, P., Rajiv, P., & Sivaraj, R. (2016). Synthesis and characterisation of Eichhornia-mediated copper oxide nanoparticles and assessing their antifungal activity against plant pathogens. Bulletin of Materials Science, 39(5), 1165–1170. https://doi.org/10.1007/s12034-016-1276-x

Velappan, S., Nivedhita, P., Vimala, R., & Raja, S. (2020 November 1). Role of Nano titania on the thermomechanical properties of silicon carbide refractories. Ceramics International, 46(16), 25921–25926. https://doi.org/10.1016/j.ceramint.2020.07.077

Vijayan, R., Joseph, S., & Mathew, B. (2018 May 19). Indigofera tinctoria leaf extract mediated green synthesis of silver and gold nanoparticles and assessment of their anticancer, antimicrobial, antioxidant and catalytic properties. Artificial Cells, Nanomedicine, and Biotechnology, 46(4), 861–871. https://doi.org/10.1080/21691401.2017.1345930

Ward, M. B., Brydson, R., & Cochrane, R. F. (2006) (Vol. 26, No. 1, p. 296). Mn nanoparticles produced by inert gas condensation. In Journal of Physics: Conference Series. IOP Publishing, 296–299. https://doi.org/10.1088/1742-6596/26/1/071.

Wheeler, S. (2005). Factors influencing agricultural professionals’ attitudes toward organic agriculture and biotechnology. Center for Regulation and market analysis. University of South Australia.

Yadav, B. C., Srivastava, R., & Yadav, A. (2009 January 1). Nanostructured zinc oxide synthesised via hydroxide route as liquid petroleum gas sensor. Sensors and Materials, 21, 87–94.

Yang, F., Hong, F., You, W., Liu, C., Gao, F., Wu, C., & Yang, P. (2006). Influence of nano-anatase TiO2 on the nitrogen metabolism of growing spinach. Biological Trace Element Research, 110(2), 179–190. https://doi.org/10.1385/bter:110:2:179

Yang, F., Liu, C., Gao, F., Su, M., Wu, X., Zheng, L., … Yang, P. (2007). The improvement of spinach growth by nano-anatase TiO2 treatment is related to nitrogen photoreduction. Biological Trace Element Research, 119(1), 77–88. https://doi.org/10.1007/s12011-007-0046-4

Zeebaree, S. Y. S., Zeebaree, A. Y. S., & Zebari, O. I. H. (2020 March 1). Diagnosis of the multiple effect of selenium nanoparticles decorated by Asteriscus graveolens components in inhibiting HepG2 cell proliferation. Sustainable Chemistry and Pharmacy, 15. https://doi.org/10.1016/j.scp.2019.100210. PubMed: 100210.

Zhang, K., Lv, S., Lin, Z., Li, M., & Tang, D. (2018 March 15). Bio-bar-code-based photo electrochemical immunoassay for sensitive detection of prostate-specific antigen using rolling circle amplification and enzymatic biocatalytic precipitation. Biosensors and Bioelectronics, 101, 159–166. https://doi.org/10.1016/j.bios.2017.10.031

Zheng, L., Hong, F., Lu, S., & Liu, C. (2005 April 1). Effect of Nano-TiO 2 on strength of naturally aged seeds and growth of spinach. Biological Trace Element Research, 104(1), 83–92. https://doi.org/10.1385/BTER:104:1:083

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Nazneen, H., Rather, G.A., Ali, A., Chakravorty, A. (2022). The Role of Plant-Mediated Biosynthesised Nanoparticles in Agriculture. In: Bandh, S.A. (eds) Sustainable Agriculture. Springer, Cham. https://doi.org/10.1007/978-3-030-83066-3_6

Download citation

DOI: https://doi.org/10.1007/978-3-030-83066-3_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-83065-6

Online ISBN: 978-3-030-83066-3

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)